Patents

Literature

101results about How to "Good oil return effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

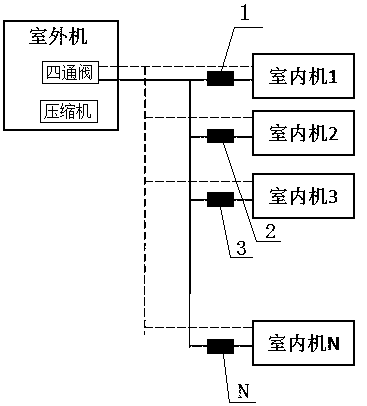

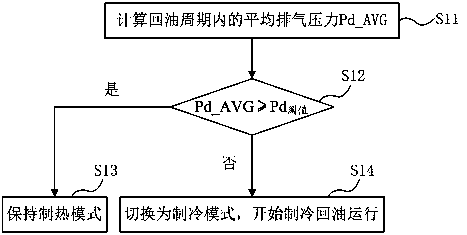

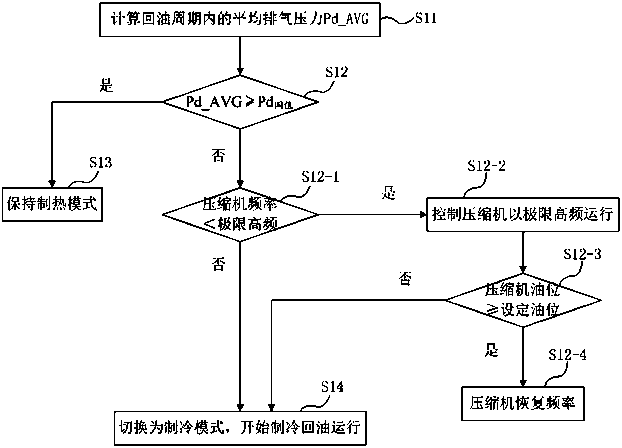

Oil return control method and system of variable refrigerant volume air conditioning system

ActiveCN108489150AGood oil return effectImprove heating effectCompressorEfficient regulation technologiesHeating effectProcess engineering

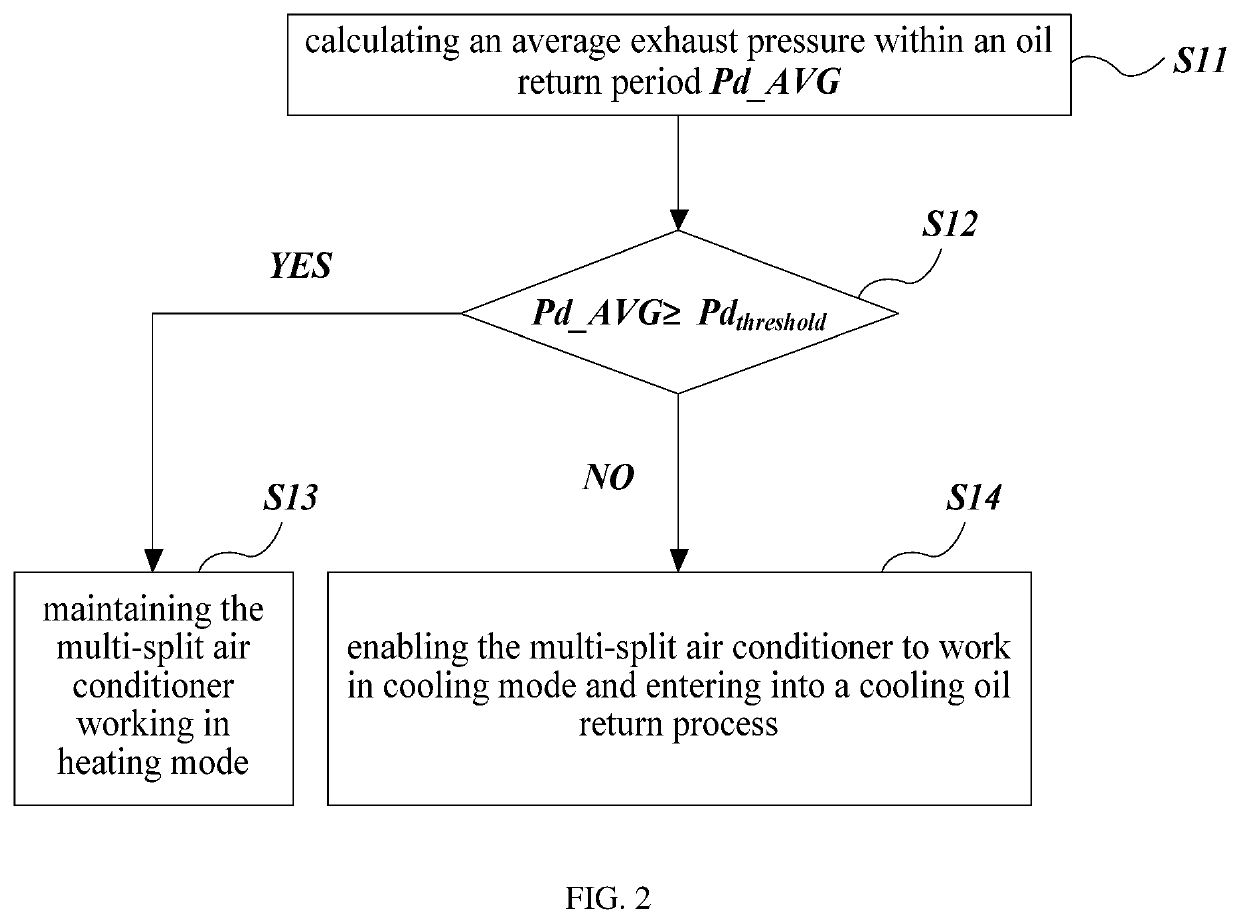

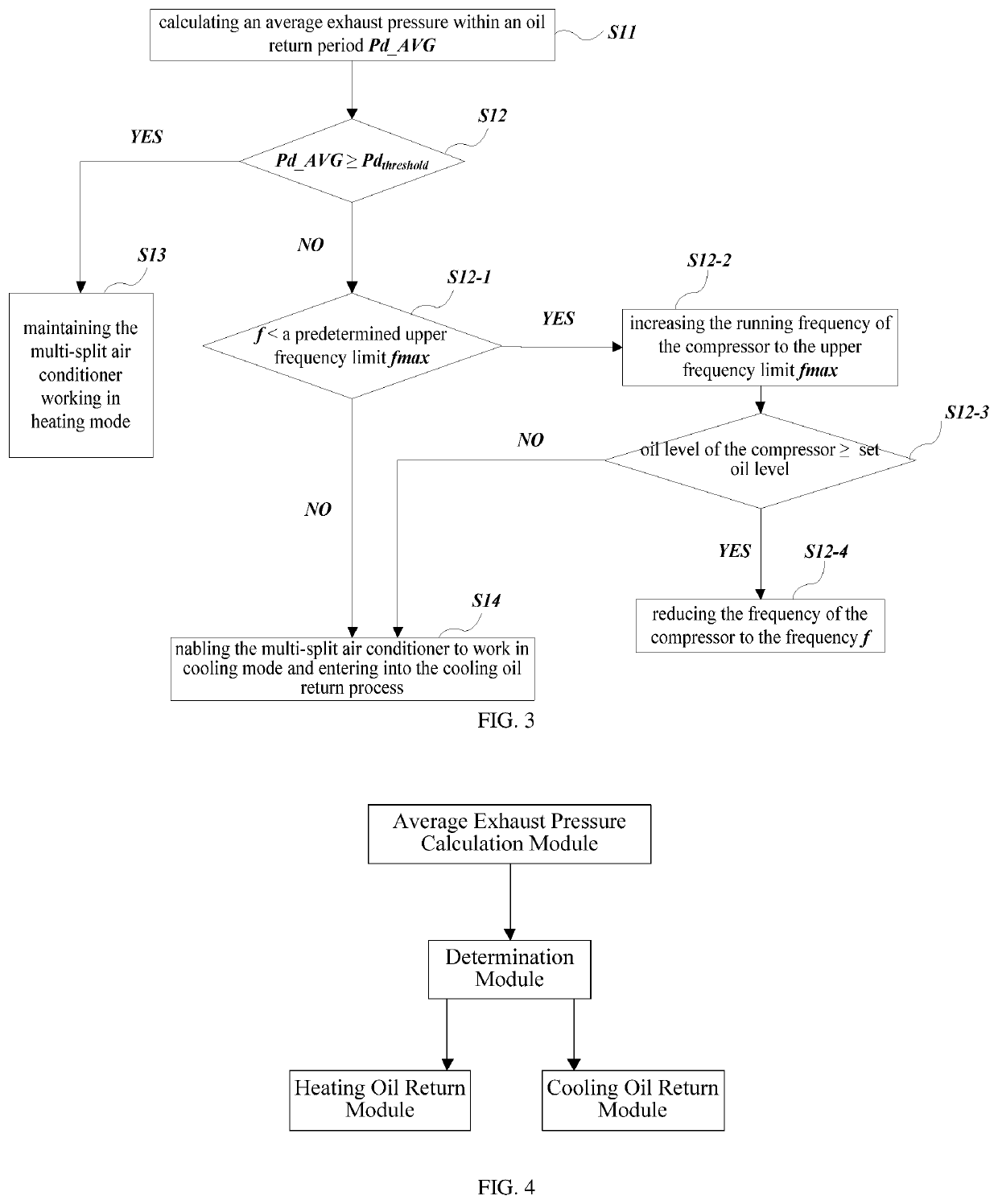

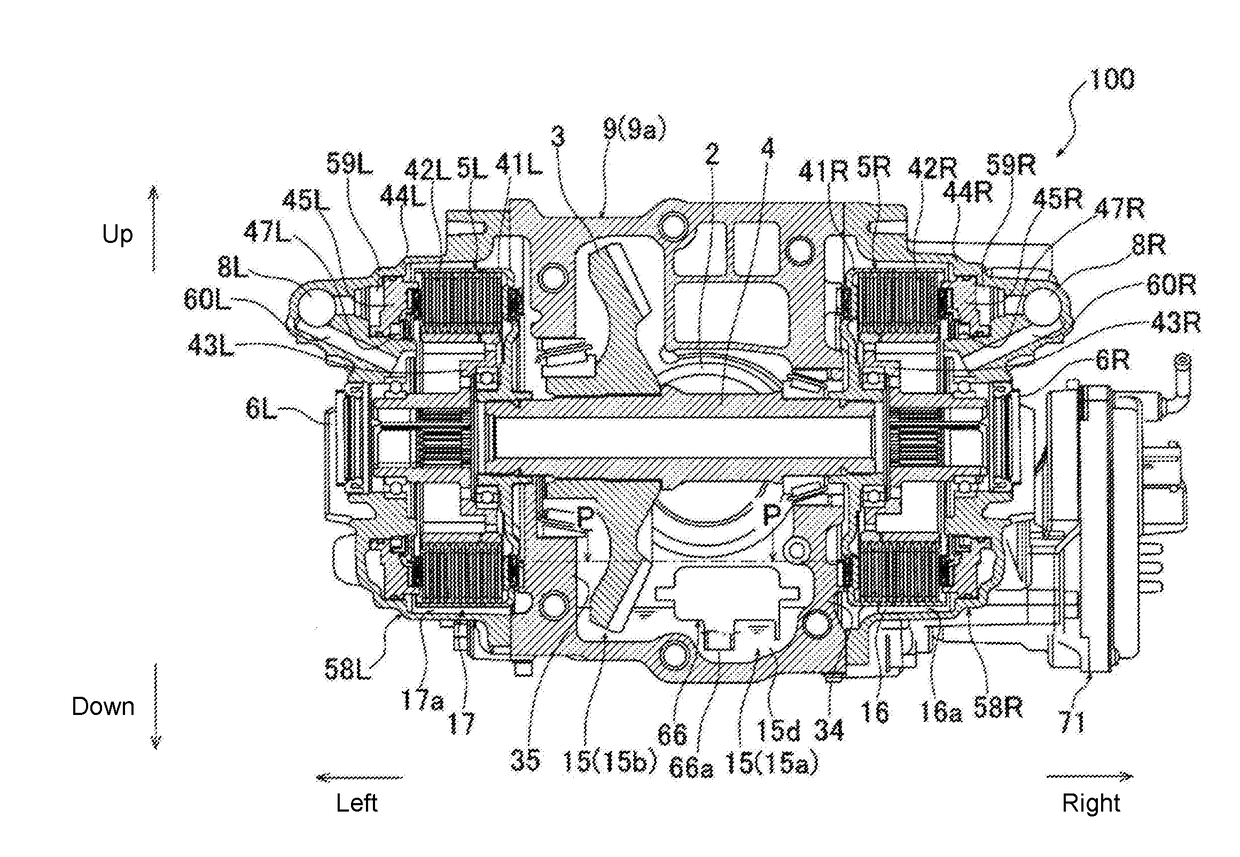

The invention discloses an oil return control method and system of a variable refrigerant volume air conditioning system. Whether the average exhaust pressure is larger than or equal to the set threshold value or not is judged by calculating the average exhaust pressure within an oil return cycle; if yes, the heating mode is kept, the good oil return effect is achieved while heating is conducted,the oil return requirement is met, and moreover, the heat effect of an indoor unit is not influenced; if no, the heating mode is switched into the refrigerating mode, a fan of the started indoor unitis controlled to stop, and refrigerating oil return operation is started; and after refrigerating oil return operation is completed, the refrigerating mode is switched into the heating mode. Thus, when the average exhaust pressure is smaller than the set threshold value, the heating mode is switched into the refrigerating mode, the fan of the started indoor unit stops operating, and the influenceon the temperature of a room where the started indoor unit is located is reduced; when the average exhaust pressure is larger than or equal to the set threshold value, the heating mode is kept, oil return is achieved while heating is conducted, accordingly, the variable refrigerant volume air conditioning system has the good oil return effect and the good heating effect, and the situation that theheating effect of the indoor unit is influenced is avoided; and the influence of oil return on the heating effect is reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

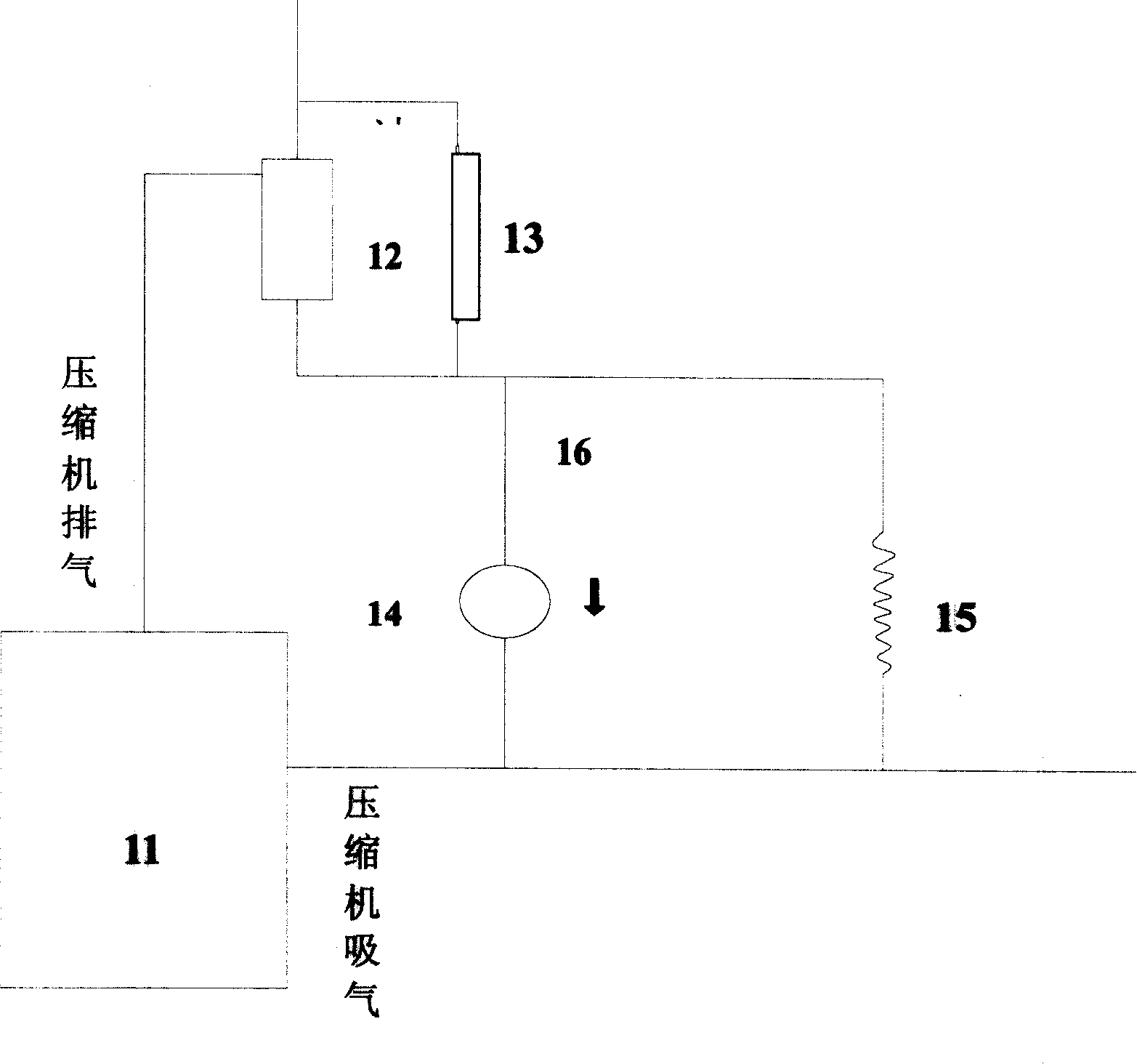

Oil eliminator auxiliary device of air conditioning system and control method thereof

InactiveCN101173656ASufficient oil returnEER/COP improvementPositive displacement pump componentsPositive-displacement liquid enginesFrequency conversionSolenoid valve

The invention relates to an auxiliary device of an oil separator in an air-conditioning system and a control method for the auxiliary device, which comprises a compressor, an oil separator and a return capillary. A pipe branch is in parallel provided with the return capillary between an oil outlet of the oil separator on exhausting side of the compressor and an air suction pipe of the compressor. A solenoid valve is connected in series on the pipe branch. The solenoid valve and an unloading valve of the air-conditioning system are merged into a whole, and oil unloading or return is carried out through controlling the solenoid valve respectively by the program. The control method for the auxiliary device of the oil separator is composed of selecting the return capillary and controlling opening period and duration of the solenoid valve. The invention has the advantages of effectively solving contradiction between normal oil return of the compressor assured by frequency conversion or variable capacity air-conditioning system and realizing high EER / COP and good cooling or heating, the unloading valve and the solenoid valve being merged into a whole, oil return of the compressor being optimized and cost of the system being not increased.

Owner:HAIER GRP CORP +1

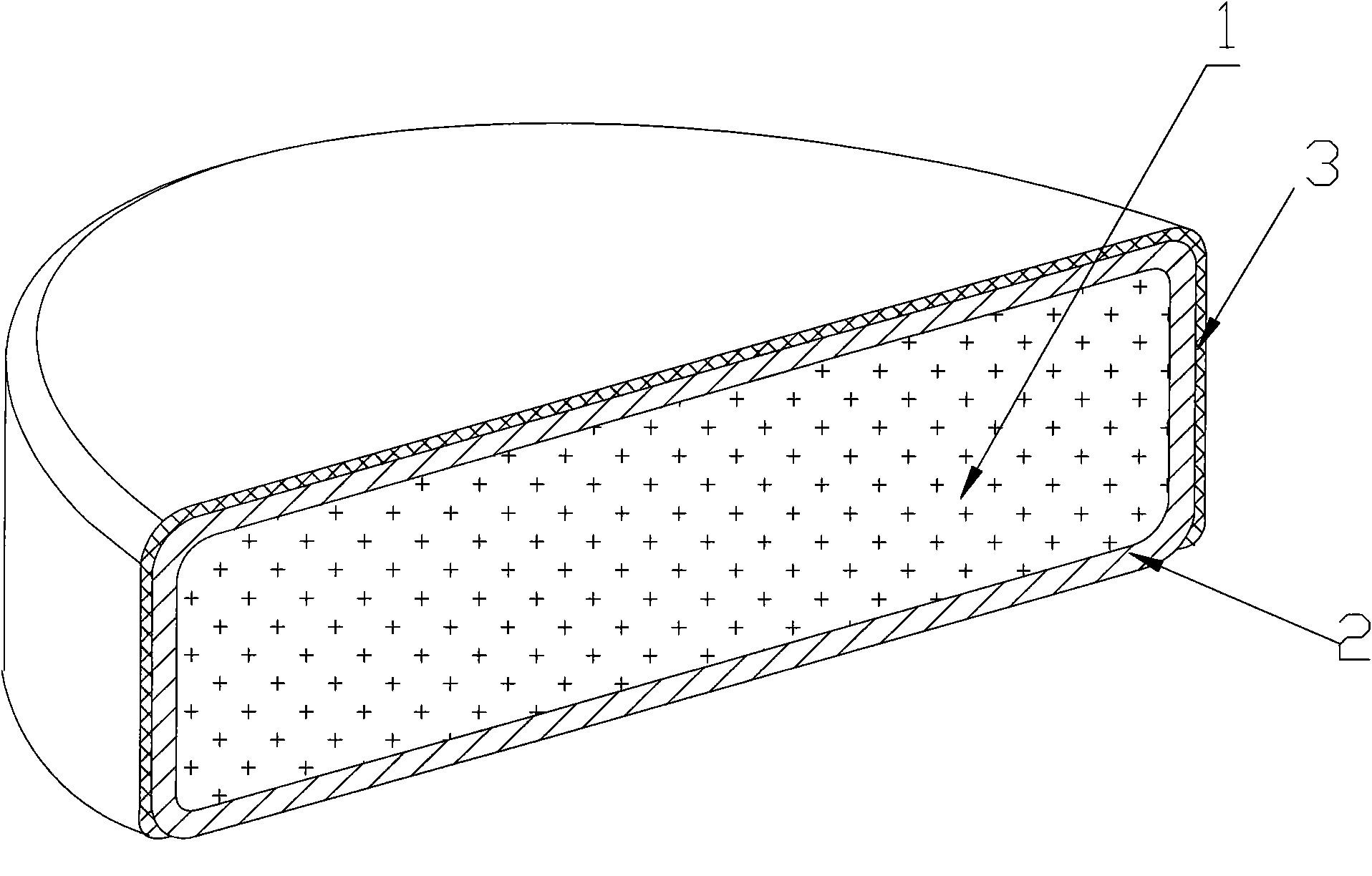

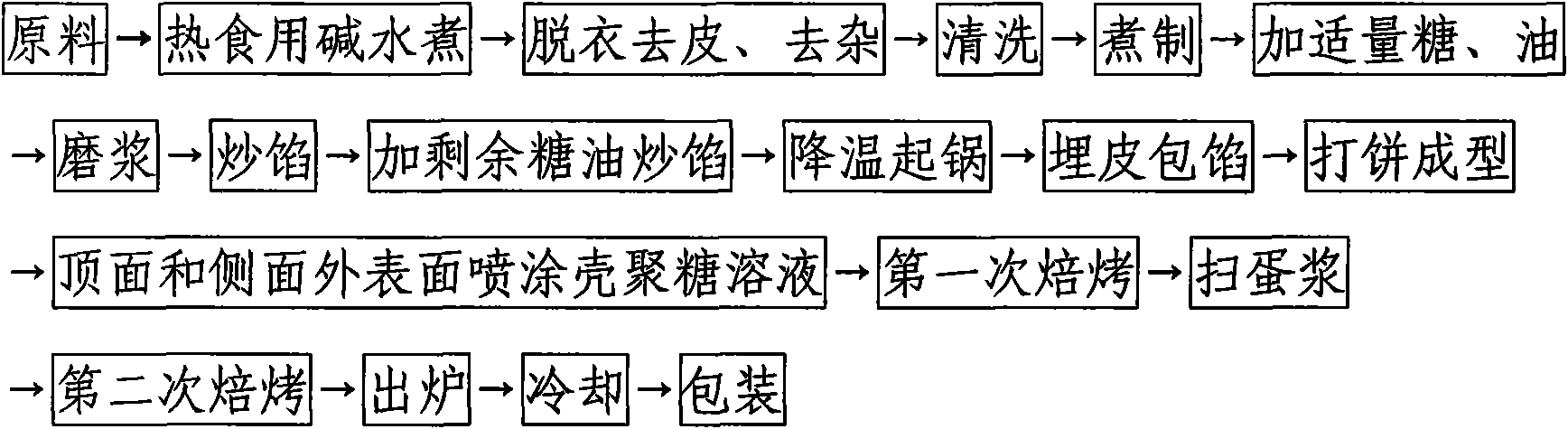

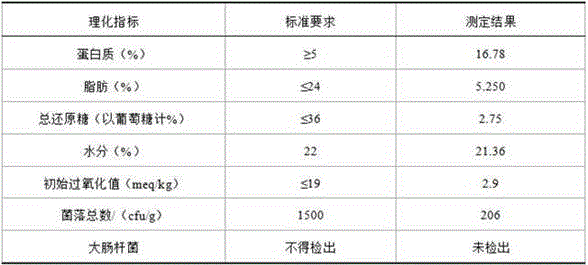

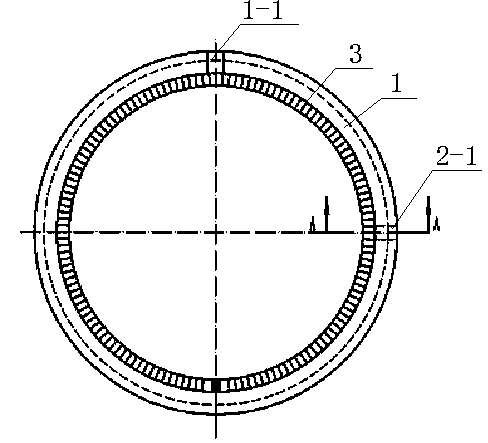

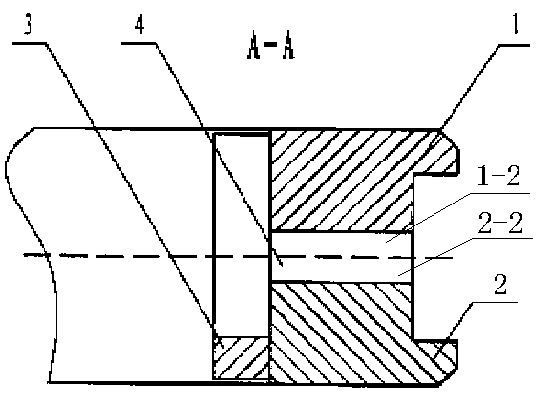

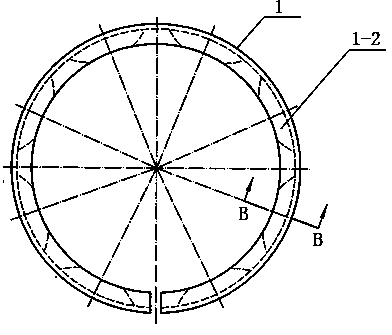

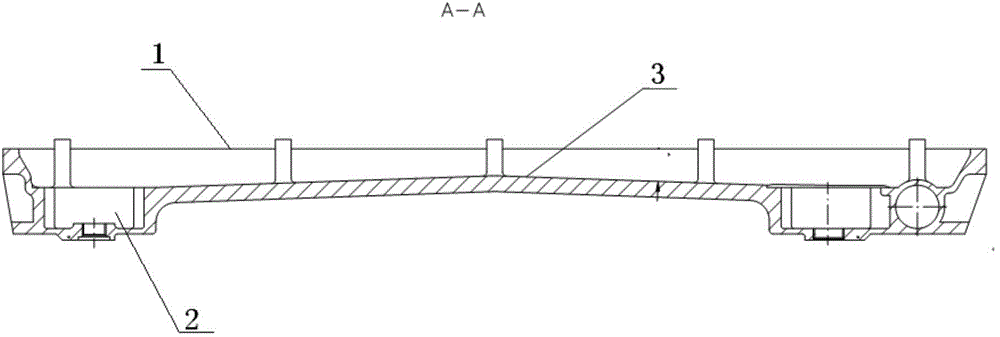

Moon cake with preservative film layer and manufacturing method thereof

InactiveCN101574102AExtended shelf lifeGood biocompatibilityPreservation by coatingBakery productsBiocompatibility TestingChemistry

