Patents

Literature

495results about How to "Low solid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

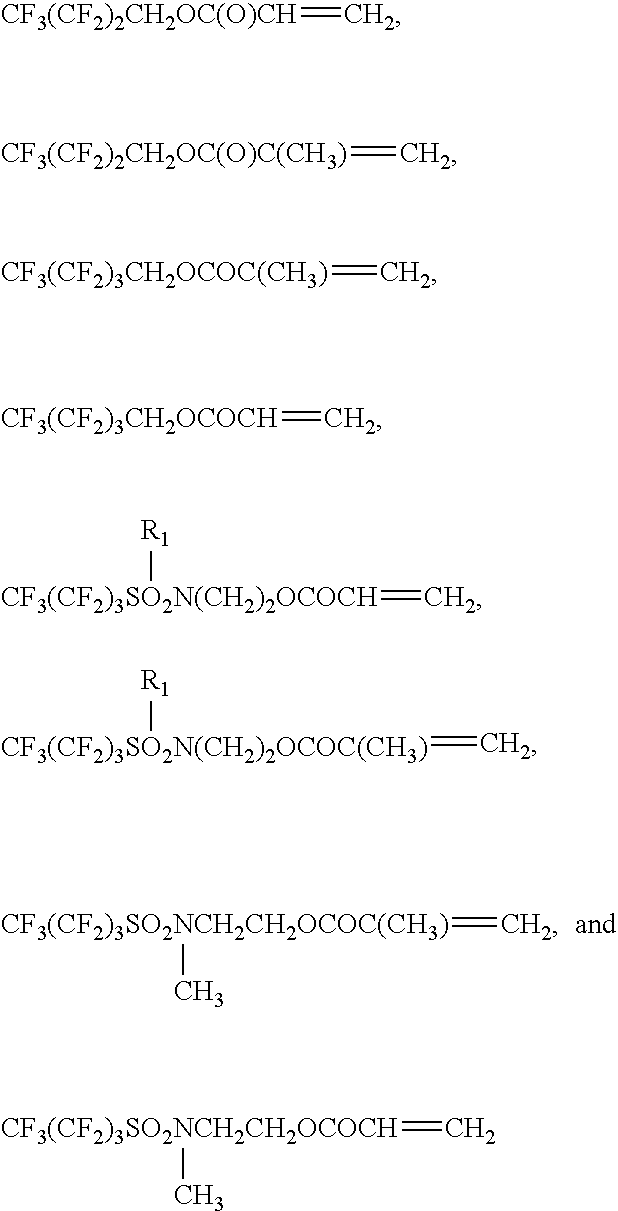

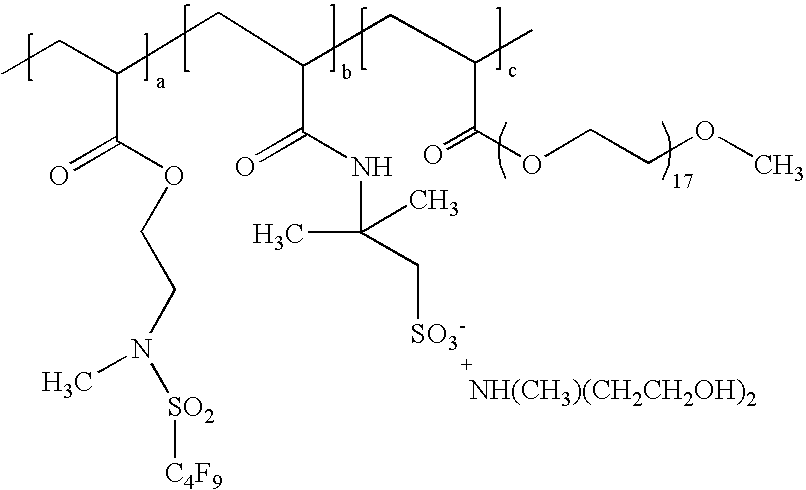

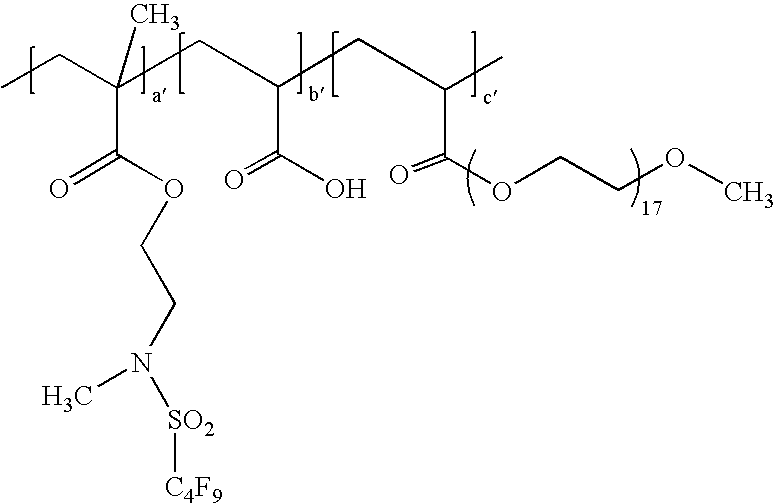

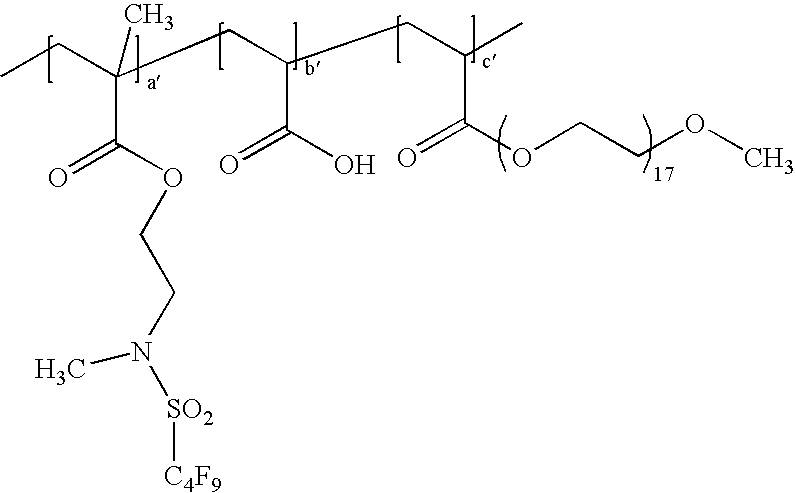

Compositions for aqueous delivery of fluorinated oligomeric silanes

The invention relates to a dilutable, non-aqueous concentrate and an aqueous dilution used for aqueous delivery of fluorinated oligomeric silanes to a substrate, a method of treating a substrate with the aqueous dilution composition to render it oil and water repellent, and articles having coatings made from the aqueous dilution.

Owner:3M INNOVATIVE PROPERTIES CO

Water super-thin steel structure fire-proof paint and preparation method thereof

InactiveCN101125980AHigh strengthImprove fire performanceFireproof paintsPentaerythritolDiammonium phosphate

The invention relates to a waterborne super thin steel structure fireproof coating and a preparation method Which is evidently different from the solvent-typed expansion foam fireproof coating, the invention solves the problems of environmental pollution, resource waste and high cost in prior solvent-typed super thin steel structure fireproof coating. The invention takes water as solvent and comprises the components with certain weight portions: water of 5-25 weight portions, waterborne resin or mixed waterborne resin of 10-30 weight portions, waterborne expansion additive of 25-50 weight portions, pentaerythritol or dipentaerythritol or starch of 5-15 weight portions, one or two components among urea, melamine and dicyano diammonium with 6-15 weight portions, ammonium dihydrogen phosphate, ammonium polyphoste or diammonium phosphate of 15-30 weight portions, expansion regulator of 3-18 weight portions, titanium dioxide of 3-12 weight portions, dispersion agent of 0.1-1.0 weight portions.

Owner:应急管理部四川消防研究所

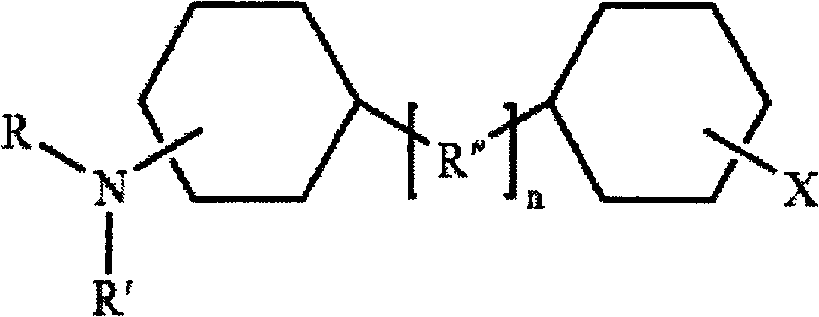

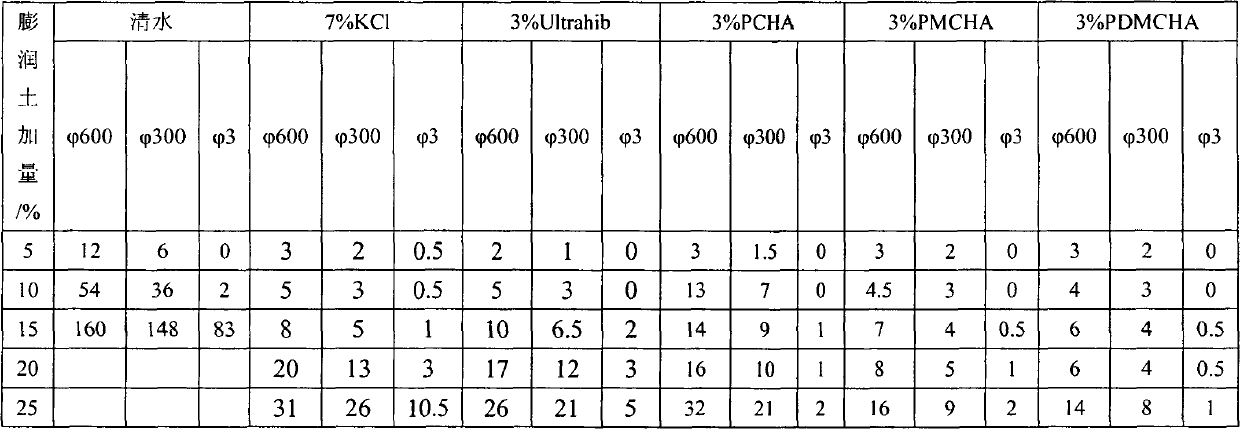

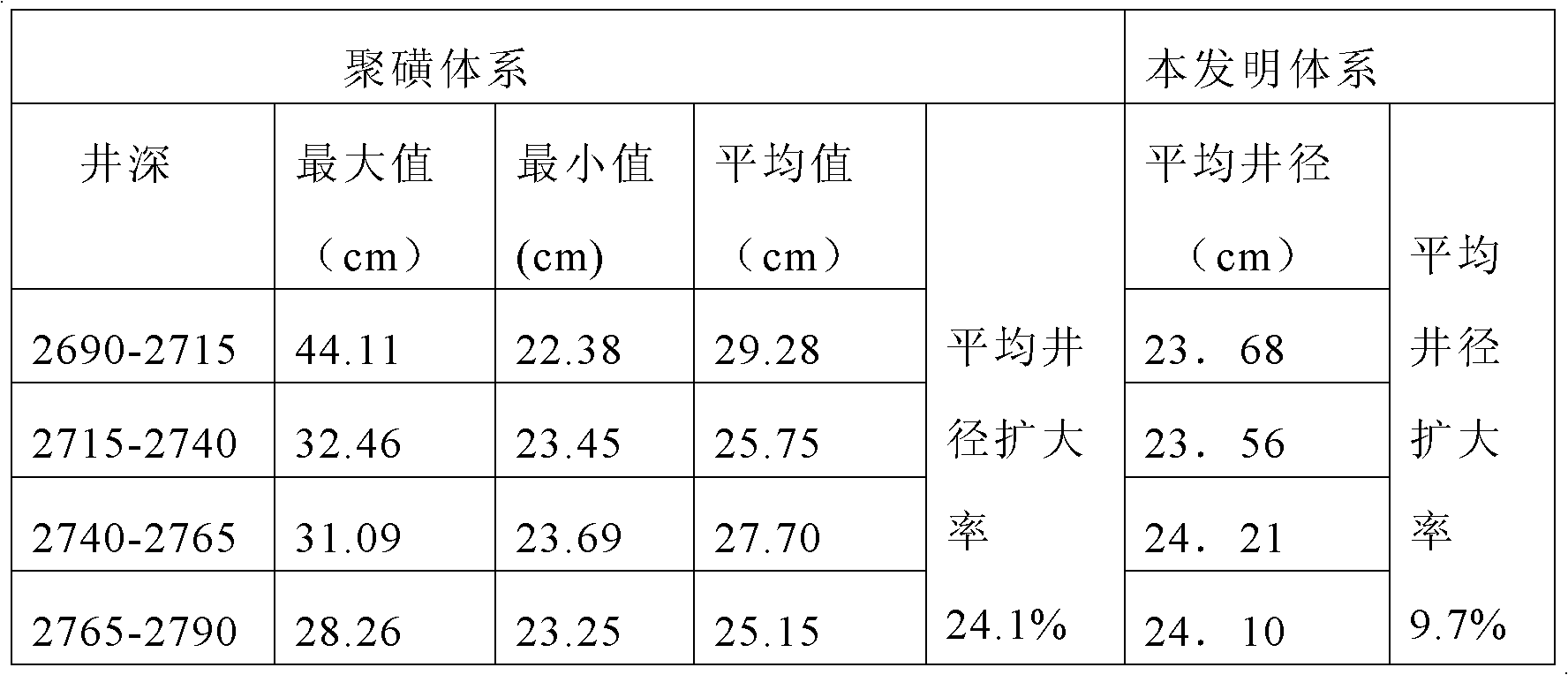

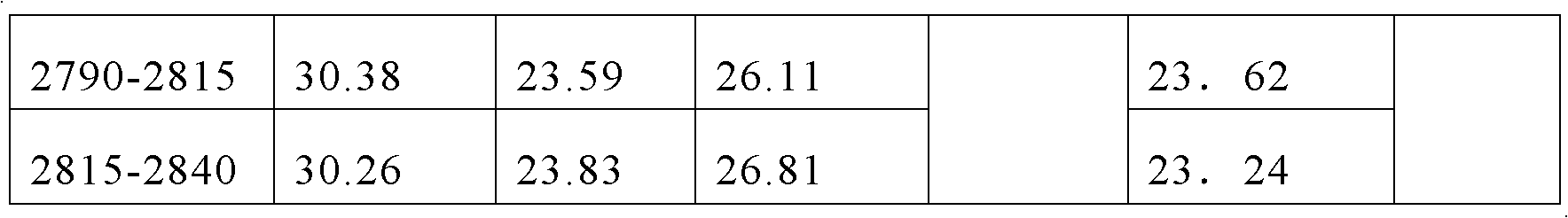

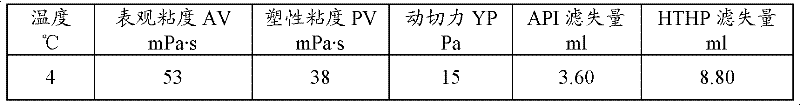

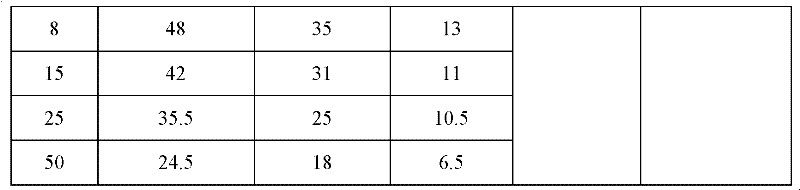

Water-based drilling fluid with high suppression and lubrication performance and preparation method thereof

The invention relates to a water-based drilling fluid with high suppression and lubrication performance and a preparation method thereof. The water-based drilling fluid mainly comprises 100 parts of fresh or sea water, 2 to 10 parts of inorganic salt, 0.2 to 5 parts of amine strong suppressant which is a product of reaction of a naphthenic amine compound and a bronsted acid, 0.1 to 1 part of coating inhibitor, 0.1 to 1 part of tackifier, 0.1 to 1.5 parts of filtrate reducer, 0.5 to 5 parts of anti-mud-coating lubricating agent, 1 to 10 parts of temporary plugging agent and a proper amount of weighting agent (added according to requirements). The drilling fluid provided by the invention has high suppression performance and lubrication performance, can effectively protect an oil gas layer and is a novel drilling fluid system which can replace oil-based drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

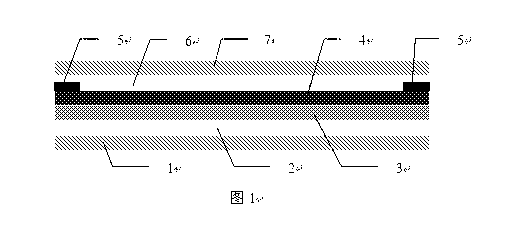

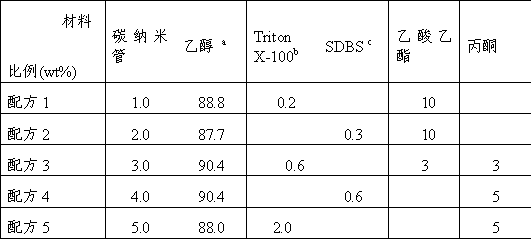

Low-temperature radiation electrothermal film and preparation method thereof

InactiveCN103305051AHigh peel strengthImprove adhesion strengthInksOhmic-resistance heatingPolyesterRadiant heater

The invention discloses a low-temperature radiation electrothermal film and a preparation method thereof. The carbon nanometer conductive ink comprises the following components in mass percent: 1 to 5% of carbon nano tube, 94 to 98% of solvent, and 0.2 to 2% of surface active agent. The preparation method comprises the following steps: manufacturing a hot melt adhesive layer on a polyester film; printing a carbon nanometer conductive ink layer onto the hot melt adhesive layer; printing a generating and heating ink layer on the ink layer; manufacturing an electrode; and then hot-processing and compounding the polyester film through a hot melt adhesive film. The low-temperature electric radiant heater film has the characteristics that the peeling strength is high and the electro thermal power can be flexibly adjusted.

