Patents

Literature

43 results about "SULFONATED PHENOL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Find patient medical information for Sulfuric Acid-Sulfonated Phenol Mucous Membrane on WebMD including its uses, side effects and safety, interactions, pictures, warnings and user ratings.

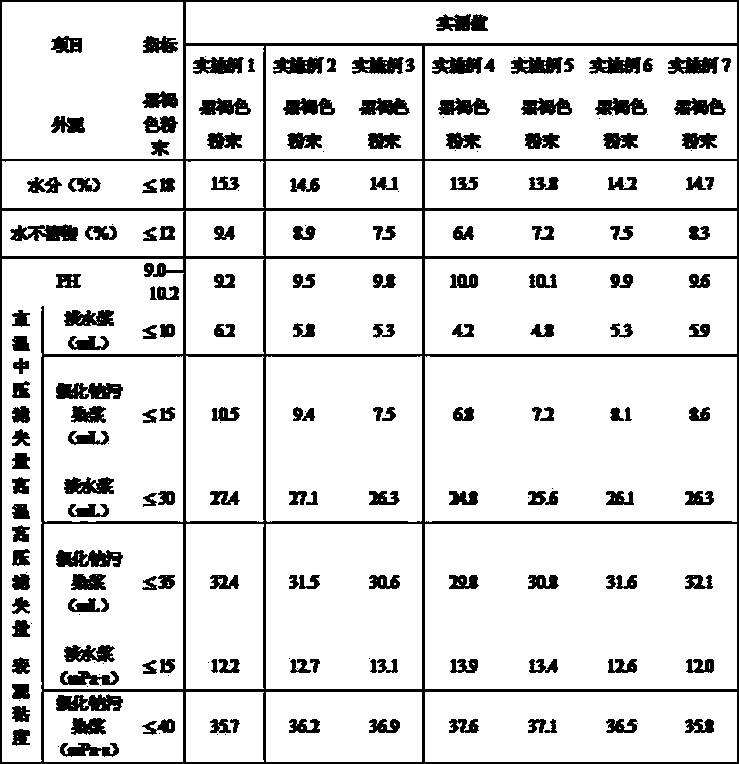

Ultra-high temperature salt-resistant drilling fluid and preparation method thereof

ActiveCN105623627AReduce fluid lossImprove rheologyDrilling compositionHigh pressureChemical cleaning

