A kind of preparation method of PE black primer

A primer and component technology, which is applied in the field of PE paint, can solve the problems of easy thickening, inconvenience, short storage period, etc., and achieve the effect of long storage time, reduced energy consumption, and not easy to thicken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of PE black primer in the present embodiment comprises:

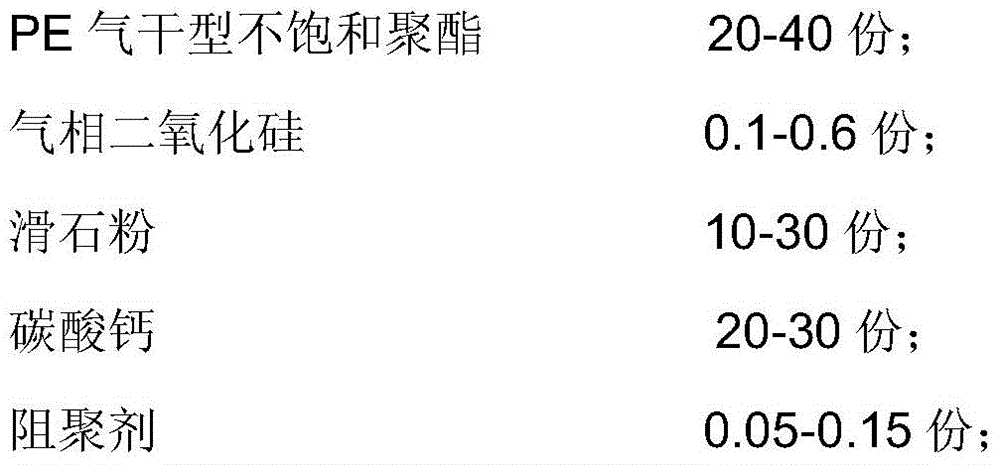

[0034] PE black primer comprises the first component and the second component, wherein, the first component comprises the composition of following weight:

[0035]

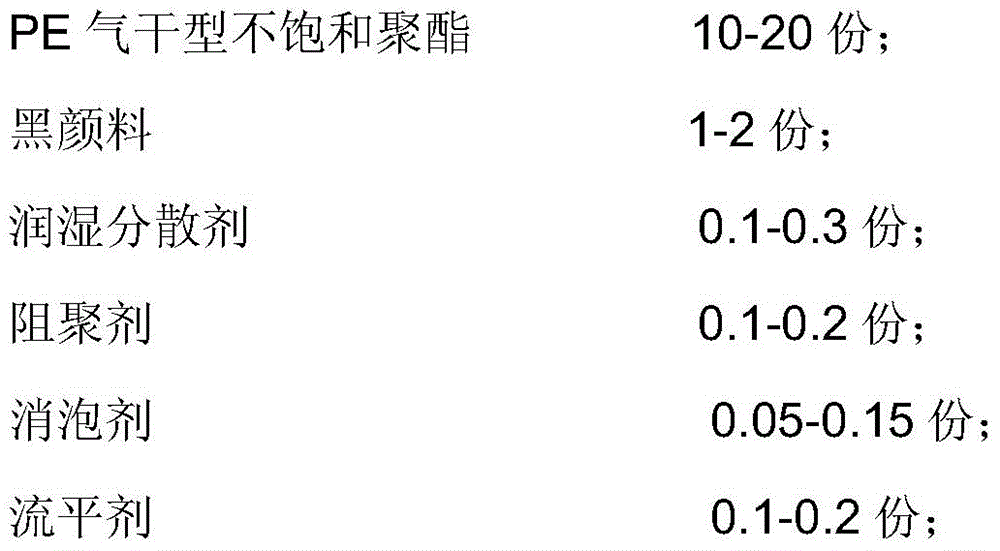

[0036] The second component contains ingredients by weight of:

[0037]

[0038] Wherein, 1wt% polymerization inhibitor solution is t-butyl hydroquinone ethyl acetate solution;

[0039] After the ingredients of the first component are mixed evenly according to the proportion, disperse at 1200rpm for 20 minutes, and then cool down to 40°C;

[0040] After the components of the second component are mixed evenly according to the proportion, disperse at 1400rpm for 20 minutes, and then grind to a fineness of 50μm;

[0041] Add 5 parts of ethyl acetate to the first component and the second component after the above treatment, mix evenly, and disperse at 800 rpm for 10 minutes to obtain a PE black primer product.

Embodiment 2

[0043] The preparation method of PE black primer in the present embodiment comprises:

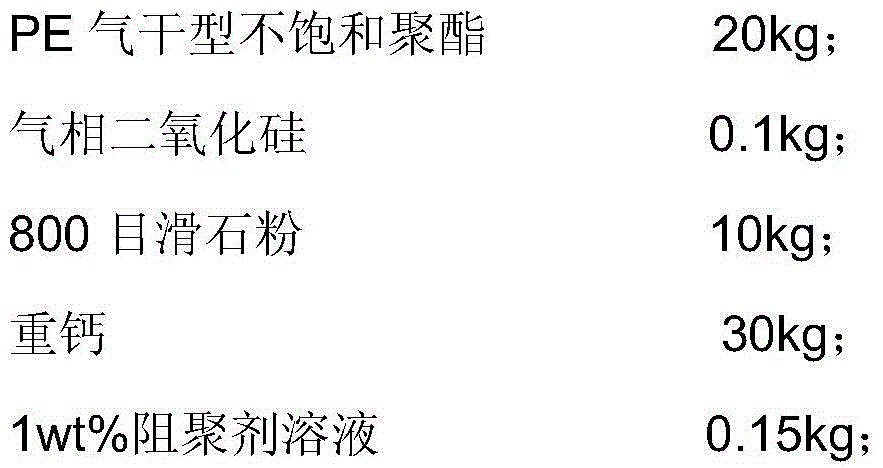

[0044] PE black primer comprises the first component and the second component, wherein, the first component comprises the composition of following weight:

[0045]

[0046]

[0047] The second component contains ingredients by weight of:

[0048]

[0049] Wherein, 10wt% polymerization inhibitor solution is tert-butyl hydroquinone butyl acetate solution;

[0050] After the ingredients of the first component are mixed evenly according to the ratio, disperse at 1400rpm for 20 minutes, and then cool down to 30°C;

[0051] After the components of the second component are mixed evenly according to the proportion, disperse at 1200rpm for 20 minutes, and then grind to a fineness of 40μm;

[0052] Add 7 parts of butyl acetate to the first component and the second component after the above treatment, mix evenly, and disperse at 1000 rpm for 15 minutes to obtain a PE black primer product. ...

Embodiment 3

[0054] The preparation method of PE black primer in the present embodiment comprises:

[0055] PE black primer comprises the first component and the second component, wherein, the first component comprises the composition of following weight:

[0056]

[0057] The second component contains ingredients by weight of:

[0058]

[0059]

[0060] Wherein, 5wt% polymerization inhibitor solution is hydroquinone butyl acetate solution;

[0061] After the components of the first component are mixed evenly according to the ratio, disperse at 1300rpm for 25 minutes, and then cool down to 35°C;

[0062] After the components of the second component are mixed evenly according to the proportion, disperse at 1300rpm for 25 minutes, and then grind to a fineness of 30μm;

[0063] Add 5 parts of ethyl acetate to the above-mentioned treated first component and the second component, mix evenly, and disperse for 15 at 900 rpm to obtain a PE black primer product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com