A large cation coated flocculant and its preparation method

A large cation and flocculant technology, which is applied in the field of large cation coated flocculants and preparations for drilling fluids, can solve the problems of insufficient stability of flocculants, achieve strong anti-slump effects, improve stability, strong inhibition and excellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

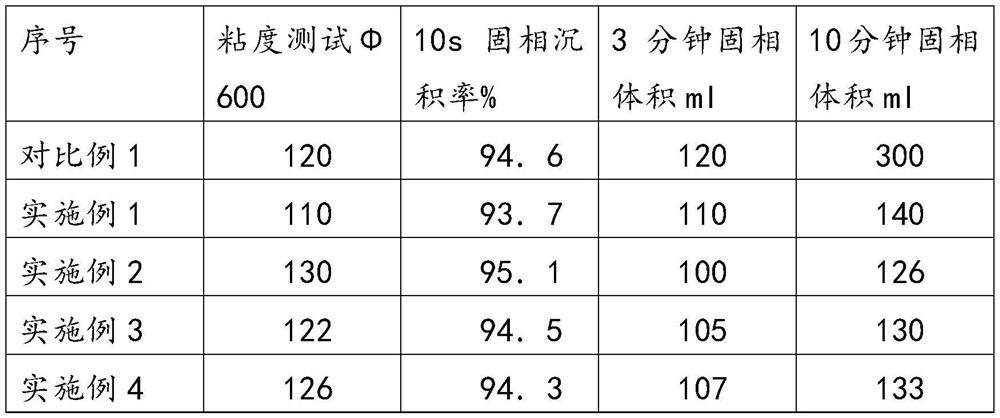

Embodiment 1

[0036] A preparation method of large cation coated flocculant, comprising the following steps:

[0037] 1) Add 100 parts of 30 wt% dimethyl diallyl ammonium chloride monomer aqueous solution into the reaction device, then add 0.02 parts of azodiisopropylimidazoline hydrochloride and stir evenly, and then pass nitrogen gas After 30 minutes, the reaction was heated in a water bath at 50° C. for 7 hours.

[0038] 2) After the reaction is completed, the reaction product is taken out, washed with ethanol, diluted with acetone, dried in an oven at 50° C. for 24 hours, crushed to obtain polydimethyldiallylammonium chloride for use.

[0039] 3), prepare 25wt% ammonium sulfate solution, use distilled water to prepare, preparation method is prior art, the applicant does not carry out detailed description here.

[0040] 4) 25 parts of dimethyl diallyl ammonium chloride monomer, 3 parts of dimethyl allyl p-methyl benzyl ammonium chloride monomer, 50 parts of acrylamide monomer, 20 parts ...

Embodiment 2

[0046] A preparation method of large cation coated flocculant, comprising the following steps:

[0047] 1) Add 100 parts of 40 wt% dimethyl diallyl ammonium chloride monomer aqueous solution into the reaction device, then add 0.05 parts of azodiisopropylimidazoline hydrochloride and stir evenly, and then pass nitrogen gas After 40 minutes, the reaction was heated in a water bath at 60° C. for 7 hours.

[0048] 2) After the reaction is completed, the reaction product is taken out, washed with ethanol, diluted with acetone, dried in an oven at 50° C. for 24 hours, crushed to obtain polydimethyldiallylammonium chloride for use.

[0049] 3) Prepare 28wt% ammonium sulfate solution using distilled water. The preparation method is prior art, and the applicant does not describe in detail here.

[0050] 4) 40 parts of dimethyl diallyl ammonium chloride monomer, 5 parts of dimethyl allyl p-methyl benzyl ammonium chloride monomer, 50 parts of acrylamide monomer, 20 parts Acrylic acid m...

Embodiment 3

[0056] A preparation method of large cation coated flocculant, comprising the following steps:

[0057] 1) Add 100 parts of 35 wt% dimethyldiallylammonium chloride monomer aqueous solution into the reaction device, then add 0.03 parts of azodiisopropylimidazoline hydrochloride and stir evenly, and then pass nitrogen gas After 30 minutes, the reaction was heated in a water bath at 50° C. for 7 hours.

[0058] 2) After the reaction is completed, the reaction product is taken out, washed with ethanol, diluted with acetone, dried in an oven at 50° C. for 24 hours, crushed to obtain polydimethyldiallylammonium chloride for use.

[0059] 3), prepare 26wt% ammonium sulfate solution, use distilled water to prepare, preparation method is prior art, the applicant does not carry out detailed description here.

[0060] 4) 30 parts of dimethyl diallyl ammonium chloride monomer, 3 parts of dimethyl allyl p-methyl benzyl ammonium chloride monomer, 50 parts of acrylamide monomer, 20 parts A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com