Rotor assembly, pump rotor assembly, assembling method of pump rotor assembly and compressor

A component and rotor technology, which is applied in the field of compressors, rotor components, pump body rotor components and their assembly methods, can solve the problems that the balance block is easy to form disturbances and unfavorably form a stable and continuous flow field, so as to achieve the effect of improving oil return, Effects of noise reduction and fluid noise avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

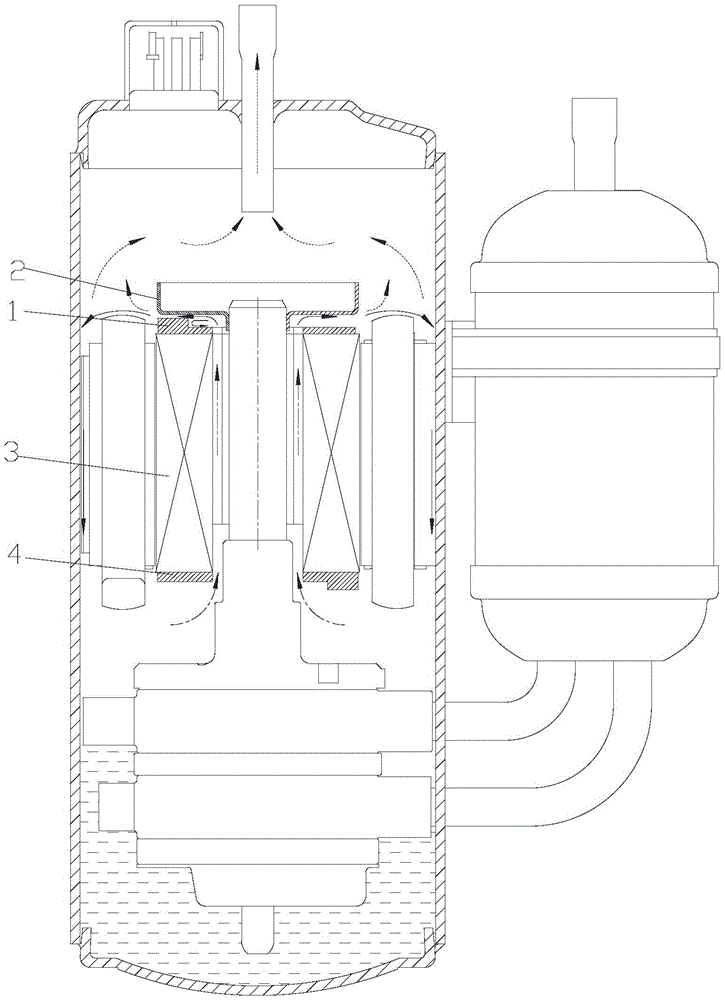

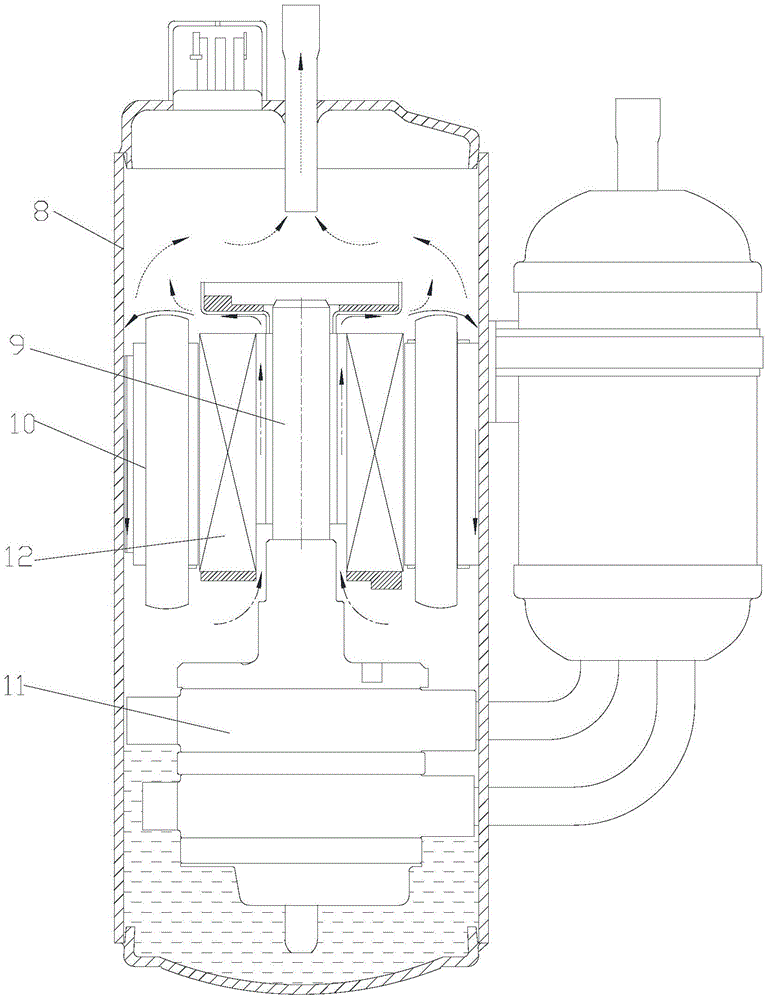

[0027] The solid line arrows in the figure indicate the flow direction of refrigeration oil, the dotted line arrows indicate the flow direction of refrigerant gas, and the dotted line arrows indicate the flow direction of oil-gas mixture.

