Patents

Literature

165results about How to "Raise the firing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel glaze and preparation process thereof

The invention discloses an enamel glaze which belongs to the technical field of ceramic materials, and the enamel glaze comprises a colored glaze basic glaze, an enamel glaze basic glaze and coloring pigments. The invention further discloses a preparation process of the enamel glaze and an application of the enamel glaze. The preparation process can improve the firing temperature of the enamel colored glaze, expand the firing range of the glaze, improve the viscosity of the enamel colored glaze and ensure that coloring metal oxides can not be diffused or the color can not be dimmed due to the flowing of the glaze by optimizing the formula of the enamel colored glaze, adopting an appropriate amount of zinc oxide for replacing heavy metal flux materials, such as lead oxide and the like, integrating the applicable color development performances of a variety of coloring materials and introducing a rare earth compound of yttrium oxide. The preparation process can further ensure that the coloring metal oxides in the enamel glaze can not be oxidized by oxygen or water vapor in the air through the way of underglaze color, thereby further ensuring that a product can not change the color or fade forever, closing heavy metals contained in the coloring oxides for avoiding solventing-out and solving the problem of heavy metal pollution.

Owner:SHENZHEN YONG FENG YUAN IND

Hydro-conversion catalyst for heavy oil and residual oil and its preparing process

The present invention belongs to the field of heavy oil and residual oil hydrotransforming technology. The heavy oil and residual oil hydrotransforming catalyst has siliceous alumina carrier, relatively strong acidity and especially protonic acid amount higher than that in available residual oil hydrotransforming catalyst. The siliceous alumina carrier is prepared through one colloid forming process, during and after which silicon is added to make alumina possess more strong acid centers and ideal pore structure. The catalyst of the present invention is used in the hydrotransforming treatment of heavy oil, residual oil and other inferior oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

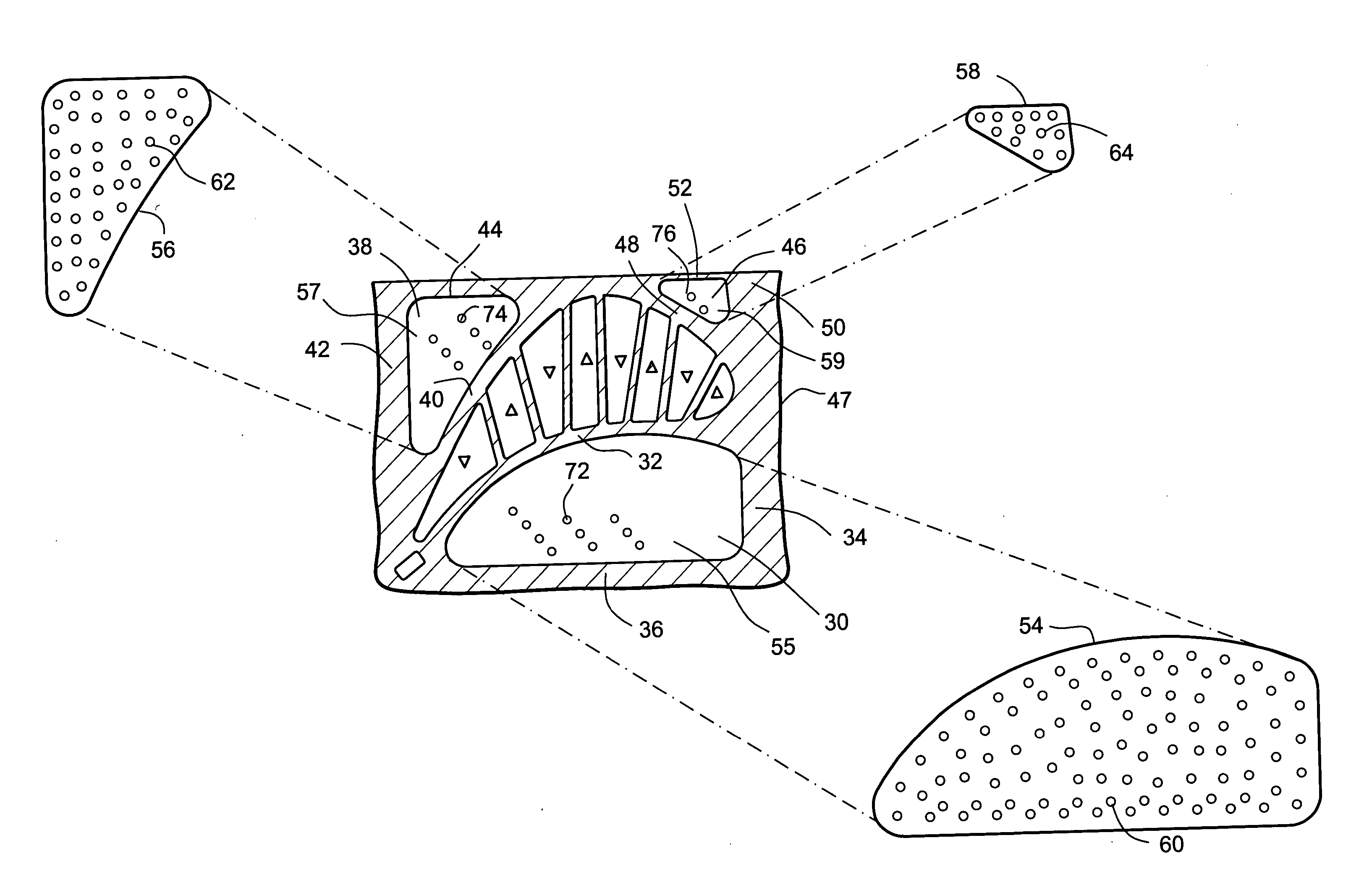

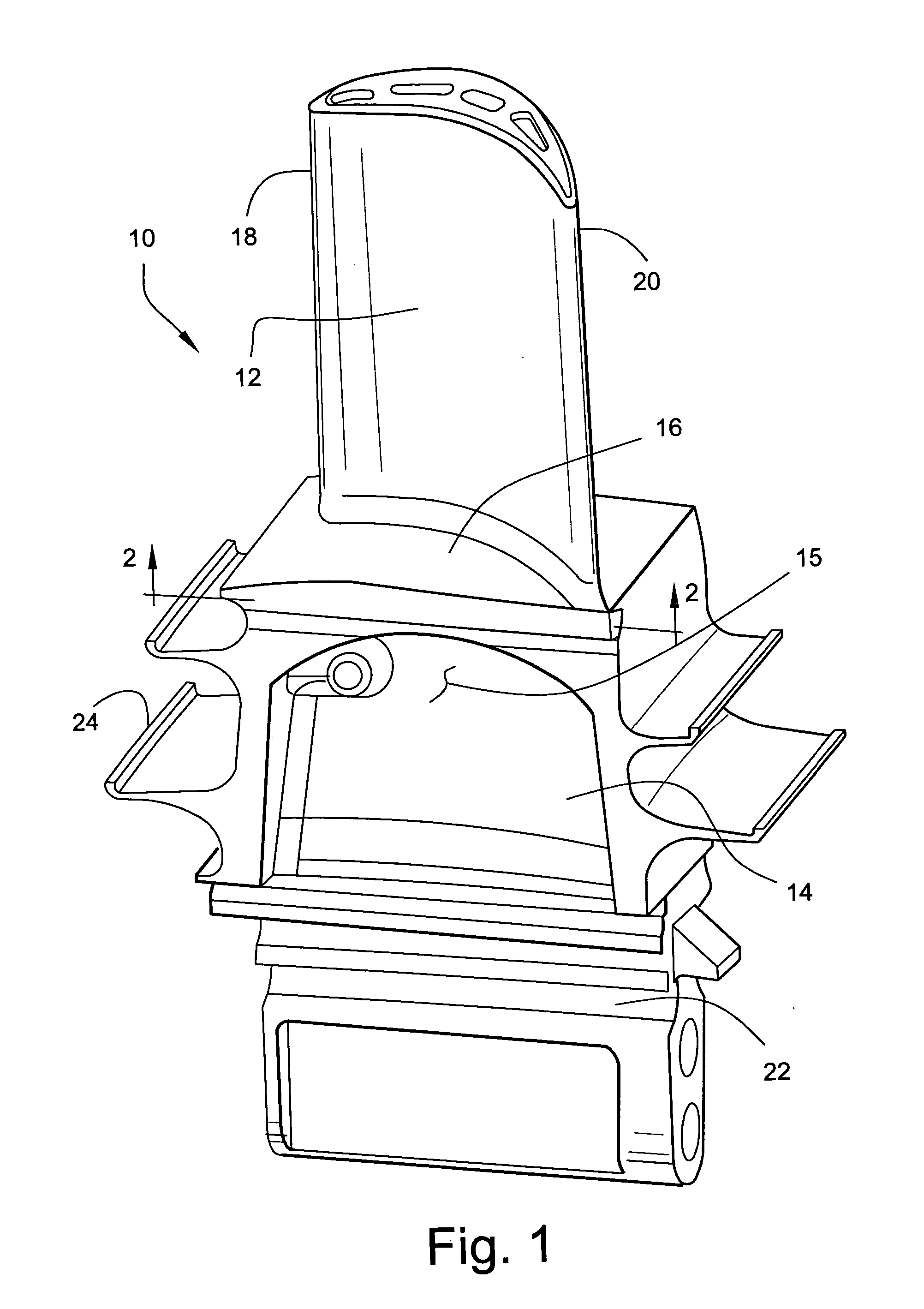

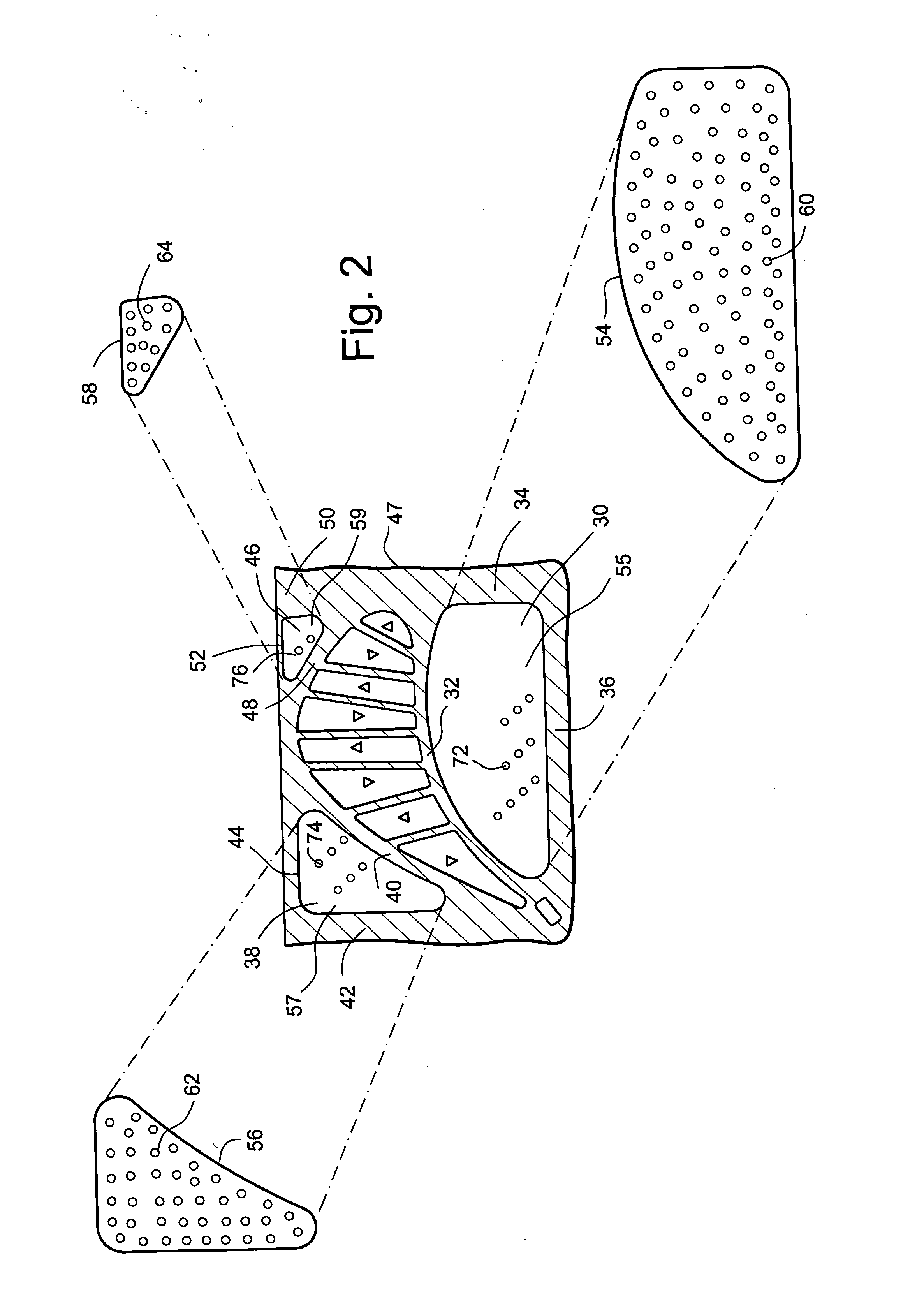

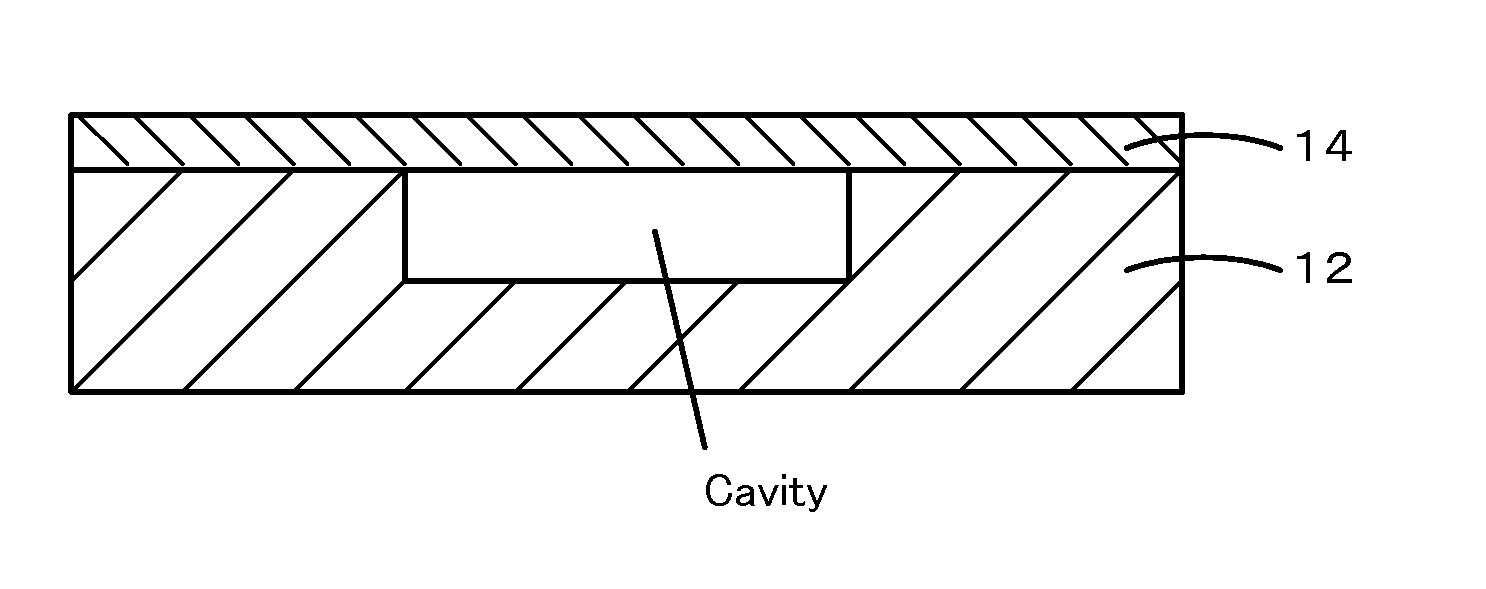

Apparatus and methods for cooling turbine bucket platforms

A turbine bucket includes a platform interfacing between an airfoil and a shank. The platform is provided with a plurality of cavities covered by impingement cooling plates along the platform underside. Purge air supplied in the gaps between adjacent buckets flows through holes in the impingement plates to impingement cool opposite wall portions of the platform. The cooling air in the cavities is transmitted through film cooling holes in the platform to form a thin film of insulating air along the surface of the platform exposed to the hot gas in the hot gas path.