The invention discloses a moon cake with a preservative film layer, which comprises filler (1) and a cake skin (2) wrapped on the filler (1). The moon cake is characterized in that the preservative film layer (3) is wrapped on the top surface and the side surface of the cake skin (2) and comprises chitosan as a main component. The effect of restraining microorganisms can be achieved by spraying a chitosan preservative film layer with bacteriostatic performance on the surface of the cake skin, which is an economic and feasible moon cake preservative method for effectively prolonging the shelf life of a moon cake; the health care function of the traditional moon cake is enhanced by utilizing the chitosan function in the components of the preservative film layer so that the moon cake as a traditional food develops towards a new health care functional characteristic direction to obtain the effect of killing two birds with one stone; and the chitosan is a basic amylase widely existing in the nature. The chitosan has the advantages of nature, innocuity, good biocompatibility, and the like and is proved by searches not to influence the health.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

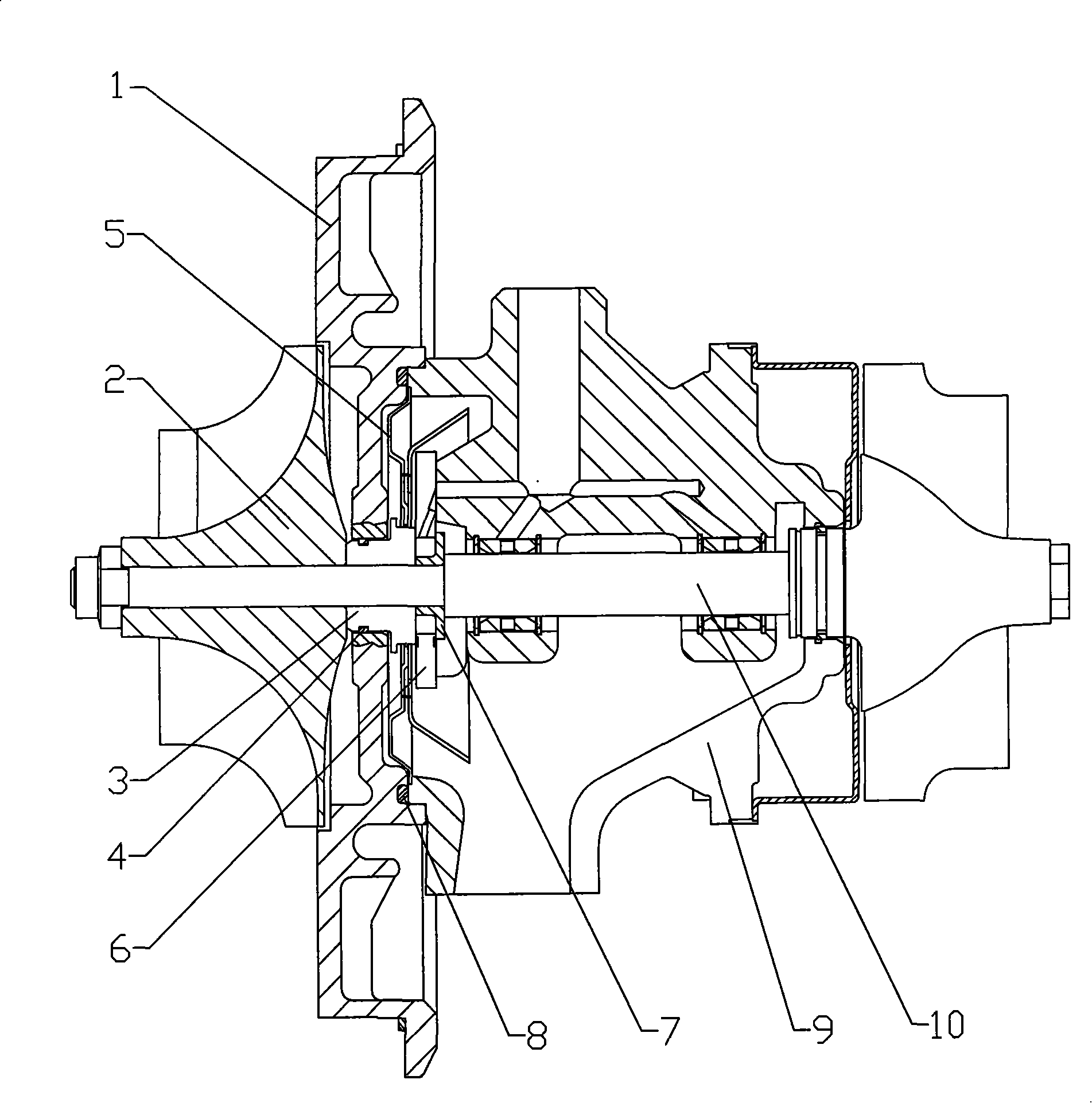

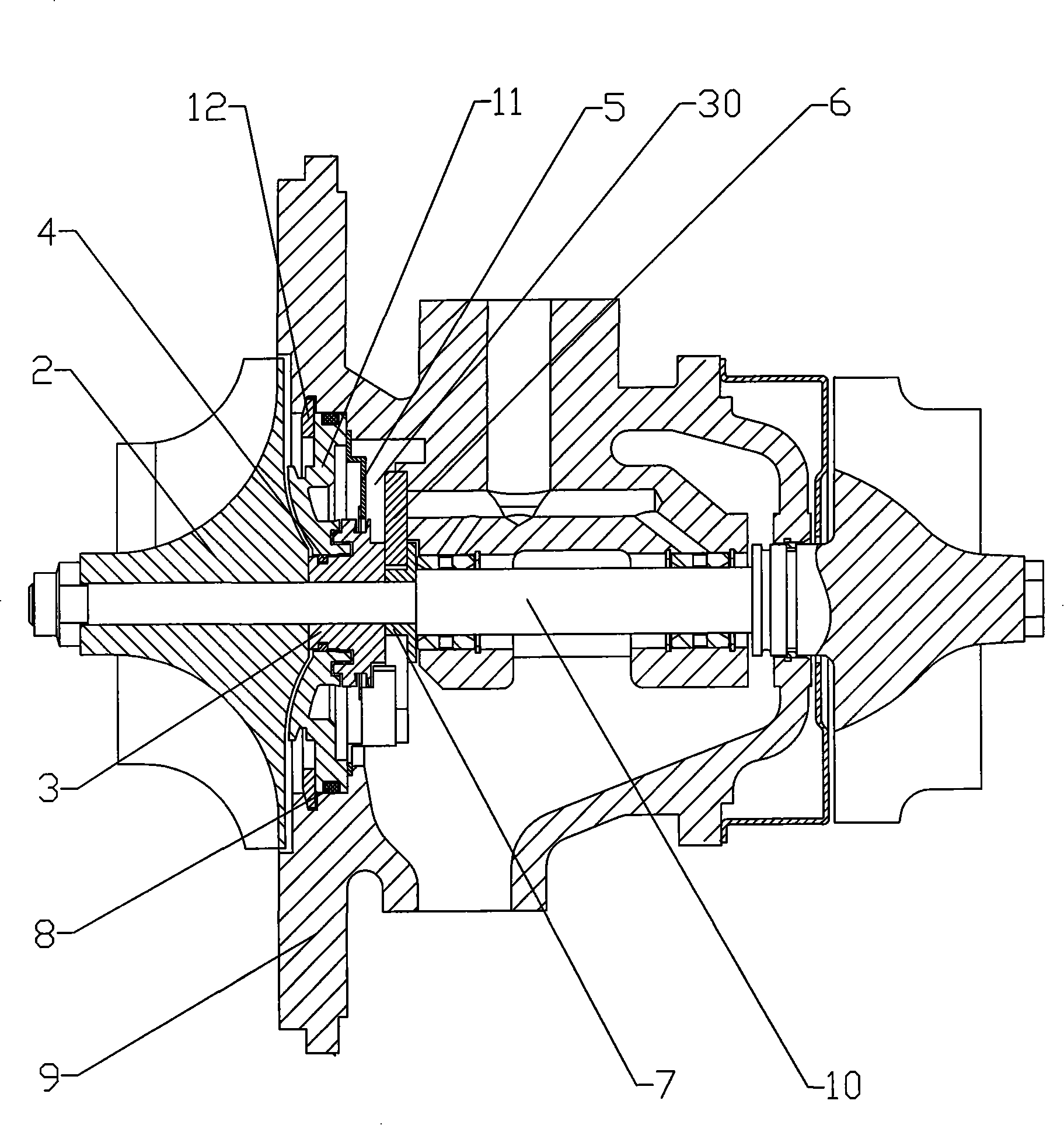

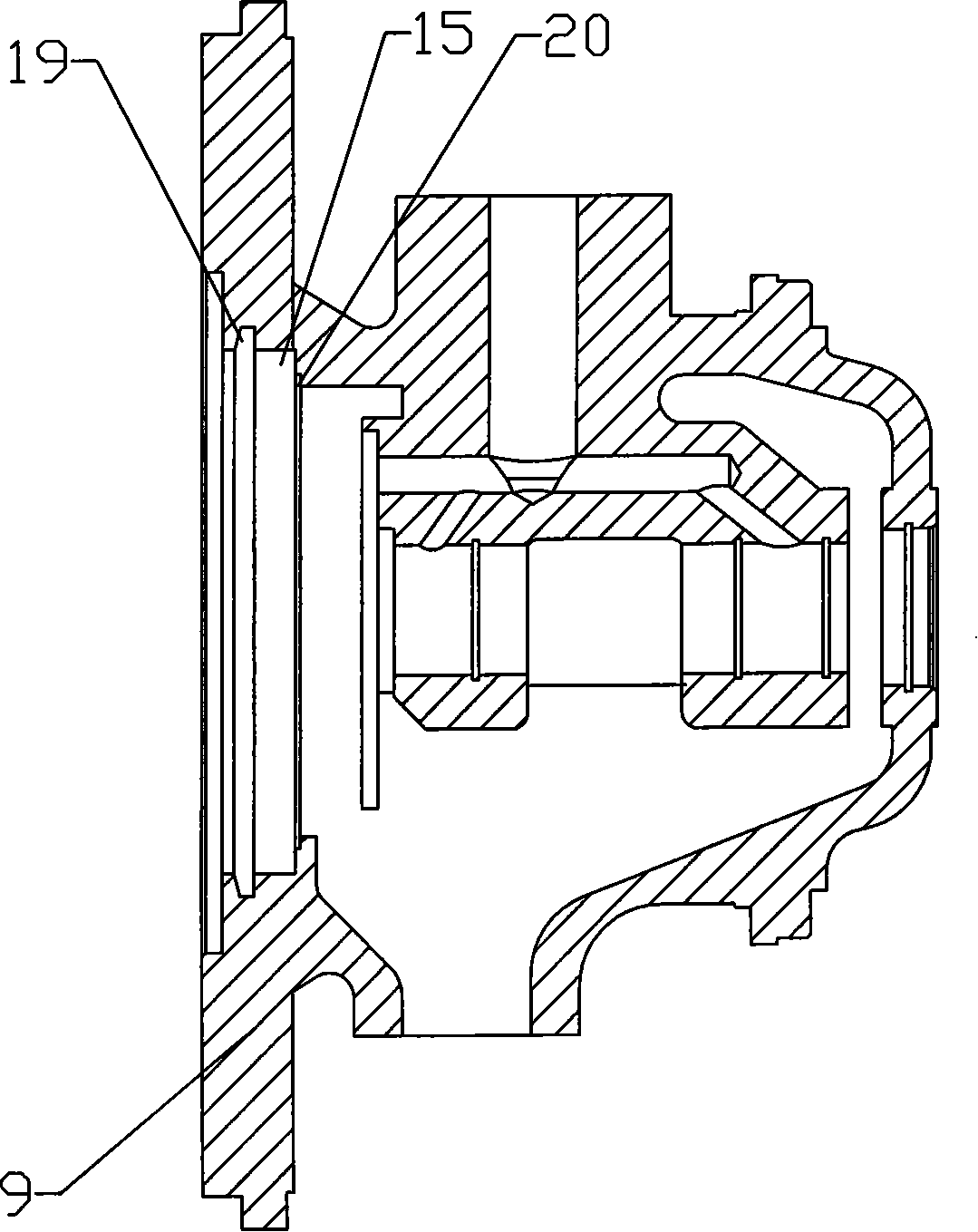

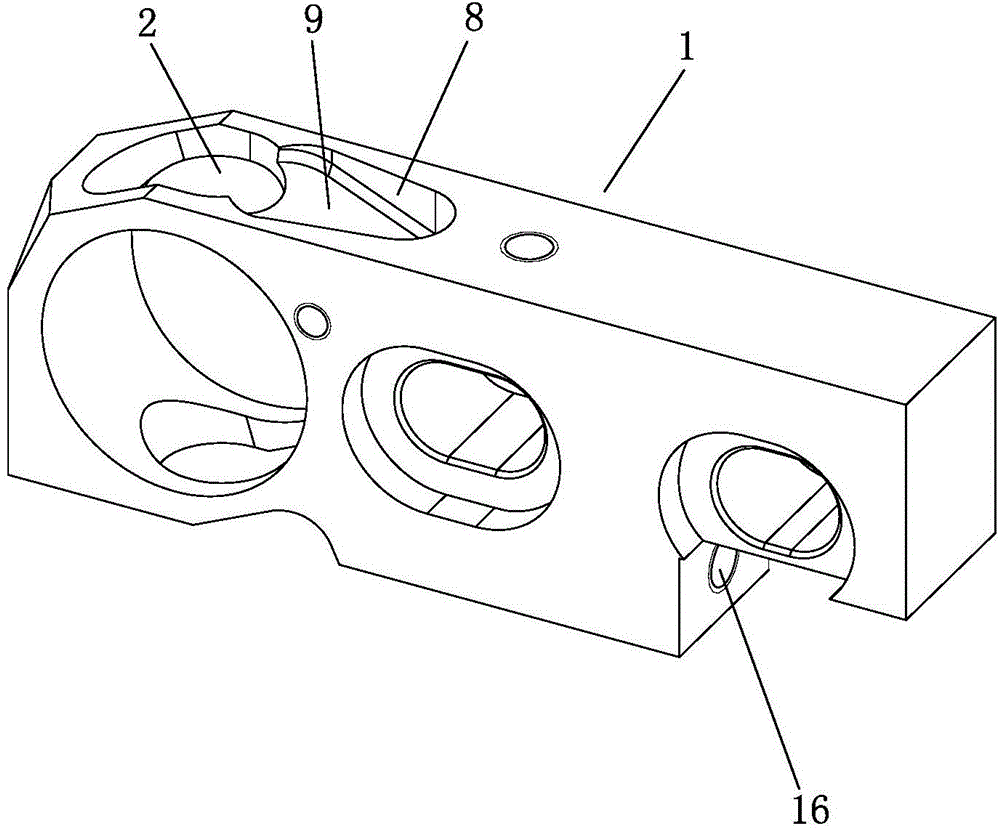

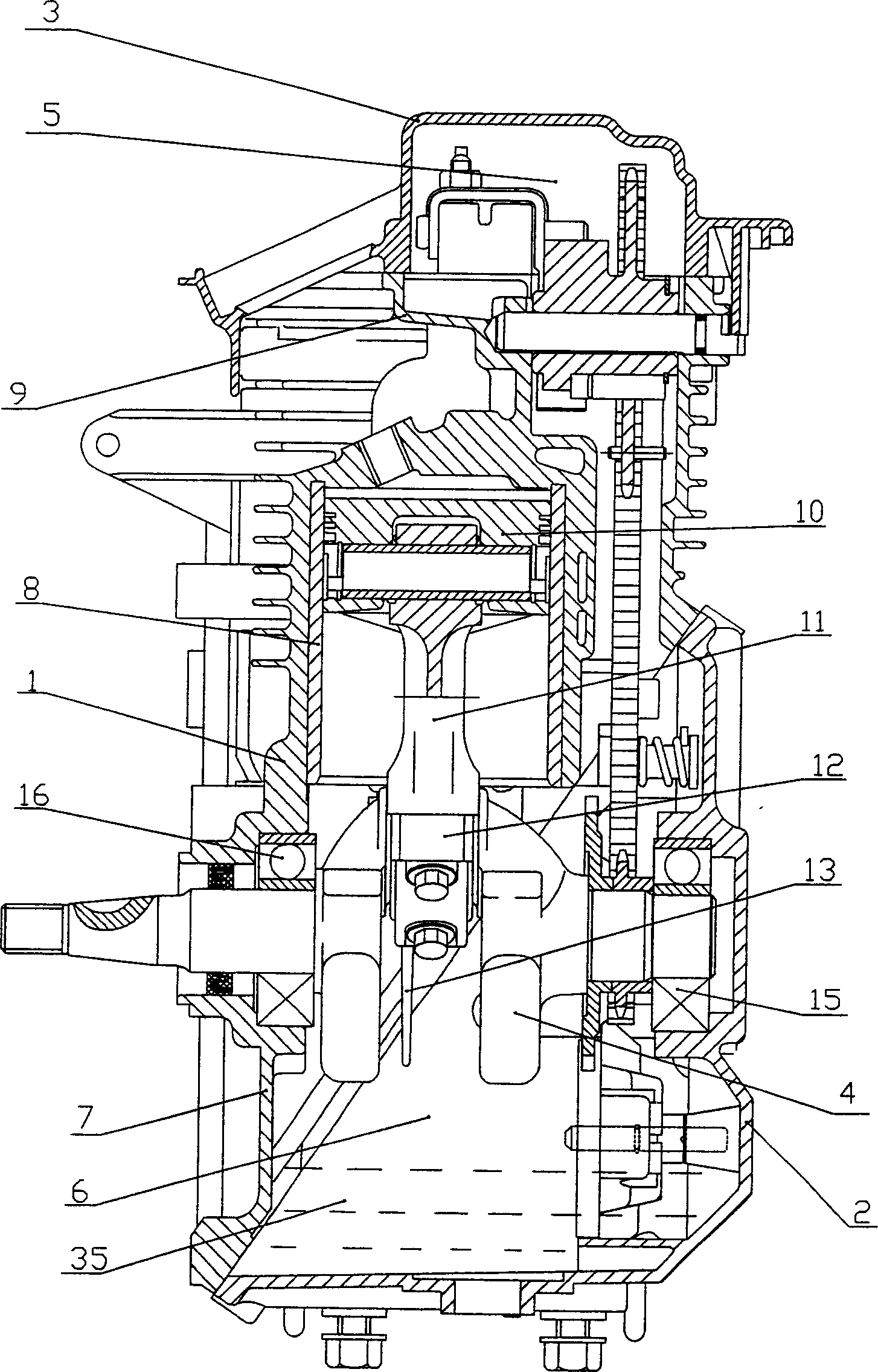

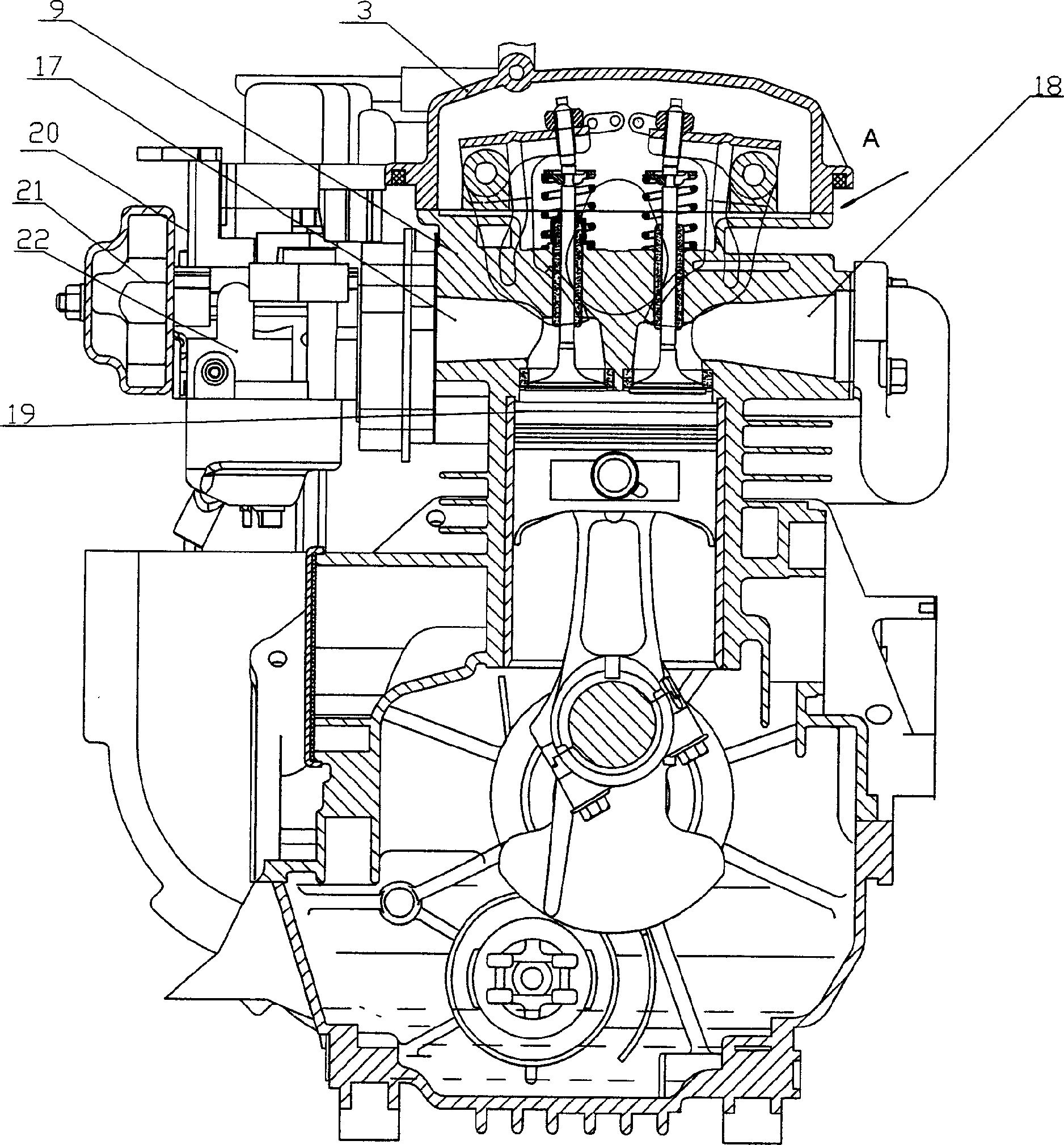

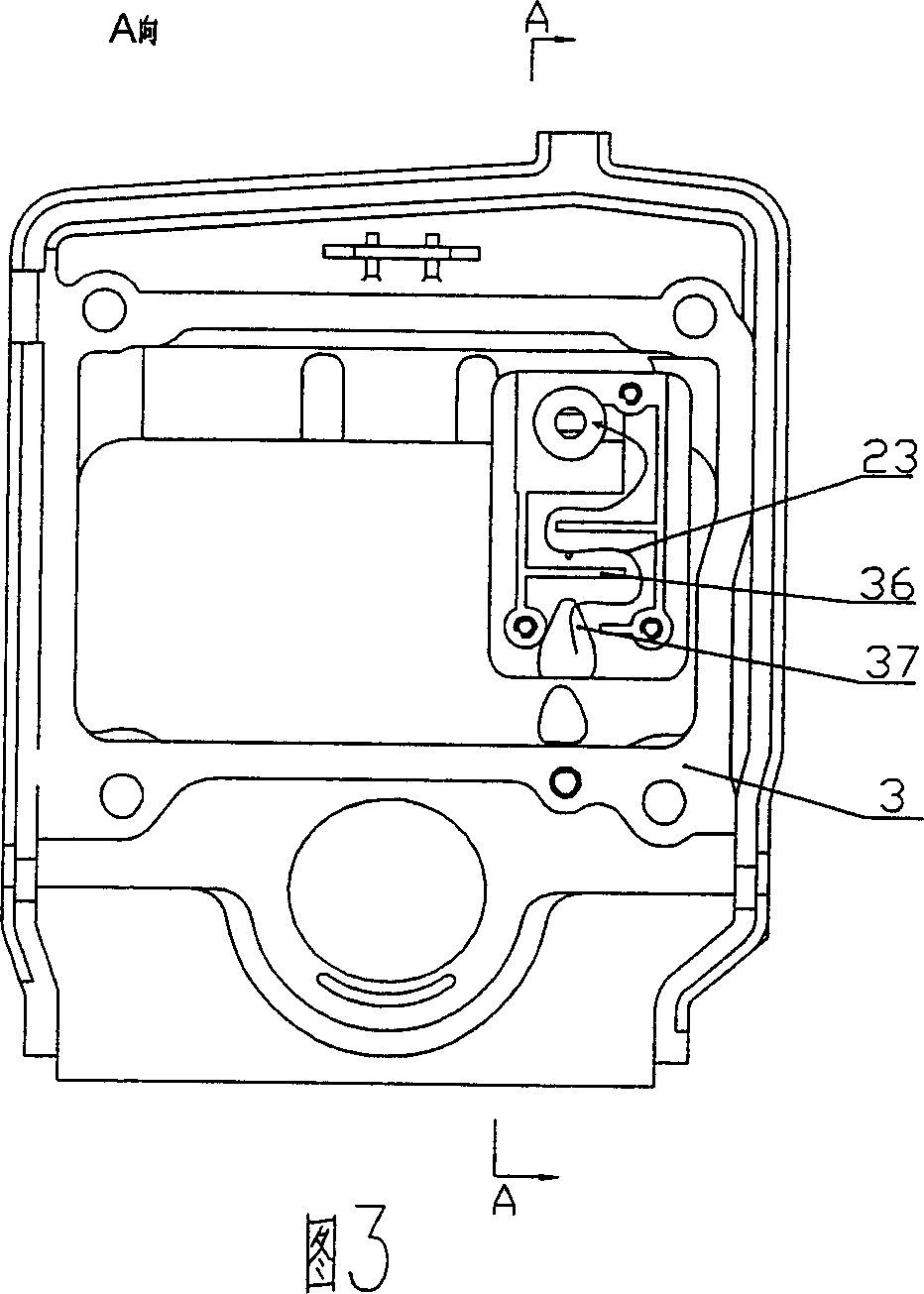

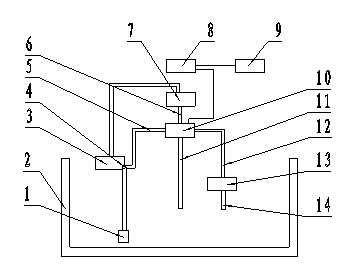

Exhaust-driven turbo-charger central rotor device

InactiveCN101187333AEfficient use ofAvoid deformationEngine sealsMachines/enginesImpellerTurbocharger

The invention discloses a kernel rotor device of an exhaust-gas turbocharger, comprising a middle casing, a thrust sleeve, a thrust bearing, an oil baffle, and a shaft gland, wherein a blade wheel is arranged on a turbine shaft on one end of the shaft gland, the middle casing on the one end of the blade wheel is provided with a chamber, a sealing ring sleeve base is arranged in the chamber, and the sealing ring sleeve base comprises a ring-shaped component which is sealed with the inner walls of the chamber and a lantern ring which is dynamically sealed by the shaft gland and is arranged on the turbine shaft. A ring-shaped connecting member is fixedly connected between the ring-shaped component and the lantern ring, one lateral side of the ring-shaped connecting member which faces the blade wheel is provided with an arc-shaped end face which is relative to the shape of the blade wheel. The original connection between a linking disk and the middle casing is changed into the connection of the middle casing and the sealing ring sleeve to remove the linking disk with large size, thereby avoiding deformation of the product. The original projection sealing is changed into notch sealing to enlarge the oil return space of the product, and the original screw pressing is changed into a circlip pressing, thereby providing conveniences for assembly, easily adopting an automatic assembly line, and reducing the cost of the product.