Owner:KMT纳米科技(香港)有限公司

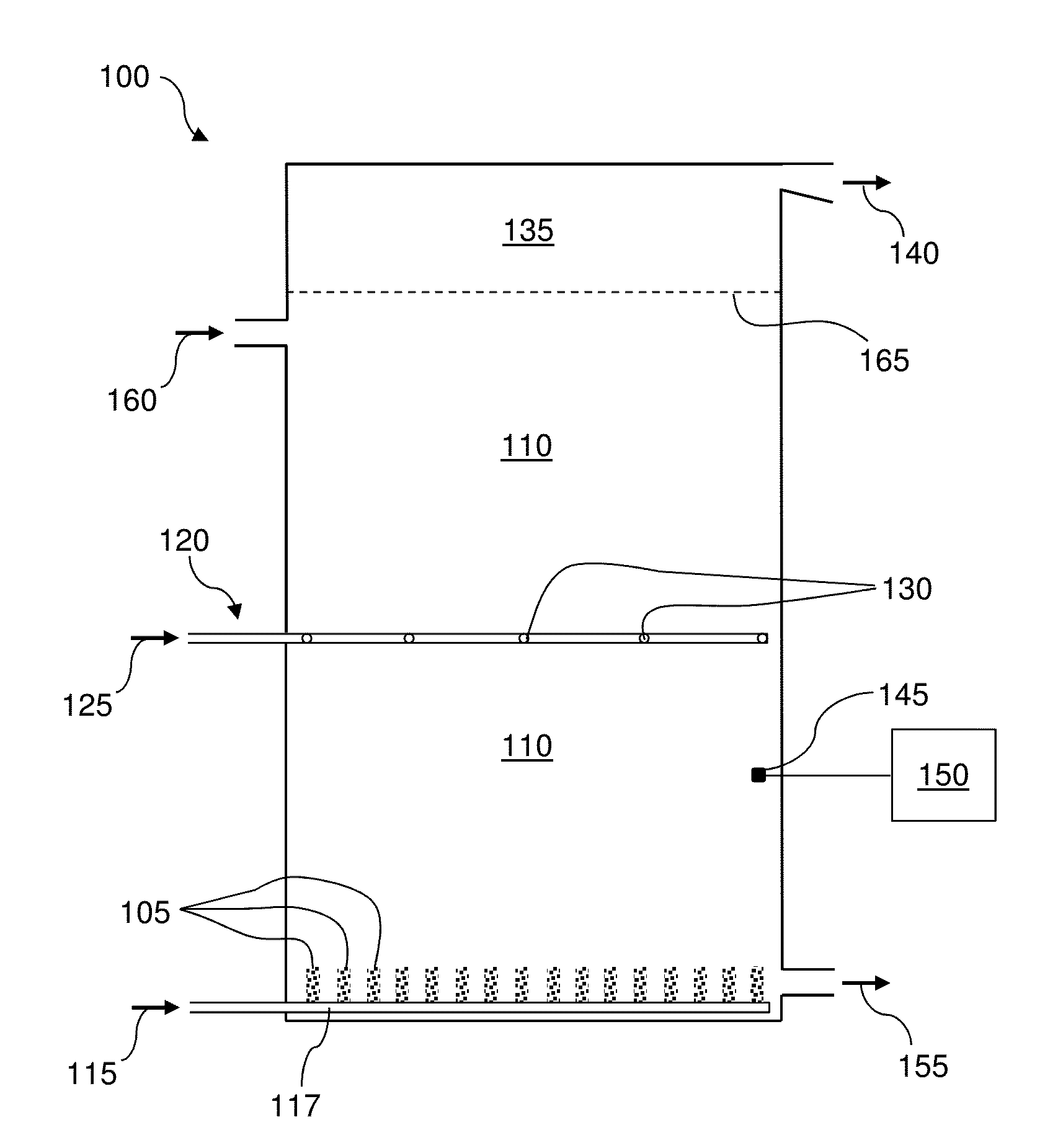

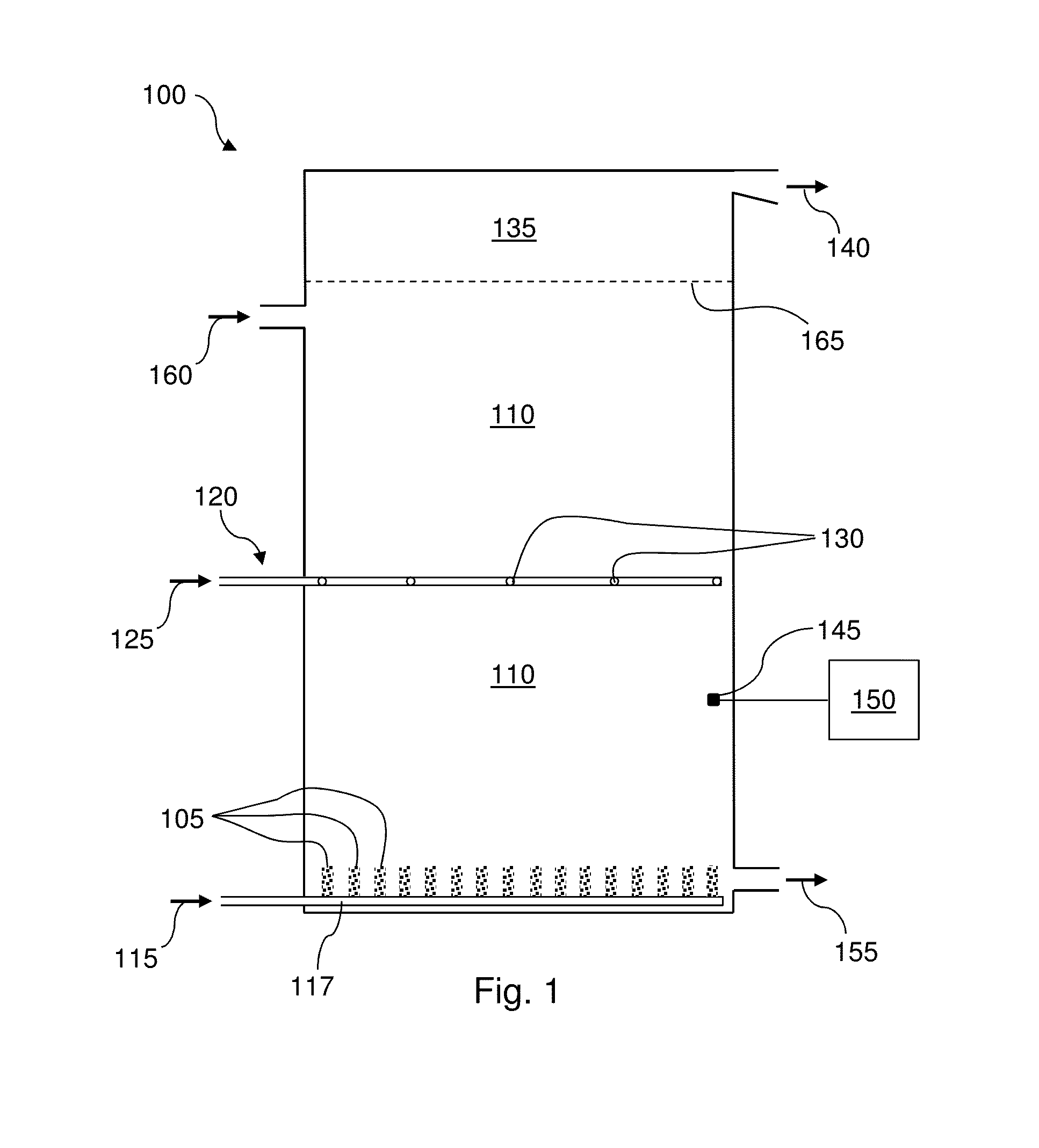

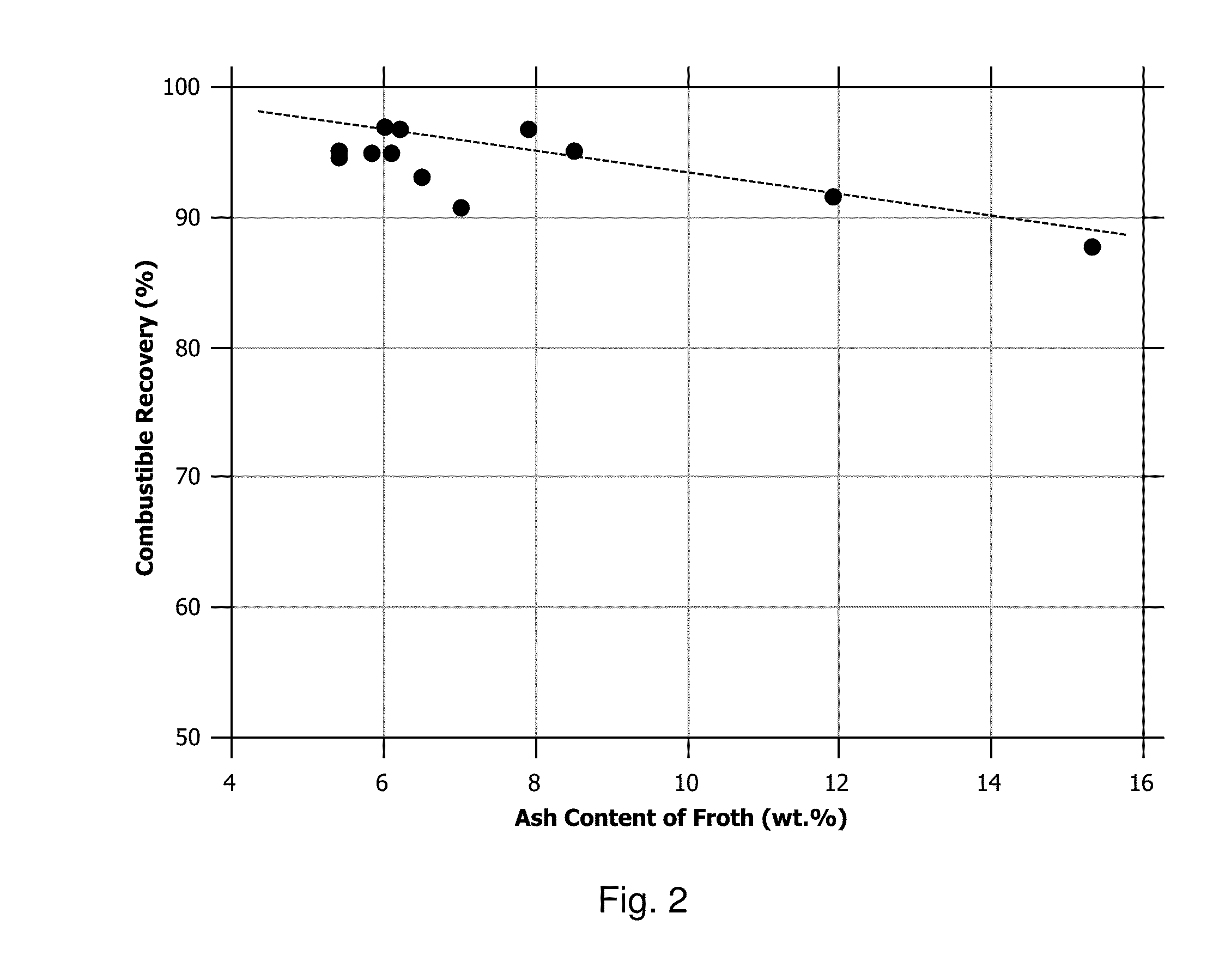

Flotation separation of fine coal particles from ash-forming particles

InactiveUS20160082446A1Provide froth-building capacityEasy to separateSolid fuelsLiquid carbonaceous fuelsPrillSlurry

Coal fines are processed by flotation separation to separate coal particles from ash-forming component particles. Coal fines are mixed water under high shear mixing conditions to form an aqueous slurry of coal fines containing between 15 wt. % and 55 wt. % coal fines. The aqueous slurry is introduced into a coal flotation cell to separate coal particles from ash-forming component particles by flotation separation, wherein the coal fines have a particle size less than 500 μm, and more preferably less than 300 μm. Bubbles are generated in the coal flotation cell having a bubble size and bubble quantity selected to float the coal particles and to form a coal-froth containing at least 15 wt. % solid particles. The solid particles include coal particles and ash-forming component particles. The coal-froth is collected for further processing.

Owner:EARTH TECH USA

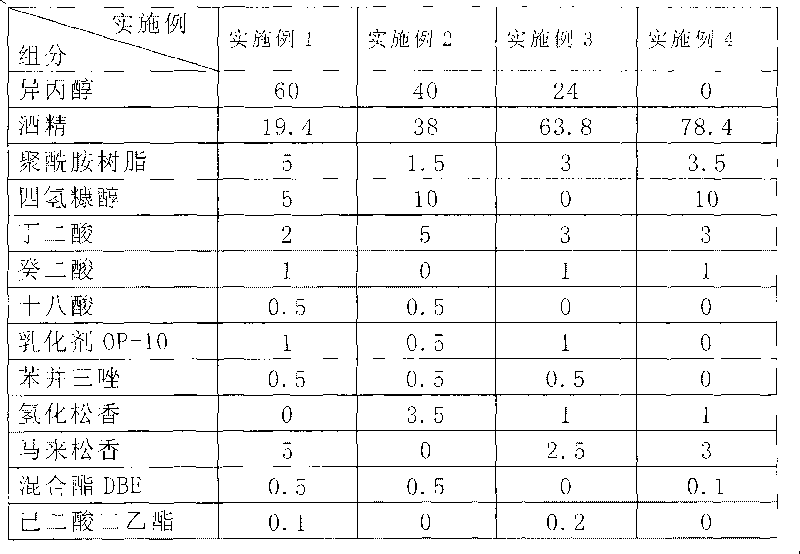

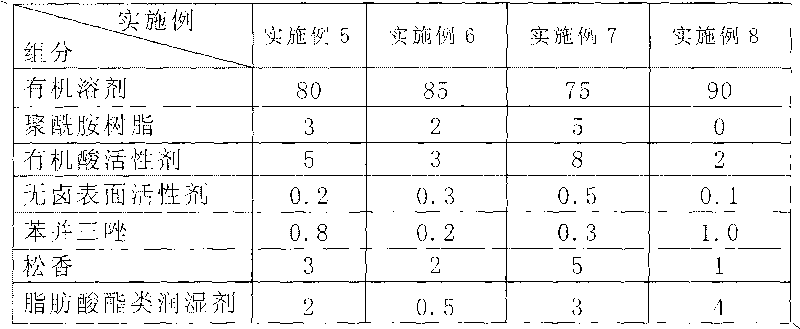

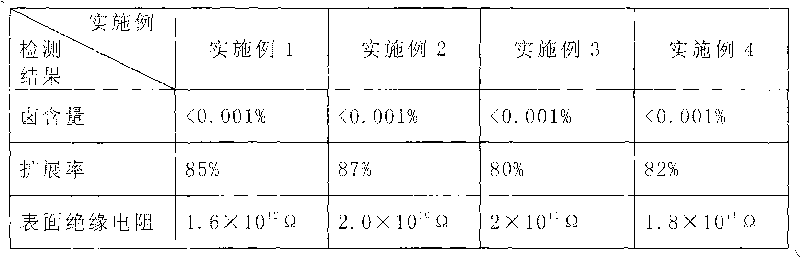

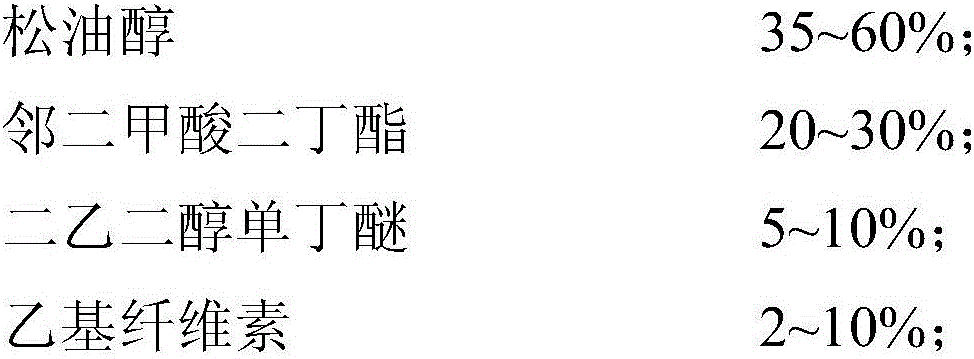

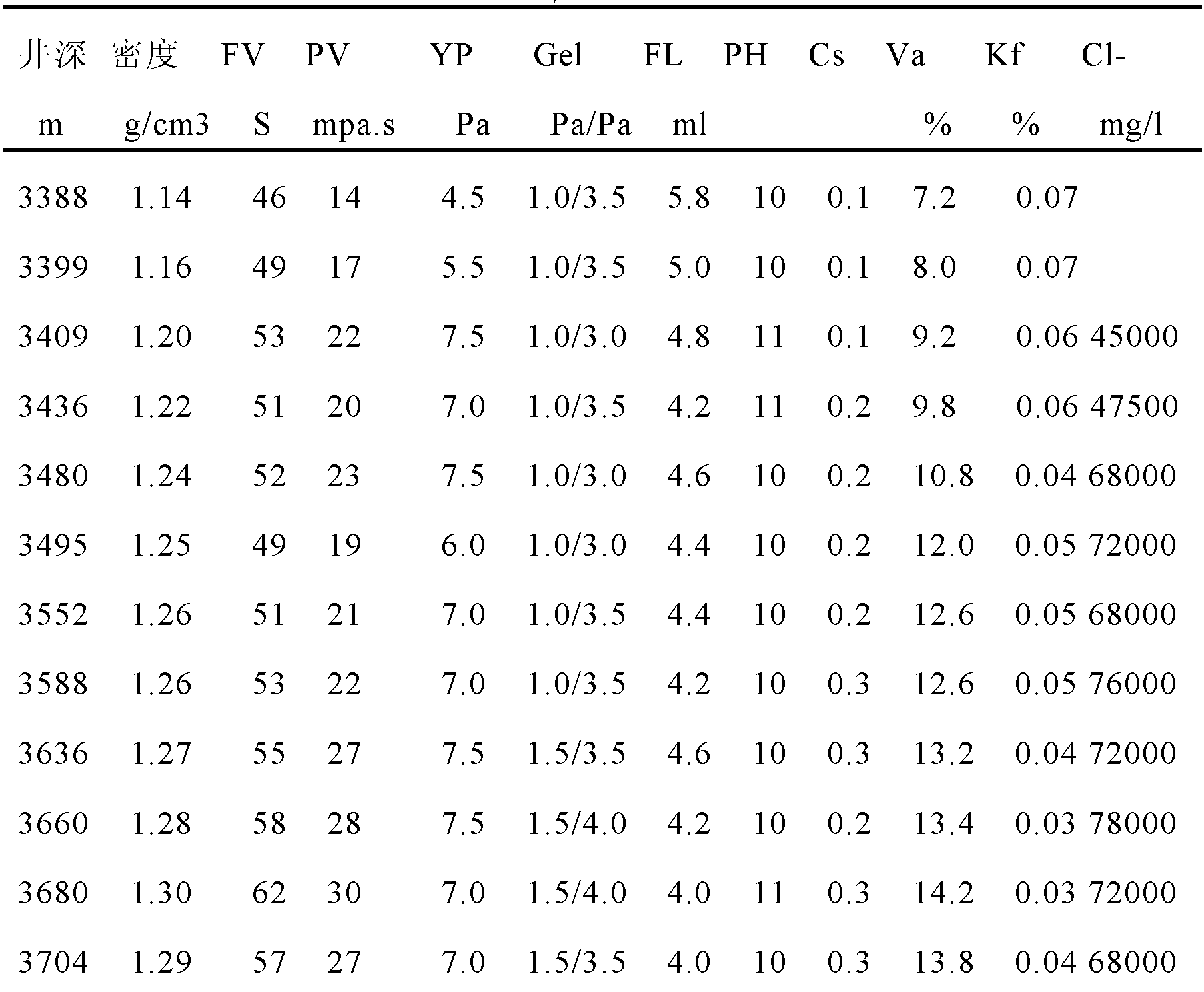

Halogen-free and cleaning-free soldering flux for lead-free solder

InactiveCN101733589ALow solid contentLess rosin contentWelding/cutting media/materialsSoldering mediaAntioxidantHigh surface

The invention relates to a halogen-free and cleaning-free soldering flux for a lead-free solder, belongs to the technical field of PCB soldering of the electronic industry, and solves the problem that dielectric residues are maintained on a printed board soldered by using the prior soldering flux. The halogen-free and cleaning-free soldering flux for the lead-free solder comprises the following components according to part by weight: 1-5 parts of rosin, 75-90 parts of organic solvent, 1-10 parts of organic acid activating agent, 0.01-1 part of halogen-free surfactant and 0.01-1 part of antioxidant. The halogen-free and cleaning-free soldering flux for the lead-free solder in the invention has low solid content, small rosin content, high surface insulation resistance, and replete and smooth solder joint, is free from corrosion and halogen, has no toxicity and strong penetrating odor, and does not pollute environment basically. Residues are hardly remained on the surface of a PCB soldered by the soldering flux.

