Patents

Literature

794 results about "Silicone fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone fluids, also commonly known as silicone oils, are polydimethysiloxane polymers. The viscosity of silicone fluids is caused by the chain length of the polymer. For example, our lowest viscosity fluid, Allcosil 200/0.65's polymer constituent is the dimer, hexamethyldisiloxane.

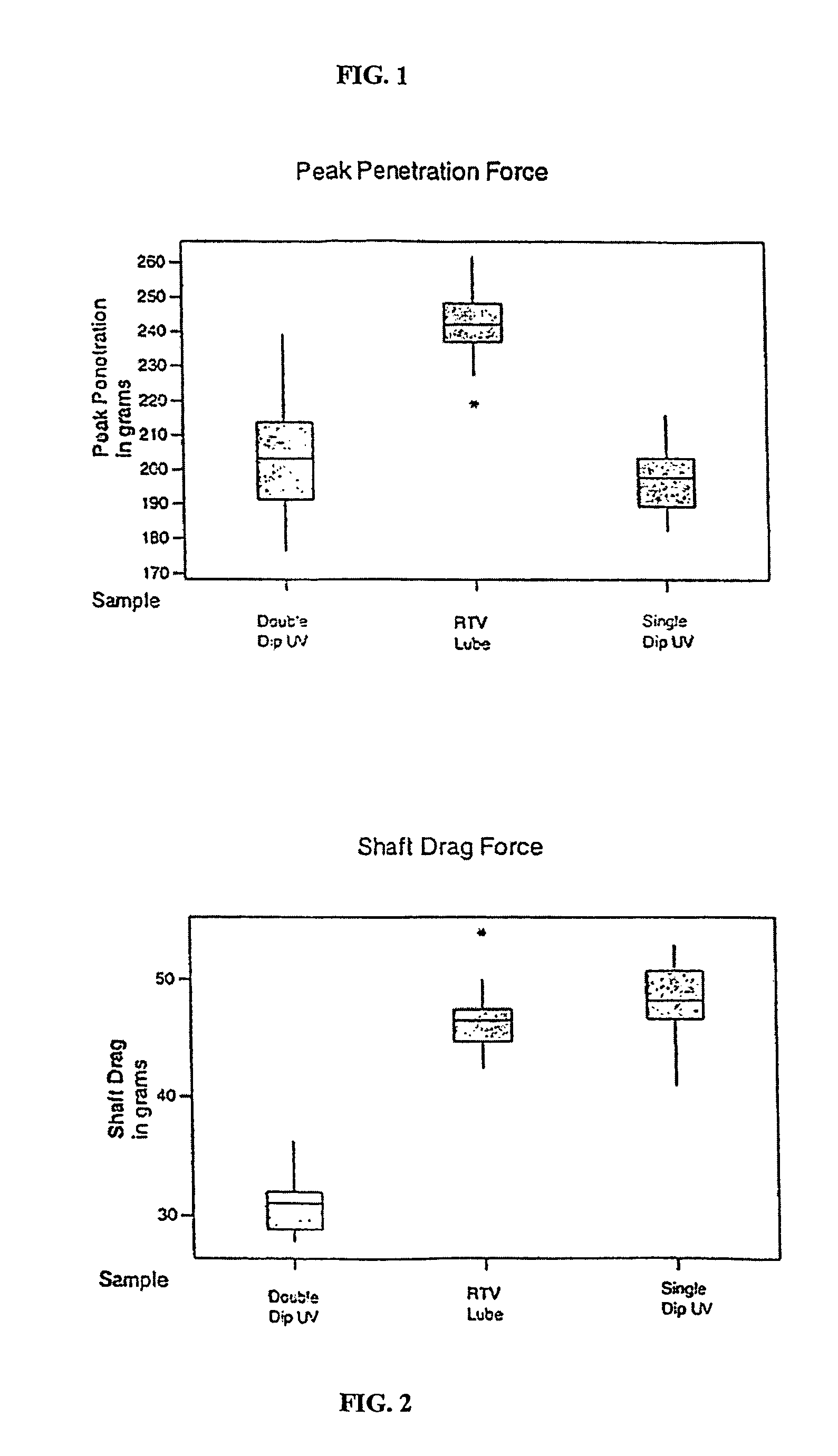

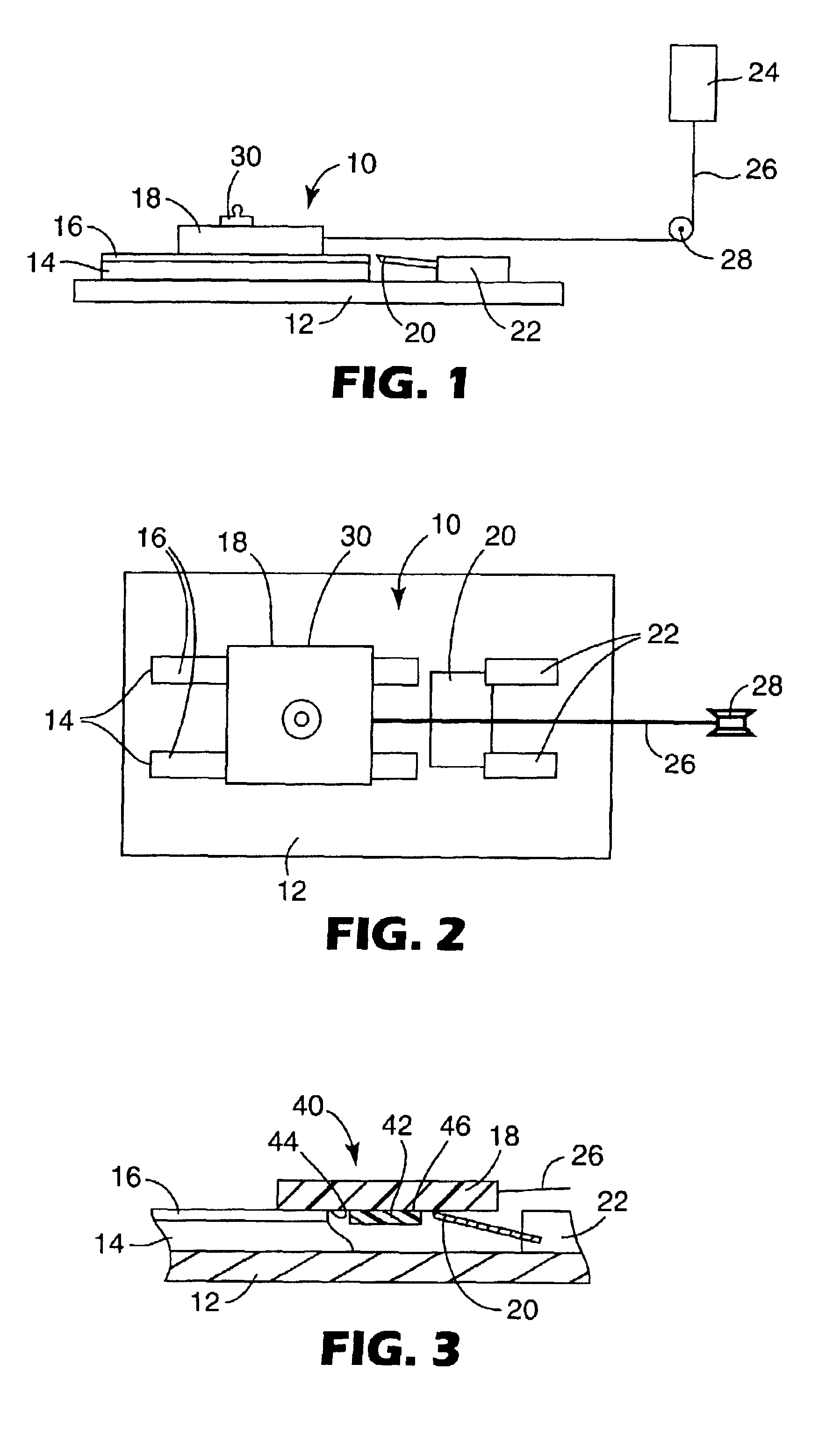

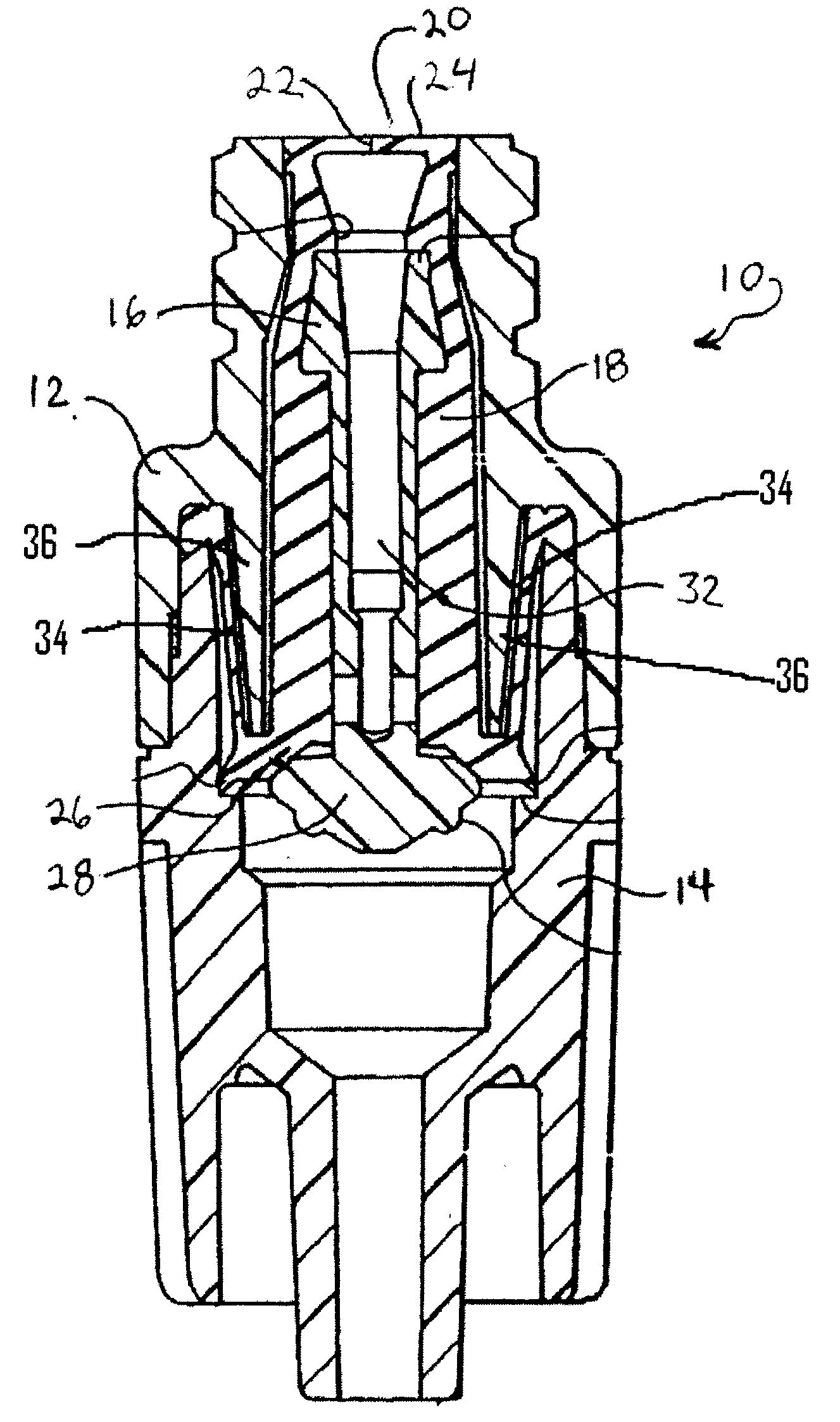

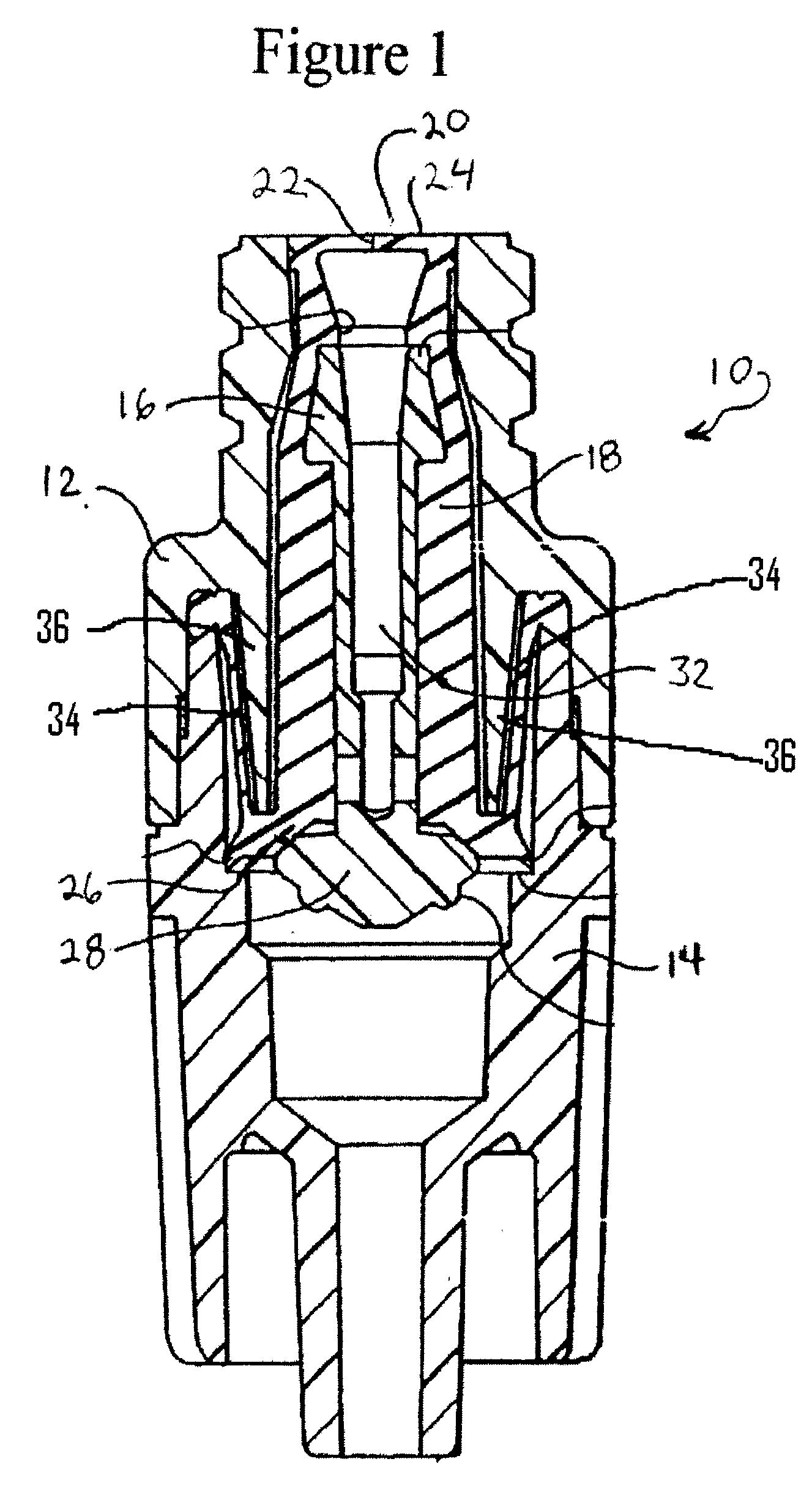