Owner:KANGYUE TECH

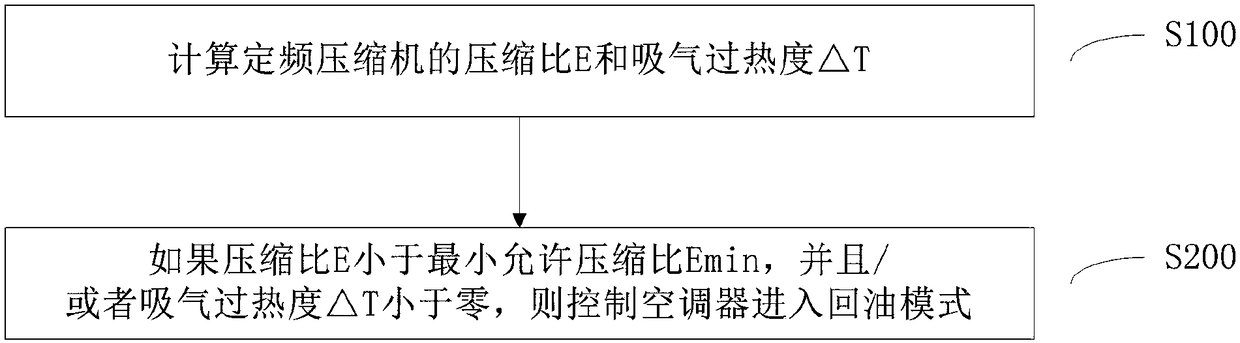

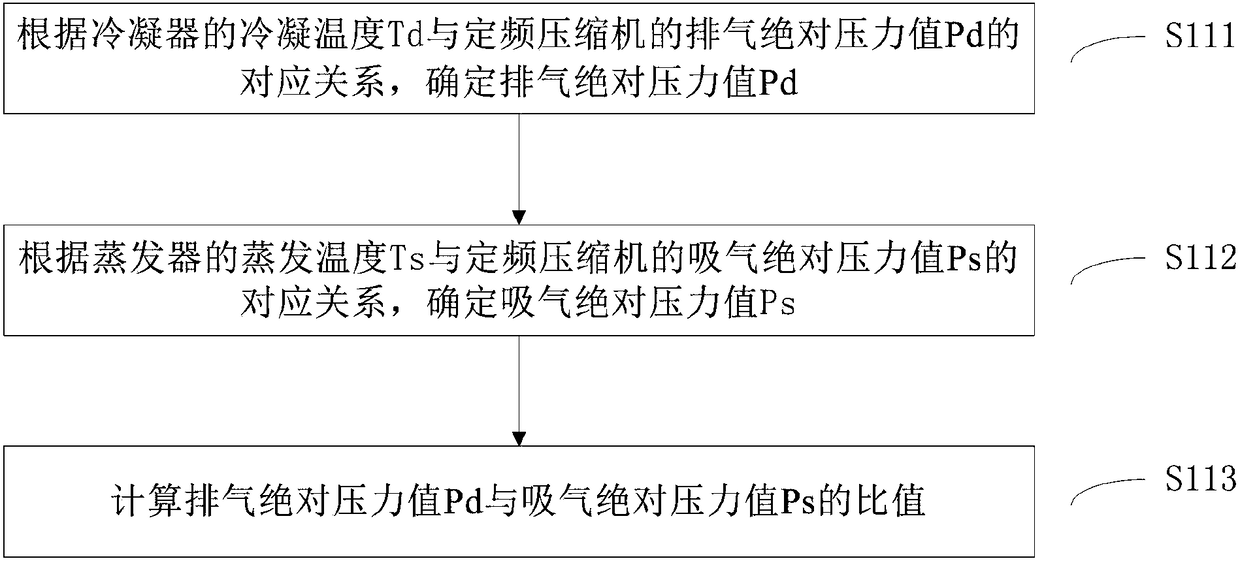

Return oil control method for air conditioner

ActiveCN108224849AImprove stabilityImprove reliabilityCompressorEfficient regulation technologiesFailure rateControl manner

The invention relates to the technical field of air conditioners, in particular to a return oil control method for an air conditioner, and is intended to solve the problem that an existing technical scheme to improve the return oil effect of a fixed frequency compressor is unable to basically solve the poor return oil issue. To this end, the return oil control method for the air conditioner comprises: calculating compression ratio E and / or suction vapor overheat delta T of a fixed frequency compressor; if the compression ratio E is less than minimum allowable compression ratio Emin and / or thesuction vapor overheat delta T is less than zero, controlling the air conditioner to enter a return oil mode. During operation of the fixed frequency compressor, when the compression ratio E is less than the minium allowable compression ratio Emin and / or the suction vapor overheat delta T is less zero, the air conditioner is controlled to enter the return oil mode; through the above control manner, the return oil control method for the air conditioner can provide improved return oil effect for the compressor, reduced failure rate for the compressor and extended life for the compressor.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Rotary oil seal of multi-head spiral oil return line

The invention discloses a rotary oil seal of a multi-head spiral oil return line, which comprises a rubber body, a skeleton and a seal lip. The rubber body, the skeleton and the seal lip are integrated, the seal lip is made from a polytetrafluoroethylene sheet, and the contact surface of the seal lip made from the polytetrafluoroethylene sheet and a shaft is provided with 2-7 spiral oil return lines of which the direction of rotation is in accordance with that of the shaft and intersected with the end of the polytetrafluoroethylene sheet for making the seal lip. By adopting the deign of multi-head helical line, the invention has the advantages of big oil return capability, reliable seal, long service life, energy conservation and environment protection, and is capable of preventing the entry of dust.

Owner:YANTAI RUNFUXIANG OIL SEAL

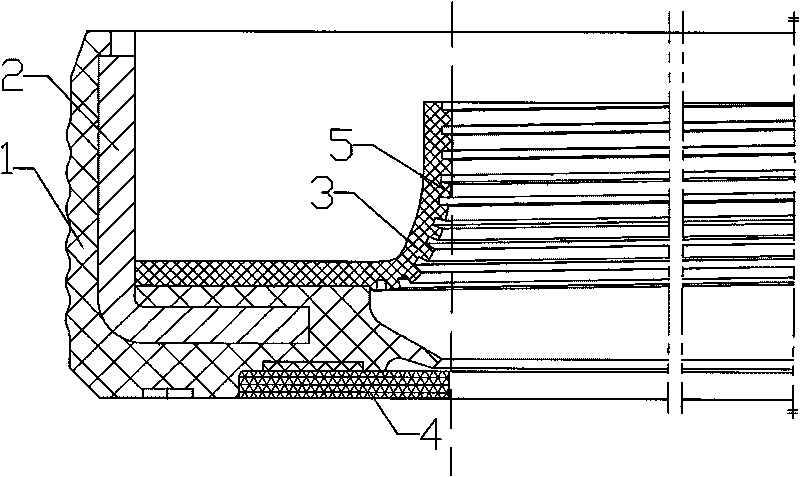

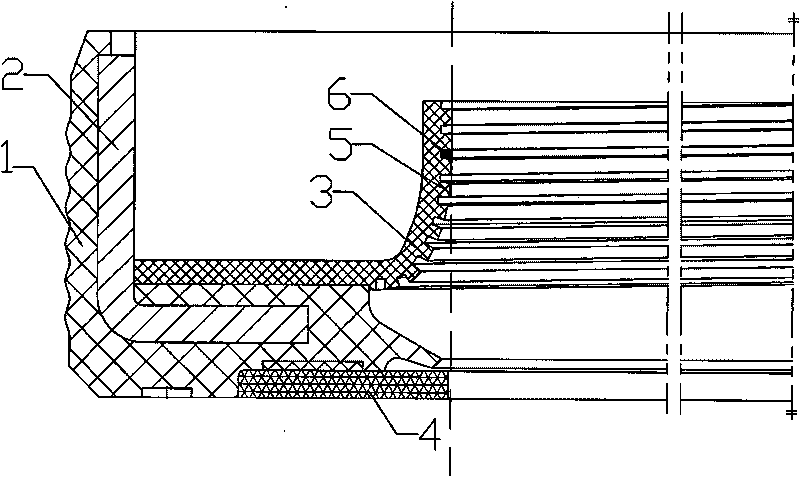

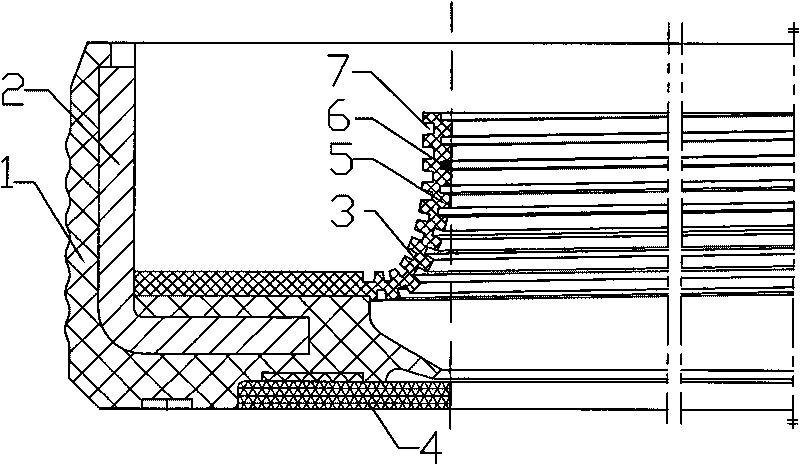

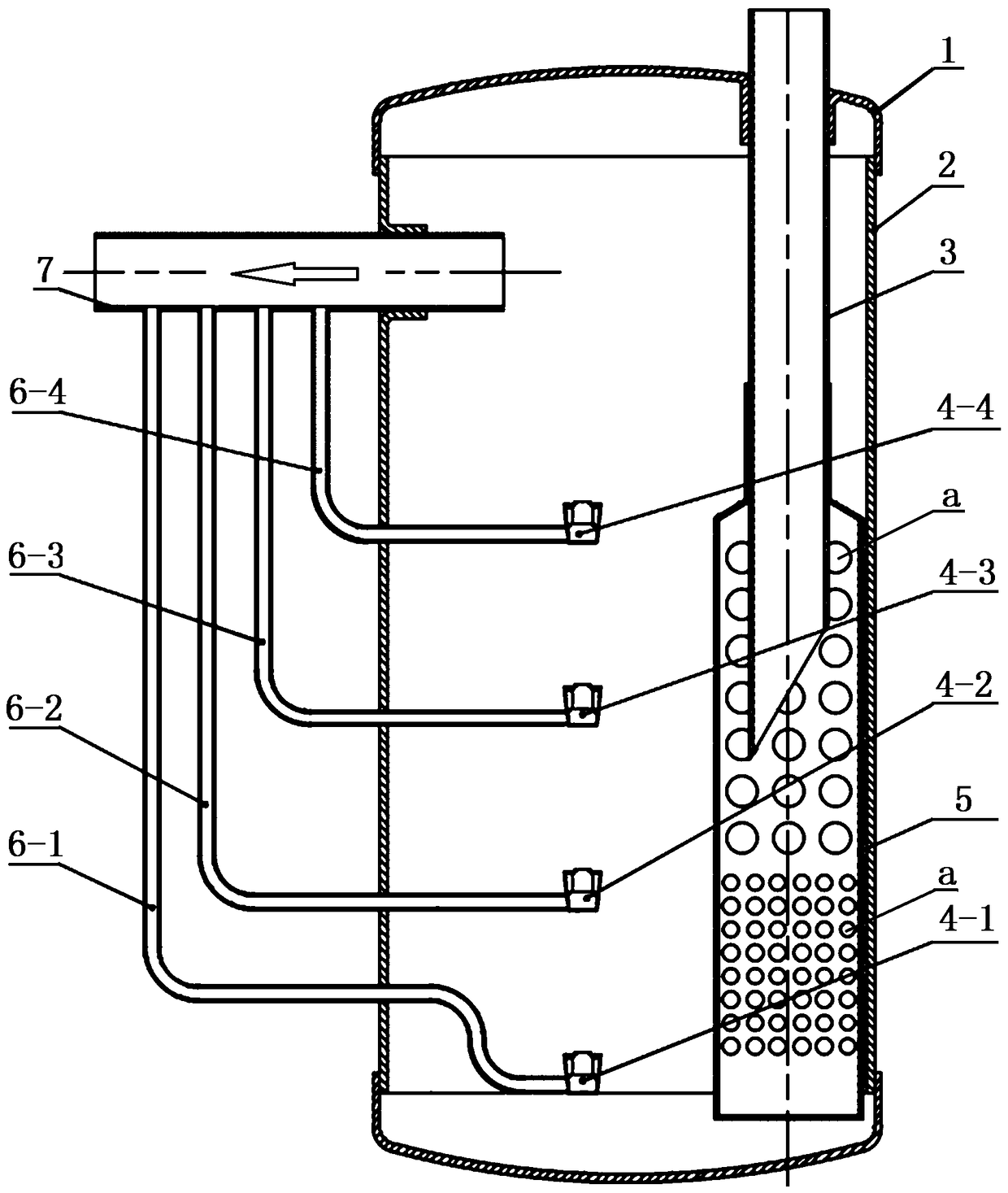

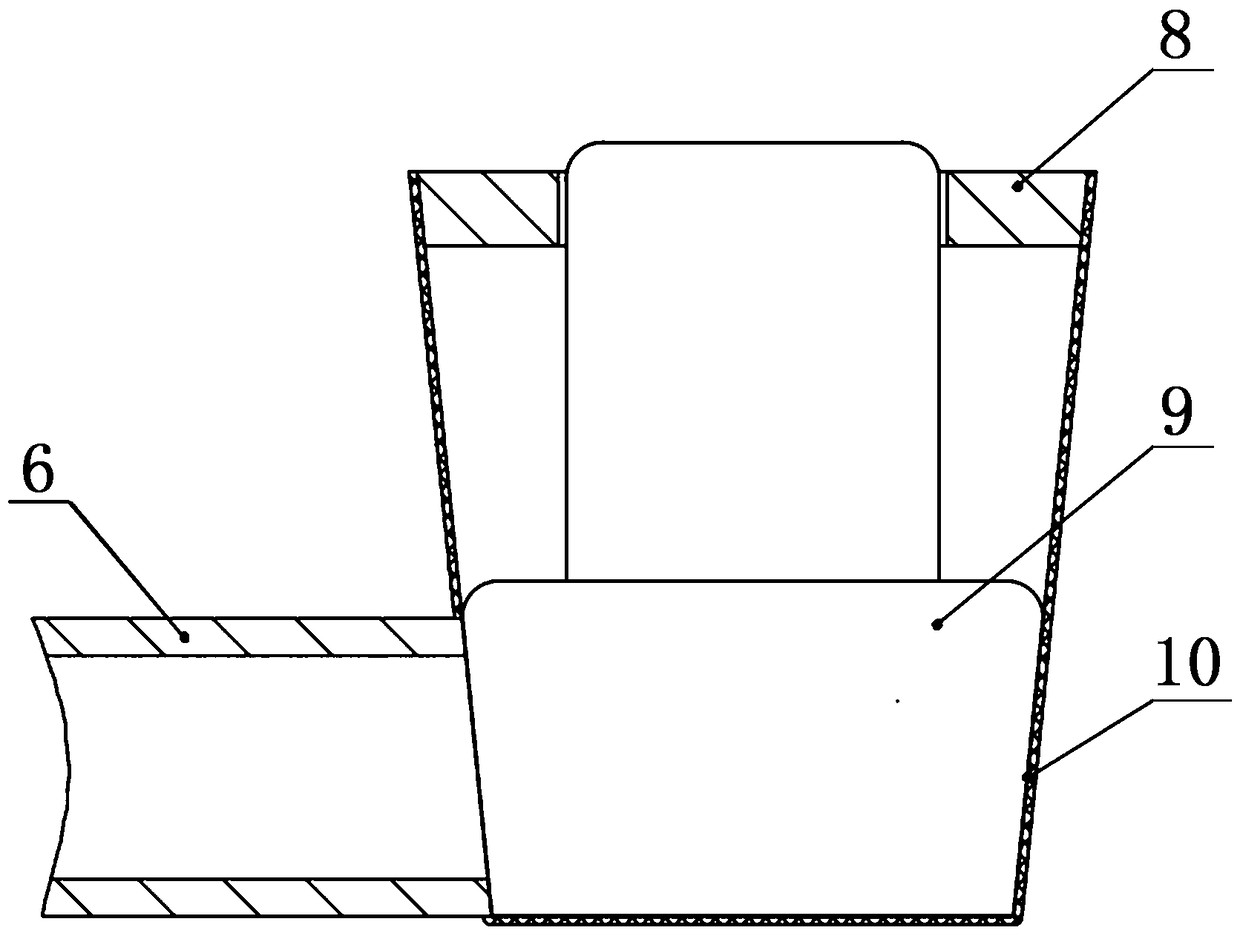

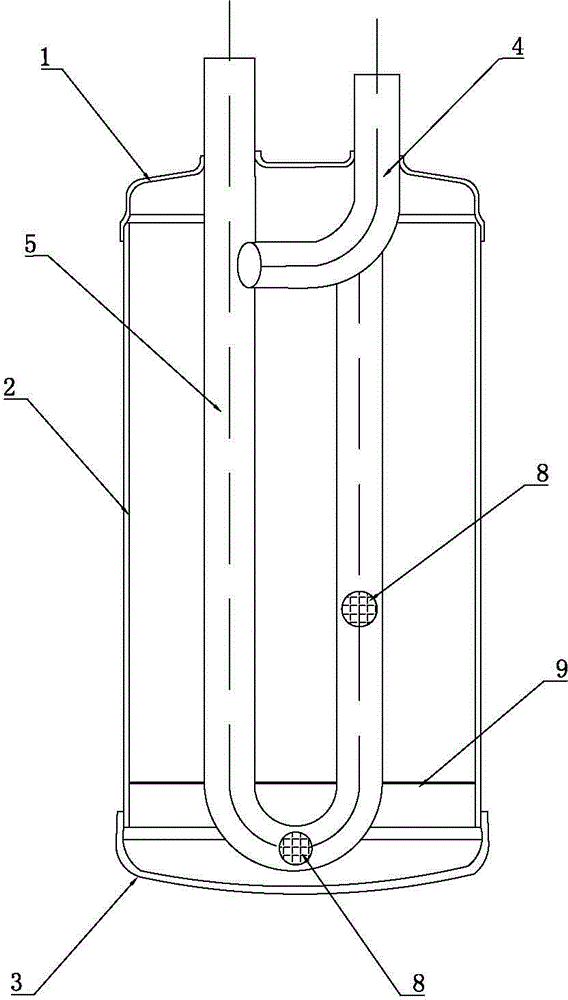

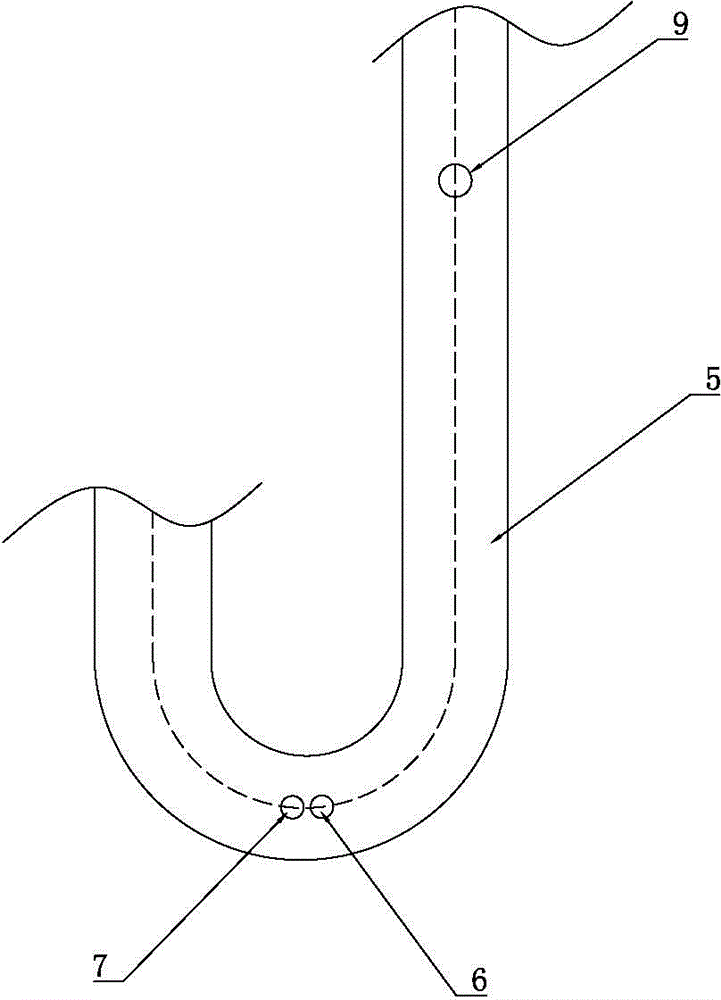

Multi-channel oil returning floater gas-liquid separator

PendingCN109140847AWith throttling effectSolve the disadvantage that the oil return cannot be adjusted according to the oil level changeCompressorVapor–liquid separatorLiquid state

The invention discloses a multi-channel oil returning floater gas-liquid separator. The multi-channel oil returning floater gas-liquid separator comprises a separator body shell, and an end cover arranged at the top of the body shell; and a gas-liquid separation system connected with an evaporator of an air conditioning unit and a multi-channel oil returning system connected with an intake port ofa compressor are arranged in the separator body shell. The multi-channel oil returning floater gas-liquid separator has the following characteristics: (1) multiple oil returning pipes with differentheight positions are used for returning oil according to the load change of an air conditioner and different working conditions, so that the defect of incapability of adjusting the oil returning according to the oil level change in the load change of the air conditioner due to fixed position of an oil returning hole of a traditional gas-liquid separator is solved, and the oil returning effect is effectively guaranteed; (2) a gas-liquid separation cylinder is arranged in an inlet of the gas-liquid separator for improving the gas-liquid separation effect; and (3) the oil returning pipes achievea throttling effect, so that liquid-state refrigerants in the returned oil are gasified, and the liquid shock risk of the compressor is reduced; and meanwhile, returned gas can be cooled to reduce harmful overheat and energy consumption.

Owner:HENAN UNIV OF URBAN CONSTR +1

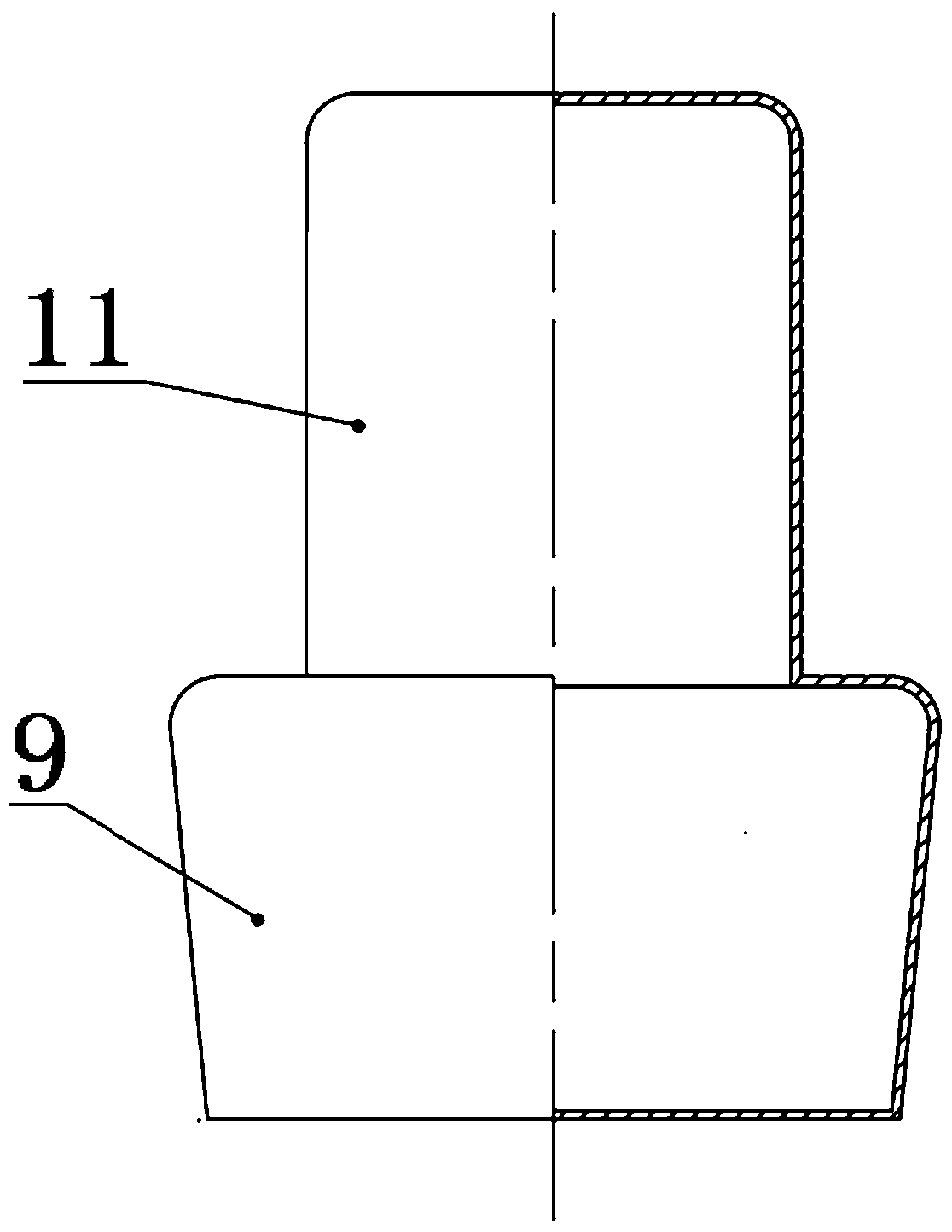

Forced oil return mechanism of upper looper slide bar of sewing machine

ActiveCN105274747AAvoid affecting the orderlyGood oil return effectLubrication/cooling devicesEngineeringReturn channel

The invention belongs to the technical field of sewing machines, and particularly to a forced oil return mechanism of an upper looper slide bar of a sewing machine. The forced oil return mechanism of the upper looper slide bar of the sewing machine comprises an upper looper slide bar seat, the upper looper slide bar in an upper looper slide bar hole of the upper looper slide bar seat, the upper looper slide bar seat is fixedly provided with oil absorption cotton, the oil absorption cotton contacts with and is connected to the upper lopper slide bar, the upper looper slide bar seat is provided with an oil return channel, the oil return channel is connected to an oil tube, the oil tube is connected to an oil pump, and the oil pump can make oil on the upper lopper slide bar forcedly return through the oil absorption cotton and the oil return channel. The forced oil return mechanism can make oil on the upper lopper slide bar forcedly return, oil stain can be prevented from being thrown away along with motion of the upper looper slide bar, so no oil stain splashes on the cloth, the cloth will not be polluted, order production cannot be affected. The forced oil return mechanism is good in oil return effect, simple in structure, low in cost and can be applied to the present sewing machine. The oil absorption cotton can be fixed to the upper looper slide bar seat through a cover plate, so the oil absorption cotton is convenient to mount and dismount, only the cover plate needs mounting / dismounting, and other parts do not need mounting / dismounting.