Owner:上海一远电子科技有限公司

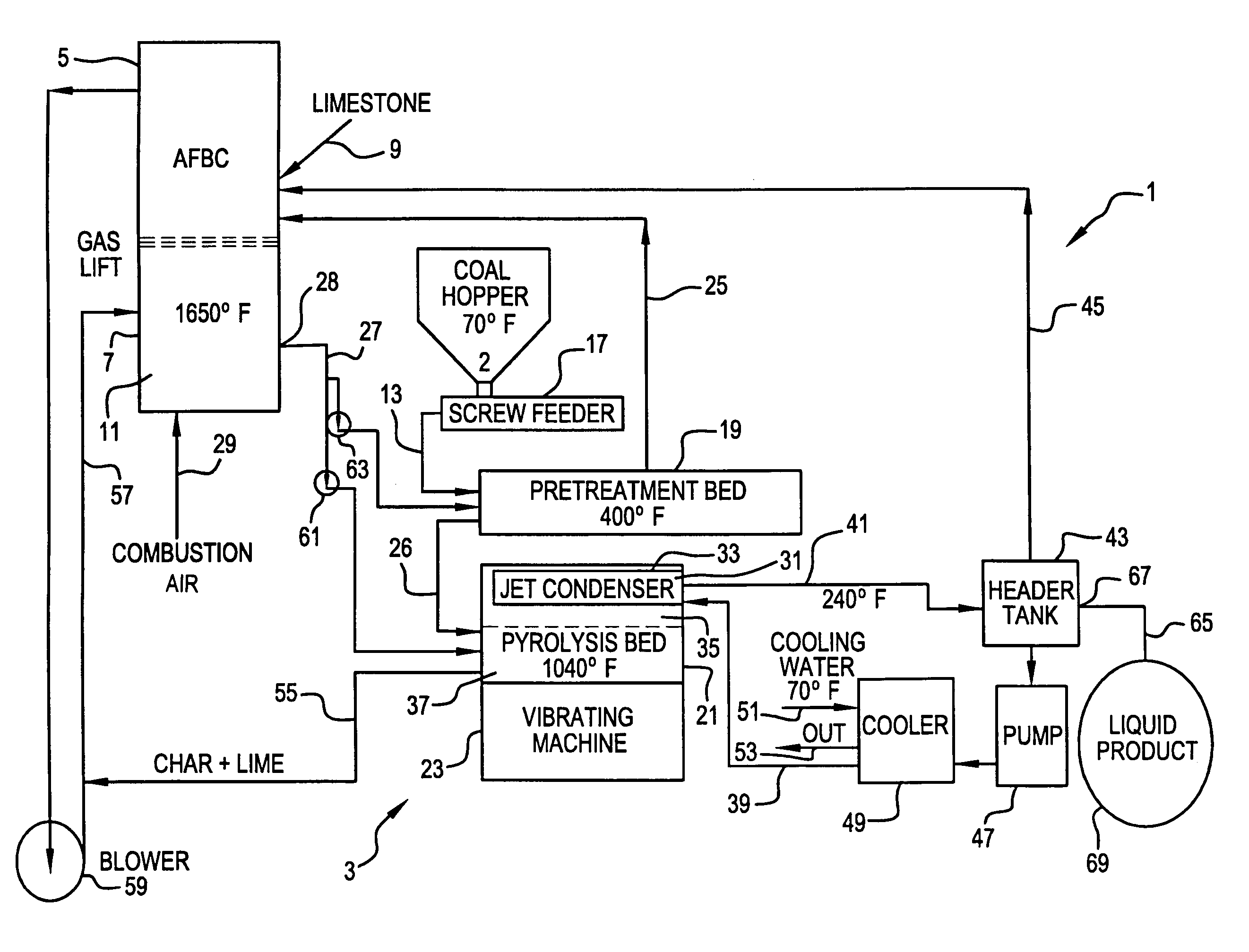

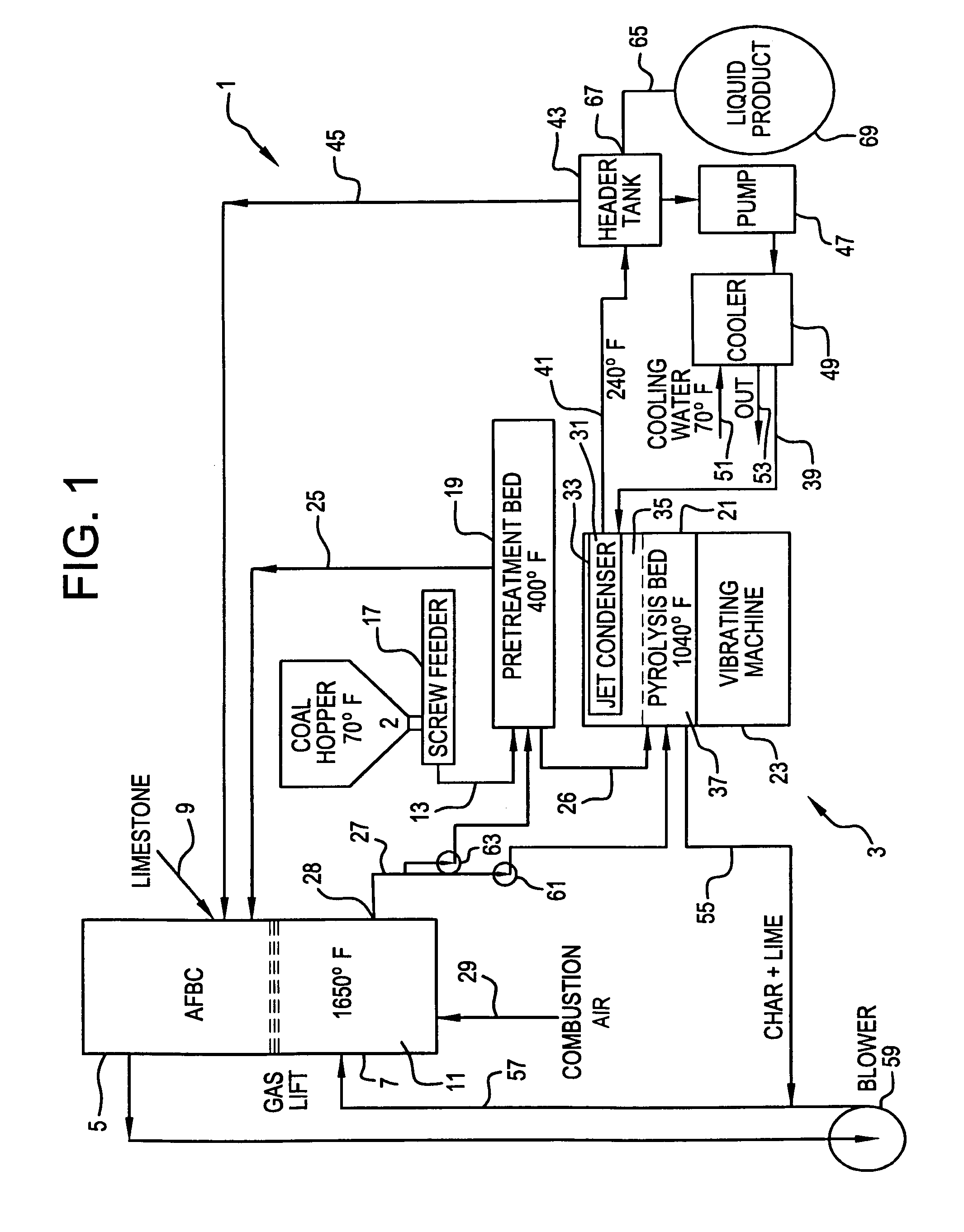

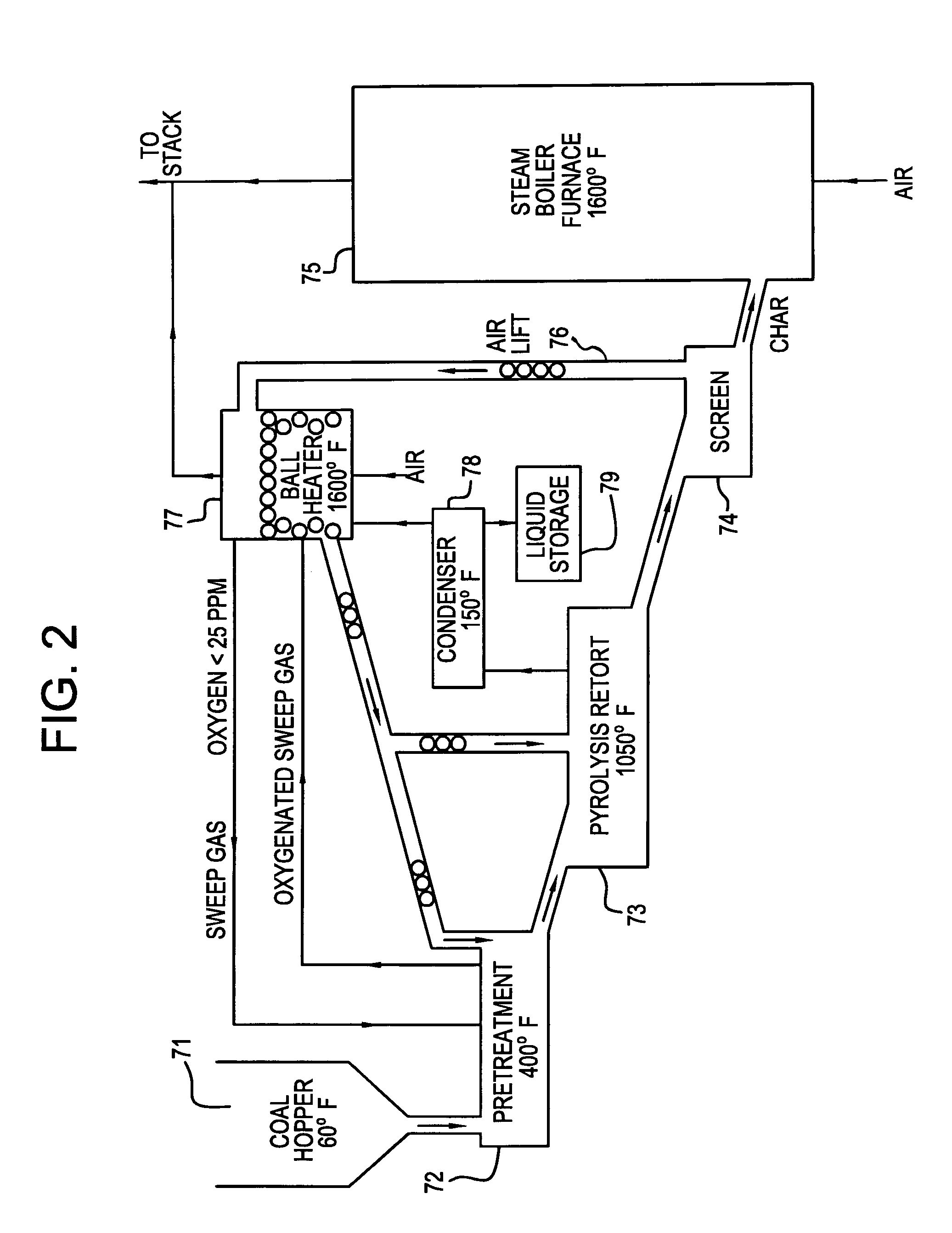

Pretreatment process to remove oxygen from coal en route to a coal pyolysis process as a means of improving the quality of the hydrocarbon liquid product

InactiveUS7008459B1Heat loss minimizationOxygen in-leakage can be kept extremely lowMechanical conveying coke ovensDirect heating destructive distillationLiquid productFlue gas

A process and apparatus for coal pyrolysis pretreatment. The apparatus is made up of a pretreatment vessel for holding a bed of coal particles, a preheater for heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and an oxygen remover for removing oxygen released from the heated coal particles. The apparatus can also have a flue gas source as an oxygen removal sweep gas to the bed of coal, a collector for collecting non-condensable combustible gases, and the preheater having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles. The process involves heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and preventing air from contacting the bed of coal particles in addition to collecting non-condensable combustible gases or the preheating step accomplished by having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles.