Medical device lubricant comprising radiation curable silicon material

ActiveUS7354628B2Improve performanceEliminate delaysIncision instrumentsSurgical needlesEpoxyVinyl ether

Owner:CARDINAL HEALTH IRELAND UNLTD

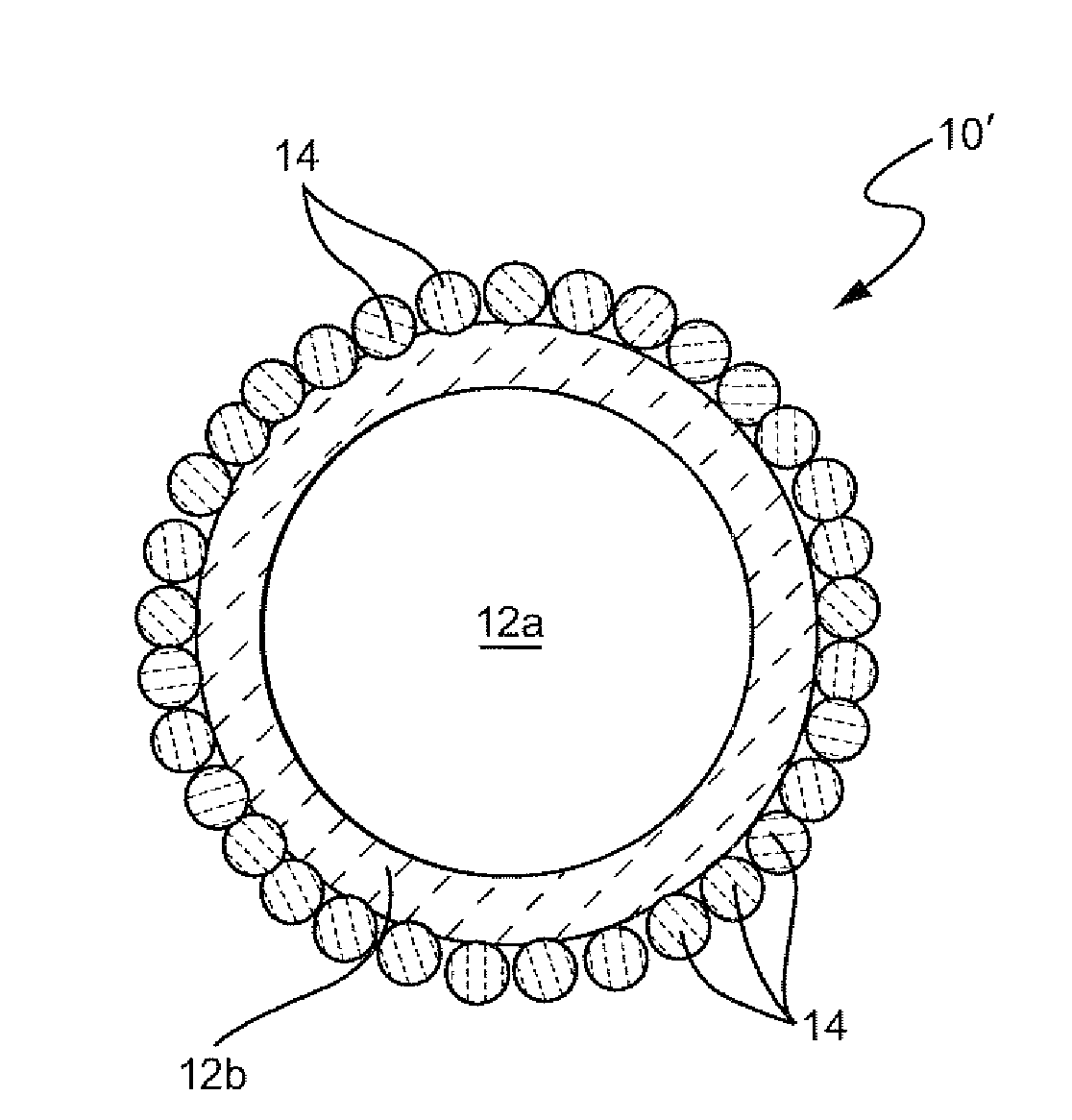

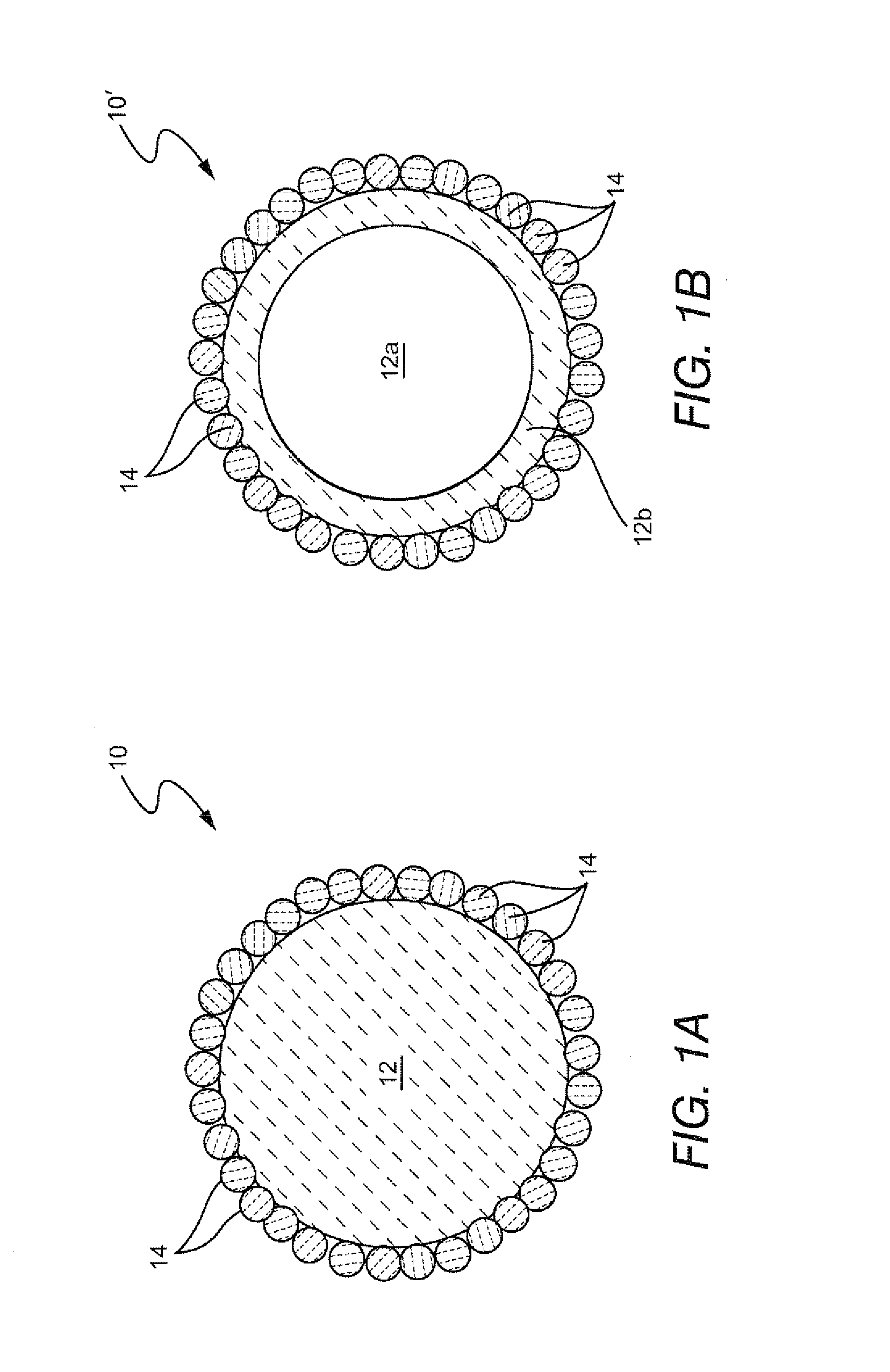

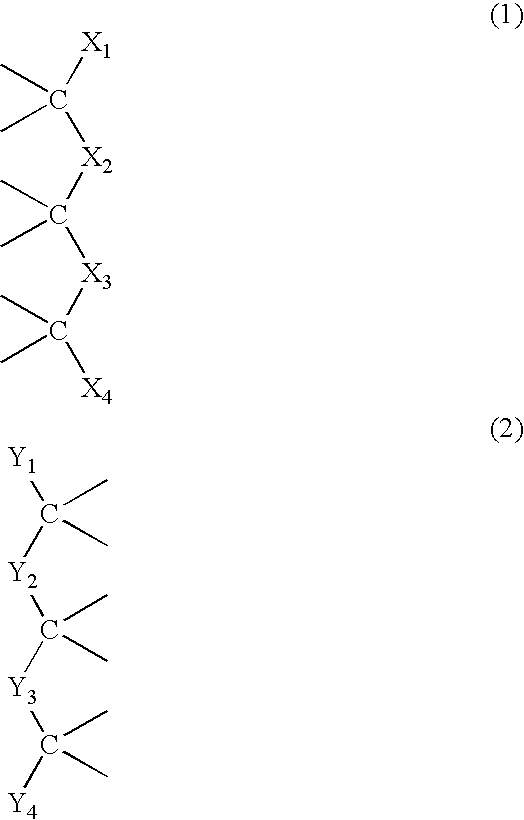

Additive particles having superhydrophobic characteristics and coatings and methods of making and using the same

InactiveUS20090298369A1Non-macromolecular adhesive additivesLiquid repellent fibresCoating systemSilanes

