Ester type fire-resistant hydraulic fluid and preparation method thereof

A hydraulic oil, flame-retardant technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of short service life, achieve the effects of low cost, reduced use cost, and simplified process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

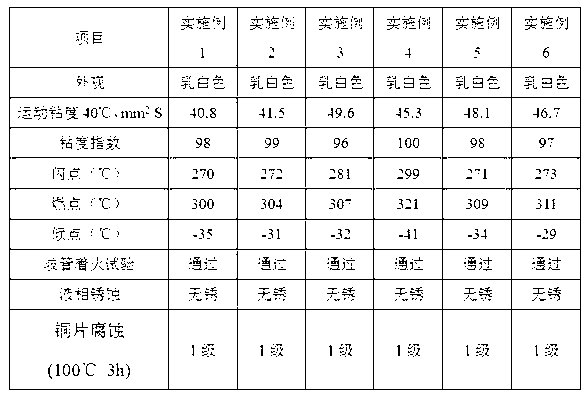

Examples

Embodiment 1

[0028] 948kg castor oil trimethylol propane ester, 50kg diphenolic propane, 0.05kg methyl silicone oil ester, 0.5kg tricresyl phosphate, 1kg benzotriazole, 0.1kg demulsifier T1001 are added in the still, Stir at room temperature for 20 minutes; then add the base oil wetting liquid obtained by mixing 2kg of N-salicylethylamine and 2kg of castor oil trimethylolpropane ester at room temperature, stir well, filter, and take a sample to measure 40 ℃, 100℃ viscosity, flash point, copper corrosion and appearance, after passing the package.

Embodiment 2

[0030]Add 958kg hydrogenated castor oil pentaerythritol ester, 30kg diphenolic propane, 0.05kg methyl silicone oil, 0.5kg tricresyl phosphate, 1kg benzotriazole, 0.1kg demulsifier T1001 into the kettle, stir at room temperature for 30 Minutes; then add the base oil wetting liquid obtained by mixing 2.2kg of N, N'-disalicylidenediamine and 2.2kg of hydrogenated castor oil pentaerythritol ester at room temperature, stir well, filter, and take a sample to measure 40 ℃, 100℃ viscosity, flash point, copper corrosion and appearance, after passing the package.

Embodiment 3

[0032] 968kg hydrogenated rapeseed oil neopentyl glycol ester, 20kg diphenolic propane, 0.05kg methyl silicone oil, 0.5kg tricresyl phosphate, 1kg benzotriazole, 0.1kg demulsifier T1001 are added in the kettle, Stir at room temperature for 40 minutes; then add 2.4kg of N,N'-di-salicylidenediamine and 2.4kg of hydrogenated rapeseed oil neopentyl glycol ester at room temperature to mix the resulting base oil wetting liquid, fully Stir evenly, filter, take samples to measure viscosity, flash point, copper sheet corrosion and appearance at 40°C and 100°C, and pack after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com