Patents

Literature

31results about How to "Strong collapse resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

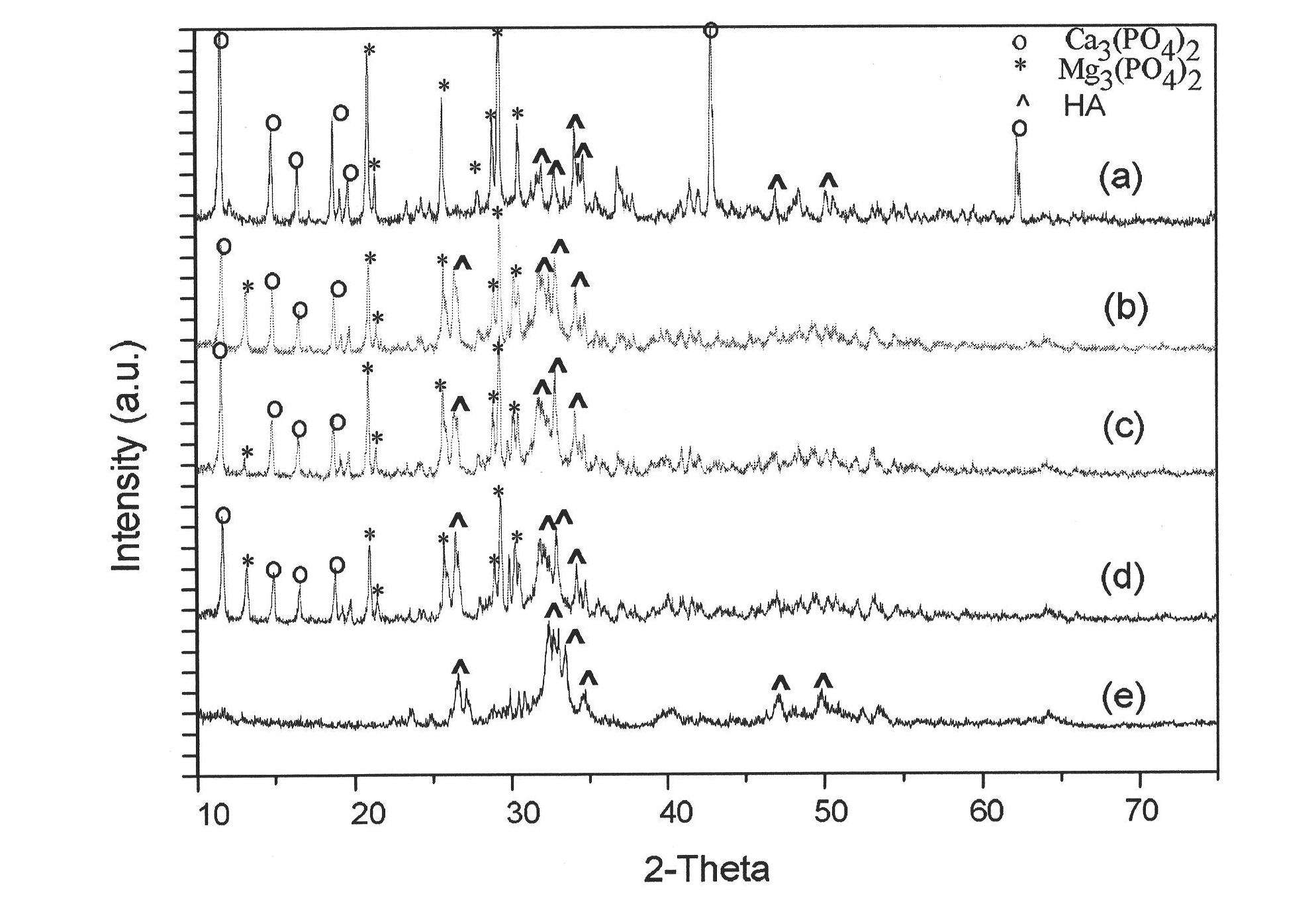

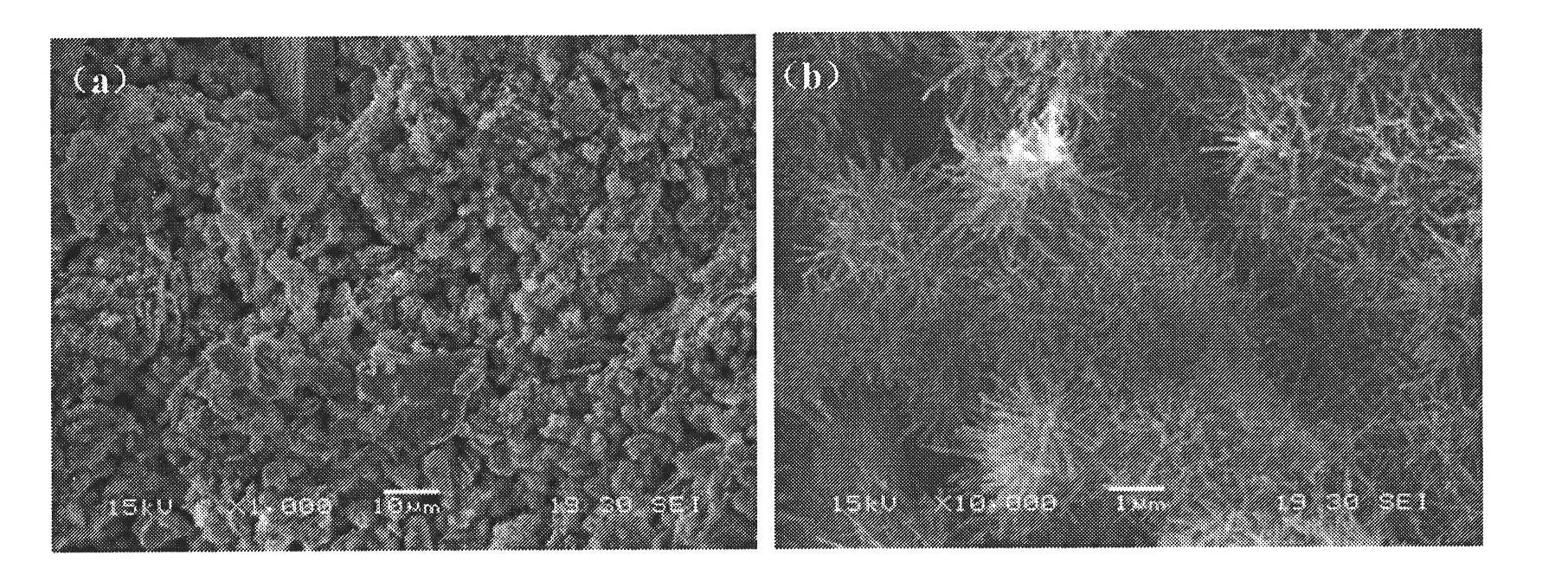

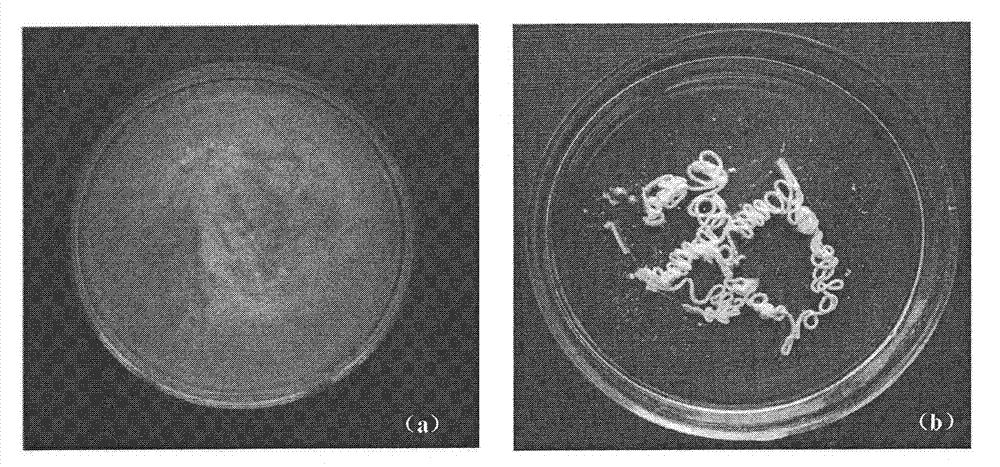

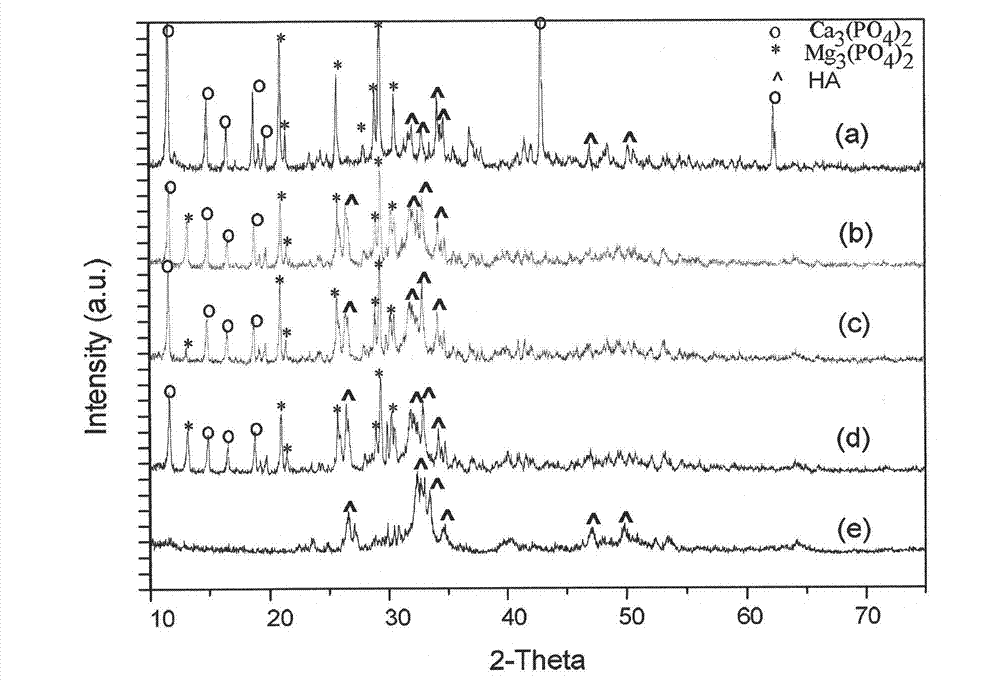

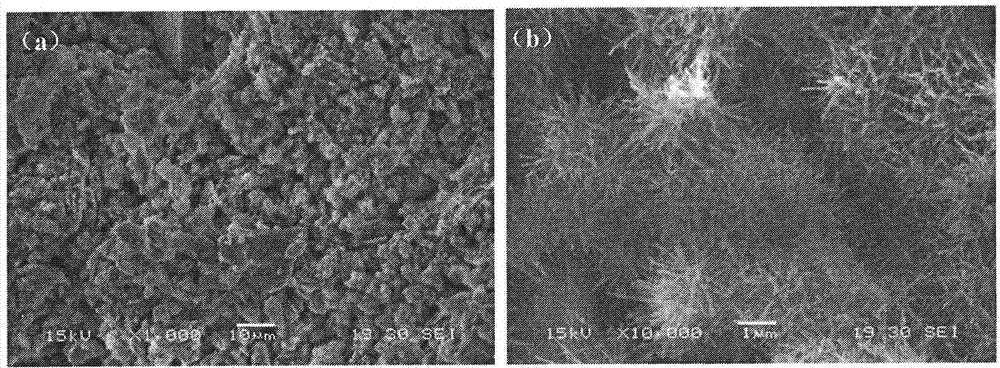

Calcium magnesium injectable bone cement and preparation method and application thereof

The invention discloses a product used for forming calcium magnesium injectable bone cement, comprising solid phase powder obtained by uniformly mixing composite phosphoric acid calcium salt and magnesium phosphate powder as well as curing solution obtained by dissolving dextrin and hydrophosphate in water. The invention also discloses a calcium magnesium injectable bone cement and preparation method and application thereof. The curing solution and solid phase powder in the product are uniformly mixed and blended into paste, thus obtaining water phase high efficiency scattering-resistant rapid curing bone cement capable of being injected with calcium magnesium and injectable product used for preparing bone tissue wound repairing. The invention is low in cost of raw materials, preparation method is simple, the obtained calcium magnesium injectable bone cement has strong scattering-resistance and rapid curing speed.

Owner:EAST CHINA UNIV OF SCI & TECH

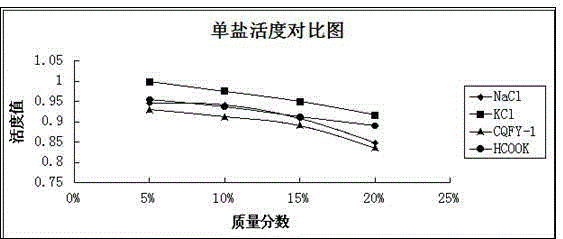

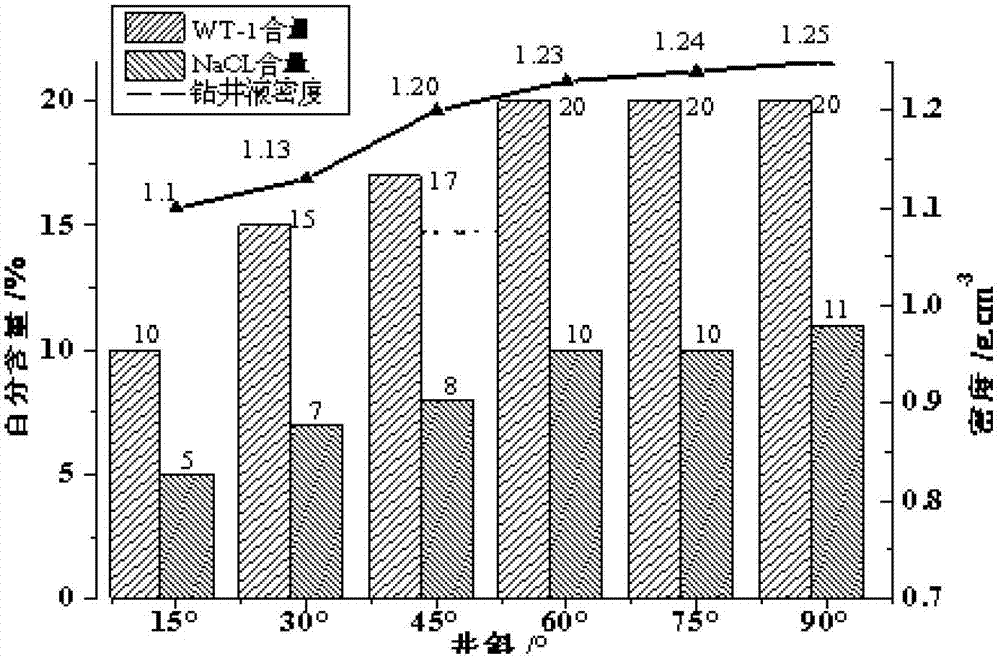

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363AAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