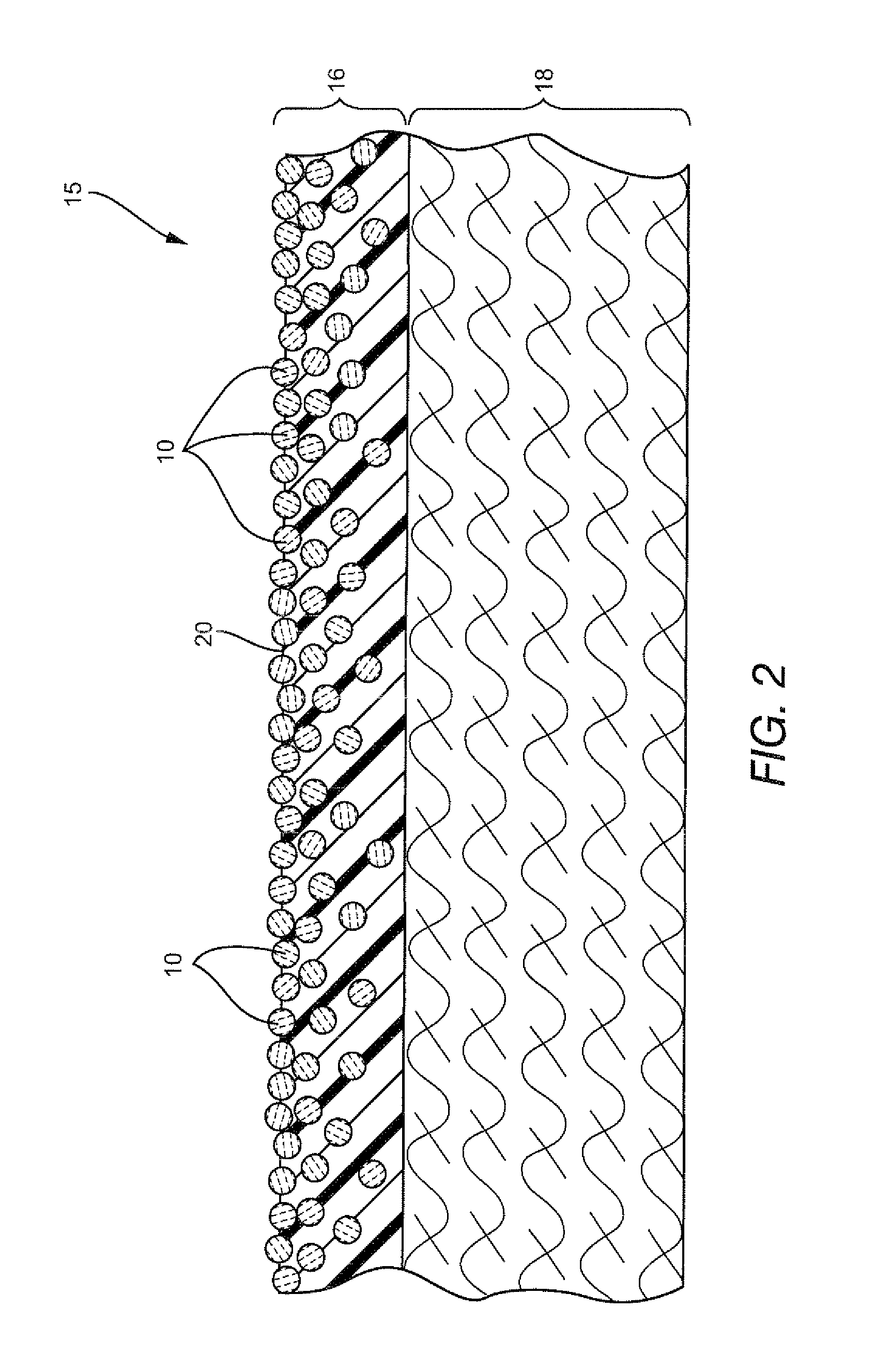

Additive particles may be employed in sufficient amounts to impart superhydrophobicity to a coating system in which the additive particles are incorporated. The additive particles include carrier microparticles and a dense plurality of nanoparticles adhered to the surfaces of the carrier microparticles (e.g., preferably by electrostatic deposition or covalent bonding). The additive particles are advantageously incorporated into a coating material (e.g., a polymeric material) in amounts sufficient to render a substrate surface superhydrophobic when coated with the coating material. The substrate may be rigid (e.g., glass, ceramic or metal) or flexible (e.g., a polymeric film or sheet or a fabric). In some preferred embodiments, both the microparticle and nanoparticles are formed of silica and are surface treated with a hydrophobic treatment so as to impart superhydrophobic properties thereto. Especially preferred are particles treated with silicone fluid comprised of a polysiloxane and / or a perfluoro silane having between 1 and 40 carbon atoms.

Owner:LUNA INNOVATIONS

Antiperspirant compositions

InactiveUS6410003B1Excellent propertyLow visible depositCosmetic preparationsToilet preparationsAminalCyclohexane

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

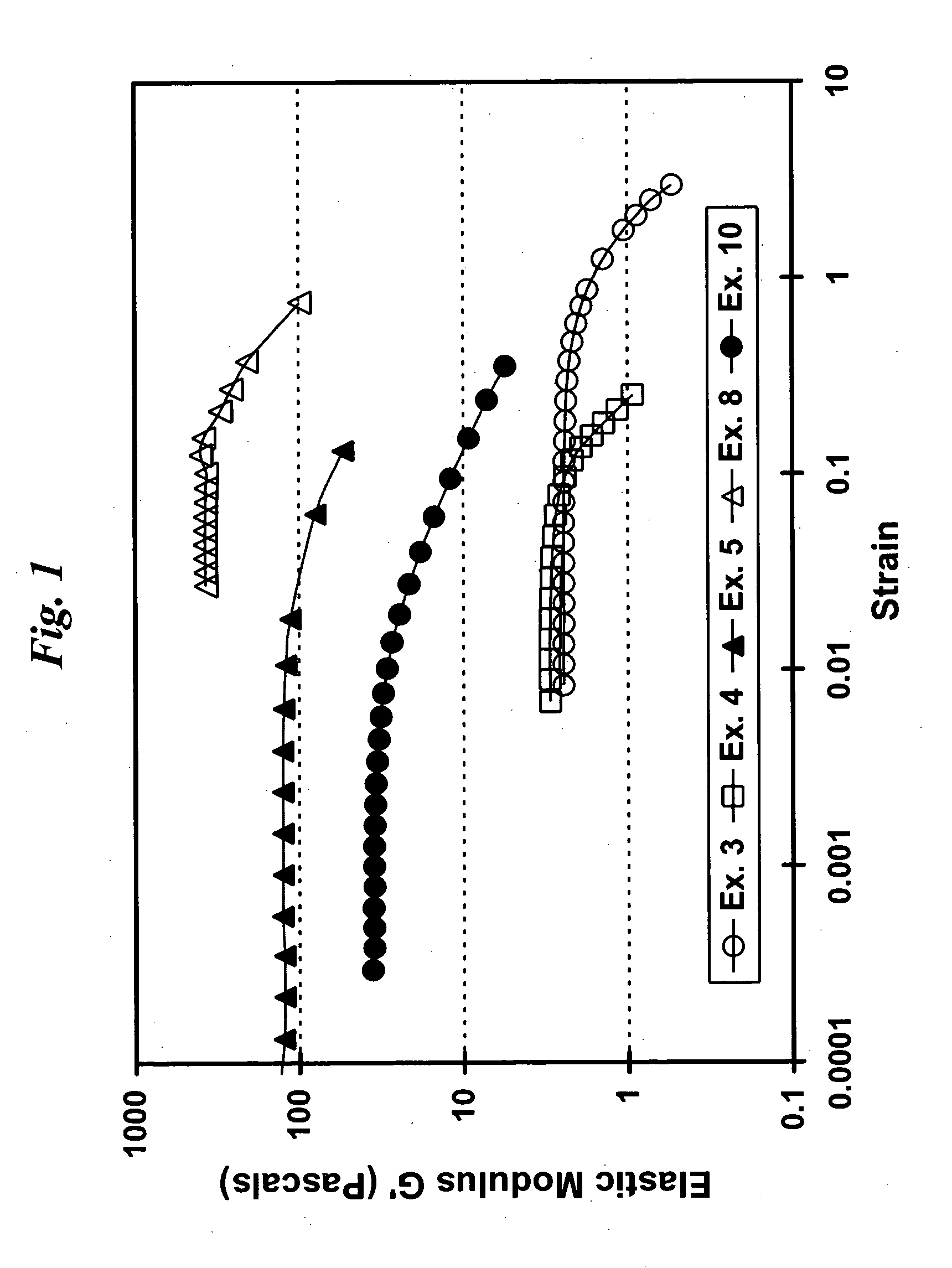

Rheologically stabilized silicone dispersions

ActiveUS20050250668A1Good lookingConducive to preservationOrganic detergent compounding agentsFibre treatmentElastomerWater dispersible

Aqueous dispersions of silicone oils are prepared without the need for surfactants, solvents, hydrotropes or emulsifiers by employing water soluble and / or water dispersible polymers providing inventive compositions which exhibit a rheological Critical Strain value greater than zero and less than about 0.5. Disclosed according to the present invention are compositions and methods of use of the aqueous dispersions of silicone fluids for cleaning, preserving, protecting, and otherwise treating a variety of surfaces, including household surfaces, such as floors, counter tops, furniture, walls, and automotive surfaces, such as tires, rubber, vinyl, upholstery, fabric, plastic and general elastomer surfaces.

Owner:ENERGIZER AUTO INC

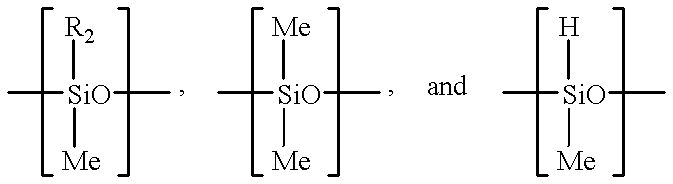

Grafted rubber-like silicone gel with enhanced oil compatibility and its synthetic process

InactiveUS6331604B1Improve compatibilityReduce capacityCosmetic preparationsToilet preparationsSilicone GelsVegetable oil

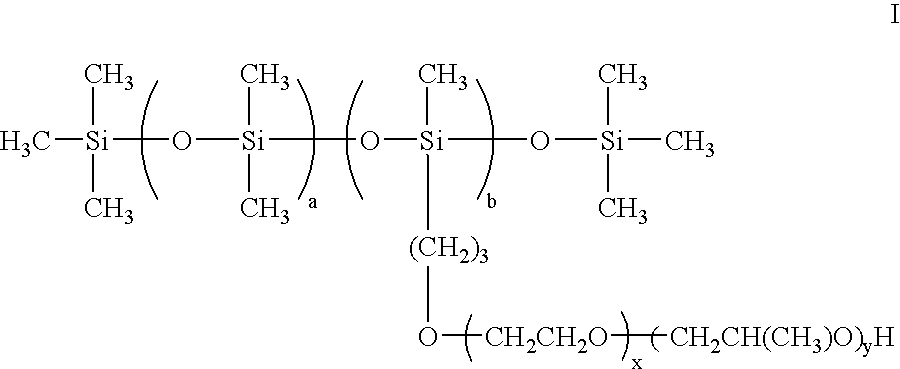

Fatty alcohol or aliphatic glycol-grafted rubber-like silicone gels with enhanced oil compatibility are synthesized by 1) reacting a fatty alcohol or a aliphatic glycol with methylhydrodimethylsiloxane copolymer in the presence of a platinum catalyst in a reaction medium of a silicone fluid or a cosmetic oil or a mixture thereof, and 2) further reacting the mixture with a vinyl-functional siloxane polymer. The resulting compounds may be used as gelling agents for hydrocarbon oils, vegetable oils and silicone oils. The efficient synthetic process approaches a 100% yield.

