Recovery method of terephthalic acid/isophthalic acid refinement mother liquor

A mother liquor recovery and mother liquor technology, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems that affect the normal operation of the oxidation batching system, the unfavorable stable operation of the oxidation unit, and the complexity of the process, so as to shorten the material cycle. , equipment and pipeline material requirements are low, and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

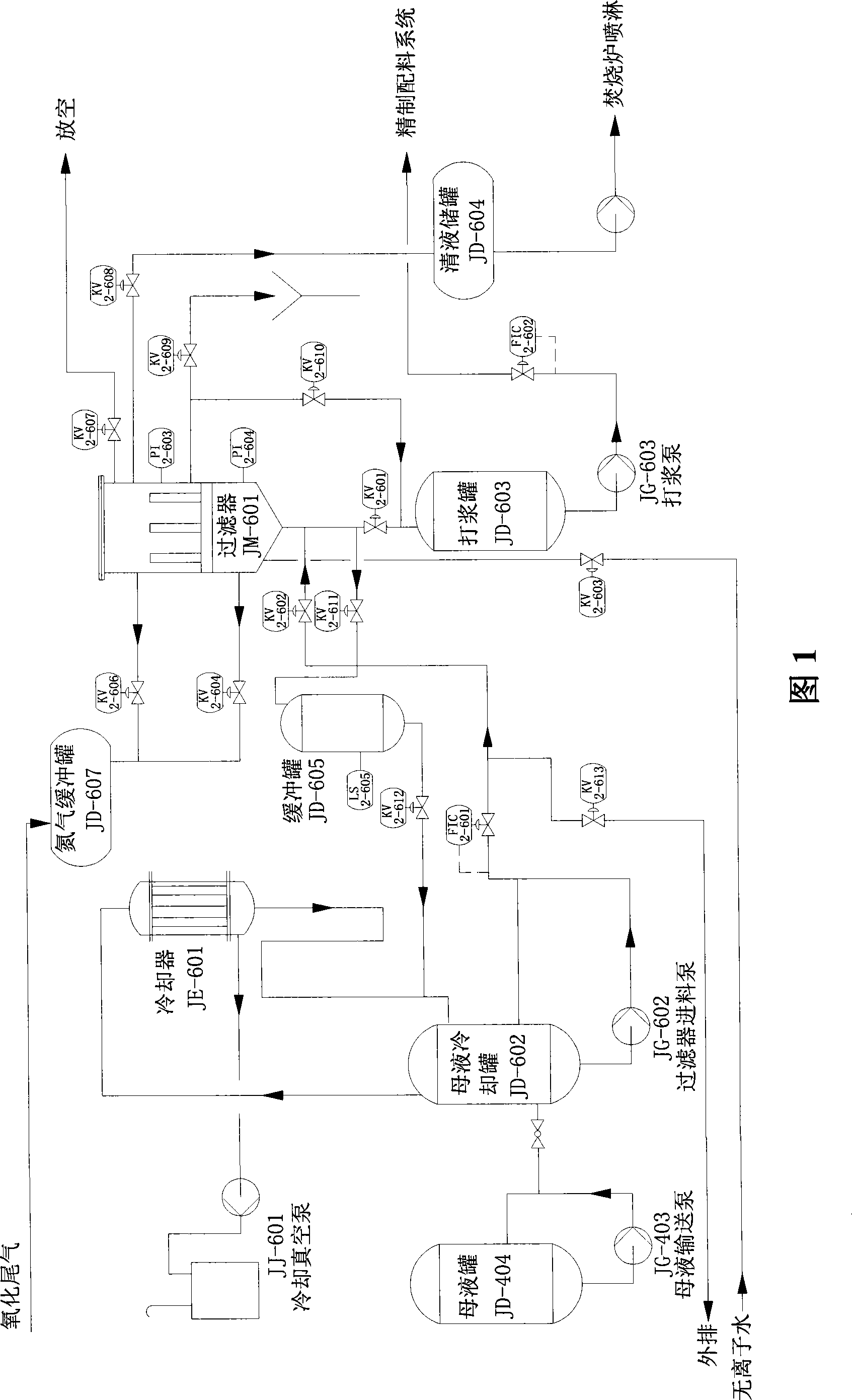

Method used

Image

Examples

Embodiment

[0020] Since the mother liquor recovery system was put into use in June 2007, the operation of the system has been analyzed.