Owner:JACK SEWING MASCH CO LTD

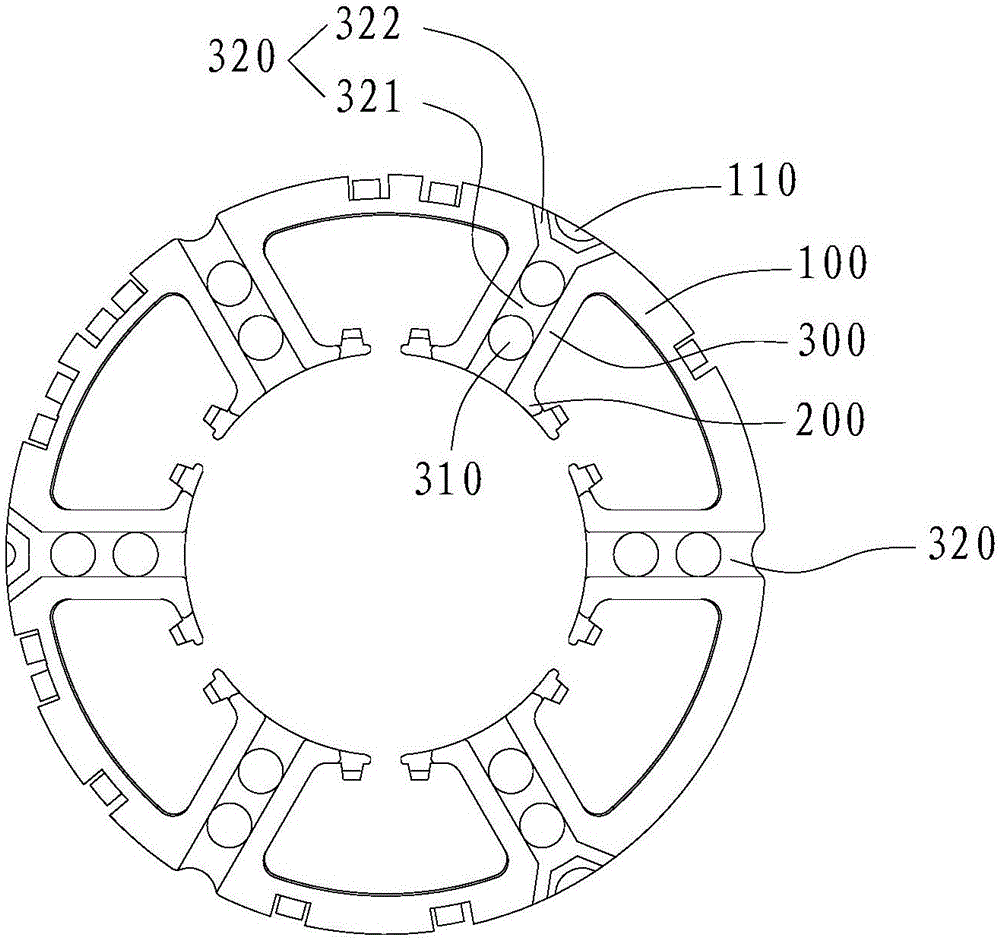

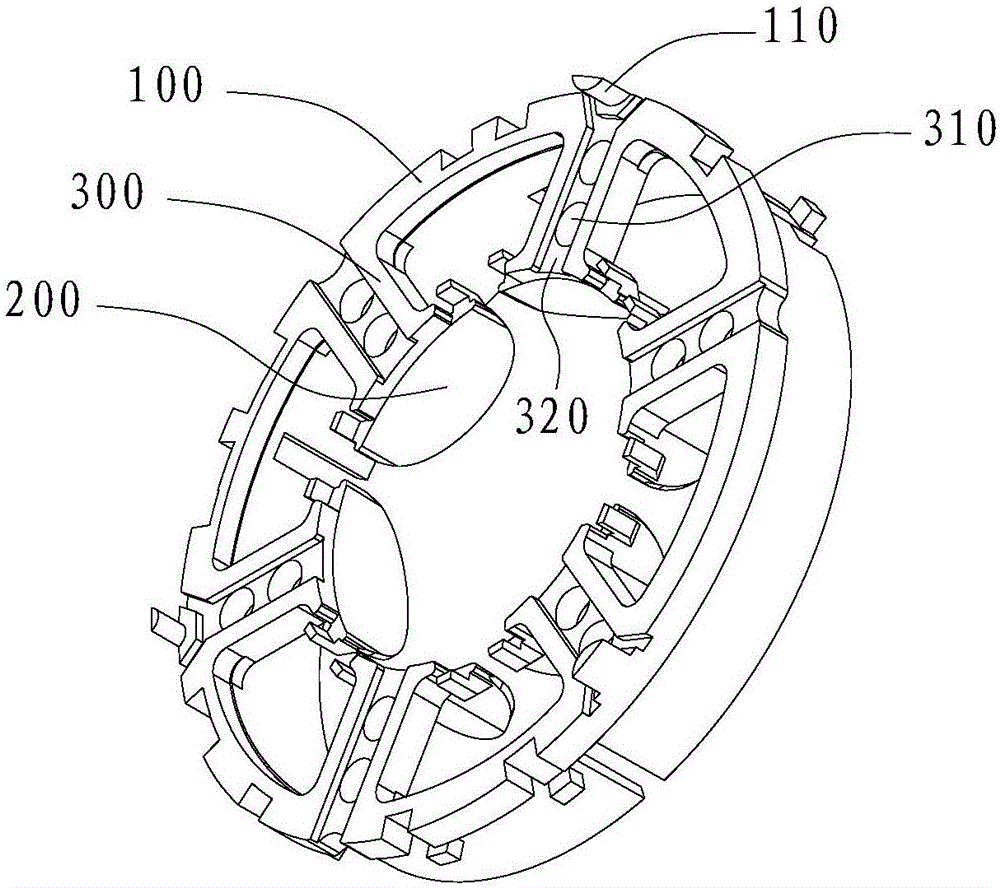

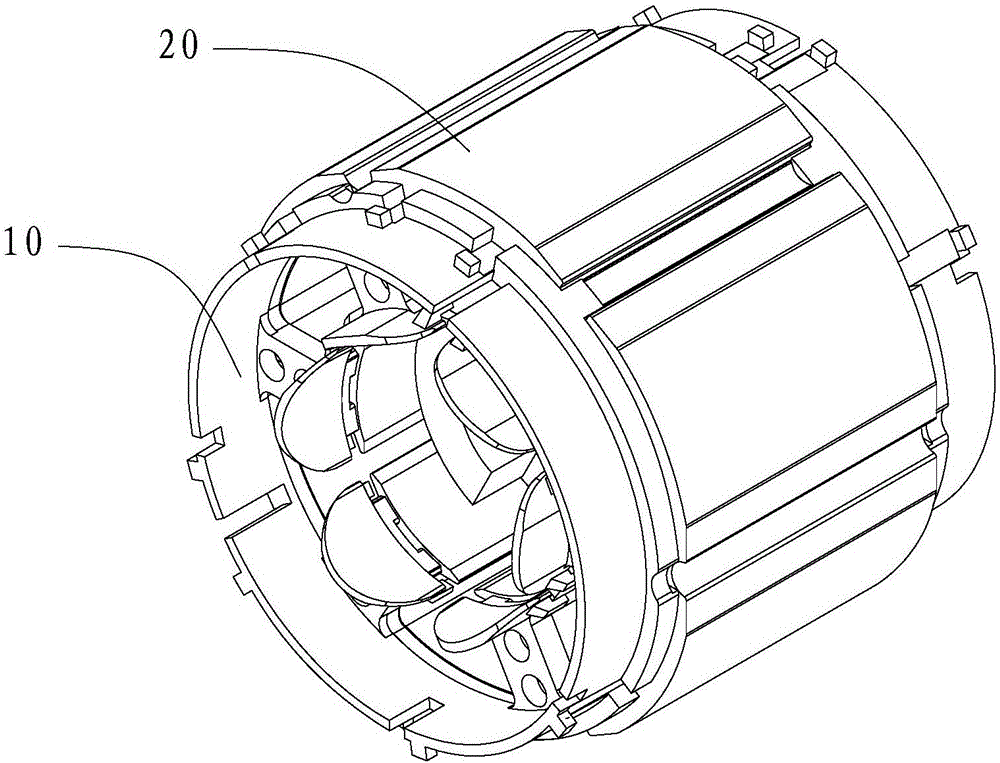

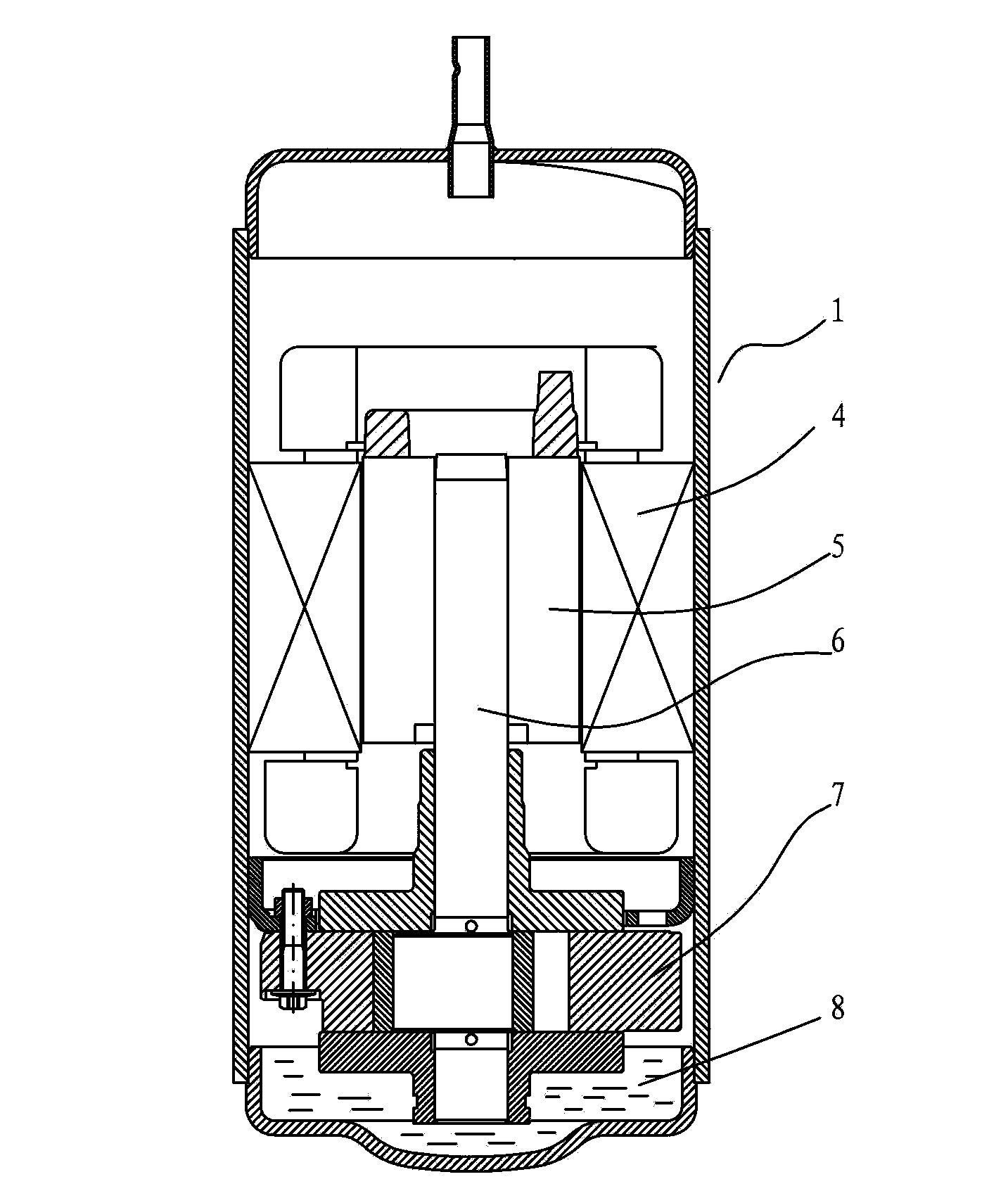

Compressor motor, motor stator and motor insulation skeleton of compressor motor

ActiveCN106160294AImprove efficiencyExtended service lifeWindings insulation shape/form/constructionCooling effectMotor insulation

The invention provides a motor insulation skeleton. The motor insulation skeleton comprises a skeleton outer wall, a skeleton inner wall and a plurality of skeleton winding parts, wherein the skeleton outer wall and the skeleton inner wall are annularly circled, the plurality of skeleton winding parts are connected between the skeleton outer wall and the skeleton inner wall, gas channels are formed in the skeleton winding parts, inlets of the gas channels are positioned in the skeleton inner wall, and outlets of the gas channels are positioned in the skeleton outer wall. When a motor rotor rotates, gas can flow from the skeleton inner wall to the skeleton outer wall through the gas channels, and then flows from the outer wall of a stator to an exhaust end, so that a flow area is increased, and the oil return effect of a compressor is increased; additionally, the gas flows through the skeleton winding parts, so that a part of heat generated by a stator winding can be removed, the cooling effect on the stator winding is achieved, the motor efficiency is improved, and the service life of a motor is prolonged. The invention further provides a motor stator on which the motor insulation skeleton is installed, and a compressor motor on which the motor stator is assembled.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

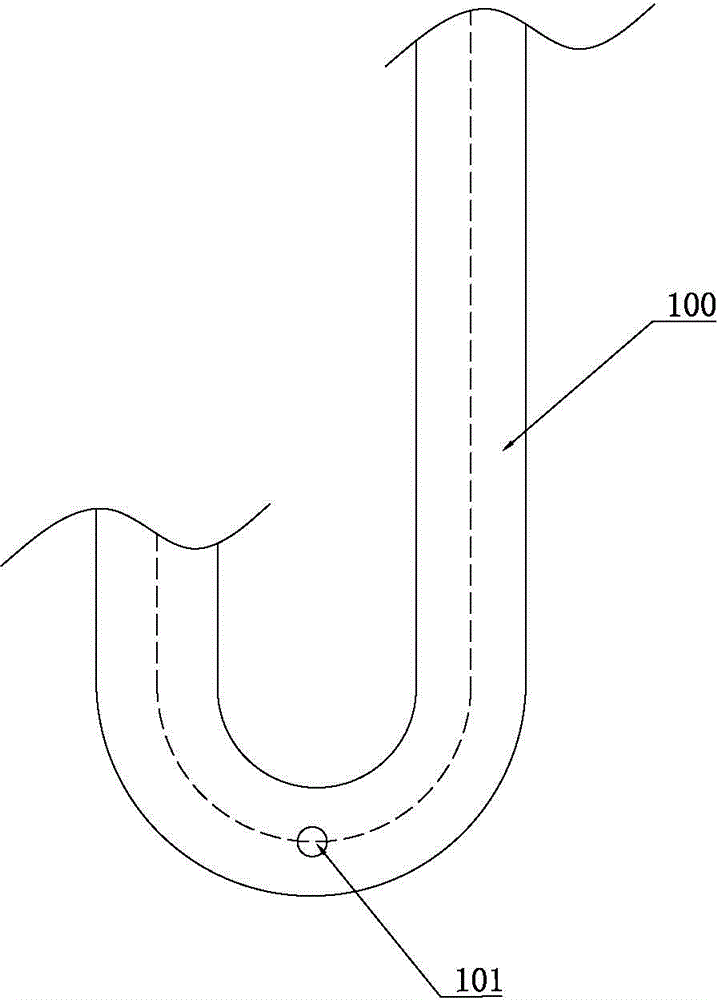

Gas-liquid separator

ActiveCN104949406AGuaranteed lubrication effectReduce wearRefrigeration componentsVapor–liquid separatorEngineering

The invention provides a gas-liquid separator, and belongs to the technical field of air conditioner. The structure of the gas-liquid separator comprises a closed drum body, an air inlet pipe and a U-shaped air outlet pipe. The air inlet end of the air inlet pipe is arranged outside the drum body. The air outlet end of the air inlet pipe is inserted into the drum body. The U-shaped air outlet pipe is arranged on the drum body, and the air outlet end of the U-shaped air outlet pipe is stretched out of the drum body. Two oil return holes which are adjacent and are arranged side by side are formed in one side face of the U-shaped bottom of the U-shaped air outlet pipe. Oil returning is conducted simultaneously, the stable oil return can be achieved, the oil return quantity can be controlled, and backflow quantity of liquid refrigerant is reduced under the regulation of refrigerant oil attenuating, so that the lubricity of the refrigerant oil is guaranteed, the oil return quantity inside the compressor is guaranteed, therefore wear to the running components in the compressor can be reduced, and liquid slugging of the compressor can be prevented effectively at the same time. According to the gas-liquid separator, the principle that the oil return property of the compressor is improved by changing the hole diameter of an oil return hole in the prior art, and an oil return property of the compressor is improved by arranging the two adjacent and abreast oil return holes.

Owner:GUANGDONG EUROKLIMAT AIR CONDITIONING & REFRIGERATION

Air-exchanging structure of crank case of four-stroke engine

ActiveCN1818355AGuaranteed lightweightSimple structureMachines/enginesCrankcase ventillationFour-stroke engineCrankcase

Owner:WUXI KIPOR POWER CO LTD

Refrigeration device

InactiveCN103388919AStrong solvencyImprove oil returnCompression machines with non-reversible cycleBase-materialsRefrigerantMineral oil

The invention discloses a refrigeration device, comprising a refrigeration cycle which is at least composed of a compressor, a condenser, a swelling mechanism and an evaporator, wherein an R32 refrigerant and refrigerating machine oil are filled in the refrigeration cycle; the refrigerating machine oil is formed by mixing more than two of polyalkane glycol ether, polyvinyl ether, poly alpha olefin, alkylbenzene and mineral oil randomly; the second-layer separate temperature of one of the random more than two and the R32 refrigerant is lower than 10 DEG C below zero; the second-layer separate temperature of the other of the random more than two and the R32 refrigerant is higher than 10 DEG C below zero; the kinematic viscosity of the refrigerating machine oil is 2-100mm2 / s when the temperature is 40 DEG C; more than one of antioxygen, acid catcher, antifoaming agent and extrusion antiwear agent is added into the refrigerating machine oil. The refrigerating machine oil and the R32 refrigerant have excellent dissolving capacity, the oil return property of the system is improved, and the reliability of the compressor and the system performance are improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Tea flavor minced fillet mooncake and preparation method thereof

InactiveCN106259799ASolve wasteSolve processabilityDough treatmentBakery productsMaltitolAlpha-amylase

The invention discloses a tea flavor minced fillet mooncake and a preparation method thereof. A mooncake wrapper is prepared by taking low gluten flour as the basic material and adding composite maltitol syrup, plant oil, skim milk powder, alkaline water and sodium dehydroacetate. Mooncake stuffing is prepared by taking minced fillet as the basic material and adding maltitol, glutinous rice powder, plant oil, purified water, composite tea powder, baijiu, salt, instant dry yeast, sodium dehydroacetate and alpha-amylase. The tea flavor minced fillet mooncake is prepared through the procedures of minced fillet preprocessing, wrapper and stuffing making, forming, baking, cooling, packaging and the like. The prepared finished product is golden in color, free of fishy smell, fresh in tea aroma and soft in taste, has the advantages of being high in protein and low in fat and calorie, has the health-care effects of clearing away heat and toxin, refreshing people and arousing the brain, helping digestion and promoting appetite, preventing ageing and cardiovascular diseases, enhancing memory and the like, and can be preserved at normal temperature.