Owner:MACLEAN JOHN DR

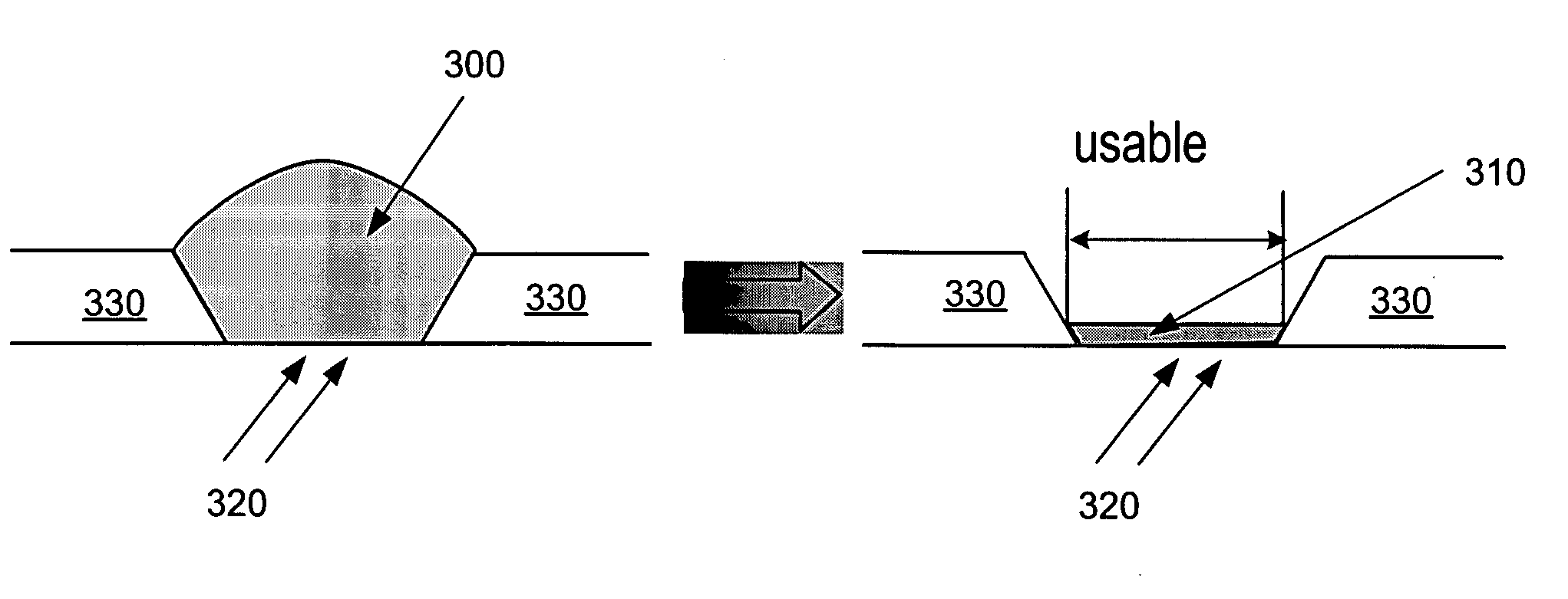

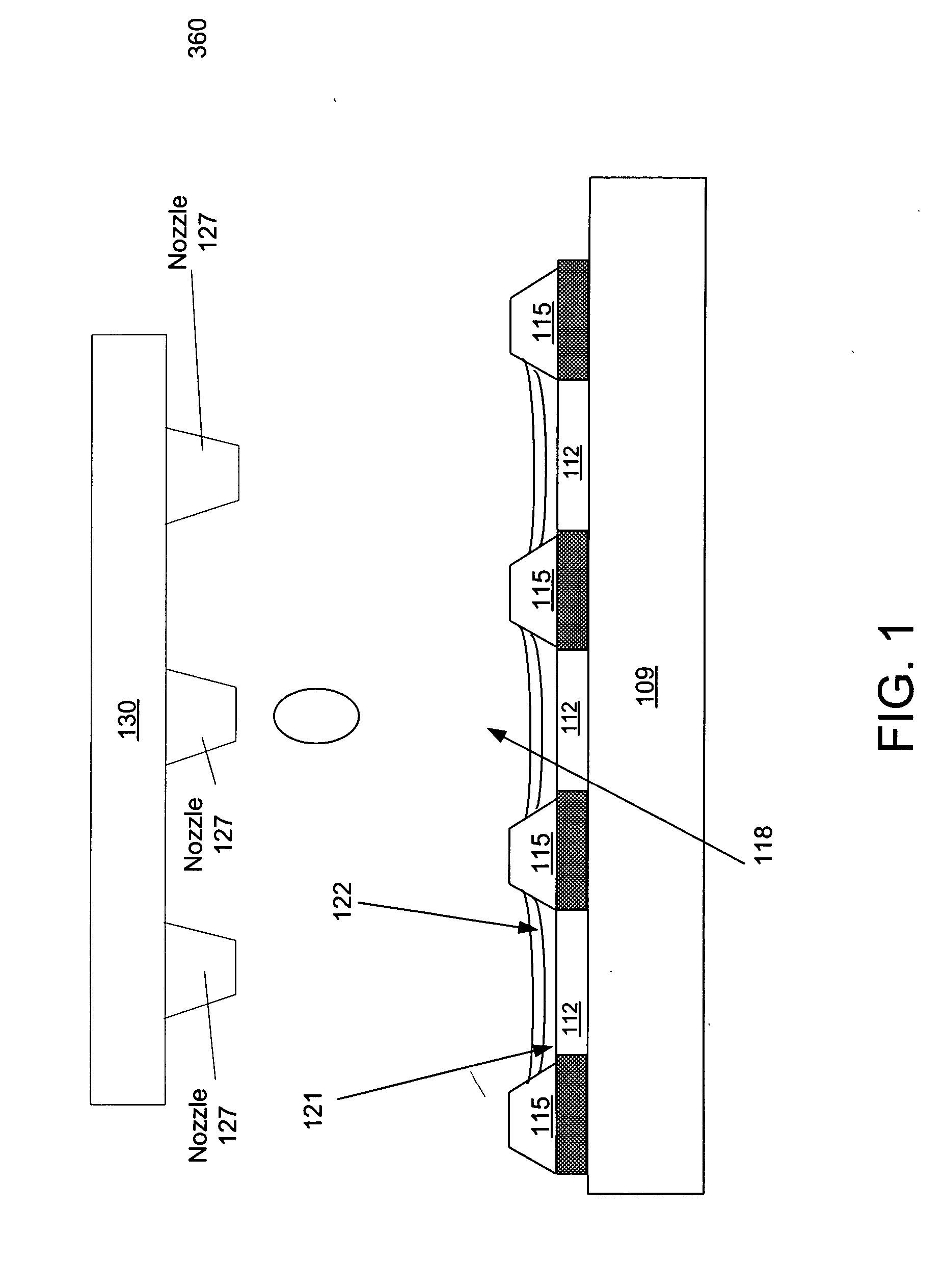

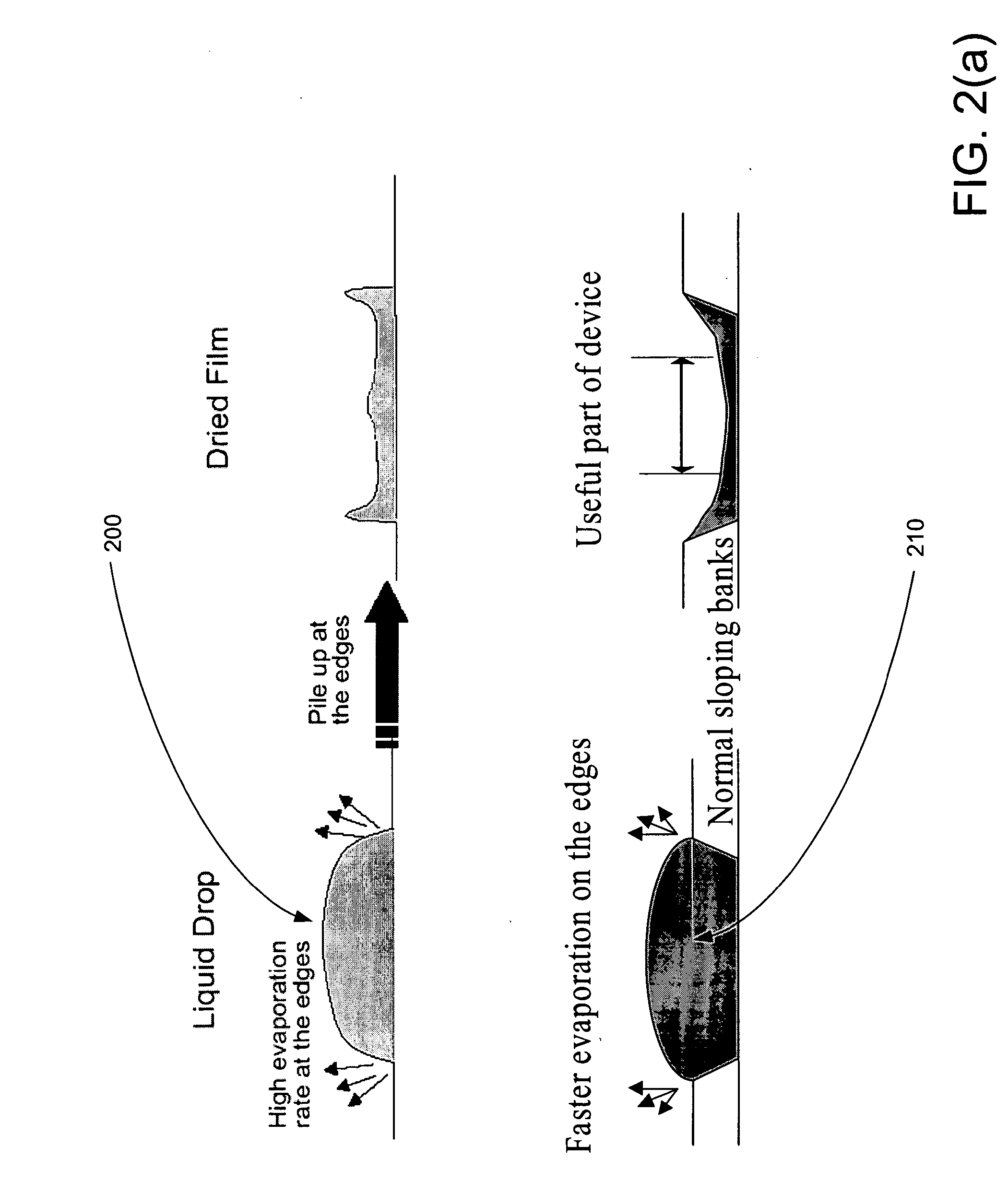

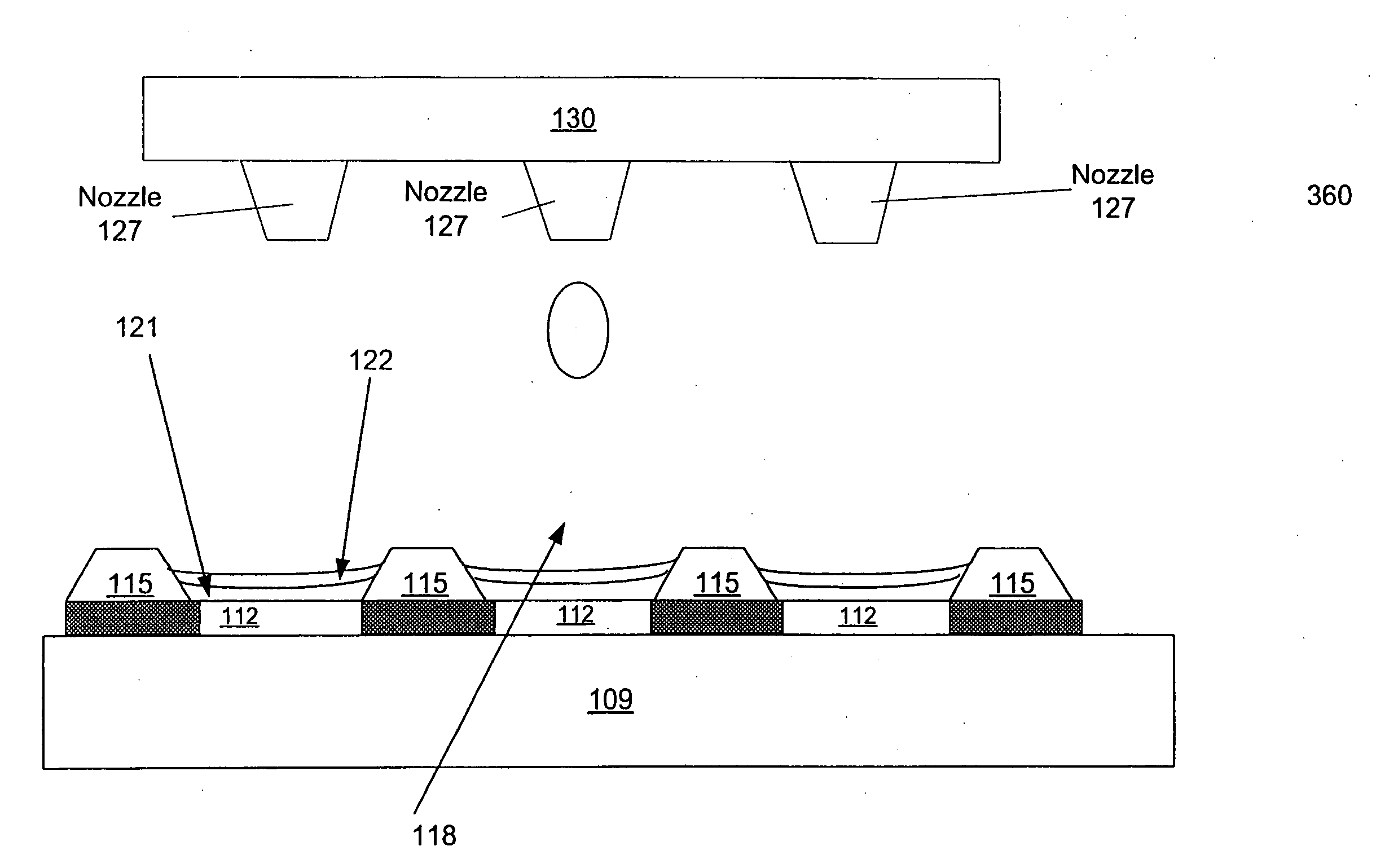

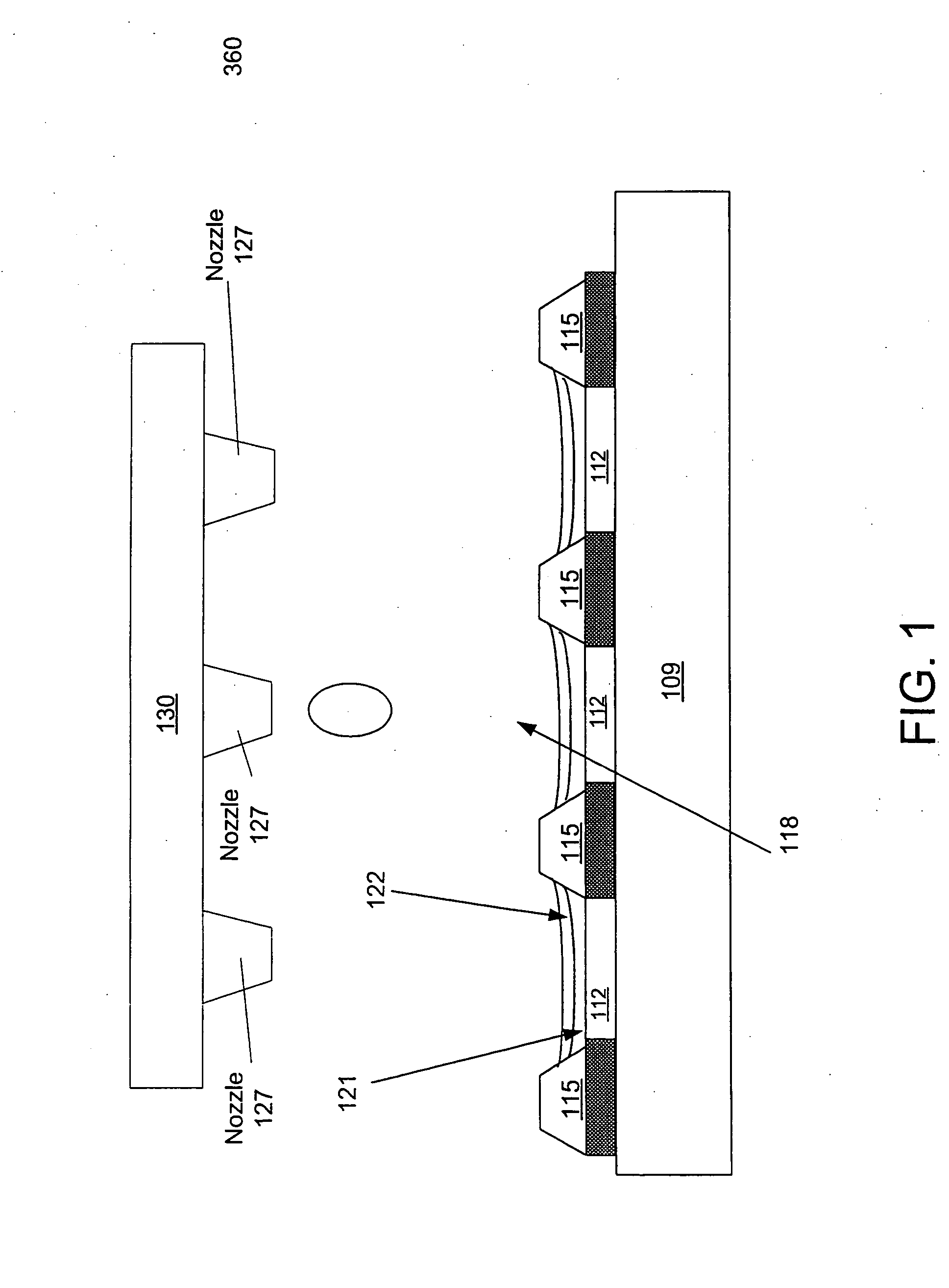

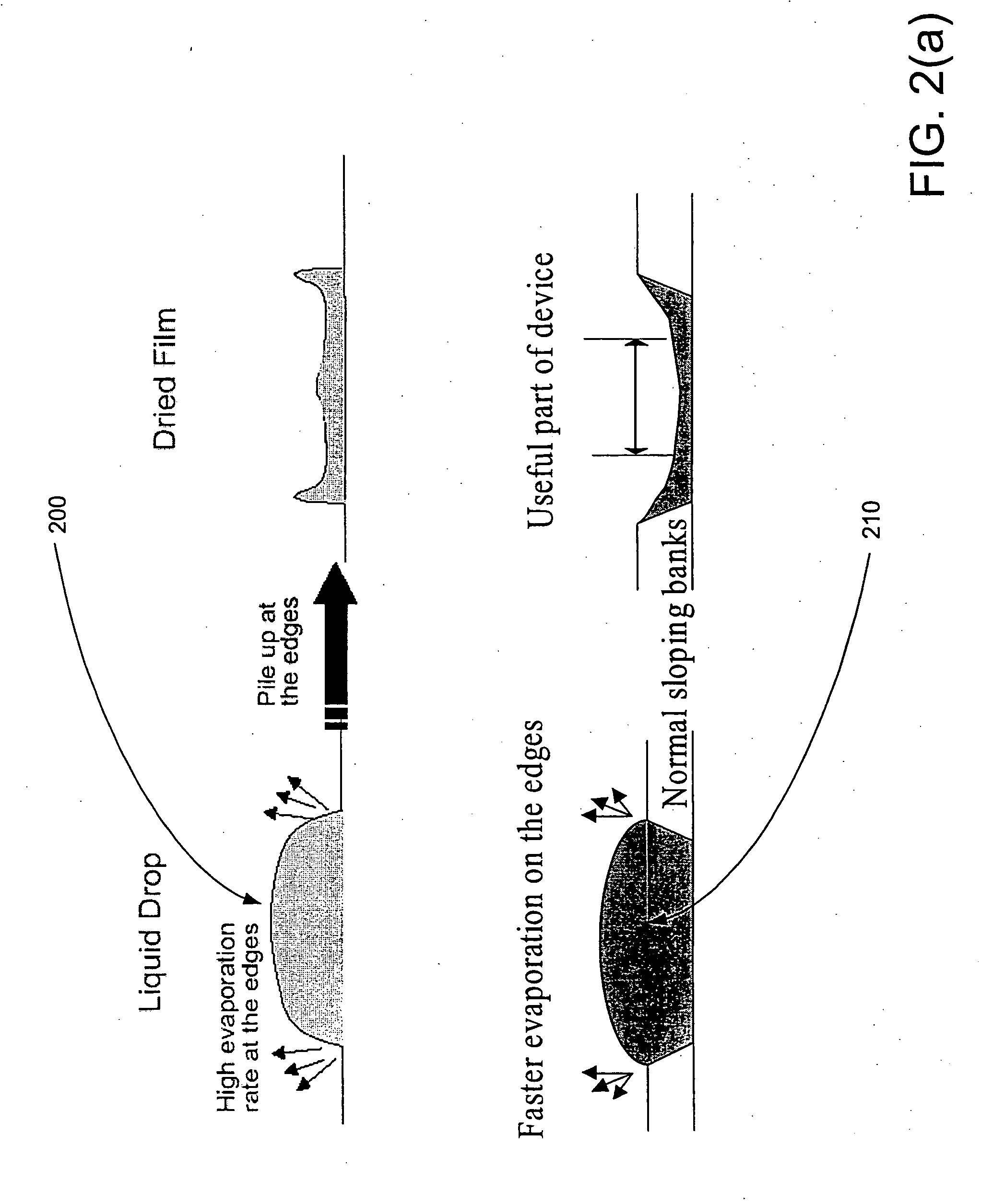

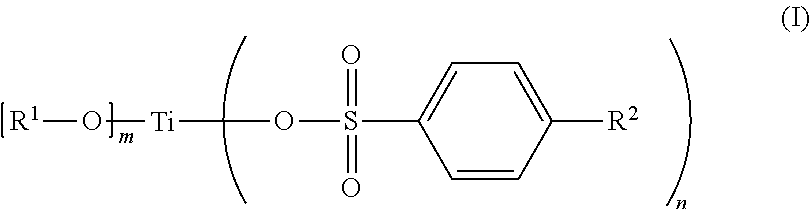

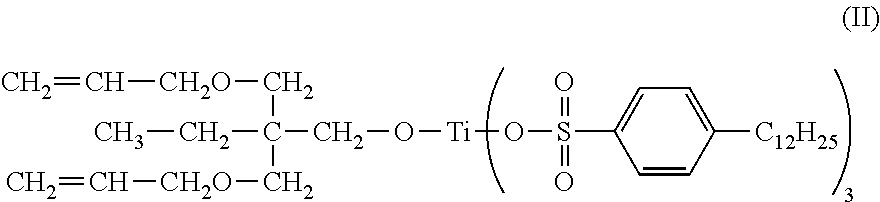

Printing of organic electronic devices

InactiveUS20050153114A1Uniform and flatter profileExtended drying timeDecorative surface effectsSolid-state devicesConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