Owner:GRANT INDS

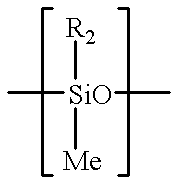

Natural insect and arthropod repellent

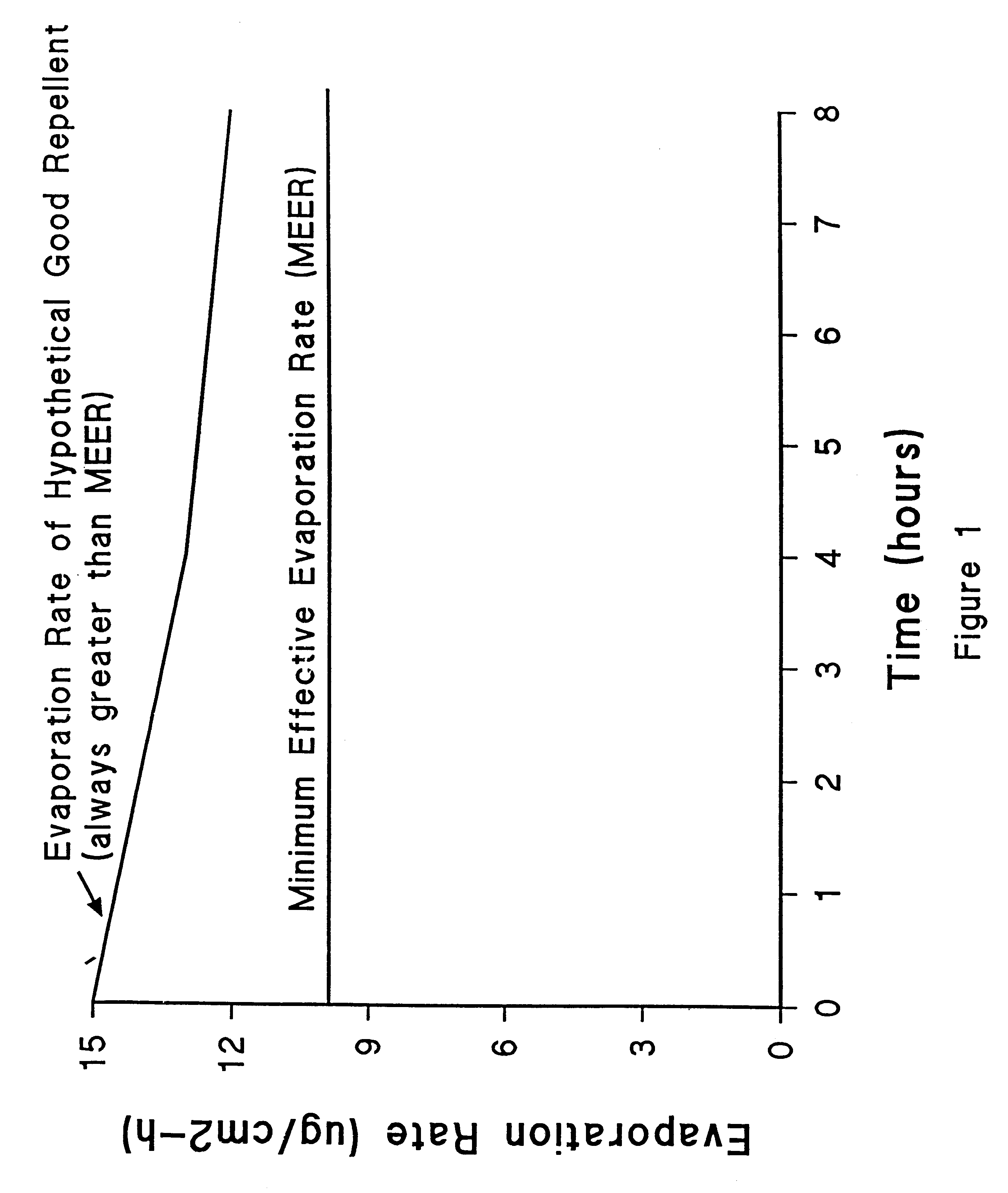

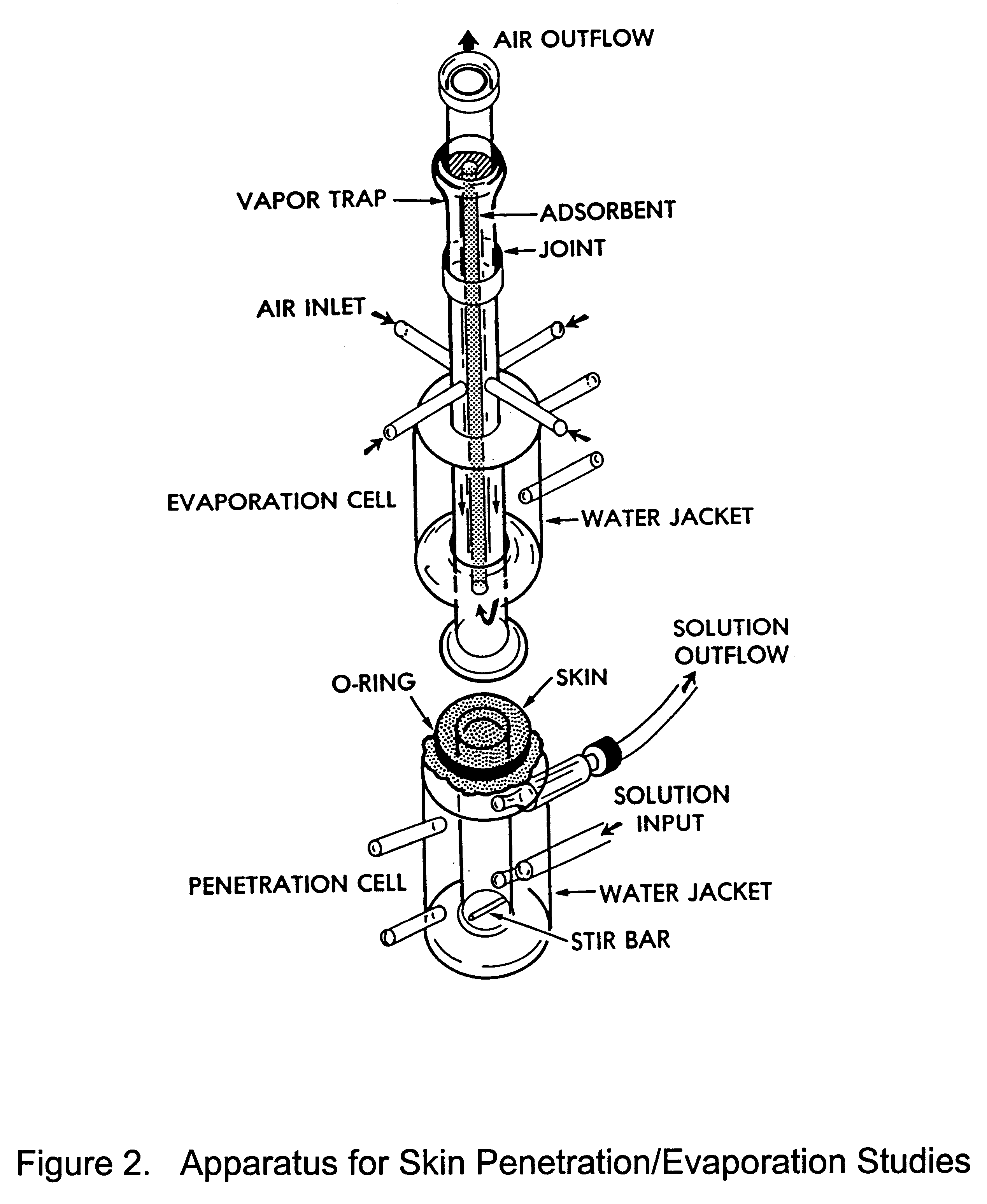

InactiveUS6306415B1Avoid damageSafe, long-lasting, effective and pleasantBiocideCosmetic preparationsCarboxylic acidStable fly

A topical insect repellent with extended duration of protection was obtained from mixtures of molecules based on two or more volatile repellent organic molecular species occurring naturally on the human skin surface. The novel repellent comprises mixtures of lower, intermediate, and higher volatility organic molecules. Active ingredients for formulations are obtained from homologous series of carboxylic acids, alcohols, ketones, and lactones which span a similar range of volatility and which occur naturally on the skin surface. Volatile silicone fluid imparts mildness and water repellency to the repellent formulations. The new natural repellent exhibits the longevity and repellency that is comparable to N,N-diethyl-m-toluamide (DEET), a synthetic compound employed in almost all commercial formulations, but the inventive natural repellent is more acceptable than DEET, which has an unpleasant odor and imparts a greasy feel to the skin. The inventive insect repellent, formulated in a volatile silicone fluid, was shown to repel and incapacitate stable flies. This finding demonstrated that repellency was not limited to mosquitoes, but extends to other biting flies or insects, thus demonstrating the utility of the novel insect repellent for protecting pets and livestock as well as humans.

Owner:STRATACOR

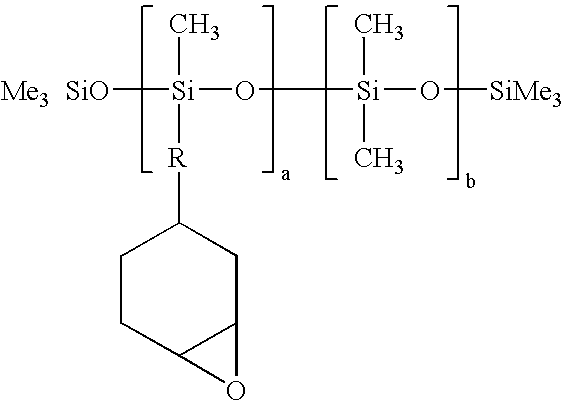

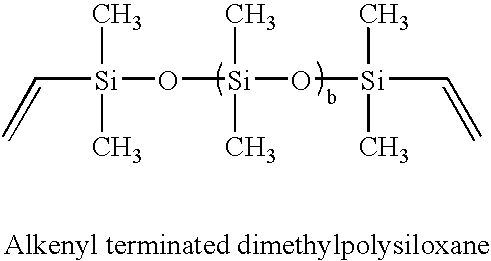

Photocured silicone sealant having improved adhesion to plastic

InactiveUS6908682B2Improve adhesionExtended service lifeOther chemical processesCouplings bases/casesAdhesion forceHydrogen

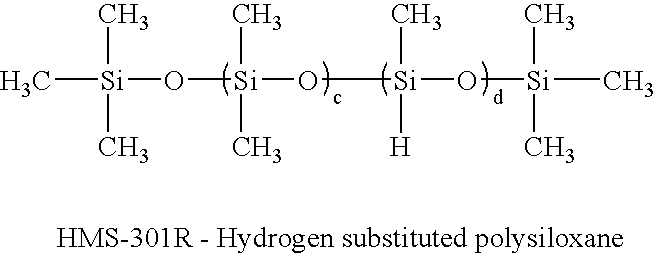

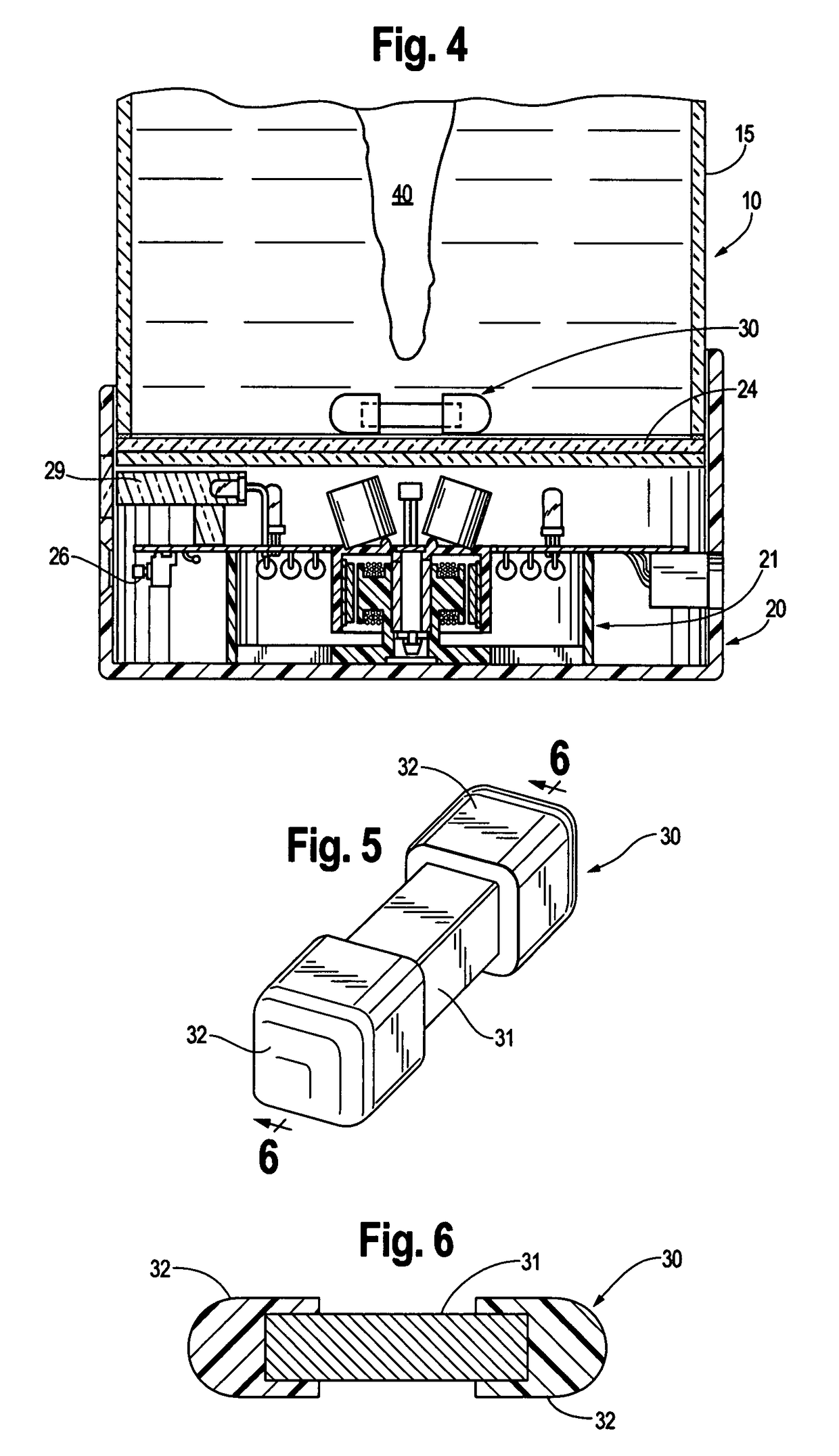

A curable composition for use as a sealant, in which the curable composition comprises a silicone fluid in an amount from about 80 wt % to about 90 wt %, a vinyl group containing polyorganosiloxane in an amount from about 10 wt % to about 20 wt %, a hydrogen containing polysiloxane in an amount from about 0.5 wt % to about 2.0 wt %, and a hydrosilation photocatalyst in an amount from about 5 ppm to about 100 ppm. The sealant cures in about 1 second to about 20 seconds during reaction of the vinyl group containing polydiorganosiloxane and the hydrogen containing polysiloxane, by exposure to ultraviolet radiation, in the presence of the hydrosilation photocatalyst. The sealant has an adhesion force to plastic from about 2.0 N / 100 mm to about 4.0 N / 100 mm.

