Lead-free graphene/nano-silver composite electronic silver paste and preparation method thereof

A technology of graphene and nano-silver, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems that do not conform to the social development trend of green environmental protection, and reduce the environment and human body. hazards, simple preparation process, and the effect of reducing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

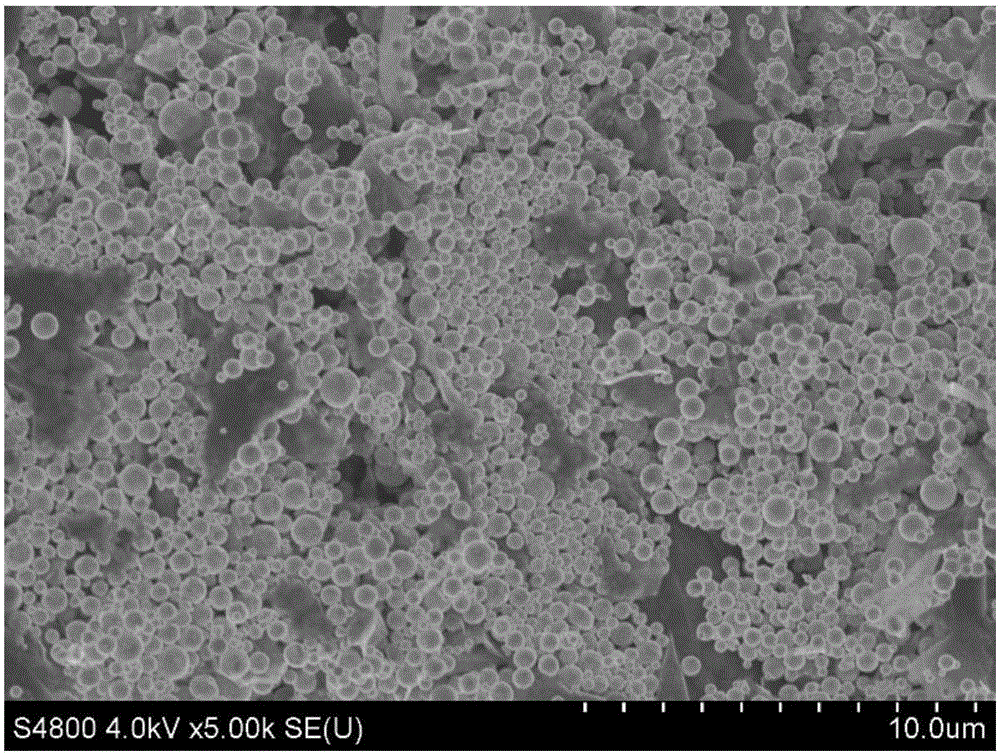

[0068] 1. Preparation of graphene / nano-silver composite powder

[0069] The graphene / nano-silver composite powder has uniform compounding and good dispersion, the nano-silver powder is silver nanoparticles with a particle size of 0.4 μm, and the mass fraction of the modified graphene is 2%. The preparation steps are as follows:

[0070] (1) Amino modification on the surface of silver nanoparticles:

[0071] Get 5g of silver nanoparticles, ultrasonically disperse it in the mixed solution of 400mL ethanol and deionized water (the volume ratio of deionized water-ethanol is 1:3), after the dispersion is uniform, add 40mL of (3-aminopropyl ) triethoxysilane reagent, in a water bath at 40°C, with magnetic stirring, and react for 6h. The modified silver powder can be obtained by washing with ethanol and deionized water for several times, and then drying in vacuum.

[0072] (2) Carboxyl modification on the surface of graphene:

[0073] Take 500mg of flake graphene powder and ultra...

Embodiment 2

[0088] 1. Preparation of graphene / nano-silver composite powder

[0089] Directly adopt the graphene / nano-silver composite powder with a graphene content of 2% prepared in Example 1.

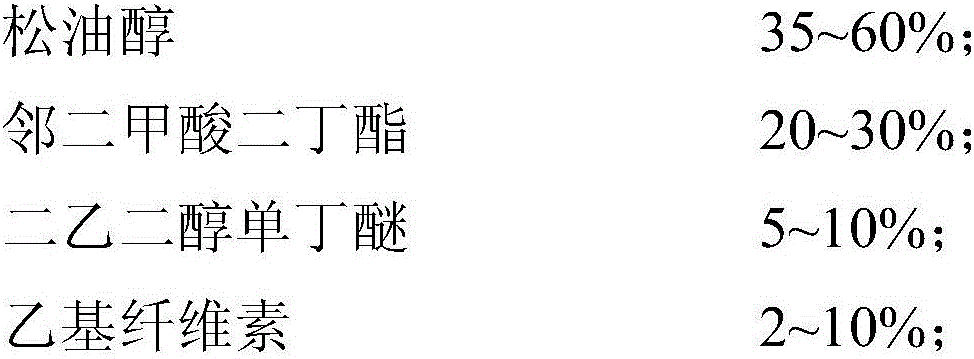

[0090] 2. Preparation of Organic Binders

[0091] In terms of mass percentage, take by weighing 55% terpineol, 20% dibutyl phthalate, 10% diethylene glycol monobutyl ether, 3% castor oil, 2% polyethylene glycol, 3 % of additives (tributyl phosphate and Span 80, the mass ratio is 1:2), after mixing evenly, heat to 80°C, slowly add 7% ethyl cellulose, dissolve for 50min, and obtain a uniform and transparent organic adhesive mixture.

[0092] 3. Preparation of lead-free glass powder

[0093] Weigh 30% of B by mass ratio 2 o 3 , 45% Bi 2 o 3 , 10% SiO 2 , 5% Al 2 o 3 , 5% ZnO, 5% V 2 o 5 , mixed evenly by ball milling, placed in a crucible, and melted at 1200°C for 2 hours. The obtained glass liquid is quenched in deionized water, and the obtained glass particles are ball-milled and pass...

Embodiment 3

[0097] 1. Preparation of graphene / silver composite silver powder

[0098] Directly adopt the graphene / nano-silver composite powder with a graphene content of 2% prepared in Example 1.

[0099] 2. Preparation of Organic Binders

[0100] In terms of mass percentage, take by weighing 55% terpineol, 20% dibutyl phthalate, 10% diethylene glycol monobutyl ether, 3% castor oil, 2% polyethylene glycol, 3 % of additives (tributyl phosphate and Span 80, the mass ratio is 1:2), after mixing evenly, heat to 100°C, slowly add 7% ethyl cellulose, dissolve for 50min, and obtain a uniform and transparent organic adhesive.

[0101] 3. Preparation of lead-free glass powder

[0102] Weigh 30% of B by mass ratio 2 o 3 , 45% Bi 2 o 3 , 10% SiO 2 , 5% Al 2 o 3 , 5% ZnO, 5% V 2 o 5 , mixed evenly by ball milling, placed in a crucible, and melted at 1400°C for 2 hours. The obtained glass liquid is quenched in deionized water, and the obtained glass particles are ball-milled and passed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com