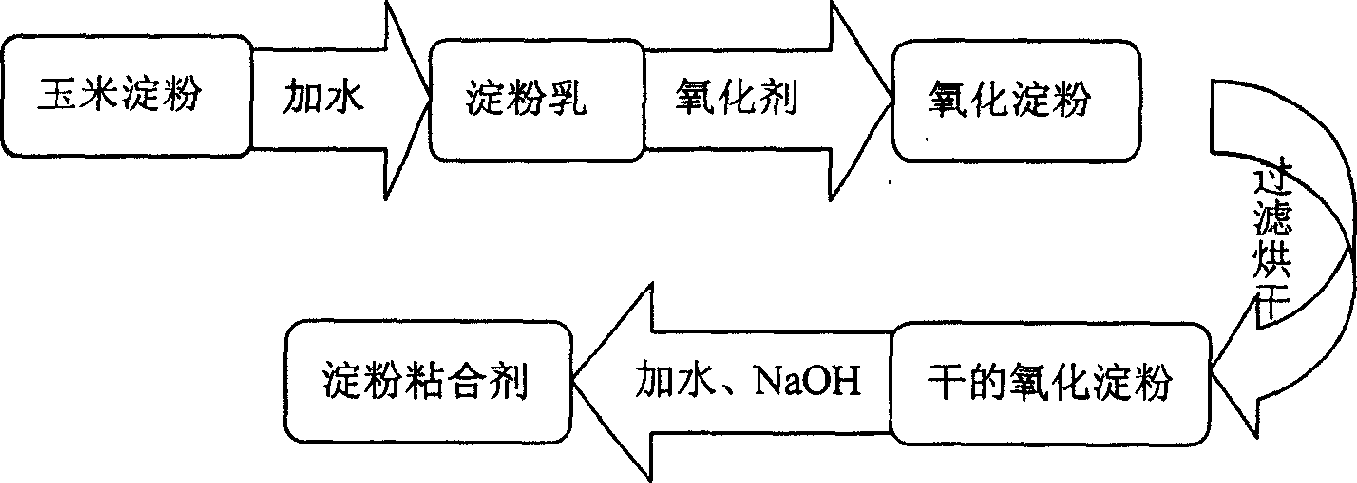

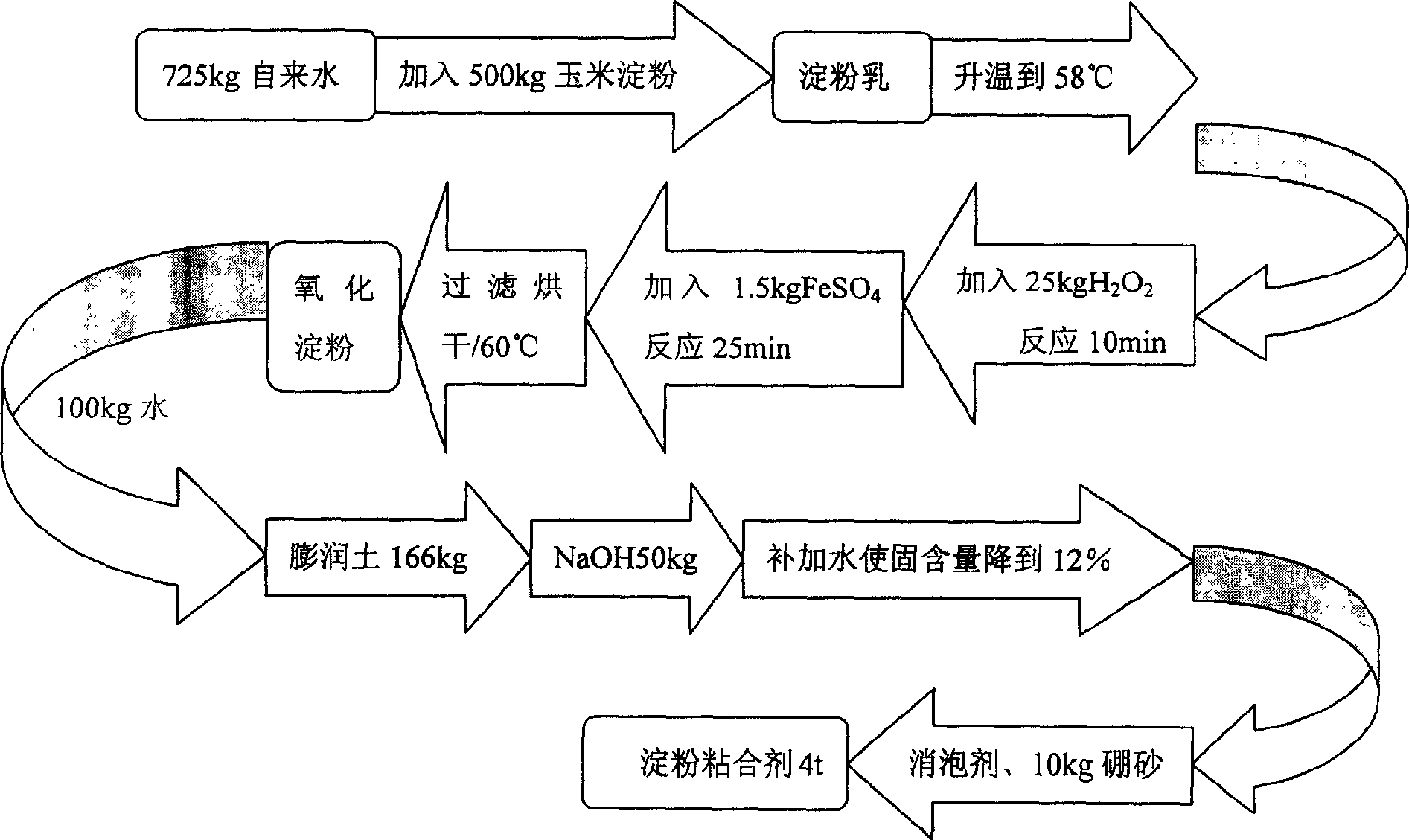

Method for preparing rapid-dry corn starch adhesive

InactiveCN1528849AHigh bonding strengthFast bond strengthStarch adhesivesSodium BentonitePolymer science

The invention discloses a manufacturing method for dry core starch adhesives, the method uses new catalyst Fe2+, reduces the use quantity of oxidant to 5%A, reduces the reaction time to 30 minutes, and produces a kind of cheap and high adhesives starch adhesives. The method adds in modified bentonite or natrium group bentonite whose weight is 30% of dried starch as the fillers before adding in NaOH, it enhances the drying speed greatly. The adhesives can be dried quickly, it doesn't counter tide, high rigidity. The cost is reduced greatly, the dry speed is enhabced greatly.

Owner:XI AN JIAOTONG UNIV

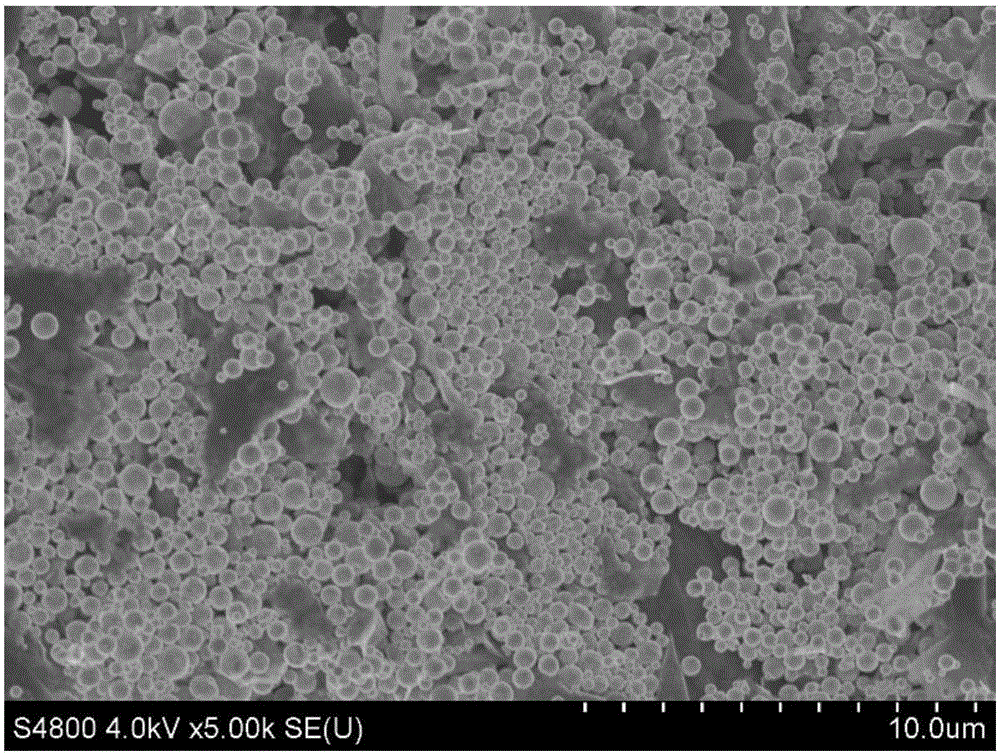

Lead-free graphene/nano-silver composite electronic silver paste and preparation method thereof

InactiveCN105976893ALow solid contentHarm reductionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention discloses a lead-free graphene / nano-silver composite electronic silver paste, which is composed of: 55-85% of graphene / nano-silver composite powder; 5-40% of organic binder; lead-free Glass powder 0.5-20%. The graphene / nano-silver composite powder is made by modifying the amino group on the surface of the nano-silver powder, modifying the carboxyl group on the surface of the graphene, and then bonding the graphene and the nano-silver powder together through acid-amine condensation to obtain a well-dispersed composite powder. Powder. The present invention uses graphene / nano-silver composite powder to replace traditional silver powder, which reduces the solid content of silver powder and effectively reduces the cost; the use of lead-free glass powder in the silver paste preparation process greatly reduces the harm to the environment and human body ; The preparation process of the composite electronic silver paste is simple, easy to operate, and beneficial to industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

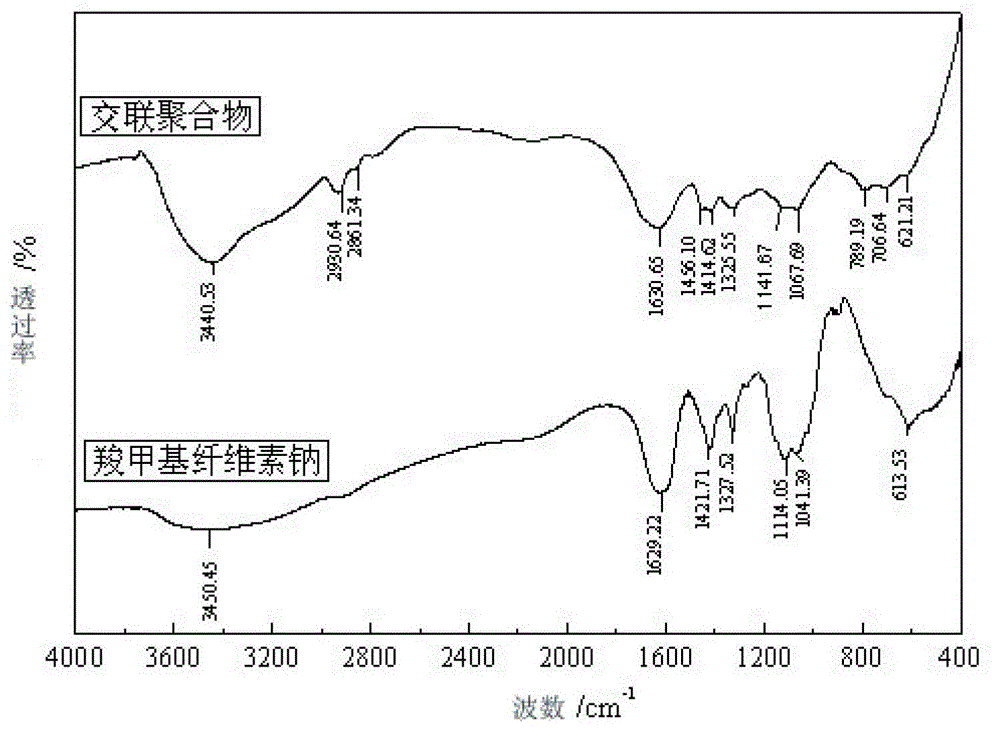

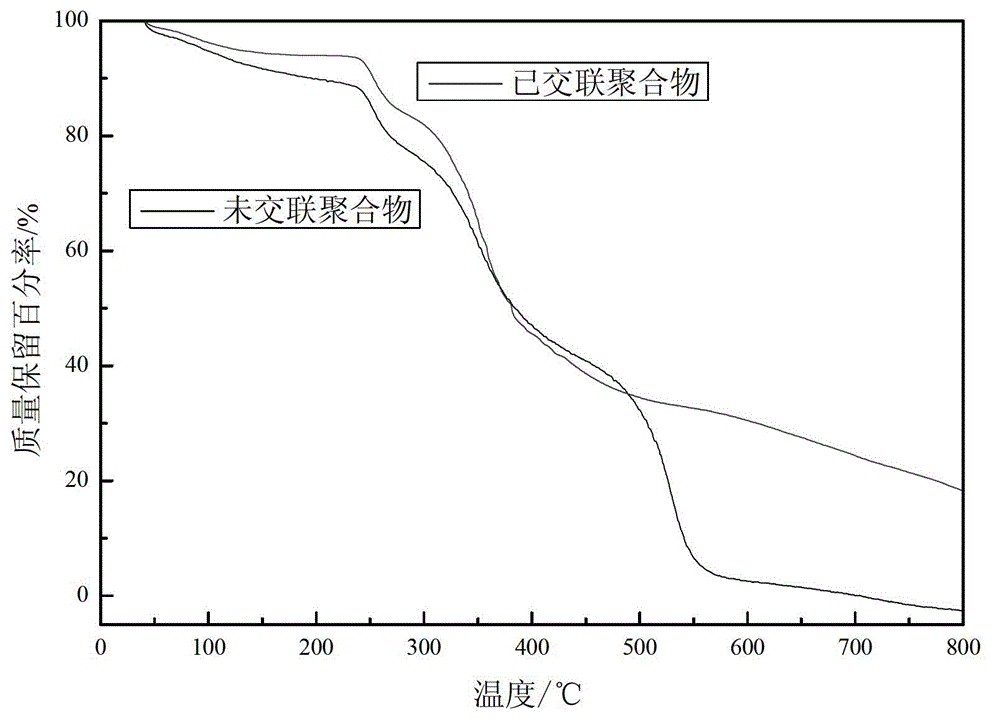

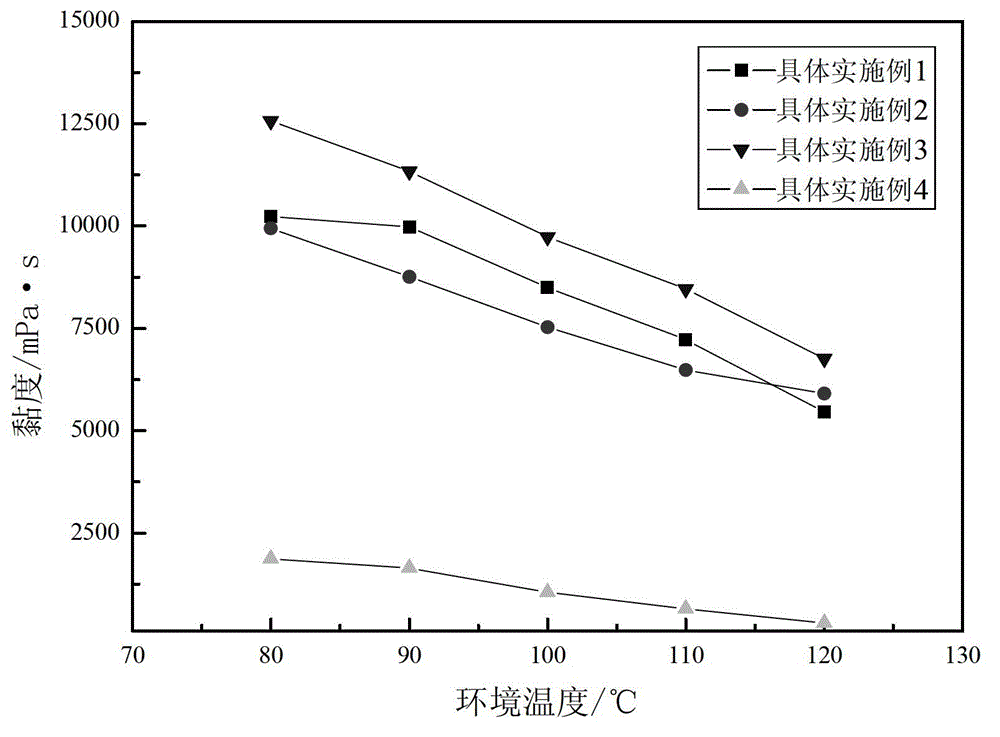

Preparation method of polymer weak gel deep profile control agent

InactiveCN103333669APlay a role in thickeningRich sourcesDrilling compositionCross-linkCarboxymethyl cellulose