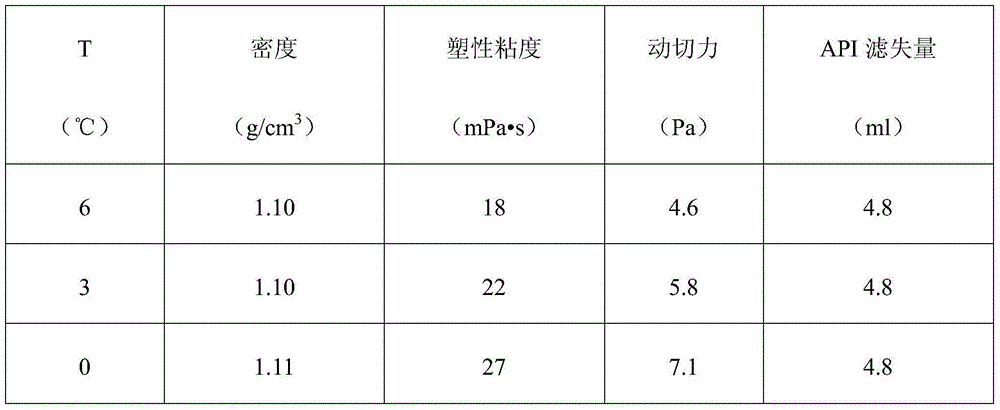

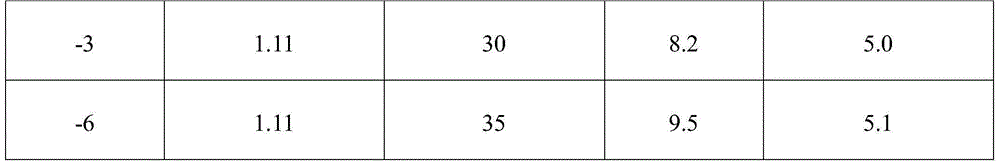

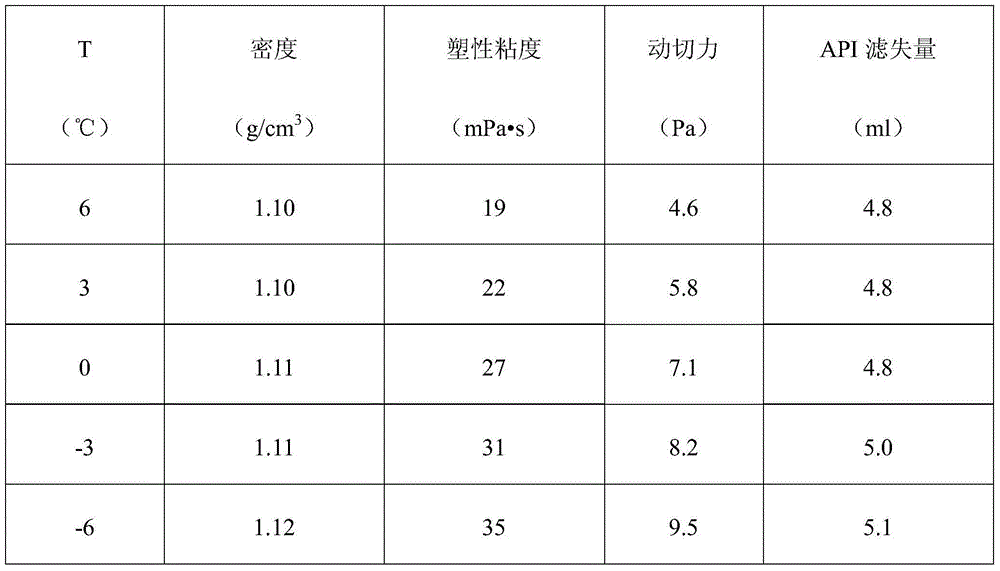

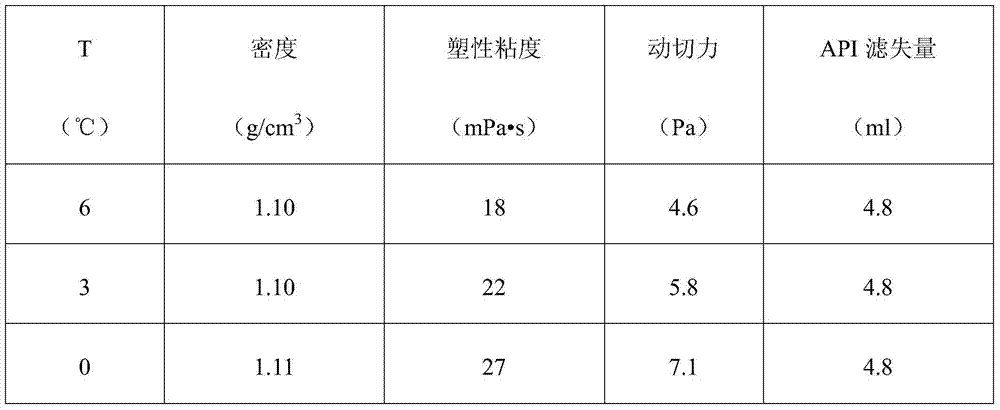

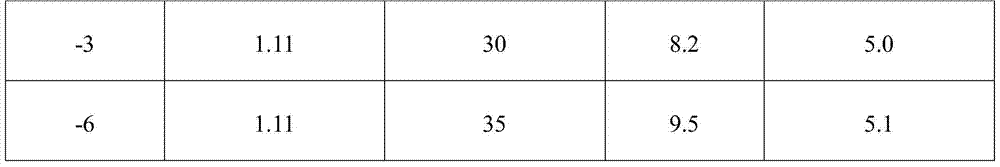

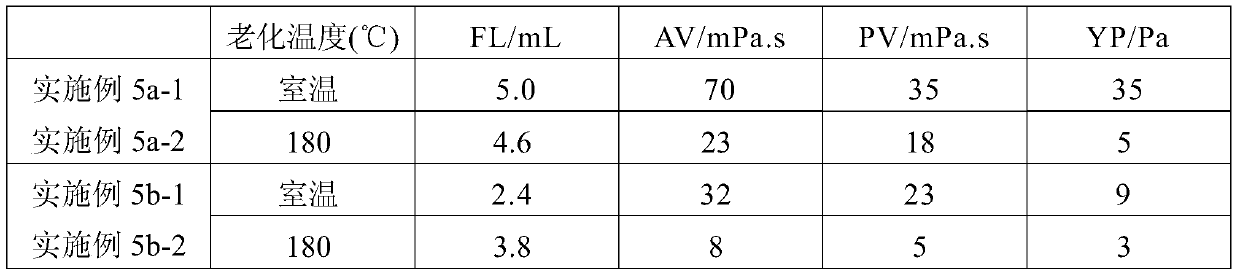

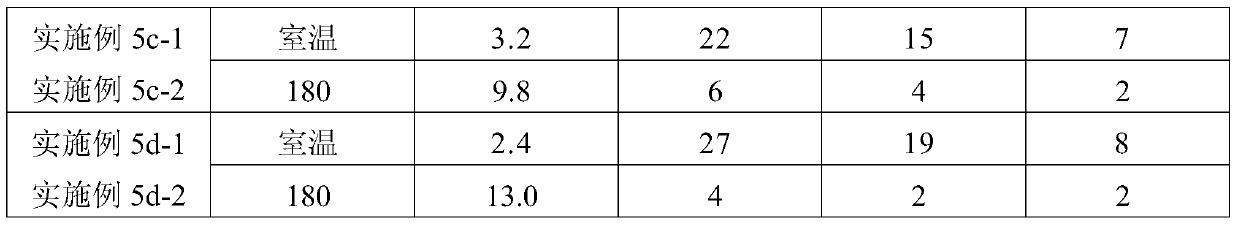

Deepwater drilling fluid

ActiveCN104559969AAvoid damageEnhanced inhibitory effectDrilling compositionSlurrySODIUM DODECYL BENZENE SULFONATE

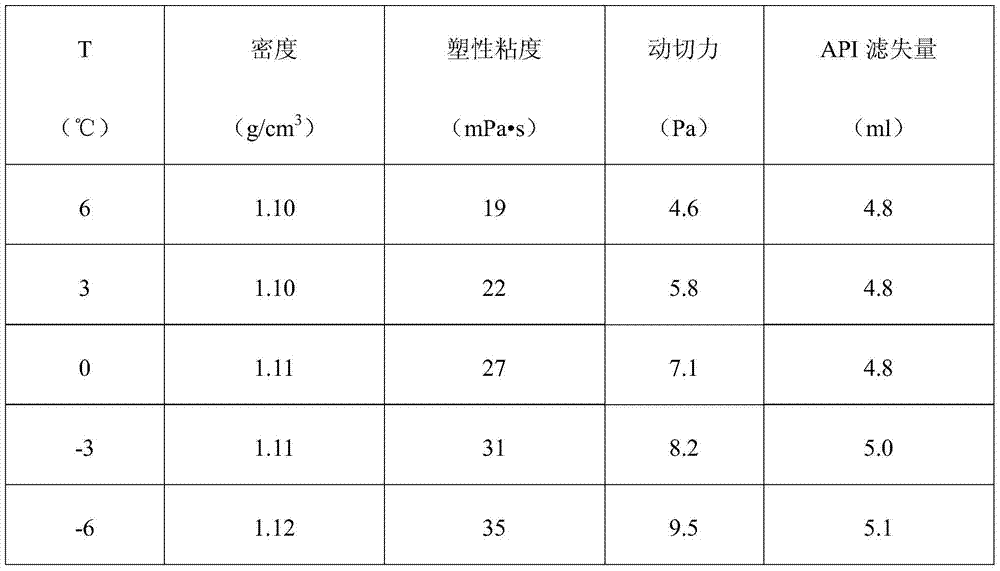

The invention discloses a deepwater drilling fluid. Every 1L of base slurry is composed of 1g of xanthan gum XC, 10-20g of sodium carboxymethyl cellulose, 20-30g of sulfonated phenol formaldehyde resin SMP-2, 30-50g of sodium silicate, 10g of polyvinylpyrrolidone PVP-K90, 15g of high modified asphalt KAHM, 50-100g of sodium chloride, 0.5g of sodium dodecyl benzene sulfonate, 0.5-1g of graphite and 0.2-0.5g of polyformaldehyde. The drilling fluid has the advantages of stable properties under cold conditions, favorable rheological behavior, high debris carrying capacity, excellent mud shale hydration expansion inhibition capacity, excellent hydrate generation inhibition capacity, low economic cost and small environmental pollution, and is especially suitable for deepwater drilling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

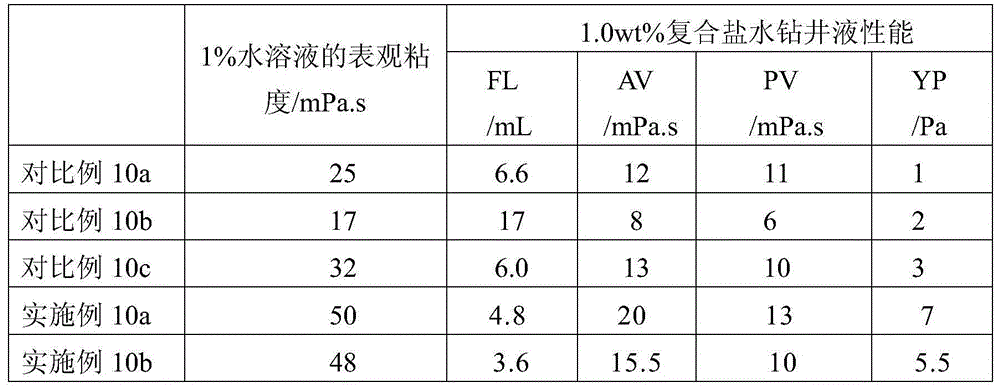

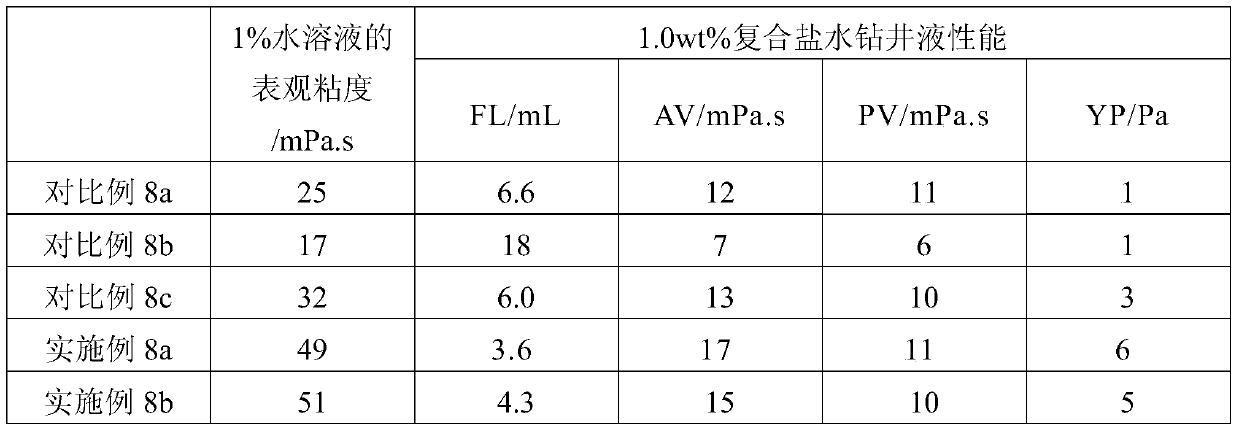

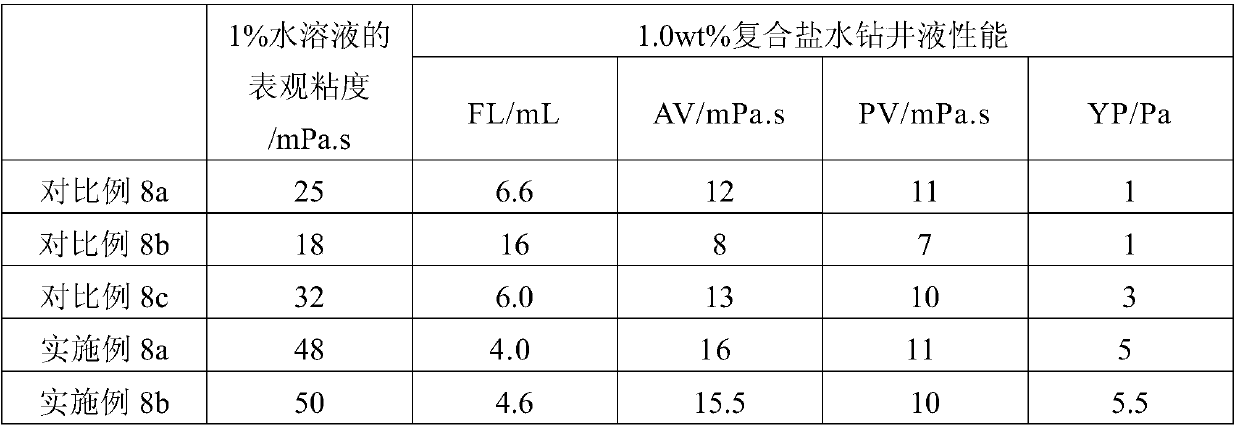

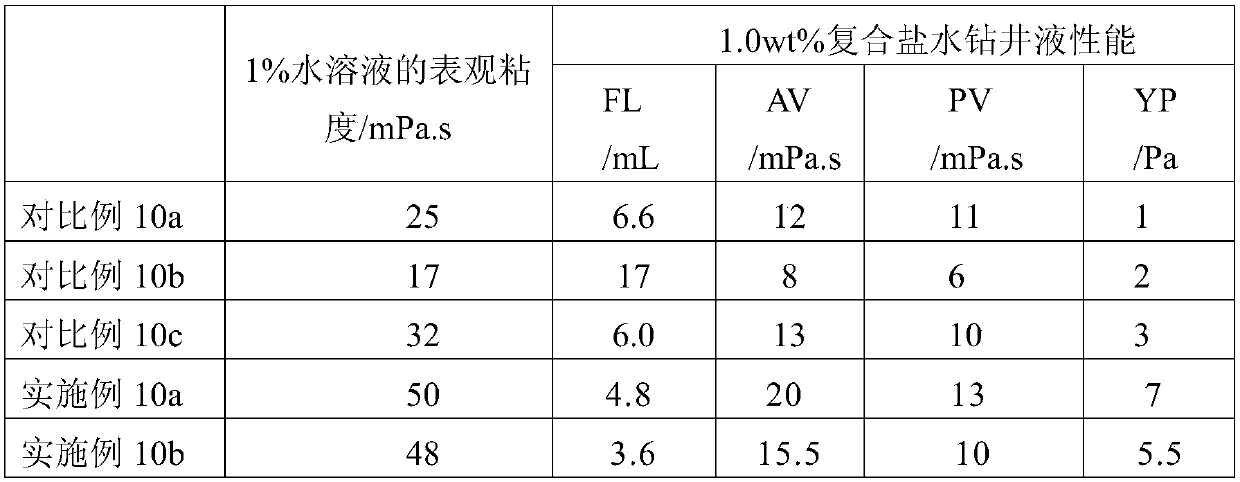

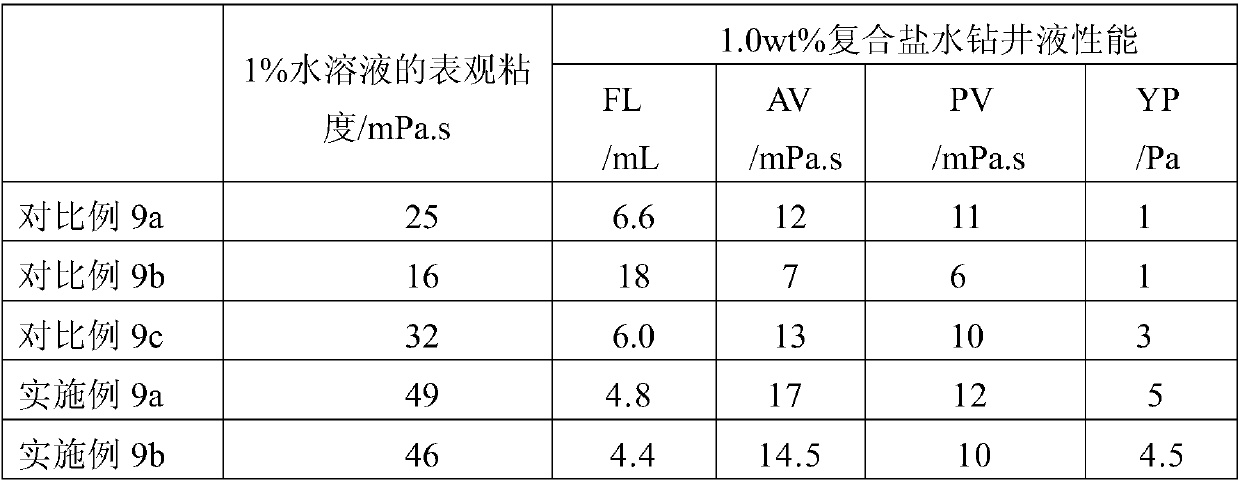

Inorganic-organic polymer processing agent for drilling fluid and preparation method thereof