Owner:武夷学院

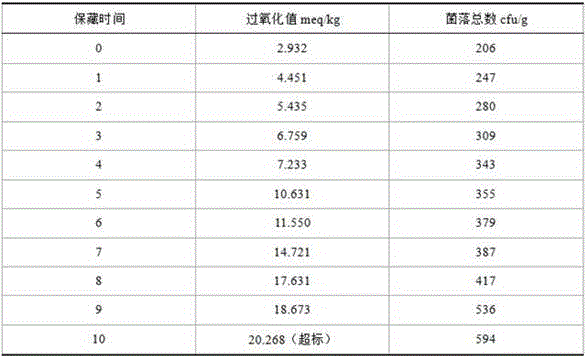

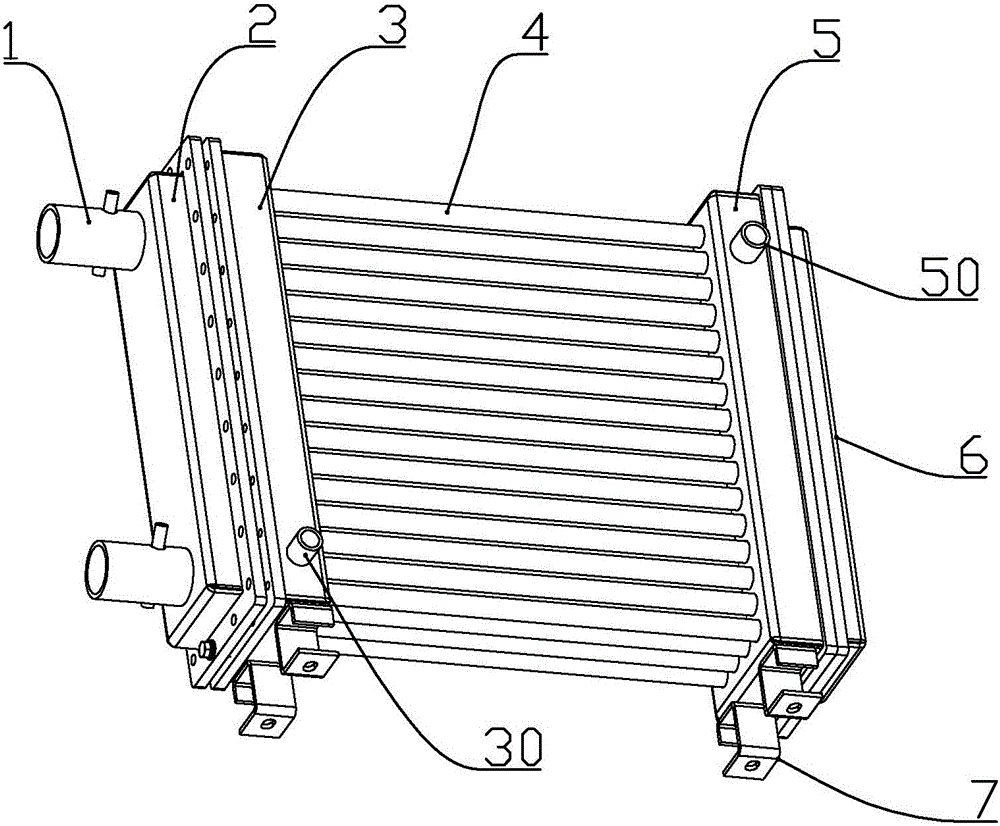

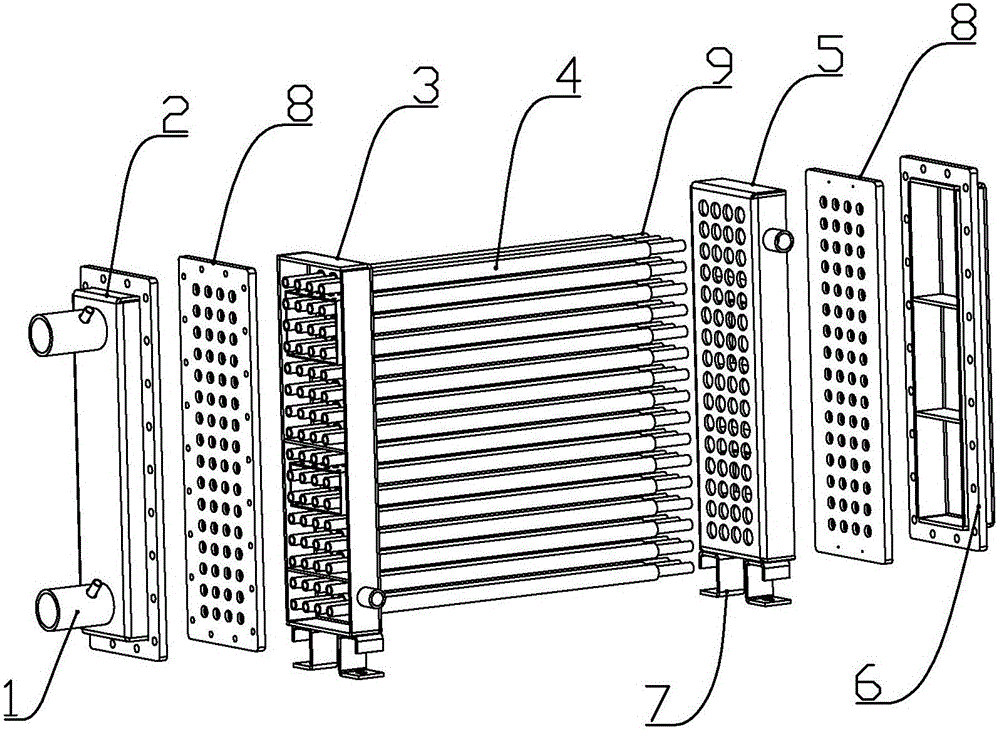

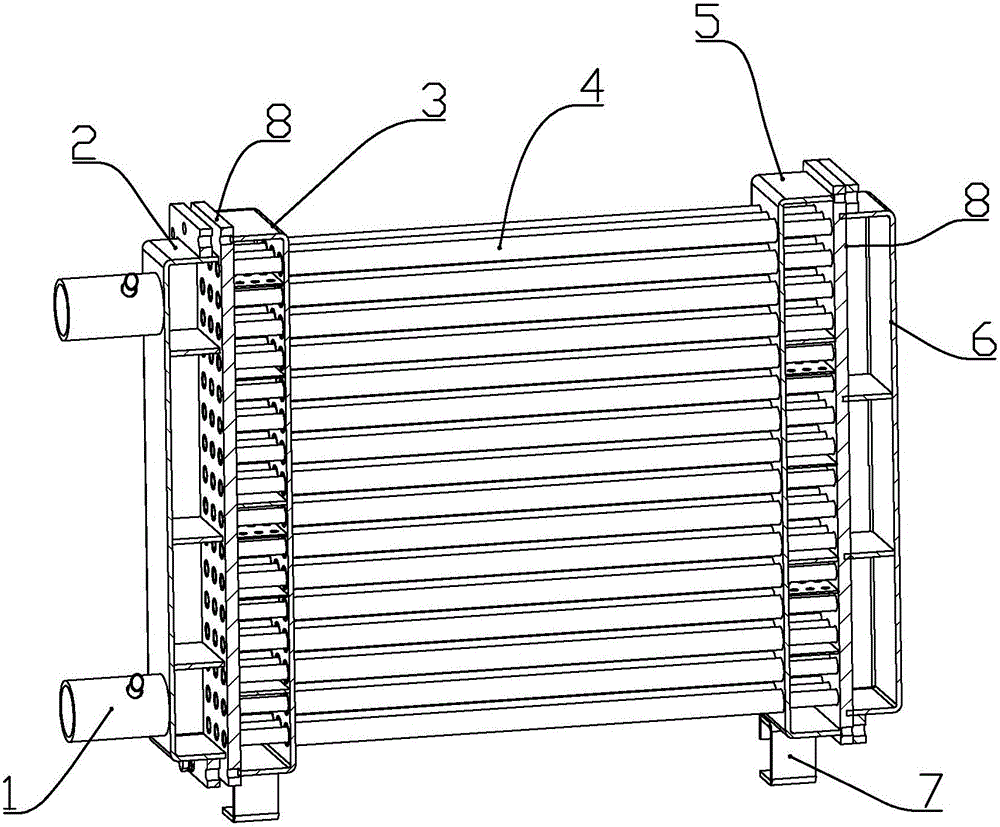

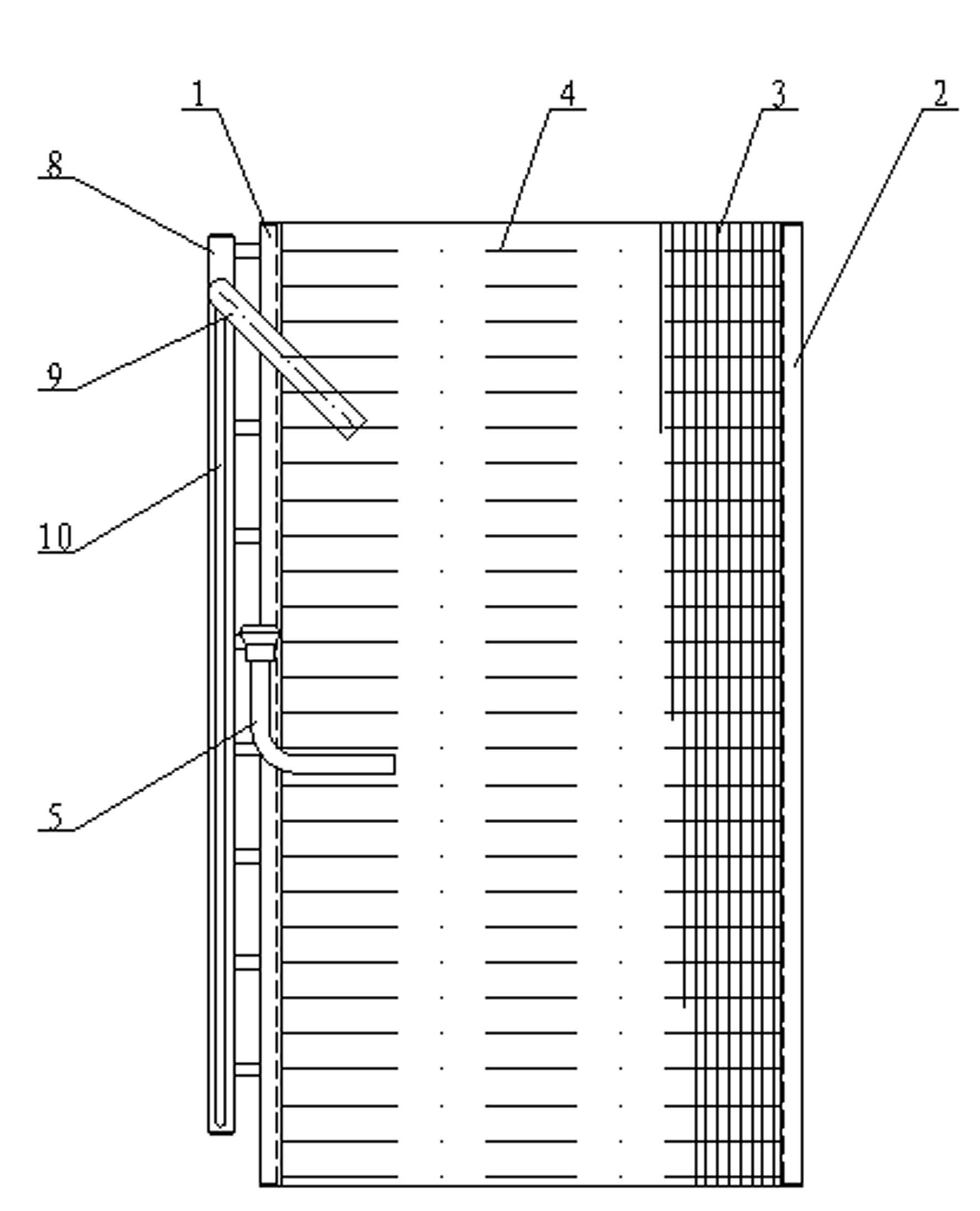

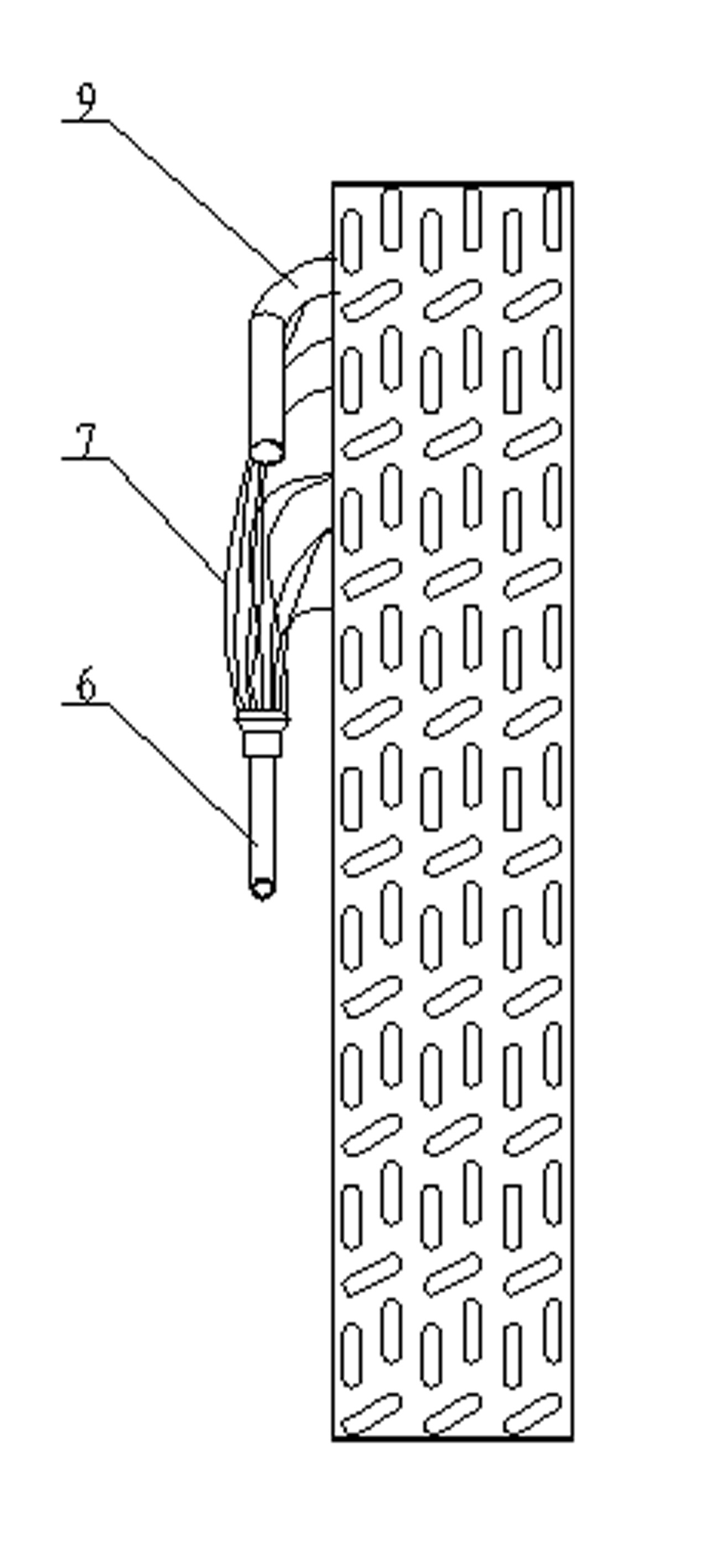

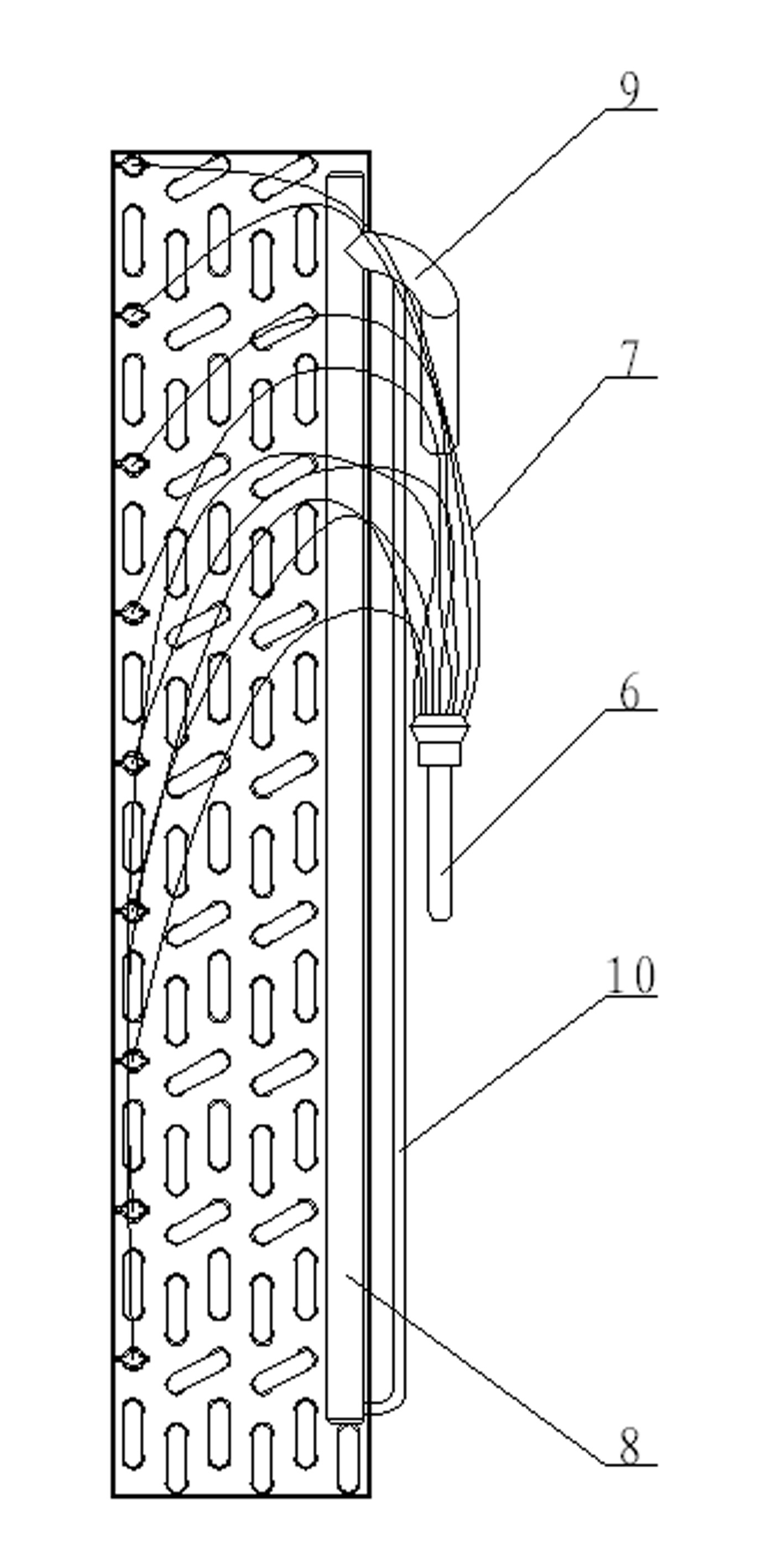

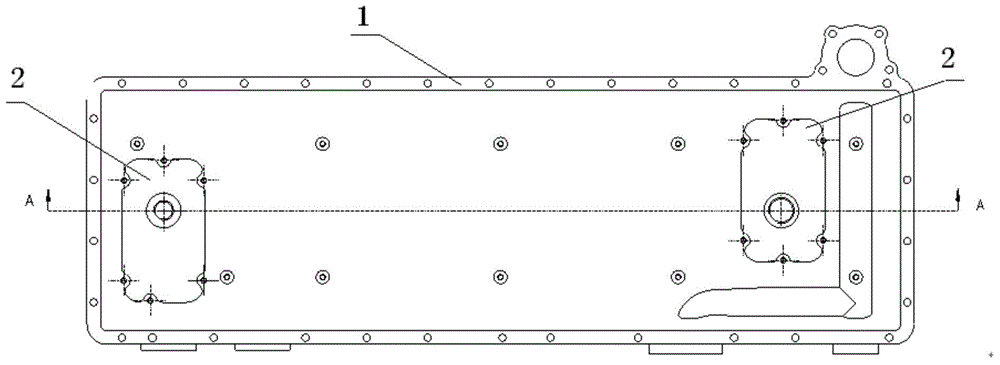

Multi-pass shell-and-tube flooded heat exchanger

ActiveCN105020942ASimple structureEasy to assemble and disassembleEvaporators/condensersStationary tubular conduit assembliesEngineeringRefrigerant

The invention discloses a multi-pass shell-and-tube flooded heat exchanger. The multi-pass shell-and-tube flooded heat exchanger comprises a plurality of outer shell tubes in array distribution, a plurality of heat exchange tubes penetrating the outer shell tubes, a first outer tube box, a second outer tube box, two tube plates, a first inner tube box and a second inner tube box, wherein the first outer tube box and the second outer tube box are respectively connected with the two ends of each outer shell tubes and are mutually communicated; the two tube plates are respectively connected with the two ends of each heat exchange tube, as well as the outer sides of the first outer tube box and the second outer tube box; the first inner tube box and the second inner tube box are respectively connected to the outer sides of the two tube plates; and the lower part of the first outer tube box is connected with a refrigerant inlet adapter, and the upper part of the second outer tube box is connected with a refrigerant outlet adapter. The multi-pass shell-and-tube flooded heat exchanger realizes passing of a refrigerant on both the shell side and the tube side, and adopts the structure that the outer shell tubes sleeve the heat exchange tubes, so that the refrigerant filling amount is much less than that of a common flooded evaporator, and the oil return performance is good.

Owner:ZHEJIANG QINGFENG REFRIGERATION EQUIP MFG

Direct type evaporator capable of automatically returning oil

InactiveCN102003843AStable air returnSave installation spaceEvaporators/condensersVertical tubeGas collecting tube

The invention relates to a direct type evaporator capable of automatically returning oil. The direct type evaporator comprises a plurality of evaporation tubes which thread through a left tube plate, a plurality of fins and a right tube plate from top to bottom, wherein one end of each evaporation tube is respectively connected to a liquid dividing head of an evaporator liquid inlet tube through a plurality of capillary tubes, the other end of the evaporation tube is respectively communicated with a gas collecting tube, and a gas return tube communicated with a compressor is arranged on the top of the gas collecting tube. The direct type evaporator further consists of an oil return small vertical tube, wherein the bottom port of oil return small vertical tube is communicated with the gas collecting tube, the bottom port of the oil return small vertical tube is lower than the port of the bottommost evaporation tube connected to the gas collecting tube, and the upper port of the oil return small vertical tube is communicated with the gas return tube. By communicating the bottom part of the gas collecting tube and the gas return tube with the independent oil return small vertical tube, the evaporator can realize the return of oil accumulated at the bottom part of the gas collecting tube, has simple structure, and is convenient for the overall installation. The oil return small vertical tube is stable and excellent to return oil, has good oil return effect and can ensure that a refrigeration device is safely used.

Owner:JIANGSU JOSUN AIR CONDITIONER

Oil ring of piston ring set of internal combustion engine

InactiveCN104214004AEnough oil return channelExtended service lifePiston ringsMachines/enginesPiston ringInternal combustion engine

The invention provides an oil ring of a piston ring set of an internal combustion engine, and relates to the technical field of a structure of a combined oil ring of a piston ring set of a diesel engine. The oil ring comprises an upper oil scraper ring and a lower oil scraper ring, wherein the upper oil scraper ring is provided with an opening, the lower oil scraper ring is provided with an opening, and the upper oil scraper ring and the lower oil scraper ring are mutually overlapped. The oil ring is characterized in that the openings of the upper oil scraper ring and the lower oil scraper ring are staggered by 60-120 degrees, the circumference of the upper oil scraper ring is uniformly provided with 6-12 oil drain grooves, the circumference of the lower oil scraper ring is uniformly provided with 6-12 oil drain grooves, the oil drain grooves of the upper oil scraper ring and the oil drain grooves of the oil drain grooves of the lower oil scraper ring are the same in number, correspond with each other one by one, and are also oppositely arranged to form oil drain holes, and the inner circular surfaces of the oil scraper rings are provided with a wavy support spring. The oil ring has the advantages that the defect of poor oil scraping property and certain side gap between an oil ring and a piston groove of the traditional oil piston assembly of the diesel engine are overcome, and the condition of oil mixing of the engine during idling is effectively prevented.

Owner:仪征威龙发动机零部件有限公司

Lubricating oil return mode of supercharger of turbocharged engine

InactiveCN102705073AGood oil return effectMeet lubrication requirementsMachines/enginesLubrication temperature controlHeat balanceControl valves

The invention relates to a lubricating oil return mode of a supercharger of a turbocharged engine, and aims to lubricate the supercharger. An oil return channel A which accords with the cold operating condition of an engine, an oil return channel B which accords with the normal operating condition of the engine, oil return channels C and D which accord with the operating condition of the engine in high temperature environment, and a supercharger oil return control valve are arranged on a cylinder body of the engine, so that oil return lines of lubricating oil in the supercharger of the engine in different operating states are cyclically switched. The operating efficiency of the engine is improved; the high temperature characteristic of the lubricating oil in the supercharger is reasonably utilized, so that the heat balance of the engine is realized; and meanwhile, the oil return performance of the supercharger of the engine is improved, the probability that the oil in the supercharger leaks is reduced, and the power performance and economy of the engine are effectively improved.

Owner:GREAT WALL MOTOR CO LTD

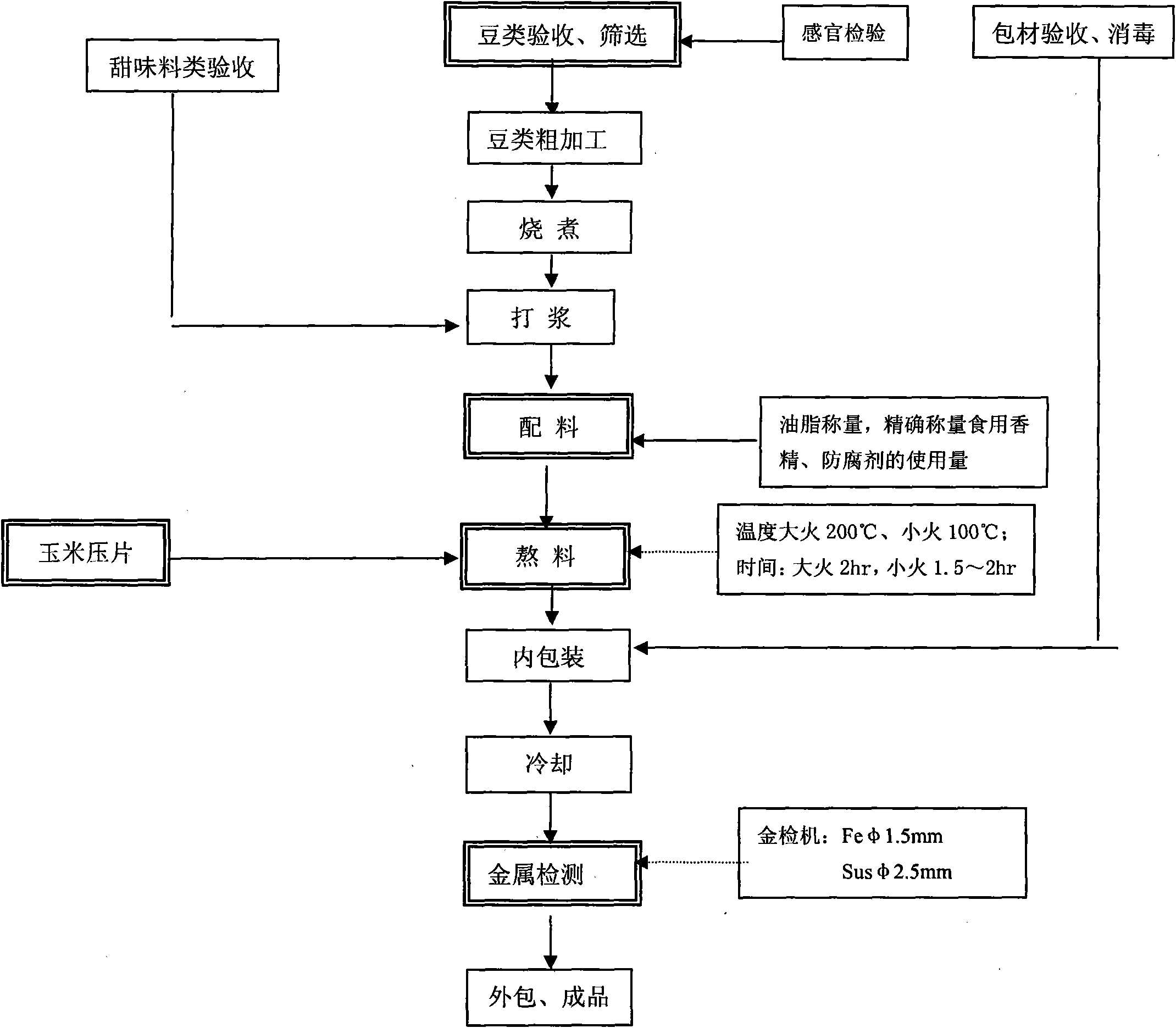

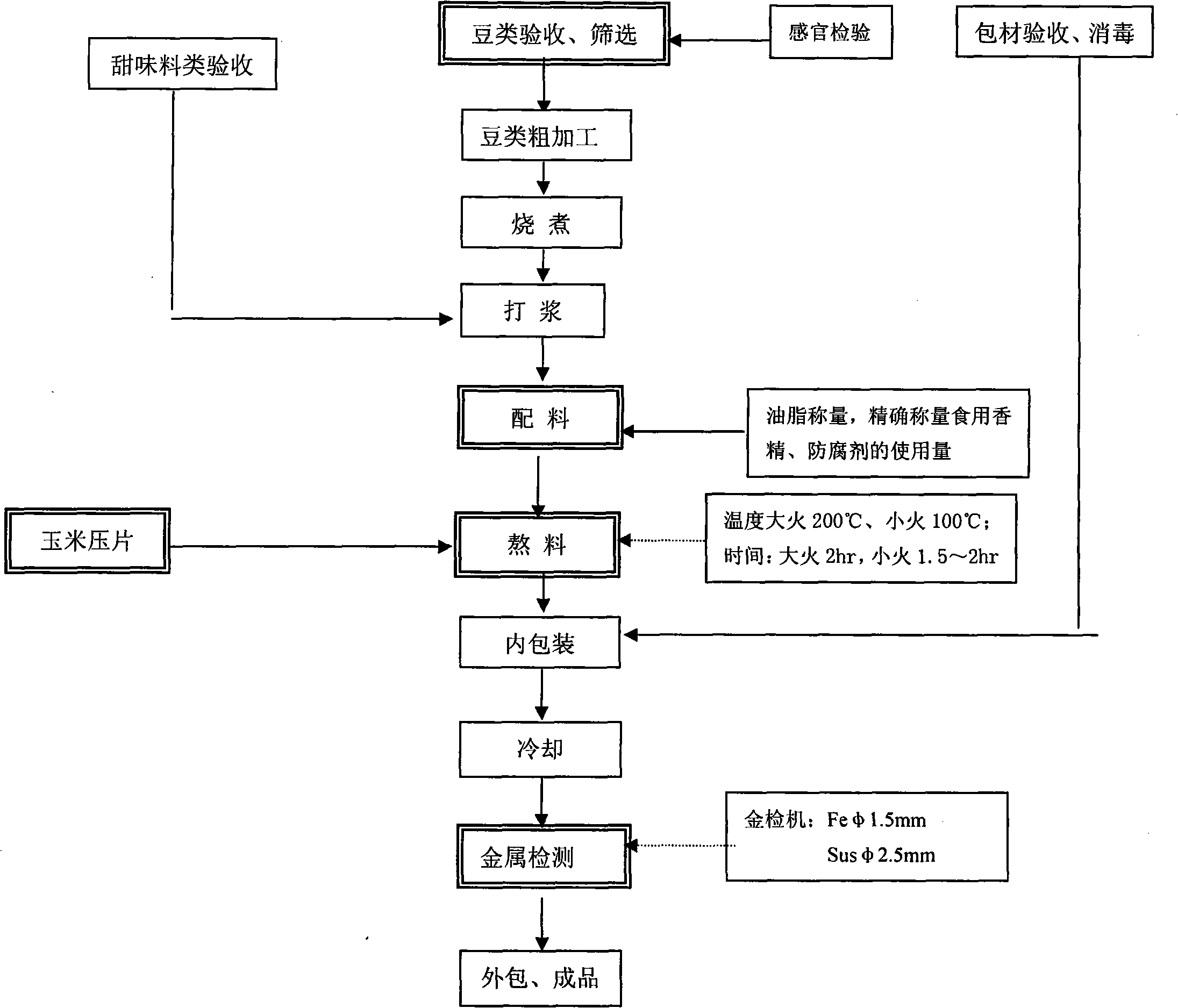

Corn paste stuffing and production method thereof

InactiveCN101869132AGreat tasteFocus on premium featuresBakery productsStarch gelatinizationPreservative

The invention relates to a corn paste stuffing and a production method thereof. The corn paste stuffing comprises the following raw materials in percentage by weight: 20 to 30 percent of beans, 25 to 40 percent of corn, 30 to 42 percent of sweetener, 9 to 18 percent of grease, 0.2 to 0.4 percent of edible essence and 0.03 to 0.1 percent of preservative. The production method comprises the following steps of: inspecting, accepting and treating the raw materials, comprising rough processing of washing and peeling of the beans; cooking the beans to make starch in the beans form paste; mixing and pulping the cooked beans and the sweetener; weighing the grease, the essence and the preservative, accurately controlling the using amount of the auxiliary materials, and putting the auxiliary materials into the pulped mixture; pressing the corn to form pressed corn; boiling materials with a wok, namely boiling the mixture added with the auxiliary materials for 3.5 to 4 hours, then adding the pressed corn into the boiled mixture, and fully and uniformly blending various raw materials together; and packing the cooked stuffing and cooling the stuffing to obtain a finished product. The corn paste stuffing produced by the method has the characteristics of visible granules, floppy mouthfeel and high nutrition reserving degree.