Owner:GENERAL ELECTRIC CO

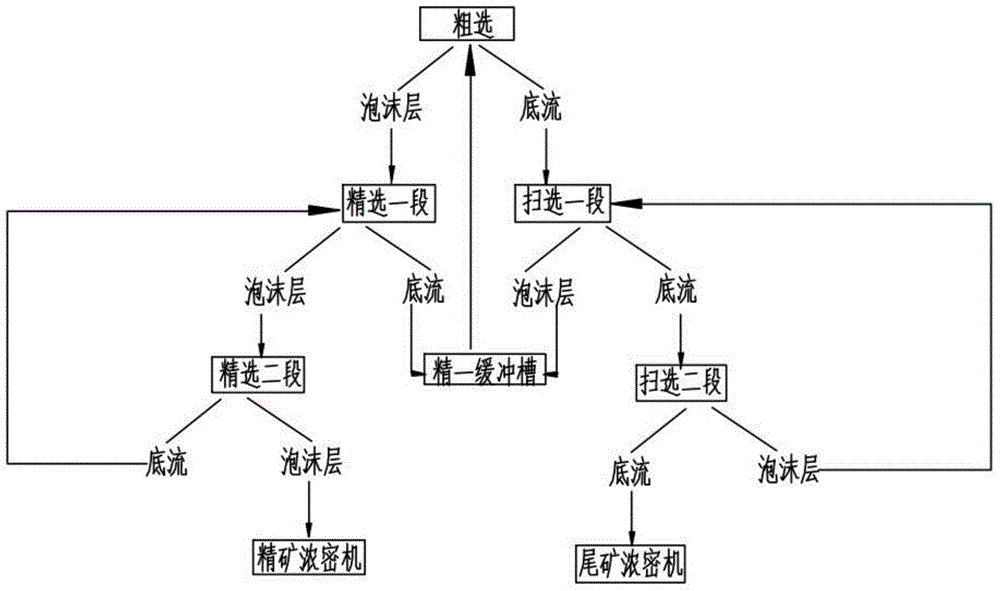

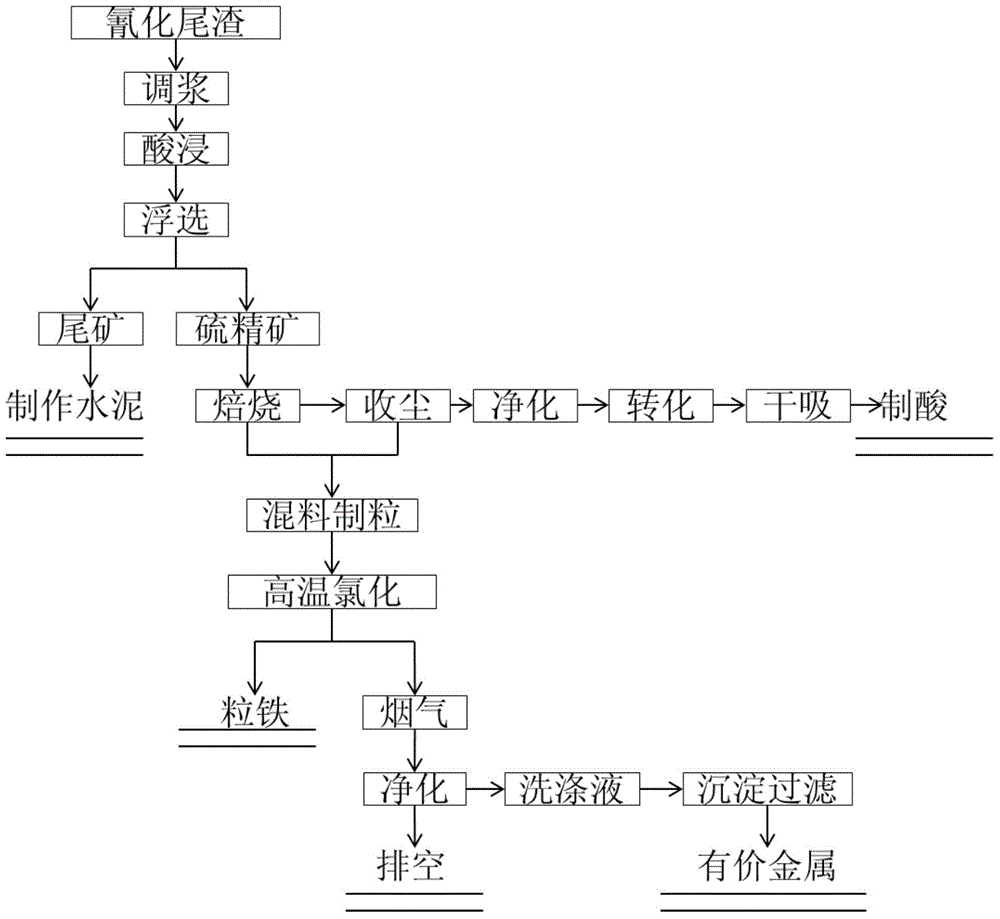

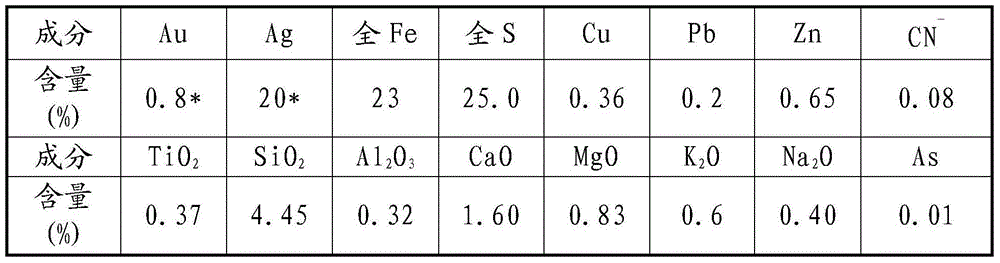

Comprehensive recycling method of cyanide tailing slag

ActiveCN103981370AEfficient separation and recoveryImprove utilization efficiencySolid waste managementSulfur compoundsCyanideSulfur

The invention belongs to the technical field of metallurgical waste slag recovery and in particular relates to a comprehensive recycling method of cyanide tailing slag. Cyanide tailings is floated to obtain sulfur concentrate and tailing, sulfur concentrate is roasted by weak oxygen to obtain sulfuric acid, and pyritic slag is subjected to chlorination roasting to enable valuable elements to be recycled. By virtue of the comprehensive recycling method disclosed by the invention, the valuable elements can be efficiently separated and recovered from cyanide tailing slag, and cyanide tailing slag is utilized to a maximum extent, the comprehensive utilization efficiency of resources is improved and the pollution of cyanide tailing slag to the environment is reduced.