The invention relates to a preparation method of a polymer weak gel deep profile control agent. The preparation method comprises the following steps of preparing sodium carboxymethyl cellulose and distilled water into sodium carboxymethyl cellulose water solution of which the mass percentage is 1%-2%; adding acrylamide of which the mass is 2-8 times as great as that of the sodium carboxymethyl cellulose into the sodium carboxymethyl cellulose water solution, and then adding a cross-linking agent which accounts for 0.01%-2% of the total weight of the sodium carboxymethyl cellulose and the acrylamide; enabling nitrogen to enter into a closed system and isolating the air, and adding an initiating agent which accounts for 1%-2% of the total mass of the sodium carboxymethyl cellulose and the acrylamide; and discharging after carrying out constant-temperature reaction for 4-12 hours under the temperature of 30-60 DEG C. According to the preparation method disclosed by the invention, the acrylamide is grafted to the sodium carboxymethyl cellulose, polymer weal gel with a mesh structure is formed under the action of the initiating agent and the cross-linking agent, and a polymer weak gel system integrates the advantages of the sodium carboxymethyl cellulose and the acrylamide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Graphene composite copper thick film conductive slurry and preparation method thereof

InactiveCN104021842AImprove conductivityGraphene with excellent conductivity improvesNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceConductive polymer

The invention discloses graphene composite copper thick film conductive slurry. The graphene composite copper thick film conductive slurry comprises the following components in percentage by mass: 60%-80% of conductive phase, 0.5%-5% of glass phase, 15%-39.5% of organic carrier, totaling 100%. The preparation method comprises the steps of mixing the components, heating to 35-40 DEG C, and uniformly stirring. According to the graphene composite copper thick film conductive slurry disclosed by the invention, by adding graphene with an excellent conductive property, the conductive property of the slurry is improved; by bismuth oxide low-melting glass, the conductive thick film slurry has excellent electrical properties and adhesion force even when being sintered at a low temperature. The slurry has the advantages of good conductivity and small printing thickness, can be effectively applied to production of a conductive material for various products, has the advantages of simple preparation process, convenience in operation, good conductivity, uniform distribution of particle sizes and easiness in coating, and is suitable for mass production of enterprises.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Low solid phase and micro-foam drilling fluid or completion fluid capable of being used circularly

The invention discloses a low solid phase and micro-foam drilling fluid or completion fluid capable of being used circularly, comprising the following components in portions by weight: 3-4 portions ofmicro-foam and low-solid phase composite treating agent SD-LGA capable of being used circularly, 0.5-1 portion of low-density and low-solid phase tackifier SD-LGV, 0.5-1 portion of low-density regulator SD-LFD, 0.5-1 portion of low-density foam stabilizer SD-LFS, 0.5-1 portion of low-density flowing type regulator SD-LFR and 100 portions of clear water. The preparation method comprises the following steps: sequentially adding the components into the clear water in a conventional preparation method according to the weight content of each component at normal temperature and normal pressure, andthen, uniformly mixing and stirring the components for use. The drilling fluid or completion fluid has the advantages of low solid phase, low density, high foam stability, high structural strength, high fluid phase viscosity, high flexibility, high lubricity, very low toxicity, easy biodegradation, circular use, little influence on environment, little harm to a storage layer, high permeability recovery value, good effect on protection of an oil-gas layer and the like, and is widely applied to a drilling engineering technology of petroleum and geology.

Owner:DONGYING TAIER GASOLINE TECH

Strong-sealing drilling fluid for preventing collapse of carbonaceous mudstone and preparation method

InactiveCN106221684AStrong blocking abilityEnhanced inhibitory effectDrilling compositionWell drillingBlocking layer

The invention provides strong-sealing drilling fluid for preventing collapse of carbonaceous mudstone. The strong-sealing drilling fluid is prepared from water and is further prepared from, by mass of water, 5-15% of liquid phase weighting agent, 3-5% of temperature resisting agent, 3-7% of inhibitor, 0.3-0.5% of tackifier, 2.0-3.0% of fluid loss agent, 4.0-8.0% of blocking agent, 0.1-0.15% of basicity control agent, 1.0-2.0% of lubricant and 30-50% of solid weighting agent. Through the synergistic effect of bridging, filling, deformation, the fluid lock effect and the like, a blocking layer formed on the surface of the well wall is compact in cementation and has a good blocking effect on micro-cracks; the situation that drilling fluid filtrate is immersed into mud rock micro-cracks is effectively reduced, the blocking performance is highlighted, and meanwhile other performance can be considered; liquid phase density is improved, the solid phase content is reduced, and adjustment of the rheological property of the drilling fluid is promoted; reservoir protection is promoted, and the yield of an oil-gas well is increased.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Silicon polishing compositions with high rate and low defectivity

ActiveUS20120058642A1High removal rateLow particle defectivityPigmenting treatmentOther chemical processesHigh rateCarboxylic acid

The invention relates to a chemical-mechanical polishing composition comprising silica, one or more organic carboxylic acids or salts thereof, one or more polysaccharides, one or more bases, optionally one or more surfactants and / or polymers, optionally one or more reducing agents, optionally one or more biocides, and water, wherein the polishing composition has an alkaline pH. The polishing composition exhibits a high removal rate and low particle defects and low haze. The invention further relates to a method of chemically-mechanically polishing a substrate using the polishing composition described herein.

Owner:CMC MATERIALS INC

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363AAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

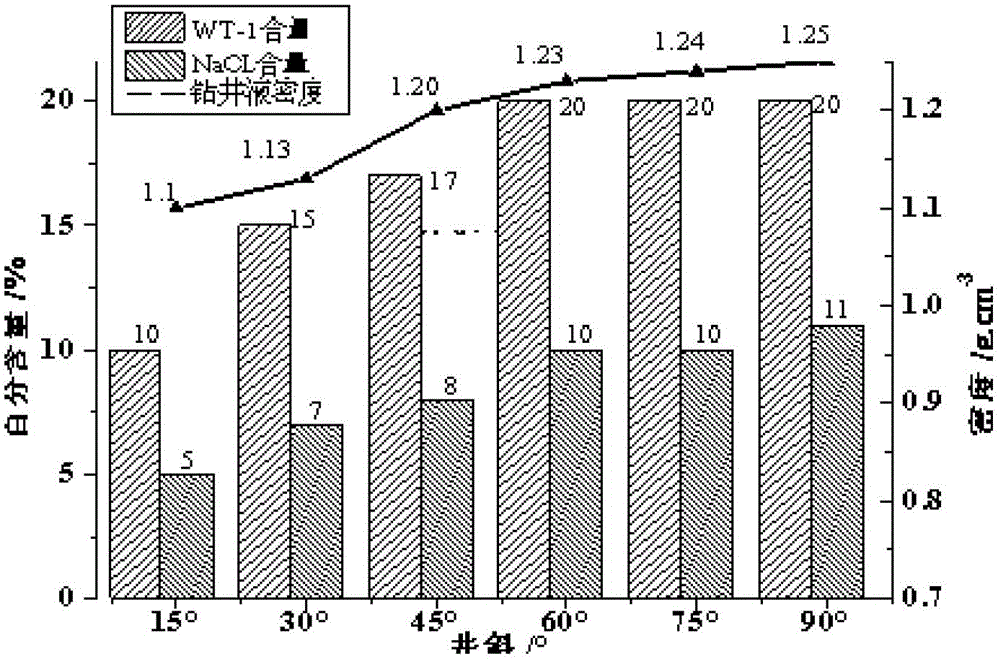

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Novel copolymerized white latex

InactiveCN101130586AImprove stabilityImprove performanceMonocarboxylic acid ester polymer adhesivesSodium bicarbonateOrganic film

The invention discloses a new typed white copolymerization emulsion in the binding technical domain, which comprises the following steps: dispensing raw materials with polyvinyl alcohol, deionized water, sodium bicarbonate, vinyl acetate, butyl acrylate, tertiary carbonate vinyl ester, dispersant, defoamer, ammonium persulphate, plasticizer and pH value adjuster; doing the polymerizing reaction in the glass lining autoclave; putting the polyvinyl alcohol and deionized water in the autoclave; heating to dissolve the materials; cooling to adding the dispersant and defoamer; adding the reacting monomer to polymerize under normal pressure at 72-80 deg. c in the stirring condition; adding fitful quantity of pH adjuster to control the pH value between 6. 0 and 7. 0; adding plasticizer DBP; forming the product with good binding property and transparent organic film, safety and environment protection to save resource.

Owner:林玉珠

Rosin-based flux for ZnSn-based lead free solder and preparation method thereof

InactiveCN102581522ALow solidsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaRosinSoldering

Rosin-based flux for a ZnSn-based lead free solder comprises rosin, an organic acidity activator, a corrosion inhibitor, a surfactant and an organic solvent. According to the invention, the solder can be additionally provided in injection, spraying or atomization method, the addition amount is easy to accurately control, the disadvantage that the prior soldering flux is hard to brush is overcome, no paste agent, stabilizing agent or thixotropic agent or other substances containing high solid content are included, the solid content of the solder is low, the wetting power to ZnSn-based solder is strong, the residue after welding is little, a metal oxide-film can be effectively removed, the expansion rate is not less than 75%, the effects of film forming and base material protection are possessed, and the preparation method is simple and practicable.

Owner:HENAN UNIV OF SCI & TECH

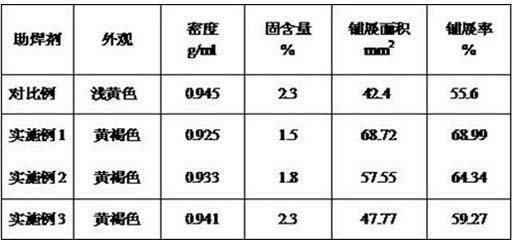

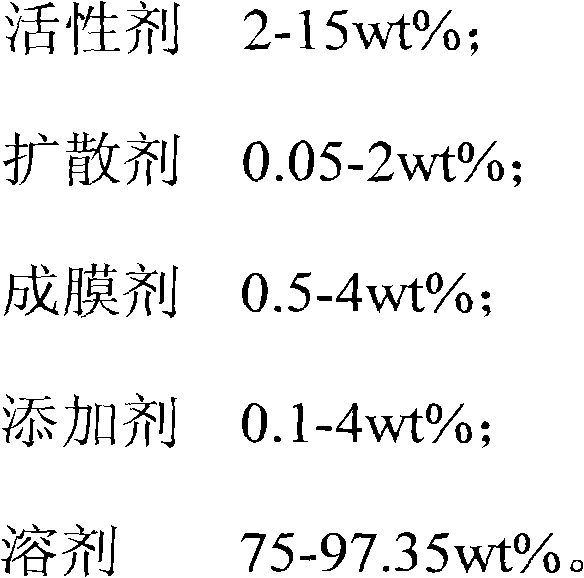

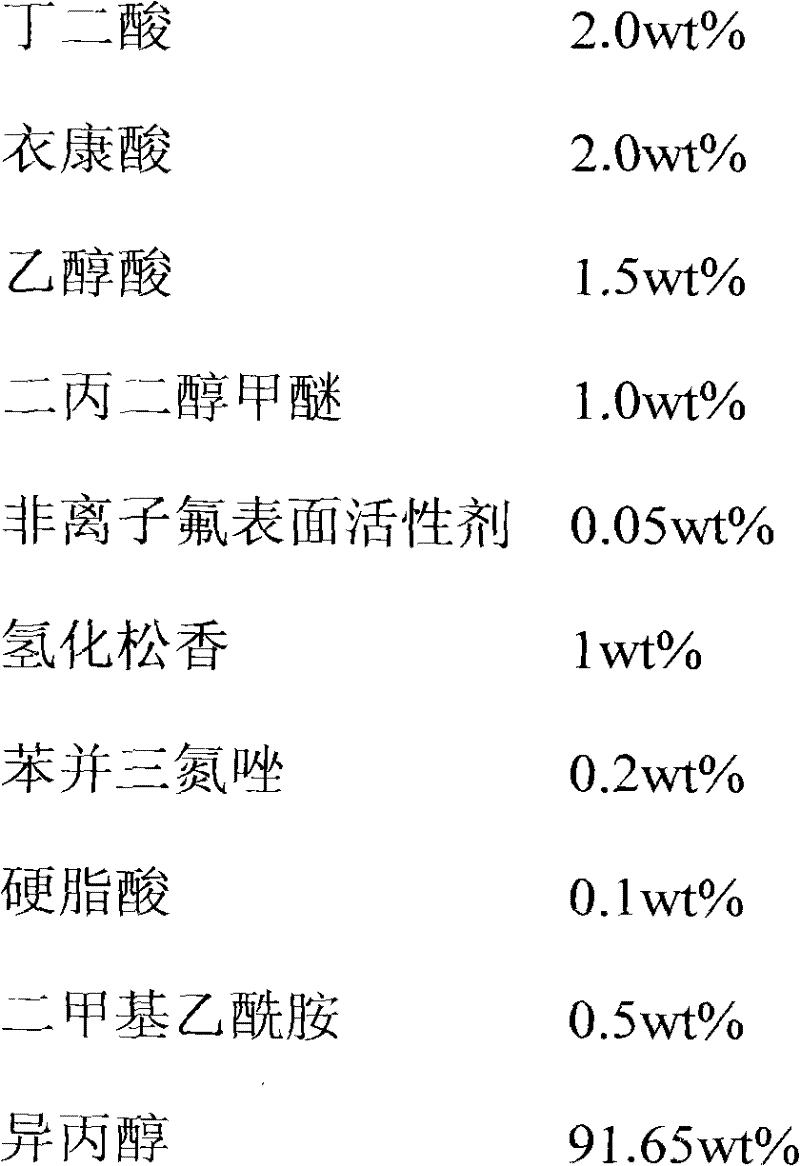

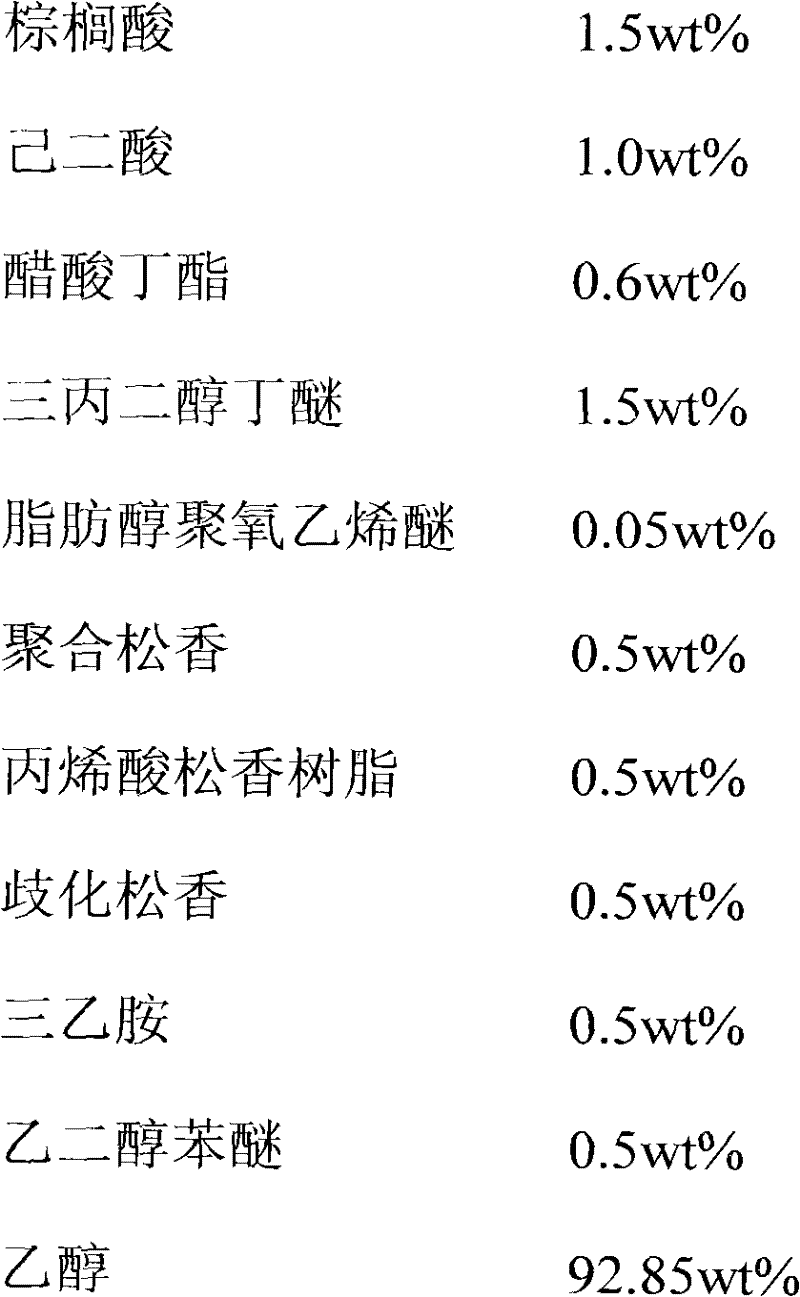

Flux

InactiveCN102513733AHigh insulation resistanceModerate weldabilityWelding/cutting media/materialsSoldering mediaSolventMaterials science

The invention belongs to the field of welding materials, and particularly relates to a halogen-free, low-residue, high-impedance and cleaning-free flux, which comprises the following components: 2-15wt% of activator, 0.05-2wt% of dispersing agent, 0.5-4wt% of film-forming agent, 0.1-4wt% of additive and 75-97.35wt% of solvent. Compared with the prior art, the flux has the advantages that the expansion ratio of the flux is higher than 80% of the standard, the flux is moderate in weldability and halogen-free, ionic contamination is at the highest I grade, the flux is applicable to high-reliability electronic products, the surface insulation resistance of the flux is at a 1010 grade after a copper mirror corrosion test, and the flux has the advantages that the flux is high in insulation impedance, high in insulation resistance, low in electric leakage risk, low in solid content, environment-friendly, clean and cleaning-free, residue is less, a post-weld board is tack-free and the like.

Owner:广东中实金属有限公司

Highly-effective high accuracy sapphire polishing liquid and preparation method thereof

ActiveCN101230239AEnhanced flattening efficiencyReduce the burden onEdge grinding machinesPolishing compositionsSurface-active agentsSolid content

The invention provides an efficient high-precision sapphire polishing solution and the preparing method, which relates to the polishing technology on sapphire, in particular to the polishing solution technology which can finely polish the surface. Firstly, nano silica sol particles, the particles diameters of which are 15-80 nanometers, are dispersed into water to form suspension; and then complexation agent is added into the suspension; and then surface active agent is added into the suspension; finally, the PH value of the suspension is regulated to 10-11. The invention has simple and rational production process, can be produced simply, contains low solid content, has high polishing efficiency, has strong stability, can hardly deposit on the surface of the polishing machine and the object to be polished, can hardly be air-dried on the surface of the sapphire after polishing due to the unique fluidity, and can lighten the burden of the following cleaning process greatly.