[0021] 1. The effect of JM-601 filter

[0022] (1) Filter effect

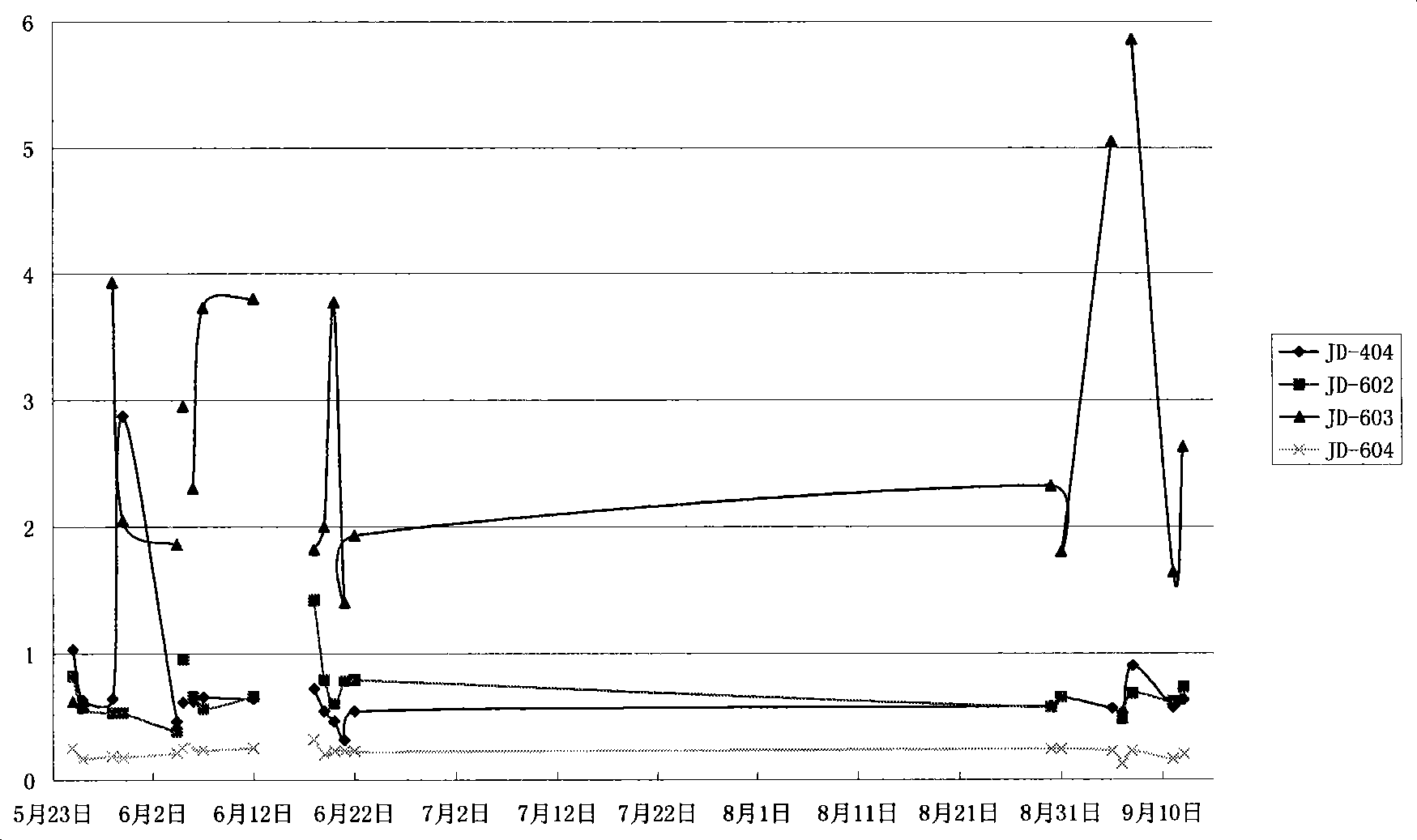

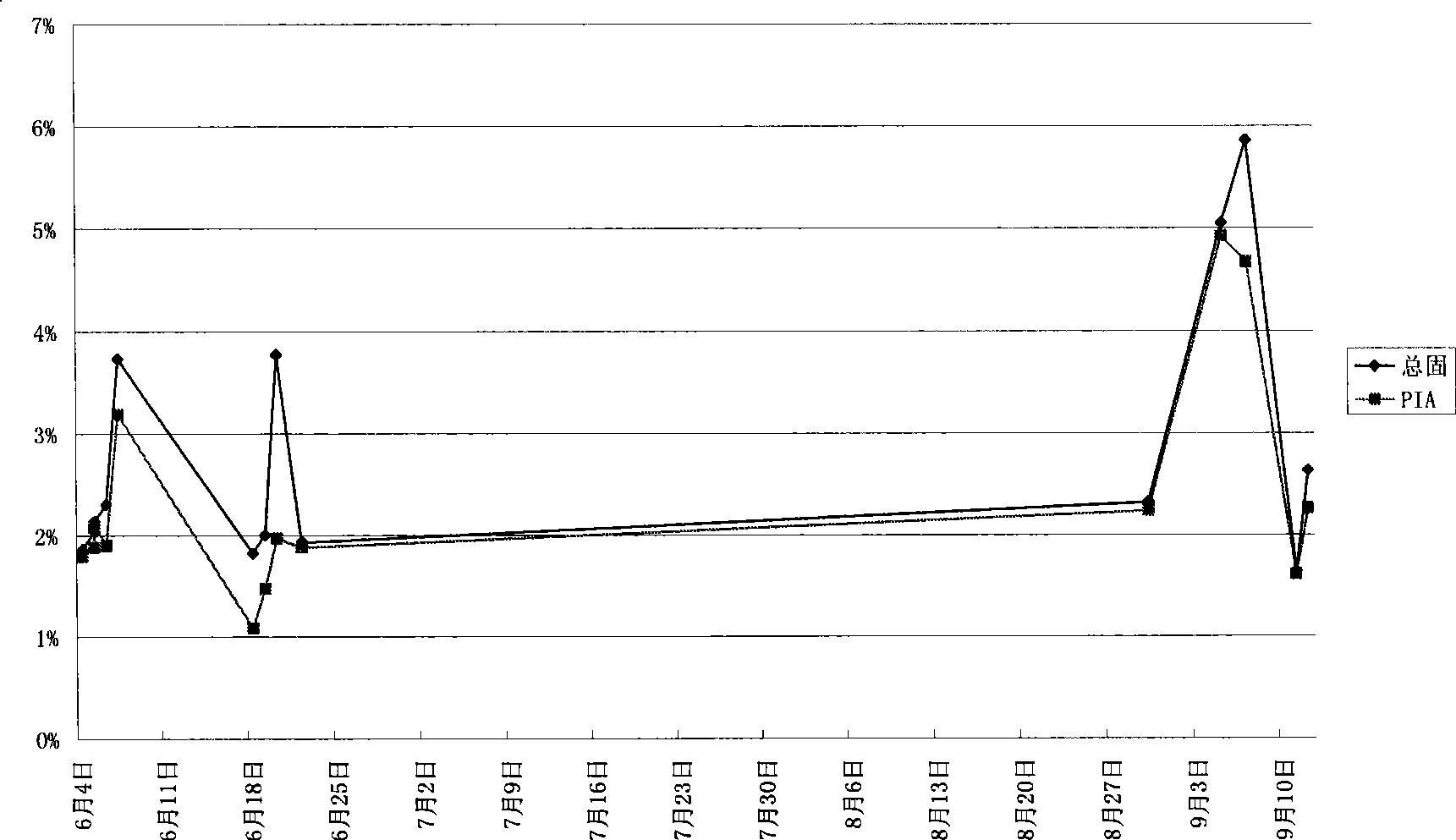

[0023] The filtering effect of JM-601 mainly depends on the total solids after filtering. See Table 1 for details. figure 2 :

[0024] Table 1: Total Solids Analysis Data

[0025] Sampling position JD-404 JD-602 JD-603 JD-604 May 25 1.03 0.82 0.62 0.25 May 26 0.63 0.57 0.17 May 29 0.64 0.53 3.93 0.19 May 30 2.87 0.53 2.05 0.18 June 4 0.46 0.38 1.86 0.21 0.52 0.53 2.03 0.18 June 5 0.61 0.95 2.95 0.25 0.6 0.66 2.13 0.25 June 6 0.62 0.66 2.3 0.25 June 7 0.65 0.56 3.73 0.23 June 12 0.64 0.66 3.8 0.25 0.74 0.51 3.14 0.28 June 18 0.72 1.42 1.82 0.32 June 19 0.54 0.79 2 0.2 June 20 0.46 0.6 3.77 0.23 June 21 0.31 0.78 1.4 0.23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com