Owner:ZHAOJIN MINING +1

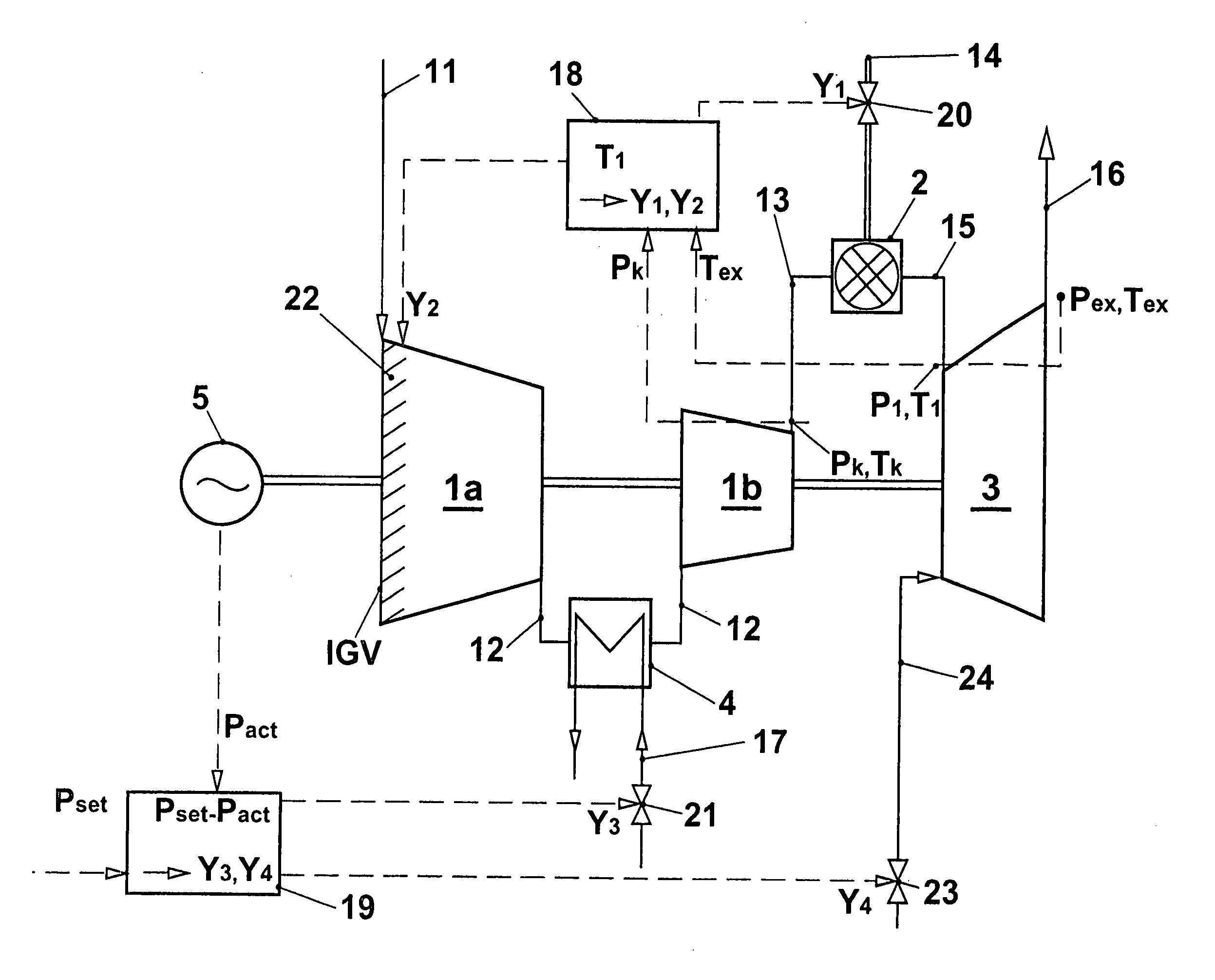

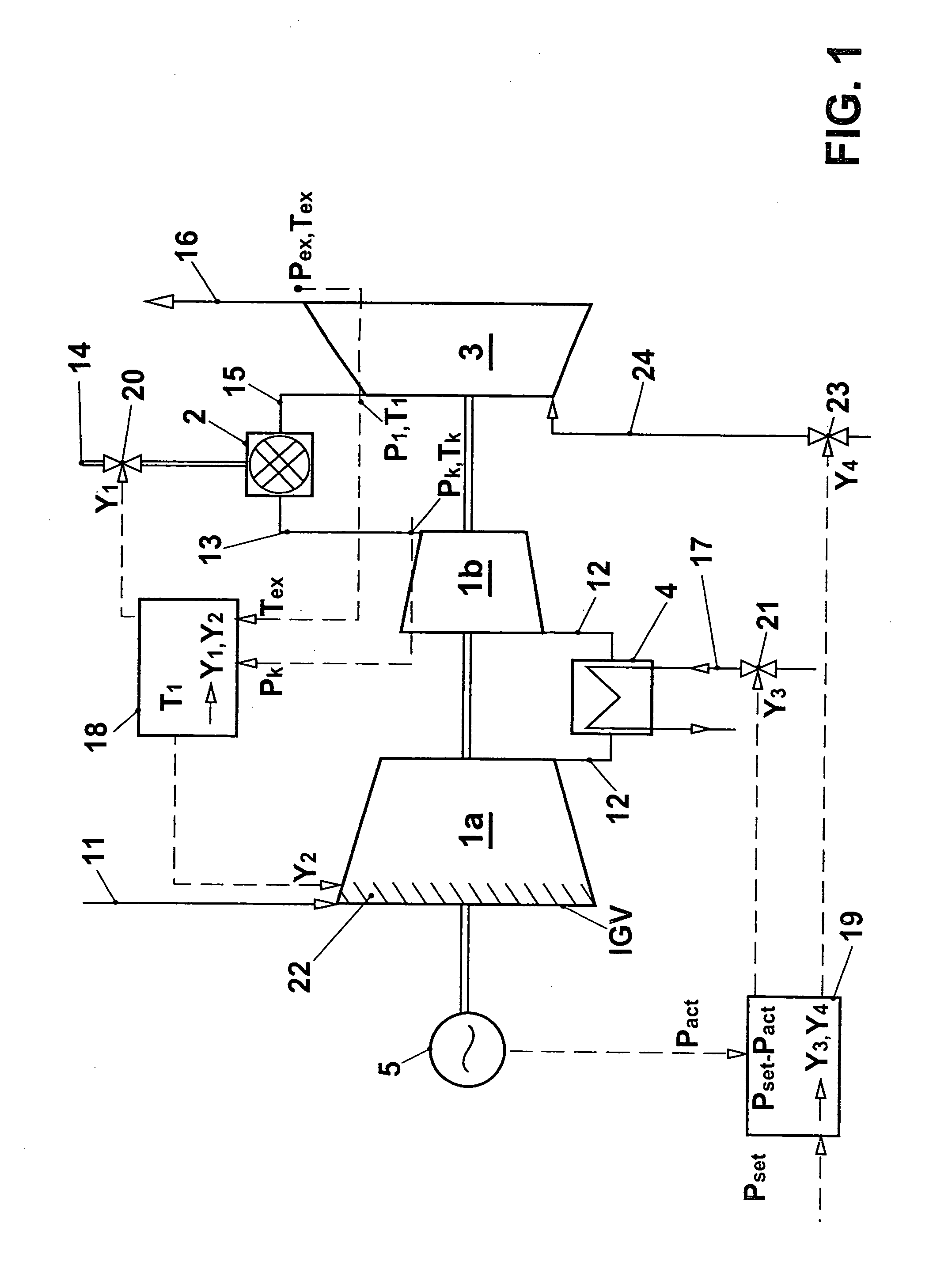

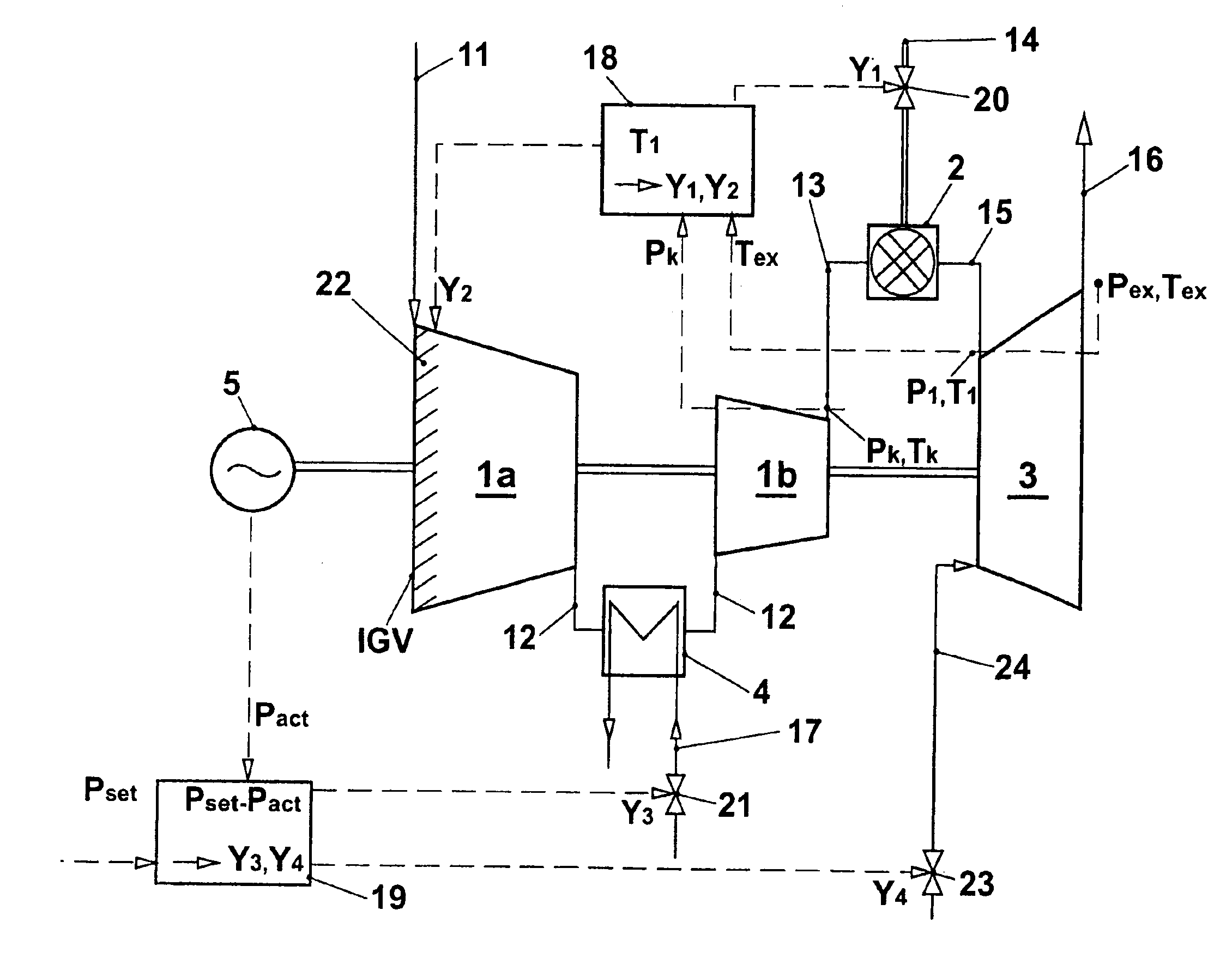

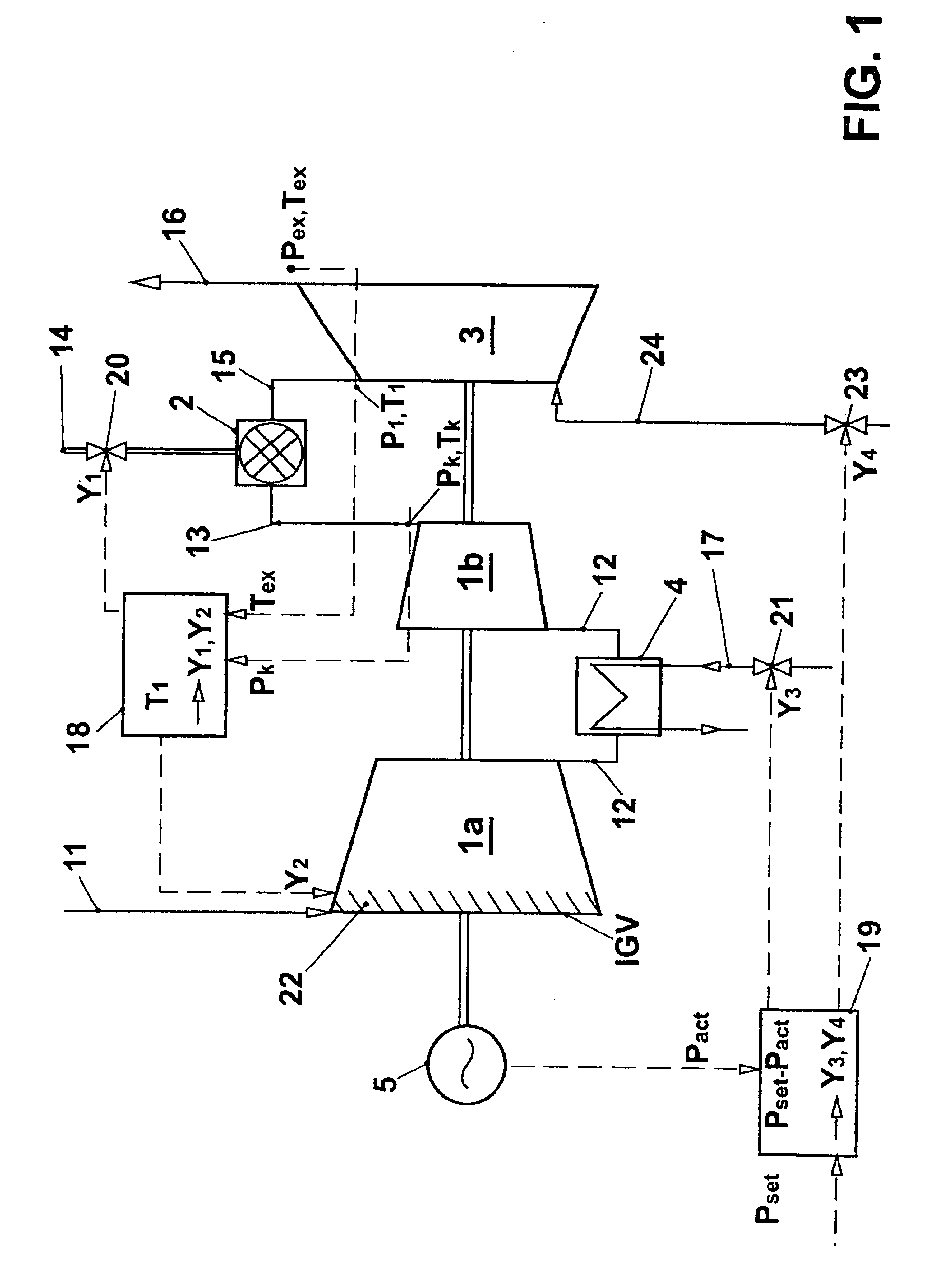

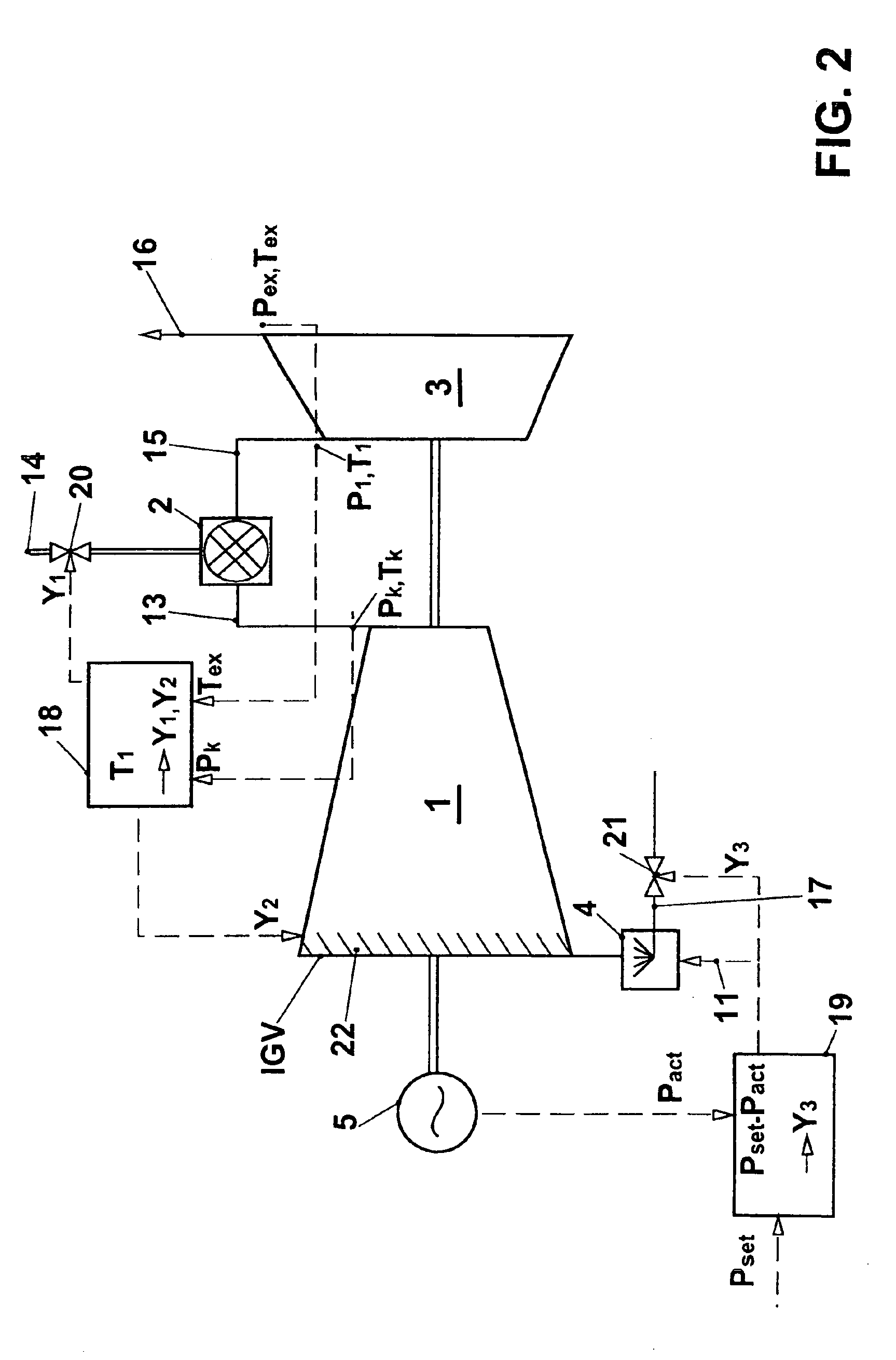

Method for operating a gas turbine group

InactiveUS20050109033A1Increase powerReduces compressor outlet temperatureEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

