Shale inhibitor and preparation method thereof

A shale inhibitor and raw material technology, applied in the field of oil drilling, to achieve the effect of inhibiting hydration expansion and reducing ammonia odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

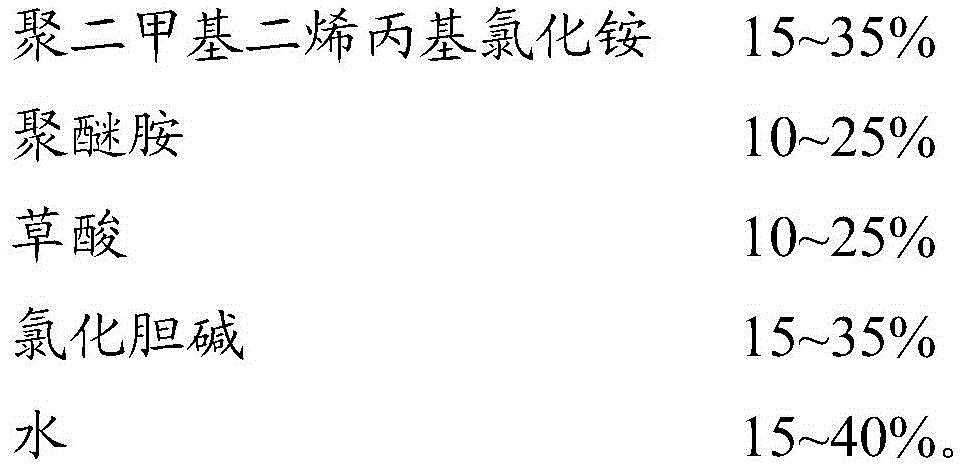

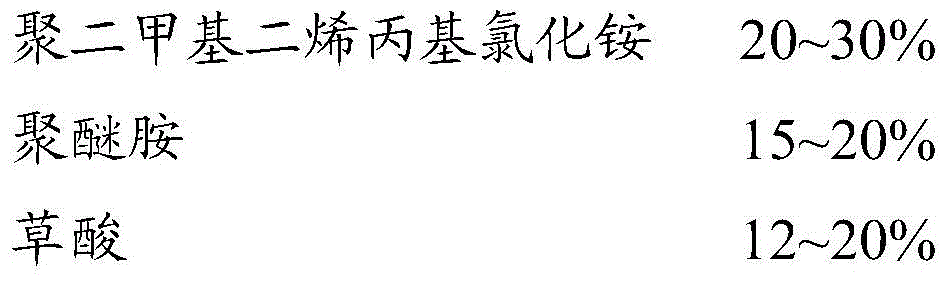

Method used

Image

Examples

preparation example Construction

[0029] The present invention also discloses a preparation method of shale inhibitor, comprising the following steps:

[0030] 1) adding water and polyetheramine into the reactor to obtain the first mixed solution;

[0031] 2) adding oxalic acid to the first mixed solution obtained in step 1), and controlling the temperature in the reactor to obtain a second mixed solution;

[0032] 3) Add polydimethyldiallylammonium chloride and choline chloride to the second mixed solution obtained in step 2), and stir to react to obtain polyamine shale inhibitor.

[0033] The sources of all raw materials in the present invention are not particularly limited, and they can be commercially available.

[0034] Wherein, water, polyetheramine, oxalic acid, polydimethyldiallyl ammonium chloride and choline chloride are all the same as above, and will not be repeated here.

[0035] In the present invention, the polyamine shale inhibitor obtained by reacting polyetheramine with oxalic acid first, a...

Embodiment 1

[0041] Take 25g of pure water and 15g of polyetheramine into the reaction kettle, stir evenly to obtain the first mixture; add 15g of oxalic acid to the first mixture, and react at 75°C for 3 hours to obtain the second mixed solution; Add 15g of polydimethyldiallylammonium chloride and 30g of choline chloride, keep the temperature in the reactor, and react for 1.5h to obtain polyamine shale inhibitor.

Embodiment 2

[0043] Add 18g of ultrapure water and 10g of polyetheramine into the reaction kettle, stir evenly to obtain the first mixture; add 12g of oxalic acid to the first mixture, and react at 80°C for 4 hours to obtain the second mixed solution; Add 25g of polydimethyldiallylammonium chloride and 35g of choline chloride to the reactor, keep the temperature in the reactor, and react for 2 hours to obtain the polyamine shale inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com