A natural polymer environmentally friendly drilling solution

A natural polymer, environmentally friendly technology, applied in the field of oilfield drilling fluids, can solve the problems of difficult well control safety, high friction, torque, difficult performance maintenance, etc., to achieve good economic and social benefits, environmental protection, strong performance. Anti-collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

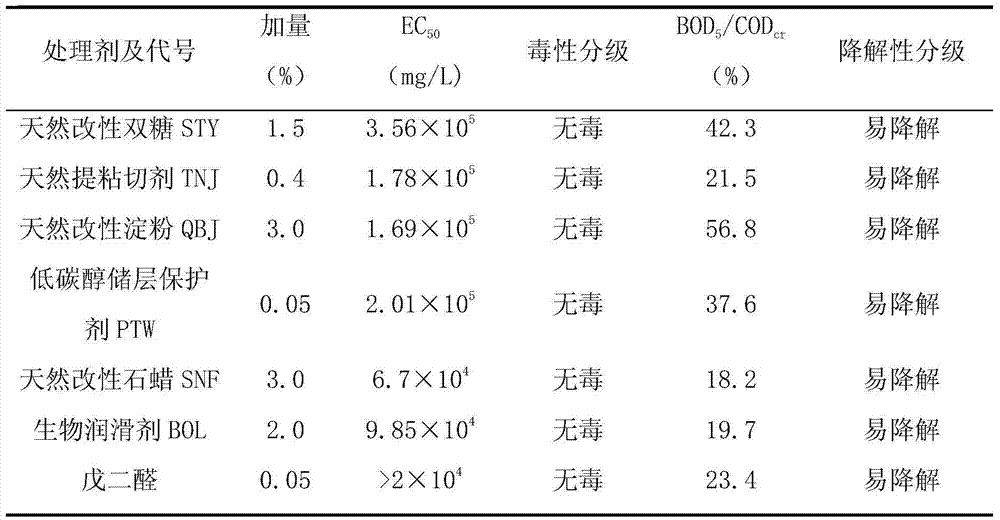

[0021] This embodiment provides a natural polymer environment-friendly drilling fluid, which consists of the following components by weight percentage: 0.3%-2.0% natural anti-slump agent, 1.0%-5.0% plugging agent, 0.3%-2.0% 0.5% viscosifier, 0.5%-3.0% fluid loss reducer, 0.5%-2.5% lubricant, 0.02%-0.05% low-carbon alcohol reservoir protection agent, 0.03%-0.08% glutaraldehyde , The remainder is water.

[0022] Among them, the natural anti-slump agent is a carboxymethyl modified disaccharide, and the disaccharide is one of sucrose, lactose and maltose, or a mixture of any two or a mixture of the three; the blocking agent has a particle size ranging from 1 to 20 μm The natural modified paraffin wax, the natural modified paraffin wax is natural paraffin obtained through hydrogen peroxide or persulfuric acid oxidation modification; Lifting viscosity cutting agent is the mixture of xanthan gum and polyanionic cellulose sodium salt by volume ratio 2:1; The water-losing agent is hyd...

Embodiment 2

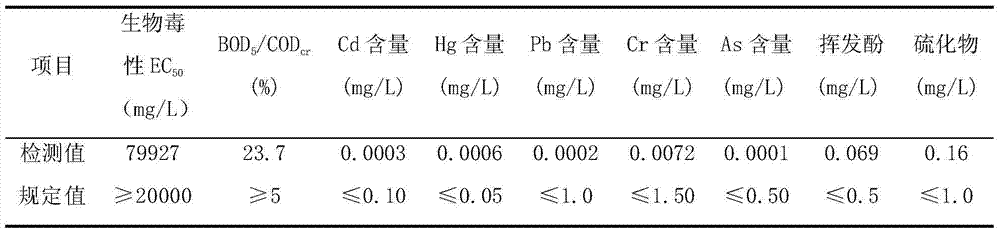

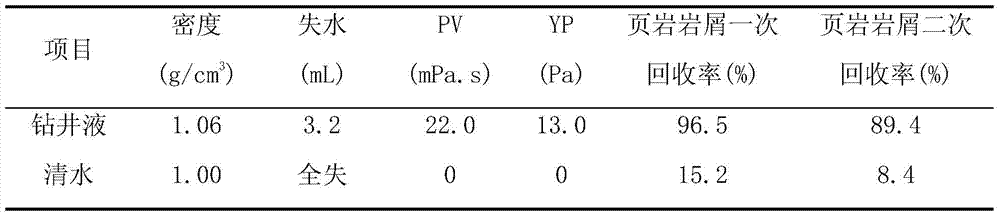

[0026] This embodiment provides a natural polymer environment-friendly drilling fluid, which is composed of the following components by weight percentage: 90.0% clear water, 1.5% natural anti-slump agent, 3.0% plugging agent, 0.4% viscous cutting agent, 3.0% fluid loss reducer, 2.0% lubricant, 0.05% low-carbon alcohol reservoir protection agent, 0.05% glutaraldehyde. Among them, the natural anti-slumping agent is carboxymethyl modified disaccharide, and the disaccharide is sucrose; the blocking agent is natural modified paraffin wax with a particle size range of 1-20 μm; the viscosifying agent is xanthan gum and polyanionic cellulose The sodium salt is a mixture of 2:1 by volume; the fluid loss reducer is hydroxypropyl starch; the lubricant is bio-oil refined from gutter oil or waste cooking oil; the low-carbon alcohol reservoir protection agent is ethylene glycol and propane A mixture of triols in a volume ratio of 2:1.

[0027] The following performance evaluation experimen...

Embodiment 3

[0068] This embodiment provides a natural polymer environment-friendly drilling fluid, which is composed of the following components by weight percentage: 89.59% clear water, 0.3% natural anti-slump agent, 5.0% plugging agent, 0.5% sticking and cutting agent, 2.0% fluid loss reducer, 2.5% lubricant, 0.03% low-carbon alcohol reservoir protection agent, 0.08% glutaraldehyde. Among them, the natural anti-slumping agent is carboxymethyl modified disaccharide, and the disaccharide is a mixture of sucrose and lactose; the blocking agent is natural modified paraffin wax with a particle size range of 1-20 μm; the viscosifying agent is xanthan gum and A mixture of polyanionic cellulose sodium salt at a volume ratio of 2:1; the fluid loss reducer is hydroxypropyl starch; the lubricant is bio-oil refined from gutter oil or waste cooking oil; the low-carbon alcohol reservoir protection agent is A mixture of ethylene glycol and glycerol in a volume ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com