Owner:江苏集萃中以科技产业发展有限公司

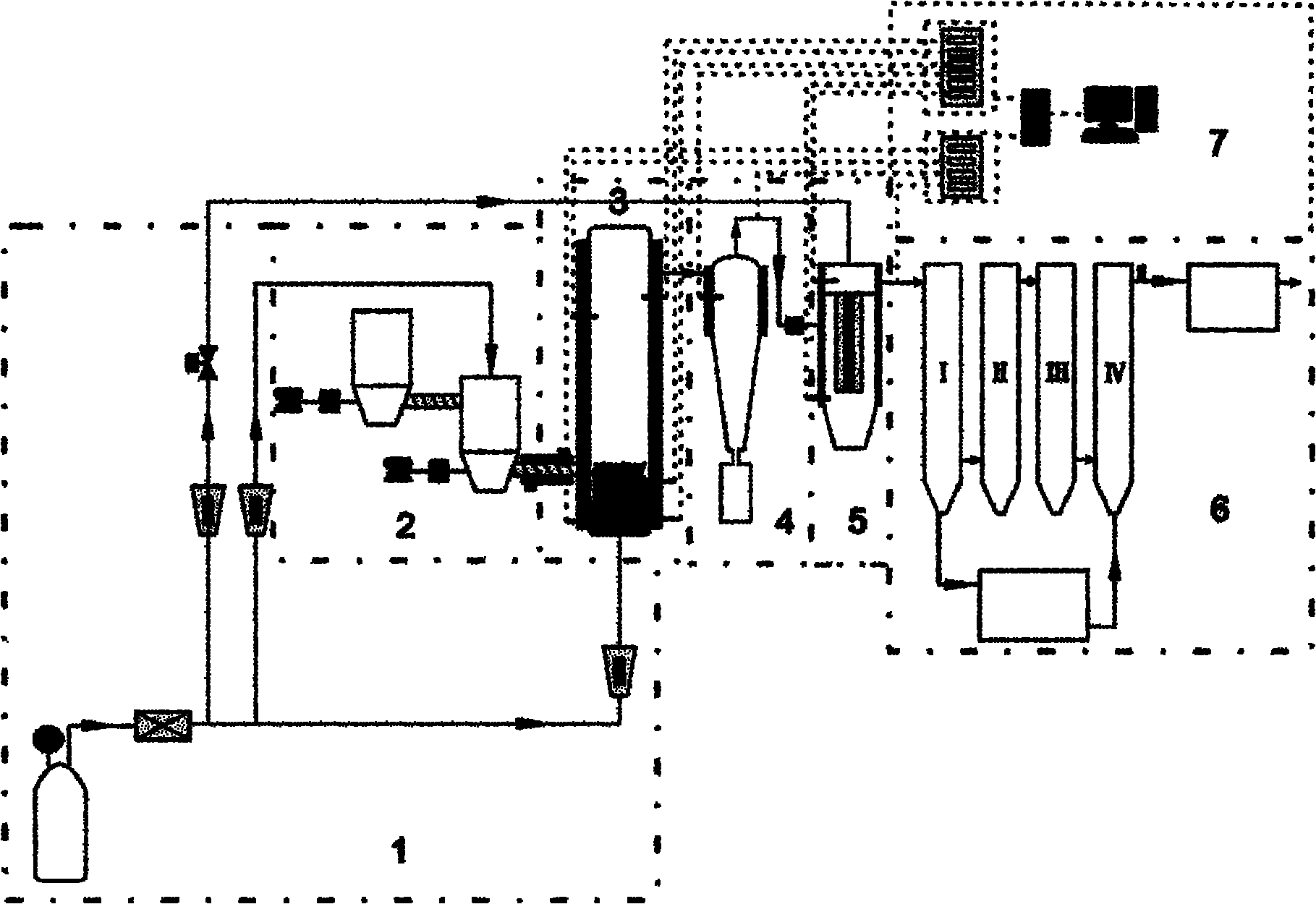

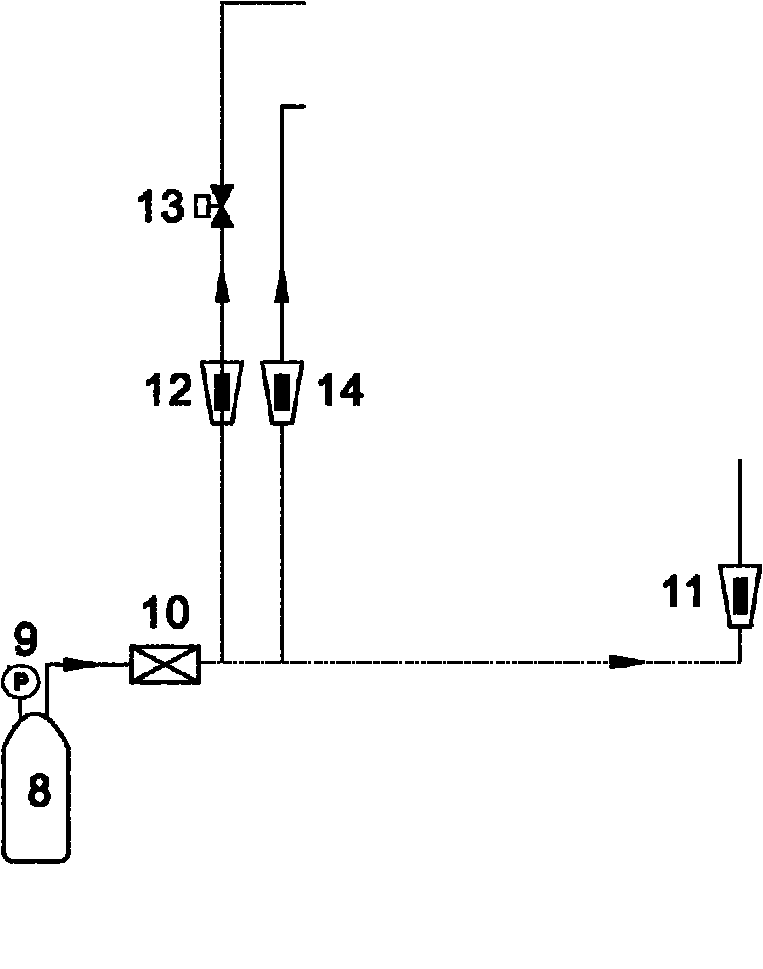

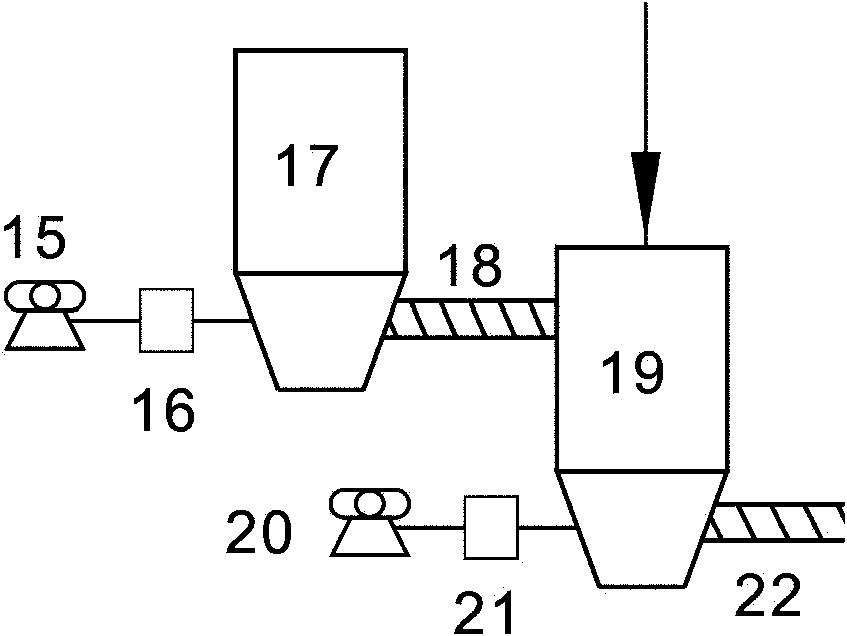

Device for preparing biofuel by quick thermal cracking of biomass

The invention relates to the technical field of biofuel, in particular to a device for preparing the biofuel by the quick thermal cracking of biomass. The device comprises an air carrier system, a feeding system, a fluidized bed reactor, a cyclone separator, a hot vapor filter, a biofuel collection system, sensing mechanisms and a data acquisition and control system, wherein the feeding system is connected with the fluidized bed reactor; the cyclone separator, the hot vapor filter and the boilfuel collection system are connected in series through a pipeline in turn; the air carrier system is connected with the fluidized bed reactor, the hot vapor filter and the feeding system respectively; many groups of sensing mechanisms are positioned at the test points of the fluidized bed reactor, the cyclone separator and the hot vapor filter respectively; and the data acquisition and control system is connected with the plurality of sensing mechanisms and acquires the temperature and pressure of each test point. The device has the characteristics of simple and practical structure and lasting and stable feed and improves boifuel quality.

Owner:SHANGHAI JIAO TONG UNIV

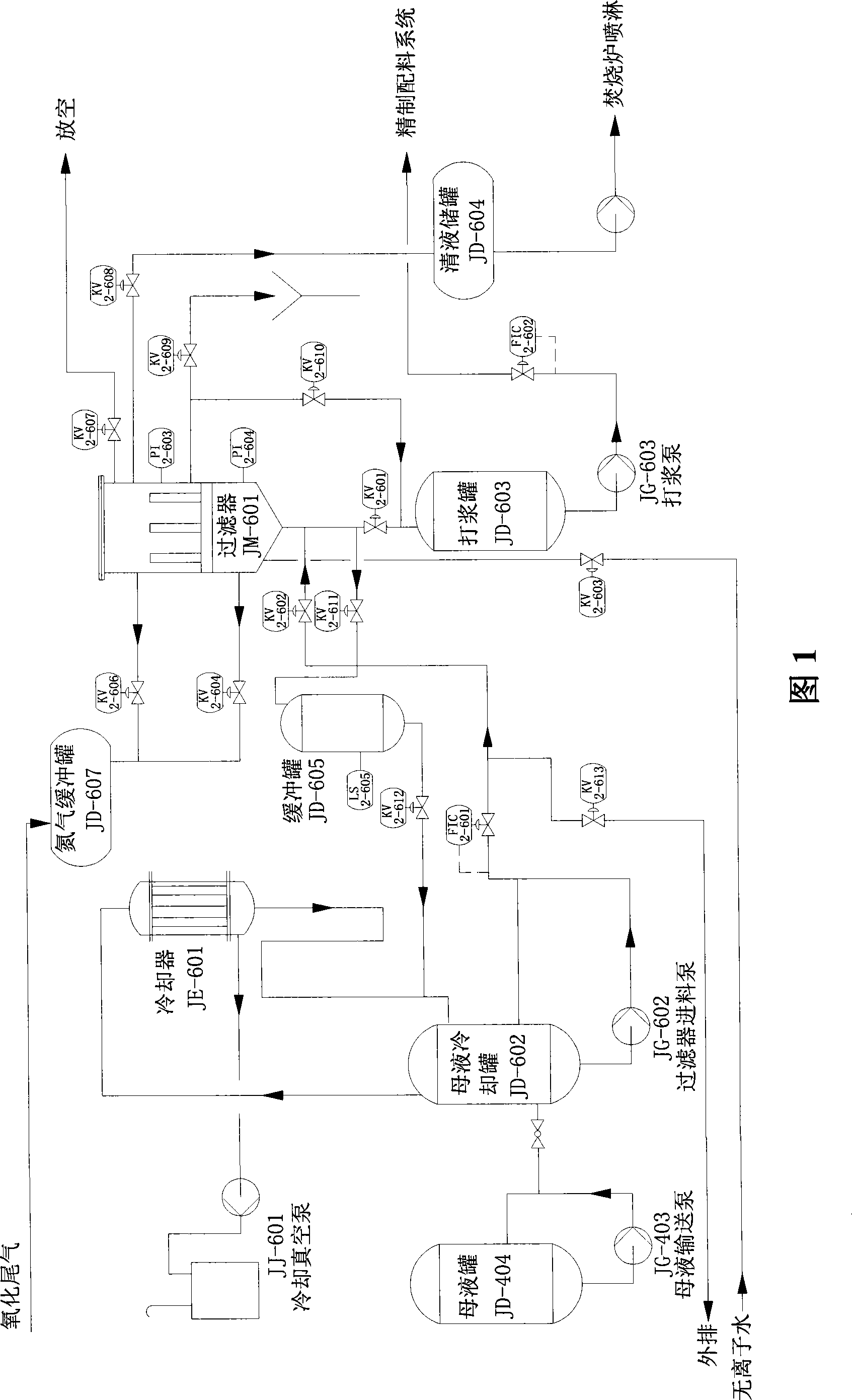

Recovery method of terephthalic acid/isophthalic acid refinement mother liquor

ActiveCN101391952AEasy to separateLow solid contentCarboxylic compound separation/purificationChemical oxygen demandBuffer tank

The invention discloses a recycling method of mother liquor, particularly a method for recycling refined mother liquor of phthalic acid / m-phthalic acid. The method comprises the steps: the mother liquor in a mother liquor tank is pumped into a mother liquor cooling tank, and the cooling tank is vacuumized, the air after flash evaporation is pumped into a cooler, after condensation, the gas returns back to the mother liquor cooling tank; the mother liquor after cooling in the mother liquor cooling tank is pumped into a filter for filtering; after filtering of the mother liquor, the filtering liquor is put into a filtering liquor collecting tank and then pumped into an incinerator for tail gas drenching; after a filter cake is formed on the inner surface of the filter element of the filter, the filtering liquor at the upper part of the tube plate of the filter is discharged; the filtering liquor at the inner lower side of the filter element and lower part of the tube plate of the filter is discharged to a buffer tank; the filter cake blow-dried by oxydic tail gas is pressed into a pulping tank; and deionized water is added into the filter to wash the undischarged filter cake to the pulping tank. By adopting filtering technology with high accuracy, the method recovers the useful components in the centrifuger mother liquor, reduces the values of solidity and chemical oxygen demand (COD) of filtering liquor, and improves the environment.

Owner:CHINA PETROLEUM & CHEM CORP

Printing of organic electronic devices

InactiveUS20060159842A1Uniform profileExtended drying timeSolid-state devicesSemiconductor/solid-state device manufacturingConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OLED

Special coloring agent of diammonium phosphate compound fertilizer and preparation method thereof

InactiveCN101671209AGood colorSolve easy fadingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLiquid stateDiammonium phosphate

The invention discloses a special coloring agent of a diammonium phosphate compound fertilizer, comprising the following constituents: 40-50 parts of humic acid salt, 0.1-3 parts of carbon soot, 2-4 parts of acid black, 1-2 parts of acid brilliant scarlet, 0.2-1 part of sodium hexametaphosphate, and 40-56.7 parts of water by weight parts; the preparation process is that: the material is prepared by weight parts, water is added in a vertical round reaction tank, and then the humic acid salt, the carbon soot, the acid black and the acid brilliant scarlet are added and are stirred uniformly, andthen sodium hexametaphosphate is added, the mixture is stirred continuously and uniformly, so as to obtain the special coloring agent of the diammonium phosphate compound fertilizer; the invention solves the problems that the diammonium phosphate particles produced under an acid slurry condition are easy to decolorize and the chromaticity is unstable; the special coloring agent of the diammonium phosphate compound fertilizer is green and environmental-protection, has no pollution and is beneficial to the growth of crops; the product is in a liquid state and transported closely, and has convenient usage; the raw material is cheap and easy to obtain, the cost is low and the economic benefit is good.

Owner:中化重庆涪陵化工有限公司

Aqueous Wax Emulsions Having Reduced Solids Content for Use in Gypsum Compositions and Building Products

ActiveUS20120216722A1Low solid contentRetaining or improving its ability to resist absorption of waterInksCeramicwareBuilding productEmulsion

Aqueous wax emulsions are disclosed herein for use in gypsum formulations and other building products which emulsions include water; a paraffinic hydrocarbon; a montan wax component; and a hydrocarbon component. Optional emulsion and strength additives may be included in the emulsion or in a slurry formed from such emulsion for preparing a settable gypsum composition herein. The hydrocarbon component is at least one hydrocarbon compound having from 5 to 20 carbon atoms or at least one hydrocarbon resin which is based on the at least one hydrocarbon compound as a monomer, wherein the resin is at least a dimer comprising the hydrocarbon compound and the resin has a molecular weight (Mw) of no greater than about 3,000, wherein the hydrocarbon compound is saturated or unsaturated, functionalized or nonfunctionalized and is aliphatic, alicyclic, or aromatic, wherein the hydrocarbon component has a softening point of from about 22° C. to about 110° C.

Owner:OU HENRY

Water-based non-clay drilling fluid having strong inhibition

The invention relates to a water-based non-clay drilling fluid having strong inhibition which comprises, 0.2%-0.5% of construction agent, 0.8%-6% of at least a fluid loss additive, 3%-25% of at least an inhibiting agent, 0.2%-0.8% of at least a pH conditioning agent, and balancing water.