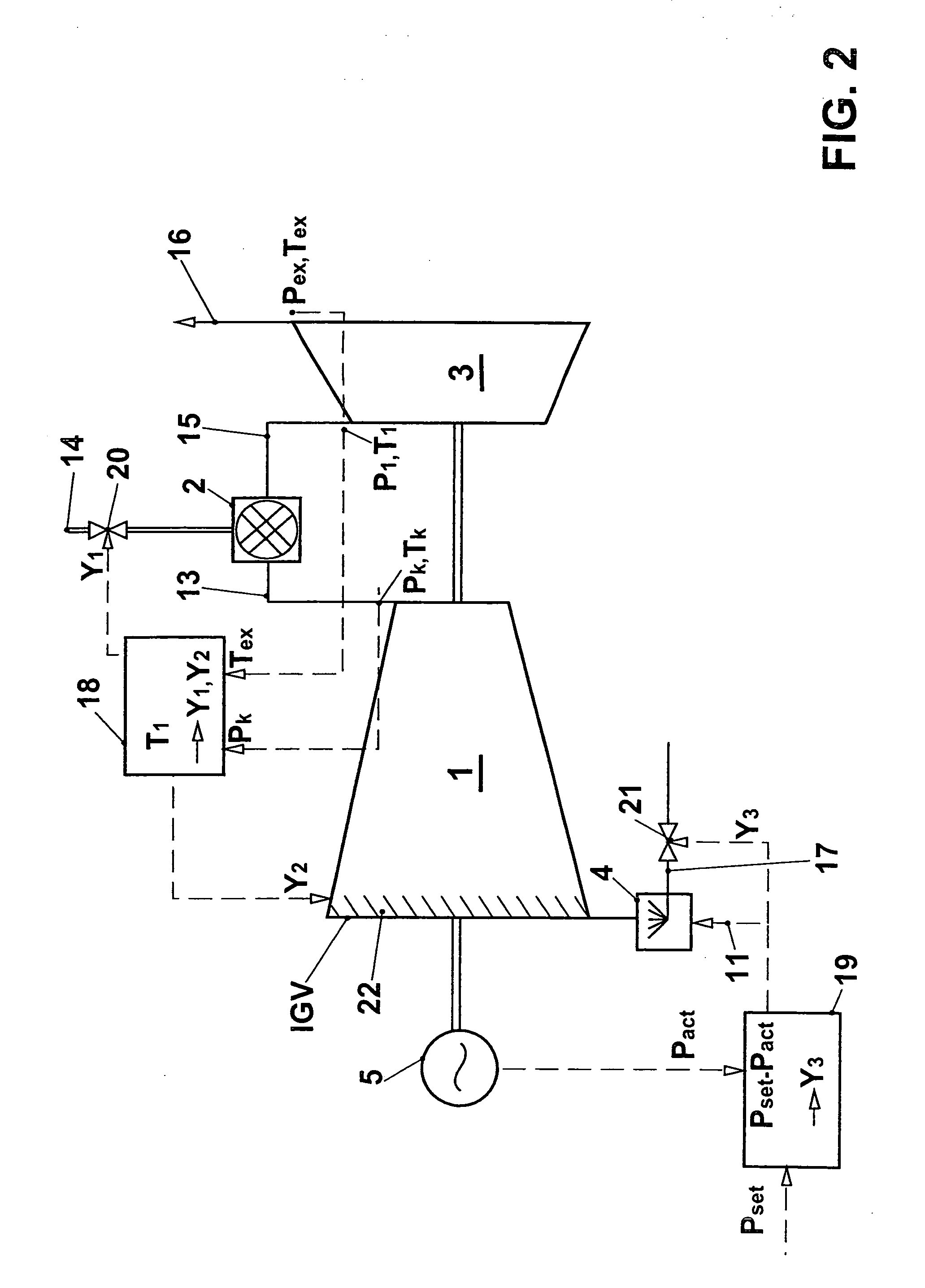

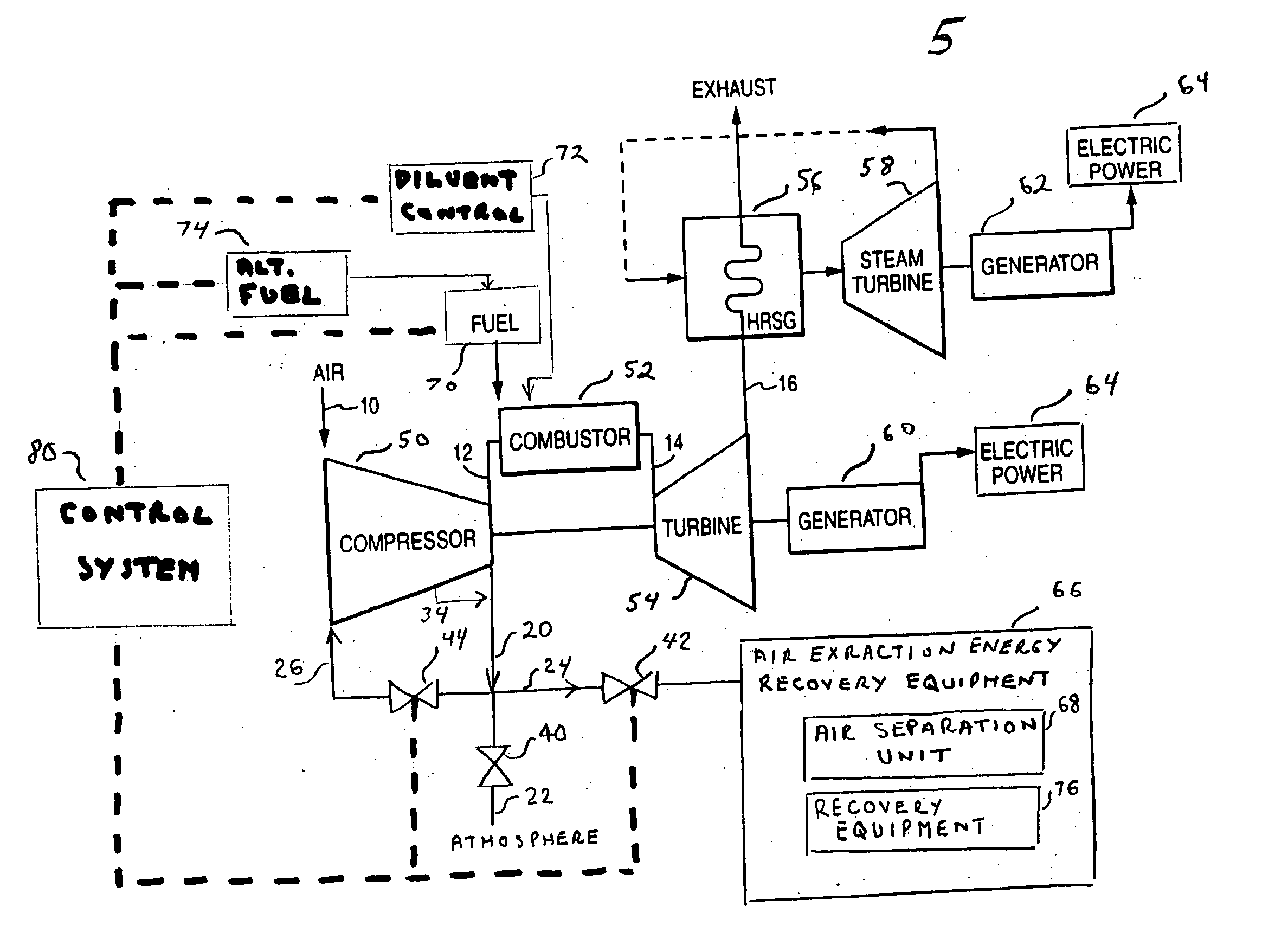

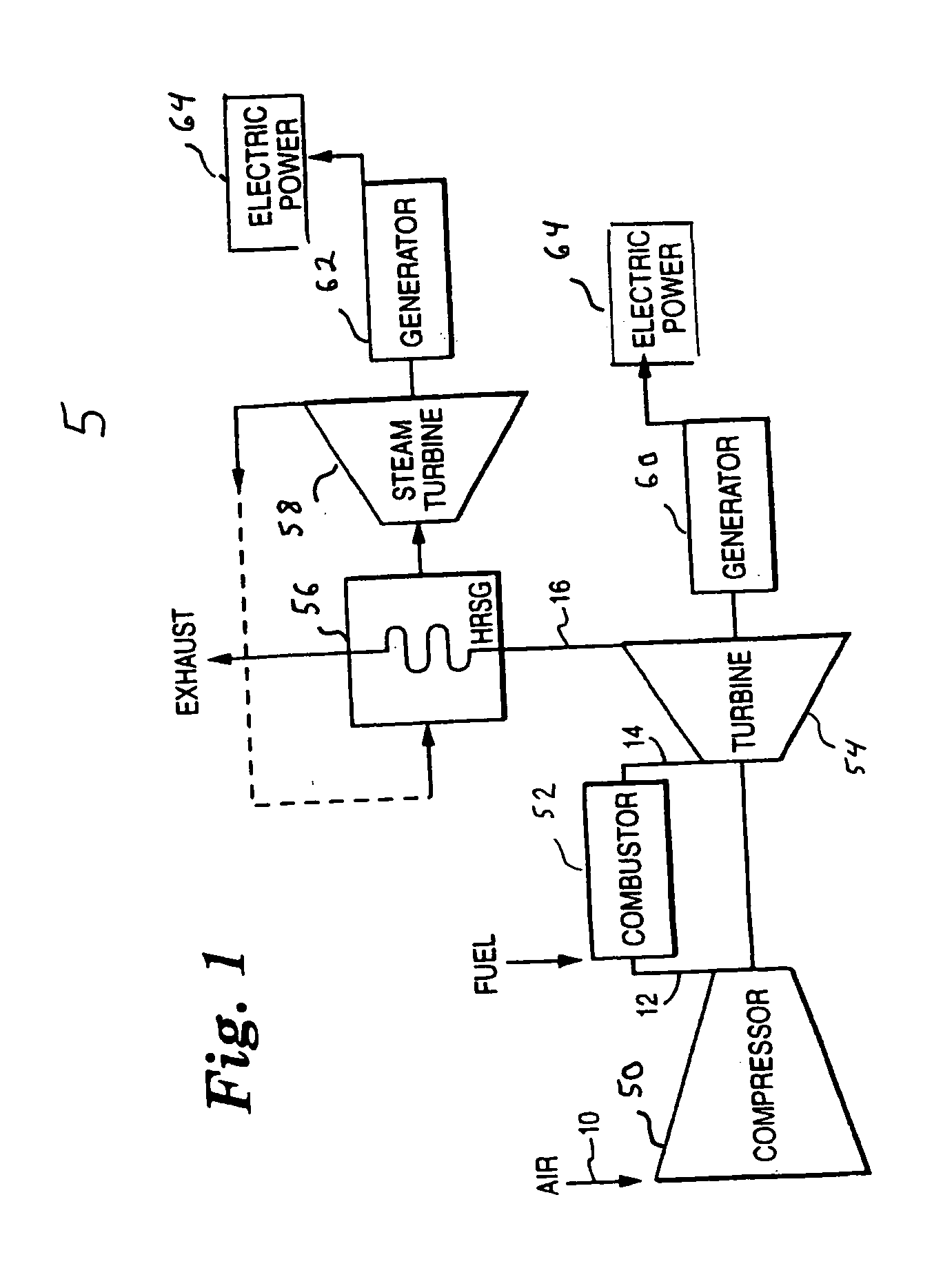

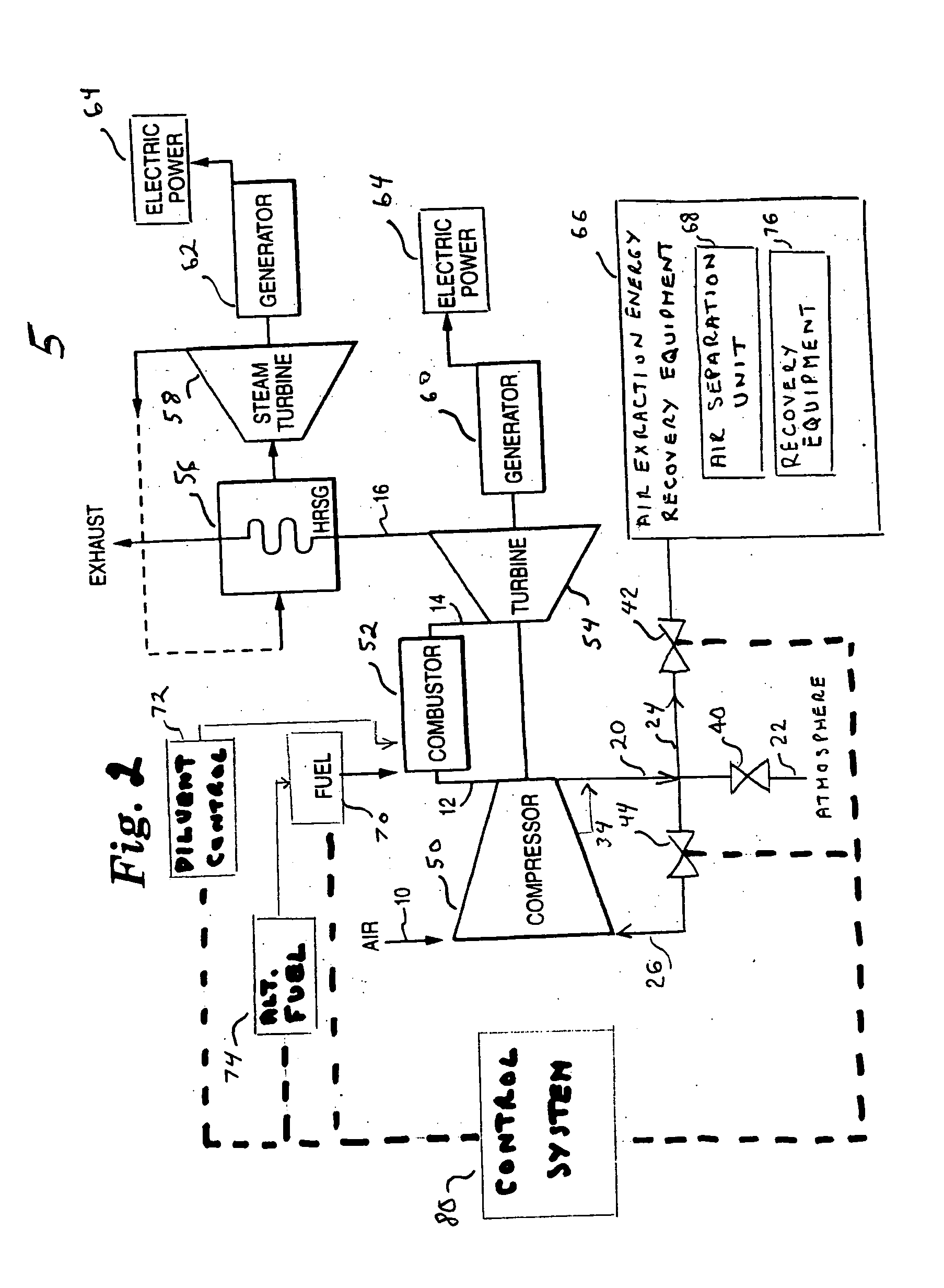

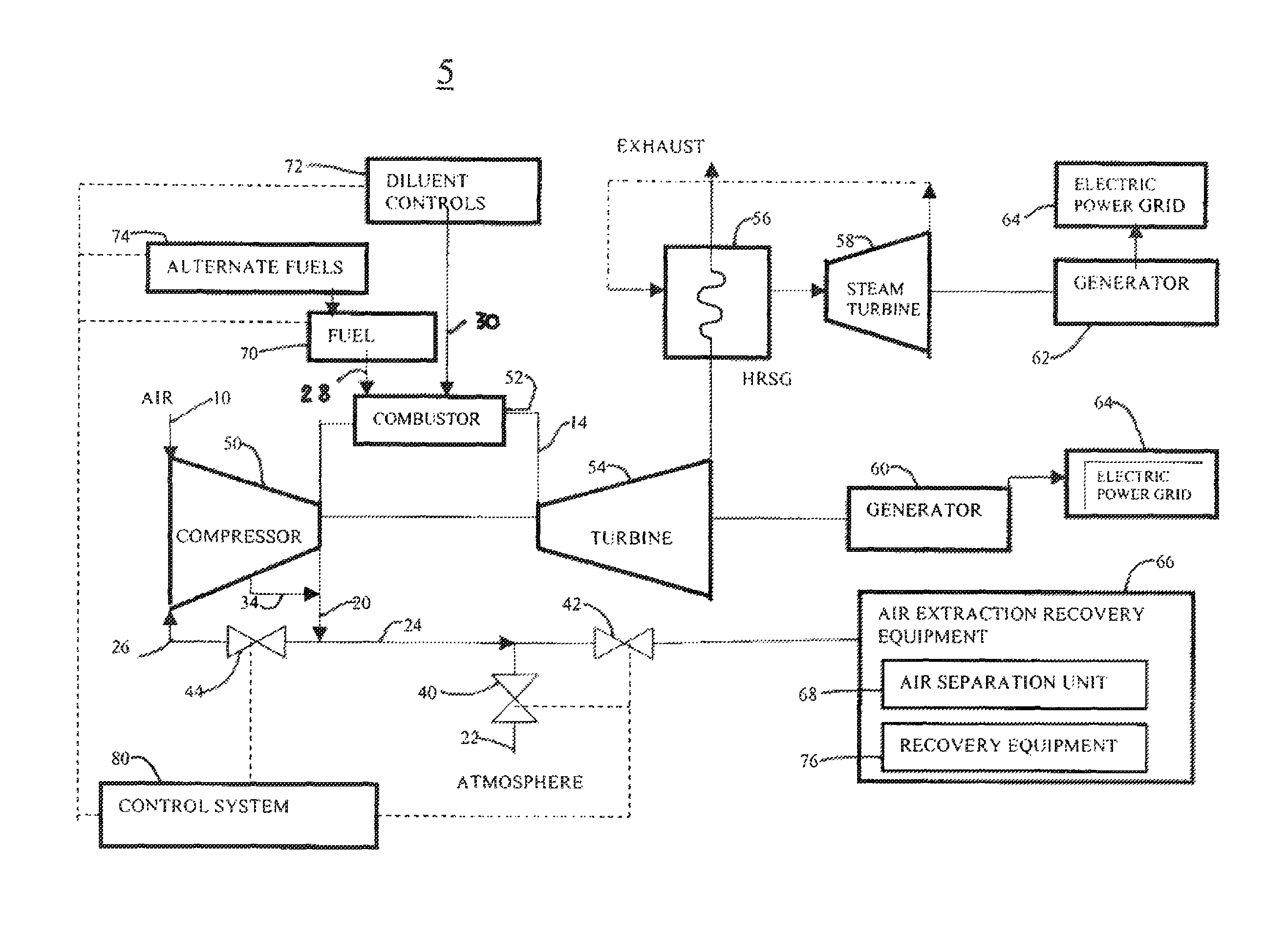

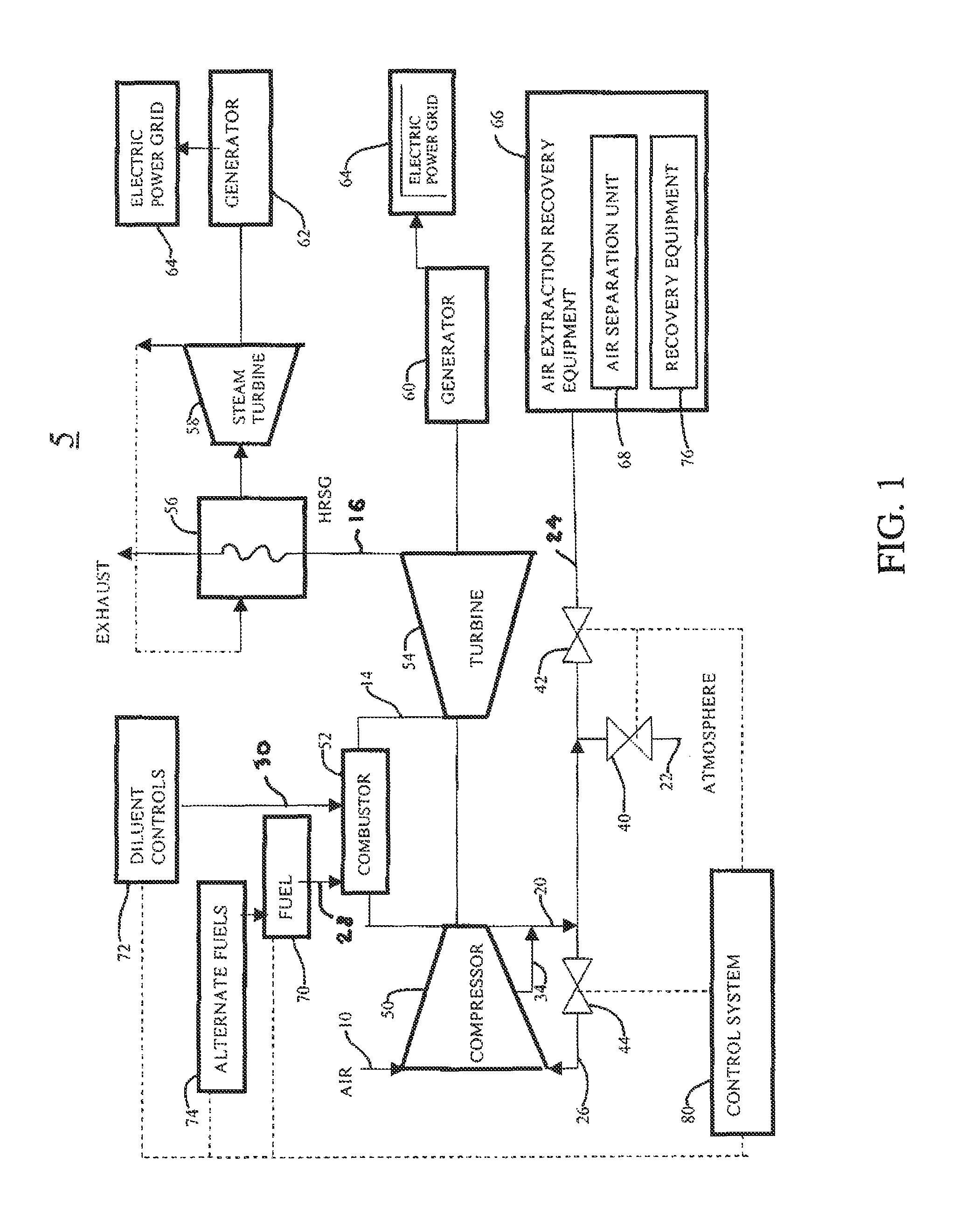

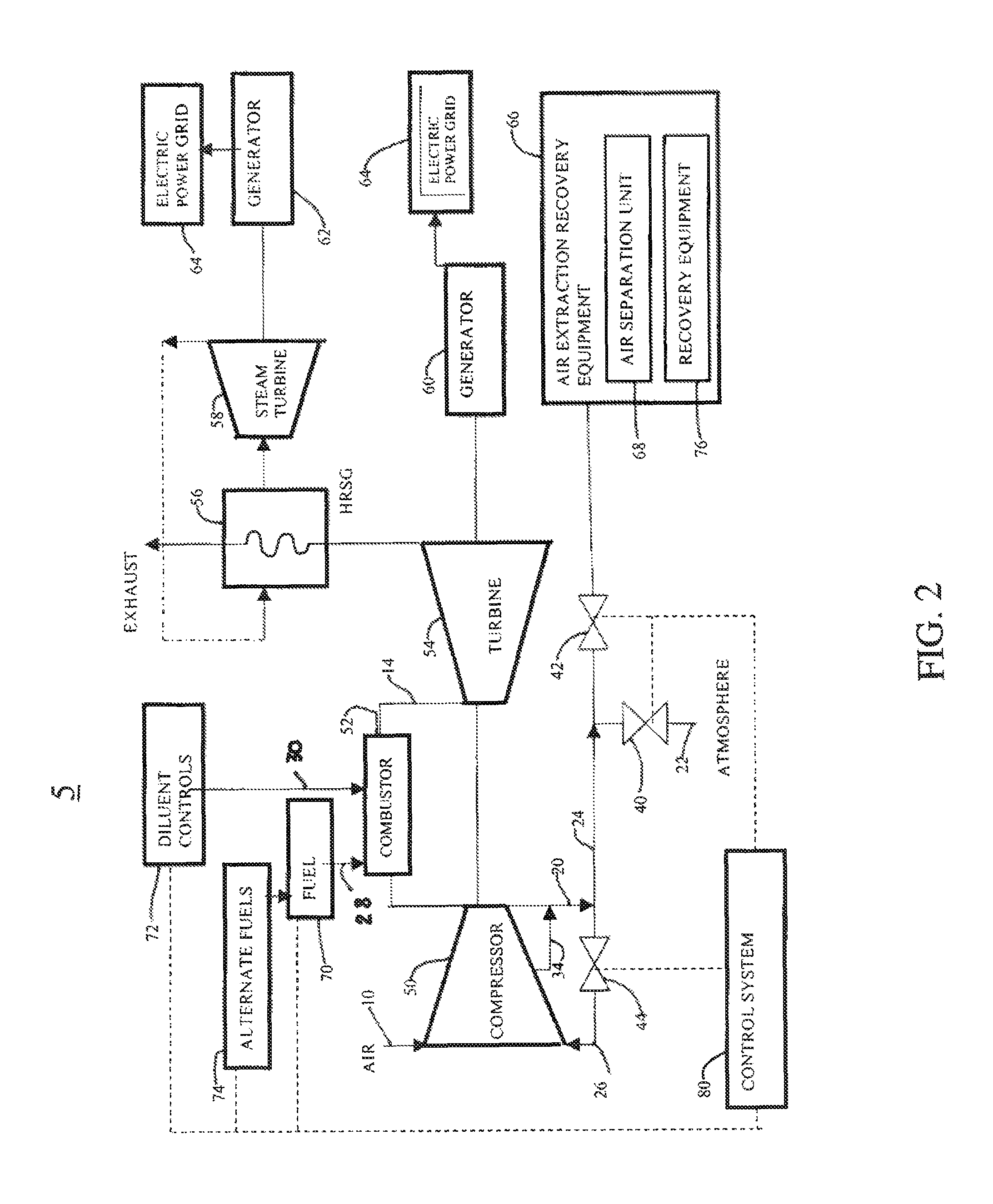

Method for gas turbine operation during under-frequency operation through use of air extraction