ActiveCN105154030AParticipation responds wellIncrease the amount of introductionDrilling compositionPolymer scienceFiltration

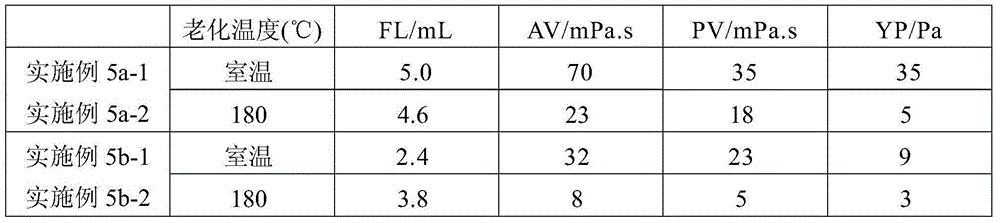

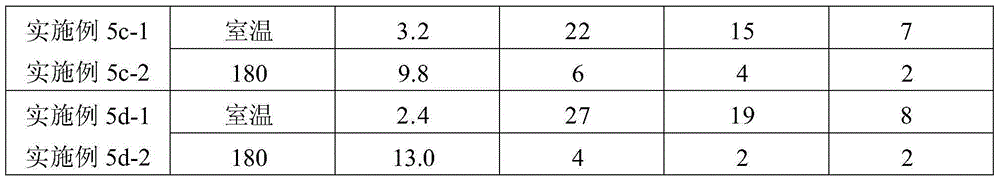

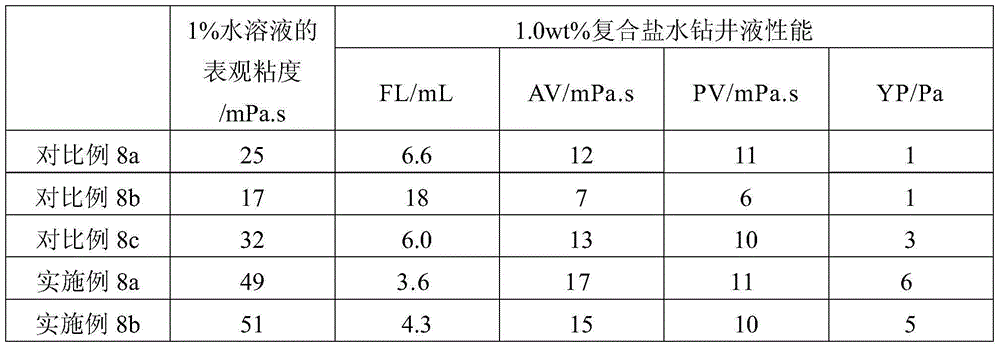

The invention provides an inorganic-organic polymer processing agent for drilling fluid polymerized from sulfonic acid monomer, carboxylic acid monomer, nonionic monomer and inorganic material in the presence of initiator, and the inorganic material includes bentonite. The inorganic-organic polymer processing agent for drilling fluid has good effect on filtration reduction effect in fresh water drilling fluid, brine drilling fluid, saturated brine drilling fluid and compound brine drilling fluid. The inorganic-organic polymer processing agent for drilling fluid has strong anti-sloughing capability and high permeability recovery, can control hydration and dispersion of the shale effectively, can control mud making of the clay effectively, and has good effect on hydrocarbon reservoir protection. Moreover, the preparation method is simple, the sources of raw materials are wide, and the promotion prospect is wide. The invention also provides a preparation method of inorganic-organic polymer processing agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

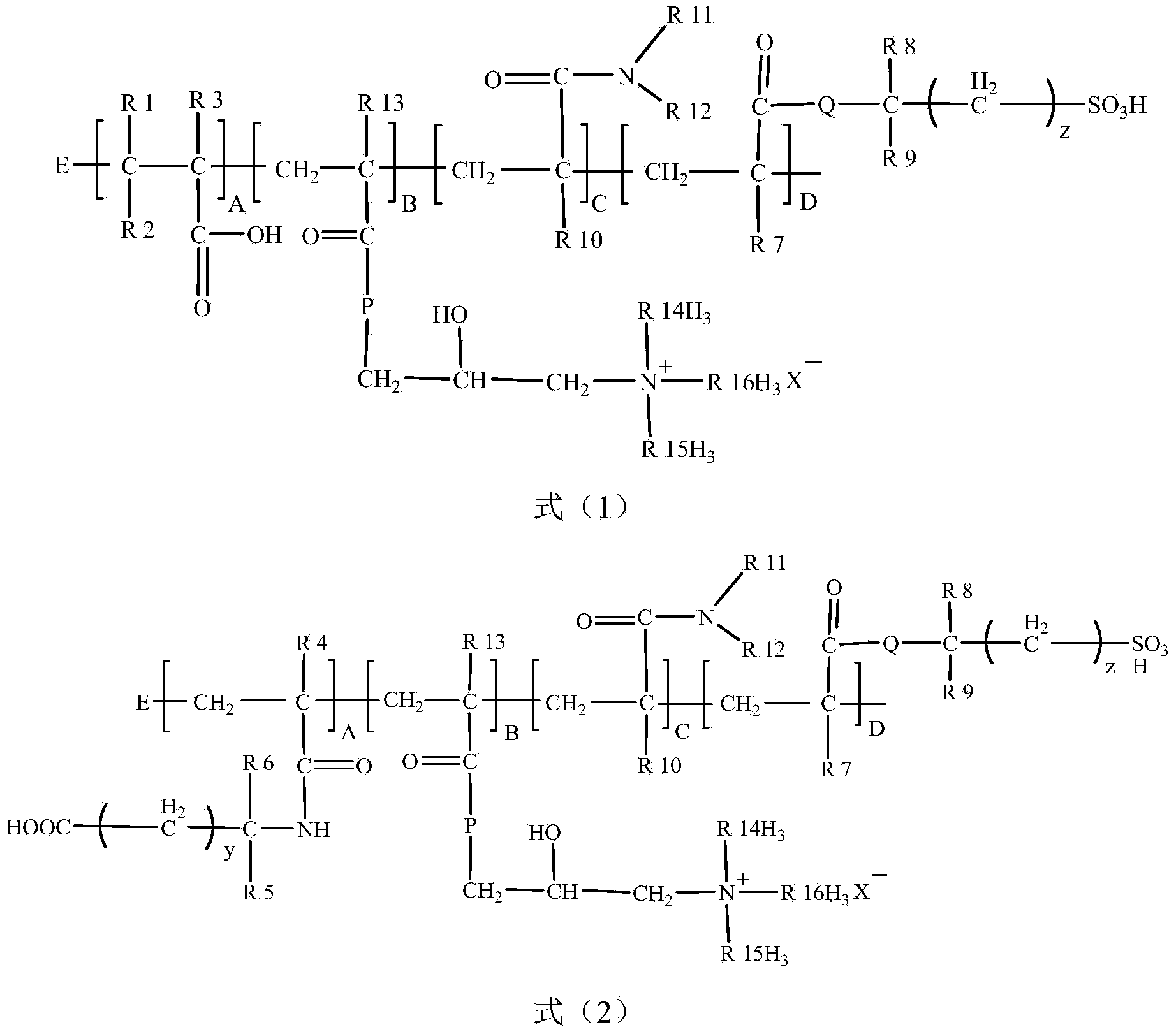

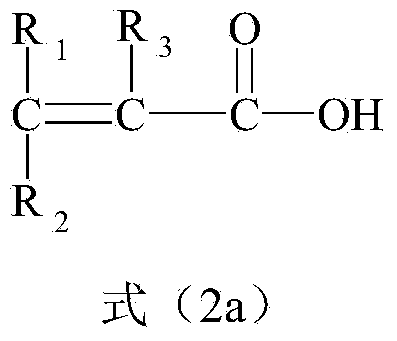

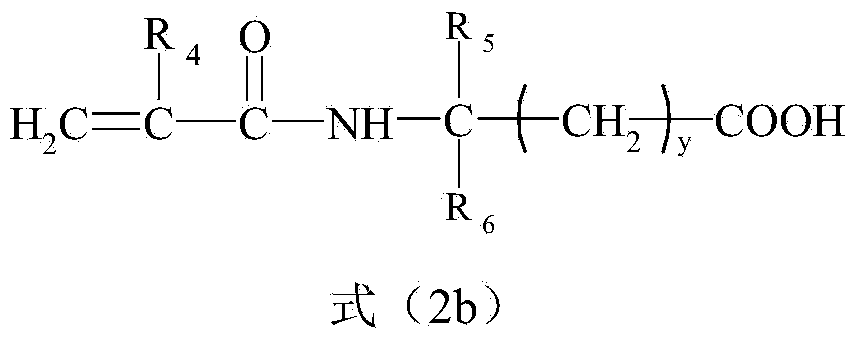

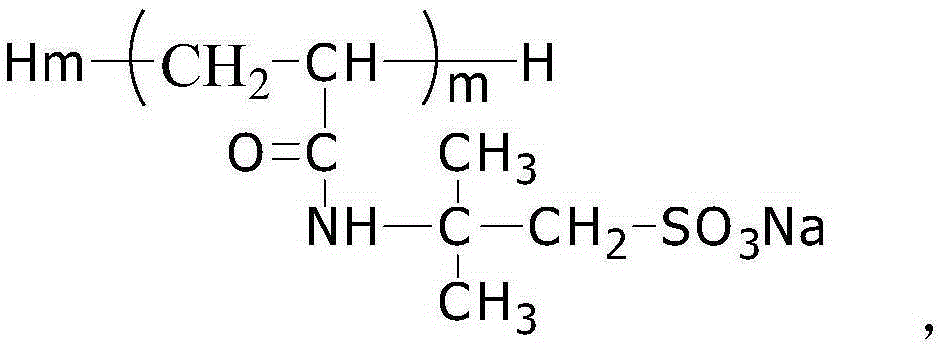

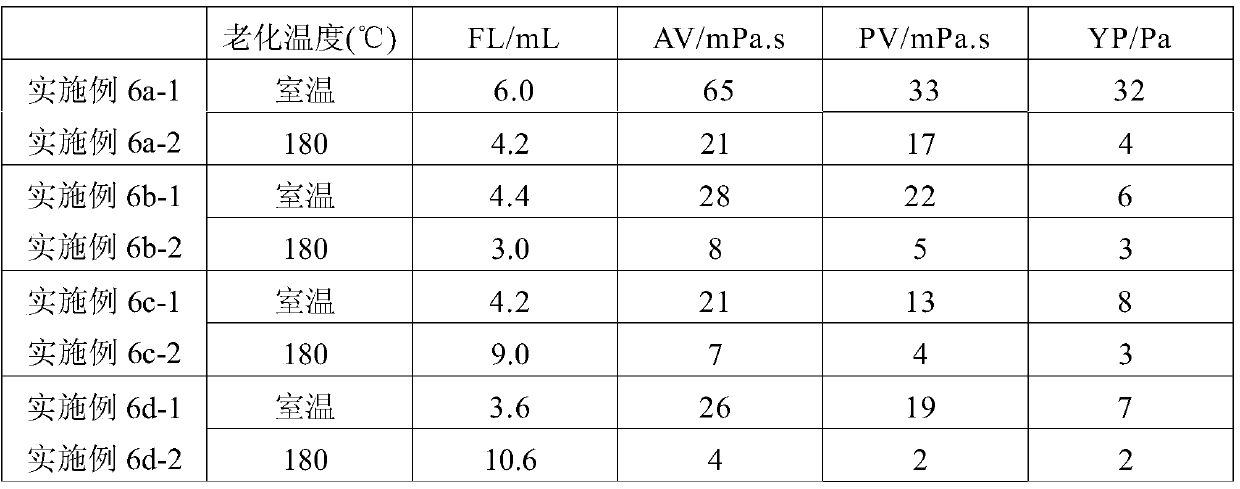

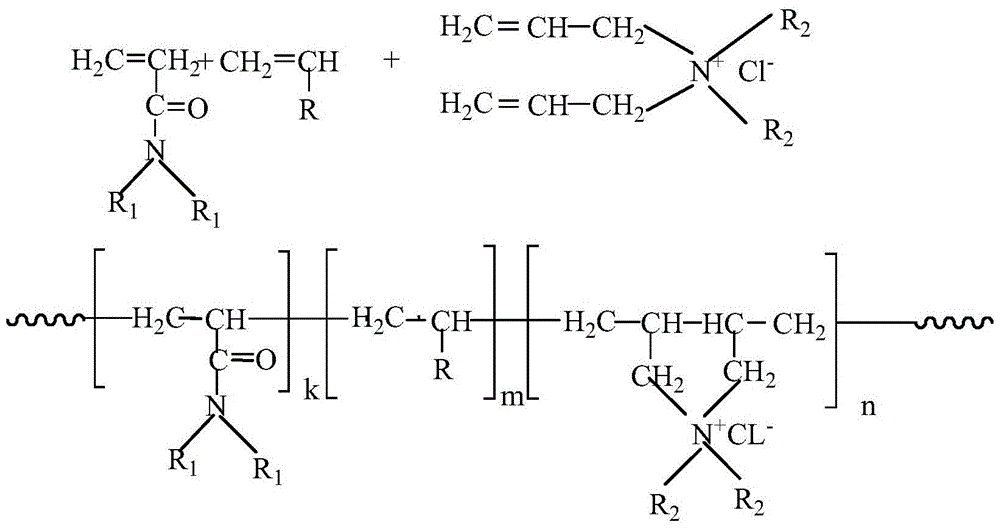

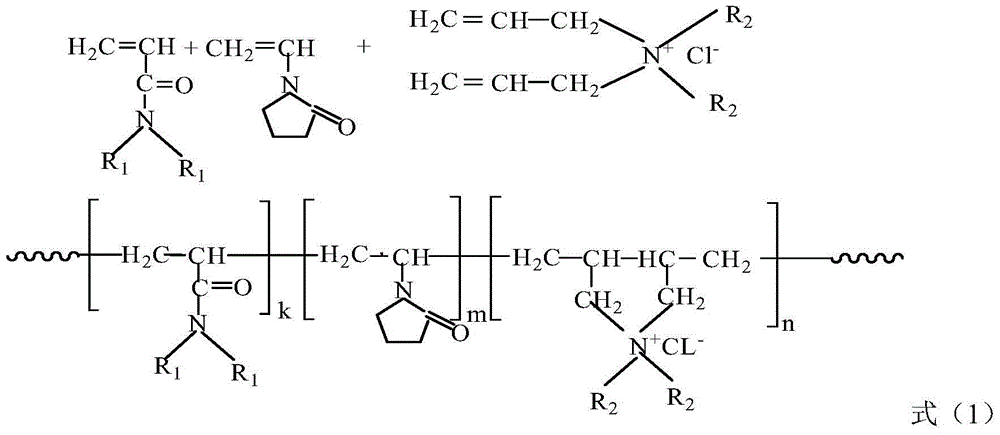

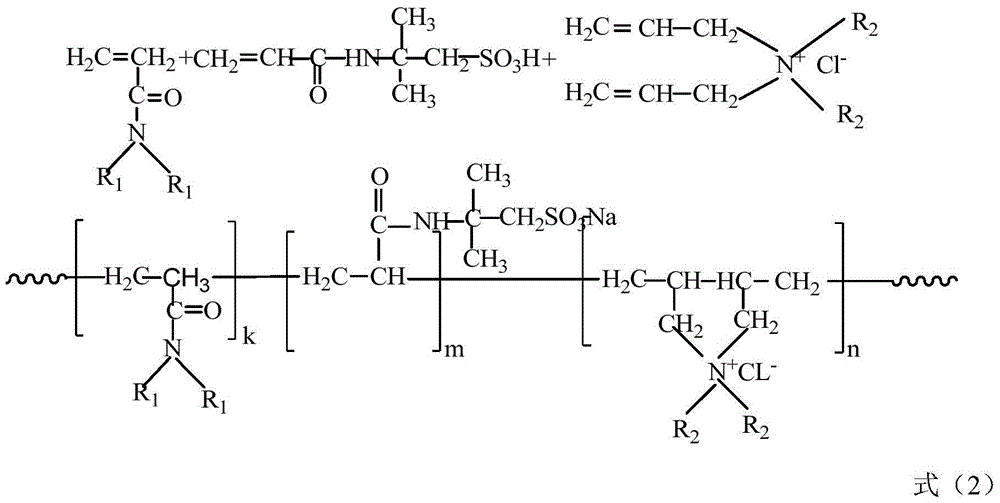

Treating agent for zwitter-ion inorganic-organic monomer polymer drilling fluid and preparation method of treating agent

ActiveCN104357026AImprove thermal stabilityExcellent calcium resistanceDrilling compositionCarboxylic acidSolvent

The invention relates to a treating agent for a zwitter-ion inorganic-organic monomer polymer drilling fluid and a preparation method of the treating agent, and belongs to the technical field of synthesis and preparation of a water-soluble polymer material. The preparation method comprises the following steps: adopting carboxylic acid monomers A, sulfonic acid monomers B, nonionic monomers C, cationic monomers D and inorganic material monomers E as raw materials; feeding the raw materials, wherein the ratio of the amounts of substances of the carboxylic acid monomers A to the sulfonic acid monomers B to the nonionic monomers C to the cationic monomers D is (5-40):(25-10):(65-35):(5-15), and the dosage of inorganic material monomers E is 5%-25% of the total mass of the carboxylic acid monomers A, the sulfonic acid monomers B, the nonionic monomers C, the cationic monomers D and the inorganic material monomers E; adopting water as a solvent, and initiating polymerization through an oxidation-reduction initiation system to obtain the treating agent. The treating agent has higher anti-collapse ability, can effectively control hydration and dispersion of clay shale and mud making of clay, has a better hydrocarbon reservoir protection effect, and is high in permeability recovering value, simple in production technology, extensive in raw material sources and wide in popularization prospects.

