Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

A drilling fluid and compound salt technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. Good, reduce the probability of differential pressure leakage, the effect of strong inhibition of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In 300 cubic meters of water, add 0.3% of drilling fluid viscosity enhancing agent PAC, 3% of carboxymethyl starch GD-K, 2% of water-dispersed cationic emulsified asphalt powder SFT-1, and 0.3% of anti-salt and anti-calcium in the formula Fluid loss reducer JT-1, 1% sulfonated phenolic resin SMP-2, 2% acid-soluble temporary plugging reservoir protection agent ZDS, 1% ultrafine calcium LG-130, 0.1% caustic soda NaOH are added to high-pressure mixing Mixing is carried out in the funnel, and after mixing evenly, the compound salt low-activity anti-slump drilling fluid is obtained.

Embodiment 2

[0055] In 300 cubic meters of water, add 0.25% of drilling fluid viscosity enhancing agent PAC, 2.5% of carboxymethyl starch GD-K, 1.7% of water-dispersed cationic emulsified asphalt powder SFT-1, and 0.25% of anti-salt and anti-calcium in the formula Fluid loss reducer JT-1, 1% sulfonated phenolic resin SMP-2, 2% acid-soluble temporary plugging reservoir protection agent ZDS, 1% ultra-fine calcium LG-130, 0.1% caustic soda NaOH, evenly added Mixing is carried out in the high-pressure mixing funnel, and the composite salt low-activity anti-slump drilling fluid is obtained after mixing evenly.

Embodiment 3

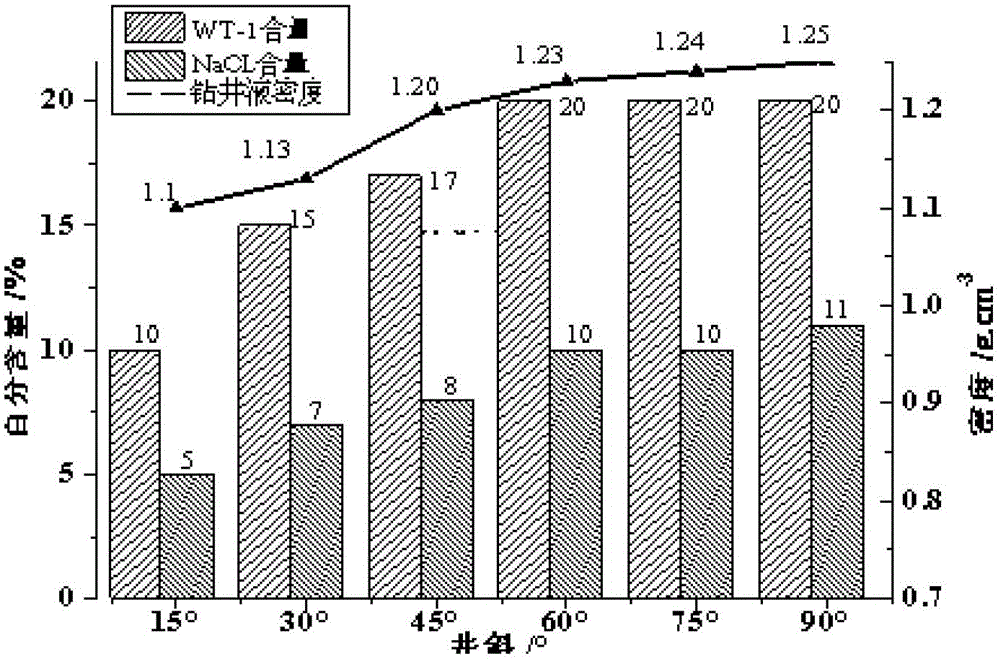

[0057] The kickoff point of Well Su 5-15-25H is 2615 meters deep (the bottom of Liujiagou is 2780 meters), and the mud system is converted at 2760 meters (well deviation 16°). The top of the Shiqianfeng Formation is dominated by reddish-brown mudstone, which is severely mud-forming, and the drill bit is prone to mud bagging. Before entering Shiqianfeng, WT-1 has a salt content as high as 10%, and the system has strong inhibition. The Shiqianfeng mudstone is formed and does not stick to the screen cloth. formula:

[0058] 0.2%PAC+0.2%JT-1+1%LG-130+2%ZDS+2%GD-K+1.5%SFT-1+1%SMP-2+0.1%NaOH+92%Water. (The above is abbreviated) Evenly add to the high-pressure mixing funnel for mixing, and after mixing evenly, the compound salt low-activity anti-slump drilling fluid is obtained.

[0059] Step 1) Drive the prepared compound salt low-activity anti-slump drilling fluid into the wellbore with a mud pump to replace the original drilling fluid in the wellbore;

[0060] Step 2) After spud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com