ActiveUS20070271929A1Reducing diluent flowRaise the firing temperatureGas turbine plantsEngine componentsElectricityPower grid

In a gas turbine electric power generator where rotational speed of the gas turbine is synchronized to the electrical frequency of a power grid and the gas turbine includes a compressor component, an air extraction path, and means for controlling an amount of compressor air extraction, a method is provided for controlling output power produced by a gas turbine. The method includes initiating compressor air extraction and controlling the amount of compressor air extraction.

Owner:GENERAL ELECTRIC CO

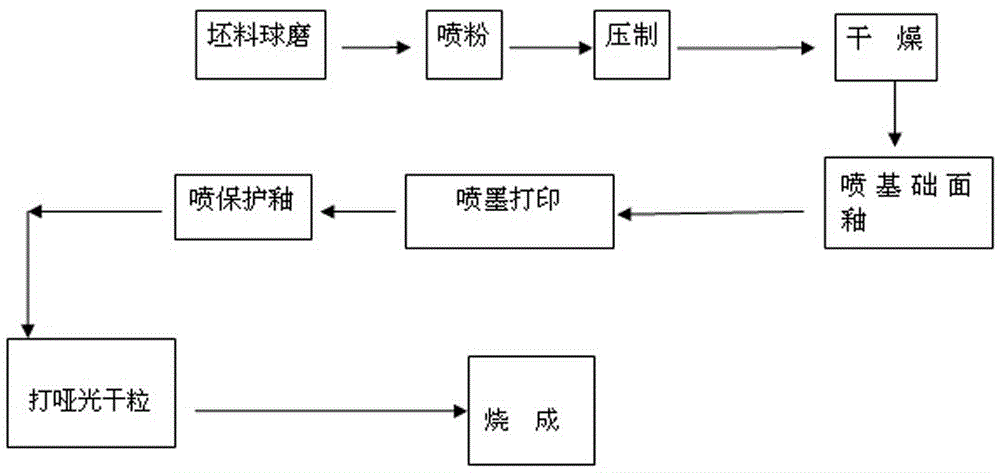

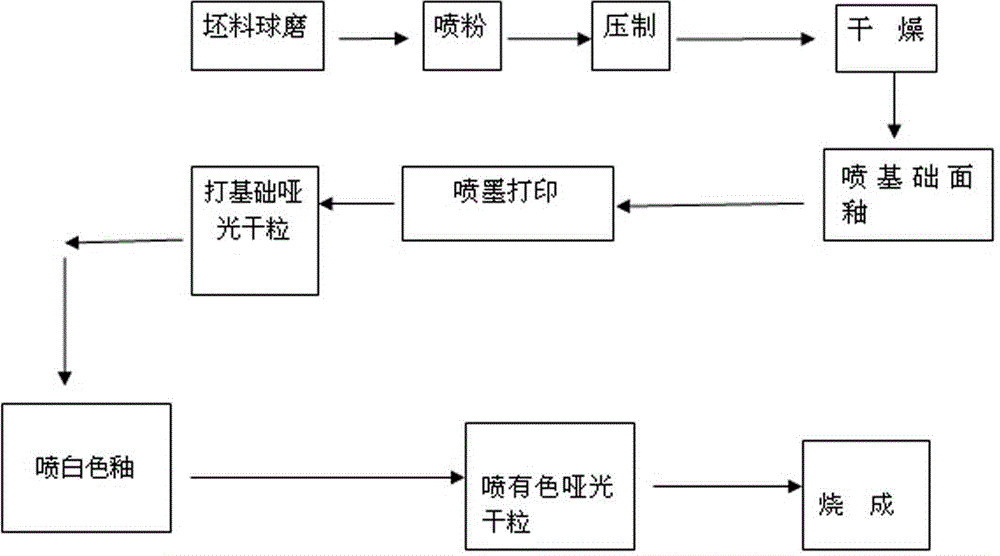

Dry particle glaze rock simulated ceramic tile production process

The invention provides a dry particle glaze rock simulated ceramic tile production process, which relates to a ceramic production process, in particular to a production process of a rock simulated ceramic tile. The rock simulated ceramic tile comprises a ceramic tile body and a glaze surface, and is characterized in that the glaze surface is prepared from the following ingredients including 25 to 40 percent of basic surface glaze, 15 to 25 percent of protection glaze, 0 to 0.05 percent of mica sheets, 4 to 6 percent of water washing ball soil slurry, 15 to 25 percent of gluewater, 5 to 10 percent of inorganic cermic ink, 8 to 15 percent of white dull gloss dry particles, 0 to 12 percent of colored dull gloss dry particles, 0.5 to 1.5 percent of aluminum oxide slurry and 0.02 to 0.04 percent of dispergators. The production process comprises a single-point product manufacturing process and a multi-point product manufacturing process. The problems of poor accumulation effect of the existing dull gloss dry particles on the tile surface and flowing of gluewater into a glaze jar are solved; in addition, the dry particles with strong three-dimensional effects can be obtained through firing in one step; the visual layering effect of products is good; the hardness and the wear-resistant degree are both superior to those of the existing product.

Owner:FOSHAN NANOGRESS BUILDING MATERIALS CO LTD

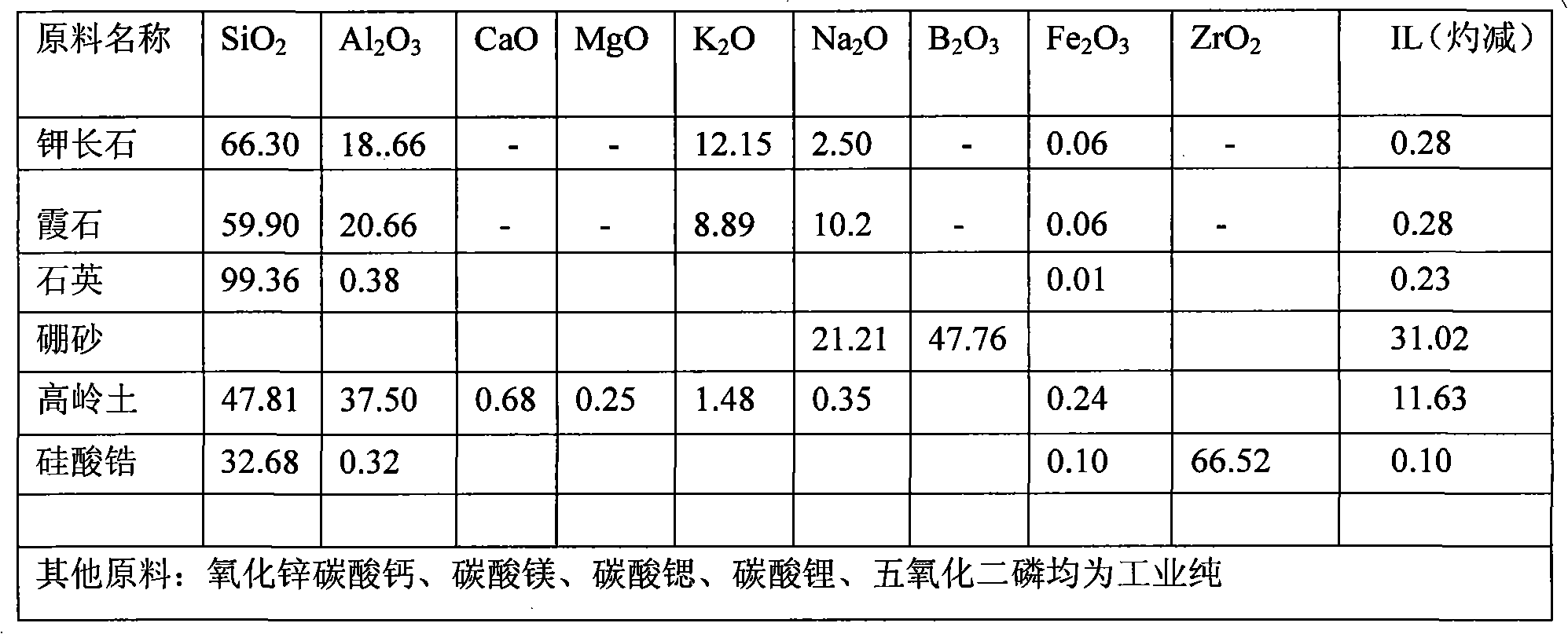

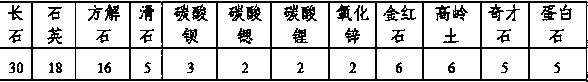

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

Ceramic tile with bulged particle effect and preparation method of ceramic tile

The invention relates to a ceramic tile with a bugled particle effect and a preparation method of the ceramic tile. The method comprises the steps of applying cover glaze with a specified formula to a blank body, wherein the sintering temperature of the cover glaze is more than 1120 DEG C, and by weight percent, the cover glaze comprises more than 57% of SiO2 and more than 22% of Al2O3; applying dry granular glaze slurry to the blank body coated with the cover glaze through a linear glaze sprayer, wherein the specific gravity of the dry granular glaze slurry is 1.27-1.38g / mL.

Owner:MONALISA GRP CO LTD

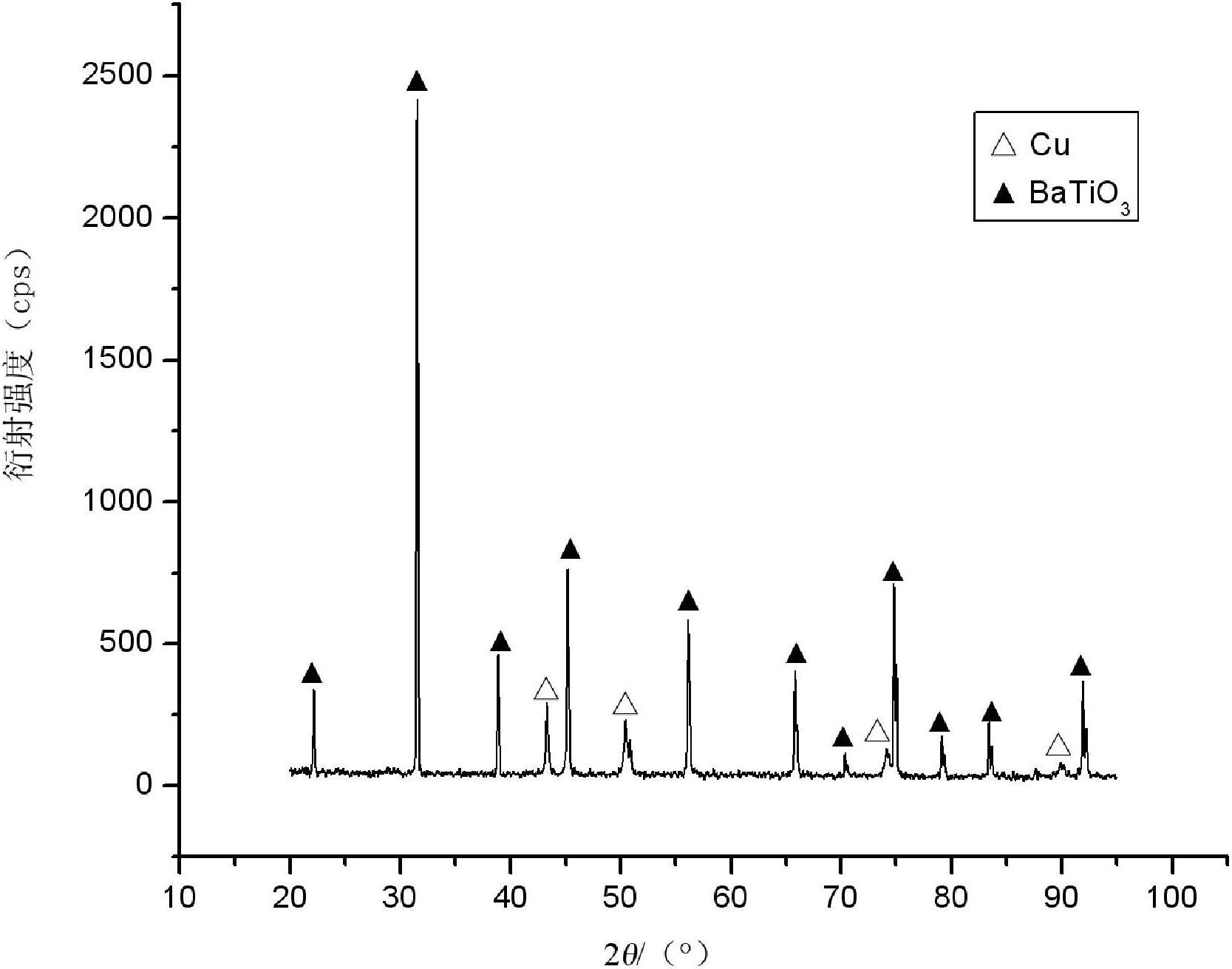

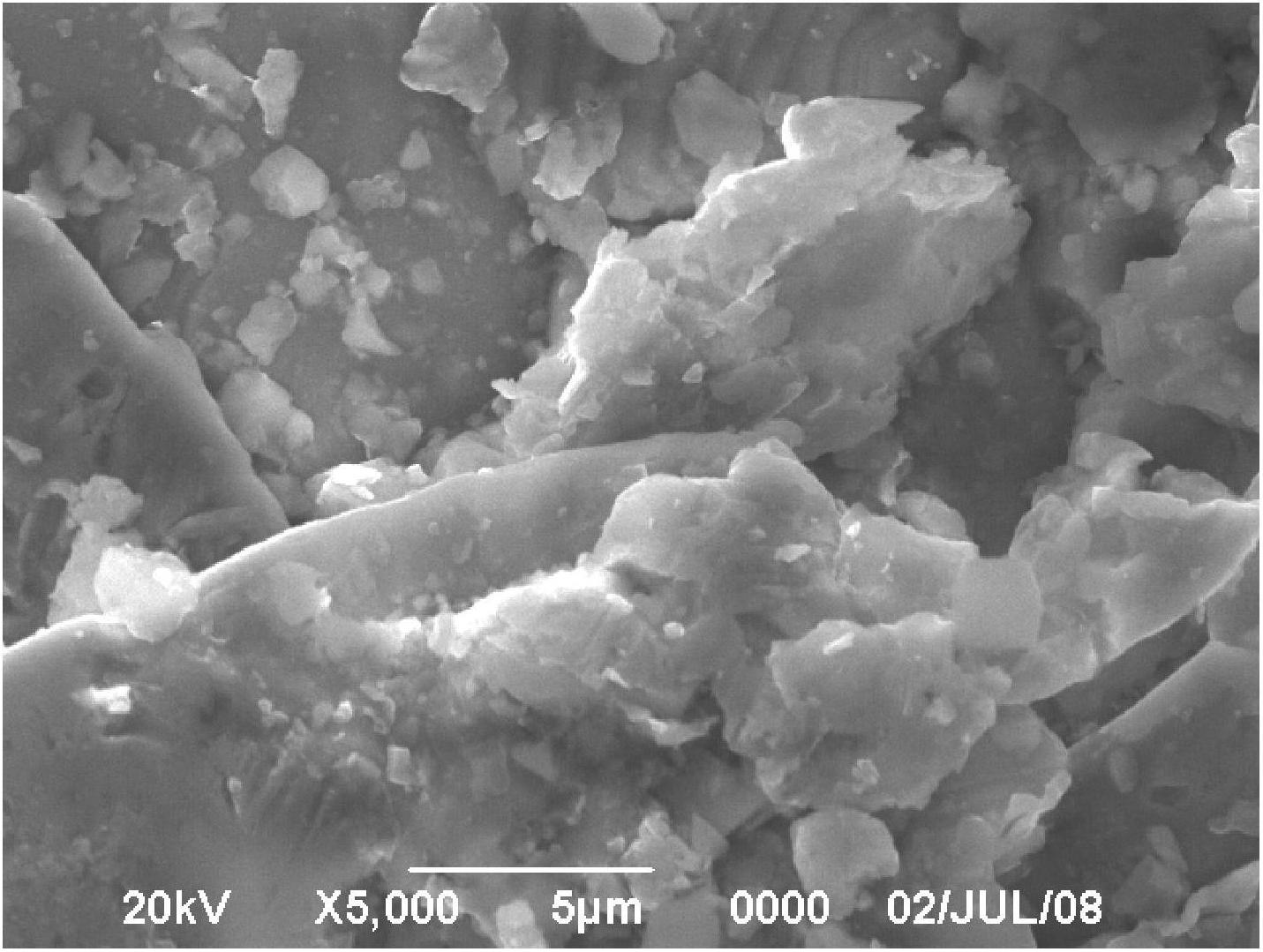

Conductive copper paste for surface electrodes of chip ceramic capacitor and preparation method thereof