Owner:CHINA PETROCHEMICAL CORP +1

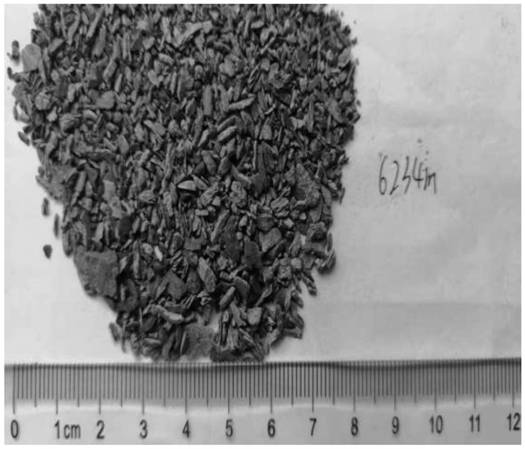

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly chlorine-free drilling fluid and preparation method thereof

InactiveCN105255459ANo pollutionEasy to degradeDrilling compositionPhysical chemistryEnvironmental engineering

The invention relates to environment-friendly chlorine-free drilling fluid, which is characterized in that the environment-friendly chlorine-free drilling fluid is prepared from the following components in percentages by weight: 8 to 18 percent of chlorine-free strongly inhibitory compound salt; 0.2 to 0.3 percent of drilling fluid tackifier; 1.5 to 3 percent of water-dispersible cationic emulsified asphalt powder; 0.2 to 0.4 percent of salt-resistant and calcium-resistant filtrate reducer; 0.2 to 0.5 percent of natural polymer filtrate reducer; 2 to 4 percent of acid-soluble temporarily plugged reservoir protection agent; 0.1 percent of caustic soda; and the balance of clean water. The environment-friendly, chlorine-free, low-density, low-solid phase, strong-chemical inhibition and anti-collapse drilling fluid can inhibit the collapse of mudstone sections under the condition of low density, and meets the friction drag reduction of long open hole sections with low solid phase.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Positive-charged polyglycol anti-collapse drilling fluid

InactiveCN105038736AStrong collapse resistanceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention discloses a positive-charged polyglycol anti-collapse drilling fluid which mainly solves the problems of low anti-collapse capacity and narrow application range in the water-based drilling fluid in the prior art. The positive-charged polyglycol anti-collapse drilling fluid comprises the following components in parts by weight: 2-4 parts of sodium bentonite, 0.1-0.2 part of sodium carbonate, 3-5 parts of positive-charged polyglycol, 2-4 parts of high-molecule inhibitor, 2-4 parts of positive-charged wall protector, 0.5-3 parts of fluid loss additive for drilling fluids, 1-2 parts of plugging agent for drilling fluids, 4-6 parts of low-fluorescence water-based lubricant RY-838, 2-3 parts of low-fluorescence sulfonated asphalt and 100 parts of water. By blending the weighting agent, the density of the drilling fluid reaches 1.30-1.45 g / cm<3>. The positive-charged polyglycol anti-collapse drilling fluid has the advantages of high anti-collapse capacity, longer stability period, high temperature resistance, high solid-phase content, wide application range and the like.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

Method for manufacturing anti-friction silicon-based collapse prevention well drilling liquid

InactiveCN104962257AStrong collapse resistanceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention discloses a method for manufacturing anti-friction silicon-based collision prevention well drilling liquid. The method includes heating water until the temperature of the water reaches 80 DEG C, adding sodium bentonite into the water at the rotational speed of 600-800rpm, uniformly mixing the sodium bentonite and the water with each other at the rotational speed of 600-800rpm to obtain first mixtures, adjusting the rotational speed until the rotational speed reaches 3000-4000rpm, adding sodium carbonate into the first mixtures, stirring the sodium carbonate and the first mixtures for 30-60min, then stirring the sodium carbonate and the first mixtures at the stirring speed of 9000-10000rpm for 30-40min to obtain second mixtures, and maintaining the second mixtures; sequentially adding organic silicon stabilizers for well drilling liquid, organic silicon diluents and organic silicon potassium humate into the second mixtures at the stirring speed of 6000-8000rpm and stirring the organic silicon stabilizers for the well drilling liquid, the organic silicon diluents, the organic silicon potassium humate and the second mixtures at the stirring speed of 6000-8000rpm for 30-60min to obtain third mixtures; adding encapsulating agents for the well drilling liquid and filtrate-loss reducers for the well drilling liquid into the third mixtures; adding blocking agents for the well drilling fluid, low-fluorescence water-based lubricants RY-838 and low-fluorescence sulfonated bitumen into the third mixtures and uniformly mixing the blocking agents for the well drilling fluid, the low-fluorescence water-based lubricants RY-838, the low-fluorescence sulfonated bitumen and the third mixtures with one another to obtain fourth mixtures; regulating pH (potential of hydrogen) values of the fourth mixtures; regulating the density of the fourth mixtures. The method has the advantages of high collapse prevention capacity, wide application range, capability of prolonging stability periods and the like.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

Drilling fluid with aquo-complex inhabitation performance

InactiveCN105542731AAvoid damageEnhanced inhibitory effectDrilling compositionCelluloseIsooctyl alcohol

The invention discloses drilling fluid with aquo-complex inhabitation performance. The drilling fluid is prepared by adding a treating agent into basic mud. The treating agent in each L of the basic mud is prepared from 1-2 g of potassium polyacrylamid KPAM, 40-60 g of sulfonated-pheno-formoldehyde resin SMP-2, 10-40 g of sulfonated bitumen SAS-1, 10 g of extreme-pressure lubricant KRH, 15-30 g of superfine calcium carbonate QS-2, 10-20 g of low-viscosity polyanionic cellulose LV-PAC, 85-170 g of aquo-complex inhibitor and 10 g of isooctyl alcohol. The partial treating agent used in the drilling fluid has multiple functions for ocean oil gas drilling and has advantages of being economical, low in cost, easy to decompose and small in environment damage. The drilling fluid has strong shale hydration inhibiting and collapse preventing functions, is good in rheological property, has an obvious aquo-complex inhibiting effect, meets various requirements needed by ocean oil gas drilling working conditions, and is suitable for ocean oil gas drilling operation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Anti-sloughing drilling fluid as well as preparation method and application thereof

ActiveCN113637464AStrong collapse resistanceRemarkable anti-collapseDrilling compositionWell drillingGraphene

The invention relates to an anti-sloughing drilling fluid for a fractured carbonate rock stratum and a preparation method and application of the anti-sloughing drilling fluid in the field of petroleum drilling. The anti-sloughing drilling fluid can be prepared from the following components in parts by weight: 1000 parts by weight of water, 15 to 40 parts by weight of drilling fluid bentonite, 5 to 35 parts by weight of a micro-nano blocking agent, 20 to 70 parts by weight of a temperature-sensitive blocking anti-collapse agent, 15 to 30 parts by weight of graphene hydrogel and 0 to 1600 parts by weight of an inert weighting agent. The anti-sloughing drilling fluid disclosed by the invention has high anti-sloughing performance, rheological property, temperature resistance and lubricating property, can effectively reduce the well wall instability risk of a fractured carbonate rock stratum, reduce bit bouncing and blocking and ensure underground safe construction, and has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

