Water-based drilling fluid system for deepwater operation and preparation method thereof

A water-based drilling fluid and water-based fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor thermal stability, unfavorable pressure control, increased viscosity, etc., and achieve excellent rheology and enhanced inhibition Good rheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

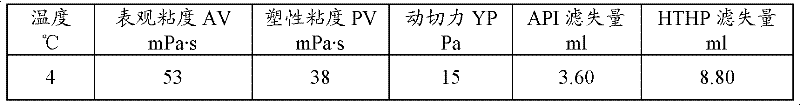

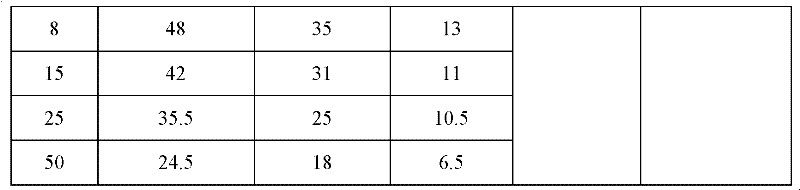

Embodiment 1

[0038] Use barite as a weighting agent, and the configuration density is 1.2g / cm 3 Seawater-based deepwater water-based drilling fluid: Measure 400ml of seawater with a measuring cylinder and place it in the slurry cup, add 0.8g of anhydrous sodium carbonate, 60g of NaCl, and 12g of inhibitors (purchased from CNOOC PF-HAB), 2g cationic polyacrylamide with a weight-average molecular weight of 600,000 (purchased from COSL PF-LV60), 2g low-viscosity polyanionic cellulose, 8g modified starch, 12g polymeric alcohol lubricant, 0.8g Xanthan gum, 12g oily lubricant, 12g KCl, stir at high speed for 20min, add 35g barite, stir at high speed for 40min.

Embodiment 2

[0040] Limestone is used as a weighting agent, and the configuration density is 1.15g / cm 3 Seawater-based deepwater water-based drilling fluid: Measure 400ml of seawater with a measuring cylinder and place it in the slurry cup, add 0.8g of anhydrous sodium carbonate, 60g of NaCl, and 12g of inhibitors (purchased from CNOOC PF-HAB), 2g cationic polyacrylamide with a weight-average molecular weight of 600,000 (purchased from COSL PF-LV60), 2g low-viscosity polyanionic cellulose, 8g modified starch, 12g oily lubricant, 0.8g xanthan Glue, 12g oily lubricant, 12g KCl, stir at high speed for 20min, add 25g of limestone, stir at high speed for 40min.

Embodiment 3

[0041] Embodiment 3 (field configuration)

[0042] The preparation density is 1.12g / cm 350 cubic meters of seawater-based deepwater water-based drilling fluid: pour 40 cubic meters of seawater into the mud tank, add 0.1 tons of anhydrous sodium carbonate, 7.5 tons of sodium chloride, and 1.5 tons of inhibitors through the mixing pump (purchase COSL PF-HAB) , 0.25 tons of cationic polyacrylamide with a weight average molecular weight of 600,000 (purchased from COSL PF-LV60), 0.25 tons of low-viscosity polyanionic cellulose (purchased from COSL PF-PAC-LV), 1 ton of modified starch ( Purchased from COSL PF-FLOCAT), 1.5 tons of oil-based lubricant (purchased from COSL PF-LUBE), circulated with a mixing pump for 20 minutes, and then added 0.1 tons of xanthan gum (purchased from COSL PF-XC-H) Then change the shear pump to shear for 1 hour. Finally, add seawater to a volume of 50 cubic meters and keep stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com