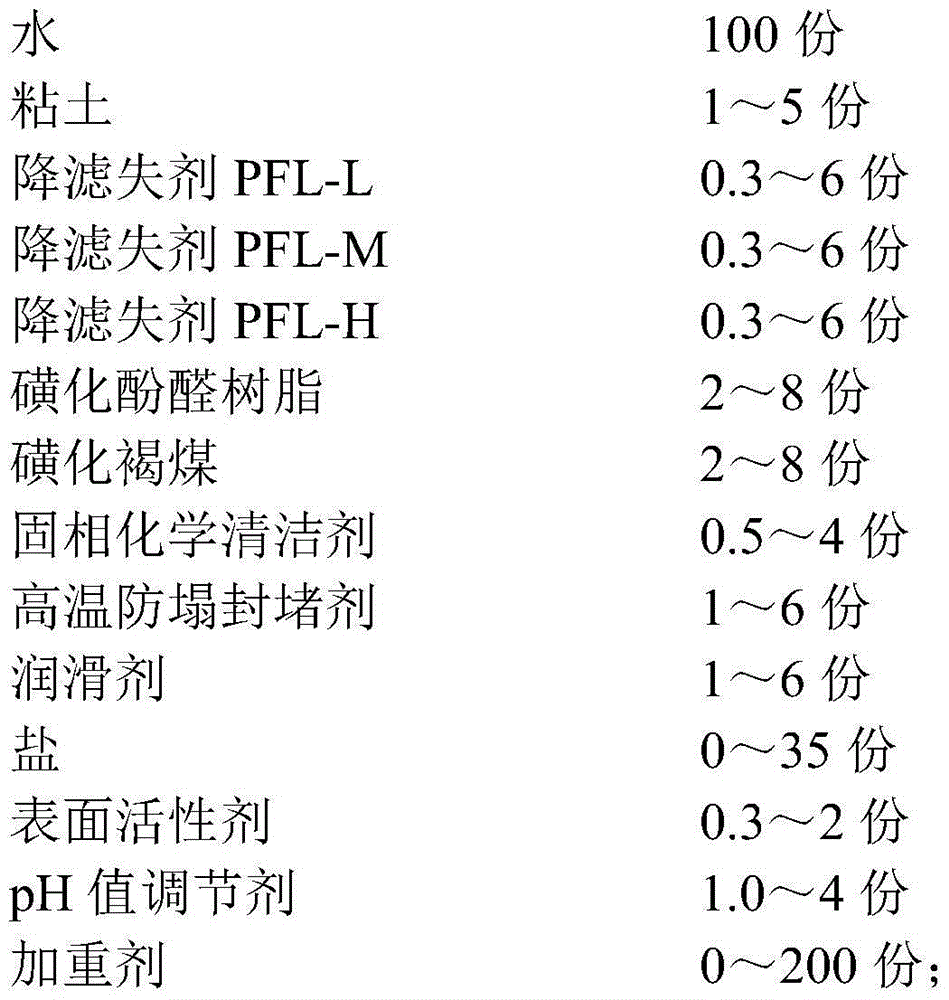

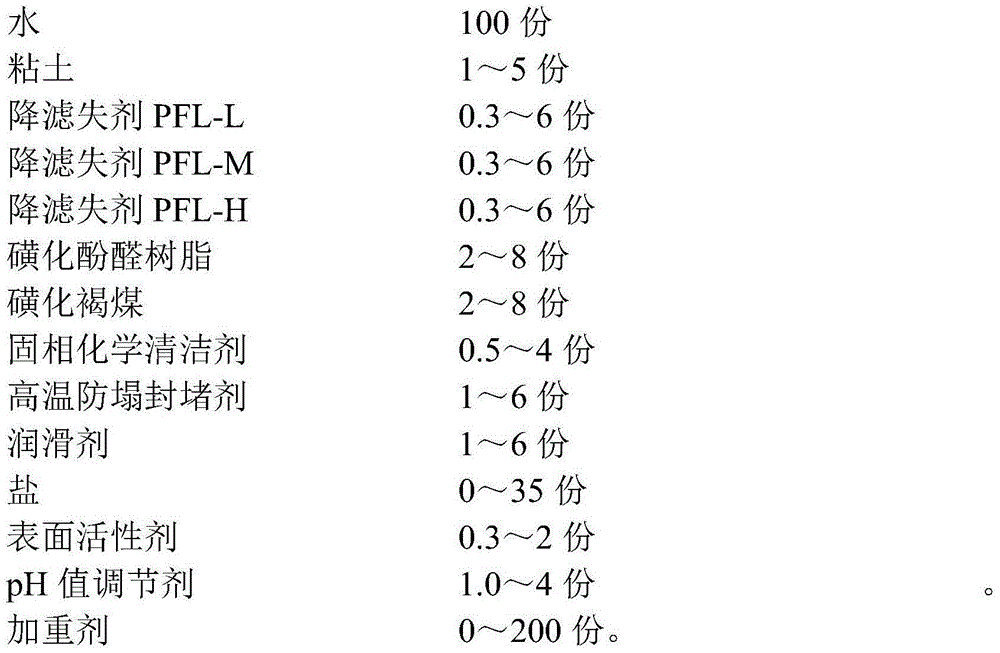

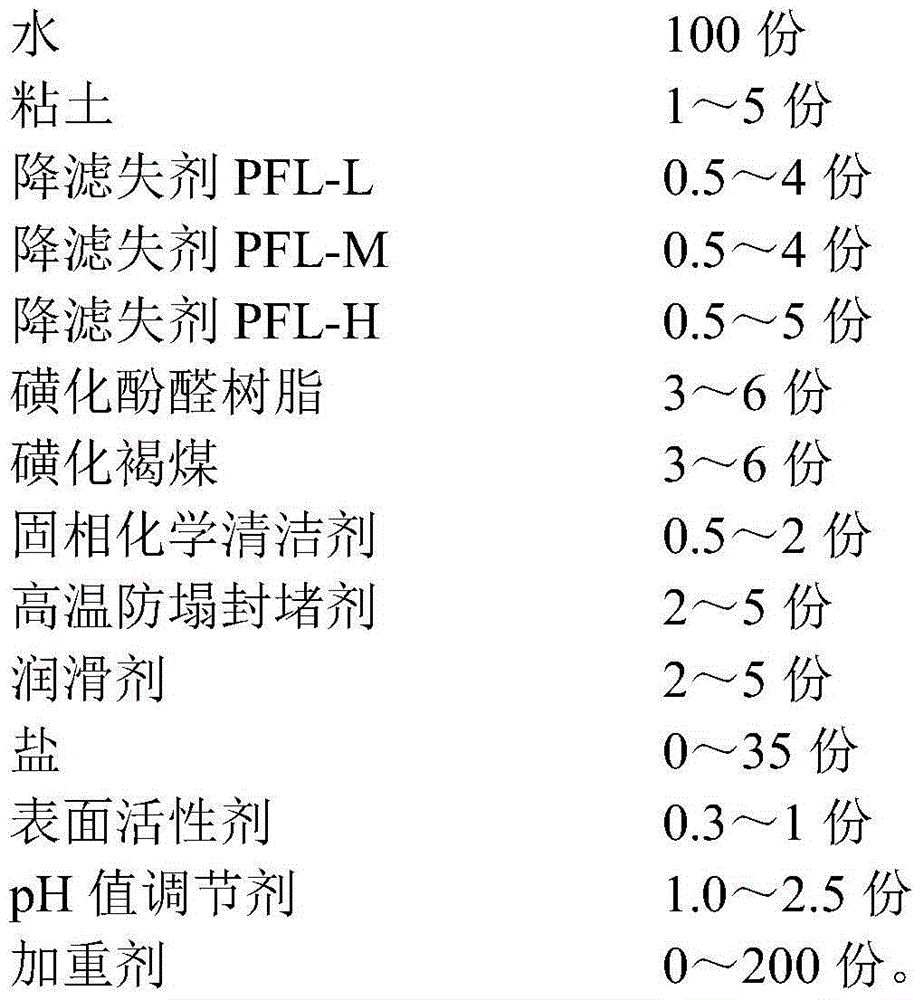

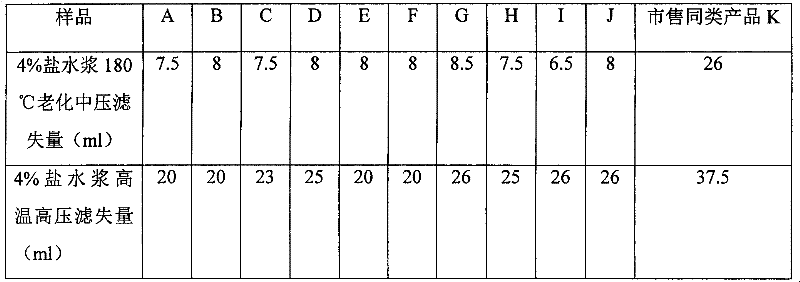

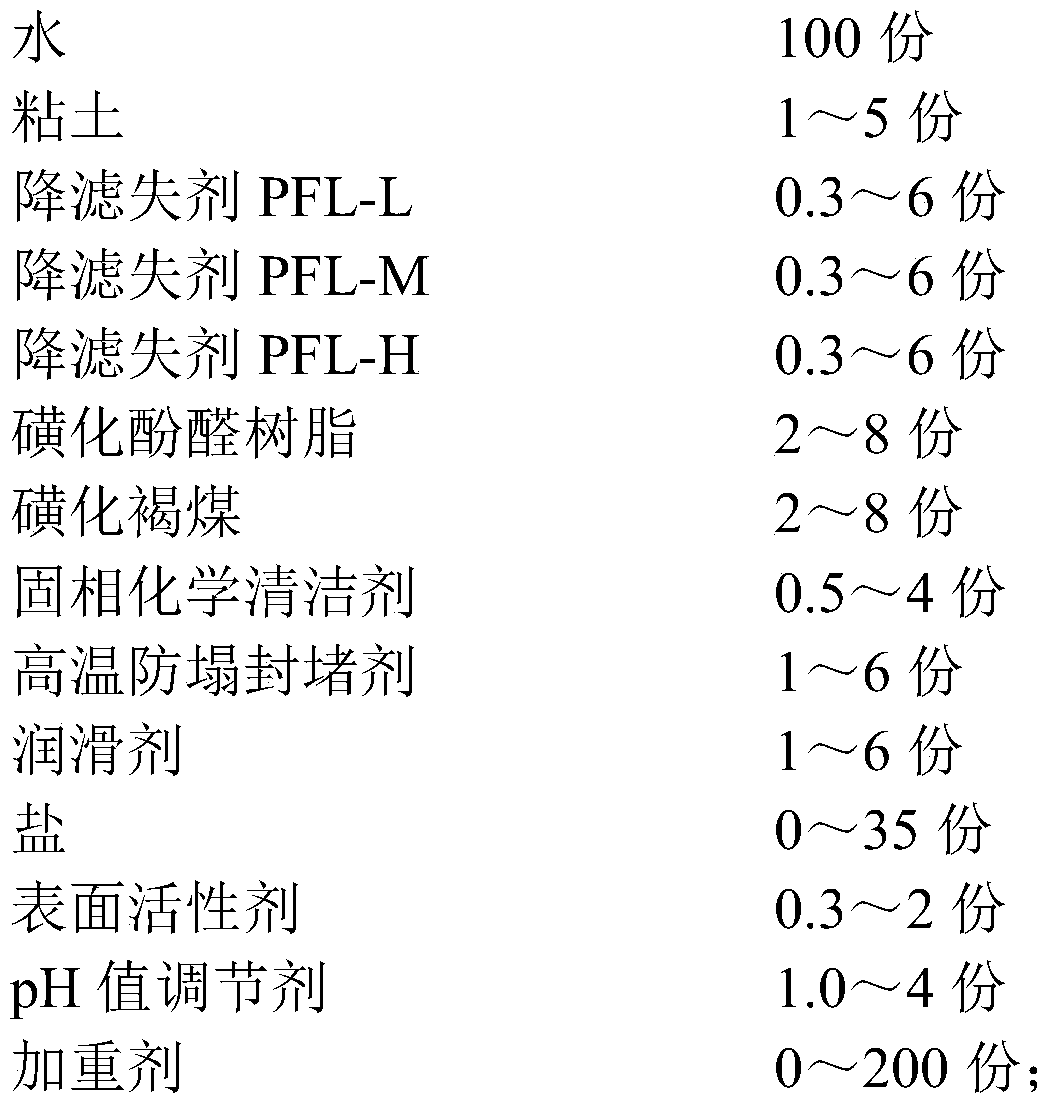

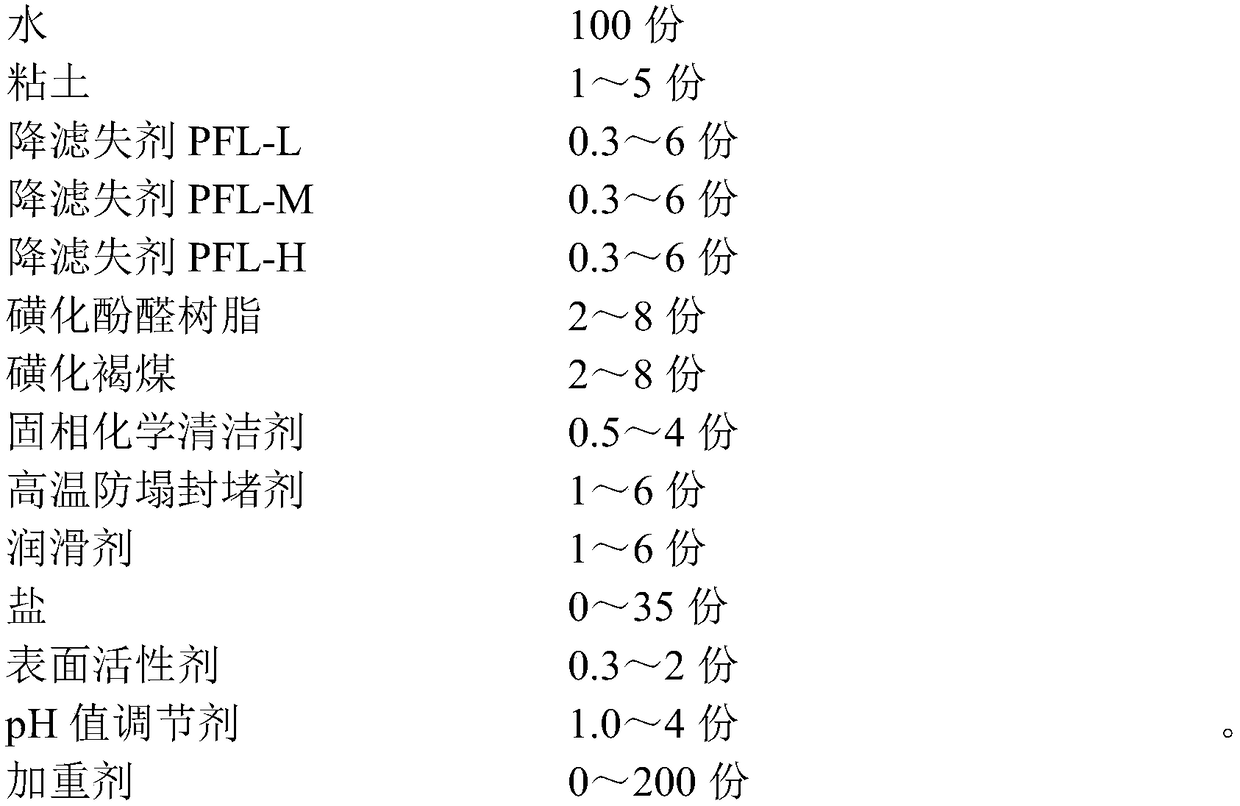

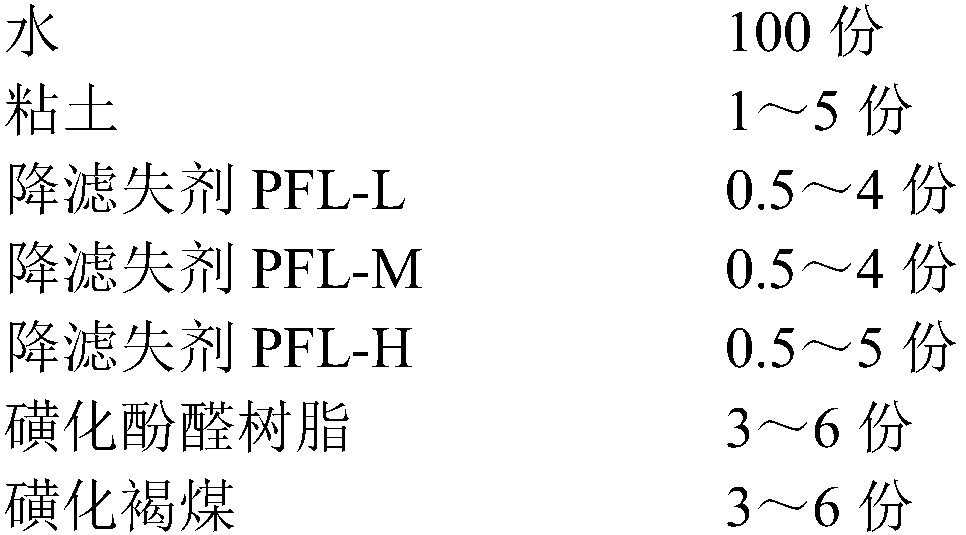

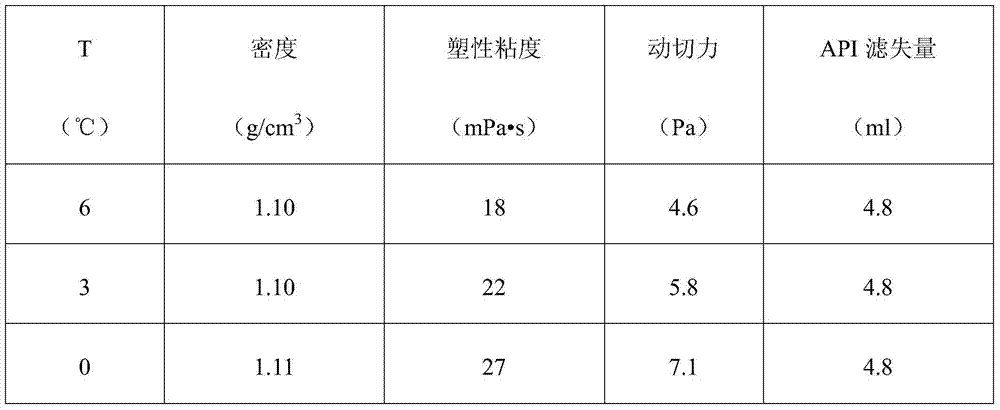

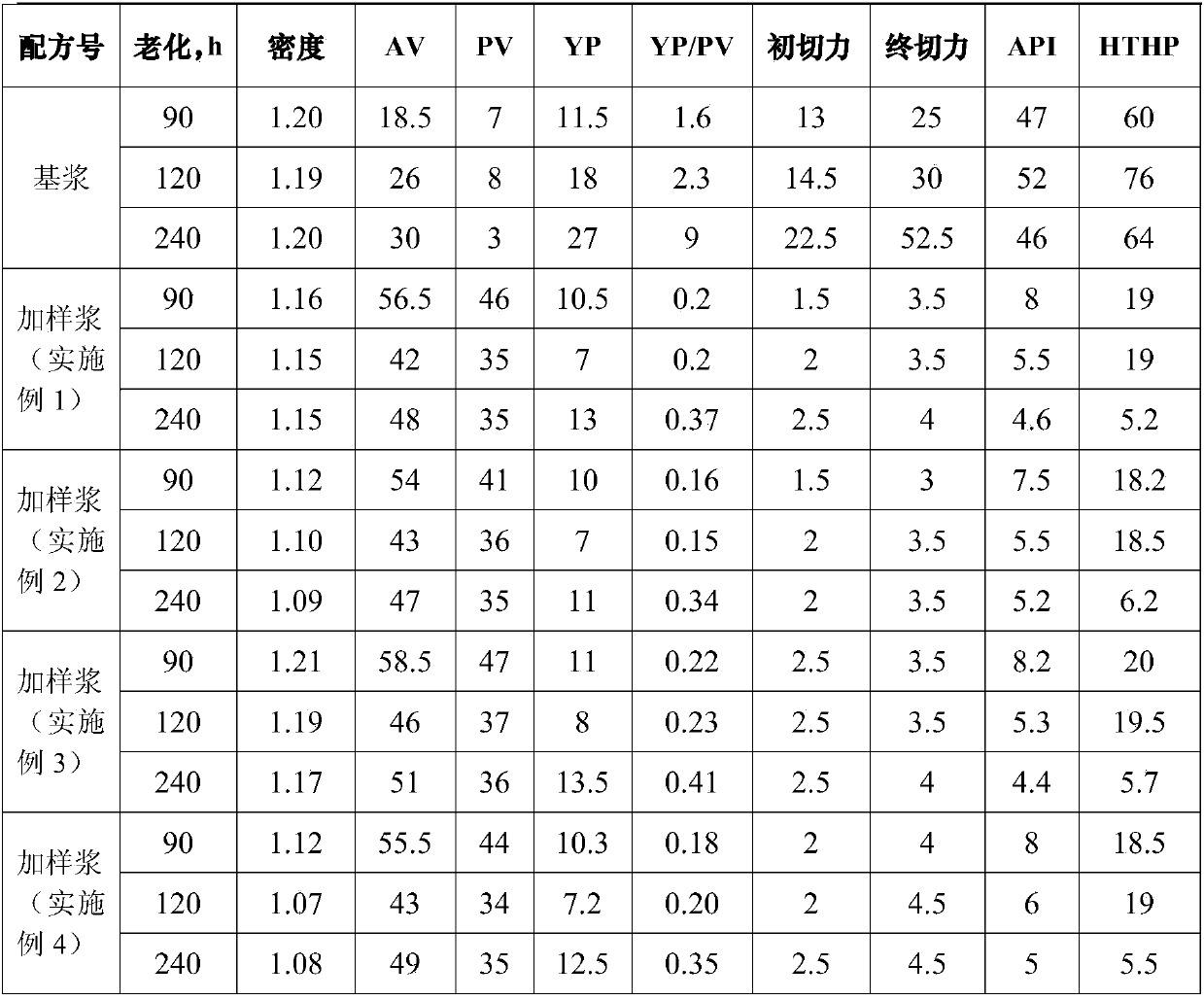

The present invention provides an ultra-high temperature salt-resistant drilling fluid for ultra-deep well and ultra-high temperature stratum drilling, and a preparation method thereof, wherein the ultra-high temperature salt-resistant drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of clay, 0.3-6 parts of a filtrate loss reducer PFL-L, 0.3-6 parts of a filtrate loss reducer PFL-M, 0.3-6 parts of a filtrate loss reducer PFL-H, 2-8 parts of a sulfonated phenol formaldehyde resin, 2-8 parts of sulfonated lignite, 0.5-4 parts of a solid-phase chemical cleaning agent, 1-6 parts of a high temperature anti-collapse blocking agent, 1-6 parts of a lubricant, 0-35 parts of salt, 0.3-2 parts of a surfactant, 1.0-4 parts of a pH value adjusting agent, and 0-200 parts of a weighting agent. According to the present invention, the ultra-high temperature salt-resistant drilling fluid is not thickened at a high temperature of more than or equal to 240 DEG C, has easily-controlled rheology and low high-temperature and high-pressure filtrate loss, can be used for bottom hole drilling construction in the high temperature (more than or equal to 240 DEG C) and high salt (saturated salt) environments, and has the good application effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phenol-urea-formaldhyde resin modified lignite filtrate loss reducer with high temperature resistance and salt tolerance, and its preparation method

InactiveCN102408882AImprove hydrophilic abilityStrong complexing abilityDrilling compositionSulfite saltTemperature resistance

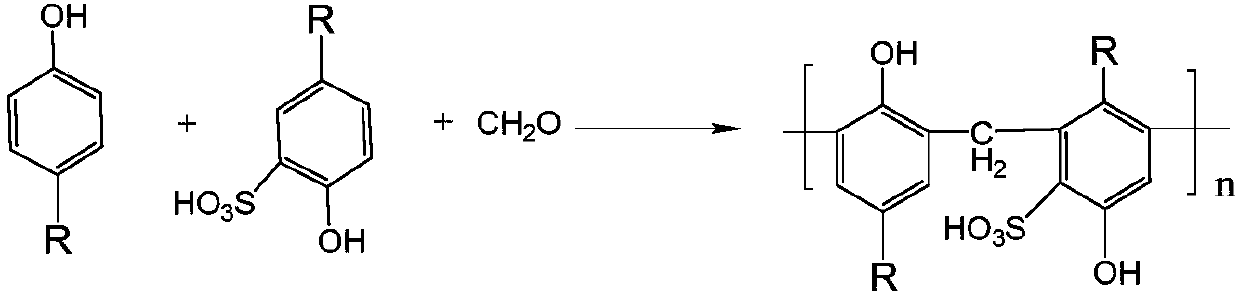

The invention relates to a preparation method of a filtrate loss reducer used for drilling fluids. With lignite as the main material, the method first prepares a sulfonated phenol-urea-formaldhyde resin mixture, which is then reacted with an alkaline solution and lignite, thus obtaining a sulfonated phenol-urea-formaldhyde resin modified lignite filtrate loss reducer. The lignite filtrate loss reducer comprises the following reactants by weight: 10%-20% of lignite; 2%-4% of one of or a mixture of NaOH and KOH; 50%-60% of water; 2%-5.5% of phenol; 8%-15% of formaldehyde; 3%-7% of urea; 0.15%-2% of a hydrolyzed acrylonitrile sodium salt; 0.125%-0.5% of polyacrylamide; and 2%-7% of a sulfonating agent (one of or a mixture of sodium sulfite, sodium bisulfite, and sodium metabisulfite).

