Rotary oil seal of multi-head spiral oil return line

A technology of oil return line and spiral, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem that the sealing performance cannot be effectively guaranteed, and achieve the purpose of improving service life, improving oil return capacity, and strong oil return capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

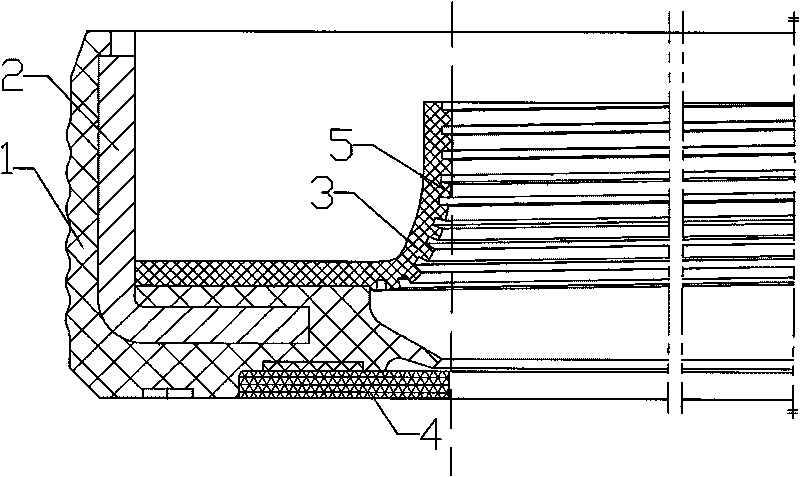

Embodiment 1

[0016] Example 1, a multi-head spiral oil return line rotary oil seal, refer to figure 1 , the rubber body 1 is bonded to the skeleton 2, the sealing lip 3 made of polytetrafluoroethylene sheet is bonded to the rubber body 1, the rubber body 1, the skeleton 2 and the sealing lip 3 are tightly combined into one, and the polytetrafluoroethylene There are 2-7 spiral oil return lines 5 on the side of the sealing lip 3 made of sheet and the shaft contact surface. The cross-sectional shape of the multi-head spiral oil return line 5 is rectangular, trapezoidal, triangular, semicircular arc or single-sided arc The distance between two adjacent oil return lines 5 is 0.3-1.2 mm, and the depth of the oil return lines 5 is 0.10-0.6 mm. In this embodiment, two oil return lines 5 with a trapezoidal section are used. , the distance between the two oil return lines 5 is 1.2mm, and the depth of the oil return line 5 is 0.6mm, which constitutes a structure of the present invention.

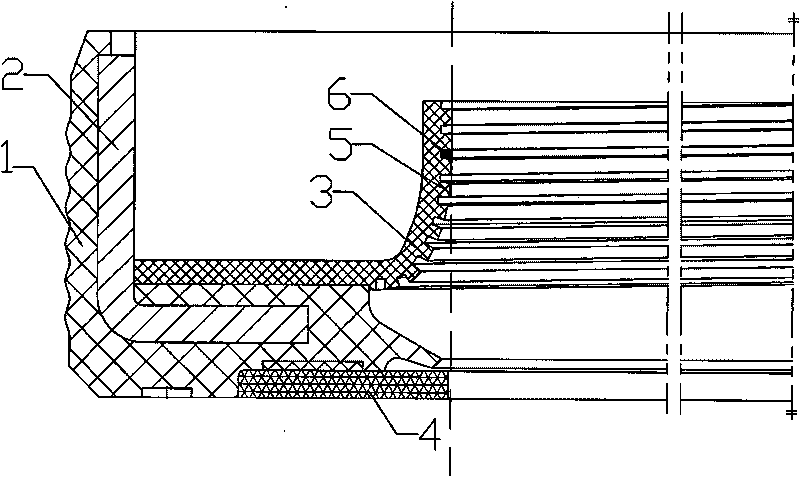

Embodiment 2

[0017] Example 2, a multi-head spiral oil return line rotary oil seal, refer to figure 2 , on the basis of Embodiment 1, an oil stop point 6 is provided on each spiral oil return line 5. In this embodiment, seven oil return lines 5 with triangular cross-sections are used, and the distance between two adjacent oil return lines 5 is Be 0.4mm, the depth 0.15mm of oil return line 5, others are identical with embodiment 1.

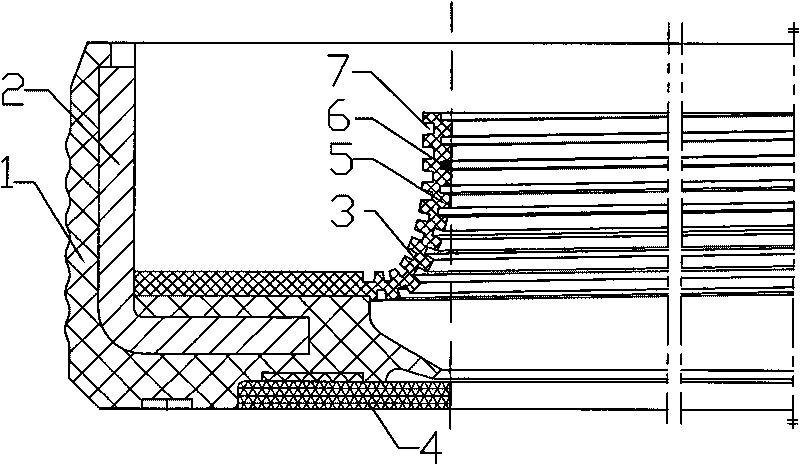

Embodiment 3

[0018] Example 3, a multi-head spiral oil return line rotary oil seal, refer to image 3 , on the basis of Example 2, on the opposite surface of the sealing lip 3 made of polytetrafluoroethylene sheets and the contact surface of the sealing shaft, there are helical lines 7 with the same number and the same direction of rotation as the 5 spiral oil return lines , the present embodiment adopts 4 oil return lines 5 with a semicircular cross-section, and there are 4 helical lines 7 correspondingly, the distance between two adjacent oil return lines 5 is 1.0 mm, the depth of the oil return line 5 is 0.35 mm, and other Exactly the same as Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com