Continuous preparation technology of high-purity low-viscosity dimethicone

The technology of a dimethyl silicone oil and a preparation process is applied in the field of continuous preparation technology of high-purity and low-viscosity dimethyl silicone oil, and can solve the problems of affecting the de-low effect and product quality, volume expansion, ion exchange resin being easily damaged, and the like, Achieve the effect of ensuring catalytic activity and product quality, improving end capping rate, and reducing the difficulty of equipment processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

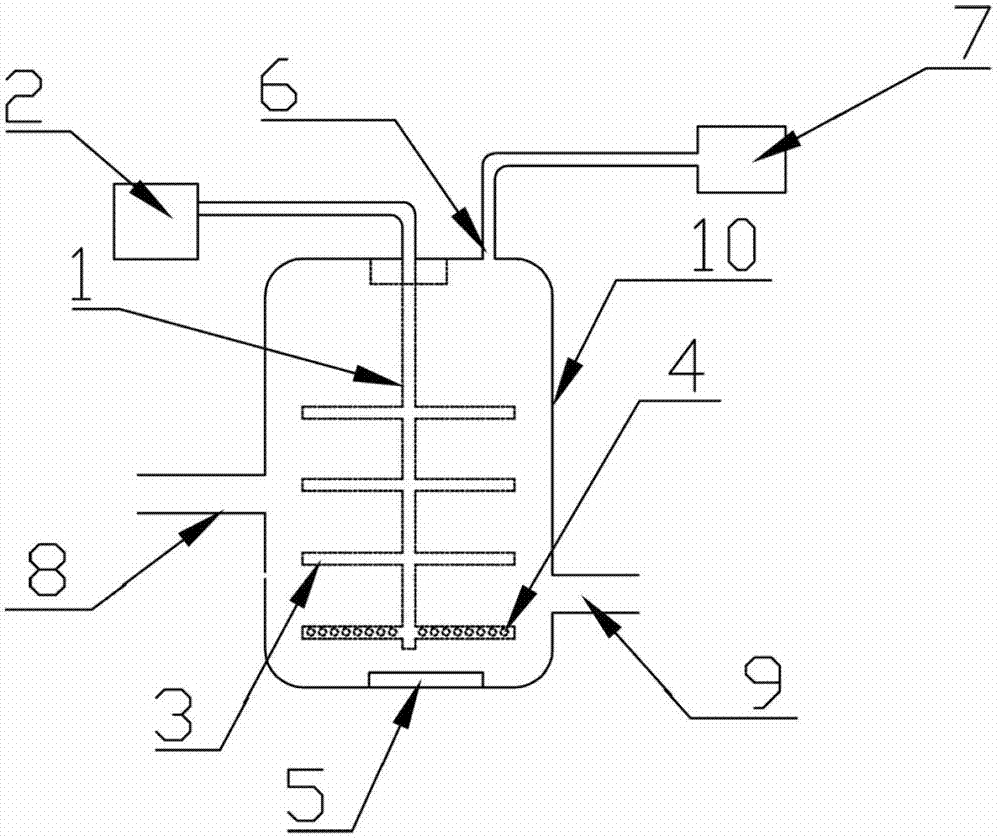

Method used

Image

Examples

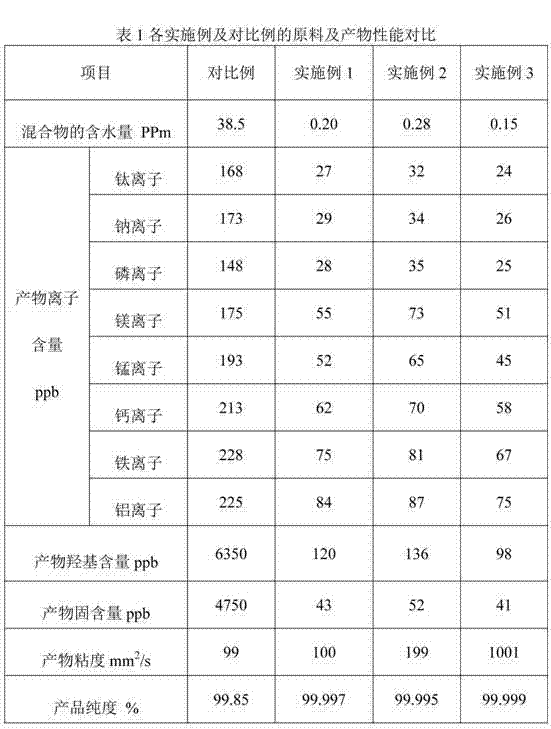

Embodiment 1

[0032] Dimethicone mixed ring (DMC) and end-capping agent (MD 2M) According to the mass ratio of 100:4.92, transport it to the pretreatment tank, first use liquid nitrogen to freeze and remove water, control the freezing temperature to -10°C, freeze and remove water for 2 hours, freeze and remove water and then transport it to the mixed drying tank , after heating up to 50°C, the vacuum degree is controlled at -0.085~-0.095Mpa, while stirring, dry nitrogen (nitrogen after vaporization of liquid nitrogen) is introduced to carry out deep dehydration for 2 hours, and the mixture after deep dehydration is sequentially dewatered by a vortex pump It is sent to stainless steel filter and ultrafiltration membrane filter for filtration to remove ions and solid impurities, and then sent to the preheater to preheat to 80°C, and then sent to the fluidized bed equipped with LDX-604 macroporous cation exchange resin Medium reaction, the reaction temperature is controlled at 60°C, and the re...

Embodiment 2

[0034] The dimethylsiloxane mixed ring body (DMC) and the end-capping agent (MDM) are transported to the pretreatment tank at a mass ratio of 100:2.16, and the water is first frozen with liquid nitrogen, and the freezing temperature is controlled at -5°C , the freezing and dehydration time is 3 hours, after freezing and dehydrating, it is transported to the mixed drying kettle. After the temperature is raised to 40°C, the vacuum degree is controlled at -0.090~-0.095Mpa, and dry nitrogen is introduced while stirring (the nitrogen gas after the liquid nitrogen is vaporized ) after deep dewatering for 3 hours, the mixture after deep dewatering is sent to stainless steel filter and ultrafiltration membrane filter to filter through vortex pump to remove ions and solid impurities, and then sent to preheater to preheat to 40 ℃, and then transported to the fluidized bed equipped with D72H macroporous cation exchange resin for reaction, the reaction temperature is controlled at 30 ℃, an...

Embodiment 3

[0036] Dimethicone mixed ring (DMC) and end-capping agent (MD 3 M) According to the mass ratio of 100:1.48, transport to the pretreatment tank, first use liquid nitrogen to freeze and remove water, control the freezing temperature to -15°C, freeze and remove water for 1h, freeze and remove water and then transport it to the mixed drying tank , the vacuum degree is controlled at -0.085~-0.095Mpa. After the temperature is raised to 70°C, dry nitrogen gas (nitrogen after vaporization of liquid nitrogen) is introduced while stirring to carry out deep water removal for 1 hour, and the mixture after deep water removal is removed by a vortex pump. Sequentially transported to stainless steel filter, ultrafiltration membrane filter to remove ions and solid impurities, and then transported to the preheater to preheat to 100 ° C, and then transported to the fluidized bed equipped with D72H macroporous cation exchange resin Reaction, the reaction temperature is controlled at 90°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com