Owner:QILU UNIV OF TECH

High-temperature-resistant compound oil-displacing agent for thermal recovery of thick oil

The invention relates to a high-temperature-resistant compound oil-displacing agent for thermal recovery of thick oil. The oil-displacing agent is a water solution and comprises the following components in parts by weight: 0.001-20 parts of sodium salt and / or calcium salt of sulfonated phenol formaldehyde resin, 0.001-20 parts of non-ionic surfactant and / or non-ionic-anion surfactant for displacing oil, wherein the number-average molecular weight of the sulfonated phenol formaldehyde resin is 2000-200000; the mass percentage of sulfur in the sulfonated phenol formaldehyde resin is 5-20 percent. The oil-displacing agent has the advantages of no alkali, strong high-temperature resistance, good interfacial property, high viscosity-reducing rate and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

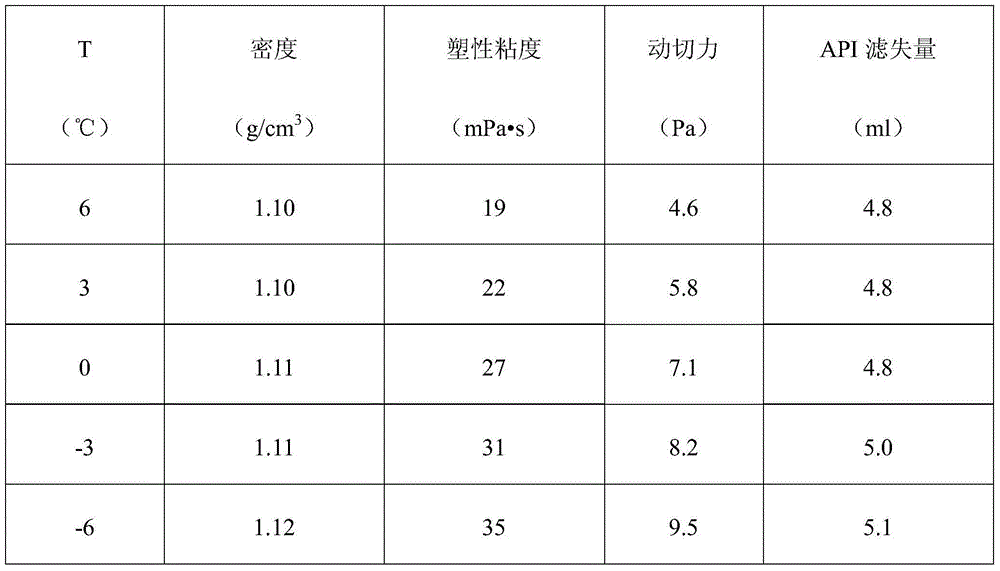

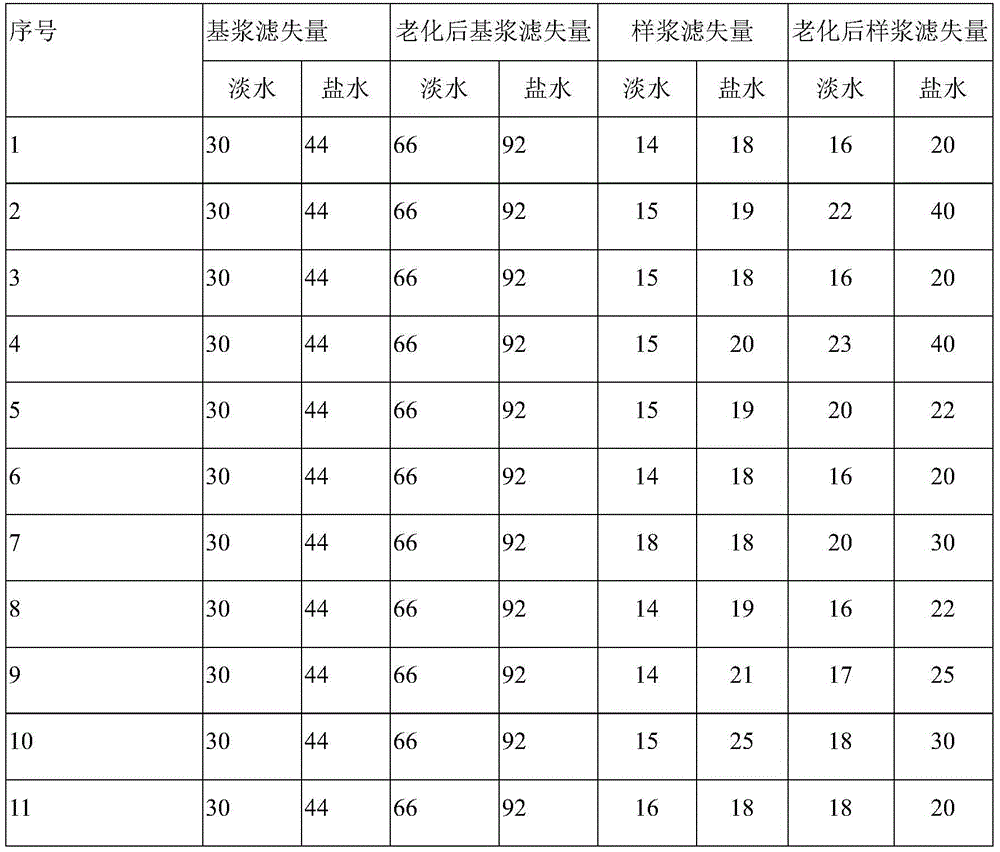

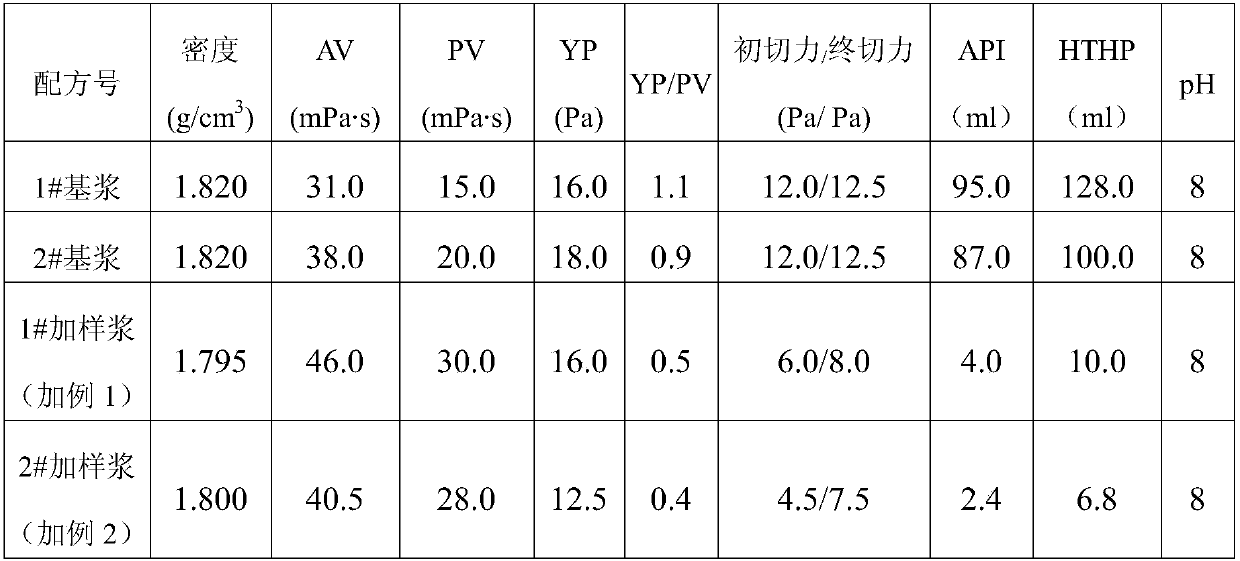

Deepwater drilling fluid

ActiveCN104559969AAvoid damageEnhanced inhibitory effectDrilling compositionSlurrySODIUM DODECYL BENZENE SULFONATE

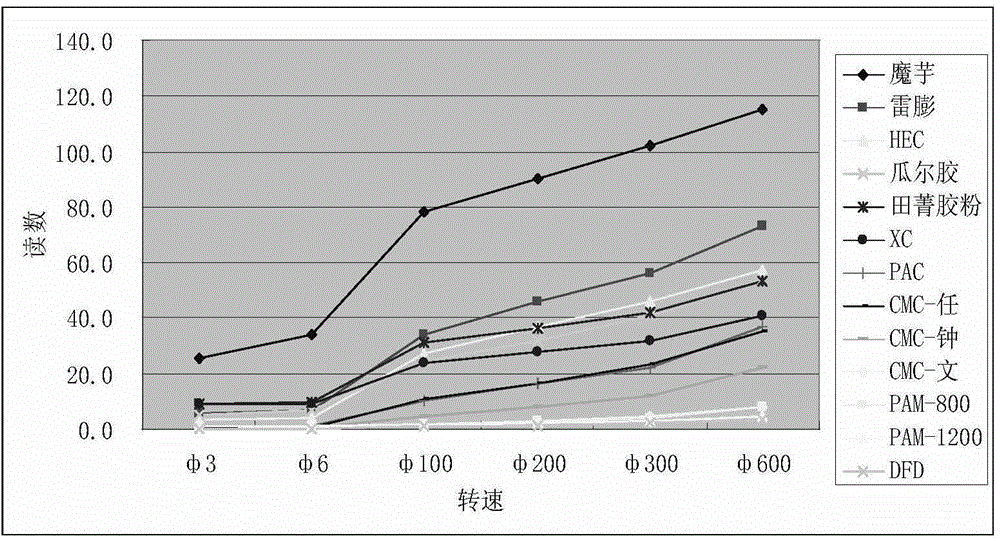

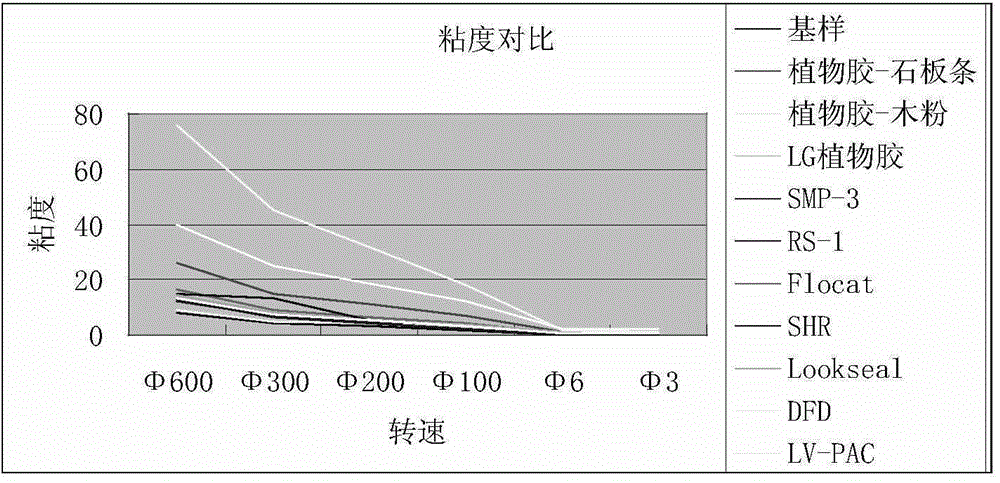

The invention discloses a deepwater drilling fluid. Every 1L of base slurry is composed of 1g of xanthan gum XC, 10-20g of sodium carboxymethyl cellulose, 20-30g of sulfonated phenol formaldehyde resin SMP-2, 30-50g of sodium silicate, 10g of polyvinylpyrrolidone PVP-K90, 15g of high modified asphalt KAHM, 50-100g of sodium chloride, 0.5g of sodium dodecyl benzene sulfonate, 0.5-1g of graphite and 0.2-0.5g of polyformaldehyde. The drilling fluid has the advantages of stable properties under cold conditions, favorable rheological behavior, high debris carrying capacity, excellent mud shale hydration expansion inhibition capacity, excellent hydrate generation inhibition capacity, low economic cost and small environmental pollution, and is especially suitable for deepwater drilling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for preparing fluid loss agent