Owner:3M INNOVATIVE PROPERTIES CO

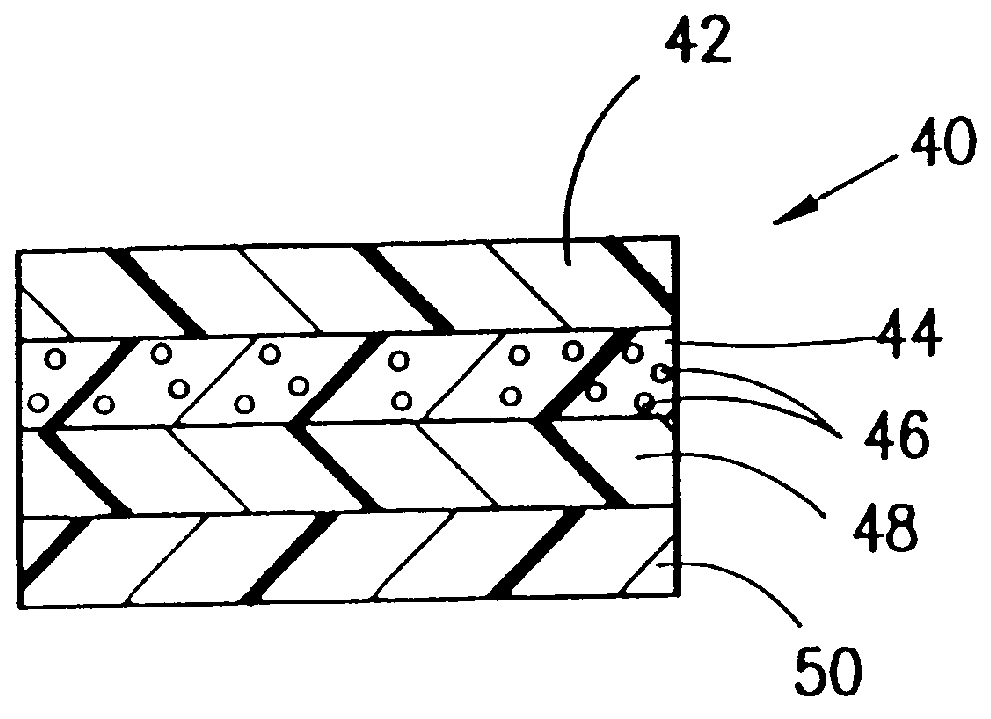

Low-oil-permeability super-soft thermally-conductive silica gel composition and thermally-conductive silica gel gasket and preparation method thereof

The present invention relates to a low-oil-permeability super-soft thermally-conductive silica gel composition and a thermally-conductive silica gel gasket, the low-oil-permeability super-soft thermally-conductive silica gel composition comprising a first liquid silica gel, a second liquid silica gel and a thermally-conductive filler, the thermally-conductive silica gel gasket is prepared from the low-oil-permeability super-soft thermally-conductive silica gel composition, the low-oil-permeability super-soft thermally-conductive silica gel composition is prepared from the following components by mass: 7 to 11.9% of a first liquid silica gel and second liquid silica gel mixed liquid, 88 to 92.9% of the thermally-conductive filler, 0.05 to 0.5% of a catalyst and 0.05 to 0.5% of an inhibitor by the preparation method comprising stirring, rolling, vulcanizing and cutting; the low-oil-permeability super-soft thermally-conductive silica gel composition is prepared by mixing the first liquid silica gel, the second liquid silica gel and the thermally-conductive filler, vinyl silicone oil and a platinum catalyst in the first liquid silica gel and vinyl silicone oil and hydrogen-containing silicone oil in the second liquid silica gel can make the prepared plastic material characterized by being low in oil permeability and low in hardness, and the like, the viscosity of the first liquid silica gel and the second liquid silica gel are 3000mPa. s-10000mPa.s, uniform mixing of the material and the thermally-conductive filler during stirring can be guaranteed, and an appropriate crosslinking degree can be achieved during the vulcanizing.

Owner:PINGHU ALLIED IND

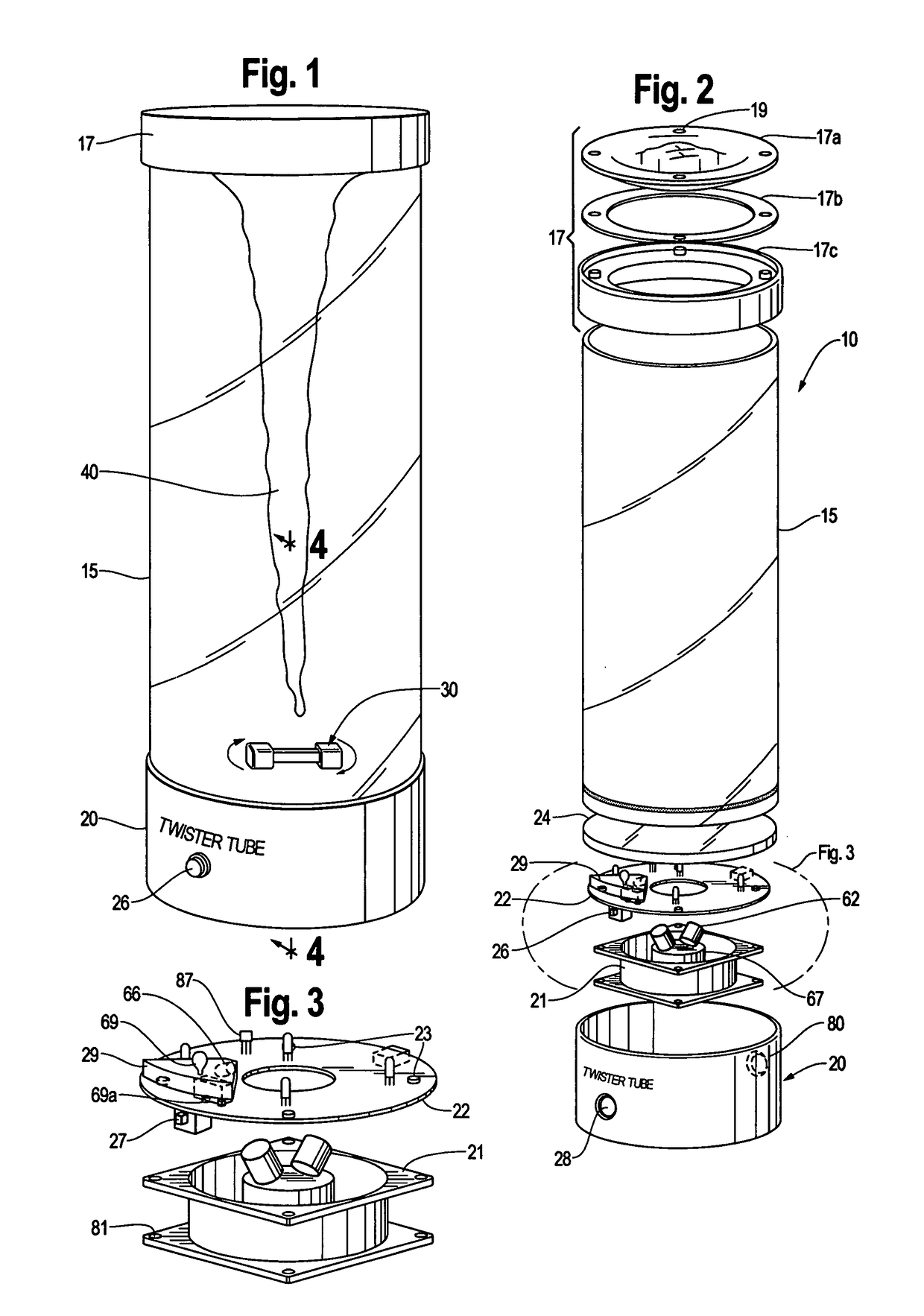

Device and method for generating vortex

A device and method for generating a visible vortex for display or educational purposes. A container houses a two-phase fluidic system of a primary fluid, such as water, and a secondary fluid such as silicone fluid carrying a powder which has no affinity for the primary fluid. The two-phase fluidic system may be stirred using a stir bar or pump to generate the vortex.

Owner:TWISTER TUBE

Process for making bisphosphonic acids using diluents other than halogenated hydrocarbons

Provided is a novel method of making bisphosphonic acids, e.g. risedronic acid, including the step of combining a carboxylic acid, phoshorous acid, and a halophosphorous compound in the presence of a diluent that is an aromatic hydrocarbon or a silicone fluid. When the diluent is an aromatic hydrocarbon, a inert support or ortho-phosphoric acid codiluent is advantageously included.

Owner:TEVA PHARM USA INC

Aesthetic, stable chromatic emulsions

A stable, chromatic water-in-silicone emulsion comprising: i) an aqueous phase containing a water-soluble polyol, a water-soluble polymer thickener, and water; and ii) a silicone phase containing an aromatic silicone, a silicone emulsifier and a silicone fluid carrier.

Owner:AVON PROD INC

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN101081653AReduce consumptionReduce thicknessFlexible coversWrappersPolyesterPolymer science

The present invention discloses one kind of multilayer high blocking film for packing liquid material, the multilayer high blocking film includes polyethylene-based heat sealing layer(s), blocking polymer layer(s) preferably of ethylene-vinyl alcohol copolymer, PVA or polyvinylidene dichloride; and protecting layer(s) of polypropylene, polyester, etc. It has the total thickness below 80 micron, preferably of 55-65 micron. The present invention discloses also the making process of the multilayer high blocking film.

Owner:刘建林

Process for the preparation of solid solventless MQ resins

Owner:DOW SILICONES CORP

Novel hair treatment compositions

InactiveUS20070141007A1Accelerated dryingChange hydrophobicityCosmetic preparationsHair cosmeticsAlcoholSilicone fluid

An aqueous and / or aqueous alcoholic leave-in composition to reduce the time to dry wet hair containing (a) at least one wetting agent having a Draves wetting value of 100 seconds of less selected in an amount sufficient to enhance the hydrophobicity of hair thereby causing water to dewet the hair, and optionally (b) at least one volatile selected from the group consisting of alcohols, dimethicone, trimethicone, and cyclomethicone and a method of shortening the time to dry wet hair.

Owner:AVON PROD INC

High efficiency master gels for thickening oil based compositions

InactiveUS20070071703A1Pronounced effect rheological propertyIncrease loadCosmetic preparationsHair removalOrganoclaySilicone fluid

The composition, preparation and use of a thickening system or master gel for oil based compositions, especially cosmetic compositions is described. These highly efficient master gels include: i) greater than about 10% to about 40% of an organoclay, ii) from about 70% to less than about 90% of a carrier oil comprising a substantially dissolved mixture of at least one silicone fluid and at least one organic oil wherein the total silicone fluids comprise from about 10% to about 90% of the carrier based on the total weight of the carrier, and ii) from 0.5% to about 6% of a polar activator. In a preferred embodiment the master gel contains from about 15% to about 30% of an organoclay and is chosen so that the viscosity of the master gel composition is at least 2.5 million cP as measured with a Brookfield viscometer at 1 rpm.

