Preparation method of heat-resisting filtrate reducer

A fluid loss reducing agent and heat-resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor fluid loss control and heat resistance, and achieve improved heat resistance and good thermal conductivity. The effect of improving performance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

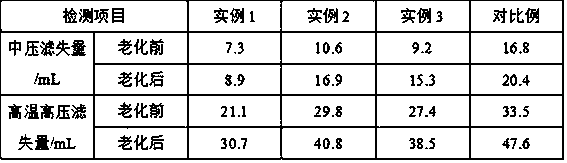

example 1

[0023]Mix phenol and formaldehyde in a beaker at a mass ratio of 4:2, adjust the pH in the beaker to 8 with a sodium hydroxide solution with a mass fraction of 8%, and then move the beaker into a digital constant temperature magnetic stirrer at a temperature of After stirring and reacting for 50 minutes at 100°C with a rotation speed of 350r / min, a mixed solution was obtained. Mix the mixed solution and formaldehyde at a mass ratio of 8:2, and add 0.3 times the mass of the mixed solution to the mixture of the mixed solution and formaldehyde in turn. Sodium sulfite, dimethylamine 0.3 times the mass of the mixed solution and 1-bromobutane 0.4 times the mass of the mixed solution were stirred and mixed for 5 hours at a temperature of 85°C and a rotational speed of 330r / min to obtain an amphoteric sulfonated phenolic resin blank , the amphoteric sulfonated phenolic resin blank was washed with deionized water for 8 times, and the washed amphoteric sulfonated phenolic resin blank was...

example 2

[0025] Mix phenol and formaldehyde in a beaker at a mass ratio of 4:2, adjust the pH in the beaker to 8 with a sodium hydroxide solution with a mass fraction of 8%, and then move the beaker into a digital constant temperature magnetic stirrer at a temperature of After stirring and reacting for 50 minutes at 100°C with a rotation speed of 350r / min, a mixed solution was obtained. Mix the mixed solution and formaldehyde at a mass ratio of 8:2, and add 0.3 times the mass of the mixed solution to the mixture of the mixed solution and formaldehyde in turn. Sodium sulfite, dimethylamine 0.3 times the mass of the mixed solution and 1-bromobutane 0.4 times the mass of the mixed solution were stirred and mixed for 5 hours at a temperature of 85°C and a rotational speed of 330r / min to obtain an amphoteric sulfonated phenolic resin blank , the amphoteric sulfonated phenolic resin blank was washed with deionized water for 8 times, and the washed amphoteric sulfonated phenolic resin blank wa...

example 3

[0027] Mix phenol and formaldehyde in a beaker at a mass ratio of 4:2, adjust the pH in the beaker to 8 with a sodium hydroxide solution with a mass fraction of 8%, and then move the beaker into a digital constant temperature magnetic stirrer at a temperature of After stirring and reacting for 50 minutes at 100°C with a rotation speed of 350r / min, a mixed solution was obtained. Mix the mixed solution and formaldehyde at a mass ratio of 8:2, and add 0.3 times the mass of the mixed solution to the mixture of the mixed solution and formaldehyde in turn. Sodium sulfite, dimethylamine 0.3 times the mass of the mixed solution and 1-bromobutane 0.4 times the mass of the mixed solution were stirred and mixed for 5 hours at a temperature of 85°C and a rotational speed of 330r / min to obtain an amphoteric sulfonated phenolic resin blank , the amphoteric sulfonated phenolic resin blank was washed with deionized water for 8 times, and the washed amphoteric sulfonated phenolic resin blank wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com