ActiveCN102311726AWith high temperature and high pressure resistanceImprove performanceDrilling compositionSulfite saltSlurry

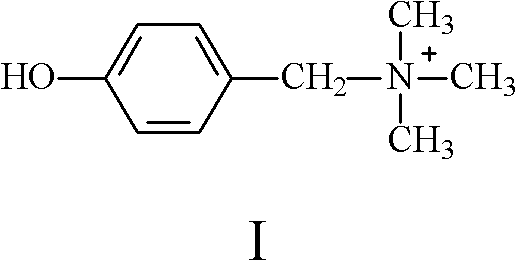

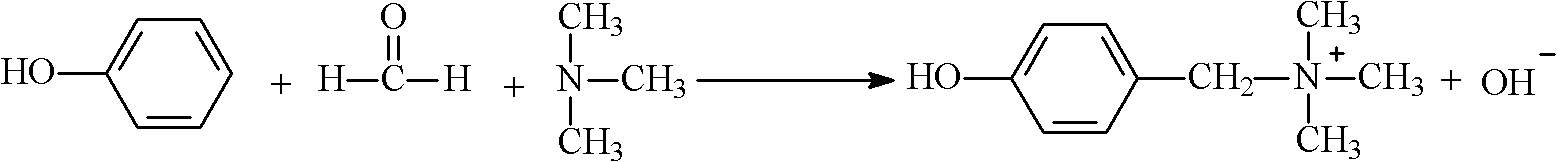

The invention provides a method for preparing a fluid loss agent. The method comprises the following steps of: a) mixing phenol, sulphuric acid, trimethylamine and a first solvent, and reacting to generate cation phenol; b) mixing an alkaline aqueous solution, lignite and a second solvent, and reacting to obtain sodium humate slurry; and c) mixing the sodium humate slurry with cation phenol, sodium sulfite and a third solvent, and carrying out polymerization to obtain the fluid loss agent. The fluid loss agent provided by the invention is obtained by firstly carrying out cationization on phenol, mixing with the sodium humate slurry and carrying out polymerization, both a humic acid group and a sulfonated phenol group are contained in the molecule of the fluid loss agent, a molecular chainis longer, and a sulfonic acid group has strong inhibition and tolerance effects to various metal ions in soil, thus mud viscosity can not be improved, a mud cake formed by a drilling fluid and soil is compact and is difficult to collapse. Besides, a benzene ring exists, thus the fluid loss agent prepared by the preparation method provided by the invention also has the characteristics of high-temperature resistance and high-pressure resistance.

Owner:河南金马石油科技有限责任公司

Water-based drilling fluid composition for trenchless drilling

InactiveCN104610942AUnderstand the purposeLearn about featuresFlushingDrilling compositionSULFONATED PHENOLSodium carboxymethylcellulose

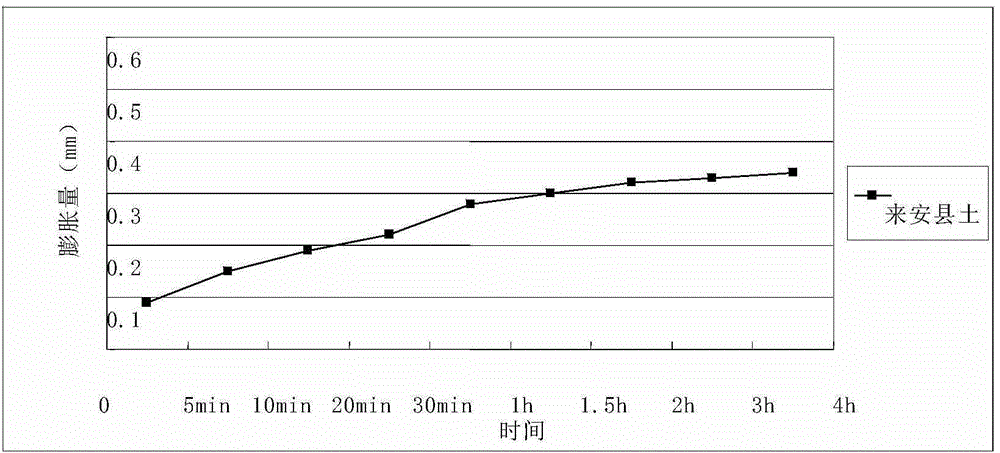

The invention discloses a water-based drilling fluid composition for trenchless drilling. The water-based drilling fluid composition for the trenchless drilling is used for horizontally and directionally drilling a sludge layer, a silt layer and a clay layer, and comprises bentonite, Laian clay or Harley soil, an anti-collapse agent, polyacrylamide, a fluid loss agent, sulfonated phenol-formaldehyde resin, a lubricant and the balance of water, wherein the anti-collapse agent can be any one of potassium humate, asphalt powder, sulfonated asphalt powder and a coal-alkali reagent; the fluid loss agent can be any one of hydrolyzed polyacrylonitrile and sodium carboxymethyl cellulose; the lubricant can be any one of an extreme-pressure lubricant, polyoxyethylene octylphenol ether and sulfonated tall oil asphalt. The invention further discloses a method for controlling mud fluid loss by using the water-based drilling fluid composition. The water-based drilling fluid composition has good effects of ensuring stability of a hole wall, carrying and suspending rock debris, stabilizing a well wall, balancing formation pressure, cooling and lubricating a drill bit and drilling tool, and the like, so that engineering can be economically and efficiently completed; the water-based drilling fluid composition has a great practical significance for a construction enterprise.

Owner:SHANGHAI MUNICIPAL GAS NO2 PIPELINES ENGINEERING CO LTD

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of acid dye color fixing agent

ActiveCN107841896AWater solubility can be easily adjusted and controlledWater Solubility Regulation and ControlDyeing processAcetic acidAcetic anhydride

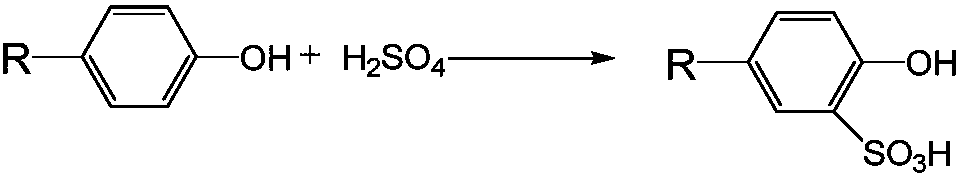

The invention discloses a preparation method of an acid dye color fixing agent. The preparation method comprises the following steps of enabling concentrated sulfuric acid to sulfonate one part of phenolic substance, so as to obtain the phenolic substance with sulfonic group; concentrating the other part of phenolic substance and formaldehyde in an organic solvent under the condition of acid neutralizing and catalyzing, so as to obtain a precondensate; mixing the products, and performing condensation reaction, so as to obtain a viscous color fixing agent. The preparation method has the advantages that the acid dye color fixing agent is synthesized by three steps; one part of phenolic substance firstly generates the sulfonating reaction with the concentrated sulfuric acid, the product generates the condensation reaction with the other part of sulfonated phenol and the formaldehyde in the organic solvent, the sulfonating degree and water dissolvability of the final product are controlled, and the color fixing effect of the final product is adjusted; the use of acetic anhydride is avoided, the synthesized product has no irritative odor of acetic acid, the final pH (potential of hydrogen) value of the product can be easily adjusted and controlled, the influence to the water dissolvability of the product is avoided, and the acid dye color fixing agent can be directly applied to thecolor fixing of chinlon and chinlon / spandex fabrics.

Owner:约克夏染料(中山)有限公司

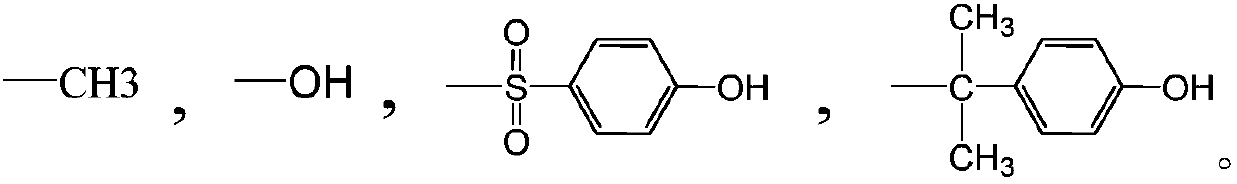

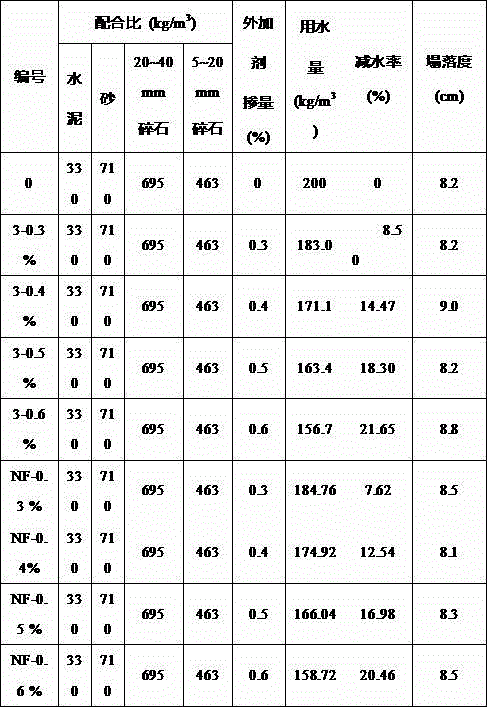

Preparation method of sulfonated bisphenol A-formaldehyde condensate superplasticizer

The invention discloses a preparation method of a sulfonated bisphenol A-formaldehyde condensate superplasticizer, which comprises the following steps of weighing bisphenol A, sodium hydrogen sulfite and water, and adding into a reaction kettle with a stirrer, a thermometer, a dropping funnel and a reflux condensing tube; dropwise adding sodium hydroxide to adjust the pH value of the solution, and increasing the temperature of the solution to 70 DEG C; dropwise adding a formaldehyde solution, and heating and reacting for 6 hours; adding urea and naturally cooling to room temperature; curing the product in the reaction kettle for 6 hours. Compared with the traditional superplasticizer adopting concentrated sulfuric acid as a sulfonating agent, the discharge of strong acid and strong base solutions is avoided in the production process, and green production is realized; compared with the traditional production process of sulfonated bisphenol-formaldehyde condensate, the influence on human bodies and environment is reduced, green production is realized, the material cost is saved, and the pollution discharge cost is reduced.

Owner:JINLING INST OF TECH

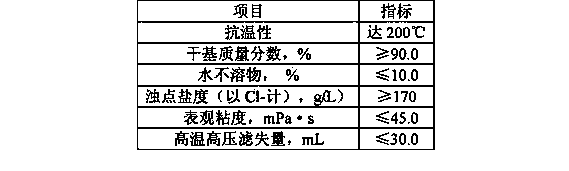

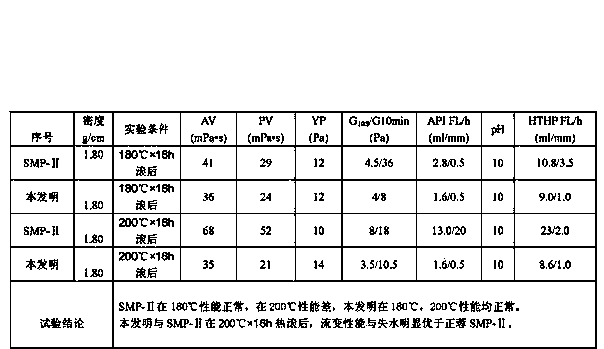

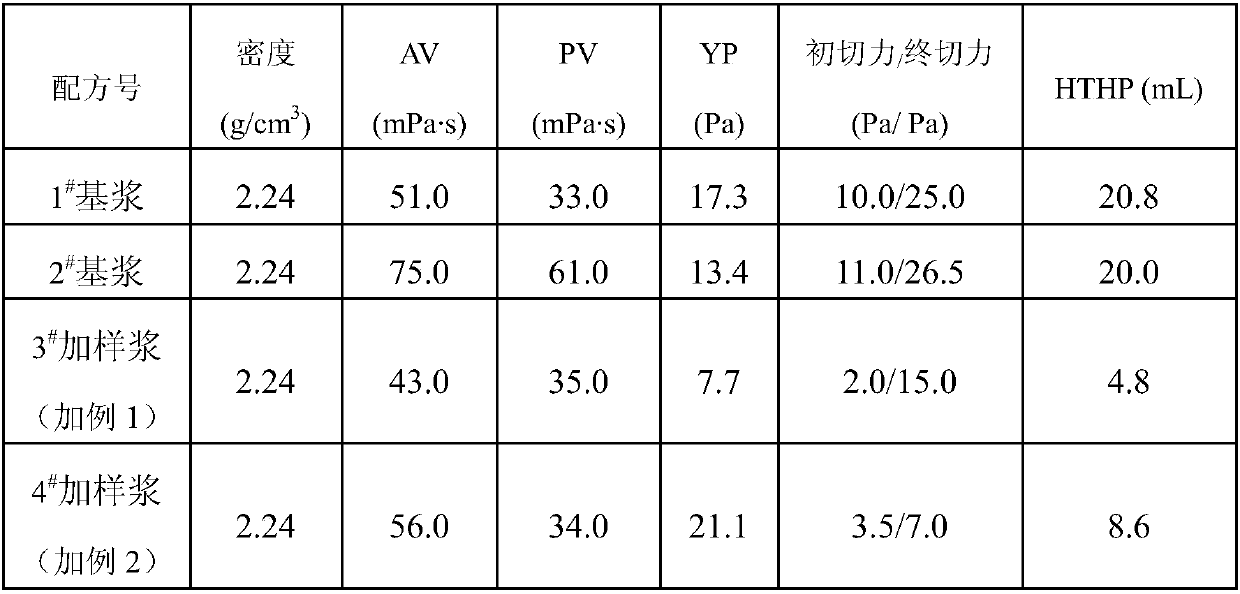

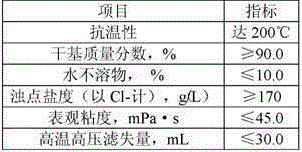

Preparation method for sulfonated-phenol-formaldehyde resin formed by modifying benzoxazine resin

ActiveCN104140509AReduce fluid lossMeet the requirements of drillingDrilling compositionWell drillingMicrometer

A preparation method for sulfonated-phenol-formaldehyde resin formed by modifying benzoxazine resin includes the steps that (1), bisphenol A type benzoxazine with the particle size smaller than or equal to 25 mm is pulverized to be powder through a pulverizing machine, wherein the particle size of the powder is 10 micrometers-125 micrometers, and the powder is standby; (2), the powder obtained in the step (1) and modified sulfonated phenolic resin agents are thrown into a reaction kettle according to the mass ratio of 1:20, mixed, stirred for one hour at the temperature of 105 DEG C and then delivered into an ultrasonic emulsifying device through a discharging pump to be ultrasonically emulsified for 20 minutes to obtain a mixed solution, and the mixed solution is standby; (3), spraying drying is performed on the mixed solution in the step (2) to obtain the modified sulfonated-phenol-formaldehyde resin. The sulfonated-phenol-formaldehyde resin can be resistant to high temperature of 200 DEG C, has an obvious effect of lowering the filter loss of drilling fluid and can meet the requirements for three high well drilling.