Owner:LIN SAMUEL QCHENG SUN

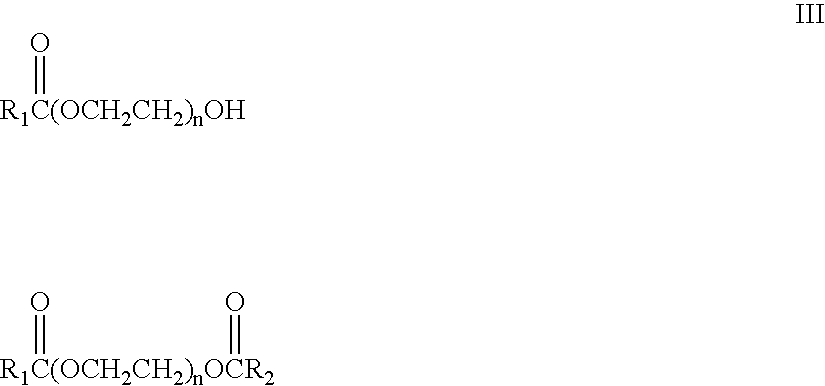

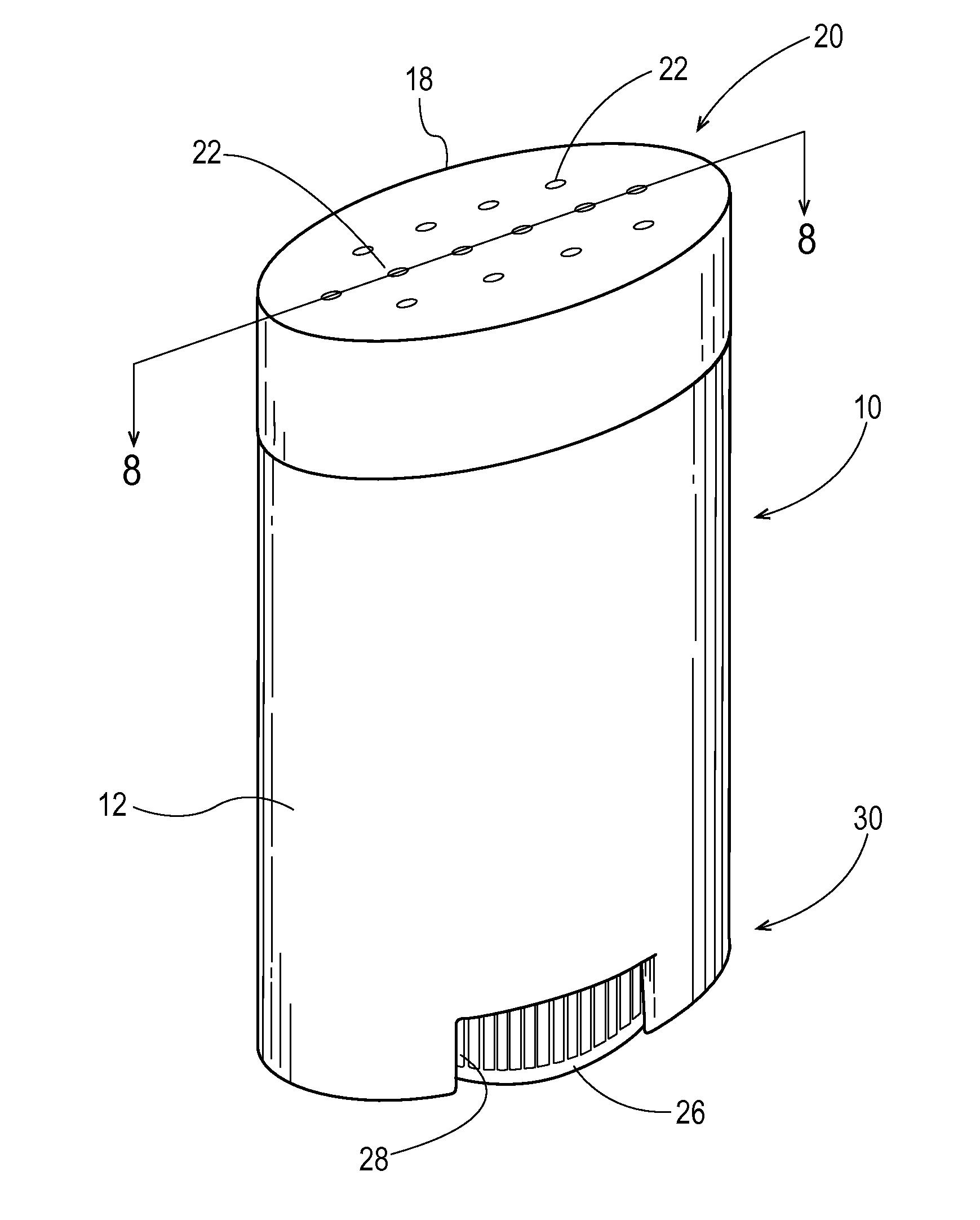

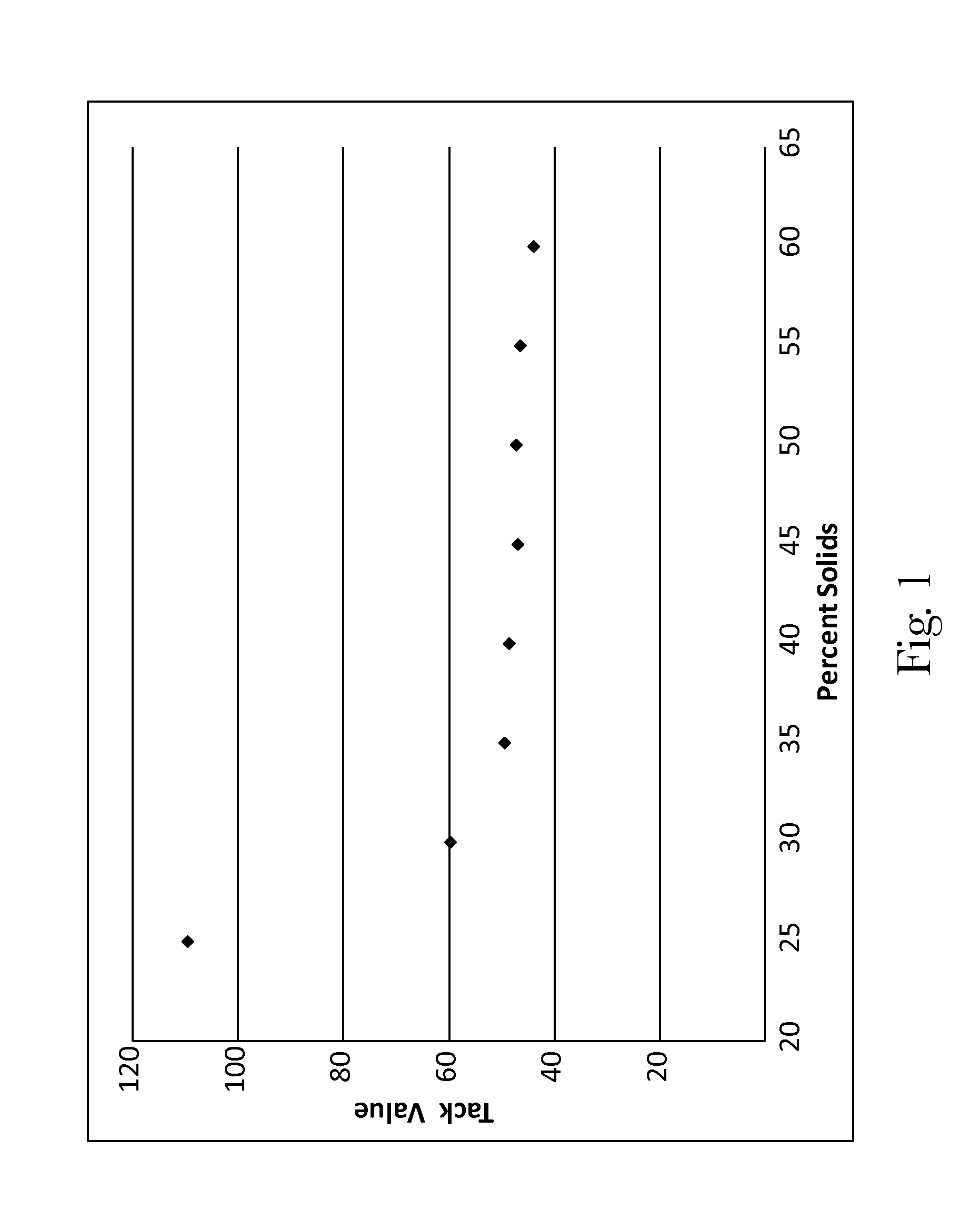

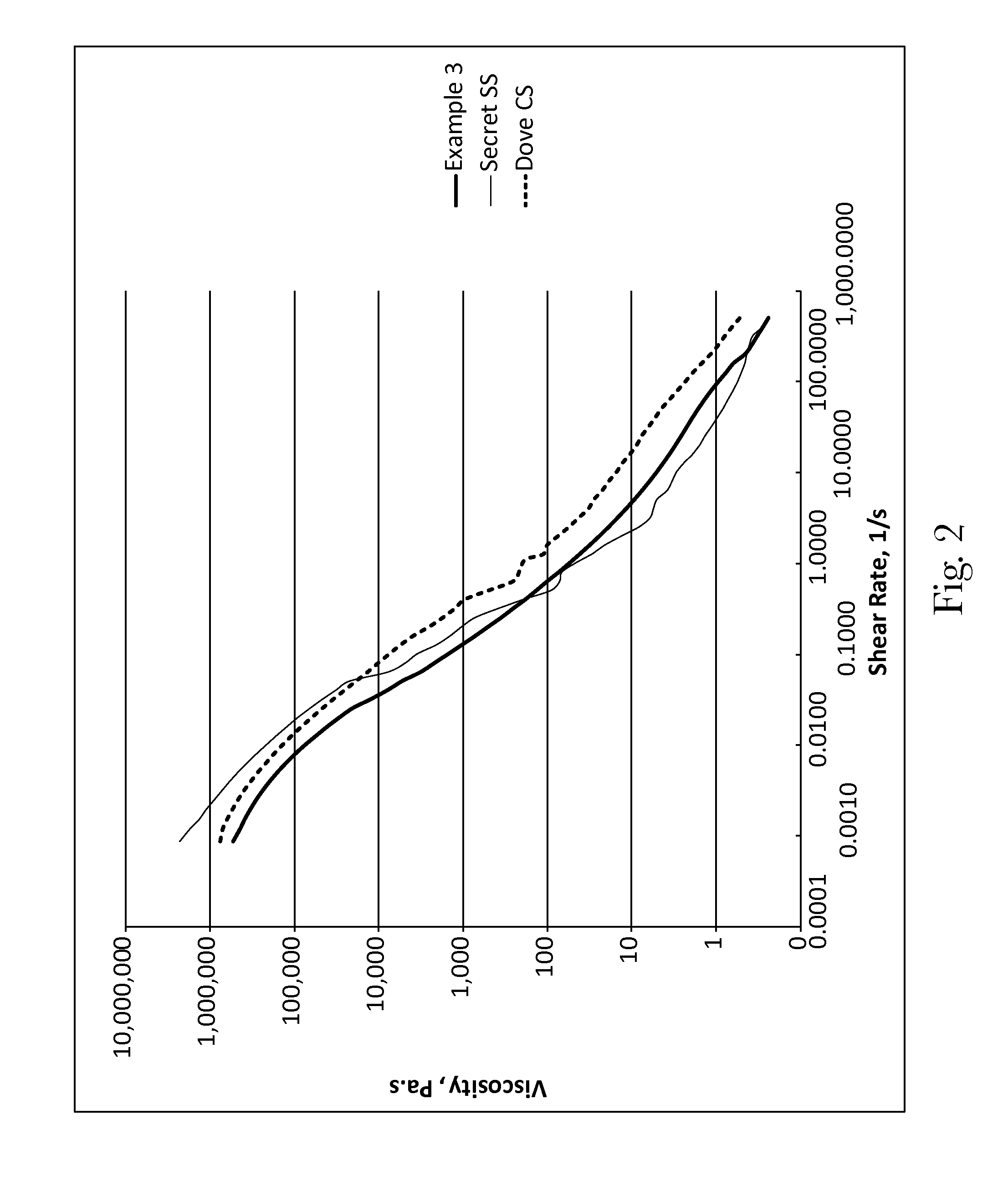

Packaged Antiperspirant Compositions

A packaged antiperspirant product is provided. The packaged antiperspirant product includes an anhydrous antiperspirant composition having from 40% to 60%, by weight of the anhydrous antiperspirant composition, of solids. The solids include an antiperspirant active, one or more waxes, and one or more fillers having a total concentration from about 15% to about 35% by weight of the anhydrous antiperspirant composition. The antiperspirant composition also has from about 35% to about 60%, by weight of the composition, of one or more carriers other than water, wherein the one or more carriers comprises a non-volatile silicone fluid. The package includes a container body having an interior chamber storing the anhydrous antiperspirant composition, a dome closing one end of the container body and having a plurality of apertures extending through the thickness of the dome. An elevator and feed screw are disposed within the container body.

Owner:THE PROCTER & GAMBLE COMPANY

Amino Silicone Nanoemulsion

InactiveUS20150030644A1Broad representationCosmetic preparationsCationic surface-active compoundsAminosilochromeSilicone oil