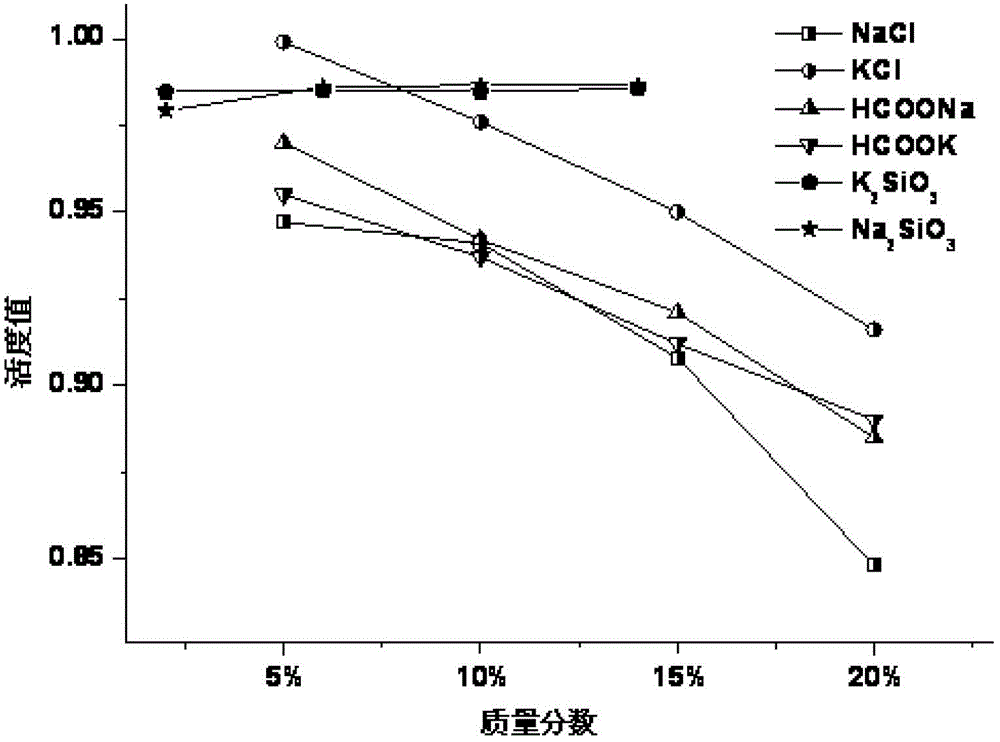

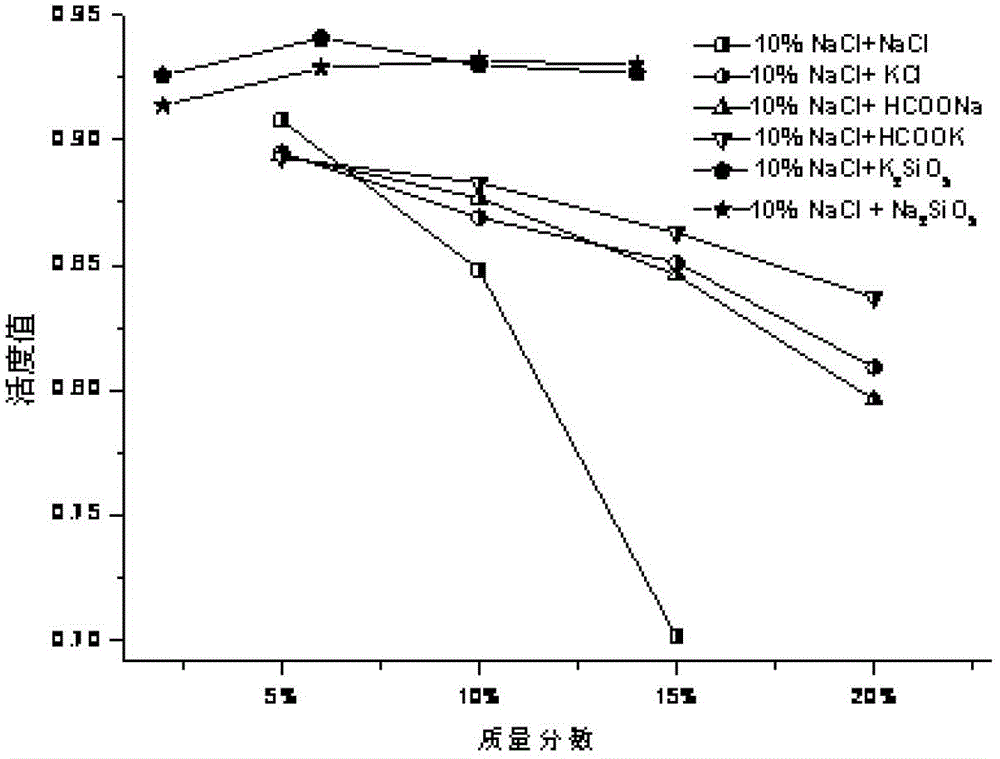

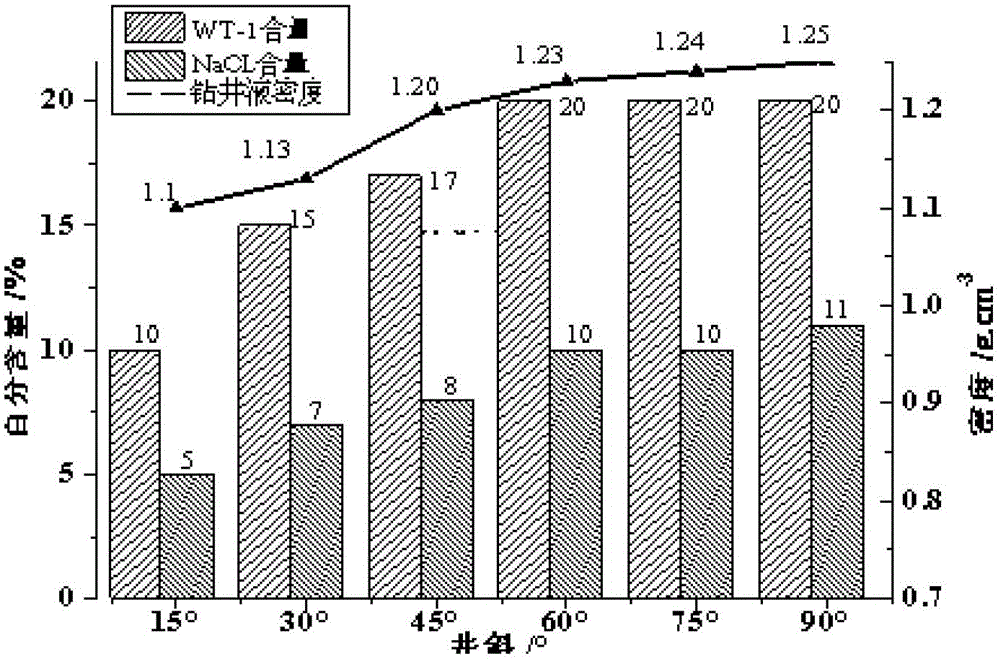

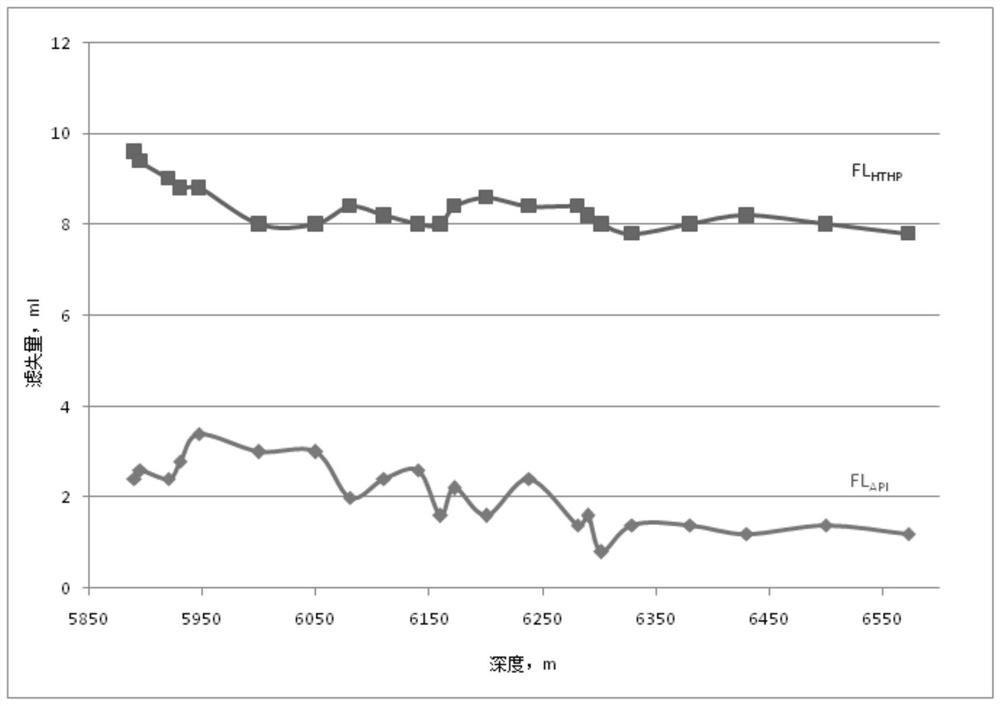

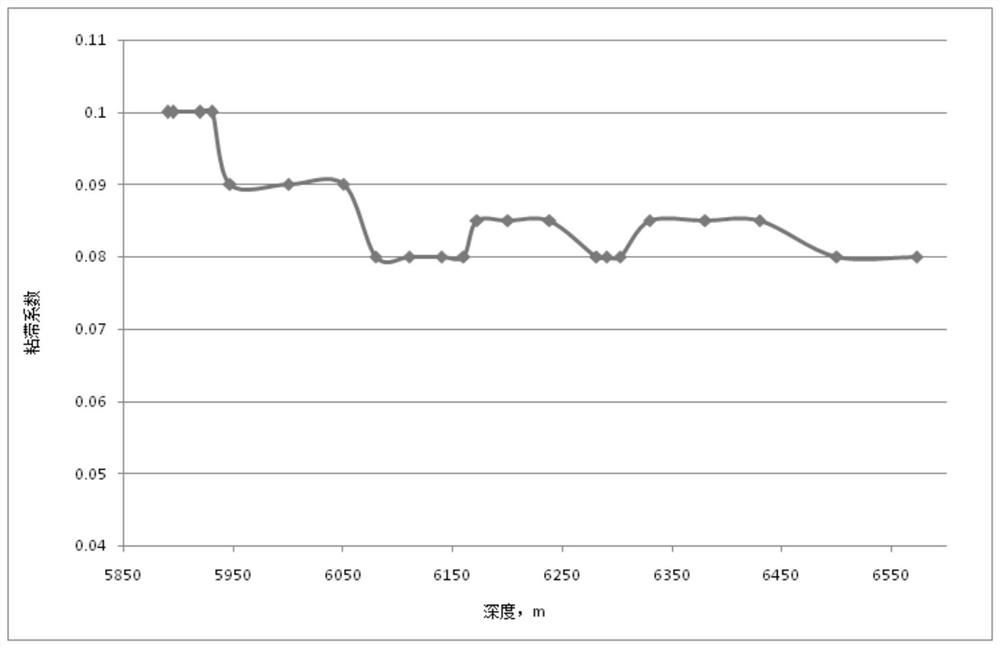

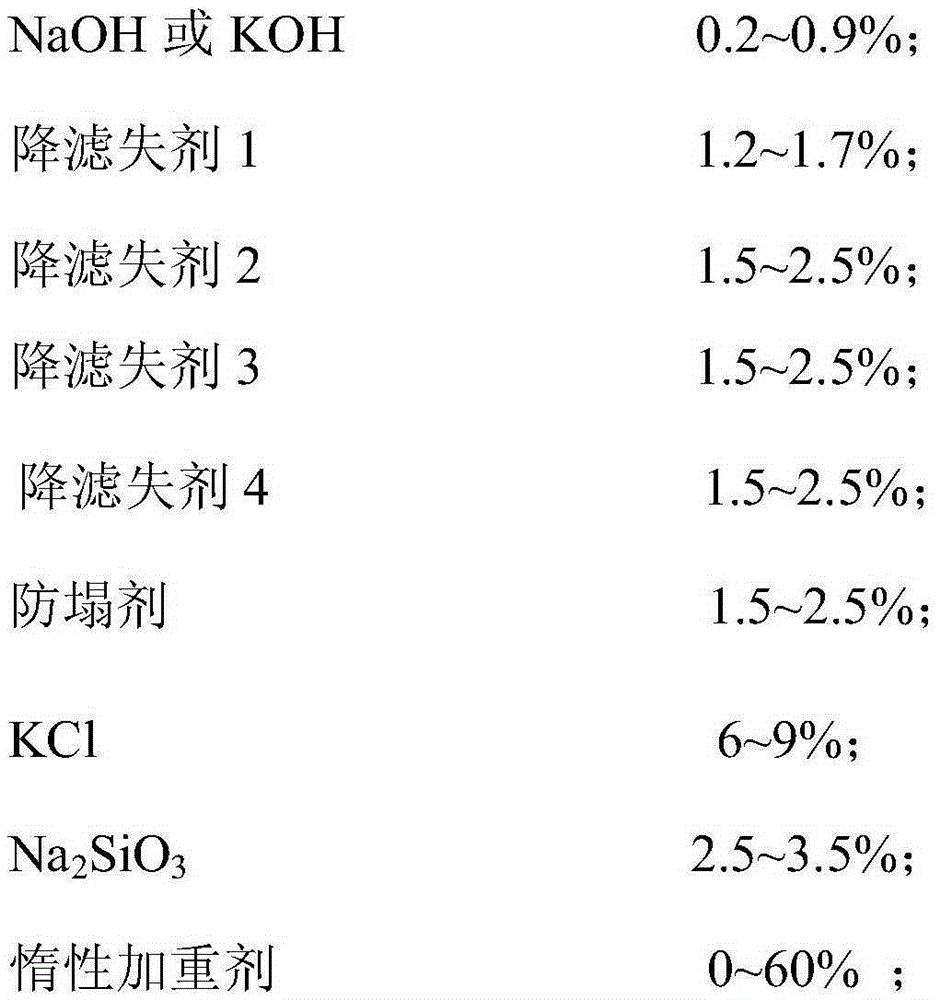

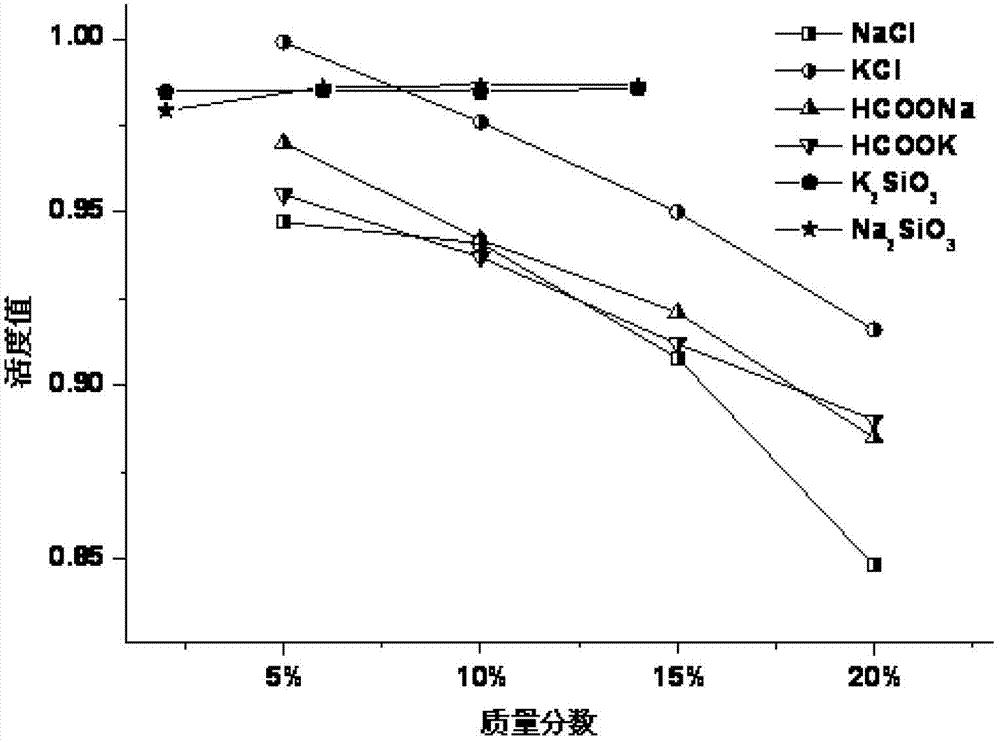

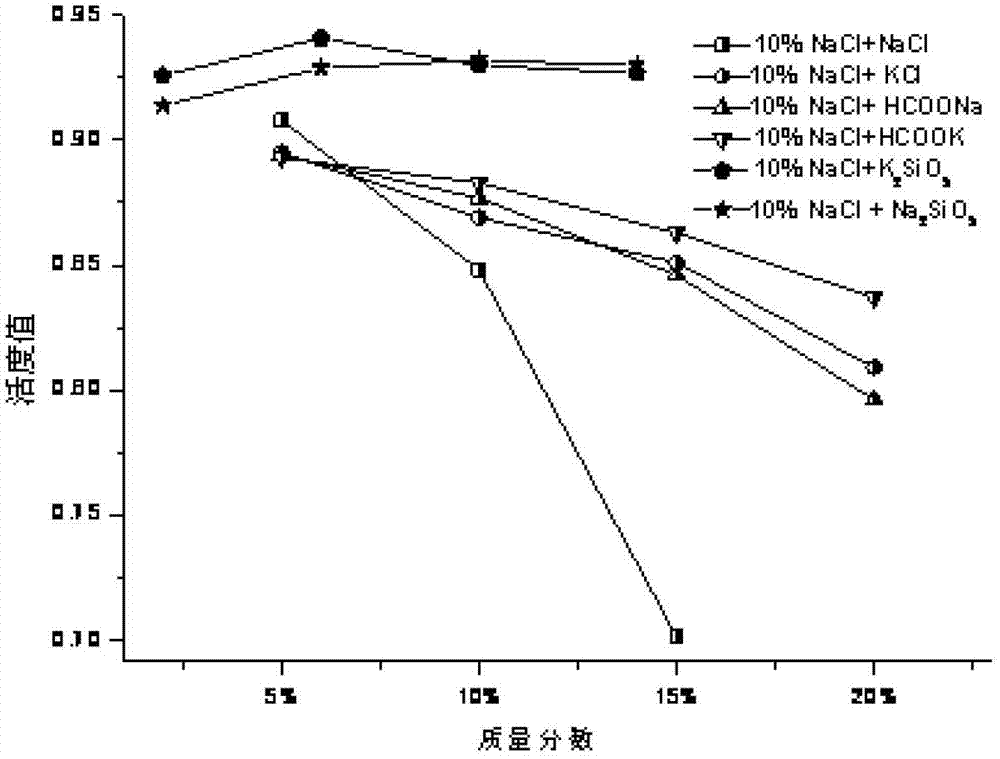

na2sio3-kcl anti-collapse drilling fluid and preparation method thereof

ActiveCN103740343BLow costSolve technical problems of collapseDrilling compositionWater basedReducer

The invention discloses a Na2SiO3-KCl anti-collapse drilling fluid and a preparation method thereof. The Na2SiO3-KCl anti-collapse drilling fluid consists of the following substances in bentonite slurry in percentage by mass: 0.12-0.2% of Na2CO3, 0.2-0.9% of NaOH or KOH, 1.2-1.7% of filtrate reducer 1, 1.5-2.5% of filtrate reducer 2, 1.5-2.5% of filtrate reducer 3, 1.5-2.5% of filtrate reducer 4, 1.5-2.5% of anti-collapse agent, 6-9% of KCl, 2.5-3.5% of Na2SiO3 and 0-60% of inert weighting agent, wherein the bentonite slurry is prepared by the steps of mixing bentonite and water based on the bentonite content of 20-32g / l, and adding Na2CO3 accounting for 0.12-0.2% of the total mass of the two. The preparation method of the drilling fluid is characterized by uniformly mixing the components in sequence according to proportions. The drilling fluid facilitates field maintenance, has stable performance, can balance the formation pressure of a high-pressure interval, and is a low-cost and highly environment-friendly ideal anti-collapse drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

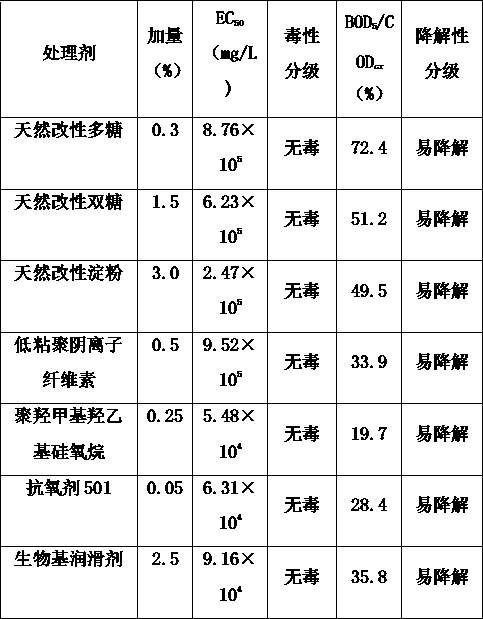

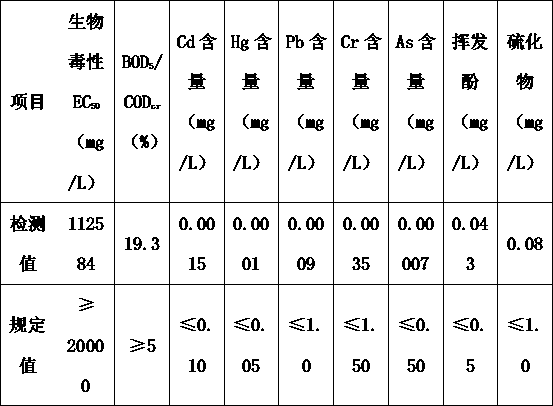

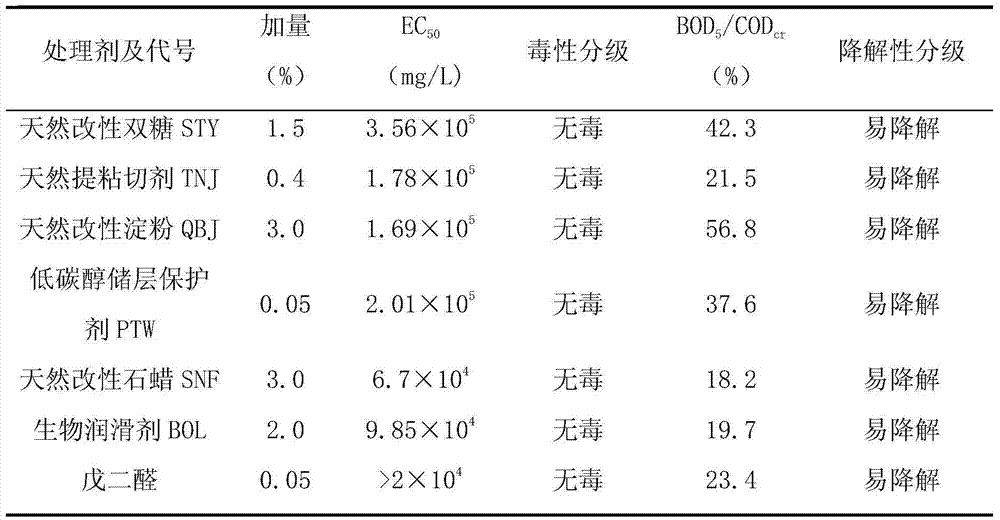

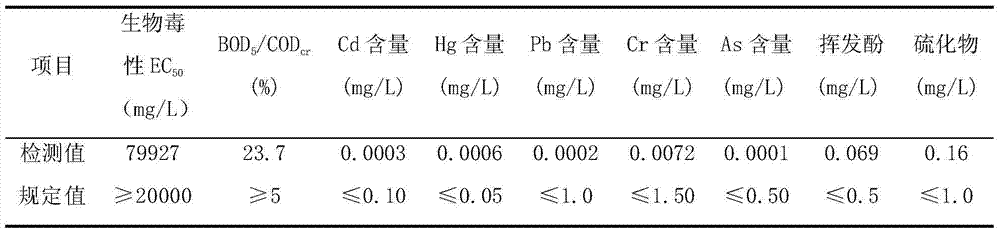

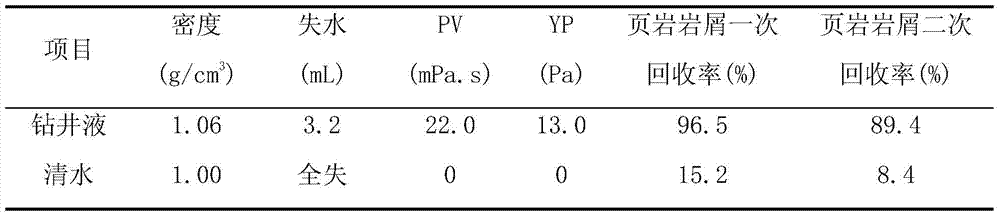

Naturally-degradable environment-friendly drilling fluid

The invention provides a naturally-degradable environment-friendly drilling fluid. The drilling fluid comprises the following components in parts by weight: 3.0%-7.0% of a shale inhibitor, 1.0%-3.0% of a natural anti-sloughing agent, 1.0%-5.0% of a natural blocking agent, 0.3%-0.5% of a natural viscosity-increasing cutting agent, 1.5%-3% of a natural fluid loss agent, 0.5%-4.0% of a lubricant, 0.1%-0.3% of polyhydroxymethyl hydroxyethyl siloxane, 0.02%-0.07% of an antioxidant and the balance of water. The drilling fluid can be applied to safe drilling and completion construction of exploratorywells, special process wells and horizontal wells in Changqing areas, six functions of stabilizing a well wall, preventing leakage and stopping leakage, carrying sand and suspending sand, purifying aborehole, protecting a reservoir and protecting the environment are realized, the drilling fluid has the characteristics of no biotoxicity, no chemical toxicity, biodegradability, environmental protection, strong anti-collapse ability, good plugging effect, effective reduction of stratum collapse ability, smooth and compact mud cake like a film, good lubricity, low damage to a low-porosity, low-permeability and low-abundance oil reservoir, and simple and feasible formula and slurry preparation process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