Owner:SICHUAN ZHENGRONG IND +1

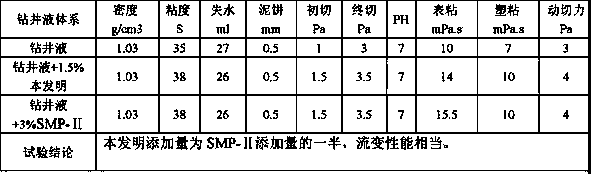

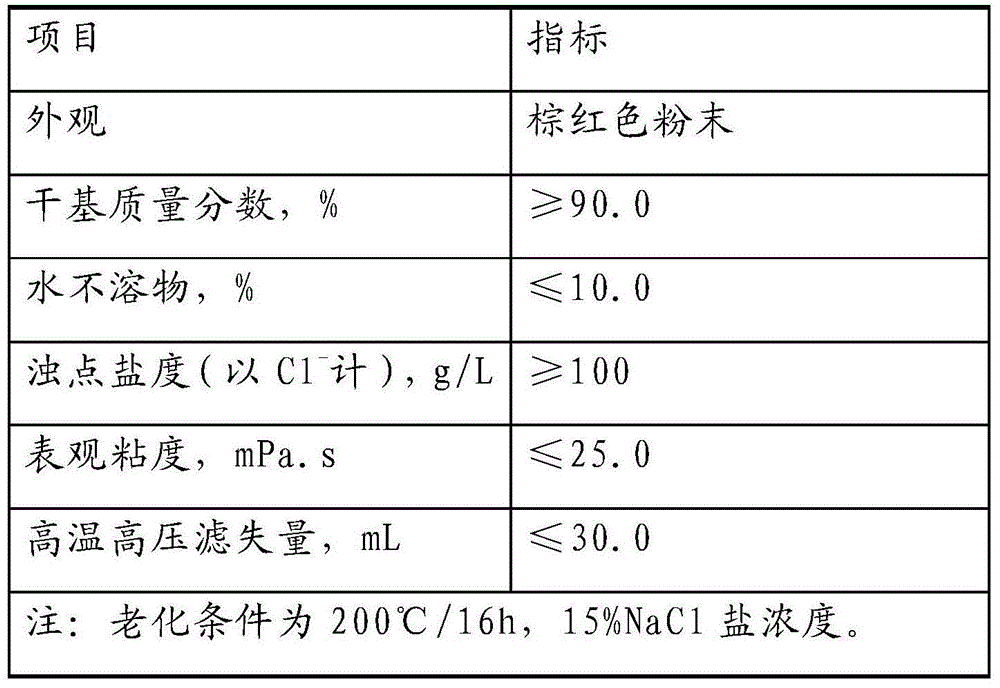

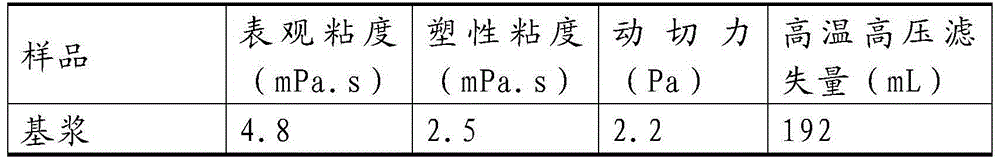

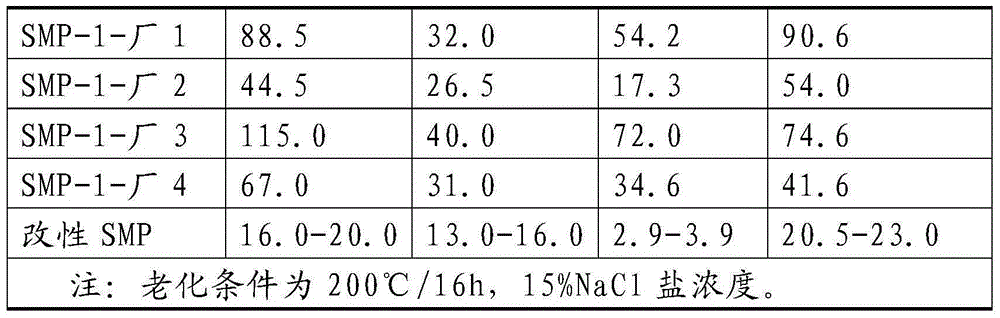

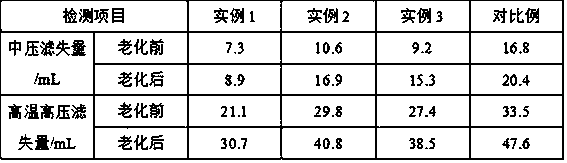

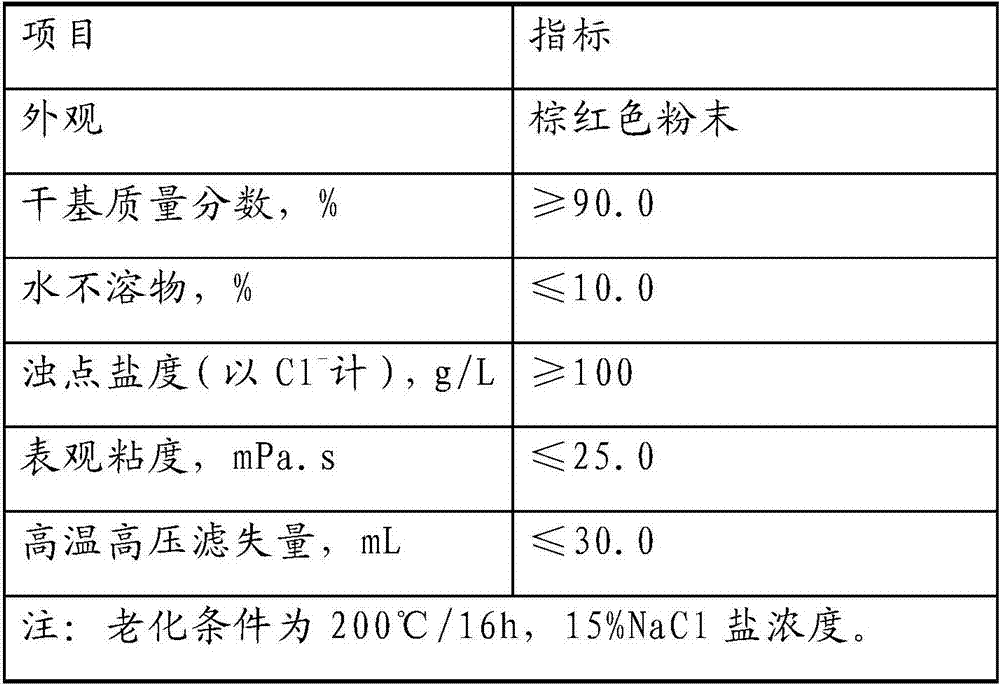

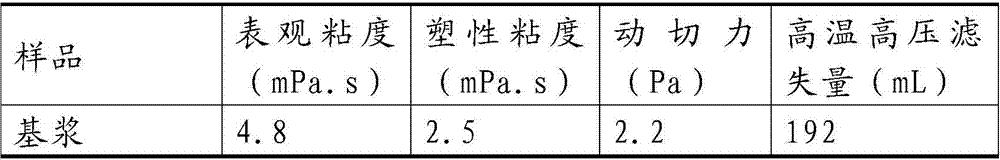

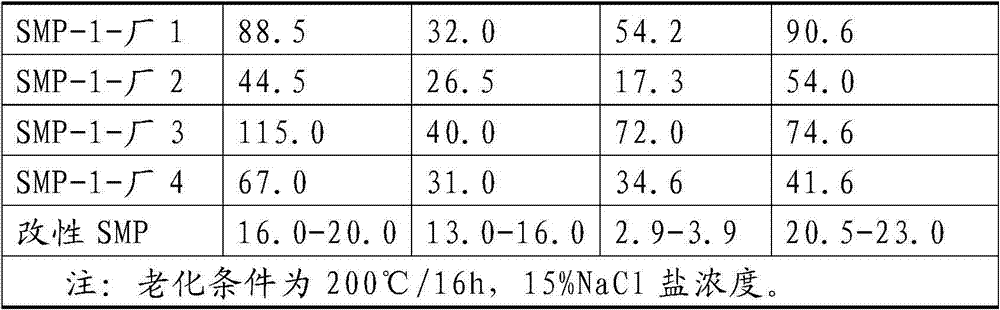

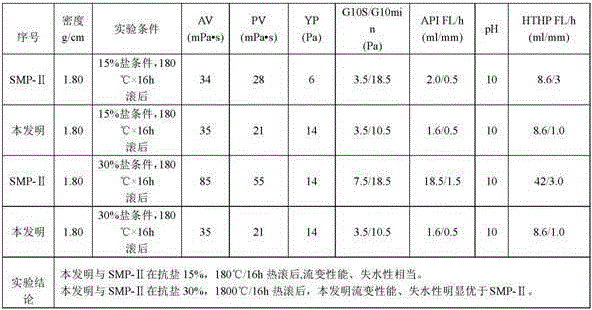

Preparation method of high-temperature-resistant modified sulfonated phenol formaldehyde resin for drilling fluids

ActiveCN104788634AReduce high temperature and high pressure filtration lossImprove performanceDrilling compositionSalt resistanceHigh pressure

The invention discloses a preparation method of a high-temperature-resistant modified sulfonated phenol formaldehyde resin for drilling fluids, which comprises the following steps: 1) adding a phenol reactant, an aldehyde reactant and an acid catalyst into a reaction kettle, mixing, and reacting at 50-110 DEG C for 10-400 minutes; 2) adding an alkali catalyst and an aldehyde reactant into the reaction kettle, keeping the temperature at 50-110 DEG C, adding a sulfonating agent in batches, and reacting for 10-600 minutes; and 3) after the reaction finishes, cooling, discharging, and carrying out spray drying to obtain the product. The temperature resistance of the modified sulfonated phenol formaldehyde resin product can reach 200 DEG C. The high-temperature high-pressure filter loss of the drilling fluid under the aging condition of 200 DEG C can be effectively lowered as compared with the base mud, and the salt resistance can reach the salt concentration of 15% NaCl.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

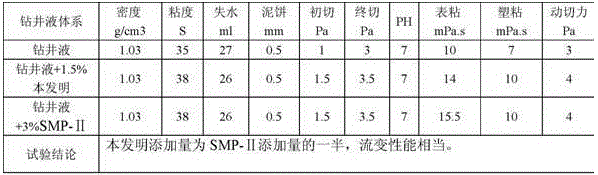

Brown coal resin for drilling fluid and production technology of brown coal resin

InactiveCN108018028AImprove salt resistanceImprove high temperature resistanceDrilling compositionFiltrationSlurry

The invention discloses brown coal resin for a drilling fluid and a production technology of the brown coal resin. Brown coal and sulfonated phenolic resin are used as main materials, sulfonated phenol humic acid with excellent salt resistance and high-temperature resistance is introduced, and the brown coal resin has remarkable high-temperature-resistant, filtration loss reduction and salt-resistant performance after being modified with a basifier and a sulfonating agent and has anti-collapse and viscosity control effects. A small amount of carboxymethyl cellulose is added, and the carboxymethyl cellulose has excellent stability and still has significant performance at 150 DEG C or above; meanwhile, trimethylamine and sulfomethyl sodium humate with excellent temperature resistance, salt resistance and calcium and magnesium ion resistance are introduced, the adsorption capacity of sulfonated phenolic resin and clay is enhanced, the temperature resistance and the salt resistance of theproduct are effectively improved, the value of the product is increased, the addition amount is small, the filtration loss reduction effect is significant, and excellent filtration loss reduction performance can be produced after only 1.0% of base slurry is added.

