Thermal shrinkage biaxially oriented film

A biaxially stretched film and thermal shrinkage technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of excessive attenuation of the thermal shrinkage rate of cigarette films, affecting the effect of cigarette packaging, and high thermal shrinkage rate And other problems, to achieve the effect of guaranteed processing performance, perfect crystallization and smooth performance

Inactive Publication Date: 2011-05-18

ZHONGSHAN FLASHLIGHT POLYTECHNIC

View PDF3 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the cigarette film is stored for a long time or the storage temperature is too high, it may cause the heat shrinkage rate of the cigarette film to attenuate too much, which will affect the packaging effect of the cigarette. This situation is more likely to occur in summer

Therefore, adjusting the degree of orientation through processes such as temperature and stretch ratio to obtain high thermal shrinkage has great instability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0018] Embodiment: the preparation of BOPP cigarette film

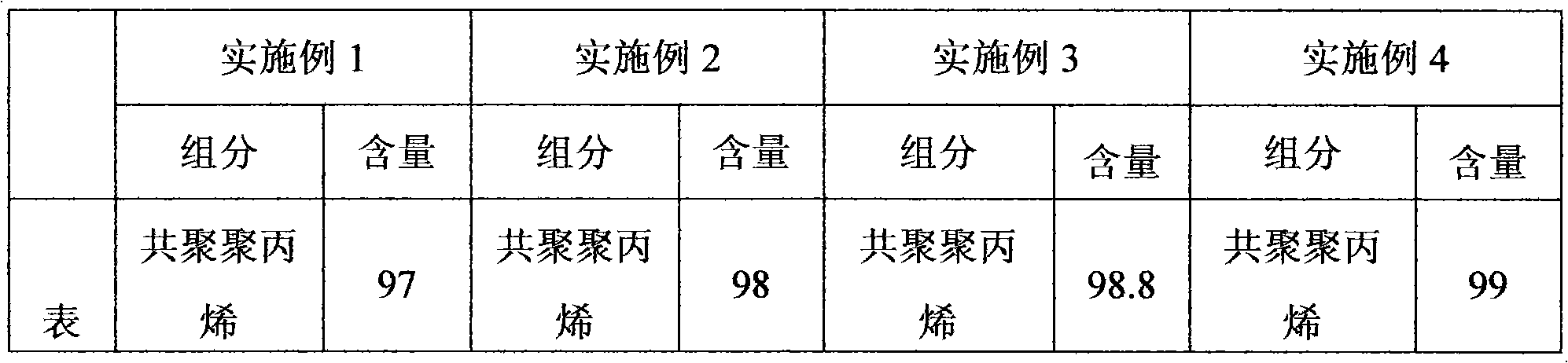

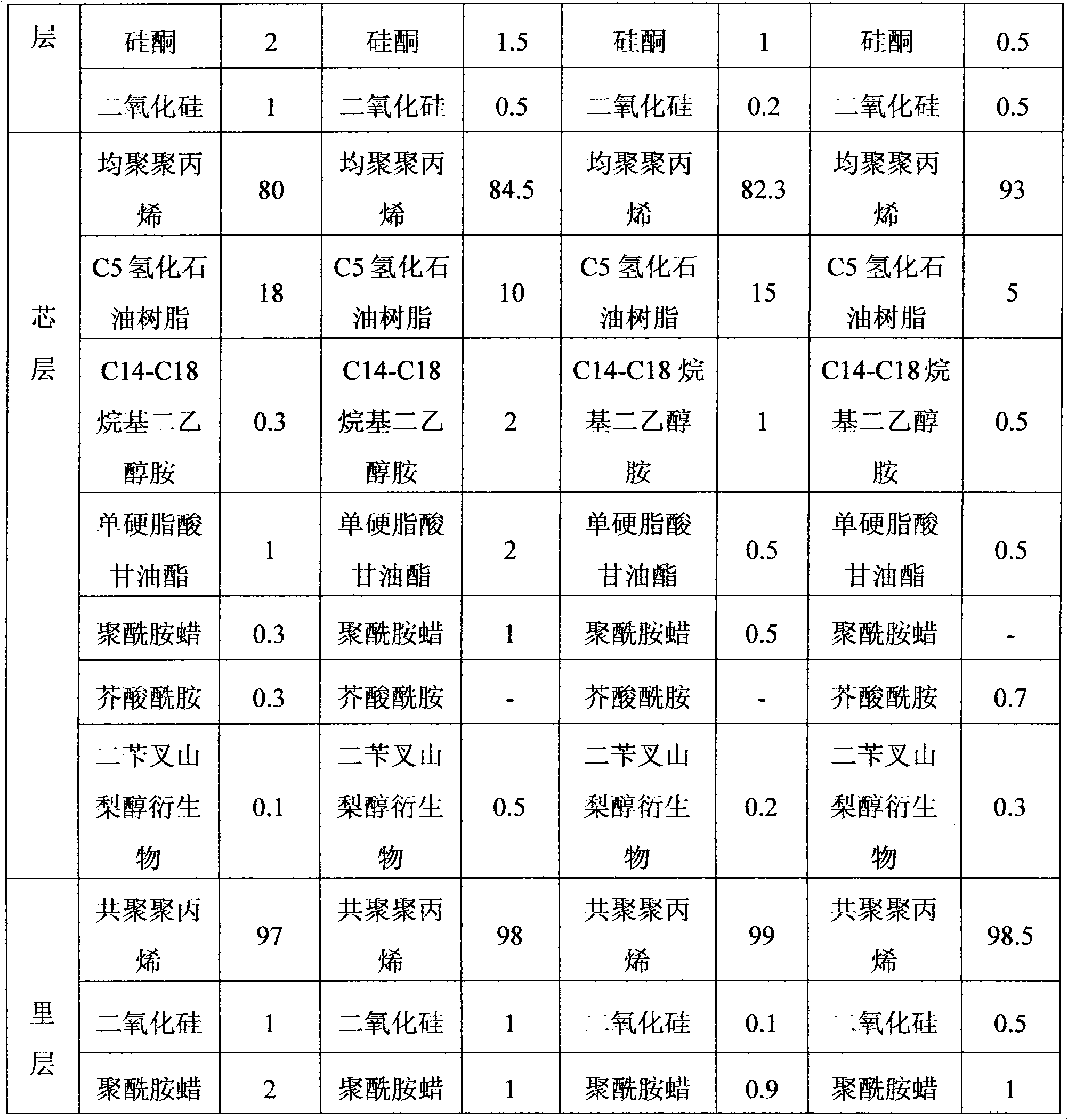

[0019] According to the formula in Table 1, each component was weighed by weight percentage and mixed.

[0020] Formulation of each layer of film of table 1 (the following each component content is weight percentage, is based on the total mass of each layer of film)

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Description

technical field [0001] The invention belongs to the technical field of heat-shrinkable stretched films. In particular, it relates to a heat-shrinkable biaxially stretched film. Background technique [0002] The Chinese invention with the publication number of 1425549 on June 25, 2003 discloses a method for producing biaxially stretched polypropylene cigarette film by the foam tube method. Compounding, extrude the primary tube film through the co-extrusion die on the extruder, quench the primary tube film, and then preheat it in a preheating oven with a temperature of 260°C-400°C. The transverse inflation and longitudinal stretching are carried out in an oven at ℃, the stretching temperature is 135°C-150°C, the longitudinal stretching ratio is 6.5-8.0, and the transverse stretching ratio is 5.0-8.0; Roll, slitting, rewinding, slitting again. Compared with the existing production technology of flat-drawing biaxially stretched polypropylene cigarette film, this production pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/08B32B27/18B32B27/32C08L23/14C08L23/12

Inventor 涂志刚陈新蒋建平赵素芬张莉琼

Owner ZHONGSHAN FLASHLIGHT POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com