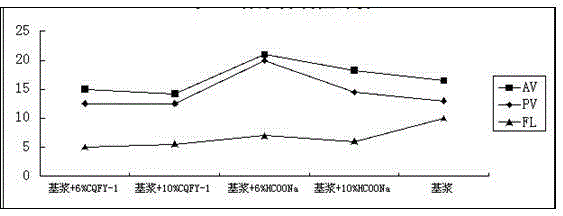

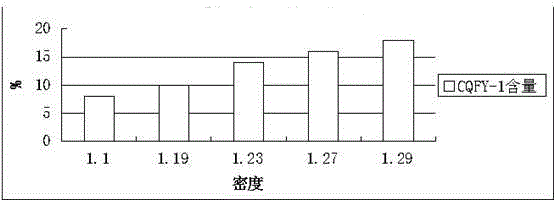

Preparing process of low-cost formate drilling flushing fluid

The invention discloses a preparing process of low-cost formate drilling flushing fluid. The preparing process includes: 1, heating water to above 80 DEG C, adding sodium bentonite, and performing uniform mixing at the speed of 600 to 800 rpm; continuing mixing at the speed of 6000 to 8000 rpm for 30 to 40 min, and performing curing; 2, adding in order sodium formate, coating agent for drilling fluid, and inhibitor for drilling fluid, and performing mixing for 30 to 60 min; 3, adding in order well-wall protectant HF-GRA-II for drilling fluid, filtrate reducer for drilling fluid, blocking agent for drilling fluid, waterborne lubricant NSR-1 for drilling fluid, low-fluorescence sulfonated bitumen, and tackifier; and 4, adjusting pH to 8 to 9 with caustic soda, and adding weighting agent to adjust density to 1.15 to 1.25 g / cm<3>. The preparing process has the advantages such that anti-collapse ability is high, the cost is lower and the applicable range is wide.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

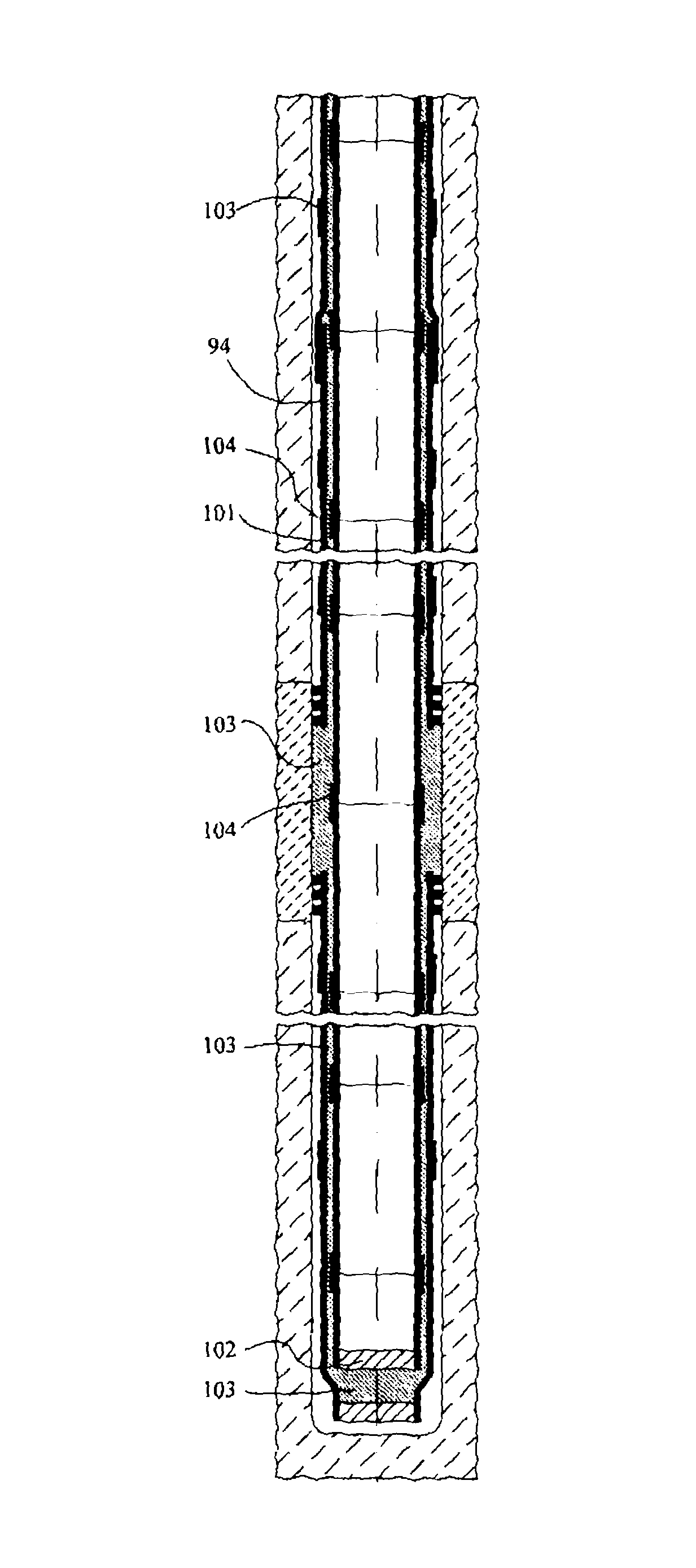

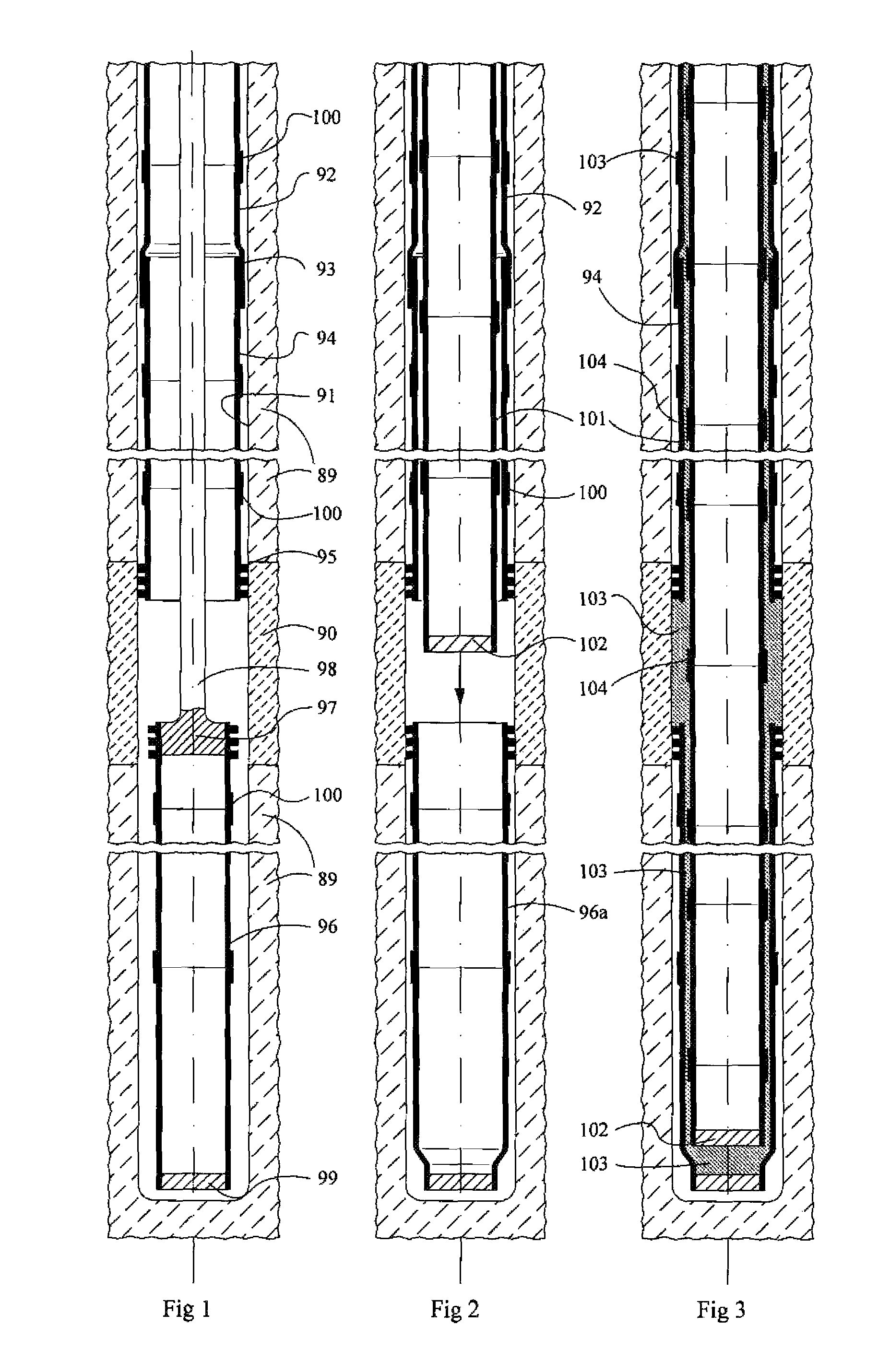

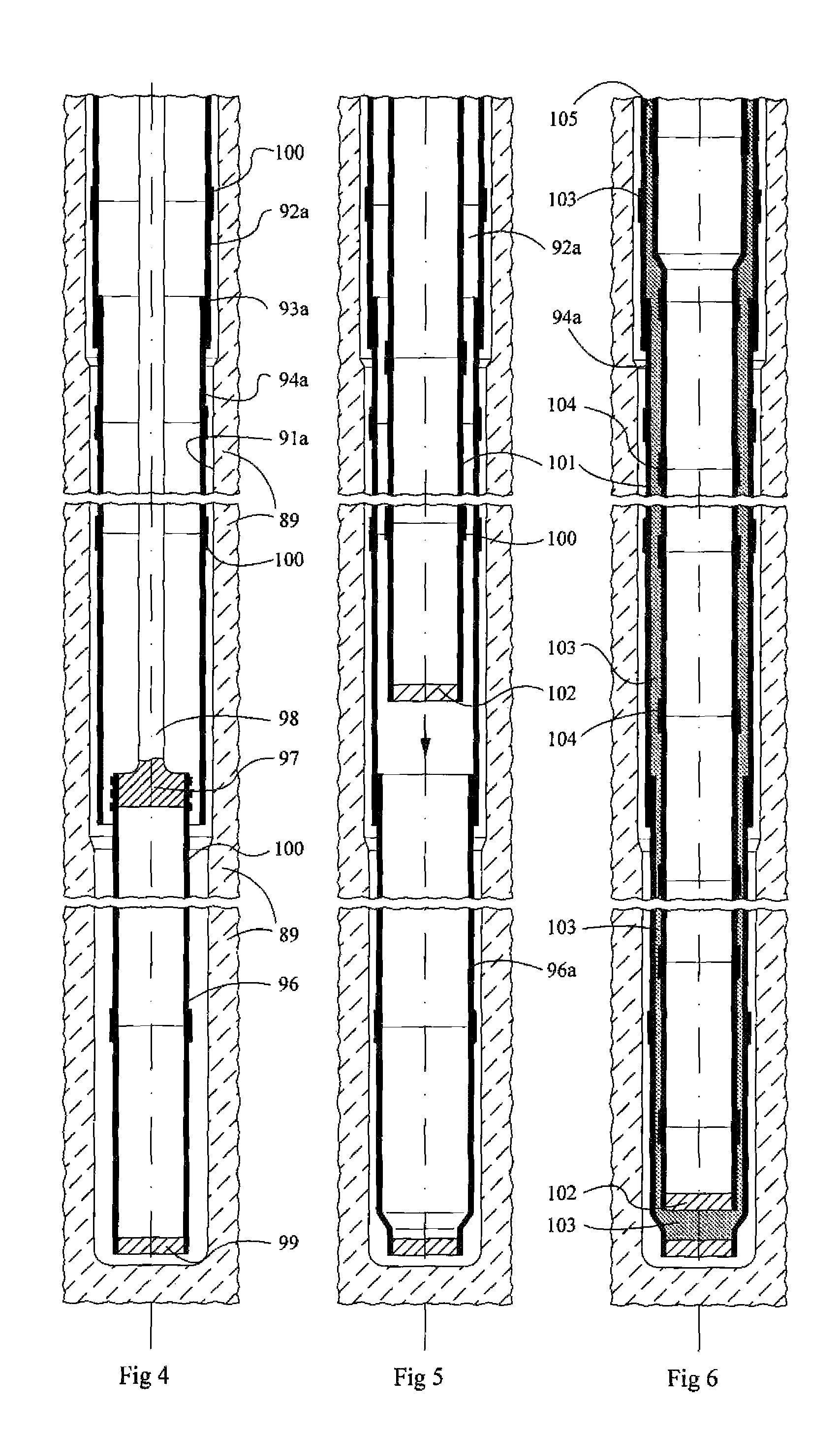

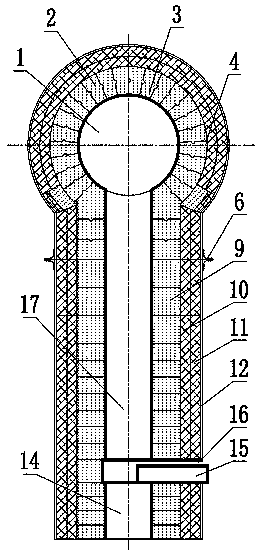

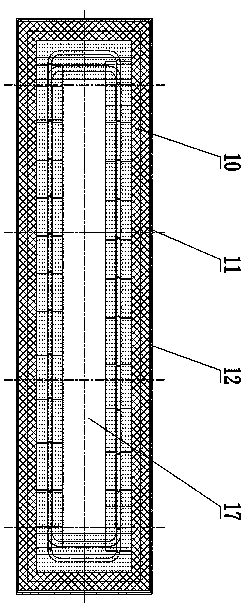

High collapse resistance solid expandable technology

InactiveUS9051789B2Improve mechanical propertiesStrong collapse resistanceDrilling rodsConstructionsCost effectivenessWellbore

Composite tubular casing with hardened material between thin pipe-in-pipe increasing the bending capability of the casing wall delivers high collapse resistance. Solid Expandable technology allows substantial wellbore slimming at the expense of collapse resistance. By combining both technologies, cost effective high collapse resistance wellbore construction can be achieved.

Owner:NOBILEAU PHILIPPE CONSTANT

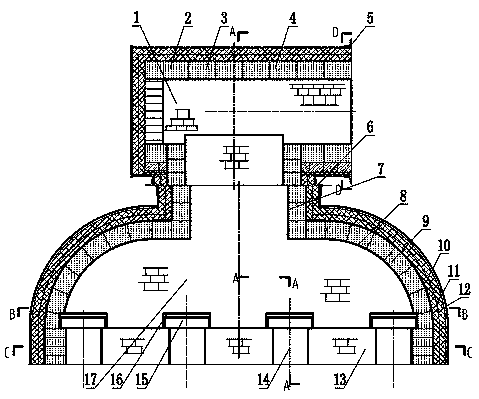

Multi-flue closed connecting bridge pipe for clean coke oven

InactiveCN108753315AStable structureStrong collapse resistanceDistillation gas withdrawalPorosityInsulation layer

The invention discloses a multi-flue closed connecting bridge pipe for a clean coke oven. Corundum, mullite, pyrophyllite, boron nitride, cordierite, trace silicon carbide, Al2O3 micro powder, kaolinand a ZrO2 micro powder composite binder are taken as materials, compressive strength MPa is higher than or equal to 10, thermal conductivity at 350 DEG C is lower than or equal to 0.25, and porosity(%) is larger than or equal to 70. A gas collecting pipe is movably supported at the top end of a bridge pipe connecting section of the connecting bridge pipe, a bridge pipe inner masonry wall is built at the lower part of a pipe cavity of a bridge pipe diversion section, at least two high-temperature flue gas channels are formed in the bridge pipe inner masonry wall, and channel gates are inserted into upper openings of the high-temperature flue gas channels; a pipe top insulation layer and a pipe bottom insulation layer which are mutually connected are arranged circumferentially at the crosssection of the gas collecting pipe; gate insertion ports are formed in the pipe wall of an ascending pipe diversion section. The connecting bridge pipe not only has stable structure, low flue gas conveying resistance and high collapse resistance, but also can control the flow and rate of high-temperature flue gas in an ascending pipe, and coke forming quality is high.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

A deep water drilling fluid

ActiveCN104559969BAvoid damageEnhanced inhibitory effectDrilling compositionSlurrySODIUM DODECYL BENZENE SULFONATE

The invention discloses a deepwater drilling fluid. Every 1L of base slurry is composed of 1g of xanthan gum XC, 10-20g of sodium carboxymethyl cellulose, 20-30g of sulfonated phenol formaldehyde resin SMP-2, 30-50g of sodium silicate, 10g of polyvinylpyrrolidone PVP-K90, 15g of high modified asphalt KAHM, 50-100g of sodium chloride, 0.5g of sodium dodecyl benzene sulfonate, 0.5-1g of graphite and 0.2-0.5g of polyformaldehyde. The drilling fluid has the advantages of stable properties under cold conditions, favorable rheological behavior, high debris carrying capacity, excellent mud shale hydration expansion inhibition capacity, excellent hydrate generation inhibition capacity, low economic cost and small environmental pollution, and is especially suitable for deepwater drilling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Inorganic-organic polymer treatment agent for drilling fluid and preparation method therefor

