A kind of low odor and low voc polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of low-odor and low-VOC polypropylene composite materials and their preparation, can solve the problems of desorption of small molecular compounds and affecting the final effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation of premix: adding the required polypropylene, talc, Accurel XP100-60 water-absorbing masterbatch, antioxidant, lubricant, light stabilizer, and metal passivator into a high-speed mixer for high-speed stirring and mixing to obtain premix;

[0035] Melt blending extrusion: The obtained premix is fed from the main feeding hopper into a parallel twin-screw extruder, so that all components are sheared and melt-blended in the parallel twin-screw extruder, wherein twin-screw extrusion The machining temperature is 180-200°C, and the cylinders are evacuated with a vacuum pump in the seventh and ninth sections respectively;

[0036] Obtainment of low odor and low VOC polypropylene composite material: cooling, drying and pelletizing the material strips from the parallel twin-screw extruder die to obtain low odor and low VOC polypropylene composite material.

[0037] The polypropylene can be purchased from Maoming Petrochemical PPK7726H.

Embodiment 1

[0038] Example 1: Preparation of low odor and low VOC polypropylene composites

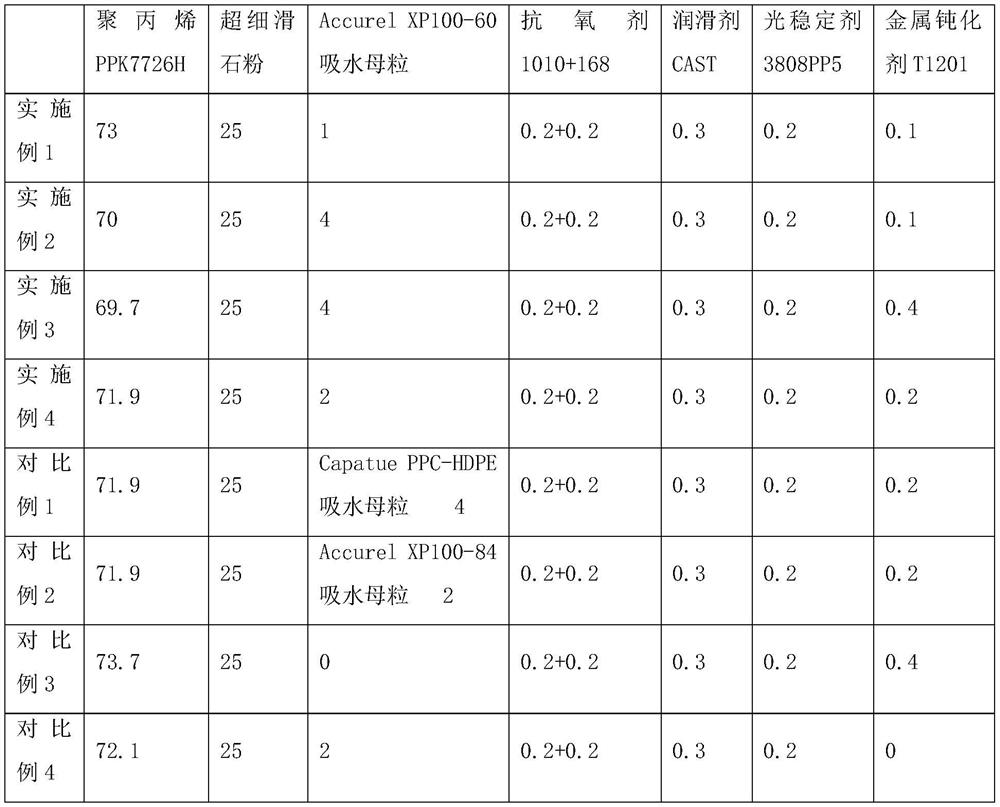

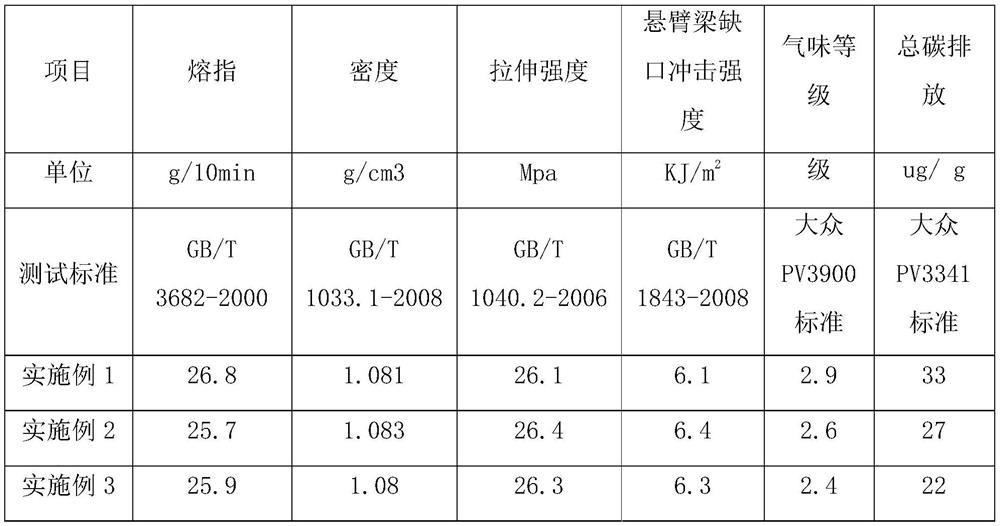

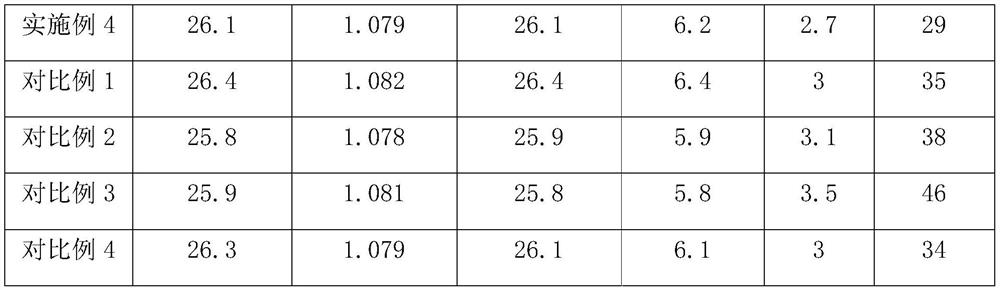

[0039] Raw materials used: see Table 1.

[0040] Preparation of Accurel XP100-60 water-absorbing masterbatch: put the plastic foam carrier Accurel XP100-60 into the low-speed mixer, and then add water to the mixer according to the mass ratio of the foam carrier Accurel XP100-60:water=6:4 , then mix for 10-30 minutes. Stop the machine to check the particles. If the surface of the foamed carrier particles is dry and there is no free-flowing water, it can be cooled to room temperature and then unloaded and packaged to obtain Accurel XP100-60 water-absorbing masterbatch.

[0041] Mix the polypropylene, talc powder, Accurel XP100-60 water-absorbing masterbatch, antioxidant, lubricant, light stabilizer, and metal passivator that are weighed in proportion, and then add to the parallel twin-screw extruder from the main feeding port. Out of the machine, all the components are sheared, melted and extruded...

Embodiment 2

[0045] Example 2: Preparation of low odor and low VOC polypropylene composites

[0046] Raw materials used: see Table 1;

[0047] The preparation method is the same as that in Example 1, and the effect is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com