Owner:YUMEN OIL FIELD KEDA CHEM

Environment-friendly composite board material for construction and preparation method thereof

The invention discloses an environment-friendly composite board material for construction and a preparation method thereof. The environment-friendly composite board material is prepared from the following raw materials in parts by weight: 30-50 parts of Portland cement, 10-15 parts of waste plastic, 5-10 parts of walnut shells, 8-15 parts of bentonite, 12-15 parts of organic silicone modified epoxy resin, 12-18 parts of rutile titanium dioxide, 15-25 parts of sulfonated-phenol-formoldehyde formaldehyde resin, 4-9 parts of fly ash, 10-20 parts of a sodium silicate solution, 2-10 parts of hydroxymethyl cellulose, 1-8 parts of mixed fiber, 11-17 parts of butyl propionate and 2-8 parts of montmorillonite powder. The prepared environment-friendly composite board material for construction is simple in preparation process and low in manufacturing cost, has the advantages of light capacity, good waterproof effect and good thermal insulation effect, has highgood chemical stability, is nontoxicand tasteless, and is an ideal thermal insulation material.

Owner:安徽嘉中金属材料有限公司

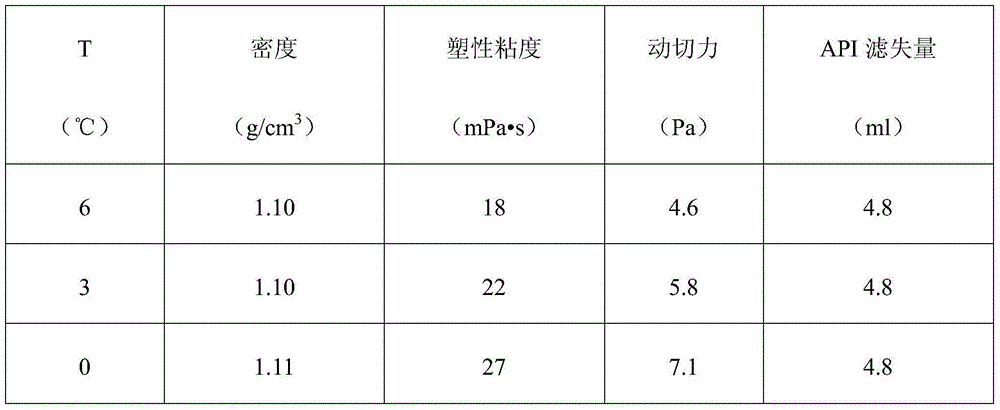

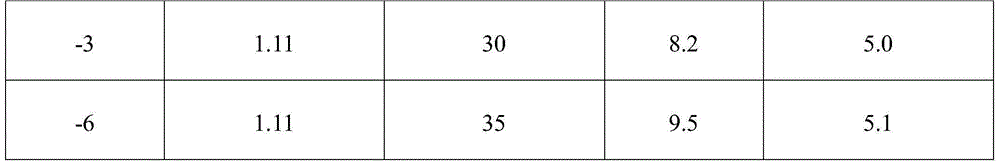

Deepwater drilling liquid

InactiveCN101705080ASolve poor rheologySolve problems such as easy formation of natural gas hydrateDrilling compositionSodium BentoniteSeawater

The invention relates to drilling liquid, in particular to deepwater drilling liquid which comprises the following components, by mass percent: 0-8% of bentonite, 0.05-5% of well wall stabilizing agent, 1-6% of visbreaking fluid loss control agent used for the drilling liquid, 1-6% of carboxymethyl sulfonated phenol formaldehyde resin used for the drilling liquid, 5% of sodium chloride NaCl to saturated sodium chloride NaCl, 5-50% of glycol and the balance of fresh water or seawater. The invention provides a formula of the drilling liquid suitable for (marine) deepwater drilling and solves the problems of poor rheological property of the drilling liquid in a deepwater drilling process, easy formation of a natural gas hydrate and the like. The formula can be suitable for deepwater drillingin the water depth within 3000m and at the temperature of 0-150 DEG C, and the long-term stability can reach 7 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Stabilizer for drilling fluids and preparation method thereof

ActiveCN105670577AAvoid degradationImprove rheologyDrilling compositionPolyethylene glycolHigh pressure

The invention relates to a stabilizer for drilling fluids and a preparation method thereof. The stabilizer for drilling fluids comprises a sulfonated lignite resin, a sulfonated phenol formaldehyde resin, high-strength polypropylene fibers, polyethyleneglycol and acetoxime. The method comprises the following step: stirring and mixing the sulfonated lignite resin, sulfonated phenol formaldehyde resin, high-strength polypropylene fibers, polyethyleneglycol and acetoxime to obtain the stabilizer. The stabilizer for drilling fluids can well inhibit the degradation of the drilling fluid in the deep well under the conditions of high pressure, high sulfur content and high risk, thereby performing the high-temperature stabilizing function, and improving the rheological property of the drilling fluid system. The stabilizer for drilling fluids has lower water loss, and the water loss change rate before and after high temperature can be controlled within 30%.

Owner:四川泓华油气田工程科技有限公司

Mud for large borehole drilling

InactiveCN105295874AHighlight the effect of leak-proof wall protectionIncrease ROPDrilling compositionMeth-Horizontal wells

The present invention provides a mud for large borehole drilling in oil drilling, and belongs to the field of oil drilling engineering. In order to solve the problem that in a oil drilling process, large borehole can easily cause wall collapse, which seriously affects the drilling speed and efficiency, and hinder progress of oil exploration and development work, the present invention provides the mud for large borehole drilling. The formula is: 30-40 parts of bentonite; 0.2-0.3 part of positive gel; 0.2-0.3 part of positive gel structuring agent; 0.6-1 part of sulfonated lignin sulfonic methyl phenol resin; 3-5 parts of lignite resin; 3-5 parts of sulfonated asphalt; 0.03-0.05 part of copolymers of vinyl monomers polyhydric; 1-3 parts of sulfonated phenol-formaldehyde resin; and 1000 parts of water. According to the mud for large borehole drilling provided by the present invention, raw materials and content for choice has outstanding leak-proof and wall protection effects, and applies to drilling in understable highly deviated wells, horizontal wells, easily dilapidated strata, and large wellbore with high earth strata dips, and high and steep constructions in East Sichuan region.

Owner:成都棕通石油配件有限公司

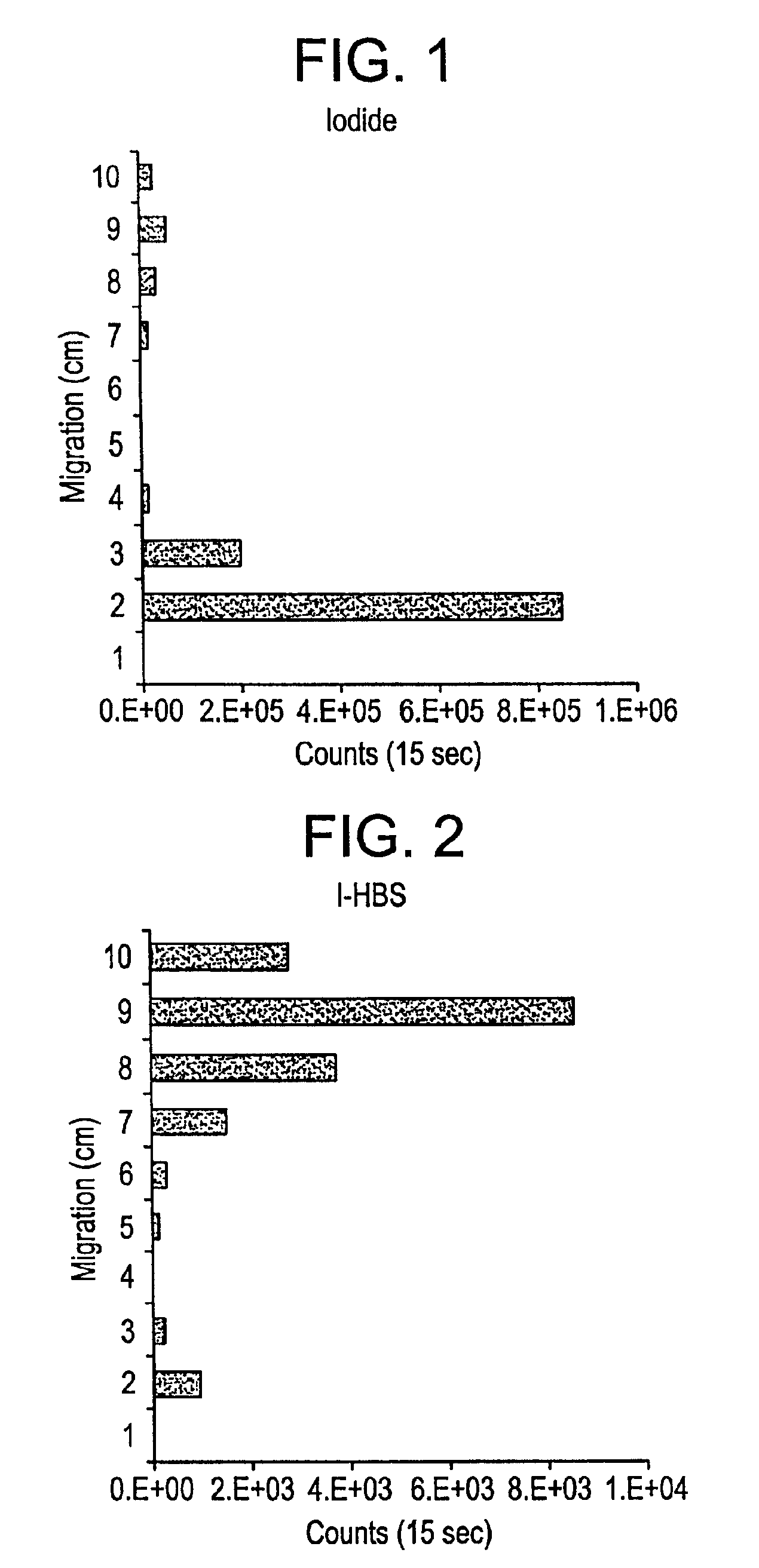

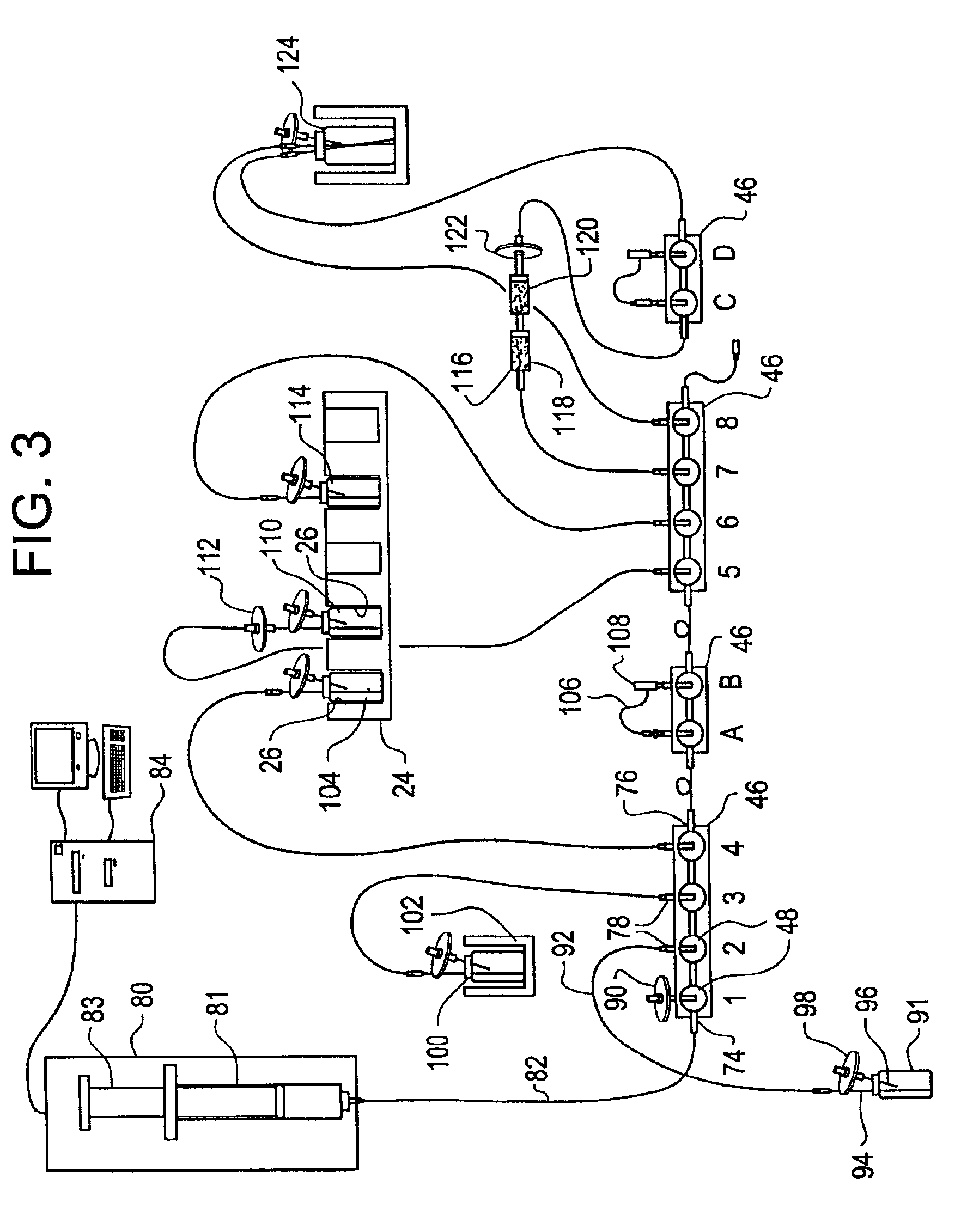

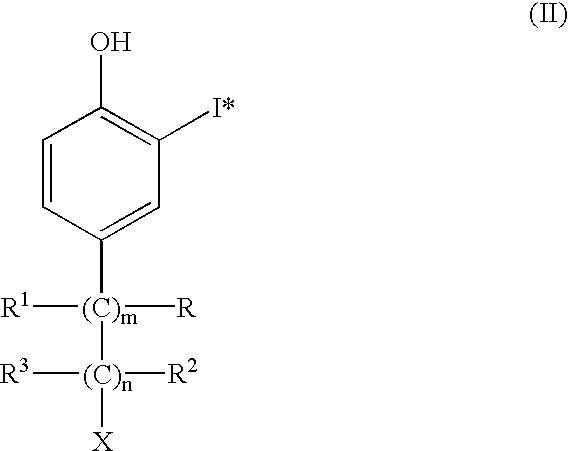

Radioiodinated sulfonated phenols and process therefore

InactiveUS6861044B2High yieldHigh purityRadioactive preparation carriersMacromolecular non-active ingredientsFencholIodine