Owner:DRILLING TECHNOLOGY RESEARCH INSTITUTE OF XINJIANG PETROLEUM ADMINISTRATION BURE

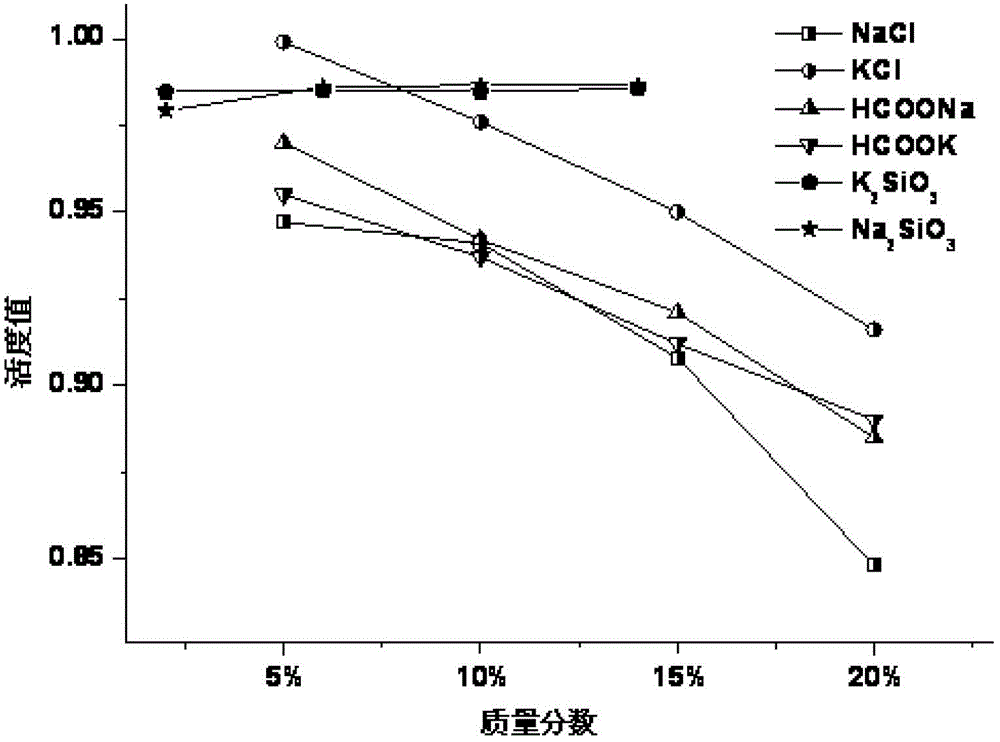

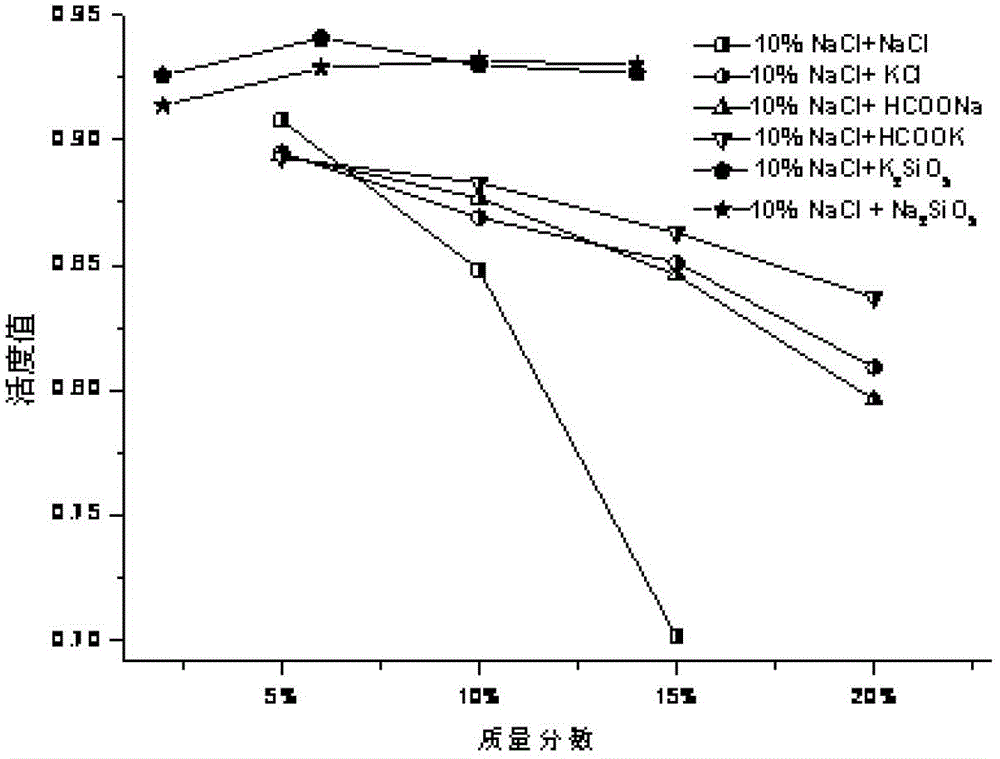

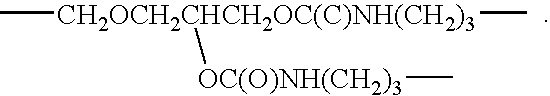

Water-based drilling fluid system for deepwater operation and preparation method thereof

ActiveCN102504771AInhibition of hydration dispersionPrevent infiltrationDrilling compositionAlkalinityWater based

The invention relates to a water-based drilling fluid system for deepwater operation, which is prepared from (by weight): 100 parts of water-based fluids, 3-4 parts of inhibitors, 0.4-0.8 parts of low molecular-weight coating inhibitors, 2.5-5.5 parts of filtrate loss reducer, 0.2-0.3 parts of alkalinity regulators, 10-20 parts of NaCl, 2-3 parts of lubricants, 0.2-0.4 parts of flow regulators, 3-5 parts of KCl and 5-80 parts of weighting agent. The invention further relates to a preparation method for the water-based drilling fluid system for deepwater operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

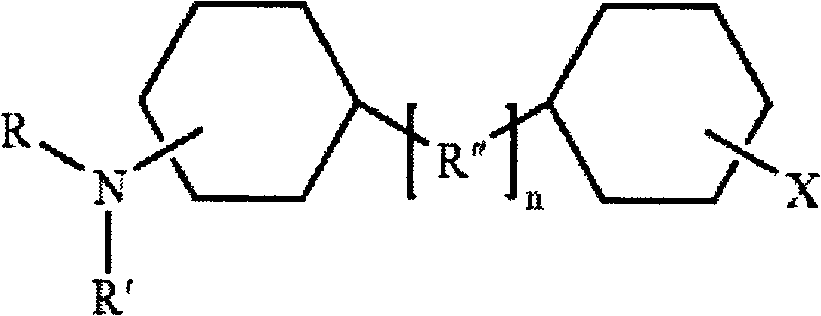

Compositions for aqueous delivery of self-emulsifying fluorinated alkoxysilanes

InactiveUS6861149B2Extended shelf lifeGood flexibilityLiquid surface applicatorsOrganic compound preparationSelf emulsifyingAlkoxyl radicals

The invention relates to compositions used for aqueous delivery of self-emulsifying fluorinated alkoxysilanes to substrates to provide oil and water resistive coatings for the substrates, a method of treating a substrate to render it oil and water repellent, and articles having coatings made from the compositions.

Owner:3M INNOVATIVE PROPERTIES CO

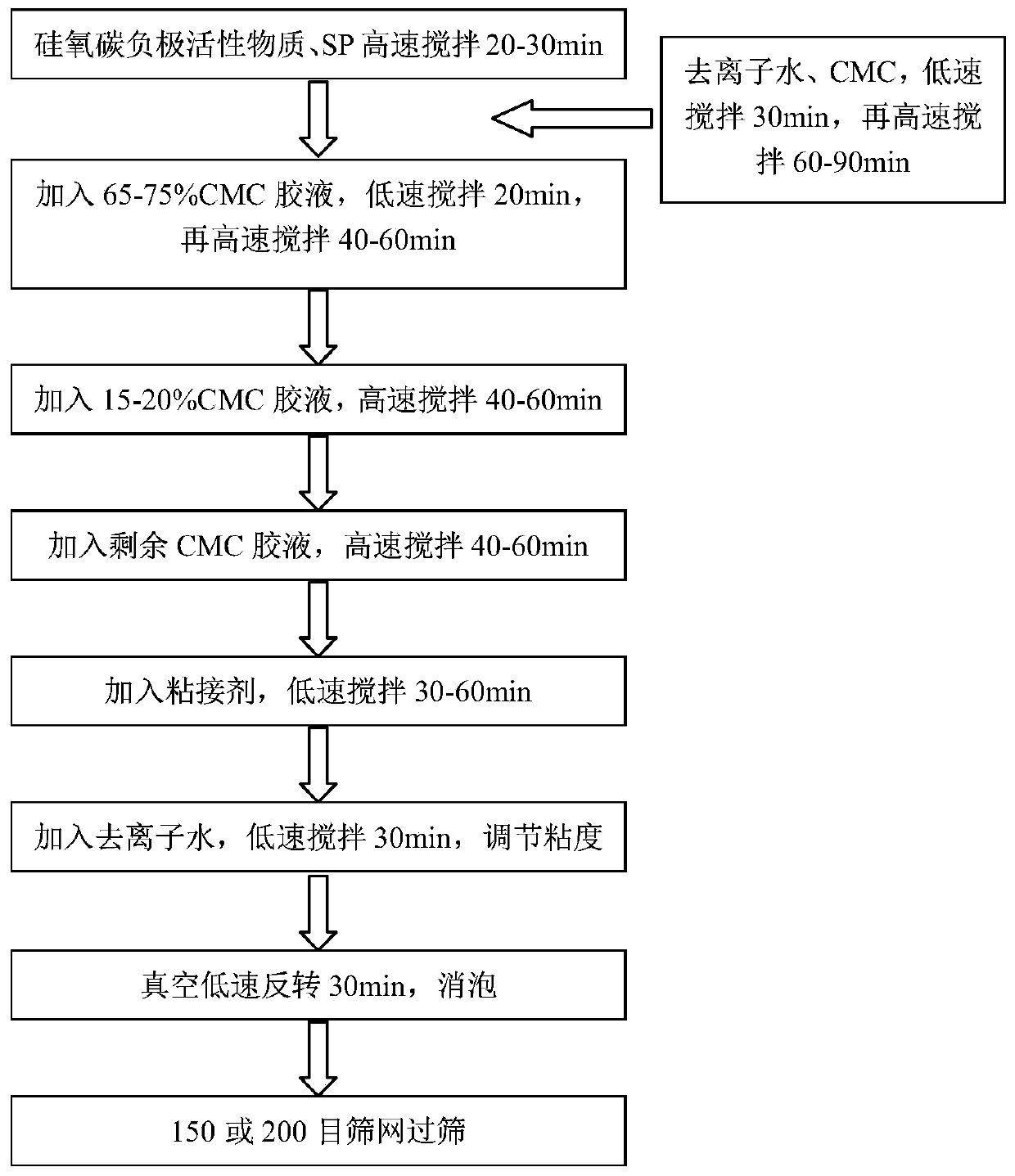

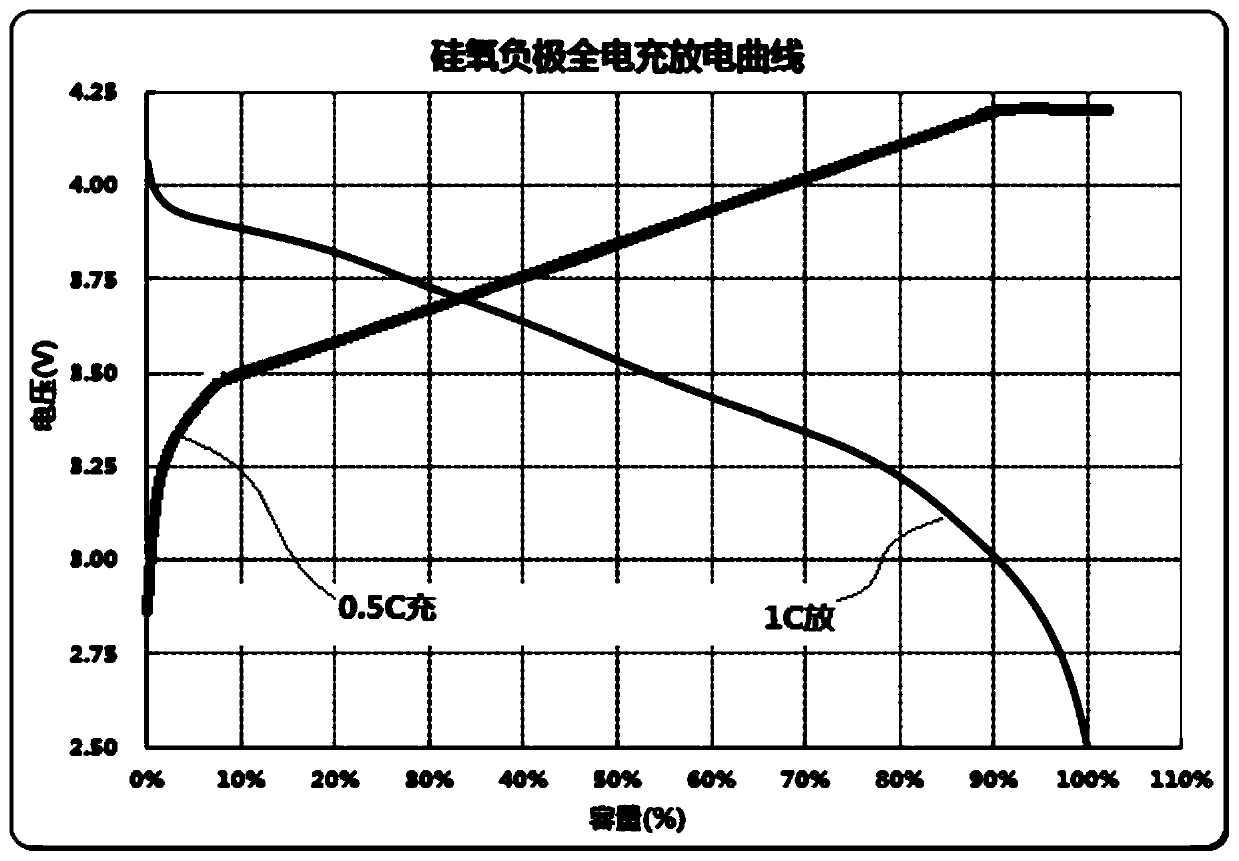

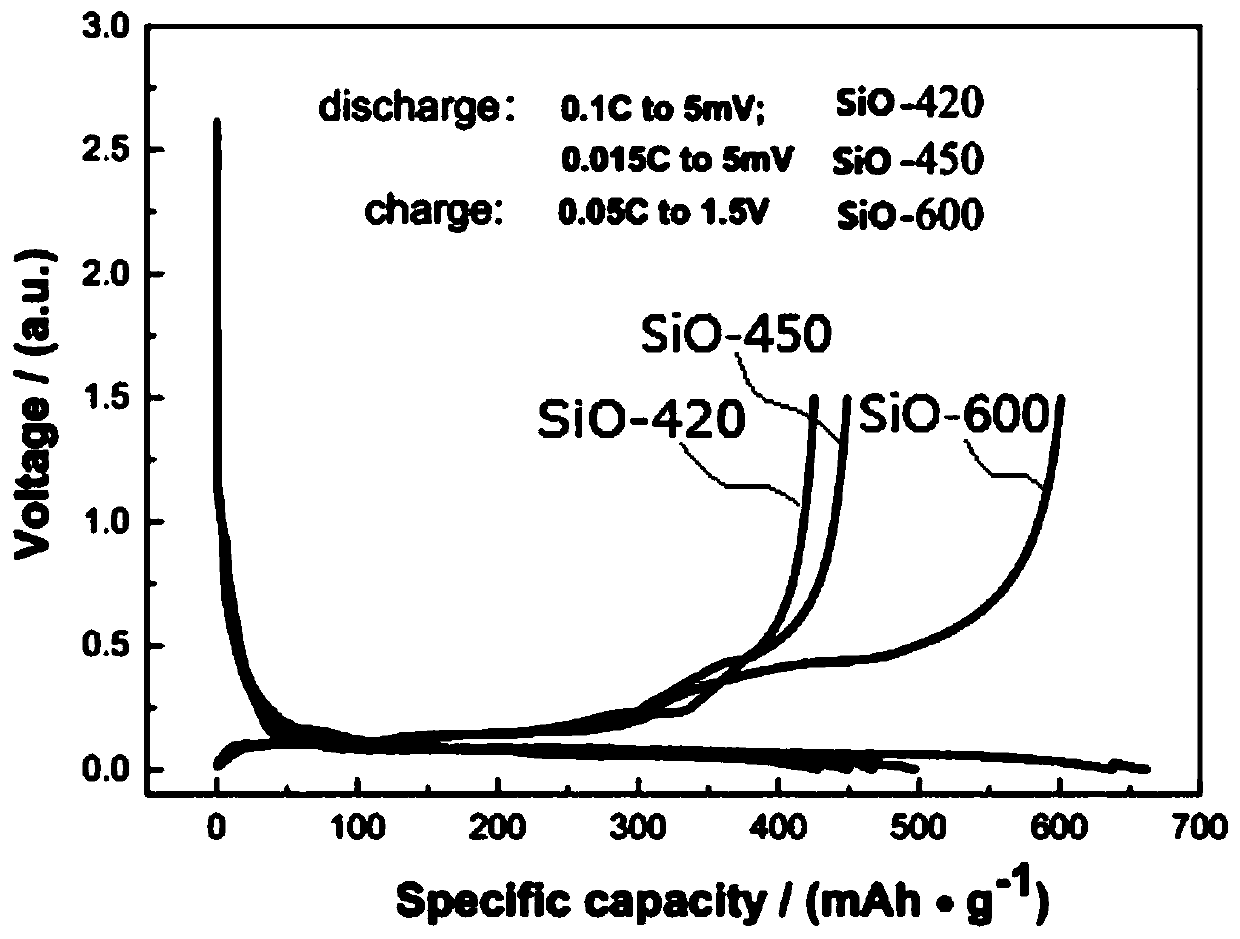

Lithium ion battery silicon oxygen anode paste, preparation method thereof, battery anode and lithium ion battery

PendingCN109950485AIncrease gram capacityImprove the first effectCell electrodesSecondary cellsGramSilicon oxygen

The invention discloses a lithium ion battery silicon oxygen anode paste, a preparation method thereof, a battery anode and a lithium ion battery, and belongs to the technical field of lithium ion battery manufacture. The lithium ion battery silicon oxygen anode paste comprises deionized water and a solid material. The solid materials comprises, with 100 total parts by weight, 93 to 97 parts of silicon-oxygen anode active material, 1 to 2 parts of CMC, binder of 1.2 to 2.0 times the CMC, and 1 to 2 parts of conductive agent SP. The solid material of the anode paste uses the 93 to 97 parts silicon-oxygen anode active material instead of the conventional graphite and the like. The prepared silicon-based anode has a much higher gram capacity than that of the graphite anode. The gram capacityof the anode active material can be greatly adjusted by adjusting the silicon content. The lithium ion battery silicon oxygen anode paste has stable later cycle stability, and high first effect.

Owner:SVOLT ENERGY TECH (MAANSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com