Owner:THE PROCTER & GAMBLE COMPANY

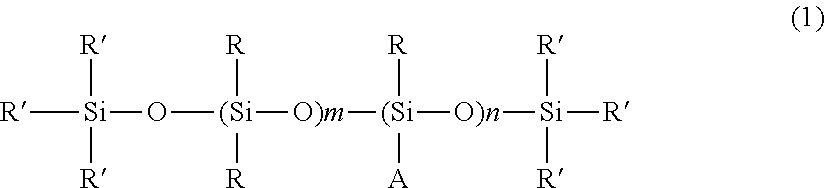

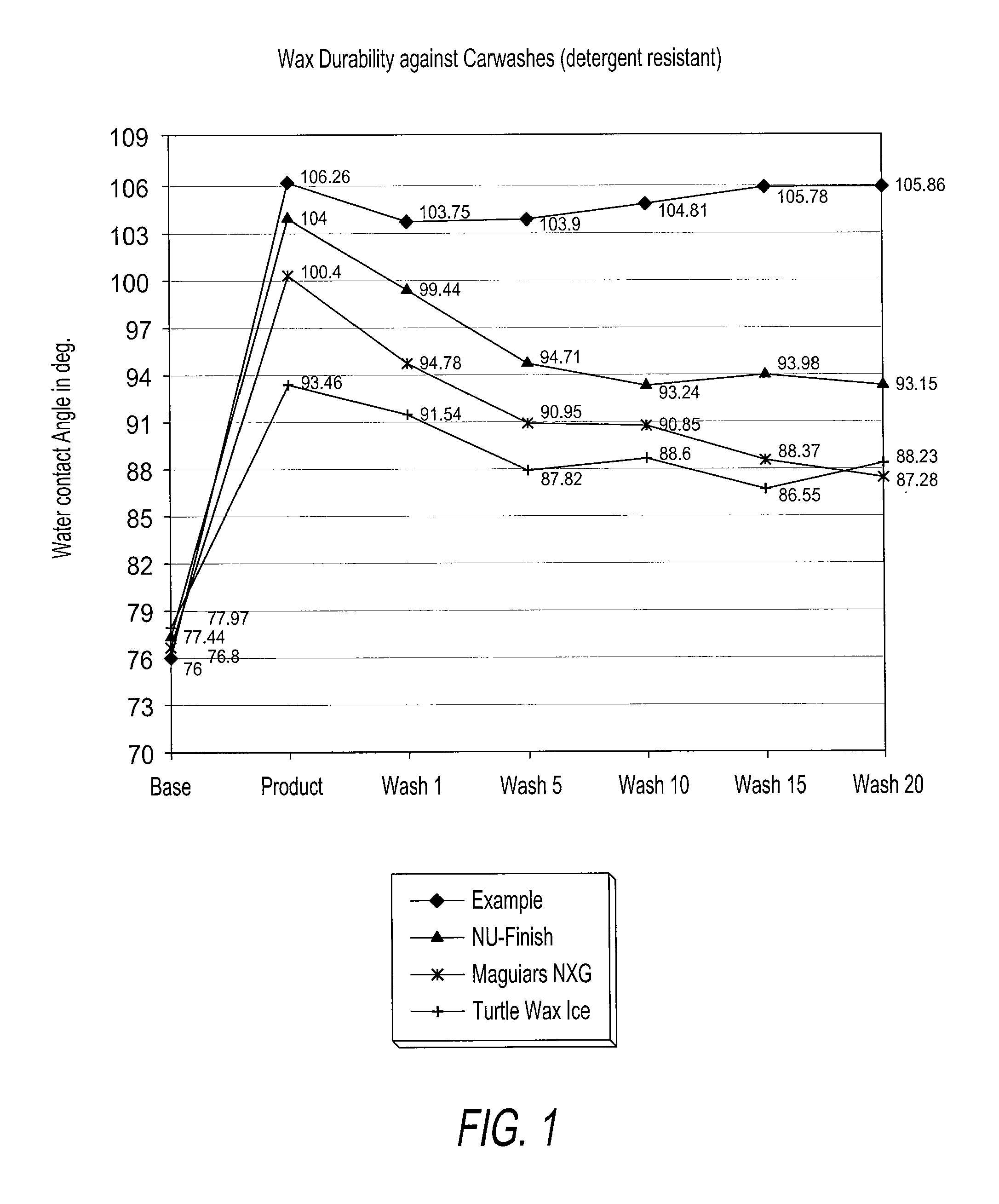

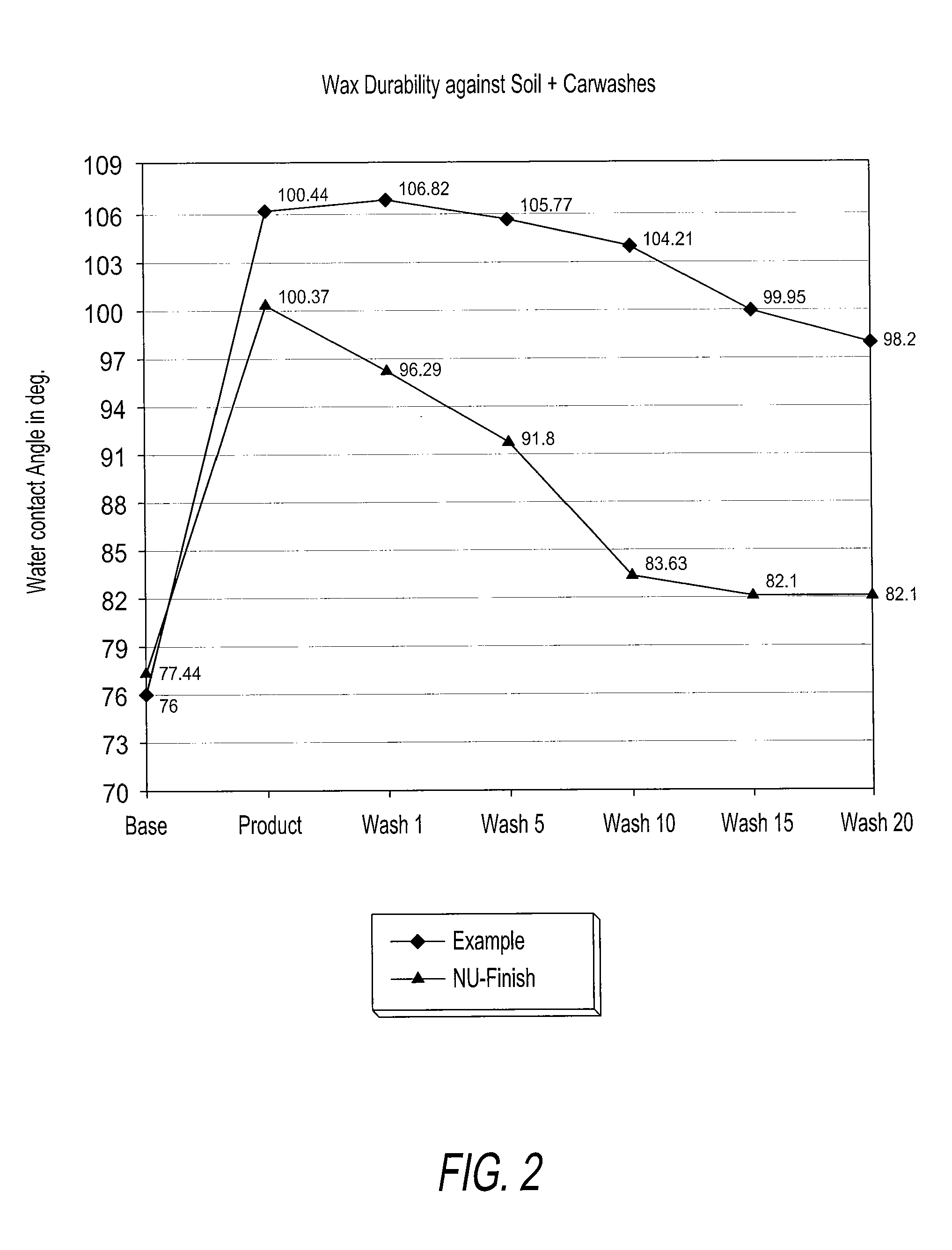

Compositions and methods for treating automotive surfaces

This disclosure relates to compositions containing a) a silicone resin, b) a first silicone fluid having a viscosity from about 1 to about 15,000 centistokes at 25° C.; c) a second silicone fluid having a viscosity from about 1 to about 30,000 centistokes at 25° C.; d) an acrylic polymer; e) a hydrocarbon solvent; and f) water. The compositions of this disclosure provide long lasting hydrophobic coatings with high water contact angles for automotive surfaces, in which the hydrophobic automotive surfaces possess self-cleaning functions, e.g., water and dirt repellency. This disclosure also relates to methods for treating automotive surfaces and to automotive surfaces coated with the compositions.

Owner:ENERGIZER AUTO INC

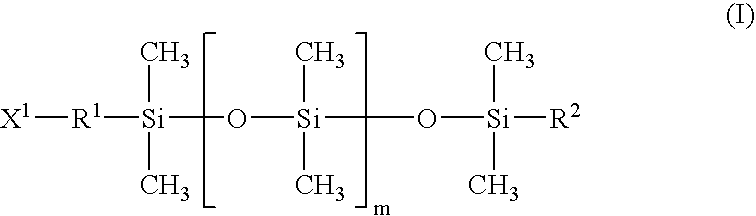

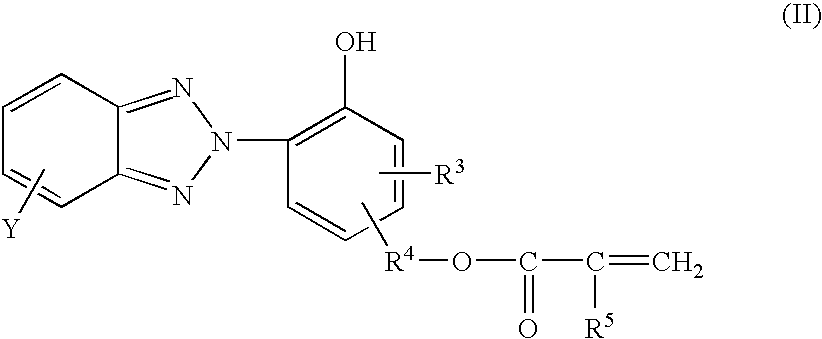

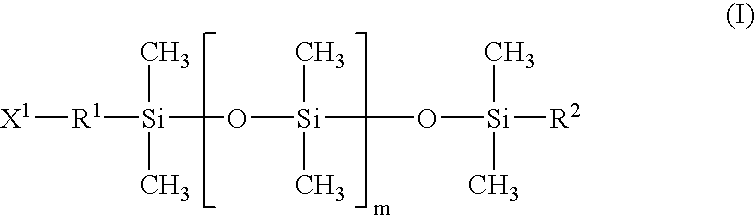

Non-aqueous liquid composition having ultraviolet-absorbing capability

InactiveUS20070098653A1Good slipperinessTransparent appearanceCosmetic preparationsHair cosmeticsPolymer scienceSilicone fluid

The present invention provides a non-aqueous liquid composition from which the coated film on the skin is transparent and slippery, does not cause stickiness and uncomfortable feeling such as creaky feeling and stretch feeling, but causes fresh feeling of use, and keeps the capability of protecting the skin from ultraviolet rays for a desired period of time even under the presence of sweat or sebum, and which is suitable for sunscreen cosmetics, a skin external preparation or a bandage preparation. The non-aqueous liquid composition comprises particles composed of at least a copolymer derived from a silicone macromer (A) and an ultraviolet-absorbing compound and silicone oil in which the particles are dispersed, wherein the silicone macromer (A) exists in the copolymer within 1 to 20 wt % of all components of the particles and orients toward the outer surface of the particle, and wherein, the ultraviolet-absorbing compound is incorporated in the polymer particle as an independent component or a part of the copolymer.

Owner:TAISEI FINE CHEM

Devices using silicone pressure sensitive adhesives containing organic wax

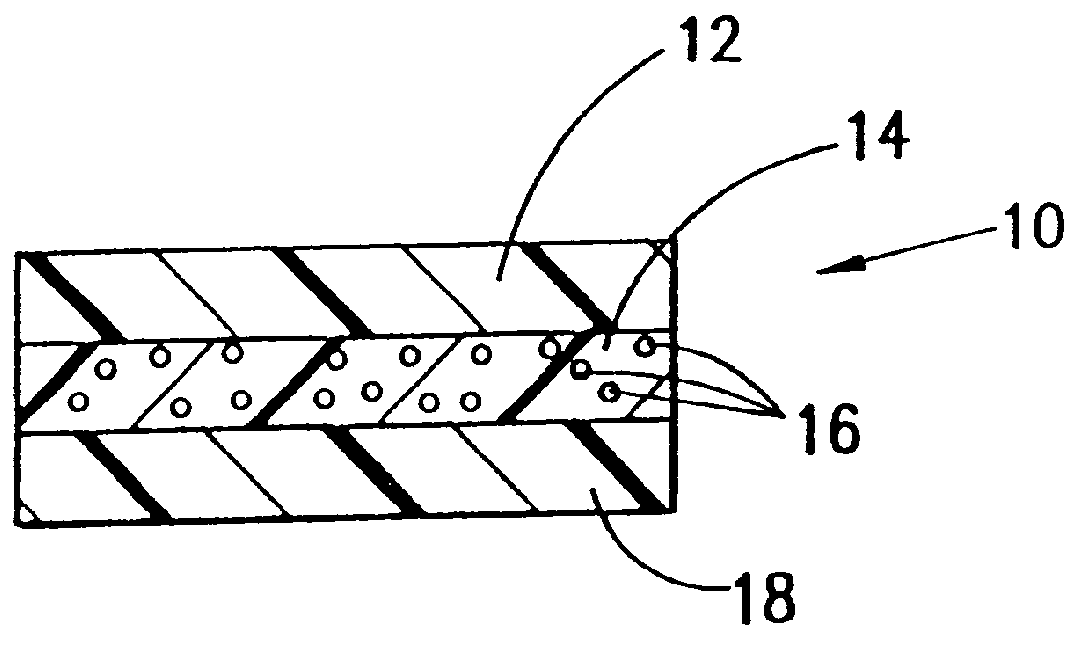

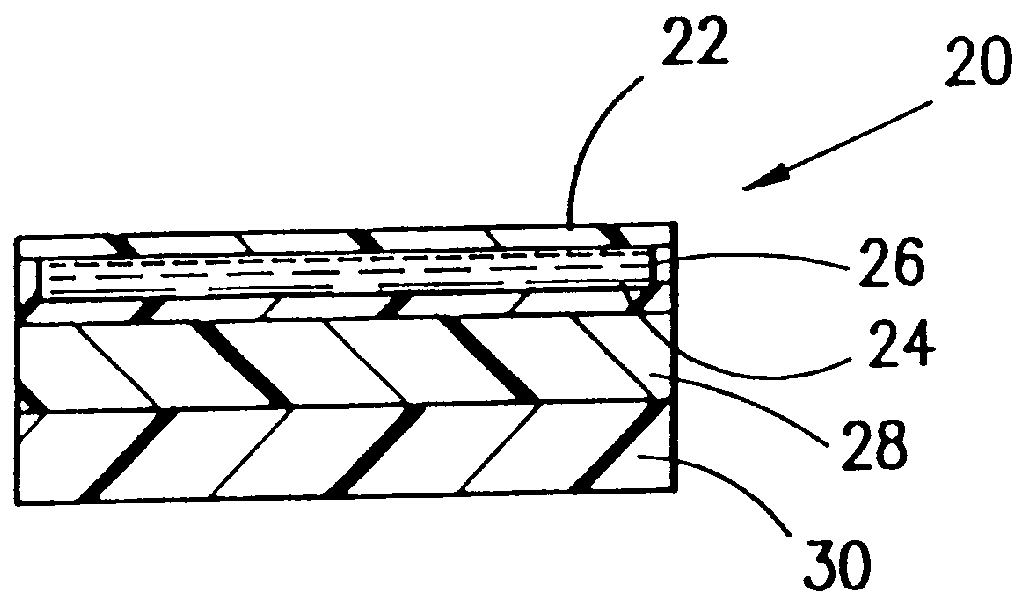

InactiveUSRE36754E1Less viscousImproves adhesive coatabilityAdhesive dressingsAbsorbent padsWaxHot melt

Hot-melt silicone pressure sensitive adhesive compositions containing organic waxes, methods of using the compositions and devices made using the compositions are disclosed. The hot-melt silicone pressure sensitive adhesive compositions include a mixture of (i) a silicate resin, (ii) a silicone fluid, and (iii) an organic wax having a melting point of between 30 DEG C. and 150 DEG C. The organic wax decreases dynamic viscosity of the adhesive at temperatures equal to or below about 200 DEG C.

