Clay inhibitor as well as preparation method and application thereof

A clay inhibitor and compound technology, which is applied in the field of preparation of concrete superplasticizer additives, can solve the problems of low cost performance and high dosage, and achieve the effects of inhibiting hydration expansion, simple preparation process, and preventing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

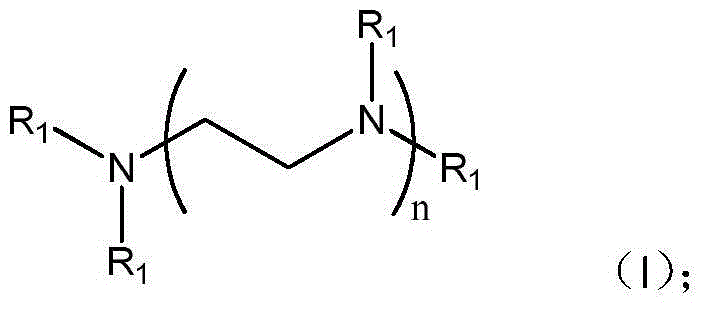

[0031] The preparation of embodiment 1 organic cationic compound A

[0032]In a 1L glass round bottom flask equipped with a thermometer, a stirrer, and a dropping funnel, add 49.6g of water and 32.9g of ethylenediamine, stir and mix evenly, keep the temperature at 20°C, and then add 330.5g of 2,3-epoxypropylene A mixed solution composed of trimethylammonium chloride and 491.6g of water was continuously added dropwise to the round bottom flask at a constant speed for 4 hours. After the dropwise addition was completed, the temperature was raised to 60°C, and the stirring was continued for 4 hours to obtain An aqueous solution of organic cationic compound A-1 with a solid content of 40%.

Embodiment 2

[0033] The preparation of embodiment 2 organic cationic compound A

[0034] In a 1L glass round-bottomed flask equipped with a thermometer, a stirrer, and a dropping funnel, add 58.8g of water and 25.1g of diethylenetriamine, stir and mix evenly, keep the temperature at 60°C, and then add 229.4g of 3-chloro-2- The mixed solution composed of hydroxypropyltrimethylammonium chloride and 536.2g of water was continuously added dropwise to the round bottom flask at a constant speed for 6 hours. After the dropwise addition was completed, the temperature was raised to 90°C, and the stirring was continued for 1 hour. That is, an aqueous solution of organic cationic compound A-2 with a solid content of 30% was obtained.

Embodiment 3

[0035] The preparation of embodiment 3 organic cationic compound A

[0036] In a 1L glass round bottom flask equipped with a thermometer, a stirrer, and a dropping funnel, add 61.1g of water and 61.1g of triethylenetetramine, stir and mix evenly, keep the temperature at 45°C, and then add 378.9g of 2,3-epoxy The mixed solution composed of propyltrimethylammonium chloride and 378.9g water was continuously added dropwise to the round bottom flask at a constant speed for 4 hours. After the dropwise addition was completed, the temperature was raised to 60°C, and the stirring was continued for 3 hours at a constant temperature. An aqueous solution of organic cationic compound A-3 with a solid content of 50% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com