ActiveCN105295857AParticipation responds wellIncrease the amount of introductionDrilling compositionAluminum magnesium silicateCarboxylic acid

The present invention provides an inorganic-organic polymer treatment agent for a drilling fluid, wherein the treatment agent is polymerized and formed by a sulfonic acid monomer, a carboxylic acid monomer, a nonionic monomer and inorganic material under the action of an initiator; and the inorganic material contains an aluminum-magnesium silicate inorganic gel. The inorganic-organic polymer treatment agent provided by the present invention has a relative strong reduction fluid loss effect in a fresh water drilling fluid, a saline water drilling fluid, a saturated saline water drilling fluid and a composite saline water drilling fluid, and further has a relative strong collapse prevention capability to control hydration and dispersion of mud shale and clay mud-making effectively. The recover value of permeability is high. The treatment agent has a relatively good hydrocarbon reservoir protecting effect. The inorganic-organic polymer treatment agent is simple in production process, wide in raw material sources, and vast in popularizing prospect. The present invention further provides a preparation method for the inorganic-organic polymer treatment agent for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

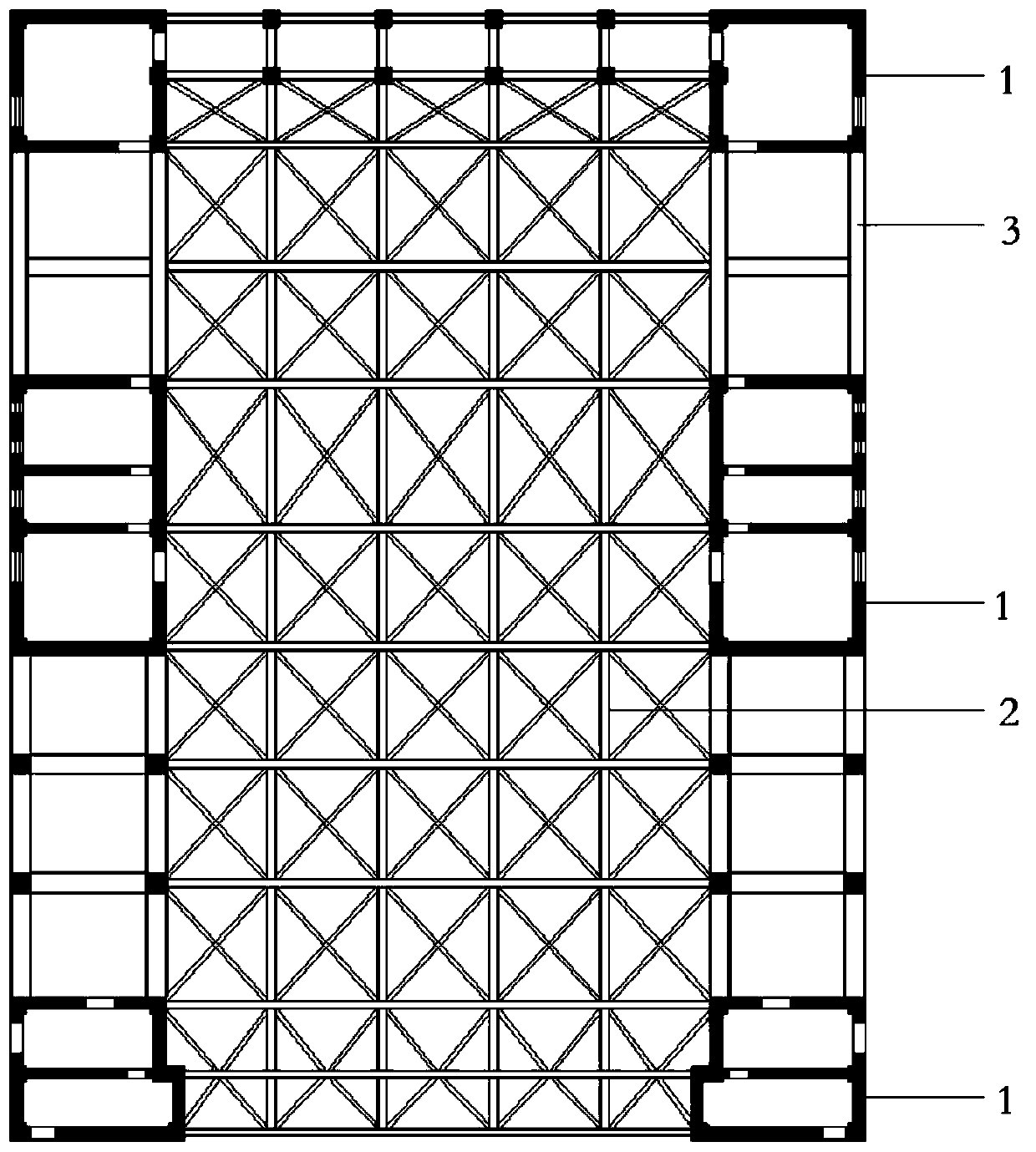

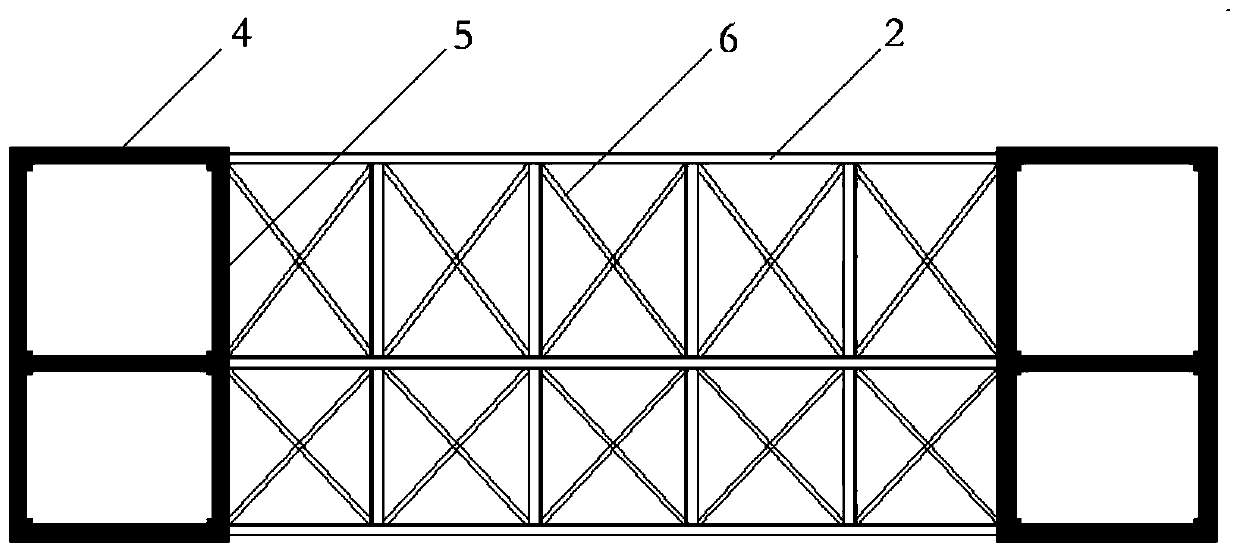

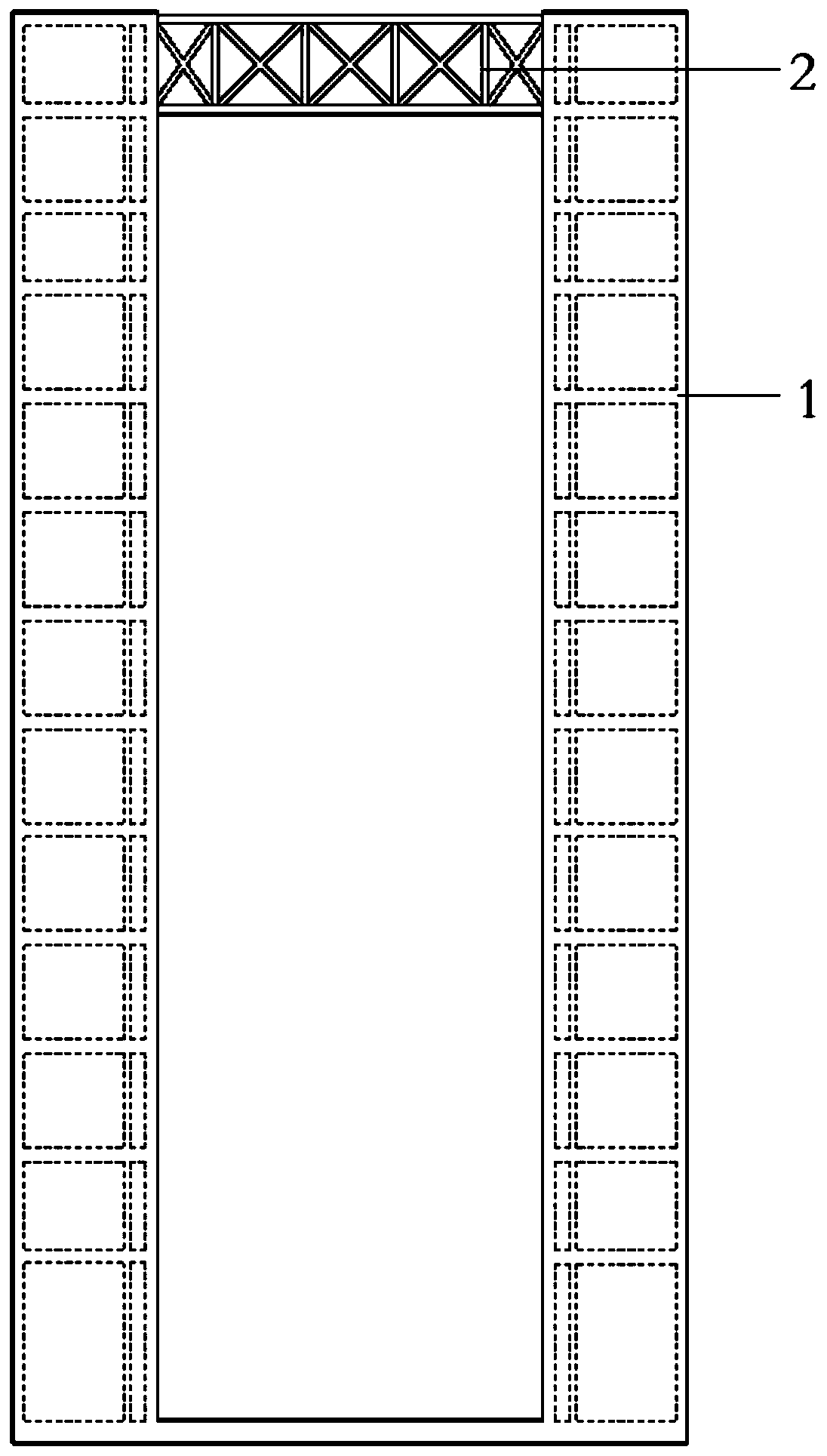

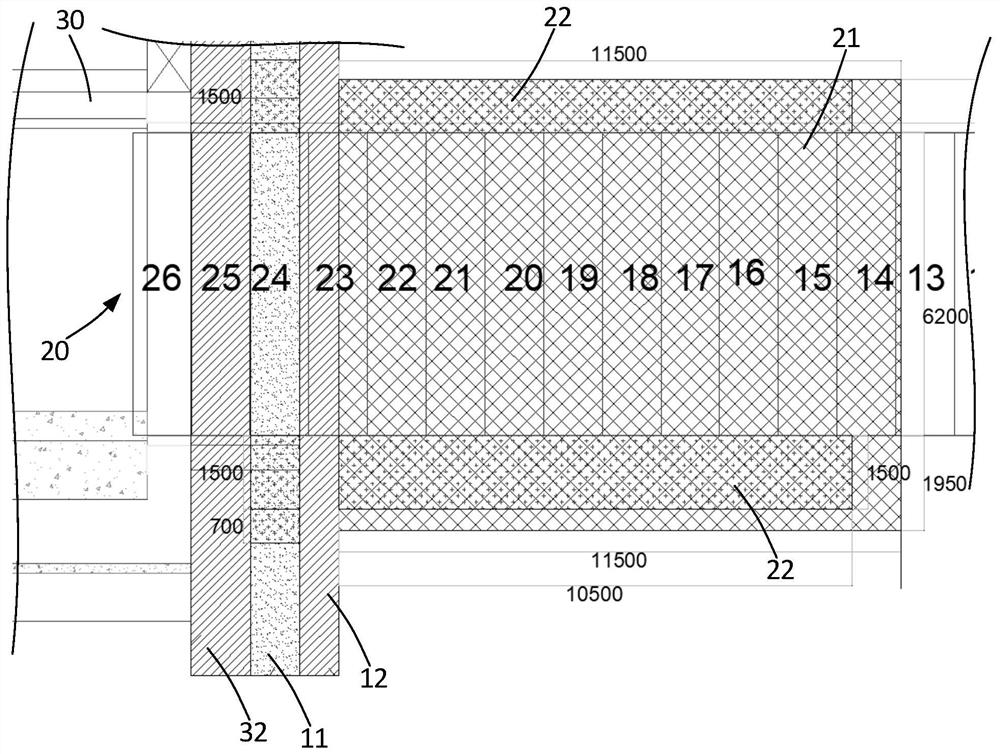

Structure support system for ultrahigh one-storied factory

InactiveCN111305379ASafe Space UtilizationReasonable structureProtective buildings/sheltersShock proofingArchitectural engineeringSteel frame

The invention discloses a structure support system for an ultrahigh one-storied factory, and belongs to the technical field of architectural engineering structures. The structure support system comprises a plurality of concrete cylinders, a roof steel truss and a plurality of frame beams. Each concrete cylinder is of a rectangular cylinder structure, the concrete cylinders are divided into two columns which are symmetric in the left-right direction, each column of concrete cylinders are linearly arrayed in the longitudinal direction, the bottoms of the concrete cylinders are fixed to a foundation, the tops of the concrete cylinders are connected into a whole through the roof steel truss, and the adjacent concrete cylinders on the same side are fixedly connected through the frame beams to form the overall structure support system. The structure support system does not adopt a traditional framed bent or steel frame structure and can meet the stress and deformation requirements of the one-storied factory with the height exceeding 40 meters.

Owner:NO 63921 UNIT OF PLA

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363BAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105295857BParticipation responds wellIncrease the amount of introductionDrilling compositionAluminum magnesium silicateSalt water

The invention provides an inorganic-organic polymer treatment agent for drilling fluid, wherein the treatment agent is formed by polymerization of sulfonic acid monomers, carboxylic acid monomers, nonionic monomers and inorganic materials under the action of an initiator; And the inorganic material includes aluminum magnesium silicate inorganic gel. The inorganic-organic polymer treatment agent provided by the invention has strong fluid loss reducing effect in freshwater drilling fluid, brine drilling fluid, saturated brine drilling fluid and composite brine drilling fluid. It also has a strong anti-collapse ability, can effectively control the hydration and dispersion of mud shale, control clay slurry, and has a high permeability recovery value, which has a good oil and gas layer protection effect. Moreover, the production process is simple, the source of raw materials is wide, and the promotion prospect is broad. The invention also provides a preparation method of an inorganic-organic polymer treatment agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105219358BParticipation responds wellIncrease the amount of introductionDrilling compositionSlurryCarboxylic acid

The invention provides an inorganic-organic polymer treating agent used for drilling fluid. The treating agent is prepared from a sulfonic acid monomer, a carboxylic acid monomer, a non-ionic monomer and an inorganic material by polymerization under the action of an initiator, wherein the inorganic material contains lithium magnesium silicate inorganic gel. The inorganic-organic polymer treating agent provided by the invention has strong effect of reducing filtrate loss in fresh-water drilling fluid, saltwater drilling fluid, saturated saltwater drilling fluid and compound saltwater drilling fluid. The treating agent also has strong anti-sloughing ability, can effectively control hydration dispersion of clay-shale and slurry making of clay, and has high permeability recovery rate and good hydrocarbon reservoir protection effects. Meanwhile, the treating agent has the advantages of simple production process, wide raw material sources and extensive popularization prospects. The invention also provides a preparation method for the inorganic-organic polymer treating agent used for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

