Modified cationic compound and preparation method thereof, and solid phase chemical cleaning agent for drilling fluids

A cationic compound, solid-phase chemical technology, applied in the field of its preparation, solid-phase chemical cleaners for drilling fluids, and modified cationic compounds, can solve the problems of reduced solid phase removal efficiency, increased mechanical removal of solid phase, and limited inhibition ability , to achieve the effects of inhibiting clay hydration and dispersion, controlling formation slurry, and protecting oil and gas layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

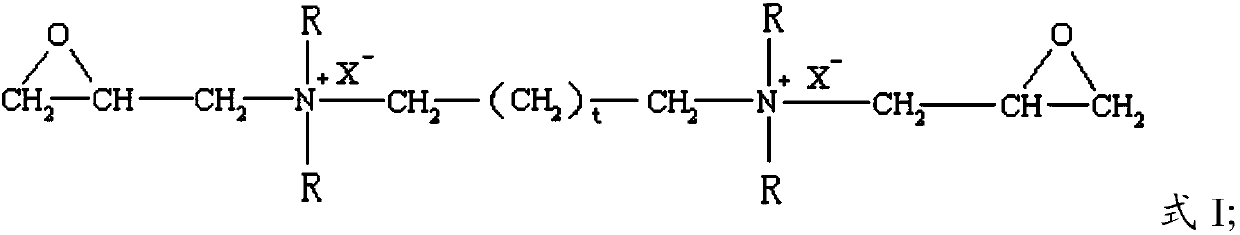

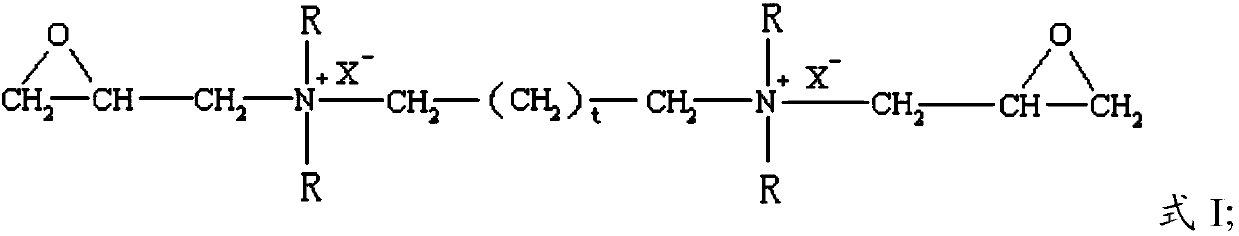

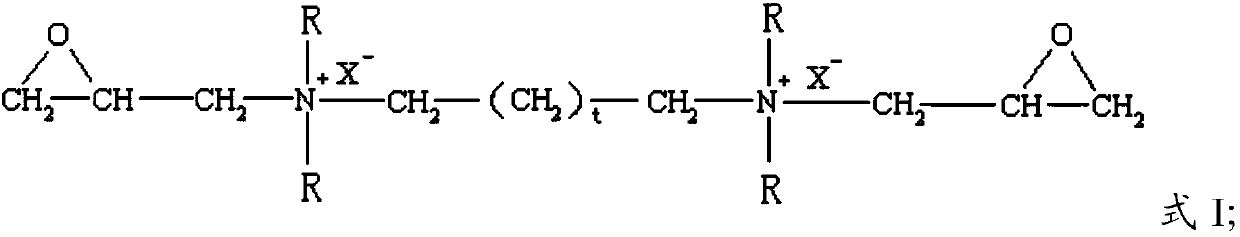

[0035] Correspondingly, the present invention provides a method for preparing a modified cationic compound, comprising: reacting tetraalkyldiamine and epihalohydrin in water in the presence of a catalyst to obtain a modified cationic compound; Tetraalkyldiamine is R 2 N-CH 2 (CH 2 ) t CH 2 -NR 2 ; The modified cationic compound has a formula I structure:

[0036]

[0037] Wherein, R is a C1-C5 alkyl group; X is a halogen; t is any integer between 0-6.

[0038] The preparation method of the present invention takes tetraalkyldiamine and epihalohydrin as reaction raw materials, and the molecular structure general formula of described tetraalkyldiamine is: R 2 N-CH 2 (CH 2 ) t CH 2 -NR 2 wherein, R is an alkyl group of C1-C5, preferably methyl or ethyl; t is any integer between 0-6, preferably 0, 1 or 2. In an embodiment of the present invention, the tetraalkyldiamine is preferably tetramethylethylenediamine, tetraethylethylenediamine, tetramethylpropylenediamine or...

Embodiment 1

[0059] 1. Preparation of modified cationic compound: Based on 100 parts by mass of raw materials, add 50 parts of water and 1 mol of tetramethylethylenediamine into the reaction kettle, and slowly add 2 mol of epichlorohydrin and 0.1 part of dodecyl under stirring Dimethyl benzyl ammonium chloride was added for 30 minutes, and reacted at 35° C. for 9 hours after the addition was completed; after the reaction time was up, vacuum dehydration was performed, and drying was performed to obtain 300 g of compound A.

[0060] The structure of compound A obtained in this example is uniquely determined, as shown in formula (1), wherein X is Cl.

[0061]

[0062] 2. The preparation method of the solid-phase chemical cleaner for drilling fluid comprises the following steps:

[0063] (1) In parts by mass, 1 part of ferric sulfate and 0.1 part of sodium silicate are mixed and ground uniformly to obtain the first mixture;

[0064] (2) Mix 100 parts of obtained Compound A with 10 parts of...

Embodiment 2

[0067] 1. Preparation of modified cationic compound: based on 100 parts by mass of raw materials, add 100 parts of water and 1 mol of tetraethylethylenediamine into the reaction kettle, and slowly add 2.1 mol of epichlorohydrin and 1 part of dodecane under stirring Dimethyl benzyl ammonium chloride was added for 60 minutes. After the addition was completed, it was reacted at 60°C for 3 hours; The structure of Compound A obtained in this example is shown in Formula I, wherein R is ethyl, X is Cl, and t is 0.

[0068] 2. The preparation method of the solid-phase chemical cleaner for drilling fluid comprises the following steps:

[0069] (1) In parts by mass, 5 parts of ferrous sulfate and 3 parts of potassium silicate are mixed and ground uniformly to obtain the first mixture;

[0070] (2) Mix 100 parts of obtained compound A with 40 parts of ammonium citrate to obtain a second mixture;

[0071] (3) Mix the first mixture and the second mixture uniformly, dry at 120° C. for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com