Owner:DOW CORNING CORP

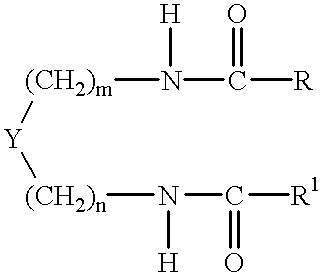

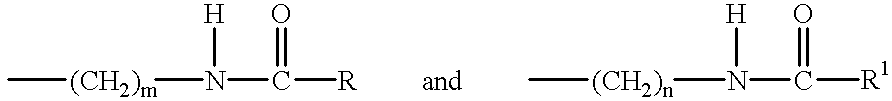

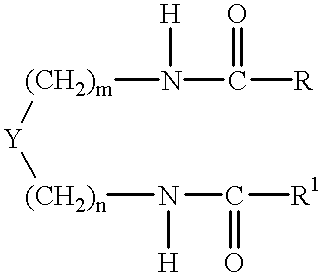

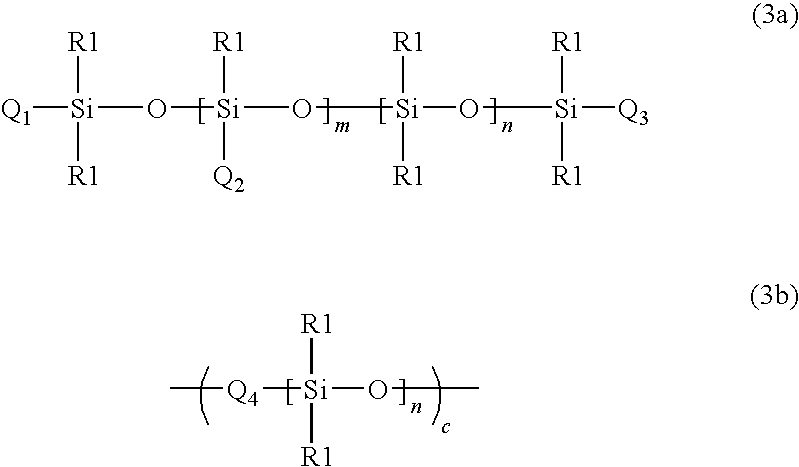

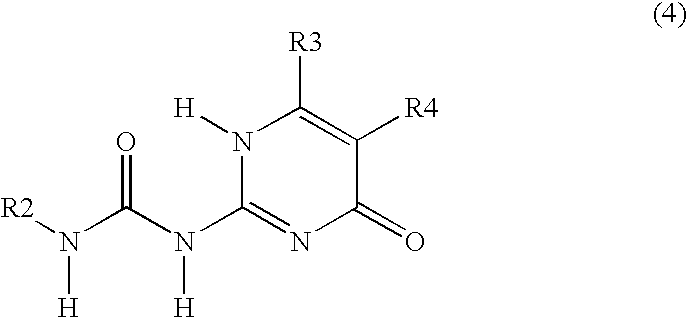

Siloxane polymers with quadruple hydrogen bonding units

Owner:SUPRAPOLIX

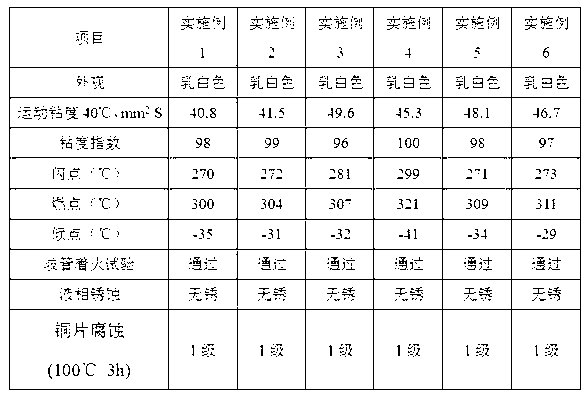

Ester type fire-resistant hydraulic fluid and preparation method thereof

InactiveCN103013635AInhibition of catalytic oxidationImprove stabilityLubricant compositionPhosphoric acidTriazole derivatives

The invention relates to an ester type fire-resistant hydraulic fluid. The hydraulic fluid comprises the following raw materials by weight percent: 95-99% of base oil, 1.0-5.0% of diphenol propane, 0.005% of dimethylsilicone fluid or dimethylsilicone grease, 0.05% of tricresyl phosphate, 0.1% of benzotriazole, 100 parts per million (PPM) demulsifying agent T1001 or LZ5957 and 0.2-0.3% of triazole derivative, thiadiazole derivative, N-salicylidene ethylamine, N, N'-bis(salicylidene)ethylenediamine, N, N'-bis(salicylidene)propylene diamine or ethylenediamine tetraacetic acid. A preparation method of the ester type fire-resistant hydraulic fluid comprises the following steps of sufficiently and evenly stirring various materials at room temperature according to a formula, and then filtering. The ester type fire-resistant hydraulic fluid has the beneficial effects that the high temperature use performance of the product is greatly improved, the service life of a hydraulic system and the oil changing period of oils are prolonged, and the ester type fire-resistant hydraulic fluid has a good flame-retardant effect and is safe to use. The preparation method has the advantages that operation is convenient, technology and equipment are simple, energy consumption is low, cost is low, and the like.

Owner:ANLU AOSEN PETROCHEM

Mold release composition and process therewith

A composition useful as a mold release agent is disclosed. The composition comprises a solvent; a silicone resin, rubber or fluid; and optionally a catalyst, a co-solvent or both, wherein the solvent is a volatile silicone. Also provided is a method of applying a thin continuous coating film on a mold. The method comprises combining a solvent, a silicone resin or a silicone rubber or a silicone fluid and, optionally, a catalyst, a co-solvent, or both, to form a release agent composition; combining said release agent coating on or onto a mold, and optionally curing the composition, wherein the solvent is a volatile silicone.

Owner:THE CHEMOURS CO FC LLC

Silicone antifoam composition

InactiveUS20070112078A1Other chemical processesFoam dispersion/preventionParticulatesInorganic particle

There is provided antifoam composition comprising an antifoaming-effective amount of at least one antifoam component, where antifoam component comprises product of the reaction of (a) at least one silicone fluid, (b) at least one silicone resin selected from the group consisting of silicone resin (i) having a ratio of M to Q units of from about 0.6 / 1 to about 0.8 / 1 and a different silicone resin (ii) having a ratio of M to Q units of from about 0.55 / 1 to about 0.75 / 1, optionally, (c) at least one inorganic particulate possessing reactive surface groups; and, optionally, (d) catalyst for the reaction of (a) and / or (b) with (c).

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method for producing carbon magma bismuth membrane electrode

InactiveCN101074941AAchieve the purpose of regenerationPotential window widthMaterial electrochemical variablesOrganic solventSample water

A method for preparing chemical modified electrode of carbon paste Bi membrane includes mixing and grinding carbon powder and modifier as well as hydrophobic organic solvent to be carbon paste, packing prepared carbon paste in electrode tube with copper screw bar in proper size to form carbon paste electrode, placing formed carbon paste electrode into sample solution containing with Bi ion and carrying out constant-potential deposit to obtain chemical modified electrode of carbon paste Bi membrane.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

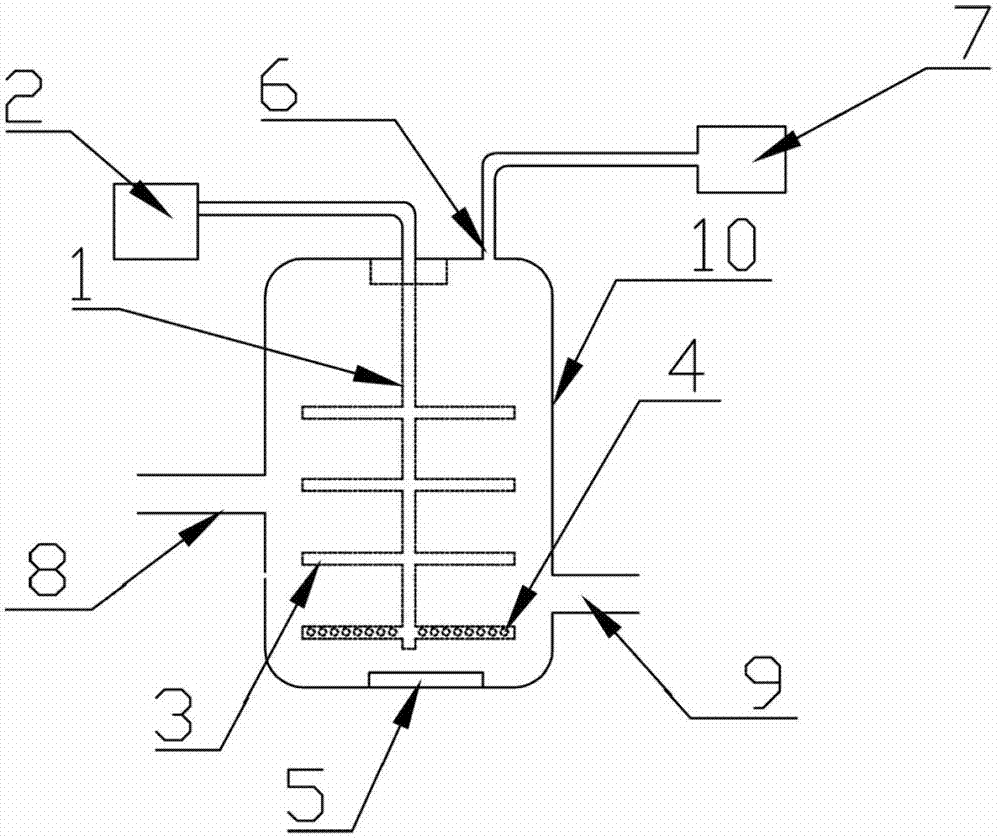

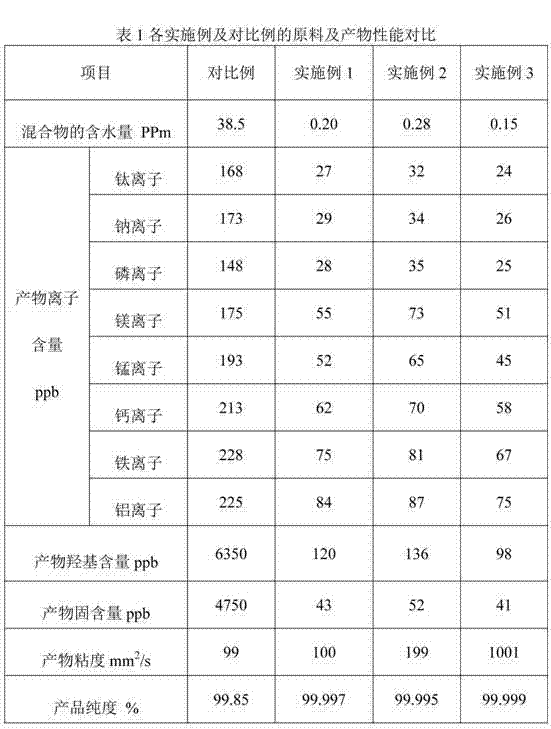

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

Lubricious or/and wettable or/and Anti-thrombin elastomeric gland materials in luer activated devices

InactiveUS20070012893A1Improve wettabilityAvoid clotsMedical devicesCouplingsElastomerClot formation

An elastomeric gland is provided for a luer activating device (LAD). and comprises a unique lubricant and / or wetting agent and / or anti-clotting agent incorporated into the elastomer gland during raw material formulation, calendar blending / molding / curing to deliver the surface lubricity and / or wettability and / or avoid slit plane re-knitting and / or gland induced valve stick down of such devices Functional additive chemistries are selected in terms of generated functional performance level, thermal stability against processing, molecular migratability, molecular weight and elastomer substrate of interest. These additives could include lubricants like chemically modified silicone oils and / or wetting agents like silicone-based surfactant. Elastomer gland with wetting agent would ease fluid path priming and minimize micro air bubble adherence to gland surface. Additives may also include anti-clotting agents intended to reduce potential for clot formation within the fluid path and interstitial space of the valve during blood sampling and infusion.

Owner:BAXTER INT INC +1

Windshield treatment and wiper blade combination

InactiveUS20130045332A1Maintain standardFine surfaceOther chemical processesPretreated surfacesEpoxyEngineering

A system for creating a water repellant coating on a windshield, comprises a water repellant surface treatment comprising a silicone-containing compound, and a water repellant wiper blade comprising a natural or synthetic or semi-synthetic rubber squeegee body and a water repellant coating comprising a hydrophobic polymeric film former and a hydrophobicity-enabling agent such as polyalkylsiloxane (modified or non-modified) silicone fluids. The polymeric film can be made from a compound selected from the group consisting of polyol resins, urethane resins, fluorine resins, epoxy resins, and silicone resins and may further include a friction reducing agent selected from the group consisting of graphite, PTFE, and molybdenum disulfide powders.

Owner:ILLINOIS TOOL WORKS INC

Low residue anhydrous antiperspirant stick composition

InactiveUS20030113282A1Residue reductionHigh product deliveryCosmetic preparationsToilet preparationsAntiperspirantsOrganic Ester

Disclosed are antiperspirant stick compositions that exhibit substantially less visible residue (whitening) upon application to the skin or after drying and which exhibit improved aesthetics and superior cosmetic properties. The compositions include a non-liquid organic ester emollient with a melting point between about 25° C. and about 60° C. (preferably isostearyl behenate); and an inert polymeric material (preferably a low molecular weight polyethylene; in addition to (a) a volatile (for example, cyclomethicone), (b) a non-volatile liquid emollient; (c) a gelling agent (for example, stearyl alcohol and hydrogenated castor oil); (d) at least one active antiperspirant material (for example, particulate antiperspirant aluminum zirconium tetrachlorohydrex salts); and (e) optionally other antiperspirant stick compatible materials.

Owner:CHURCH & DWIGHT CO INC

Attapulgite composite flame-retardant foaming agent

The invention discloses an attapulgite composite flame-retardant foaming agent. The technical scheme of the attapulgite composite flame-retardant foaming agent has the following key points that the attapulgite composite flame-retardant foaming agent is composed of attapulgite argil powder having an air purifying function, hydrogen peroxide, aluminium hydroxide, sodium polyoxyethylene fatty alcohol ether sulfate, superfine polyvinyl alcohol powder, dimethicone and water, and then the raw materials of the attapulgite composite flame-retardant foaming agent are stirred into a paste, and further stirred into the finished product of the attapulgite composite flame-retardant foaming agent. The attapulgite composite flame-retardant foaming agent is added with water and stirred at a high speed to form porous foamed mud; and the porous foamed mud is capable of quickly isolating a combustible material from air, thereby achieving the purposes of flame retarding and fire extinguishment; the attapulgite composite flame-retardant foaming agent has the effects of flame retarding, heat preservation, heat insulation and sound insulation, and also has the air purification function; and the attapulgite composite flame-retardant foaming agent is suitable for producing flame retarding and fire extinguishing products, light plates, light walls, and sound attenuation and noise reduction products.

Owner:江苏世澳非金属应用科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com