The present invention concerns the use of a radioiodinated phenolic compound of the formula wherein: m and n are independently 0, 1, 2 or 3, X is a group that is negatively or positively charged at physiological pH, R, R1, R2 and R3 are independently hydrogen, C1-C4 alkyl, or a carboxyl group, and I* is 123I, 131I or 125I, and its pharmaceutically-acceptable salts. The compound is formulated and used in vivo in an animal in brachytherapy in an implantable catheter. In addition, due to the rapid renal clearance of these compounds, they may be used to study renal function. A process to prepare these compounds is also disclosed.

Owner:THE DOW CHEM CO

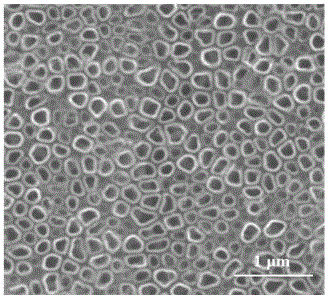

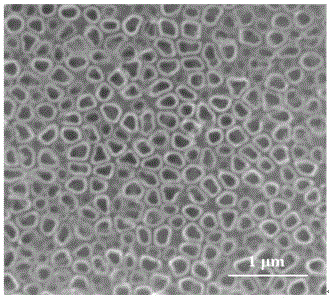

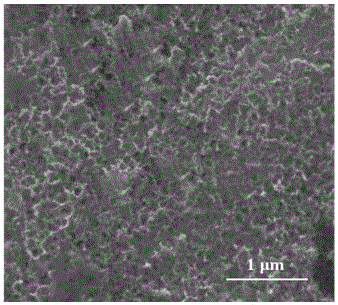

Preparation method and application of Ti3+ doped TiO2 nanotube array/sulfonated poly phenol membrane electrode

InactiveCN106299216AIncrease the diffusion coefficientShorten the transmission distanceMaterial nanotechnologyCell electrodesTio2 nanotubeAdhesive

The invention discloses a preparation method and application of a Ti3+ doped TiO2 nanotube array / sulfonated poly phenol membrane electrode. A three-dimensional orderly TiO2 nanotube array is prepared through an anodic oxidation method firstly, then a Ti3+ doped TiO2 nanotube array is prepared in a three-electrode system through an electrochemical method and serves as a working electrode, the Ti3+ doped TiO2 nanotube array / sulfonated poly phenol membrane electrode is prepared with a sulfonated phenol solution as the electrolyte through an electrochemical polymerization reaction, and no additional conductive agent or adhesive needs to be added when the obtained membrane electrode is applied to a lithium ion battery. The method is simple in process and friendly to the environment; by doping Ti3+, the conductivity of the TiO2 nanotube array is improved, and electrochemical integration of the membrane electrode is achieved; when the membrane electrode is applied to the lithium ion battery, due to the coordinative effect between a membrane and electrode materials, the charging / discharging specific capacity and circulating stability of the membrane electrode material are improved.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of sulfonated phenolic water-absorbing resin

InactiveCN102295820AIncrease elastic strengthHigh compressive strengthReaction temperatureSynthetic Polymeric Macromolecules

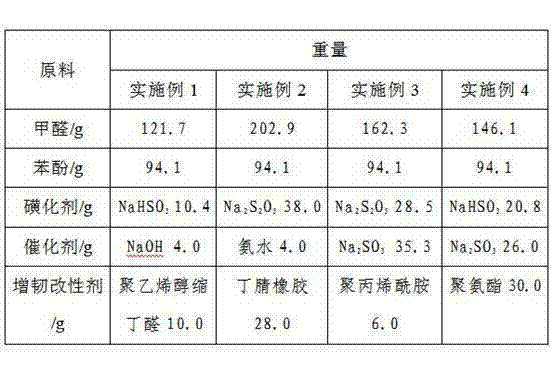

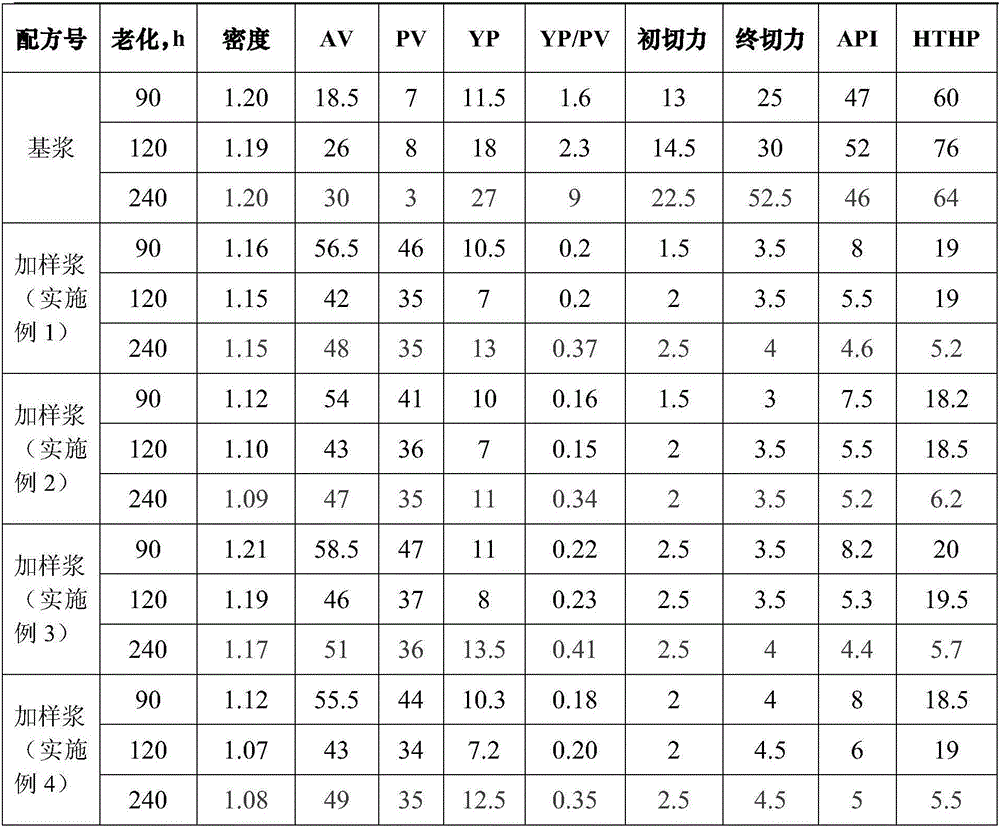

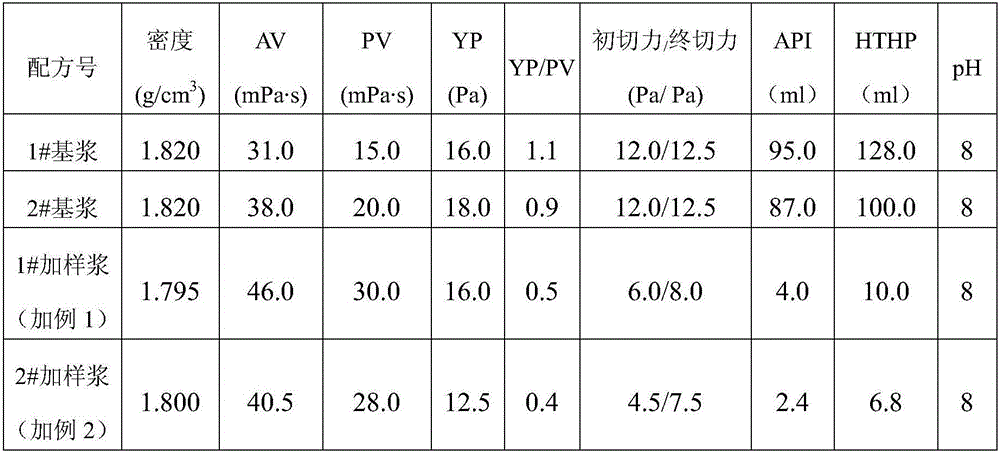

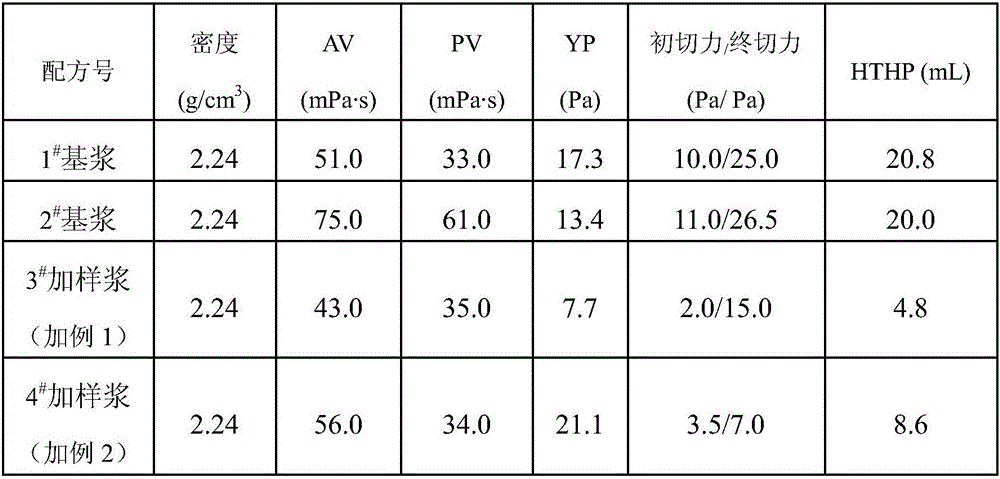

The invention relates to a method for preparing a sulfonated phenolic water-absorbing resin, and belongs to the technical field of methods for preparing high molecular water-absorbing resins. The method comprises the following steps of: adding formaldehyde into a reactor in which a reflux condenser, a thermometer and a stirrer are arranged; adding molten phenol; uniformly stirring and then addinga sulfonating agent; adding a catalyst after the sulfonating agent is fully dissolved; controlling pH value of reaction to be 8-10 and reaction temperature to be 50-60 DEG C; reacting for a time withstirring; then raising the temperature to 90-110 DEG C; continuously reacting for a certain time and then adding a toughening and modifying agent; continuously reacting; and pouring reaction liquid into a closed container for slaking before gelling to prepare the sulfonated phenolic water-absorbing resin. A product provided by the invention has higher viscoelasticity and compressive strength, water absorption multiple of 5-20, capability of resisting high temperature of 150-180 DEG C and high thermal stability, can be used for leakage stoppage operation of deep wells and ultra-deep wells in apetroleum drilling process and can also be used for other fields with higher requirements on the temperature resistance of the water-absorbing resin.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of high temperature resistant heavy oil thermal recovery compound oil displacement agent

The invention relates to a high-temperature-resistant compound oil-displacing agent for thermal recovery of thick oil. The oil-displacing agent is a water solution and comprises the following components in parts by weight: 0.001-20 parts of sodium salt and / or calcium salt of sulfonated phenol formaldehyde resin, 0.001-20 parts of non-ionic surfactant and / or non-ionic-anion surfactant for displacing oil, wherein the number-average molecular weight of the sulfonated phenol formaldehyde resin is 2000-200000; the mass percentage of sulfur in the sulfonated phenol formaldehyde resin is 5-20 percent. The oil-displacing agent has the advantages of no alkali, strong high-temperature resistance, good interfacial property, high viscosity-reducing rate and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature-resisting fluid loss agent for drilling fluid and preparation method thereof

The invention discloses a high temperature-resisting fluid loss agent for drilling fluid. The high temperature-resisting fluid loss agent is characterized by being prepared from the following components and raw materials in percentage by mass: 10 to 15 percent of abietic acid, 8 to 12 percent of glycerol, 30 to 40 percent of sulfonated bitumen, 10 to 12 percent of cationic starch, 10 to 20 percent of temporary plugging agent, 12 to 14 percent of high temperature stabilizer and 0.5 to 1.0 percent of deoxidant, wherein the cationic starch is prepared from starch tert-amino alkyl ether and quaternary ammonium starch ether; the high temperature stabilizer is prepared from sulfonated phenol-formaldehyde resin and sulfonated lignite resin; the temporary plugging agent is prepared from tert-butyl phenolic curing resin, octyl phenolic curing resin and calcium carbonate. The high-temperature resistance is up to 250 DEG C, no blistering exists, the viscosity effect is low, the compatibility is good, a product contains rigid particles and softening film-forming particles in different size grading, the product directly participate in mud cake forming, a high-strength adsorption film is formed on the surface of the mud cake, the permeability rate of the mud cake is reduced, the quality of the mud cake is improved, and the function of reducing high-temperature high-pressure filter loss is achieved.

