A polymer inhibitor for clay-free drilling fluid and preparation method thereof

A technology of polymer and drilling fluid, applied in the field of polymer inhibitor and its preparation, can solve the problems such as insufficient anti-slump resistance and insufficient temperature resistance, achieve strong anti-slump resistance, improve anti-slump ability, and inhibit water effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

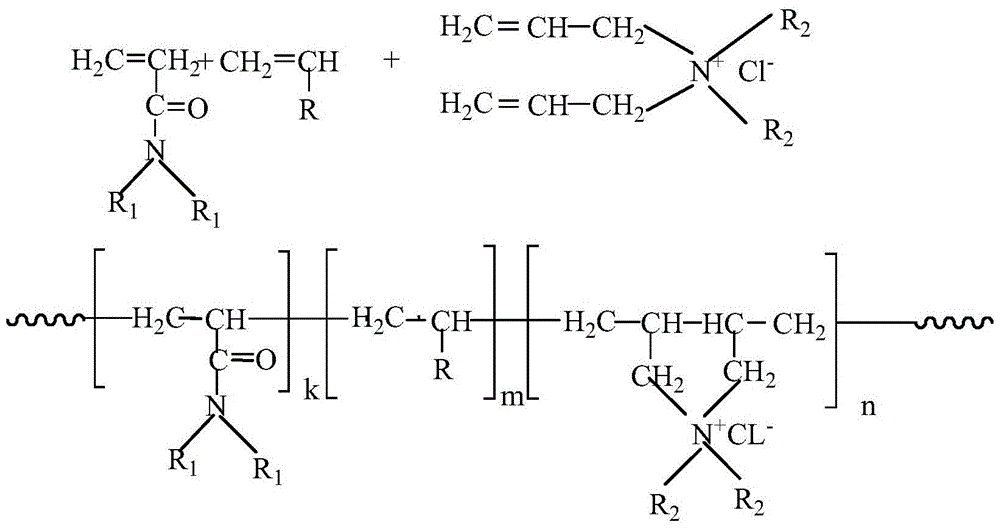

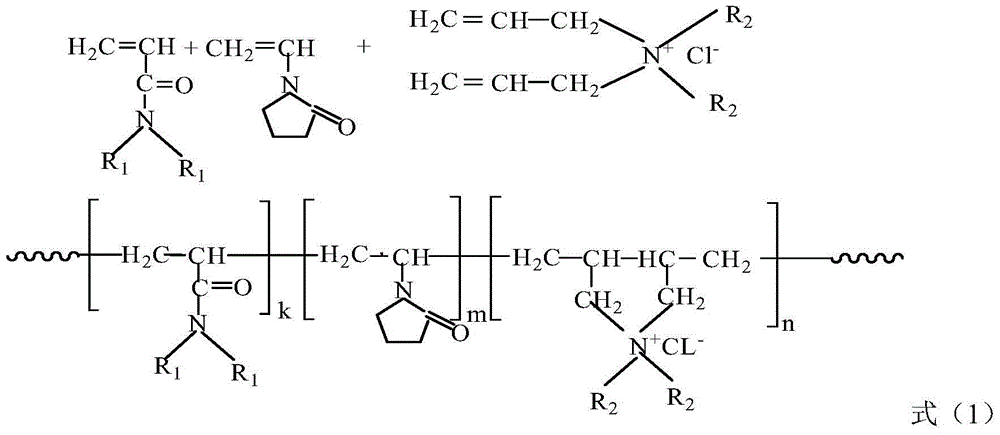

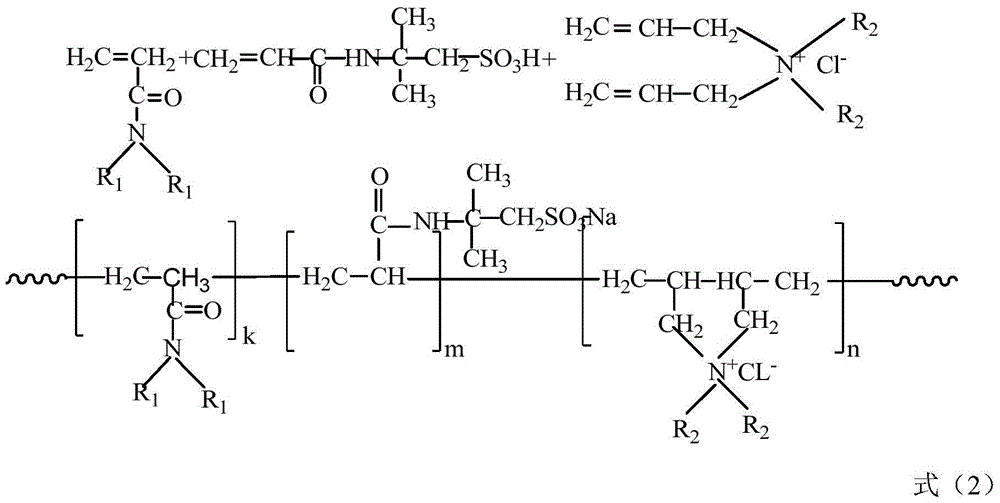

Method used

Image

Examples

preparation example 1

[0025] Add 36g of acrylamide, 20g of N,N-dimethylacrylamide, 25g of N-vinyl-2-pyrrolidone, and 19g of dimethyldiallyl ammonium chloride into 100g of water and adjust the pH value to 9. Add 0.2 g ammonium persulfate and 0.2 g sodium bisulfite, react at 30°C for 0.5h to 1h to obtain a gel-like polymer, the product is sheared, granulated, dried and crushed at 60°C to obtain clay-free Polymer inhibitors for drilling fluids.

preparation example 2

[0027] Add 60g of acrylamide, 16g of N,N-dimethylacrylamide, 14g of 2-acrylamido-2-methylpropanesulfonic acid, and 10g of dimethyldiallylammonium chloride into 100g of water and adjust the pH value to 10. Add 0.15g of ammonium persulfate and 0.15g of sodium bisulfite respectively, and react at 30°C for 0.5h to 1h to obtain a gel-like polymer. The product is sheared, granulated, and dried at 60°C. Crush to obtain polymer inhibitors for clay-free drilling fluids.

preparation example 3

[0029] Add 61g of acrylamide, 5g of N,N-dimethylacrylamide, 20g of 2-acrylamido-2-methylpropanesulfonic acid, 14g of dimethyl diallyl ammonium chloride into 120g of water and adjust the pH value to 11. Add 0.1g of ammonium persulfate and 0.1g of sodium bisulfite respectively, and react at 30°C for 0.5h to 1h to obtain a gel-like polymer. The product is sheared and granulated, and dried at 60°C. Crush to obtain polymer inhibitors for clay-free drilling fluids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com