InactiveCN102664057AMeet technical requirementsImprove liquidityFixed capacitor electrodesNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses conductive copper paste for surface electrodes of a chip ceramic capacitor. The conductive copper paste comprises the following raw materials in percentage by mass: 65 to 72 percent of metal powder, 4 to 7 percent of glass powder and 24 to 30 percent of organic binder, wherein the metal powder consists of Cu and W or Cu and Mo; the glass powder consists of CaO, ZnO, Bi2O3, BaO, SiO2, B2O3 and Al2O3; and the organic binder consists of solvent, ethyl cellulose, silane coupling agent and surfactant. The conductive copper paste is printed through silk screens and sintered under the protection of N2 gas, the performance of the obtained finished product of the chip ceramic capacitor can completely meet the technical requirements of the ceramic capacitor, and the conductive copper paste can be used for replacing conductive silver paste on the surface of the corresponding chip ceramic capacitor.

Owner:HEFEI UNIV OF TECH

Manufacturing method of magnesian pellets

InactiveCN102766763ALower the temperature of preheating stage IIHigh strengthBlast furnace detailsIron powderRoasting

A manufacturing method of magnesian pellets is particularly used in enterprises adopting a grate-rotary kiln process to manufacture the magnesian pellets. The manufacturing method of the magnesian pellets comprises ingredients by weight: 94-98% of iron powdered ore, 2-4% of high magnesium oxide (MgO) content fusing agent and 1.0-2.5% of bentonite, wherein proportion of the iron powdered ore with grain size smaller than 0.074mm is higher than 80%, and moisture content of the iron powdered ore is lower than 7.5%. The manufacturing method comprises the following steps of: evenly mixing the iron powdered ore and the high MgO content fusing agent, conducting high pressure roller-milling pretreatment, enabling the proportion of the iron powdered ore with grain size smaller than 0.005mm to be 11%-20%, and then mixing, pelletizing and roasting with the bentonite. The manufacturing method can reduce preheating temperature of the pellets, simultaneously, can further improve strength of the pellets to enter a rotary kiln, shortens high-temperature roasting time and solves the technical problems of high preheating temperature, low pellet preheating strength and long high-temperature roasting time when the MgO pellets are manufactured.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for operating a gas turbine group

InactiveUS7104071B2Increase powerIncrease mass flowEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

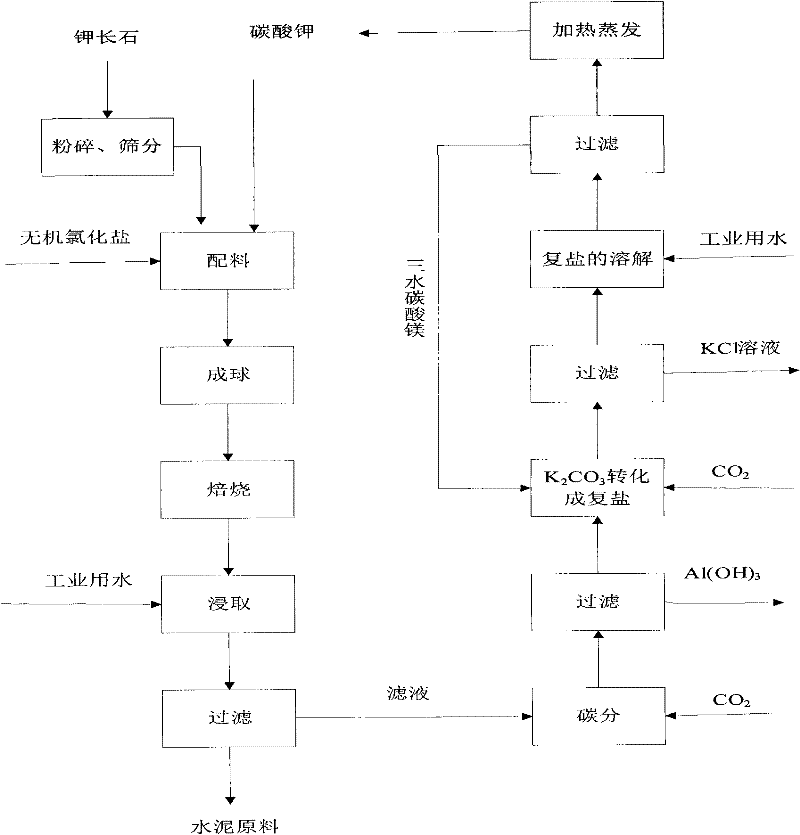

Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

InactiveCN102531710ARealize comprehensive utilizationImprove utilizationAluminium compoundsPotassium fertilisersAluminium hydroxideChloride

The invention relates to a method for producing a potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar. The method comprises the following steps of: (1) smashing potassium feldspar and inorganic chlorate, and burdening potassium feldspar, inorganic chlorate and potassium carbonate in the mass ratio of 1:(1-2):(1-10); (2) pelletizing the prepared material, and sintering at the temperature of 500-1,200 DEG C for 1-5 hours to obtain a sintered material and generate CO2 gas simultaneously; (3) soaking the material obtained in the step (2) into water and filtering; (4) introducing a filtrate obtained in the step (3) into the CO2 gas obtained in the step (2) to obtain an aluminum hydroxide precipitate, and filtering; (5) adding a filtrate obtained in the step (4) into nesquehonite, introducing CO2 gas to obtain a complex salt precipitate, filtering and crystalizing a filtrate to obtain a potassium chloride chemical fertilizer; and (6) adding water for dissolving a complex salt obtained in the step (5) to obtain a solid of nesquehonite, circularly using, heating a potassium bicarbonate solution for decomposing to obtain a potassium carbonate solution for circularly using, and repeating the step (1) to the step (6).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Strong-base corrosion-resistant ceramic glaze and preparation method thereof

The invention discloses a strong-base corrosion-resistant ceramic glaze. The ceramic glaze comprises the following components: a boron frit, quartz powder, spodumene, calcined zinc oxide, calcined talcum powder, kaolin, zirconium silicate, a toner and the like. The preparation method comprises the following steps: preparing materials according to mass parts of the components, carrying out ball milling to obtain glaze, sieving the glaze discharged out of a ball mill to obtain glaze slurry, adding water and an electrolyte to respectively adjust the concentration and thixotropy of the glaze slurry, dipping a glaze blank in the glaze slurry, carrying out drying, then putting the glaze blank into a roller kiln, and carrying out firing at a temperature of 1210-1240 DEG C to obtain a high-densityborosilicate glass body. Various pigments are wrapped in the glass body for protection, the firing temperature is low, compactness of the fired glaze is guaranteed, a complete glaze glass body with high density, high gloss and pore-free glaze surface is achieved, and Si-O bonds formed in the glaze glass are protected from being damaged, so that corrosion of strong bases can be resisted.

Owner:HUNAN HUALIAN CHINA IND

Manufacturing method of matte transparent glazed ceramic sheet

The invention provides a manufacturing method of a matte transparent glaze ceramic sheet. The method comprises the following steps: spraying a biscuit with a ground glaze, printing, spraying with a matte transparent glaze, firing, and edging to obtain the finished product, wherein the matte transparent glaze comprises the following raw materials in percentage by weight: 80-93% of frit, 3-11% of calcined zinc oxide, 4-8% of air knife soil, 0.1-0.4% of methyl cellulose and 0.2-0.6% of sodium tripolyphosphate, and the frit is prepared from calcite, barium carbonate, strontium carbonate, potassiumfeldspar, kaolin, sodium carbonate, quartz sand and dolomite. According to the invention, zirconium dioxide is not added into the obtained matte transparent glazed ceramic sheet, transparency is good, calcined zinc oxide is used for adjusting expansion of glaze to achieve the purpose of adjusting the shape of a brick, and air knife soil improves the suspension property and viscosity of the glaze;and after the matte transparent glaze is sintered, the glossiness is 5-20 degrees, the glaze surface is smooth, a printing layer can be placed below the matte transparent glaze, the printing layer isprevented from being scratched, and the matte transparent glaze layer can also be used for polishing.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Method for gas turbine operation during under-frequency operation through use of air extraction

ActiveUS8479523B2Reducing diluent flowRaise the firing temperatureGas turbine plantsEngine componentsElectricityControl system

In a gas turbine electric power generator where rotational speed of the gas turbine is synchronized to the electrical frequency of a power distribution grid and the gas turbine includes a compressor component, an air extraction path, and a control system for controlling an amount of compressor air extraction, a method is provided for controlling output power produced by a gas turbine. The method includes initiating compressor air extraction and controlling the amount of compressor air extraction.

Owner:GE INFRASTRUCTURE TECH INT LLC

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

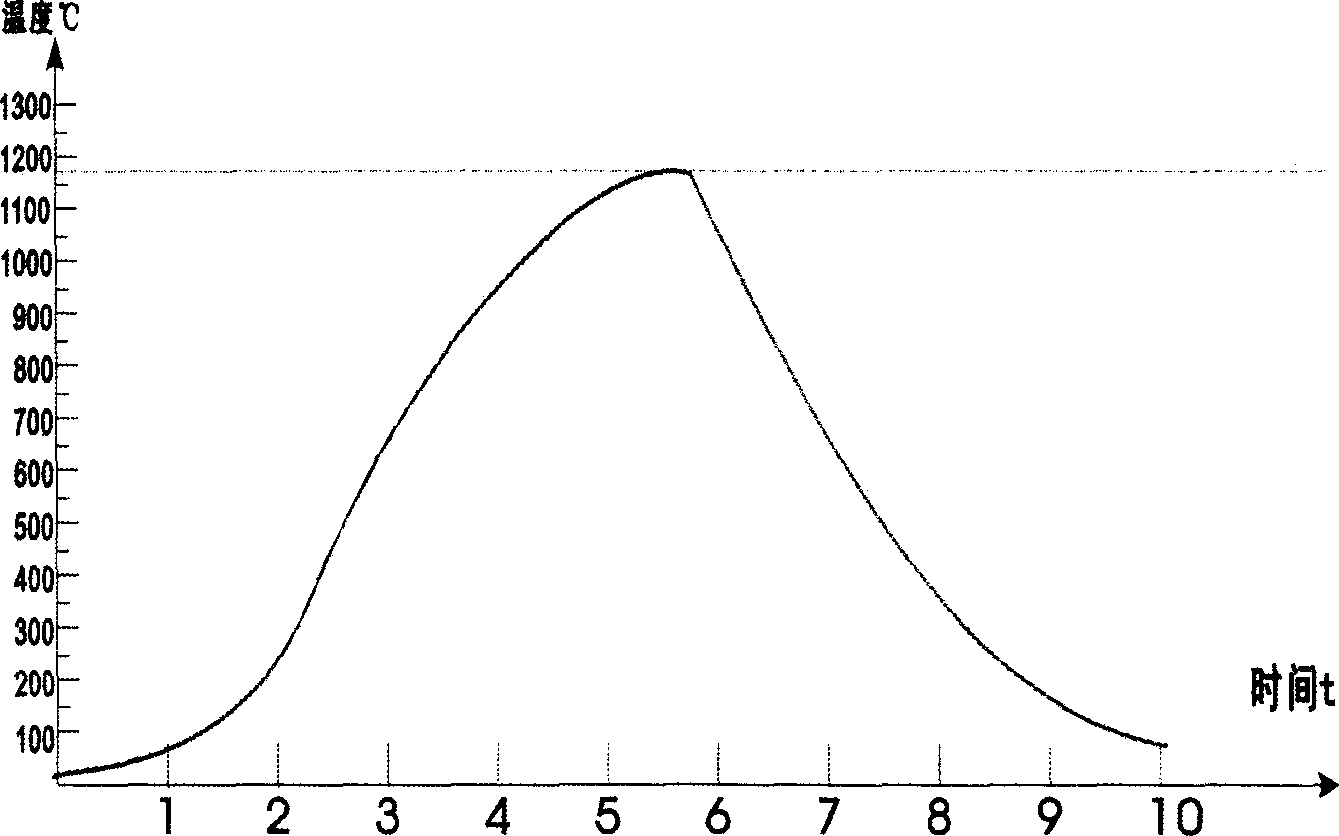

Method for manufacturing purple mud pottery

The invention discloses a method for manufacturing purple mud pottery. The method comprises the following steps: selecting drying and crushing kaolin, red porcelain clay and yellow clay, adding water into the mixture, adding screened river sand to prepare mud, molding, drying in the shade, patching, manually manufacturing a mouth, a kettle handle and the like, assembling the mouth, the kettle handle and the like with a kettle body, polishing, performing press polish, drawing, sculpturing, carving, drying in the shade at low temperature, drying at medium temperature, drying at high temperature, firing in a kiln, discharging from the kiln to obtain a finished product. Because the raw material formula is improved, the large-scale kaolin and river sand are added on the basis of the original yellow clay and red porcelain clay, the density of the pottery products is improved, particularly the firing temperature is increased, the problems that the sintering hardness and the density can not be meet during low-temperature firing are solved, the problem that high-temperature firing water seepage can not be realized is solved, and the pottery is bright in color, ideal in air permeability and exquisite in workmanship and is a brand new pottery product.