Owner:常州市鑫灿食品有限公司

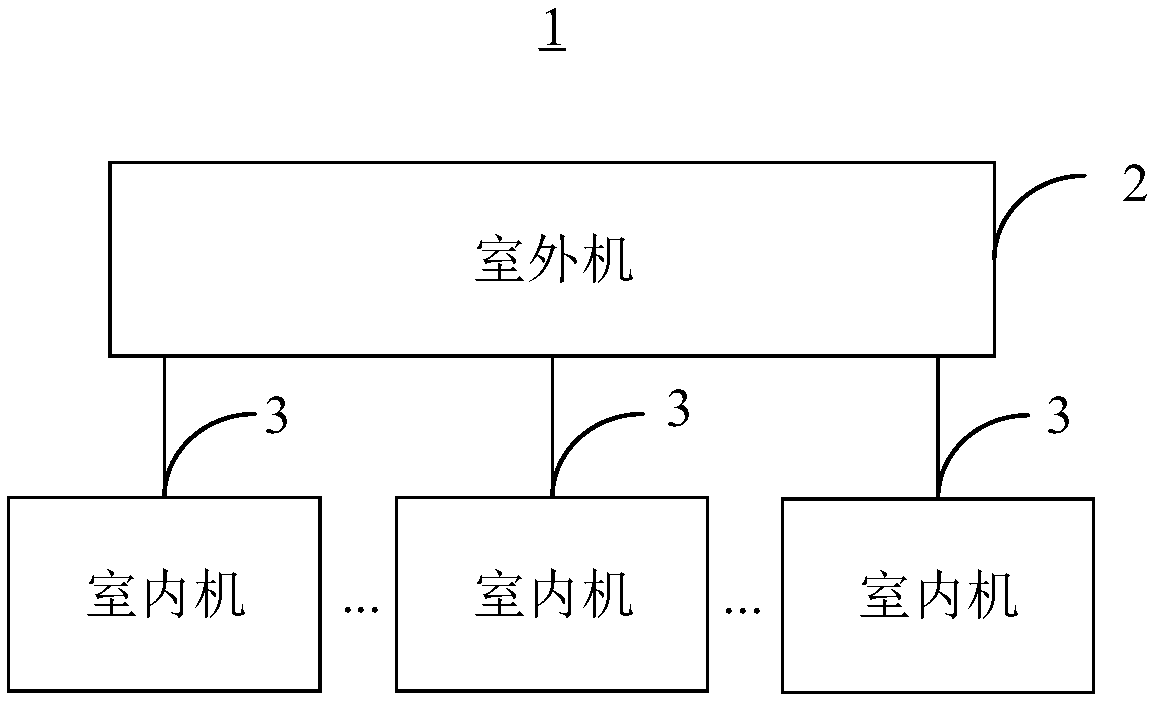

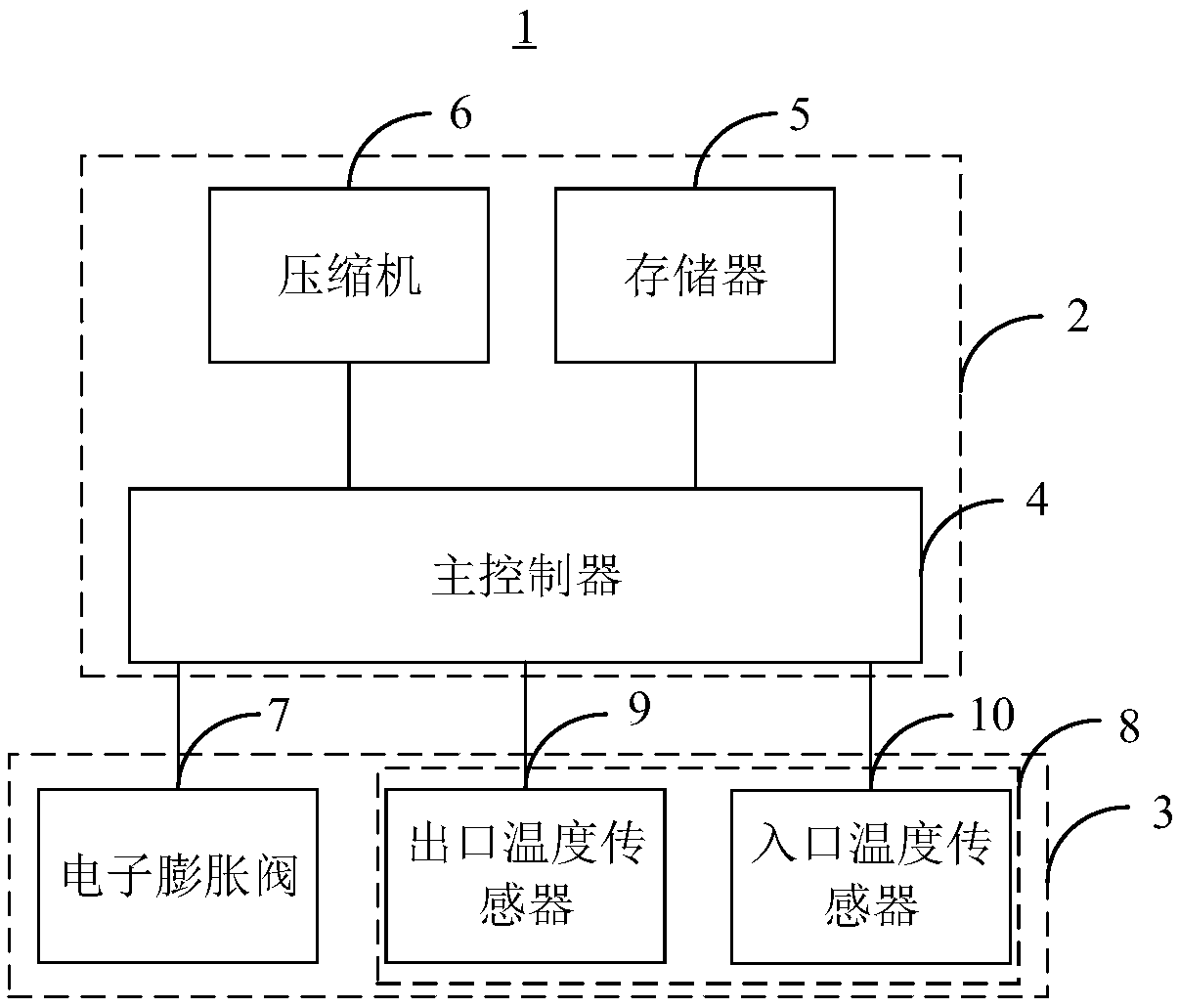

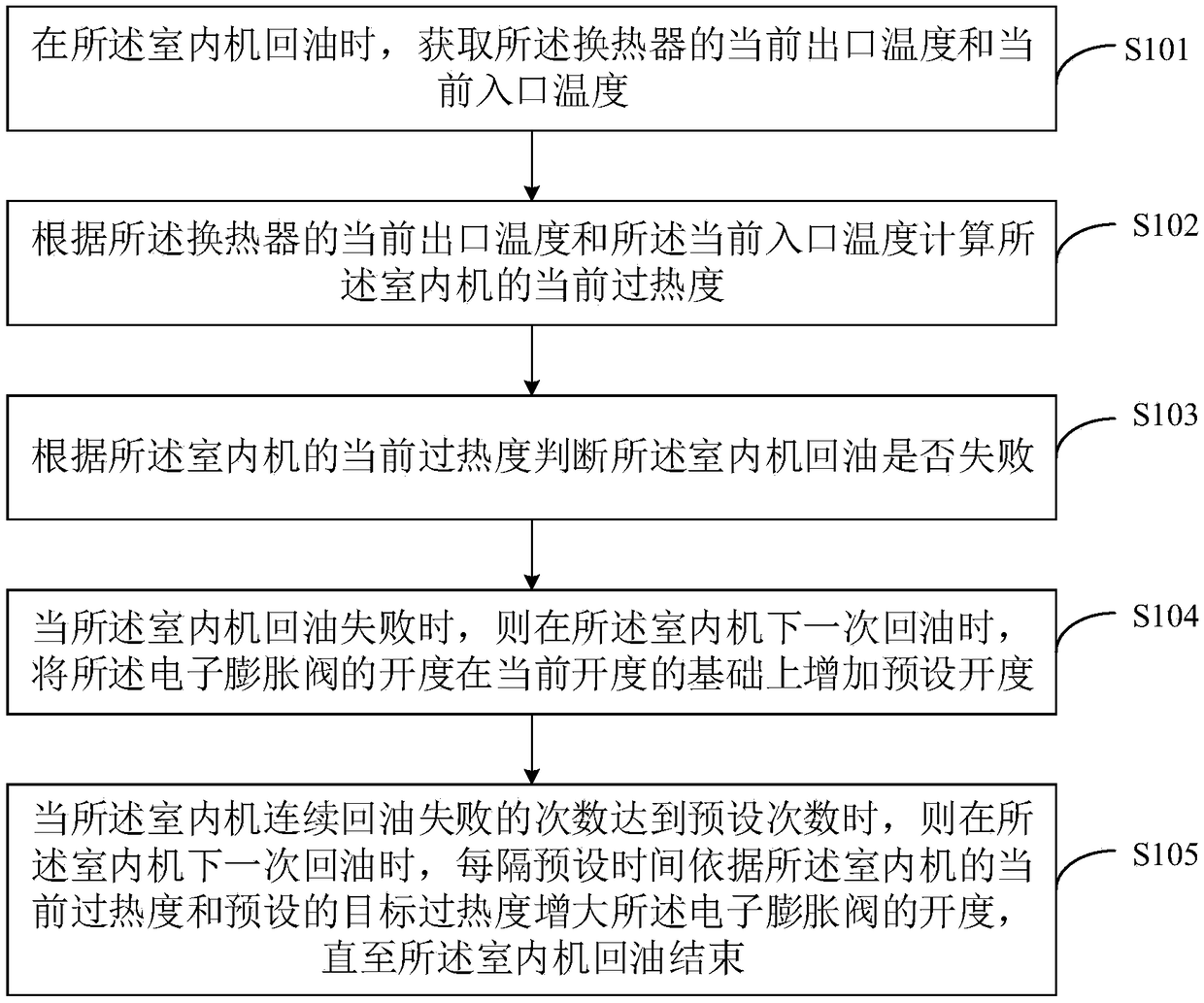

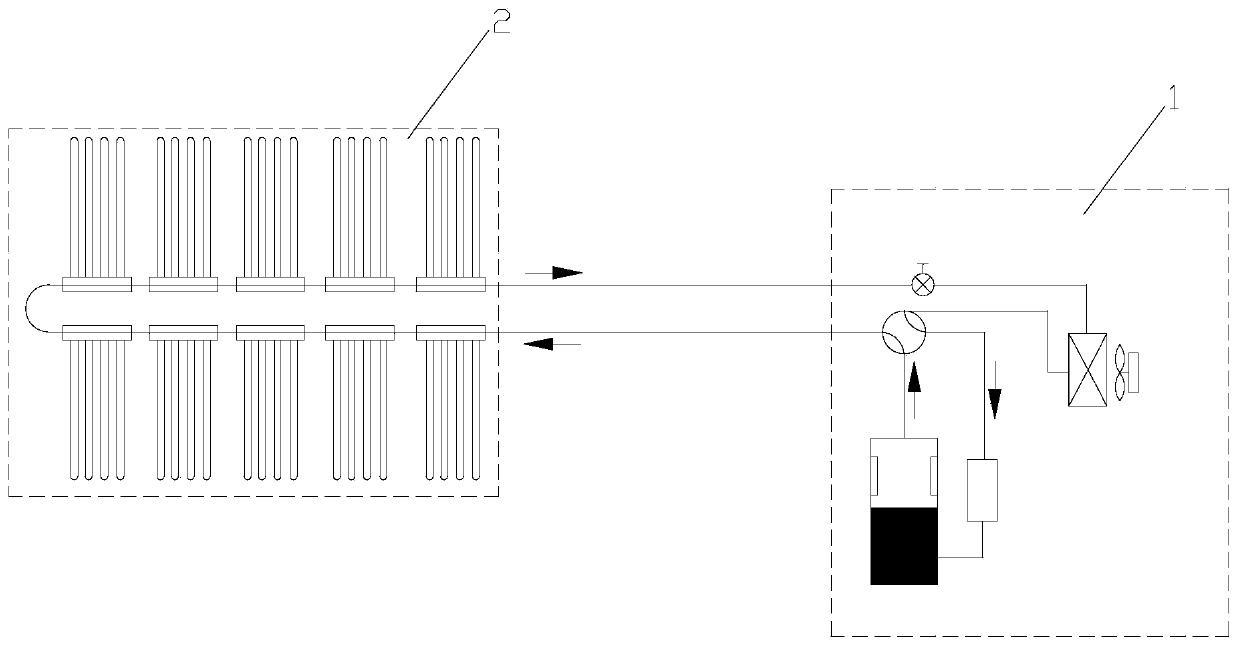

Oil return control method and device and air conditioner

ActiveCN109373634AAdvantages of oil return control methodReduce experienceCompressorRefrigeration safety arrangementElectronic expansion valveIndustrial engineering

The invention provides an oil return control method and a device and an air conditioner. When the indoor unit returns oil, the current outlet temperature and the current inlet temperature of the heatexchanger are obtained, the current superheat degree of the indoor unit are calculated according to the current outlet temperature and the current inlet temperature of the heat exchanger, whether theoil return of the indoor unit fails or not is judged according to the current superheat degree of the indoor unit. When the oil return fails, the opening degree of an electronic expansion valve is increased by a preset opening degree on the basis of the current opening degree when oil return is carried out at the next time in the indoor unit. When the number of times of the continuous oil return failure of the indoor unit reaches the preset frequency, the opening degree of the electronic expansion valve is increased according to the current superheat degree of the indoor unit and the preset target superheat degree every preset time when the indoor unit returns oil at the next time, until the oil return of the indoor unit is ended. Therefore, when the oil return of the indoor unit fails, the opening degree of the electronic expansion valve of the indoor unit is adjusted, the oil return effect of the air conditioner and the reliability of the whole machine are improved, and the compressor is prevented from being damaged due to oil shortage.

Owner:NINGBO AUX ELECTRIC +1

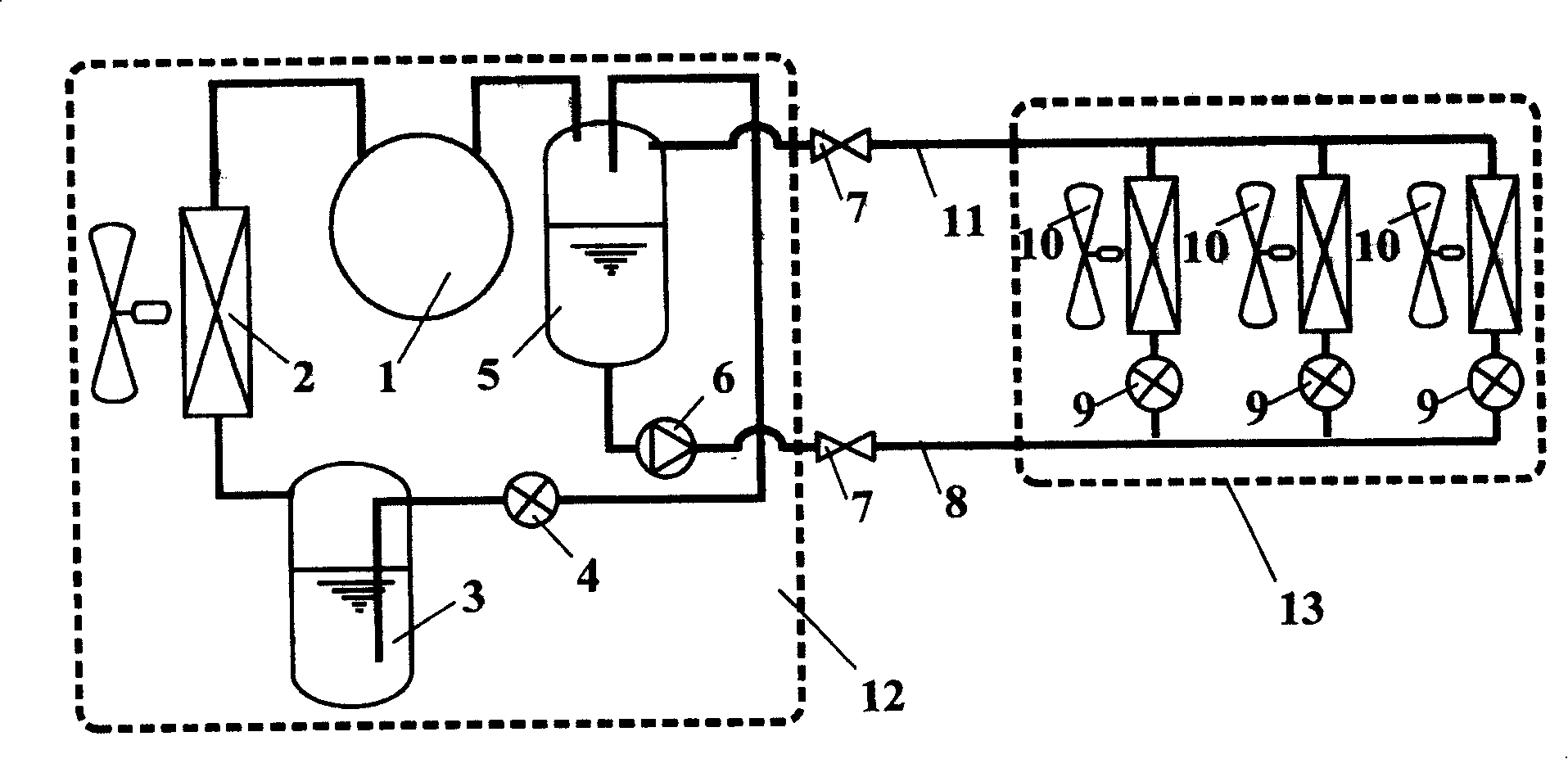

Loop heat pipe type heating and refrigerating air conditioning system

PendingCN109945545AIncrease heatingImprove cooling effectMechanical apparatusIndirect heat exchangersEngineeringLoop heat pipe

The invention relates to the technical field of air conditioners, aims to solve the problem of large on-way resistance of a refrigerant of an existing loop heat pipe type air conditioning system and provides a loop heat pipe type heating and refrigerating air conditioning system. The loop heat pipe type heating and refrigerating air conditioning system comprises at least one heating or refrigerating cycle unit, at least one loop heat pipe unit and at least one intermediate heat exchange unit, wherein the intermediate heat exchange unit is used for refrigerant heat exchange between the heatingor refrigerating cycle unit and the loop heat pipe unit. The heating or refrigerating cycle heat generated by the air conditioning system is transferred to the loop heat pipe unit through the intermediate heat exchange unit, and the loop heat pipe unit heats or cools the indoor space, so that the length of a refrigerant pipeline of the heating or refrigerating cycle unit of the air conditioning system is reduced, the resistance of a refrigerant flow is reduced, and the heating or refrigerating effect of the loop heat pipe type air conditioning system is improved. The loop heat pipe type heating and refrigerating air conditioning system is suitable for a floor heating system.

Owner:四川长虹空调有限公司

Compressor and air conditioner

ActiveCN112253457AIncrease oil returnImprove oil return efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringOil supply

The invention provides a compressor and an air conditioner. The compressor comprises a static static scroll plate, a movable scroll plate and an oil return structure; the oil return structure can collect lubricating oil in exhausted gas; a static scroll plate cover board covers the side, back on to the movable scroll plate, of the static scroll plate; a first lubricating oil chamber is arranged onthe side, facing the static scroll plate cover board, of the static scroll plate, the oil return structure can guide collected lubricating oil into the first lubricating oil chamber, and a compression cavity can communicate with the first lubricating oil chamber; and / or a second lubricating oil chamber is arranged on the side, facing the static scroll plate, of the static scroll plate cover board, the oil return structure can guide collected lubricating oil into the second lubricating oil chamber, and the compression cavity can communicate with the second lubricating oil chamber. According tothe compressor and the air conditioner, oil obtained after oil and gas in the exhausted gas are separated can be effectively supplied to a pump body structure of the compressor, the oil return amountand the oil return efficiency are improved, the oil return effect is improved, the oil supply efficiency is high, the reliability is high, abnormal abrasion of a scroll plate of a scroll compressor is reduced, and noise is lowered.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