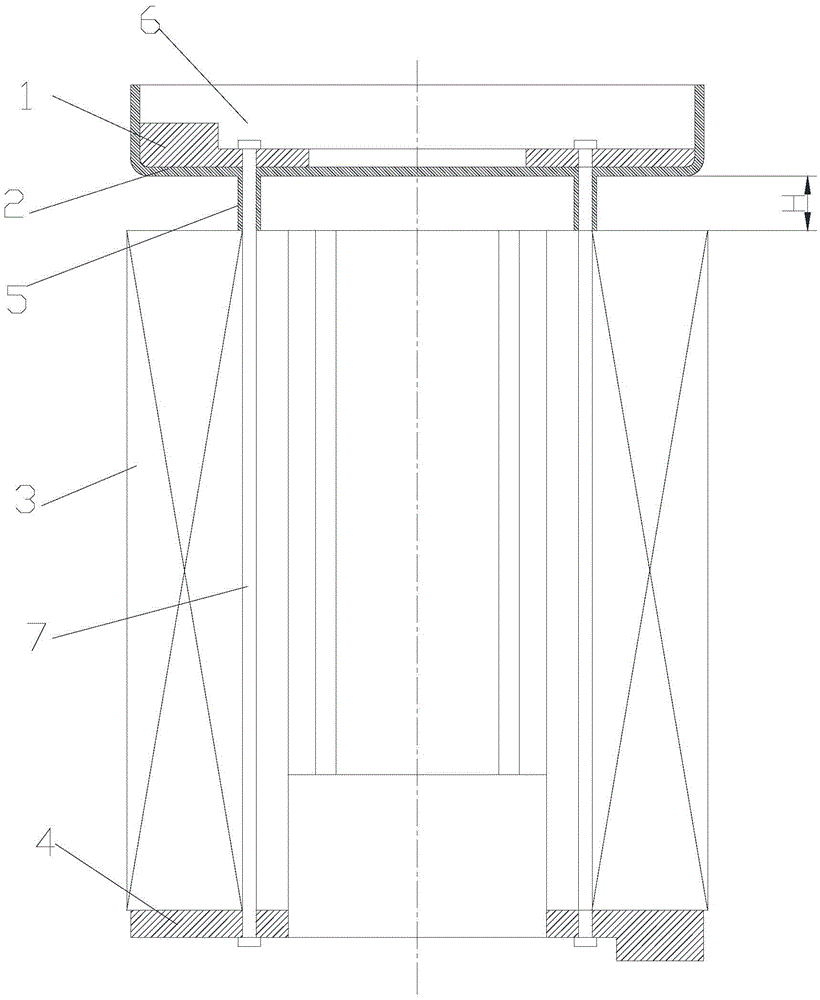

[0028] Please refer to figure 2 with image 3 As shown, the present invention provides a rotor assembly for being sleeved outside the crankshaft 9, including a first balance weight 1, an oil baffle plate 2, a rotor core 3 and a second balance weight 4, the first balance weight 1, The oil baffle plate 2, the rotor core 3 and the second balance weight 4 are sequentially arranged from top to bottom along the axial direction of the crankshaft.

[0029] Place the first balance weight 1 above the oil baffle plate 2, the space between the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com