Refrigeration device

A refrigeration device and refrigerant technology, which is applied in refrigerators, refrigeration and liquefaction, base materials, etc., can solve the problems of viscosity drop and affect the reliability of compressors, and achieve improved oil return, good solubility, improved reliability and The effect of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

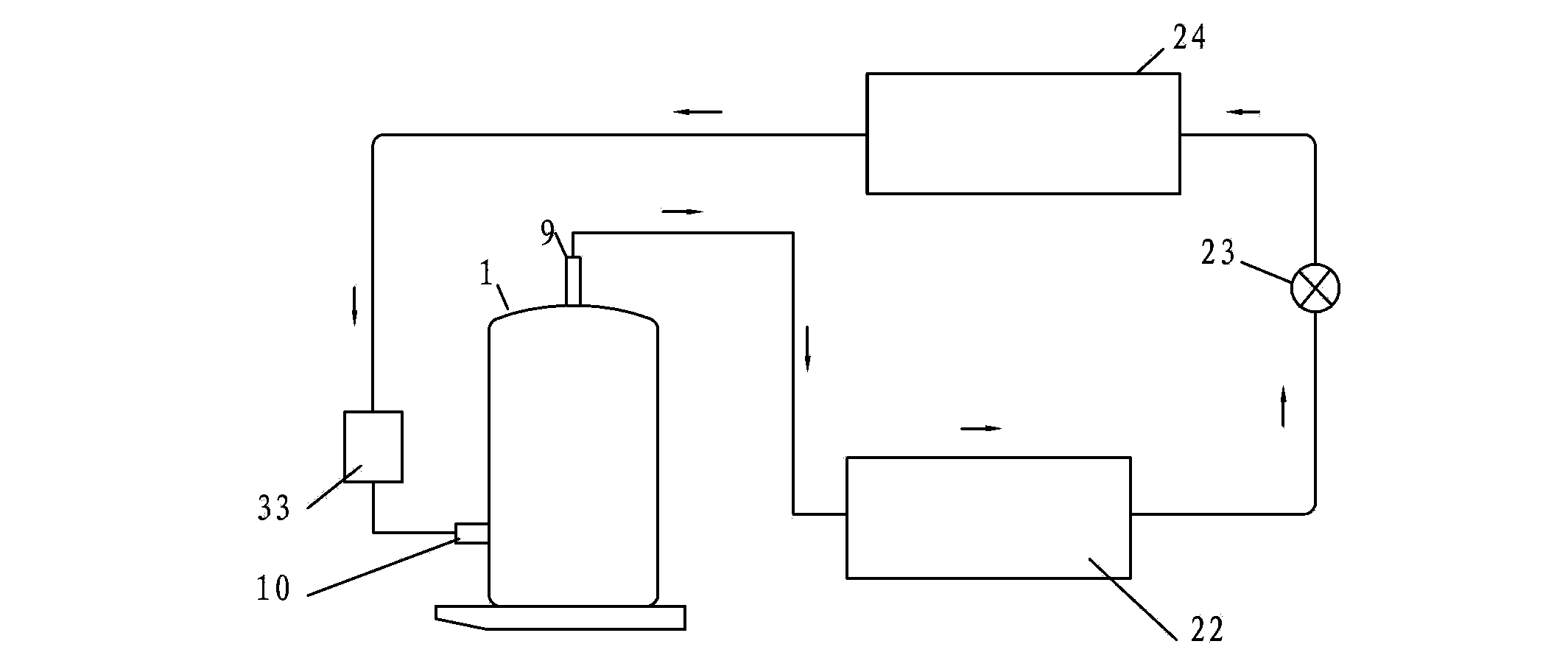

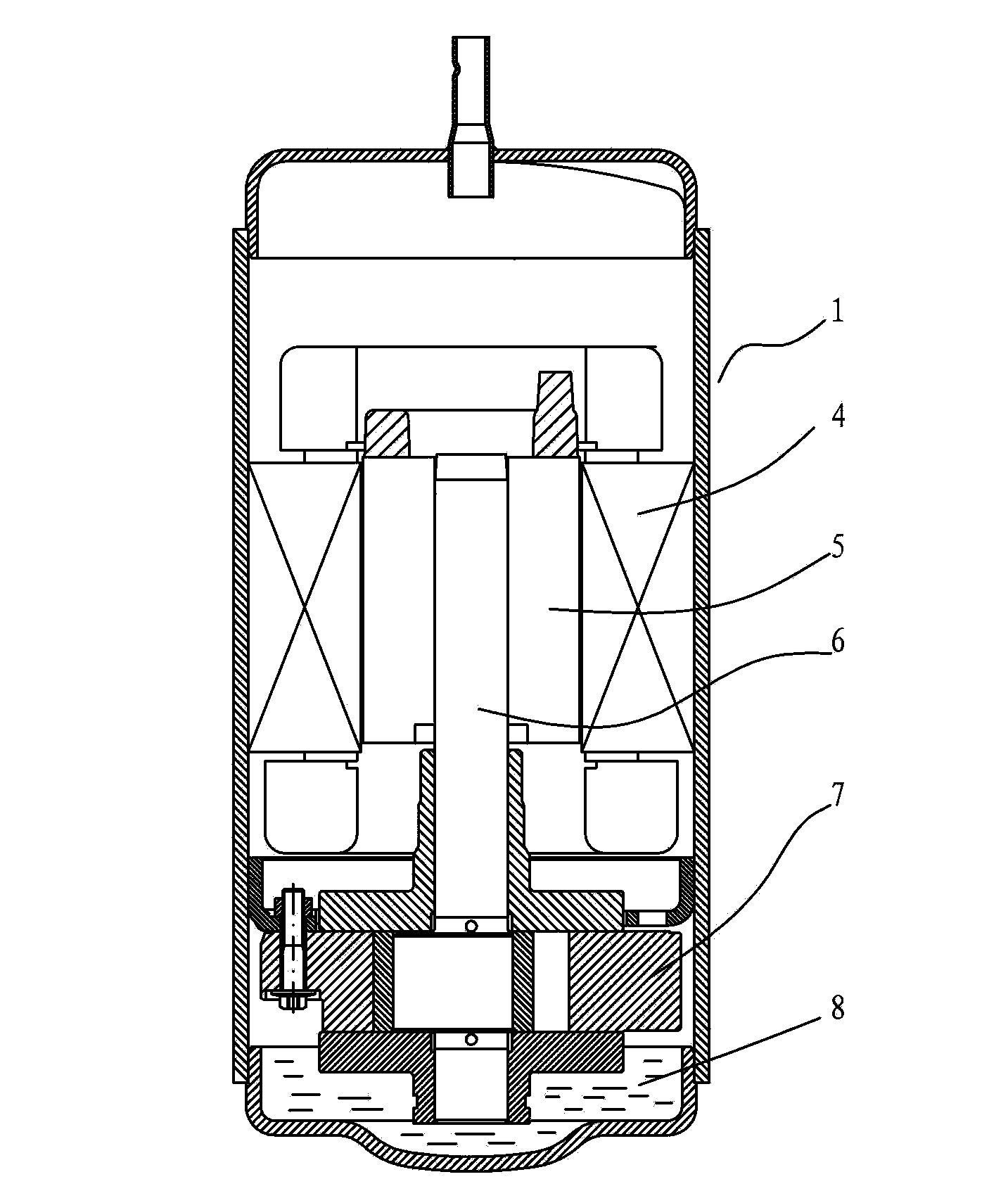

[0017] see Figure 1-Figure 2 , the refrigerating device includes a refrigerating cycle at least composed of a compressor 1, a condenser 22, an expansion mechanism 23 and an evaporator 24, and the refrigerating cycle is filled with R32 refrigerant and refrigerating machine oil, and the refrigerating machine oil is made of polyalkane di It is made by mixing any two or more of alcohol ether, polyvinyl ether, polyalphaolefin, alkylbenzene and mineral oil.

[0018] For example, refrigerating machine oil is made of polyalkane glycol ether and polyvinyl ether; or, refrigerating machine oil is made of polyalphaolefin, alkylbenzene and mineral oil; or, refrigerating machine oil is made of polyalkane glycol ether, Blends of polyalphaolefins, alkylbenzenes, and mineral oils, among others.

[0019] Wherein, the two-layer separation temperature between any two or more of them and the R32 refrigerant is below -10°C, and the two-layer separation temperature between any two or more of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com