Owner:成都西油华巍科技有限公司

A kind of ultra-high temperature salt-resistant drilling fluid and preparation method thereof

ActiveCN105623627BRheology is easy to controlReduce high temperature and high pressure filtration lossDrilling compositionActive agentWell drilling

The present invention provides an ultra-high temperature salt-resistant drilling fluid for ultra-deep well and ultra-high temperature stratum drilling, and a preparation method thereof, wherein the ultra-high temperature salt-resistant drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of clay, 0.3-6 parts of a filtrate loss reducer PFL-L, 0.3-6 parts of a filtrate loss reducer PFL-M, 0.3-6 parts of a filtrate loss reducer PFL-H, 2-8 parts of a sulfonated phenol formaldehyde resin, 2-8 parts of sulfonated lignite, 0.5-4 parts of a solid-phase chemical cleaning agent, 1-6 parts of a high temperature anti-collapse blocking agent, 1-6 parts of a lubricant, 0-35 parts of salt, 0.3-2 parts of a surfactant, 1.0-4 parts of a pH value adjusting agent, and 0-200 parts of a weighting agent. According to the present invention, the ultra-high temperature salt-resistant drilling fluid is not thickened at a high temperature of more than or equal to 240 DEG C, has easily-controlled rheology and low high-temperature and high-pressure filtrate loss, can be used for bottom hole drilling construction in the high temperature (more than or equal to 240 DEG C) and high salt (saturated salt) environments, and has the good application effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

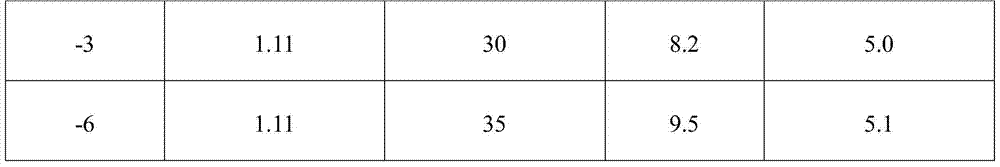

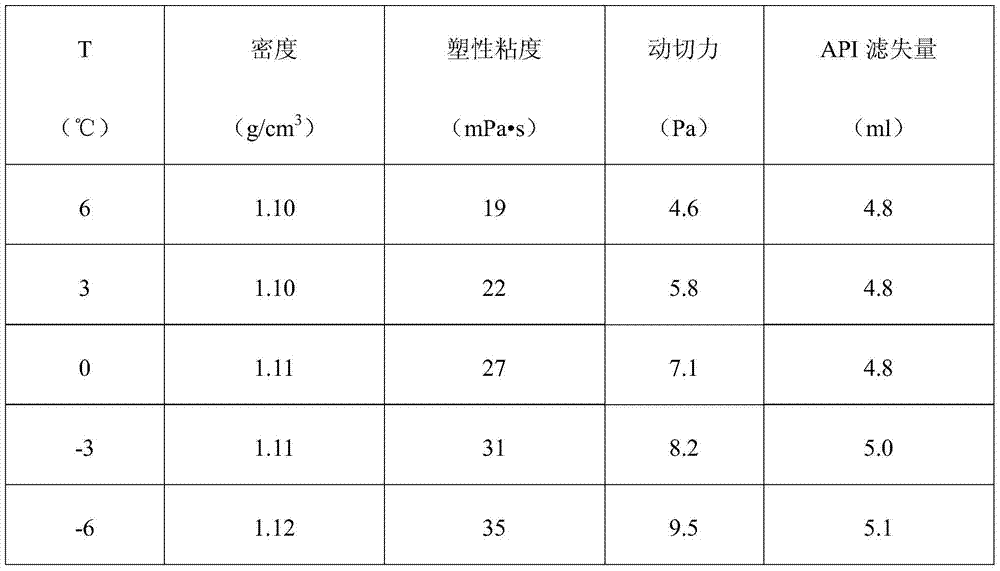

A deep water drilling fluid

ActiveCN104559969BAvoid damageEnhanced inhibitory effectDrilling compositionSlurrySODIUM DODECYL BENZENE SULFONATE

The invention discloses a deepwater drilling fluid. Every 1L of base slurry is composed of 1g of xanthan gum XC, 10-20g of sodium carboxymethyl cellulose, 20-30g of sulfonated phenol formaldehyde resin SMP-2, 30-50g of sodium silicate, 10g of polyvinylpyrrolidone PVP-K90, 15g of high modified asphalt KAHM, 50-100g of sodium chloride, 0.5g of sodium dodecyl benzene sulfonate, 0.5-1g of graphite and 0.2-0.5g of polyformaldehyde. The drilling fluid has the advantages of stable properties under cold conditions, favorable rheological behavior, high debris carrying capacity, excellent mud shale hydration expansion inhibition capacity, excellent hydrate generation inhibition capacity, low economic cost and small environmental pollution, and is especially suitable for deepwater drilling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Acidamide derivative preparation method

InactiveCN1544416AAvoid corrosionEasy to operateOrganic compound preparationCarboxylic acid amides preparationStrong acids3-Bromobenzaldehyde

A process for preparing amide derivant, comprises reacting fatty group amide with aldehydes in methyl alcohol or carbon tetrachloride or benzene or methylbenzene or dioxane or acetonitrile with the presence of catalyst, and separating the reaction product, characterized in that the catalyst is type H strong acidic positive ion exchange resin, the aldehyde is selected from the groups of paraformaldehyde, acetaldehyde, propionaldehyde, chloral, bromal, glyoxylic acid, 4-bromobenzaldehyde, 3-bromobenzaldehyde, hydrosulfide acetaldehyde, p-nitrobenzaldehyde, and 4-hydroxybenzaldehyde. The formula of the fatty group amide is described in the specification, wherein R 2 is saturated or unsaturated fatty group having 2-12 carbon atoms, the type H strong acidic positive ion exchange resin is sulphonated coal, sulfonated phenylethene copolymer or sulfonated phenol formaldehyde resin.

Owner:OCEAN UNIV OF CHINA

Preparation method of semi-solid bamboo liquid-protein hot pressboard glue

ActiveCN108795377AReduce manufacturing costImprove physical and chemical functionsProtein adhesivesLignocellulosic adhesivesMaillard reactionViscous liquid

The invention belongs to the technical field of a wood board adhesive and in particular relates to a preparation method of semi-solid bamboo liquid-protein hot pressboard glue. The preparation methodcomprises the following steps: tanking phenol and concentrated sulfuric acid to react to obtain red water-soluble sulfonated phenol; crushing bamboos until the size is 80 meshes and adding into the sulfonated phenol; supplementing a catalyst and water to obtain brownish red solid-containing viscous liquid; adding powdery protein to obtain viscous brownish red solid-containing viscous liquid; adding soda ash and regulating the pH (Potential of Hydrogen); adding a regulator to obtain brownish red viscous solid-containing glue. According to the preparation method, bamboo fibers and protein polypeptide form a Maillard reaction crosslinking agent in a hot pressing process to obtain an adhesion force adhesive; the functions of no formaldehyde, no volatile solvents and relatively good water resistance are realized.

Owner:SICHUAN UNIV

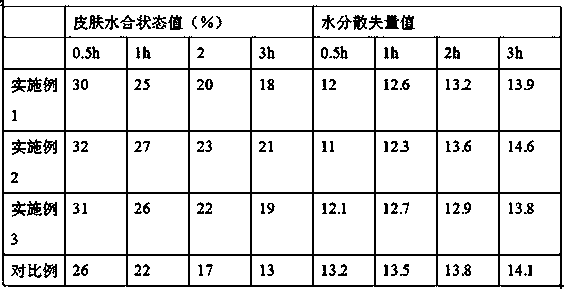

Method for preparing moisture holding and restoring lotion

InactiveCN110101645AAchieve nutrient supplyPromote repairCosmetic preparationsToilet preparationsAdditive ingredientSalicylic acid

The invention relates to a method for preparing a moisture holding and restoring lotion and belongs to the technical field of cosmetics. The method comprises the steps that firstly, silkworm cocoons and fly maggots are adopted as nutritional supplementing raw materials, and rich amino acid and antibacterial polypeptide are obtained through ball milling and enzymolysis to supply nutrients to damaged skin; meanwhile, bacterial infection is avoided; by means of sulfonated phenol, zymolyte, salicylic acid and polyglutamic acid, under the action of uric acid and formaldehyde, a similar polymer withsulfonated phenol-salicylic acid polymerized and combined with polyglutamic acid is formed firstly, chitosan is supported, and a restoring agent can fast permeate into the skin by means of an aid; the sulfonated phenol-salicylic acid polymer is combined with damaged skin collagen, polymerized ammonia acid is utilized for filling, and skin restoration is promoted; by means of ingredients in an annex solution, the blood circulation of the face skin is promoted, absorption to nutrient substances is improved, and then skin repairing is promoted.

Owner:周宇强

Preparation method of heat-resisting filtrate reducer

InactiveCN108130057ANot easy to thickenReduce fluid lossDrilling compositionPolyurethane dispersionPolymer science

The invention discloses a preparation method of a heat-resisting filtrate reducer and belongs to the technical field of oil well treating agents. The preparation method comprises the following steps:mixing ampholytic sulfonated phenol formaldehyde resin with polyurethane dispersion in a mixer according to the mass ratio ranging from 3:2 to 3:1, adding modified graphene oxide the mass of which is0.2 to 0.3 time that of the ampholytic sulfonated phenol formaldehyde resin and a dispersing agent the mass of which is 0.06 to 0.12 time that of the ampholytic sulfonated phenol formaldehyde resin; under the conditions that the temperature is 45 to 65 DEG C and the rotating speed is 250 to 300 r / min, stirring and mixing for 10 to 20 minutes, thus obtaining the heat-resisting filtrate reducer. Theheat-resisting filtrate reducer prepared according to a technical scheme provided by the invention has the characteristics of excellent filtration reducing property and heat resistance.

Owner:周益铭

A kind of preparation method of high temperature resistant modified sulfonated phenolic resin for drilling fluid

ActiveCN104788634BReduce high temperature and high pressure filtration lossImprove performanceDrilling compositionHigh pressureTemperature resistance

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

A kind of anti-high temperature fluid loss reducing agent for drilling fluid and preparation method thereof

The invention discloses a high temperature-resisting fluid loss agent for drilling fluid. The high temperature-resisting fluid loss agent is characterized by being prepared from the following components and raw materials in percentage by mass: 10 to 15 percent of abietic acid, 8 to 12 percent of glycerol, 30 to 40 percent of sulfonated bitumen, 10 to 12 percent of cationic starch, 10 to 20 percent of temporary plugging agent, 12 to 14 percent of high temperature stabilizer and 0.5 to 1.0 percent of deoxidant, wherein the cationic starch is prepared from starch tert-amino alkyl ether and quaternary ammonium starch ether; the high temperature stabilizer is prepared from sulfonated phenol-formaldehyde resin and sulfonated lignite resin; the temporary plugging agent is prepared from tert-butyl phenolic curing resin, octyl phenolic curing resin and calcium carbonate. The high-temperature resistance is up to 250 DEG C, no blistering exists, the viscosity effect is low, the compatibility is good, a product contains rigid particles and softening film-forming particles in different size grading, the product directly participate in mud cake forming, a high-strength adsorption film is formed on the surface of the mud cake, the permeability rate of the mud cake is reduced, the quality of the mud cake is improved, and the function of reducing high-temperature high-pressure filter loss is achieved.

Owner:成都西油华巍科技有限公司

A kind of preparation method of sulfomethyl phenolic resin modified with benzoxazine resin

ActiveCN104140509BReduce fluid lossMeet the requirements of drillingDrilling compositionMicrometerMass ratio

A preparation method for sulfonated-phenol-formaldehyde resin formed by modifying benzoxazine resin includes the steps that (1), bisphenol A type benzoxazine with the particle size smaller than or equal to 25 mm is pulverized to be powder through a pulverizing machine, wherein the particle size of the powder is 10 micrometers-125 micrometers, and the powder is standby; (2), the powder obtained in the step (1) and modified sulfonated phenolic resin agents are thrown into a reaction kettle according to the mass ratio of 1:20, mixed, stirred for one hour at the temperature of 105 DEG C and then delivered into an ultrasonic emulsifying device through a discharging pump to be ultrasonically emulsified for 20 minutes to obtain a mixed solution, and the mixed solution is standby; (3), spraying drying is performed on the mixed solution in the step (2) to obtain the modified sulfonated-phenol-formaldehyde resin. The sulfonated-phenol-formaldehyde resin can be resistant to high temperature of 200 DEG C, has an obvious effect of lowering the filter loss of drilling fluid and can meet the requirements for three high well drilling.

Owner:SICHUAN ZHENGRONG IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com