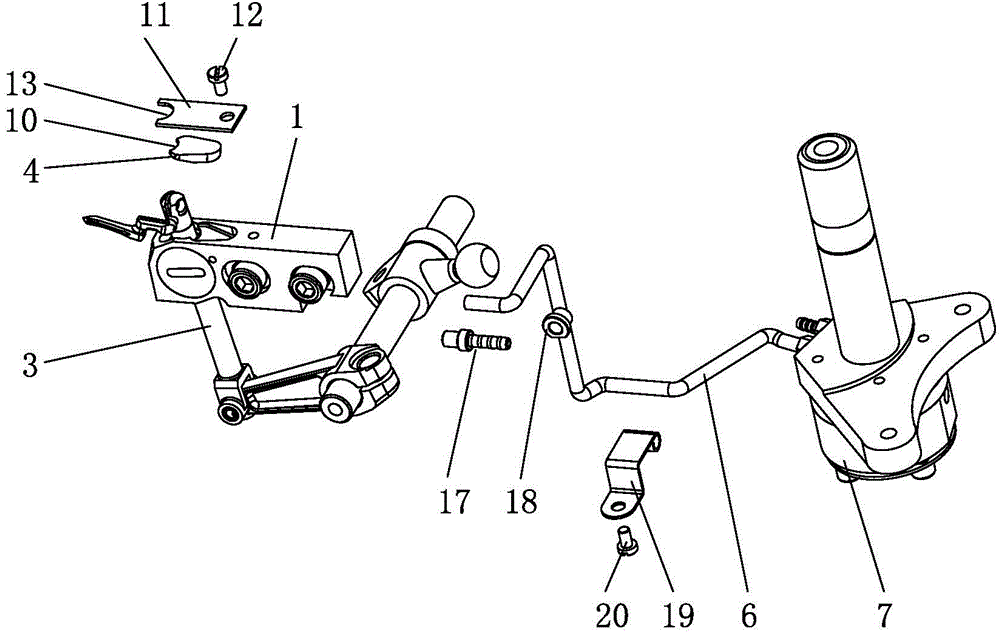

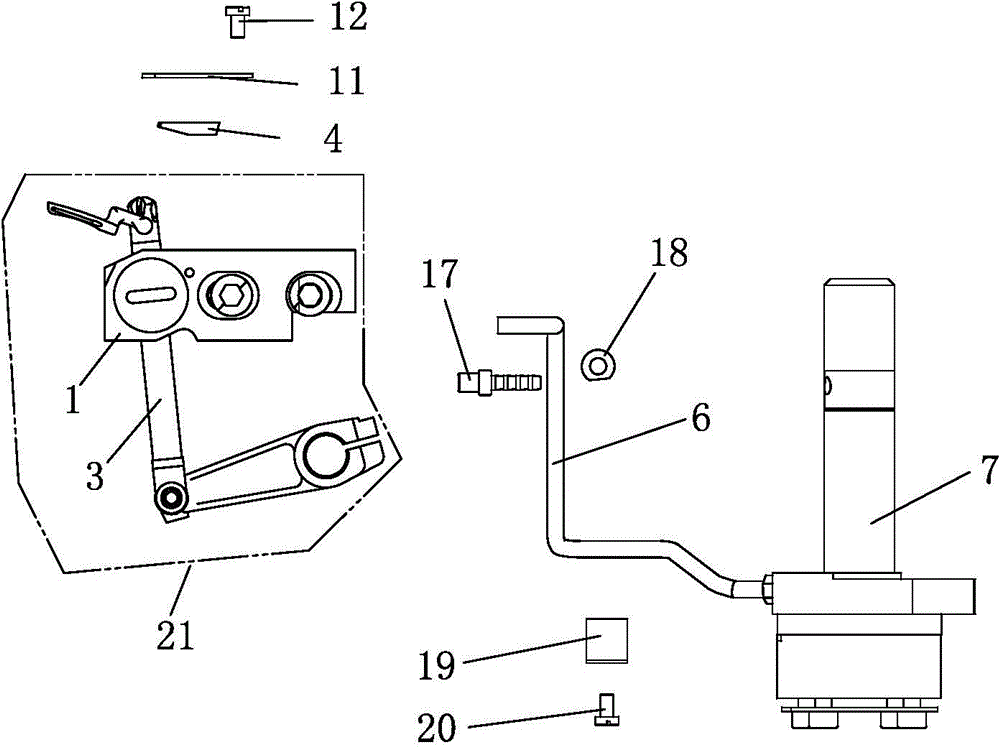

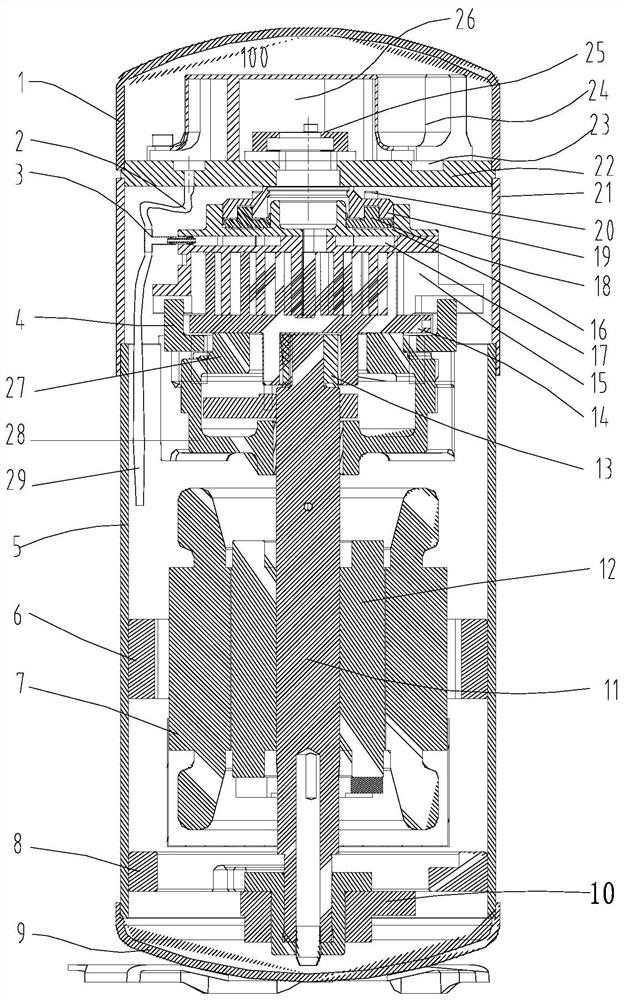

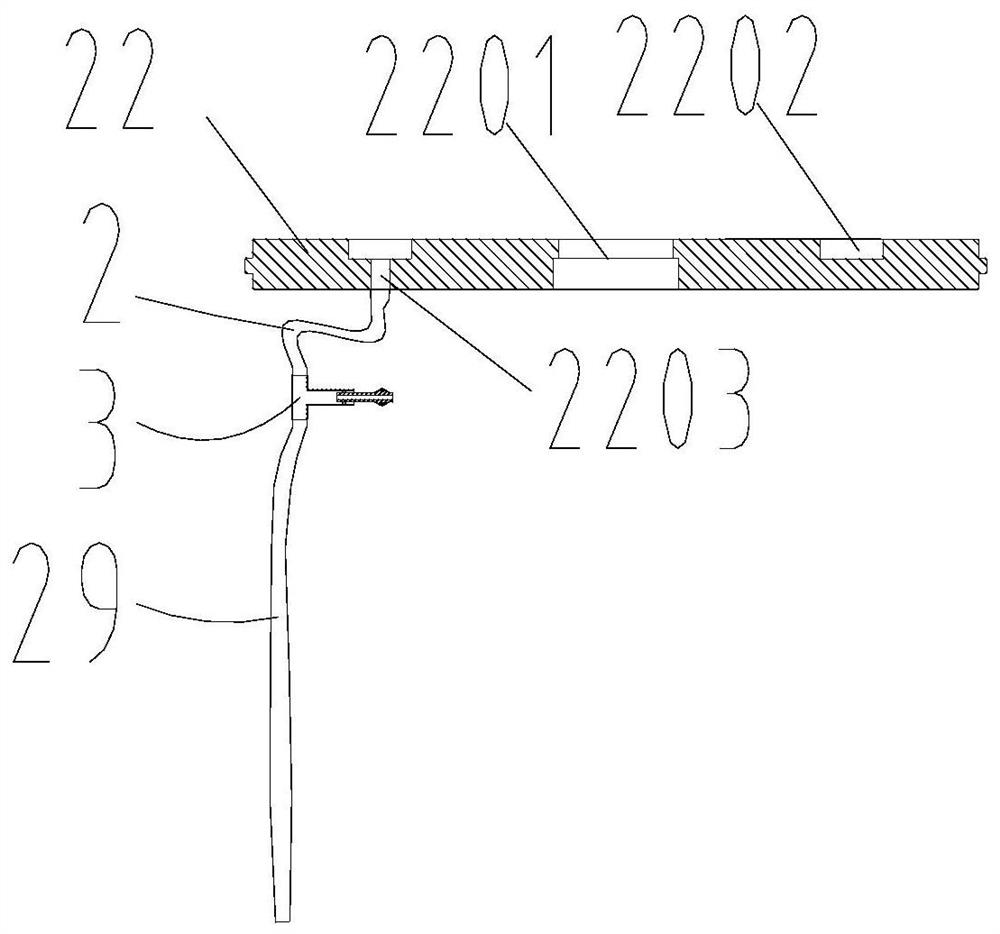

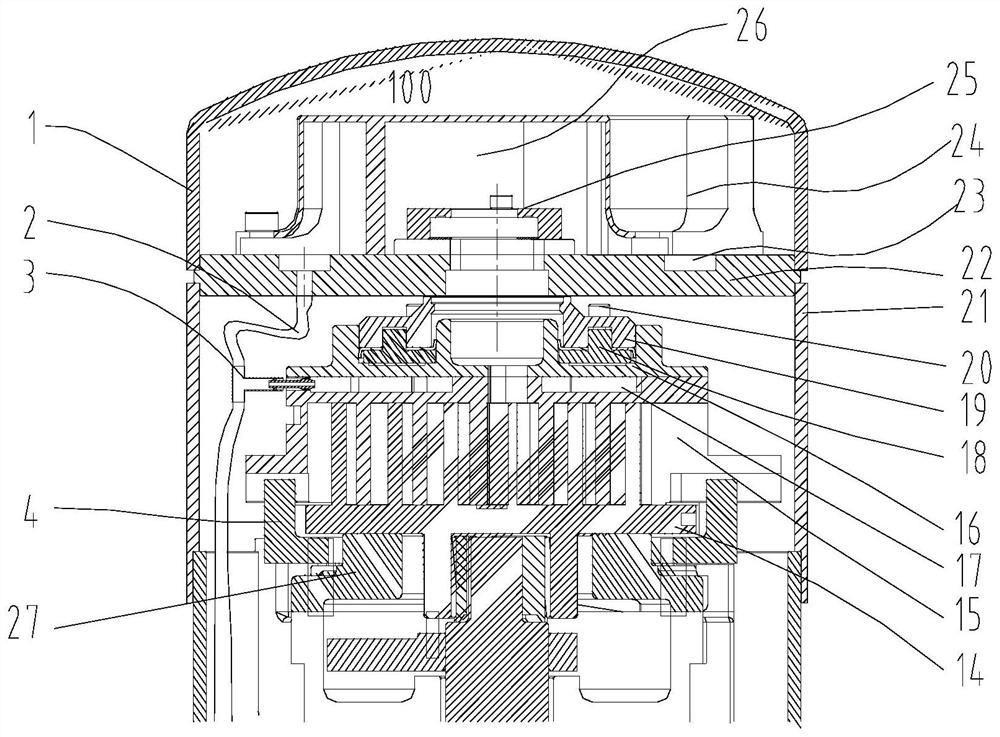

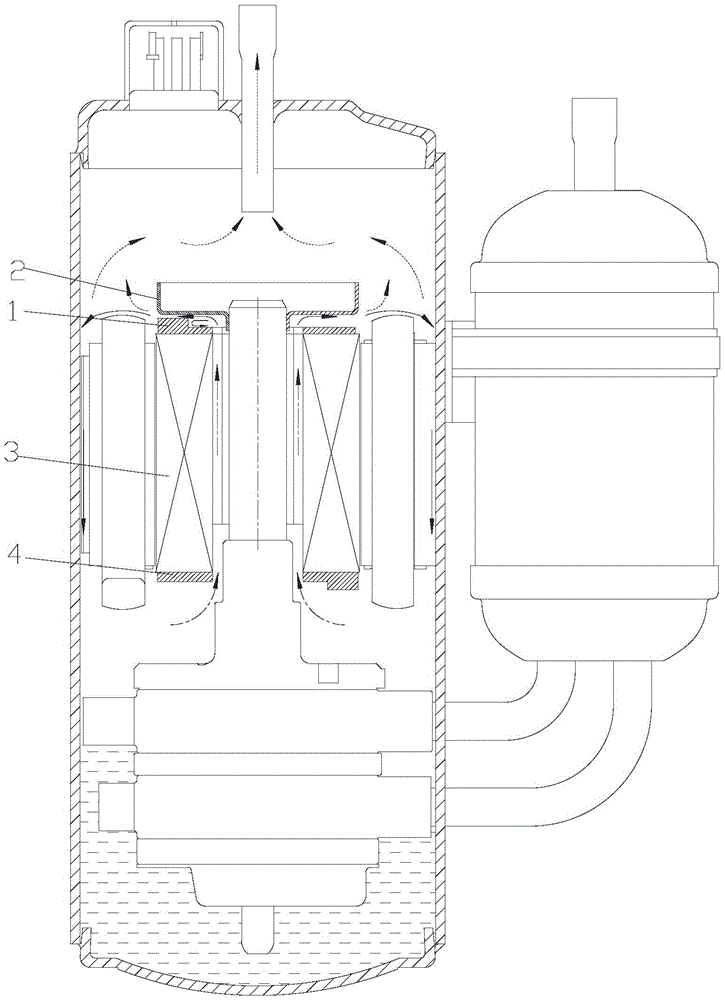

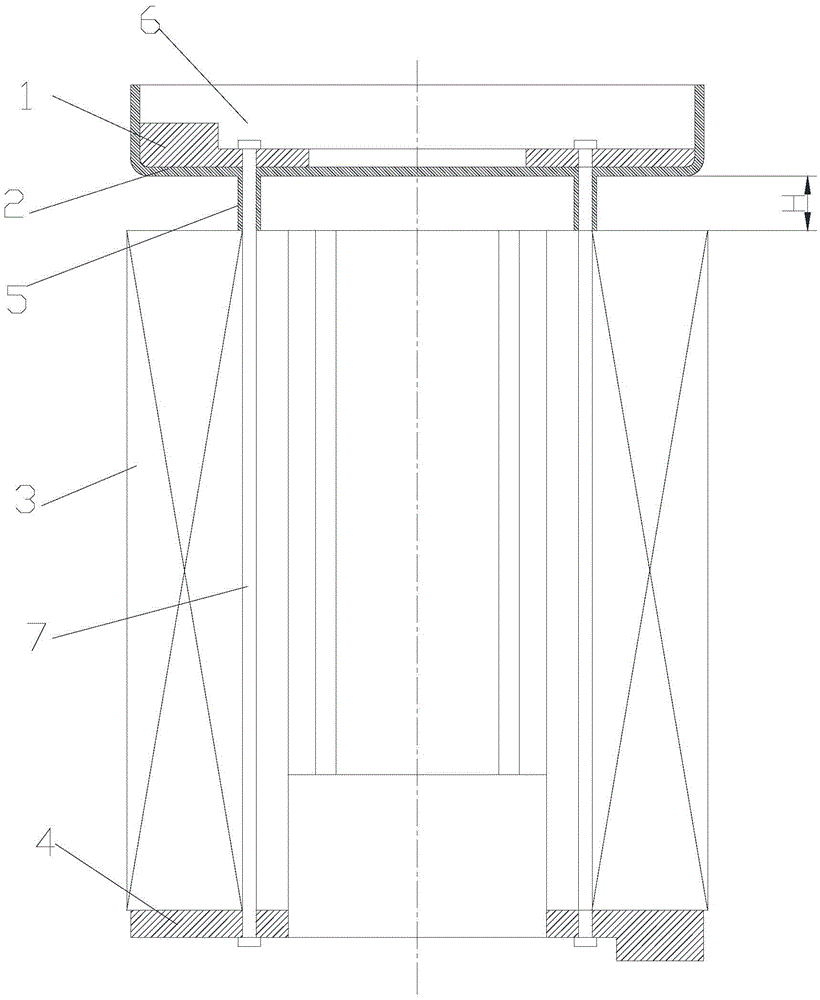

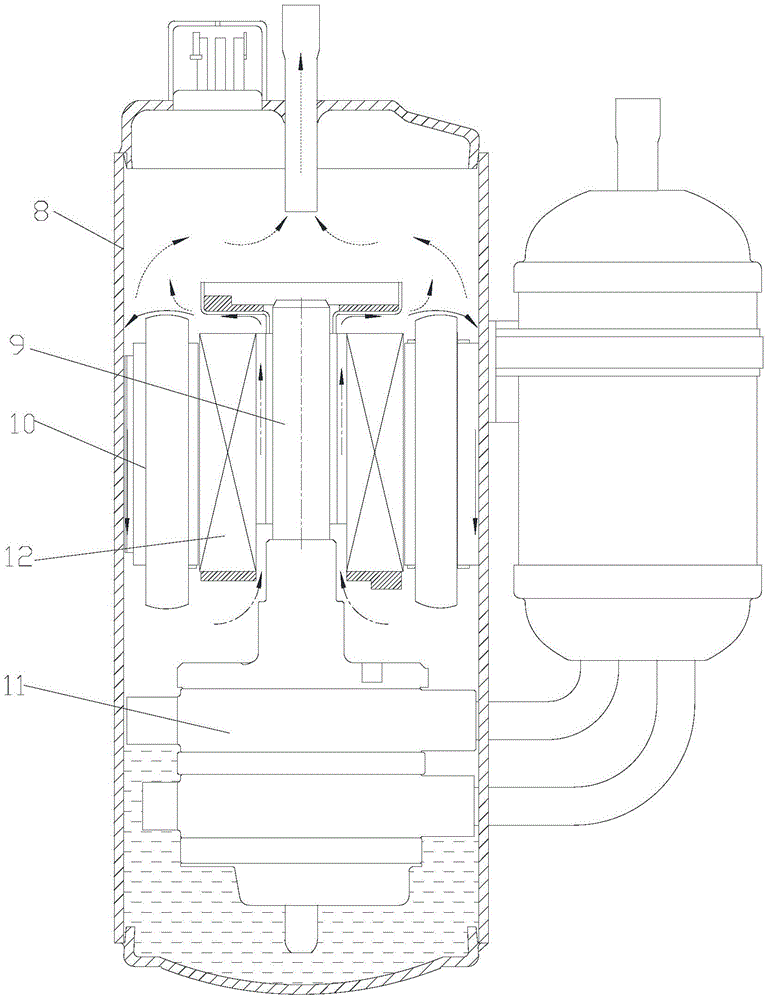

Rotor assembly, pump rotor assembly, assembling method of pump rotor assembly and compressor

ActiveCN105526168AEliminate disturbanceReduce noiseRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringMechanical engineering

The invention discloses a rotor assembly, a pump rotor assembly, an assembling method of the pump rotor assembly and a compressor. The rotor assembly sleeves a crankshaft and comprises a first balancing block (1), an oil baffle plate (2), rotor iron cores (3) and a second balancing block (4), wherein the first balancing block (1), the oil baffle plate (2), the rotor iron cores (3) and the second balancing block (4) are axially arranged along the crankshaft from top to bottom in a sequence. With the adoption of the rotor assembly, the problem that the balancing blocks in the prior art easily cause disturbance between the oil baffle plate and a rotor and a stable and continuous flowing field cannot be formed well can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

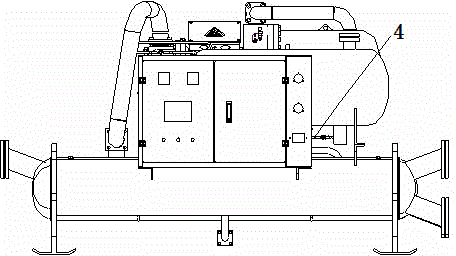

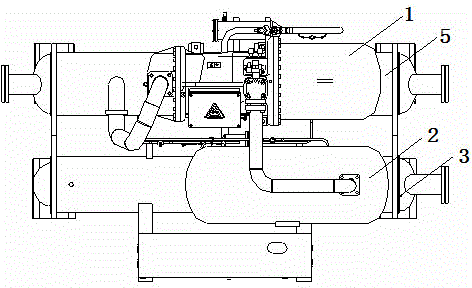

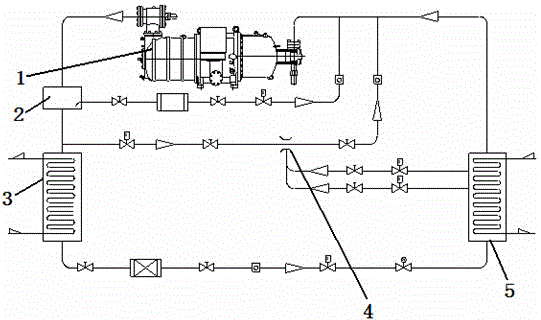

Water source heat pump unit system for low temperature water source

InactiveCN104676978AReduce freezingPrevent freezingHeat pumpsEvaporators/condensersWater source heat pumpWater source

The invention relates to an air conditioning unit device, in particular to a water source heat pump unit system for a low temperature water source. The system comprises a compressor, an oil separator, a condenser, a oil return injecting device and an evaporator; the evaporator is in a falling film type structure, a liquid distributor is arranged in the upper portion of the evaporator, the top of the evaporator is provided with a liquid incoming pipe, the port of the liquid incoming pipe contacts with the surface of the liquid distributor, the top of the evaporator is provided with an exhaust pipe, the bottom of the evaporator is provided with a discharge pipe, and heat exchange pipe beams are arranged below the liquid distributor. According to the system, water is distributed to the surface of the heat exchange pipes evenly through the liquid distributor, the heat exchange effect is fine, the refrigerant can be evaporated fully, the refrigerant storage amount is reduced, and the heat exchange pipes are prevented from freezing; meanwhile, since the level of the evaporator is low, the mixing ratio of lubrication oil is decreased, the lubrication oil can be injected to the compressor through the oil return injecting device, and the fine oil returning effect is achieved.

Owner:SHANDONG YUGIA FUERDA AIR CONDITIONER EQUIP

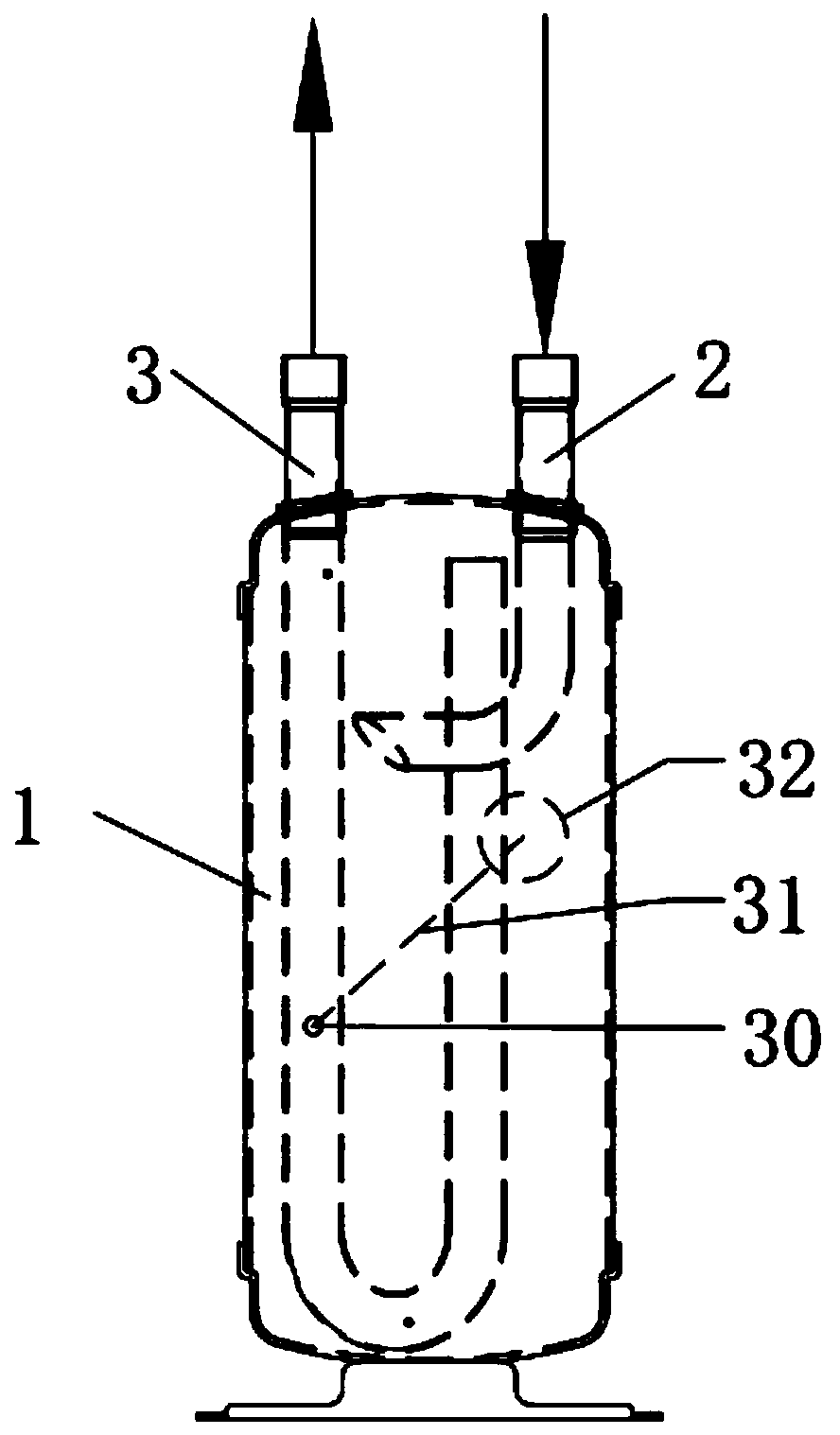

Gas-liquid separator

PendingCN109269164APriority smooth dischargeDischarge in timeRefrigeration componentsVapor–liquid separatorEngineering

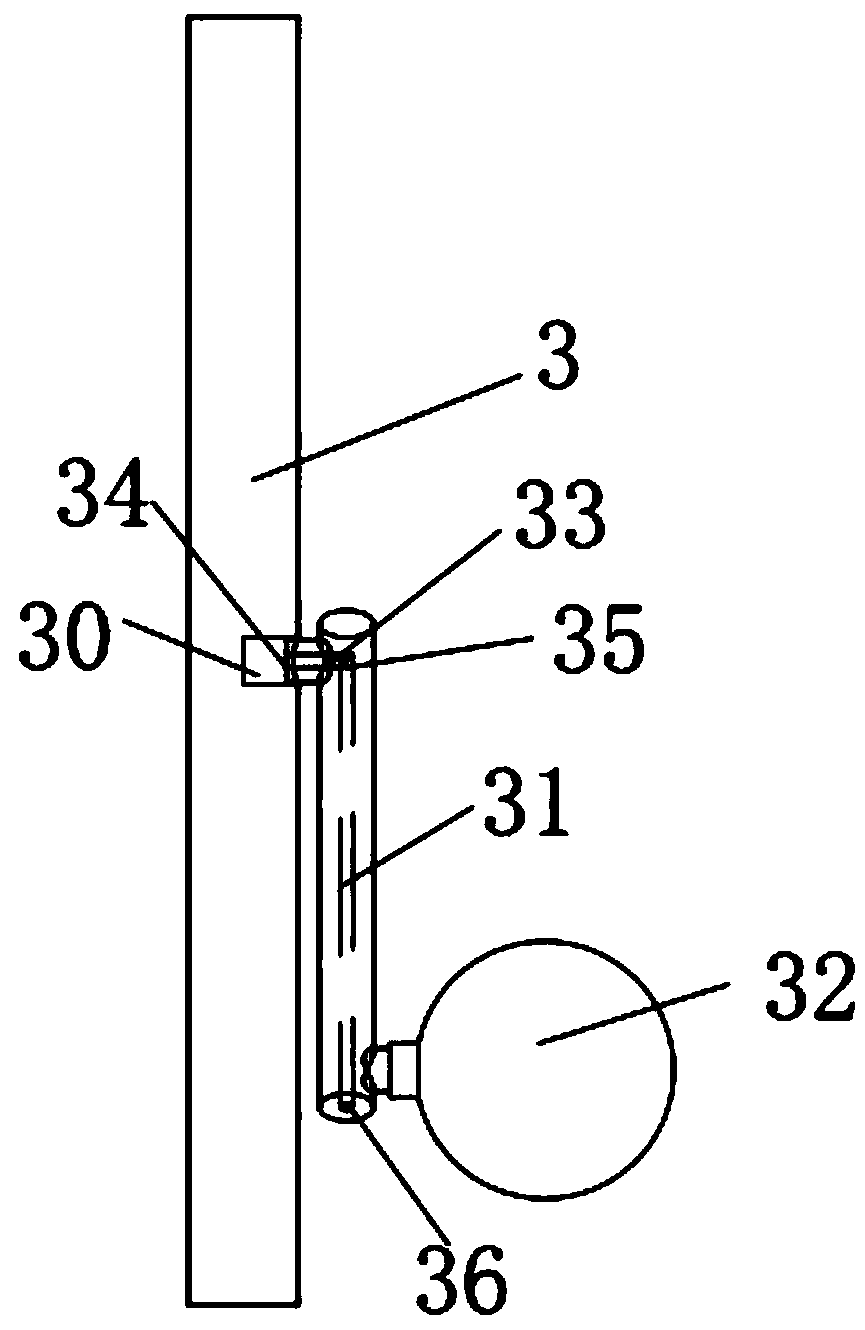

The invention belongs to the technical field of heat pump systems, and particularly relates to a gas-liquid separator which comprises a tank. An inlet pipe and an outlet pipe are arranged in the tank,gas-liquid mixture enters the tank through the inlet pipe, a supporting rod, a connecting rod and an oil return floating ball are connected onto the outlet pipe and sequentially arranged, and the oilreturn floating ball can float on the surface of liquid.

Owner:GUANGDONG NEW ENERGY TECH DEV

Oil bottom case structure with enhanced oil return function

InactiveCN104564226AAdded tilted structureImprove pooling and return capacityOilsumpsMachines/enginesReturn functionCrankcase

The invention provides an oil bottom case structure with an enhanced oil return function. The oil bottom case structure comprises an oil bottom case body, wherein an oil collecting pool is arranged at each of the front and back ends of the oil bottom case body, a bottom plate of the oil bottom case body arranged between the two oil collecting pools is of an inclined structure with the higher middle and the lower two ends, and the two oil collecting pools are not symmetrical along the transverse center line of the oil bottom case body, and are respectively positioned at the two sides of the center line. The oil bottom case structure has the advantages and positive effects that the positions and the number of the oil collecting pools are regulated, in addition, the inclined structure of the oil bottom case (or a lower crank case) is added, the backflow gathering capability of engine oil can be obviously improved, meanwhile, the continuous oil return when the engine generates front back left and right inclination can be ensured, the oil collecting pools are respectively arranged in the center symmetry positions of the two sides of the front end and the back end of the oil bottom case, in addition, the inclined structure with the higher middle and the lower two ends is designed at the inner side of the bottom plane of the oil bottom case, and when the engine inclines in the front back left and right direction, the backflow gathering effect of the engine oil is not influenced.

Owner:CHINA NORTH ENGINE INST TIANJIN

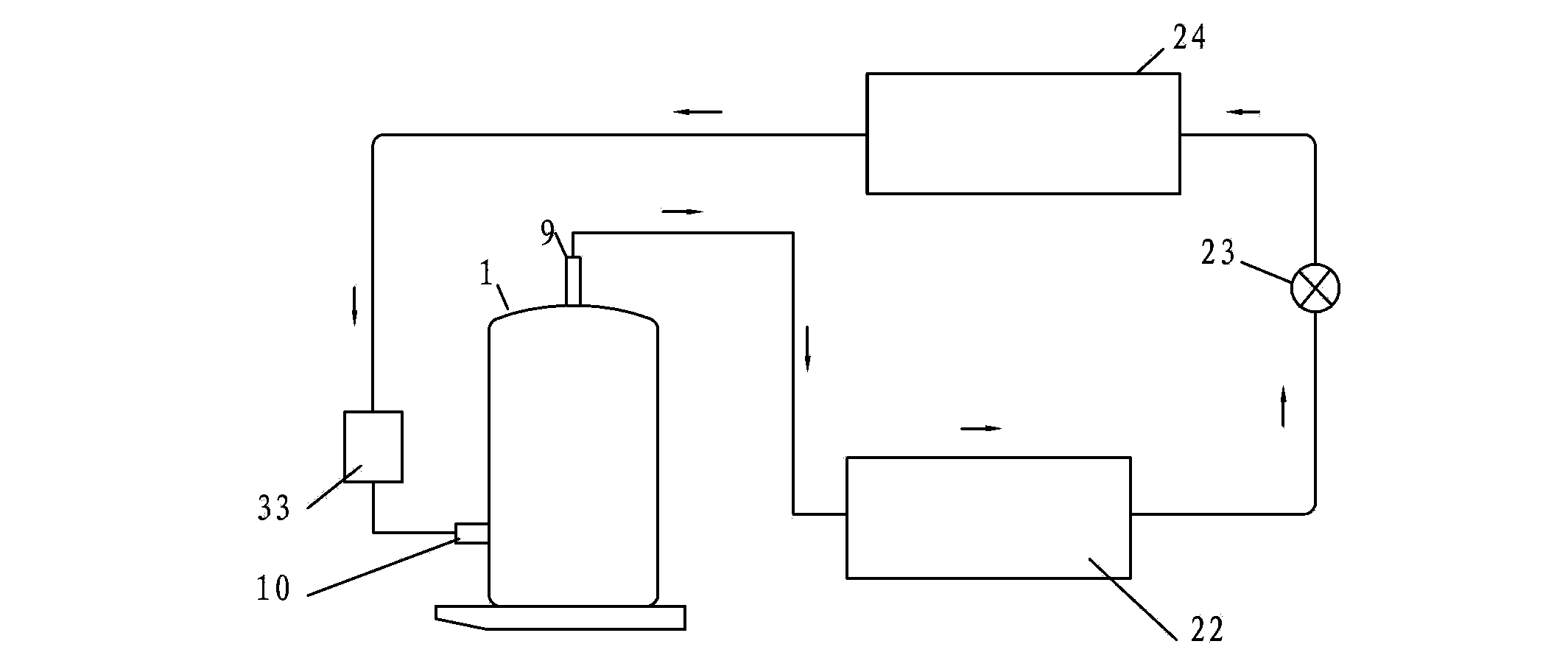

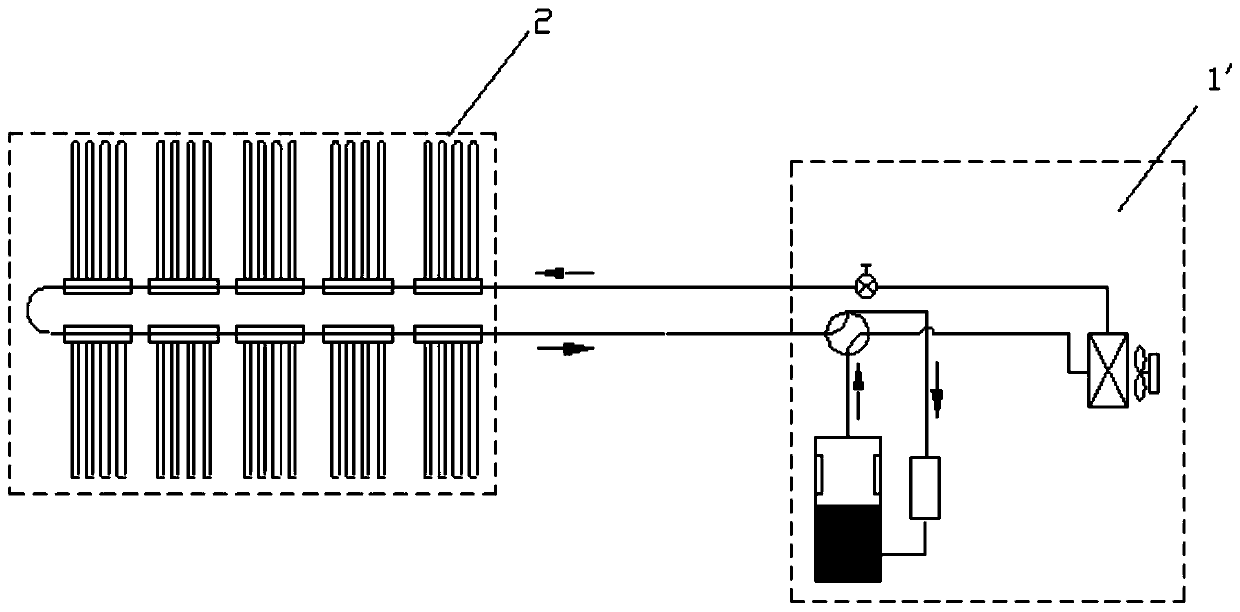

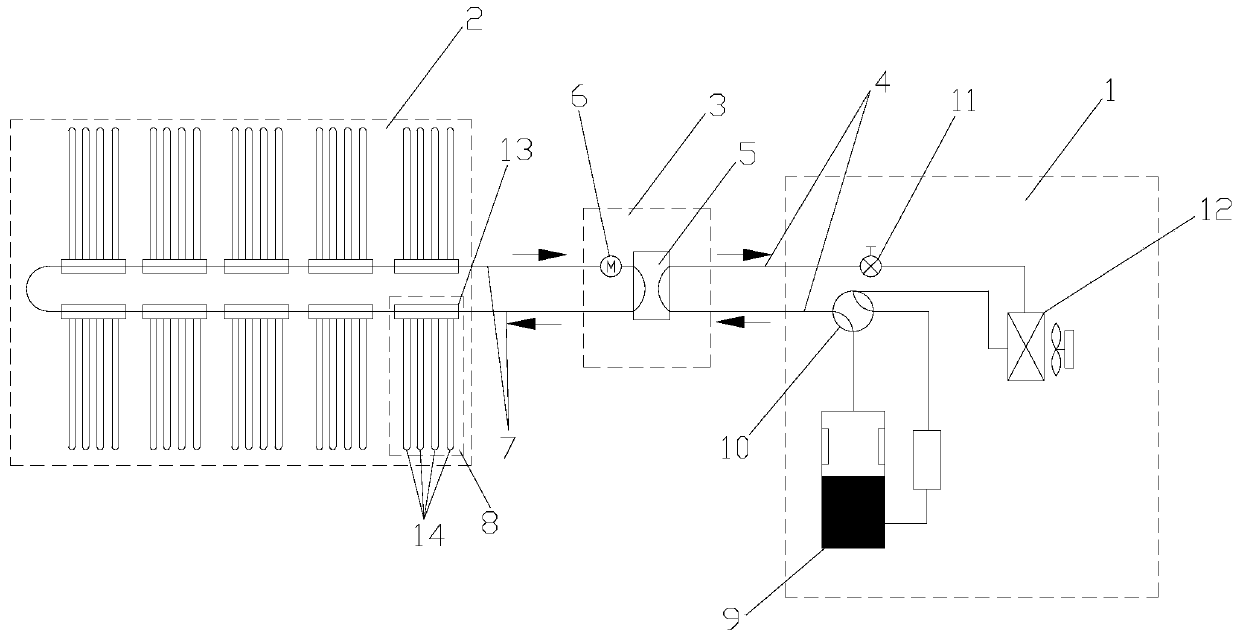

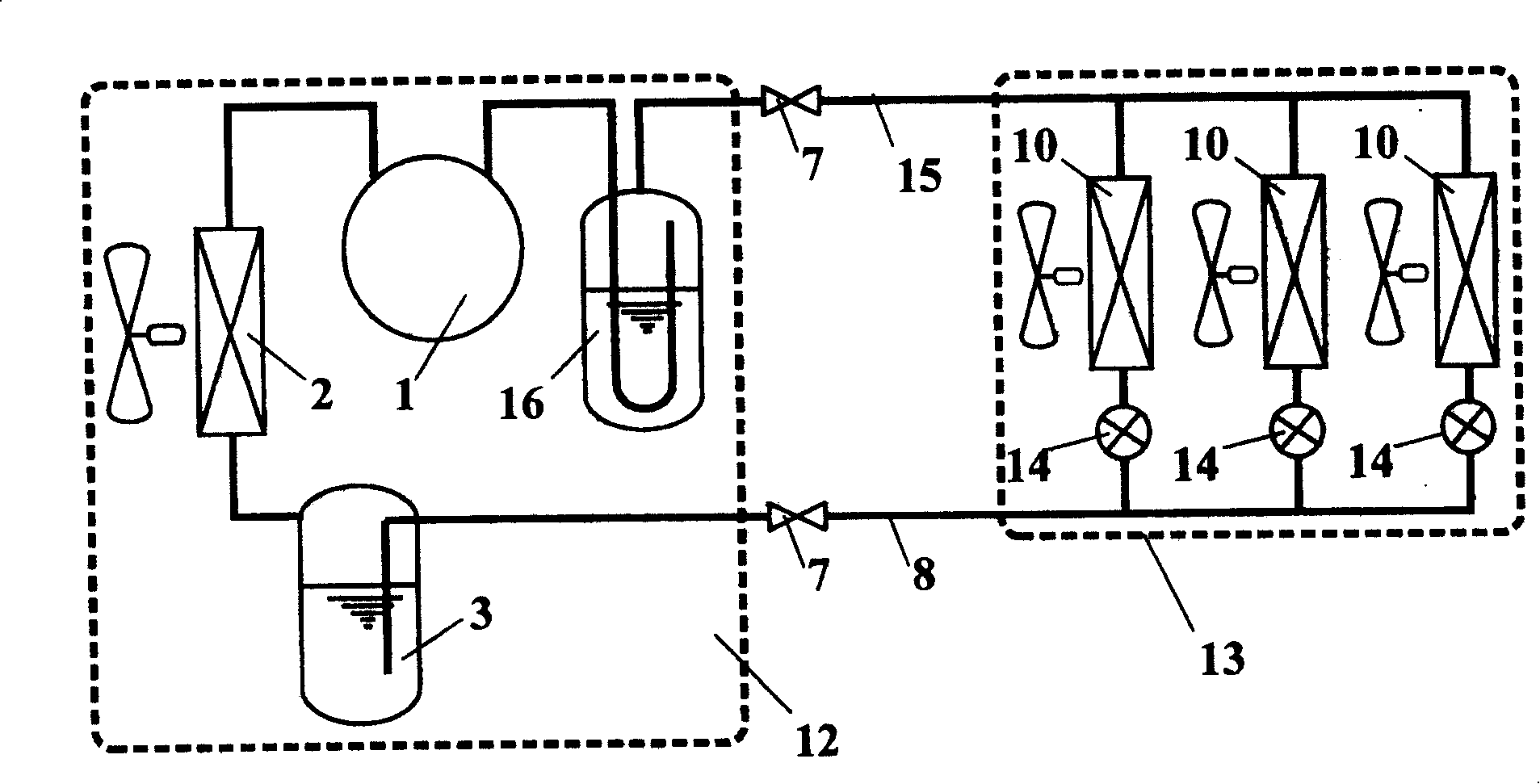

Multi-connected air conditioning unit with liquid pump

InactiveCN100395488CEasy to adjustImprove controllabilityFluid circulation arrangementAir conditioning systemsPressure cycleLiquid state

The invention relates to a liquid pump liquid supply multiple air-conditioning unit, which uses the liquid pump liquid supply to process the cold supply of multiple rooms. The invention comprises the indoor machine and the outdoor machine. It is characterized in that: the outdoor machine comprises a low pressure cycle liquid storage, a liquid pump, and a outdoor machine throttle device, while it uses the liquid pump to pressurize the low pressure liquid coolant generated by the outdoor machine to be fed into indoor heat exchangers of indoor machine via the pipeline to supply cold and form the liquid pump liquid supply multiple refrigeration cycle. Compared to present technique, the invention increases the pressure of the coolant at the inlet of electric expansion valve besides the indoor machine heat exchanger and the pressure difference uniformity between two ends of each expansion valve, improve the safety and regulation property of indoor expansion valve and the reflux property of system, and effectively enlarge the application of multiple system.