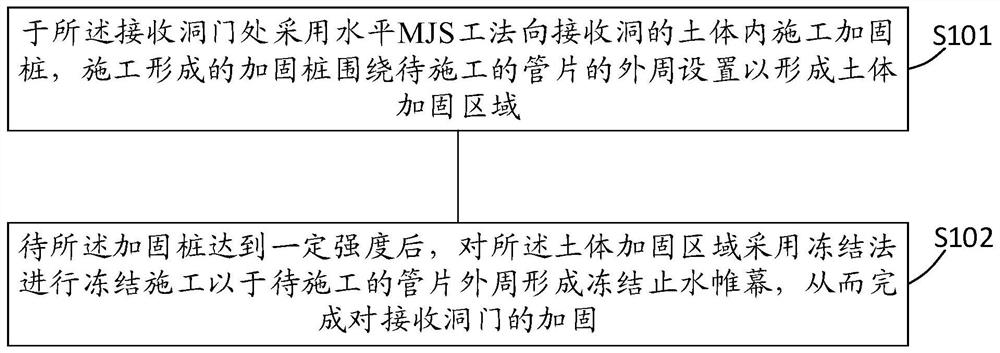

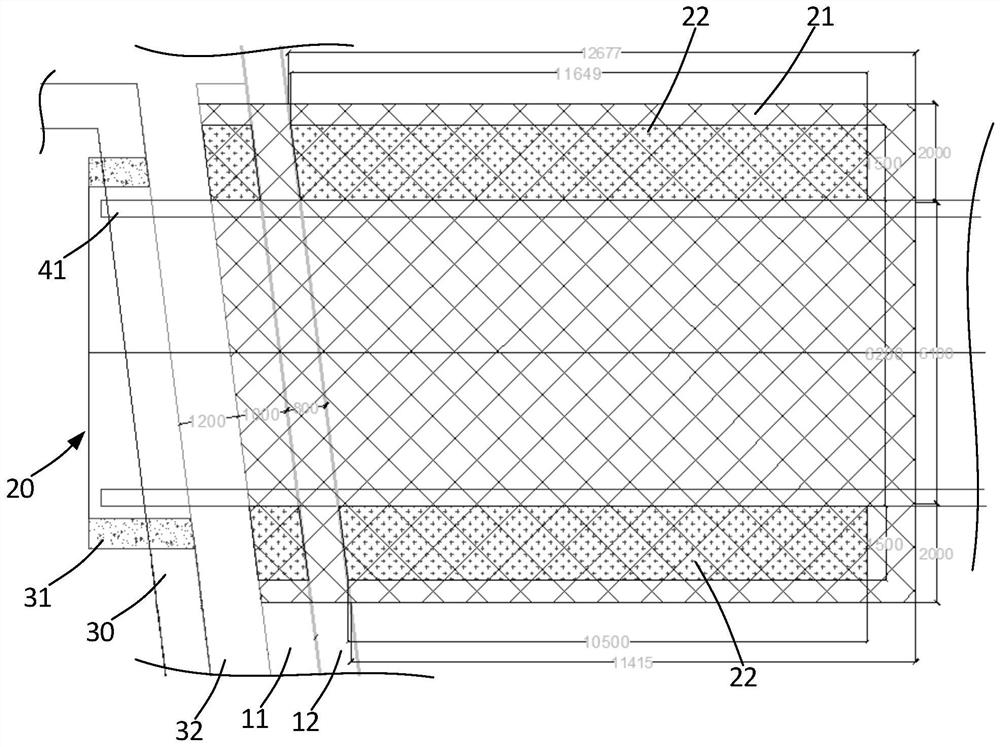

Reinforcing method for shield receiving tunnel portal

PendingCN112922608ASolve the costShort timeUnderground chambersTunnel liningSoil cementFrost heaving

The invention relates to a reinforcing method for a shield receiving tunnel portal. The reinforcing method comprises the steps that reinforcing piles are constructed in a soil body of a receiving tunnel at the receiving tunnel portal through a horizontal MJS construction method, and the reinforcing piles formed through construction are arranged around the periphery of a to-be-constructed segment so as to form a soil body reinforcing area; and after the to-be-reinforced piles reach certain strength, freezing construction is conducted on the soil body reinforcement area through a freezing method, so that a freezing waterproof curtain is formed on the periphery of the to-be-constructed segment, and reinforcement of the receiving tunnel portal is completed. According to the reinforcing method, the annular soil body reinforcing area is adopted, compared with full-section construction, the number of reinforcing piles is reduced, the cost can be reduced, and the construction period can be shortened. The freezing method is adopted for freezing to form the freezing waterproof curtain, frozen cement soil has high collapse resistance, the bearing capacity of the frozen cement soil is further improved, meanwhile, after cement is mixed into the soil body, the problems of frost heaving and thaw collapse generated in the horizontal freezing process can be effectively solved, and safe operation of surrounding buildings and structures is ensured.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

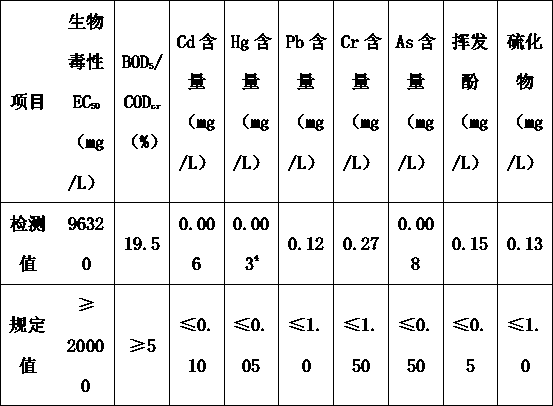

A natural polymer environmentally friendly drilling solution

ActiveCN104946214BStrong collapse resistanceEnhanced inhibitory effectDrilling compositionAlcoholBalance water

The invention provides environment-friendly natural polymer drilling fluid. The environment-friendly natural polymer drilling fluid comprises, by weight, 0.3-2.0% of natural anti-sloughing agents, 1.0-5.0% of blocking agents, 0.3-0.5% of viscosity and shear strength enhancing agents, 0.5-3.0% of fluid loss agents, 0.5-2.5% of lubricating agents, 0.02-0.05% of low-carbon-alcohol reservoir protection agents, 0.03-0.08% of glutaraldehyde, and the balance water. The drilling fluid has very high anti-sloughing ability, inhibitive ability and plugging ability, and can rapidly form a tough and compact sealing film at the region close to the well wall so as to stabilize the well wall and prevent filter liquor and solid phases from further immersing a reservoir and effectively protect the reservoir. Besides, the drilling fluid has no biotoxicity or chemical toxicity and is biodegradable and beneficial to environmental protection.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105154030BParticipation responds wellIncrease the amount of introductionDrilling compositionSodium BentoniteSalt water

The invention provides an inorganic-organic polymer treatment agent for drilling fluid, wherein the treatment agent is formed by polymerization of sulfonic acid monomers, carboxylic acid monomers, nonionic monomers and inorganic materials under the action of an initiator; And the inorganic material includes bentonite. The inorganic-organic polymer treatment agent provided by the invention has strong fluid loss reducing effect in freshwater drilling fluid, brine drilling fluid, saturated brine drilling fluid and composite brine drilling fluid. It also has a strong anti-collapse ability, can effectively control the hydration and dispersion of mud shale, control clay slurry, and has a high permeability recovery value, which has a good oil and gas layer protection effect. Moreover, the production process is simple, the source of raw materials is wide, and the promotion prospect is broad. The invention also provides a preparation method of an inorganic-organic polymer treatment agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Calcium magnesium injectable bone cement and preparation method and application thereof

The invention discloses a product used for forming calcium magnesium injectable bone cement, comprising solid phase powder obtained by uniformly mixing composite phosphoric acid calcium salt and magnesium phosphate powder as well as curing solution obtained by dissolving dextrin and hydrophosphate in water. The invention also discloses a calcium magnesium injectable bone cement and preparation method and application thereof. The curing solution and solid phase powder in the product are uniformly mixed and blended into paste, thus obtaining water phase high efficiency scattering-resistant rapid curing bone cement capable of being injected with calcium magnesium and injectable product used for preparing bone tissue wound repairing. The invention is low in cost of raw materials, preparation method is simple, the obtained calcium magnesium injectable bone cement has strong scattering-resistance and rapid curing speed.

Owner:EAST CHINA UNIV OF SCI & TECH

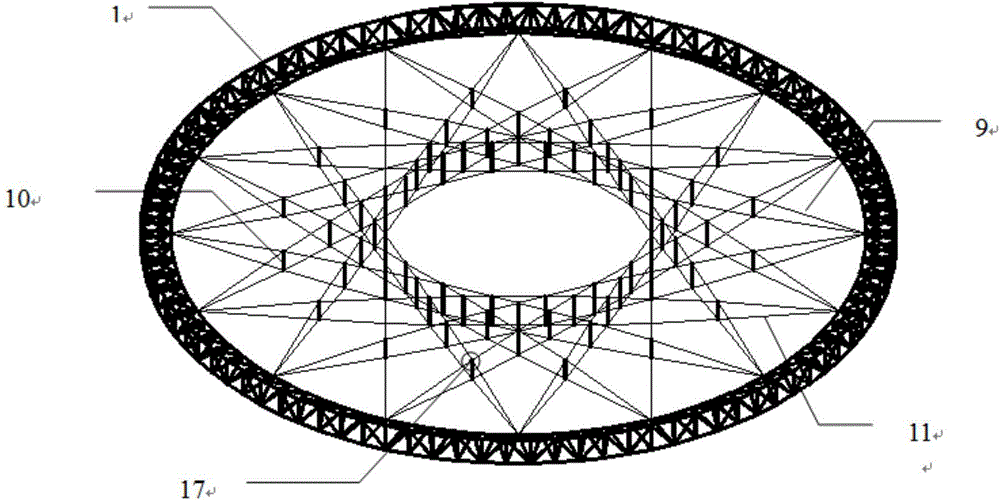

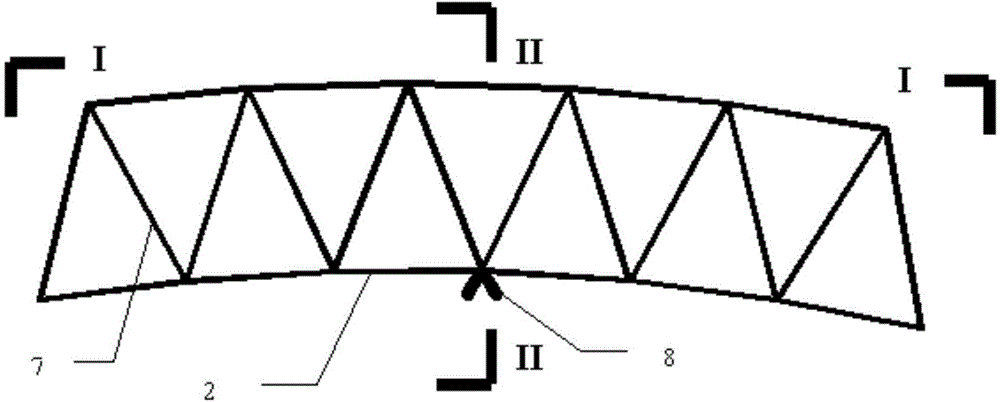

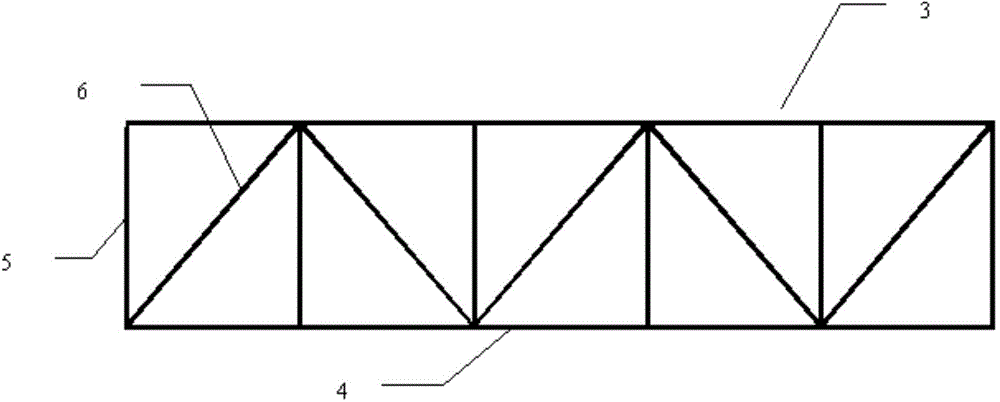

Annular cross cable truss structure

InactiveCN103074938BNovel structureReasonable structural stressBuilding roofsHorizontal forceEngineering

The invention relates to an annular cross cable truss structure, belonging to the field of a spatial cable truss structure. The structure comprises an annular stressed truss part, and a cable truss system part, wherein the cable truss system part consists of an upper string stabilizing cable, a support rod and a lower string bearing cable; a fish-bellied cable truss, stressed on a plane, is formed by connecting an upper string cable, a lower string cable and the support rod; and the annular cross cable truss structure, which has good spatial stress performance, is formed by arranging a plurality of plane fish-bellied cable trusses in an annular and cross way; the upper string cable and the lower string cable are and fixed at an ear plate of the annular stressed truss through anchorages at cable ends; and the stressed truss provides constraint to balance the horizontal force in the cables. The annular cross cable truss structure provided by the invention has the advantages of novel structure form, rational structure stress, less structure parts, strong collapse resistance, and attractive architectural style and can automatically maintain stable outside a surface, and moreover, the annular cross cable truss structure is convenient to manufacture and install, thus, the structure has stronger practical values.

Owner:BEIJING UNIV OF TECH

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105154032BParticipation responds wellIncrease the amount of introductionDrilling compositionFiltrationCarboxylic acid

The invention provides an inorganic-organic polymer processing agent for drilling fluid polymerized from sulfonic acid monomer, carboxylic acid monomer, nonionic monomer and inorganic material in the presence of initiator, and the inorganic material includes aluminium tripolyphosphate. The inorganic-organic polymer processing agent for drilling fluid has good effect on filtration reduction effect in fresh water drilling fluid, brine drilling fluid, saturated brine drilling fluid and compound brine drilling fluid. The inorganic-organic polymer processing agent for drilling fluid has strong anti-sloughing capability and high permeability recovery, can control hydration and dispersion of the shale effectively, can control mud making of the clay effectively, and has good effect on hydrocarbon reservoir protection. Moreover, the preparation method is simple, the sources of raw materials are wide, and the promotion prospect is wide. The invention also provides a preparation method of inorganic-organic polymer processing agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

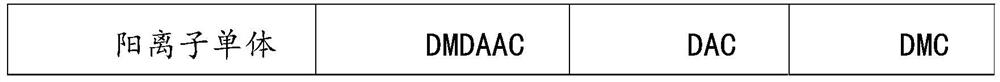

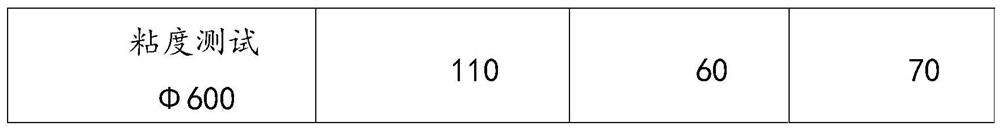

A large cation coated flocculant and its preparation method

ActiveCN111621269BHigh positive charge densityEnhanced inhibitory effectDrilling compositionMeth-Backbone chain

The invention relates to a large cationic coated flocculant, which is coated with polydimethyldiallylammonium chloride and consists of dimethyldiallylammonium chloride monomer, dimethyldiallyl p-methyl A flocculant composed of a tetrapolymer formed by the polymerization of benzyl ammonium chloride monomer, acrylamide monomer and acrylic acid monomer. This technical scheme utilizes the advantages of dimethyl diallyl ammonium chloride, which has high positive charge density, non-toxicity, high efficiency, very stable at room temperature, and stable ring structure after polymerization. The cationic quaternary ammonium group on it is not only soluble in water, but also can react with oppositely charged electrons or colloids. After maintaining the thermal stability of the anionic copolymer and having strong resistance to temperature and salt, the use of dimethyl allyl Based on the non-hydrophilic cation characteristics of p-methylbenzyl ammonium chloride, the flocculated colloidal particles will not swell because they are easily soluble in water, resulting in instability of the colloidal particles after flocculation, which improves the stability of the flocculation effect.

Owner:保定市三拓化工产品有限公司

A polymer inhibitor for clay-free drilling fluid and preparation method thereof

ActiveCN104140490BInhibits hydration swellingMeet the needs of safe and fast drillingDrilling compositionWell drillingOil field

Belonging to the technical field of preparation methods for petroleum drilling oilfield chemistry macromolecular polymers, the invention discloses a polymer inhibitor for clay phase-free drilling fluid and a preparation method thereof. The polymer inhibitor is formed by copolymerization of an organic amide monomer A, an amido hydrolysis inhibiting monomer B and a cationic monomer C according to a mass percentage of (56-76):(10-25):(14-19) under the action of an initiator and a pH value regulator. The intrinsic viscosity number of the polymer inhibitor is 2.0-3.0dl / g. The shale with a clear water recovery rate of 3.6% is employed to perform shale recovery experiment on the obtained product. A 0.5% aqueous solution of the polymer inhibitor can reach a primary shale recovery rate of higher than 90% after 16h at 200DEG C and a relative shale recovery rate of higher than 98%, and a contrast example, i.e. a 2% high temperature resistant polyamine inhibitor solution only has a primary shale recovery rate of 64.2% after 16h at 200DEG C. With good sloughing inhibiting and preventing ability under high temperature conditions, the polymer inhibitor provided by the invention can be used for weak gel clay phase-free drilling fluid to effectively inhibit hydration expansion of mud shale and ensure safe and fast drilling of a special process well, thus further improving the wellbore wall stabilization capacity.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com