Long-acting anti-swelling agent for fracturing and preparing method and application thereof

An anti-swelling agent, long-acting technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve problems such as poor long-term anti-swelling effect, and achieve inhibition of particle migration and adsorption damage Small, strong washout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

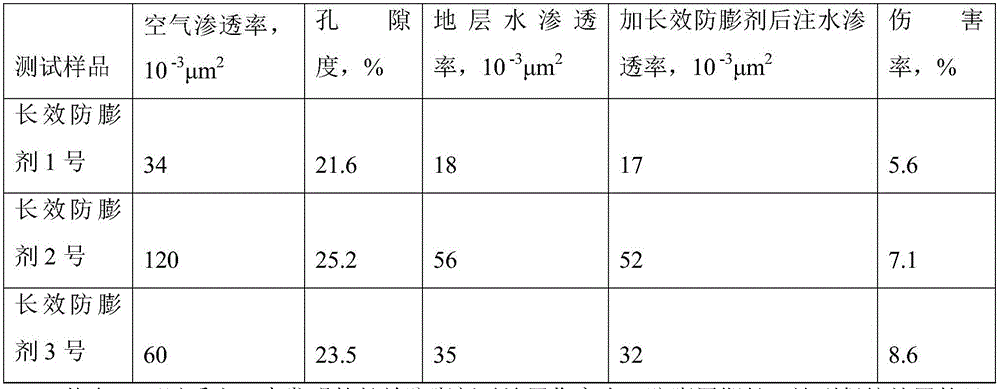

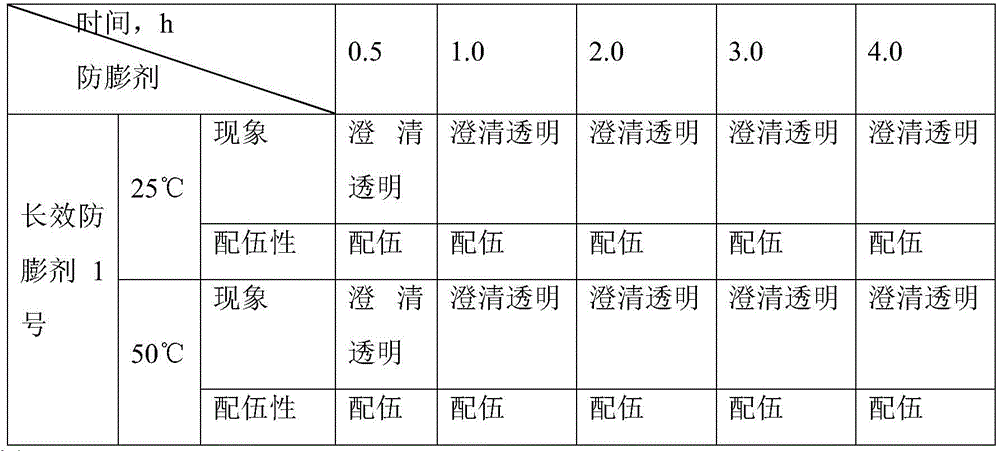

Embodiment 1

[0018] A long-acting anti-swelling agent for fracturing, in terms of mass percentage, including the following components: surfactant OP-10 50%, organic anti-swelling agent BSF 4%, inorganic anti-swelling agent KCl 15% and 31% water.

[0019] The preparation method of the above-mentioned long-acting anti-swelling agent for fracturing is as follows:

[0020] Take 31ml of water, 50g of OP-10 surfactant (from Wuhan Longruida Technology Development Co., Ltd.), and 4g of organic anti-swelling agent BSF (from Hubei Xingzhongcheng Technology Co., Ltd.) at room temperature and normal temperature. Add 15g of inorganic anti-swelling agent KCl (from Wuhan Huachuang Chemical Co., Ltd.) after cooling to 25°C, and stir for 1 hour to prepare 100g of long-acting anti-swelling agent for fracturing, marked as long-acting anti-swelling agent No. 1.

Embodiment 2

[0022] A long-acting anti-swelling agent for fracturing, in terms of mass percentage, including the following components: surfactant OP-10 60%, organic anti-swelling agent BSF 3%, inorganic anti-swelling agent KCl 8% and 29% water.

[0023] The preparation method of the above-mentioned long-acting anti-swelling agent for fracturing is as follows:

[0024] Take 29ml of water surfactant OP-10 60g and organic anti-swelling agent BSF 3g into the airtight pressure reactor at room temperature and pressure, start stirring, gradually raise the temperature to 100℃ and react for 3 hours, then cool to 25℃ and add 8g inorganic Anti-swelling agent KCl was stirred for 0.5 hours to prepare 100g of long-acting anti-swelling agent for fracturing, which was marked as long-acting anti-swelling agent No. 2.

Embodiment 3

[0026] A long-acting anti-swelling agent for fracturing, in terms of mass percentage, including the following components: surface active agent OP-10 65%, organic anti-swelling agent BSF 2%, inorganic anti-swelling agent KCl 5% and 28% water.

[0027] The preparation method of the above-mentioned long-acting anti-swelling agent for fracturing is as follows:

[0028] Take 28ml of water, 70g of OP-10 surfactant and 2g of organic anti-swelling agent BSF at room temperature and pressure, add them into the closed pressure reactor, start stirring, gradually increase the temperature to 100°C and react for 3 hours, then cool 25 After ℃, add 5g of inorganic anti-swelling agent KCl and stir for 0.5 hours to prepare 100g of long-acting anti-swelling agent for fracturing, which is marked as long-acting anti-swelling agent No. 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com