Owner:TSINGHUA UNIV

Oil passage balance system of dual parallel compressor screw water chilling unit

The invention relates to the technical field of a screw water chilling unit, particularly to an oil passage balance system of a dual parallel compressor screw water chilling unit. A first overflow pipe (6) for redundant lubrication oil output is arranged on a first compressor (2) and a second overflow pipe (7) for redundant lubrication oil output is arranged on a second compressor (3).The first overflow pipe (6) communicates with a first exhaust pipe (4) and the second overflow pipe (7) communicates with a second exhaust pipe (5). A partition (8) for isolating the lubricating oil separated from the two compressors is arranged in a twice oil separator (1). A first oil return port (9) for lubricating oil output from the first exhaust pipe (4) and a second oil return port (10) for lubricating oil output from the second exhaust pipe (5) are arranged on the twice oil separator (1). The oil passage balance system has the advantages of a nice oil return effect, a low cost and a guarantee of a reliable operation of the dual parallel compressor screw water chilling unit.

Owner:NINGBO AUX ELECTRIC

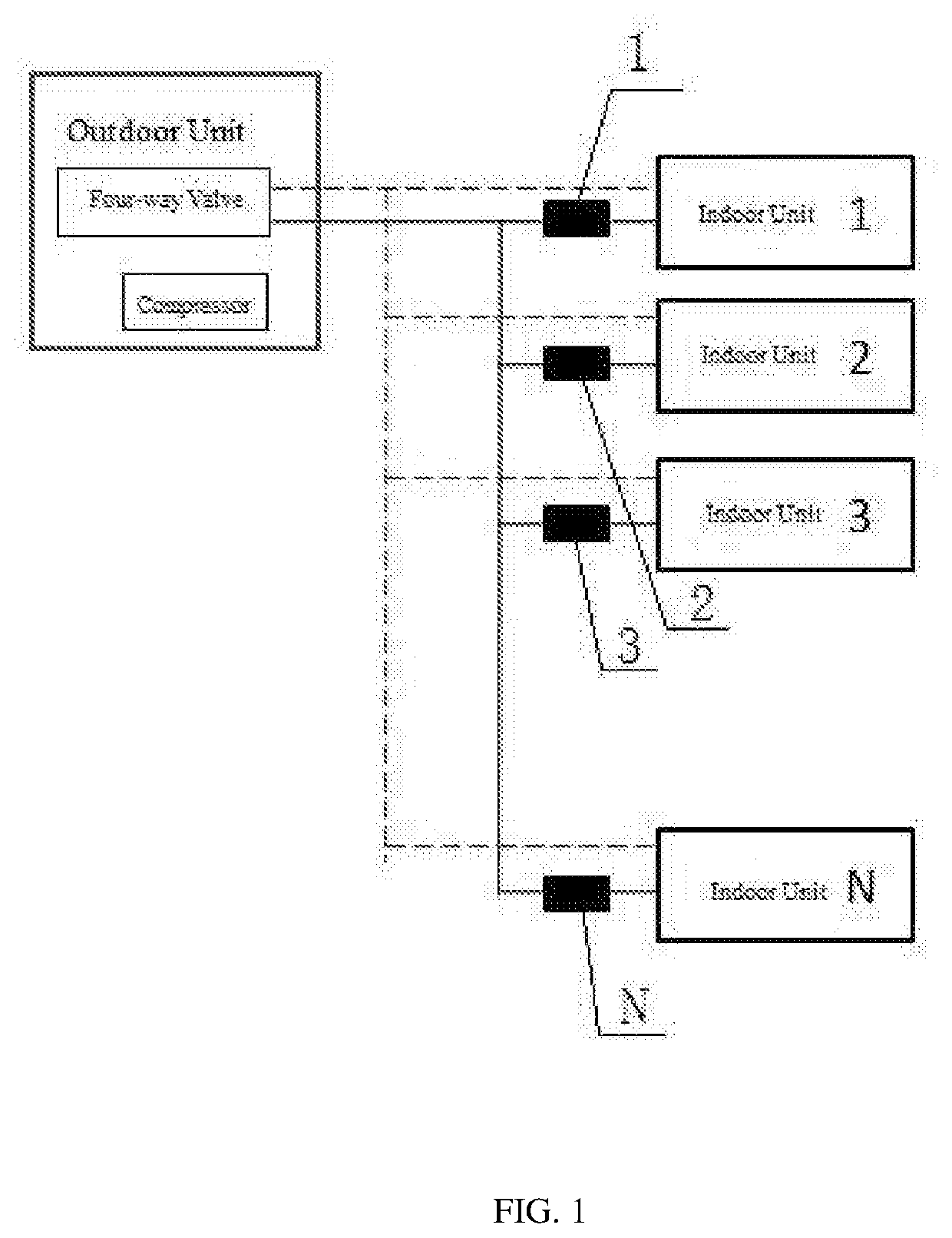

Vrv oil return control method and system

ActiveUS20210041148A1Reduce influenceReduce impactCompressorEfficient regulation technologiesProcess engineeringEnvironmental geology

An oil return control method for a multi-split air conditioner and a system accomplishing the same includes: calculating an average exhaust pressure within an oil return period Pd_AVG; determining whether the average exhaust pressure Pd_AVG≥the set threshold Pdthreshold; if Pd_AVG≥Pdthreshold, maintaining the multi-split air conditioner working in heating mode to ensure an acceptable oil return performance without affecting the air conditioning effect of indoor unit in heating mode; if Pd_AVG<Pdthreshold, switching the multi-split air conditioner to cooling mode, stopping a fan within those power-on indoor units and entering into a cooling oil return process and switching the multi-split air conditioner back to heating mode until the cooling oil return process ends. Hence, according to the oil return control disclosed by this embodiment, if it requires improving oil return performance, the multi-split air conditioner working in heating mode is only being switched to cooling mode if Pd_AVG<Pdthreshold and the fan within those power-on indoor units is being shut off to minimize the fluctuation of room temperature; the heating mode operation could be maintained if Pd_AVG≥Pdthreshold, oil return requirement and heating requirement could be satisfied at the same time to avoid affecting normal air conditioning operation significantly so as to solve the problem in the prior art.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

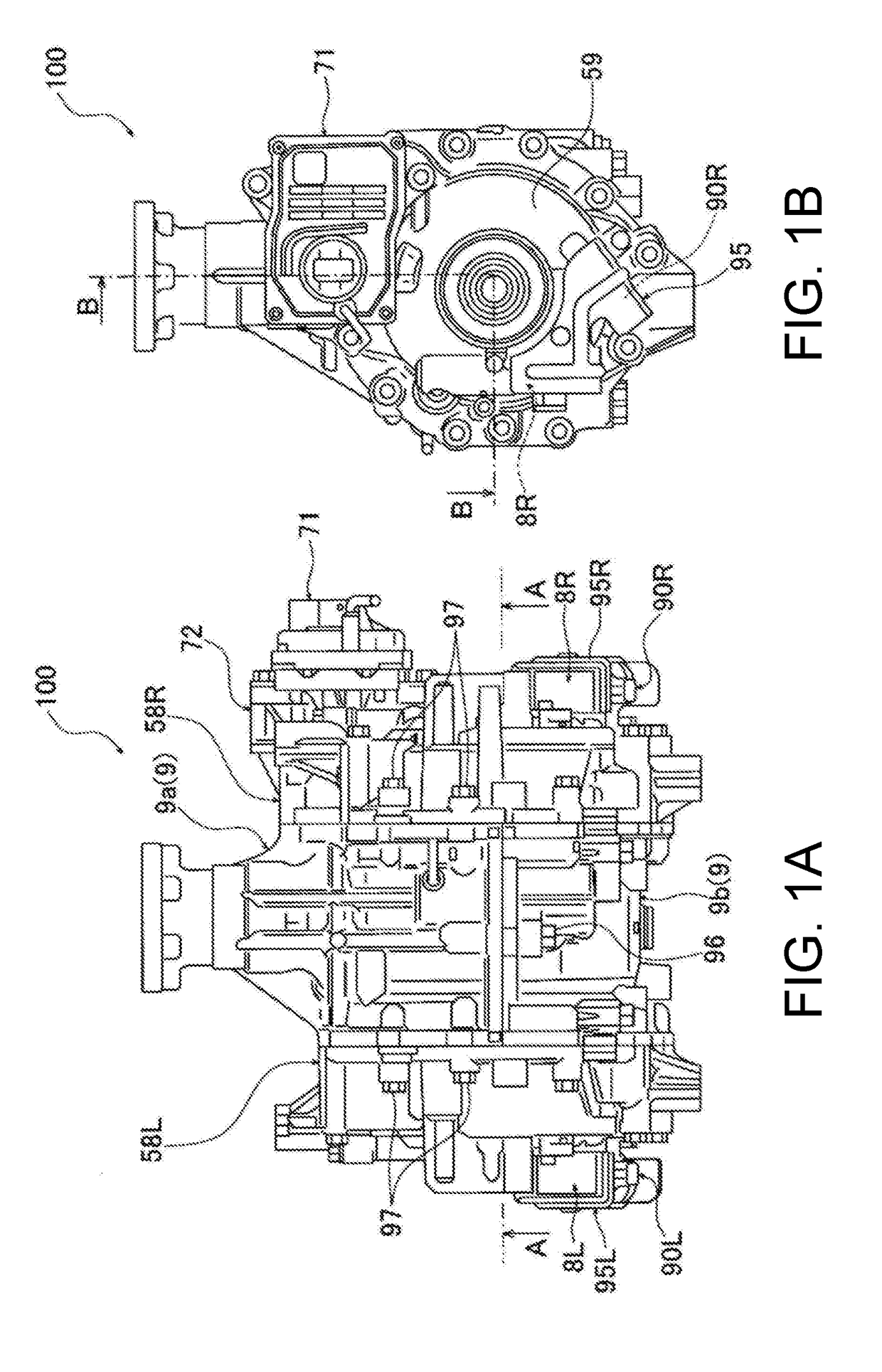

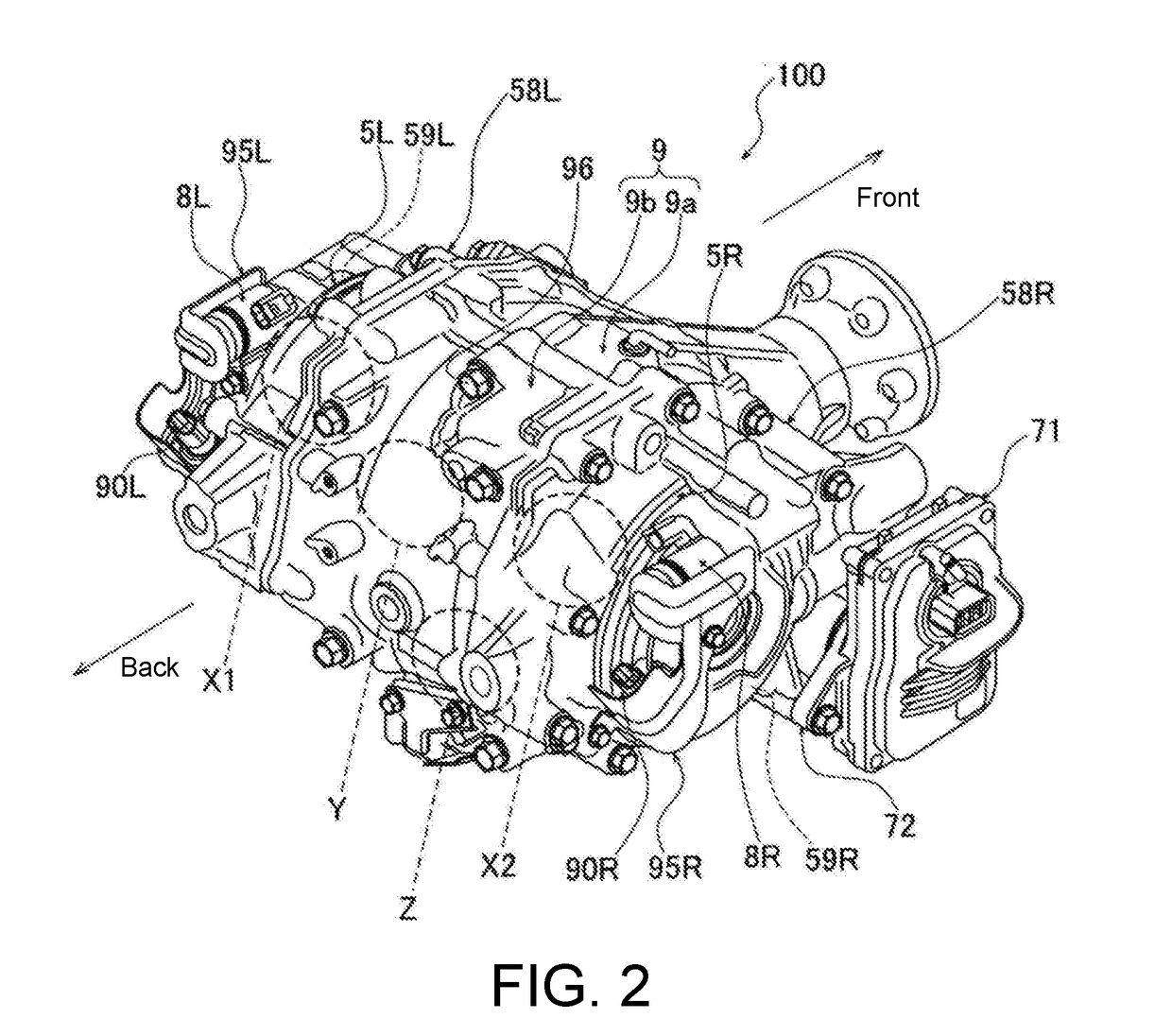

Power transmission apparatus

ActiveUS20180335128A1Prevent surfaceGood oil return effectFluid actuated clutchesGear lubrication/coolingDrive wheelTransmitted power

The power transmission apparatus includes: a gear chamber, used for accommodating gears disposed on a rotating shaft used for transmitting power to a drive wheel; a clutch chamber, disposed adjacent to the gear chamber in an axial direction of the rotating shaft, and used for accommodating a clutch used for disconnecting or connecting the power transmitted by the rotating shaft to the drive wheel; and a communicating hole, used for communicating the clutch chamber with the gear chamber, where an inclined surface facing toward the communicating hole is provided on an inner surface inside the clutch chamber opposite to an outer peripheral surface of the clutch.

Owner:HONDA MOTOR CO LTD

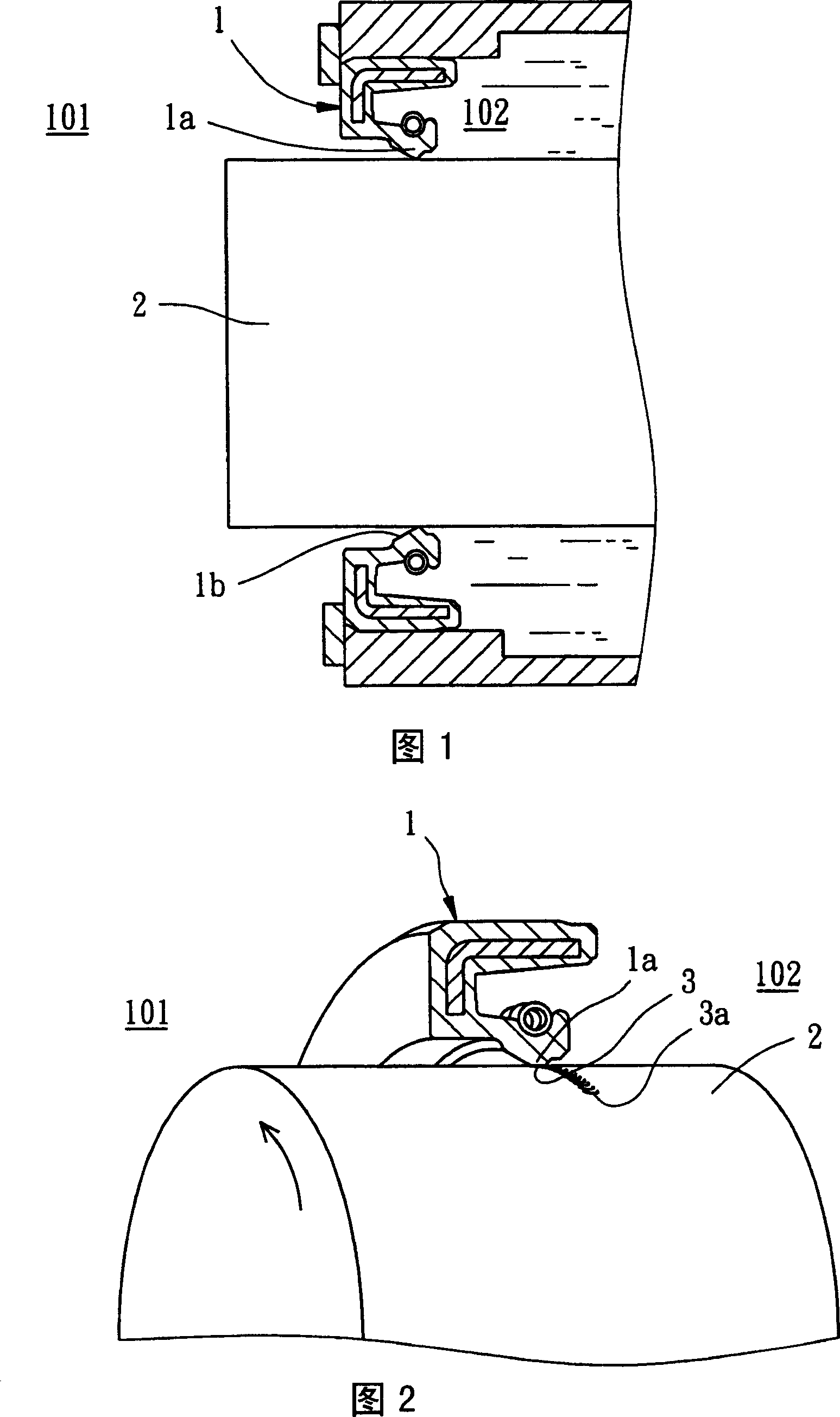

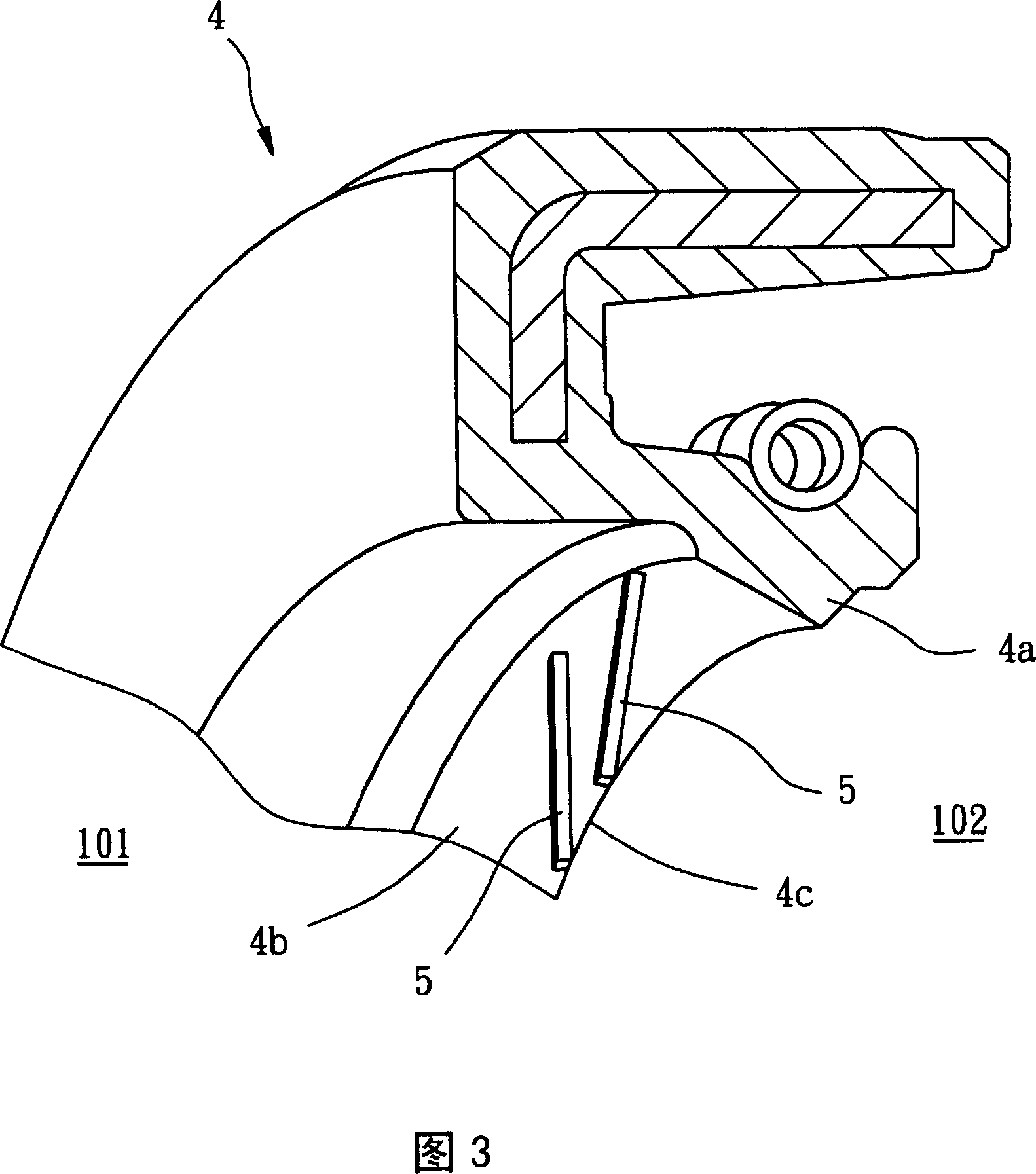

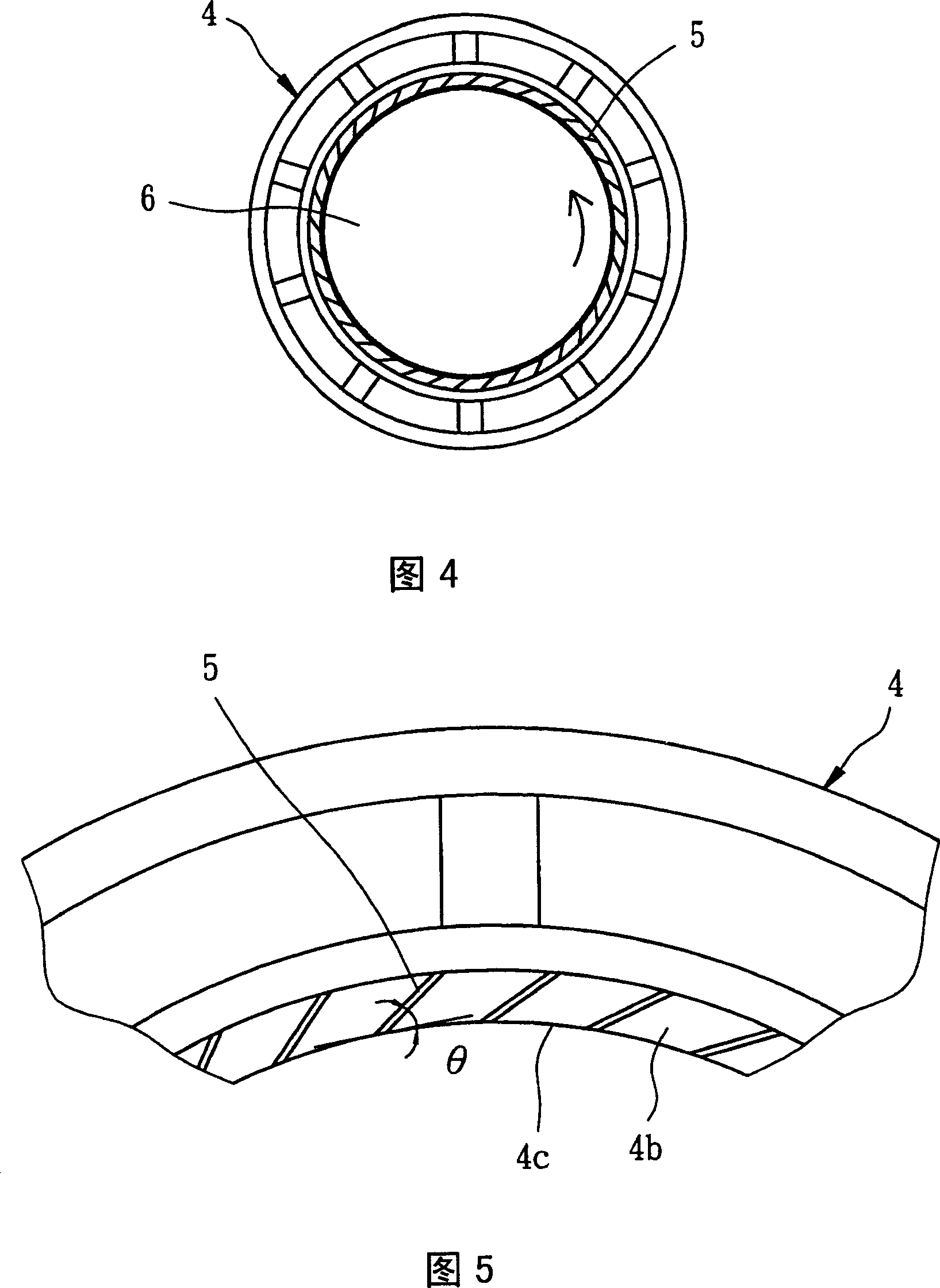

Sealing component

The invention is a sealing component, jacketed on a rotating shaft and having a sealing lip butted against the surface of the rotating shaft to isolate air from lubricant, where one side of the sealing lip facing external air is equipped with plural oil return grooves formed by salience, which are designed in two-segment turning mode, able to effectively block leakage lubricant and push the lubricant back to reduce lubricant loss.

Owner:昆山茂顺密封件工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com