Owner:SUILING TAOYUAN POTTERY CULTURE & ARTS DEV CO LTD

Alumina supporter containing flurine and its preparing process

The fluoride bearing alumina carrier consists of (accounting in the weight of catalyst): fluorine 0.5-15 wt%, assistant M 1.0-30 wt% and alunina the rest. Fluorine and assistant M are added during forming the alumina carrier in kneading mode. The said process can prepare carrier with F and M contents and F / M ratio adjustable within certain range and physical and chemical properties adjustable within certain range. The carrier can meet the requirement for various hydrogenating catalyst and features less loss of F inside the carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ferro-nickel slag ceramic and preparation method thereof

ActiveCN107935555APromote fireImprove mechanical propertiesCeramic materials productionClaywaresCeramic sinteringCalcium in biology

The invention provides a ferro-nickel slag ceramic and a preparation method thereof. The preparation method comprises the following steps of selecting one or multiple of quartz, silicon and aluminum-rich raw material and calcium raw material; mixing 20 to 65wt% of ferro-nickel slag, 0 to 10wt% of quartz, 20 to 70wt% of silicon and aluminum-rich raw material and 0 to 30wt% of calcium raw material;grinding, granulating, forming, and firing, so as to obtain the ferro-nickel slag ceramic. The preparation method has the advantages that the ferro-nickel slag can be used in a batch way, the preparation method is simple, the implementing is easy, and the industrialized production is favorably realized; the crystal phases in the prepared building ceramic materials (ceramic tiles and ceramic sintering bricks), industrial ceramics and other ceramic materials contain one or multiple of anorthite, spinel, olivine and cordierite, the sintering is easy, and the mechanical property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

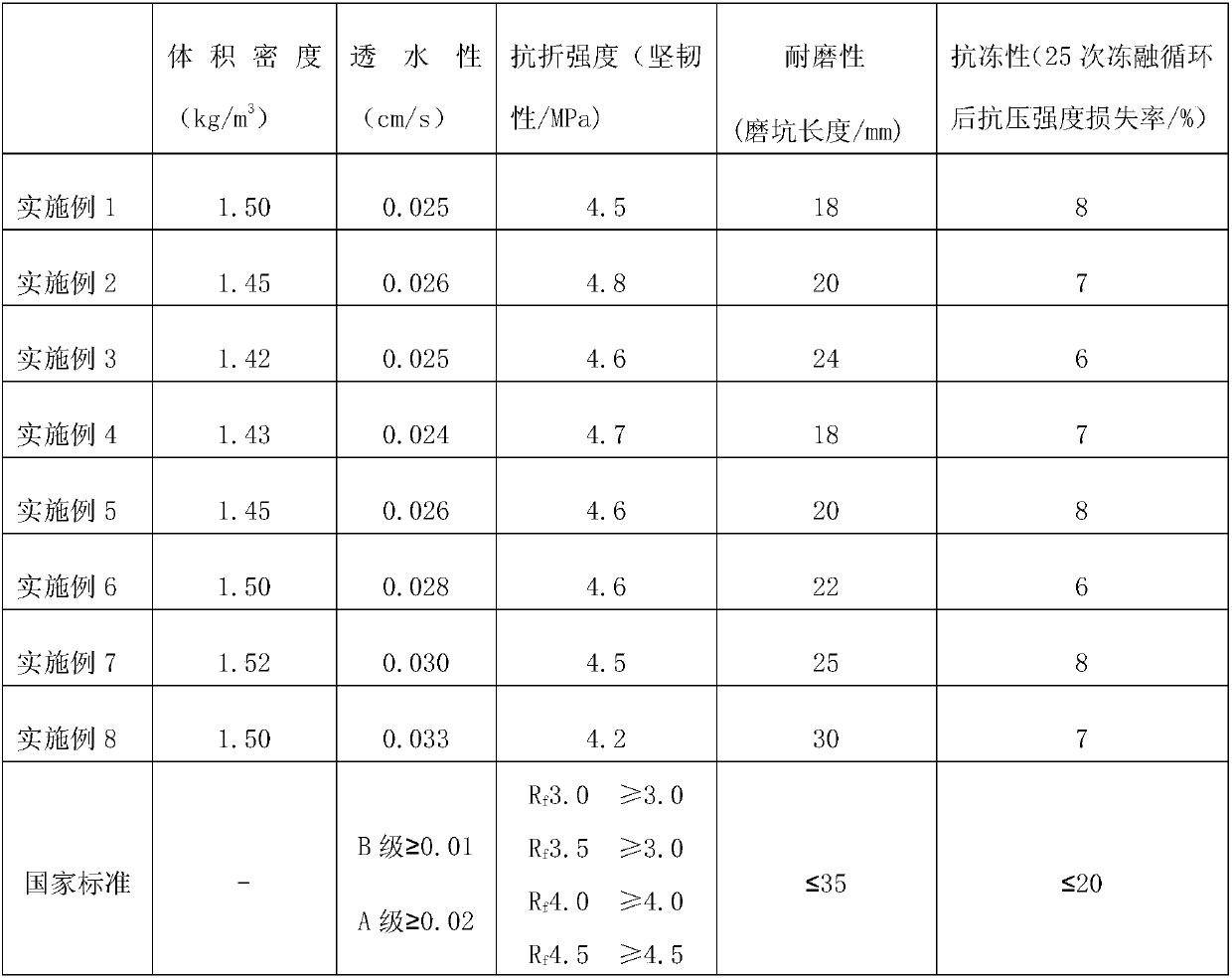

Water permeable brick based on graphene and solid wastes and preparation method thereof

ActiveCN107602072AHigh strengthImprove high temperature resistanceCeramic materials productionCeramicwareSodium BentoniteBrick

The invention provides a water permeable brick based on graphene and solid wastes. The water permeable brick is prepared from municipal sludge, municipal waste soil, construction waste, coal ash, nonmetal tailings, graphene, bentonite, sodium silicate, pore forming substance and hydroxypropyl methyl cellulose. The water permeable brick with excellent performances is acquired in the manner of utilizing the construction waste, coal ash, graphene and nonmetal tailings as aggregates and utilizing the municipal sludge, municipal waste soil, bentonite and sodium silicate to bond the aggregate grainsand thus is endowed with the performances, such as, high strength, high temperature resistance and high wearing resistance. A large amount of municipal sludge, municipal waste soil and construction waste are effectively utilized and the recycling of the coal ash and the nonmetal tailing waste resources is realized, so that the environment protection is benefited, the industrial and regional economy and the development of urbanization are promoted.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

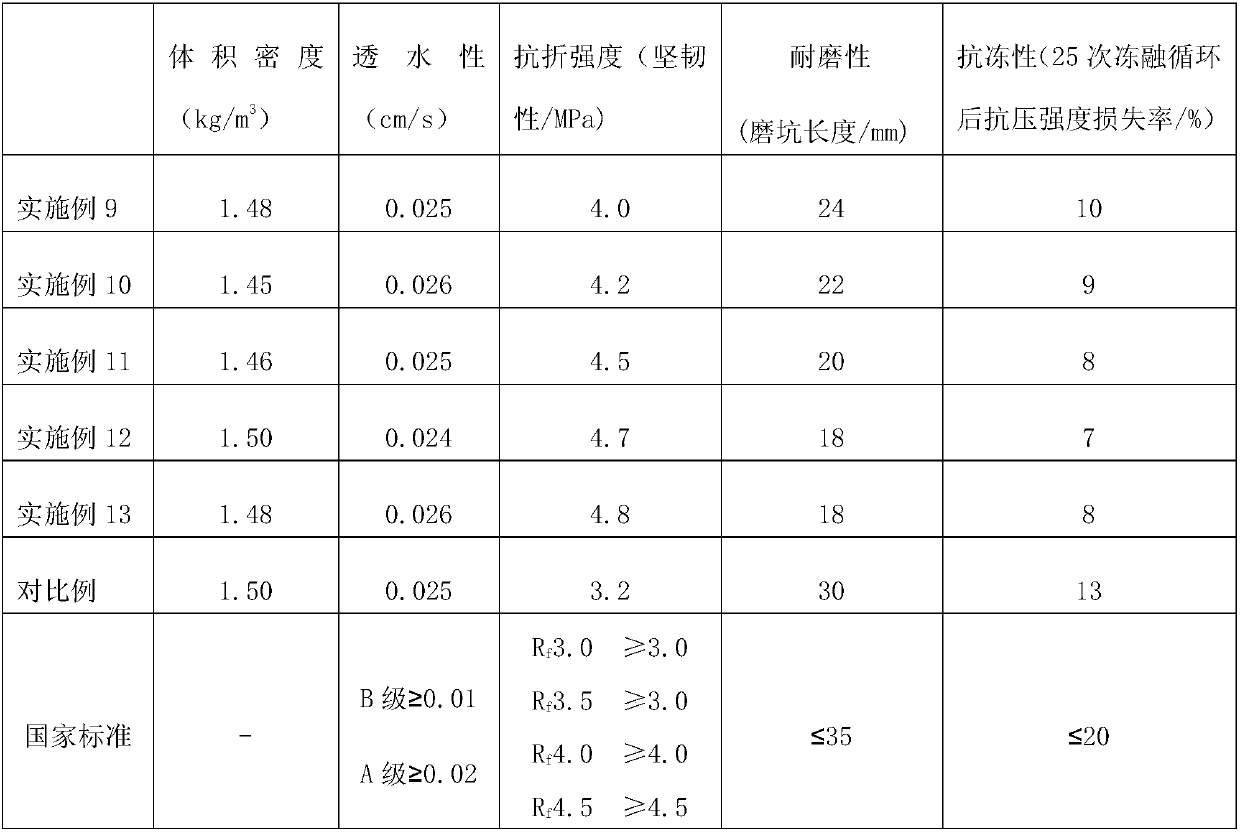

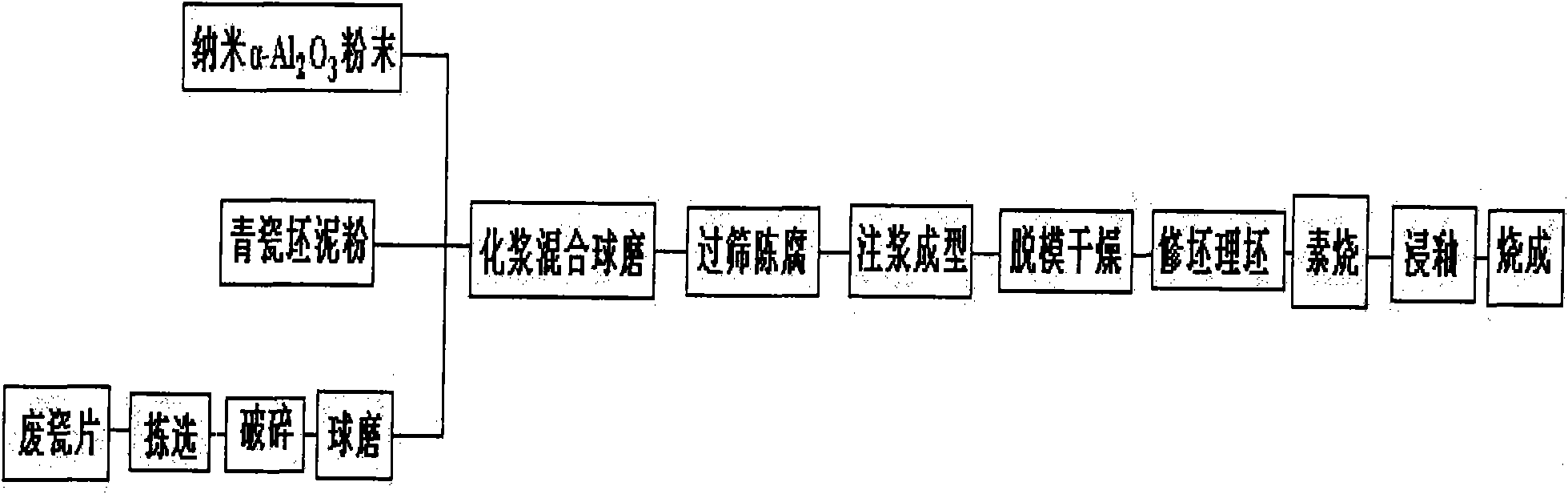

Longquan celadon reinforced blank and preparation method of product thereof

The invention discloses a Longquan celadon reinforced blank. The Longquan celadon reinforced blank comprises the following components in percentage by weight: 12-25% of alpha-Al2O3 powder, 71-87% of celadon paste powder, and 1-4% of waste porcelain powder. The invention also discloses a method for preparing a product by sintering the Longquan celadon reinforced blank. Under the premise of not changing the characteristics of the traditional Longquan celadon formula, process technology, product style and the like, the invention prepares the Longquan celadon blank with high strength by utilizing alpha-Al2O3 new materials; and since the process technical route is fundamentally not changed, and the sintering and loading device and the sintering system are not changed, the damage rate of the products is greatly reduced due to the high strength of the products and the economical benefit is remarkable.

Owner:ZHEJIANG UNIV

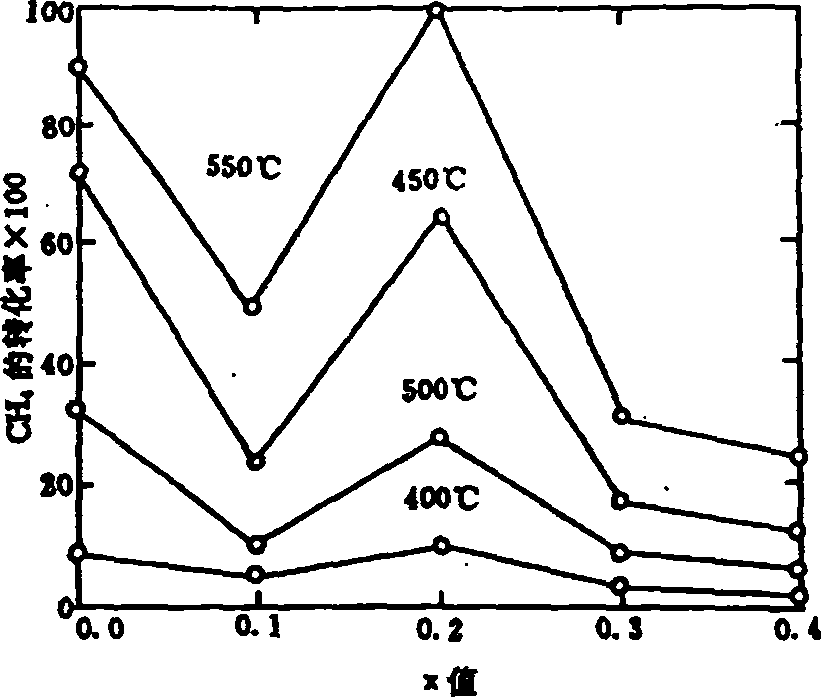

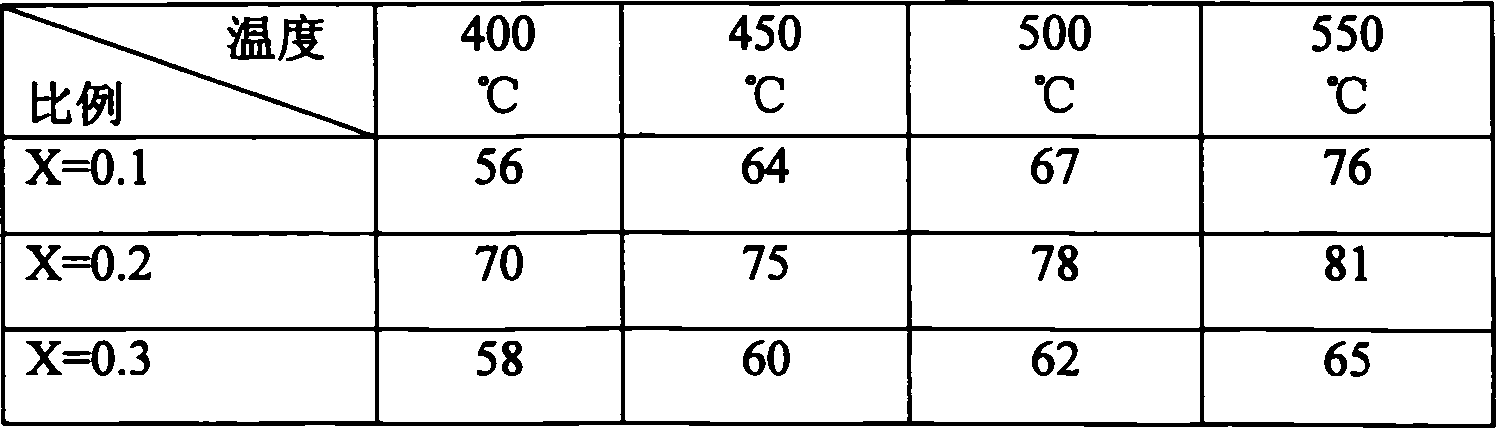

La1-xAgxMnO3 perovskite type catalyst for auto tail gas purification

InactiveCN1879961AAdaptableImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurManganese

The invention relates to a La1-X AgXMnO3 perovskite catalyst used to purify the vehicle tail gas, wherein the A of ABO3 structure of perovskite is formed by lanthanum and silver; the B is formed by manganese; 0.05<=X<=0.4; the total mol of lanthanum and silver, the mol of manganese and oxygen mol are rated as 1:1:3; via analyzing crystal phase, the perovskite structure is 95% of catalyst. The invention can adjust the ratio of lanthanum and silver to improve the application in different vehicle discharge systems. And the invention can effectively resist to the toxicity of lead and sulfur. And it has high thermal stability, with simple structure and low cost.

