Probe assembly for a fluid condition monitor and method of making same

A component and state technology, applied in the field of sensors, can solve the problems of insufficient manufacturing cost, difficulty in setting electrode elements, difficulty in providing surface area and spacing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

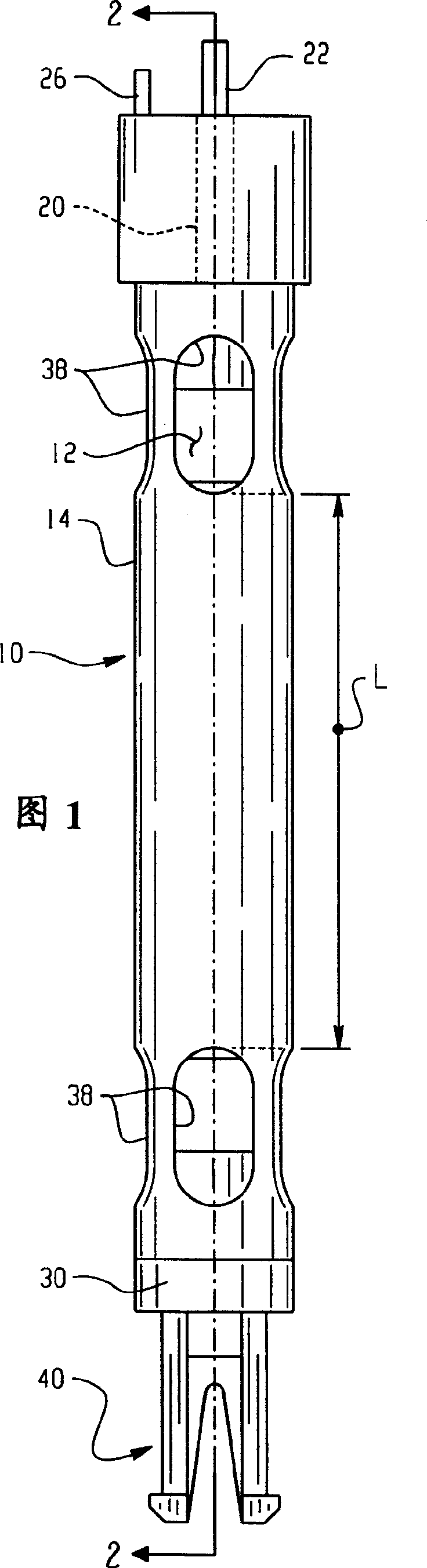

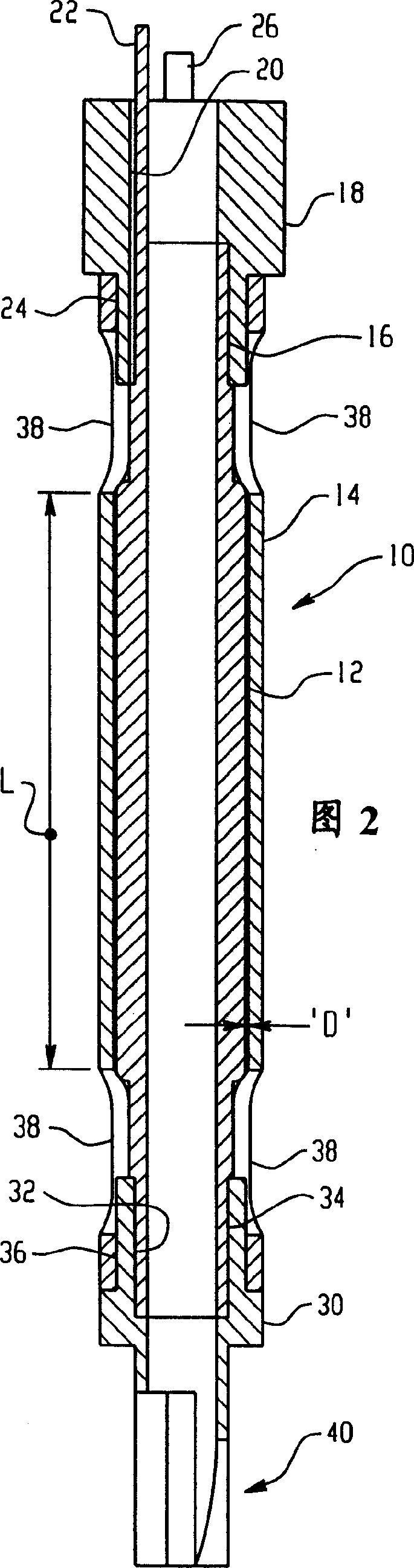

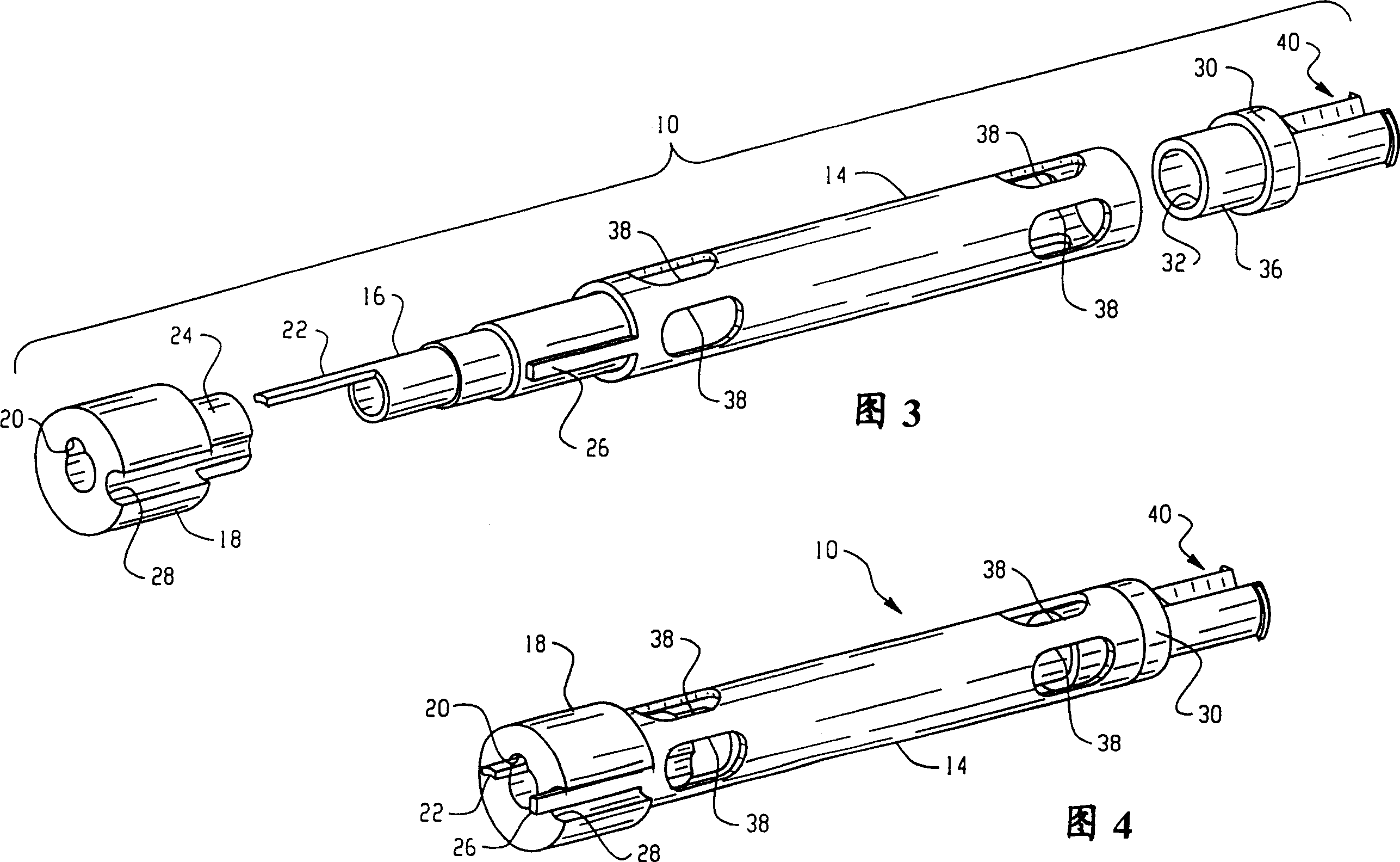

[0016] Referring to Figures 1 and 2, an embodiment of the present invention suitable for monitoring fluid in an automatic transmission of a motor vehicle, generally designated 10, includes a tubular inner electrode 12 having a certain The outer surface is distanced in length from the inner circumference of a tubular outer electrode 14 by a predetermined amount to provide a prescribed surface area for the electrodes spaced at known distances.

[0017] The inner electrode 12 has a reduced diameter portion 16 which is received within an end cap or sleeve 18 which has a passage 20 therethrough through which a connector terminal 22 extends, preferably axially Extended and shaped, and integrally formed as a member with the end portion of the internal electrode 12 .

[0018] The outer electrode 14 is received at the periphery of a reduced diameter portion 24 formed on the end cap 18 for maintaining the inner electrode 12 and the outer electrode 14 in the desired spaced apart relation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com