Owner:TIANJIN UNIV

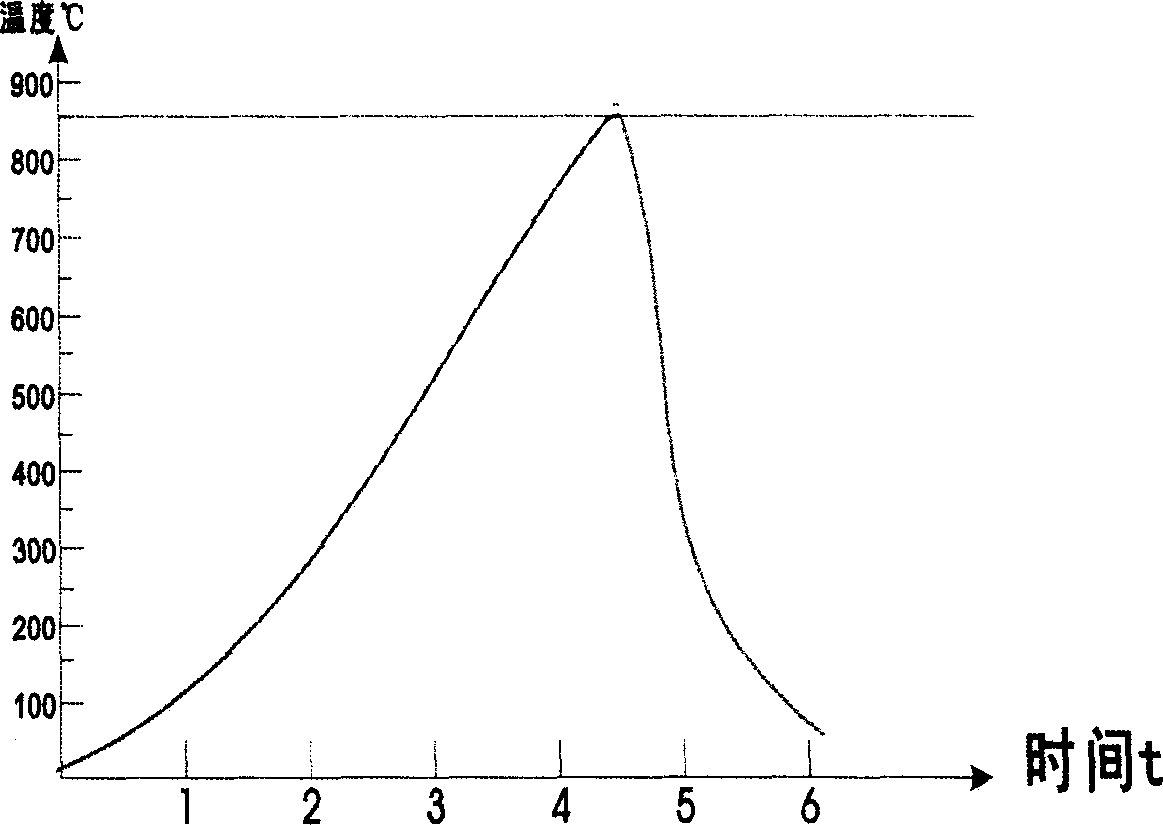

Jianshui (Country of Yunnan) purple pottery wood-fired pug and product firing method thereof

The invention discloses Jianshui (Country of Yunnan) purple pottery wood-fired pug and a product firing method thereof. The wood-fired pug is red mud pug prepared by adding water into 8 to 12 percent of argil, 28 to 32 percent of blue earth, 18 to 22 percent of loess and 38 to 42 percent of red soil. The product firing method comprises the following steps: manufacturing a purple pottery product blank from the red mud pug, then putting the blank into a smokeless wood-fired kiln, and firing pines by adopting a wood firing method, or firing the blank together with a Jianshui purple pottery argil blank, ending firing till the temperature is 1,190 to 1,210 DEG C, and cooling in the kiln to obtain a product. The firing temperature of the conventional red mud is changed via preparation of a new red mud formula, so that the difficulty in firing of Jianshui purple pottery is solved, a Jianshui purple pottery wood-fired product with rich kiln changes is obtained, and the production efficiency is improved.

Owner:云南省红河哈尼族彝族自治州民族师范学校 +1

Method for improving strength of pellets

ActiveCN103451416ARaise the firing temperatureImprove crystal bridge connectionSodium BentoniteReduction treatment

The invention provides a method for improving the strength of pellets. The method comprises the following steps: respectively and independently mixing magnetite concentrates and non-magnetite concentrates with externally matched bentonite uniformly; pelletizing, wherein pellets comprise not less than 20% of magnetite concentrates and not more than 80% of non-magnetite concentrates, and in the pelletizing process, the magnetite concentrates added for the first time account for 40-80% of total addition of the magnetite concentrates, the mixture of the non-magnetite concentrates and bentonite is added for the second time, the remaining magnetite concentrates are added for the third time, and 1.3-1.5wt% of bentonite is added in the pelletizing process to serve as a binder; carrying out pressure increase and reduction treatment on the pellets. The method has the beneficial effects that the calcination temperatures of ores at the middle layer and crystal bridge connection between the pellets can be improved, the content and existing state of water in the pellets can be changed, the preheating and drying time can be shortened, the preheating and drying temperatures can be reduced, the burst properties of the pellets can be reduced, the strength of the pellets can be improved, the use proportions of hematite, limonite and siderite in the pellets can be increased, and the production cost of the pellets can be lowered.

Owner:ANGANG STEEL CO LTD

Process for preparing ferric oxide red by adopting iron vitriol

ActiveCN102674473AReduce the mixing ratioIncrease temperatureSulfur compoundsFerric oxidesHigh concentrationSulfur dioxide

The invention provides a process for preparing ferric oxide red and recovering high-concentration sulfur dioxide burner gas for producing sulfuric acid or sulfite by taking iron vitriol and sulfur as raw materials, and adopting processes such as preparing ferrous sulfate monohydrate through concentration of iron vitriol, conducting superfine treatment on ferrous sulfate monohydrate, calcining, dust separating, and secondary dust calcining. The process provides a new technical way for preparing ferric oxide red paint by taking iron vitriol which is solid waste as a raw material, so as to effectively solve the problem that the iron vitriol which is a by-product of titanium white preparation adopting a sulfuric acid method is difficult to digest, has an important meaning in the development of the ferric oxide red industry, is suitable for large industrialized continuous production, and has the advantages that the preparation cost is low, the performance of the ferric oxide red product is high, and the dispersivity and the tinting strength of the product are higher than those of a ferric oxide red product prepared according to a classic method (namely the wet method).

Owner:HUNAN HENGGUANG CHEM

Fire retardant insulation dry powder mortar and preparation method thereof

ActiveCN105272075AReduce dosageRaise the firing temperatureSolid waste managementPolymer scienceSlag

The present invention discloses a fire retardant insulation dry powder mortar and a preparation method thereof, the fire retardant insulation dry powder mortar comprises a composite cementitious material, a lightweight aggregate, an admixture, an chemical additives and an organic polymer additive, wherein the composite cementitious material includes cement and byproduct gypsum, the lightweight aggregate is aluminum silicate glass beads, the admixtures includes fly ash, blast furnace slag and expanded vermiculite, the chemical additive includes magnesium aluminum silicate, modified seaweed glue powder, vinyl acetate-tertiary ethylene carbonate-acrylic acid polymer latex powder and 2-naphthalene sulfonate formaldehyde polymer, and the organic polymer additive is hydroxypropyl methylcellulose. The prepared fire retardant insulation dry powder mortar has high compressive strength, high fire retardant temperature, short setting time and low cost.

Owner:湖南人健宝固高新科技发展有限公司

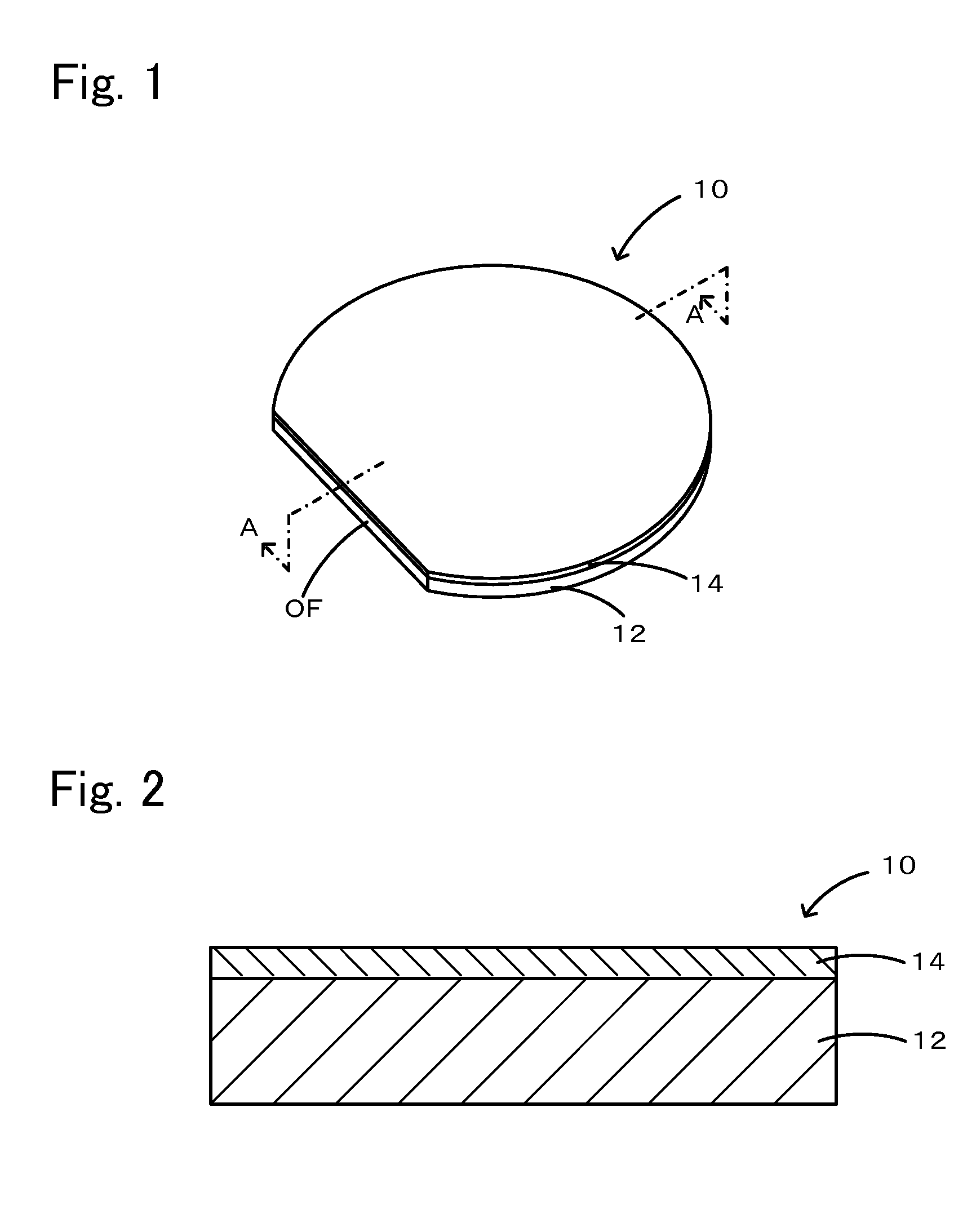

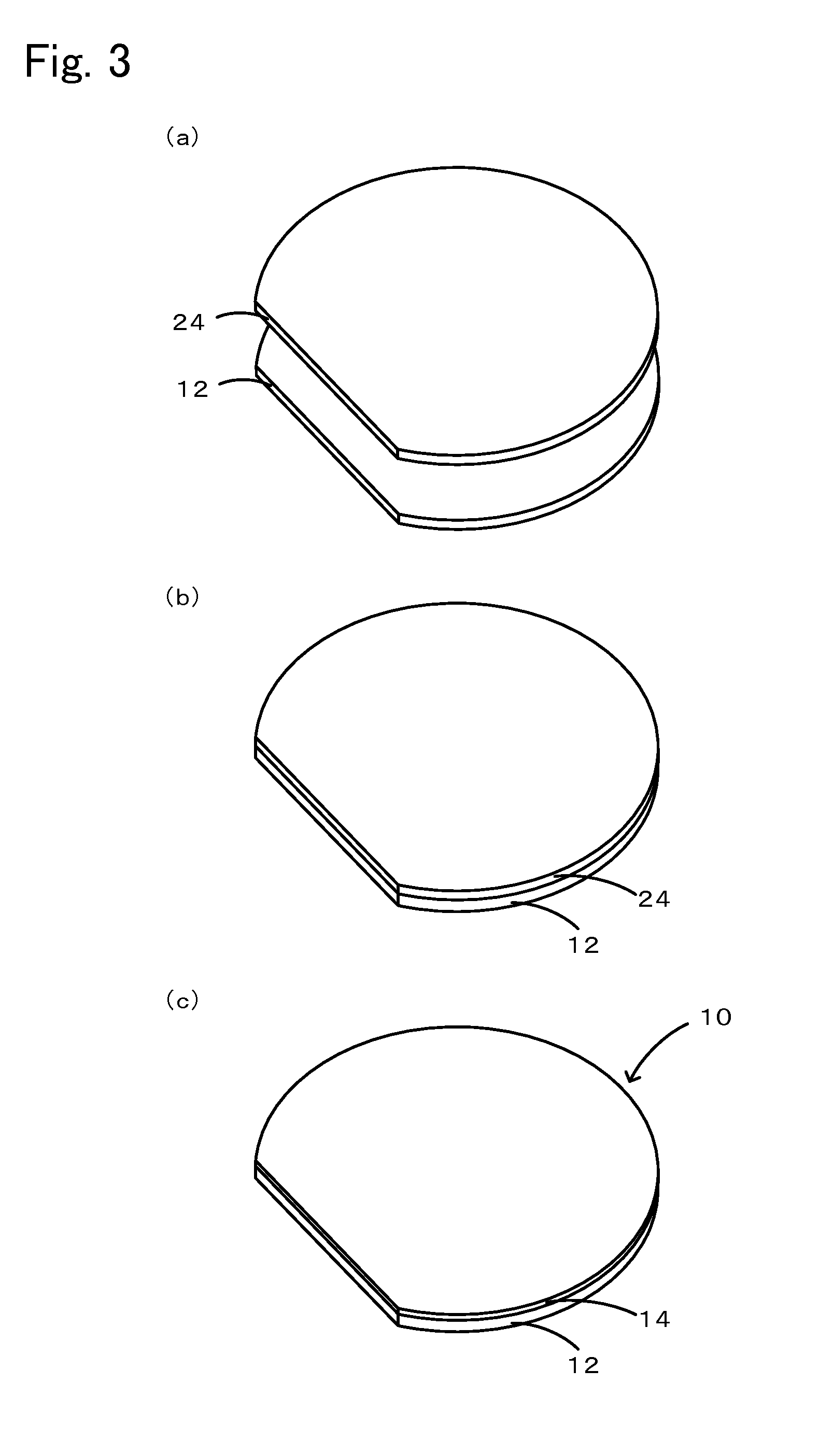

Composite Wafer and Method for Manufacturing the Same

ActiveUS20140191373A1Easily obtainIncrease light transmittanceSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalliteTransmittance

A composite wafer 10 includes a supporting substrate 12 and a semiconductor substrate 14 which are bonded to each other by direct bonding. The supporting substrate 12 is a translucent alumina substrate with an alumina purity of 99% or more. The linear transmittance of the supporting substrate 12 at the visible light range is 40% or less. Furthermore, the total light transmittance from the front at a wavelength of 200 to 250 nm of the supporting substrate 12 is 60% or more. The average crystal grain size of the supporting substrate 12 is 10 to μm. The semiconductor substrate 14 is a single crystal silicon substrate. Such a composite wafer 10 has insulation performance and thermal conduction comparable to those of a SOS wafer, can be manufactured at low cost, and can be easily made to have a large diameter.

Owner:NGK INSULATORS LTD

Ceramic basic glaze with health maintenance function and environment-friendly function and use method thereof

InactiveCN103864464ARaise the firing temperatureSolve technical problems with narrow useStrontium carbonateKaolin clay

The invention relates to a ceramic basic glaze with a health maintenance function and an environment-friendly function and a use method thereof. The ceramic basic glaze is prepared from natural mineral raw materials and industrial pure raw materials by weight percent: 30-55% of feldspar, 15-30% of quartz, 10-25% of calcite, 1-8% of talc, 3-8% of barium carbonate, 1-3% of strontium carbonate, 1-3% of lithium carbonate, 1-8% of zinc oxide, 1-8% of rutile, 3-8% of kaolin and 3-10% of negative ion generating agent; the glaze is prepared by mixing, ball-milling and screening the raw materials. The glaze manufacture process is basically same as the normal ceramic glaze process, the cost is low, the monochrome glaze, fancy glaze or transmutation glaze can be manufactured by adding different ceramic pigment, the manufactured ceramic product is integrated with functionality and beauty, and is stronger in practicability, higher in technique content and better in process applicability in comparison with the similar technique principle product on the market at present, and the manufactured ceramic product has wide application prospect.

Owner:朱仙炳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com