Apparatus and methods for cooling turbine bucket platforms

a bucket platform and cooling turbine technology, applied in the direction of blade accessories, machine/engine, engine fuction, etc., can solve the problems of increasing the distress of bucket platforms, oxidation, creep cracking, low cycle fatigue cracking, etc., to improve the output and engine efficiencies, increase the inlet firing temperature, and exacerbate the potential distress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

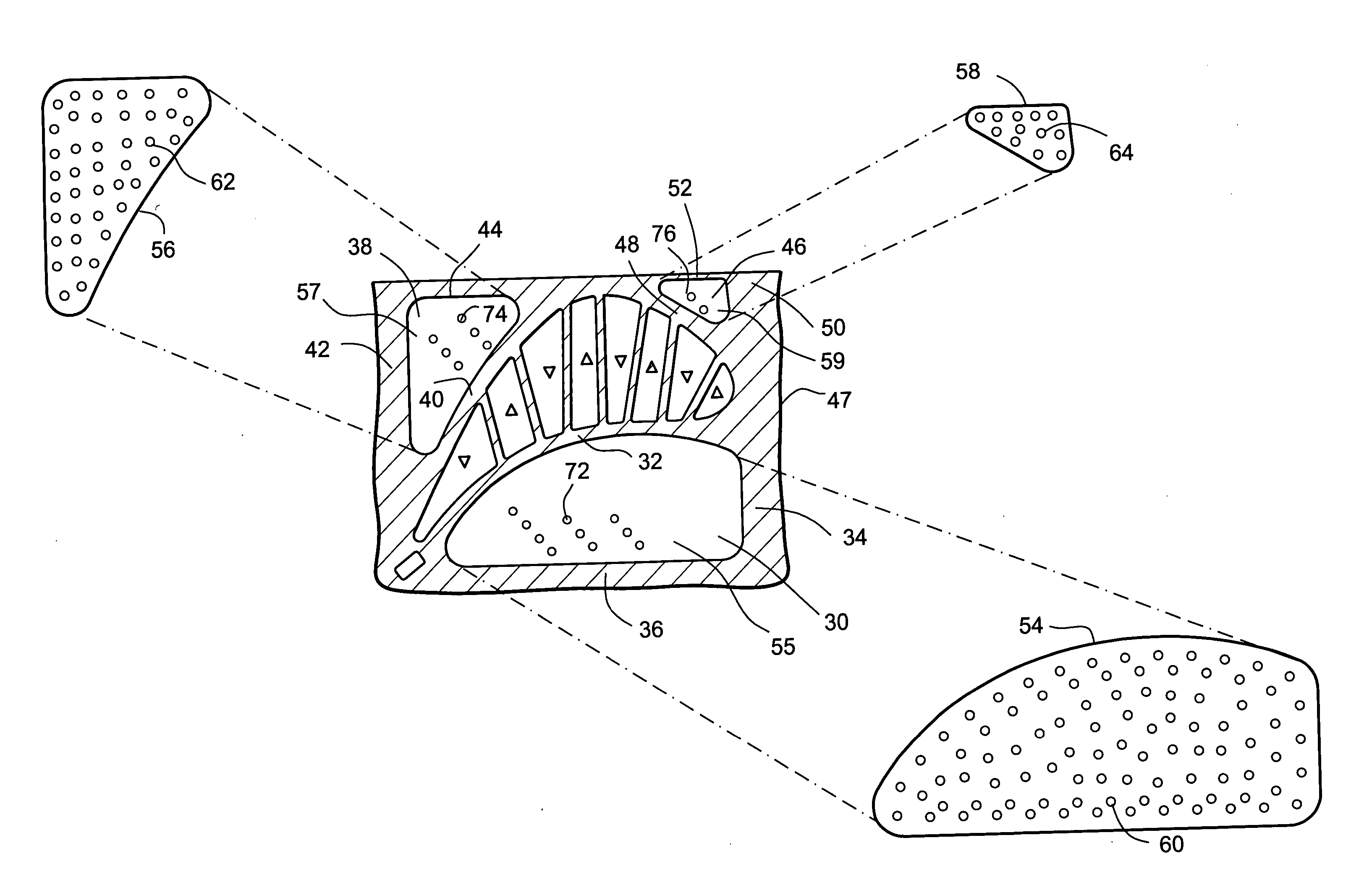

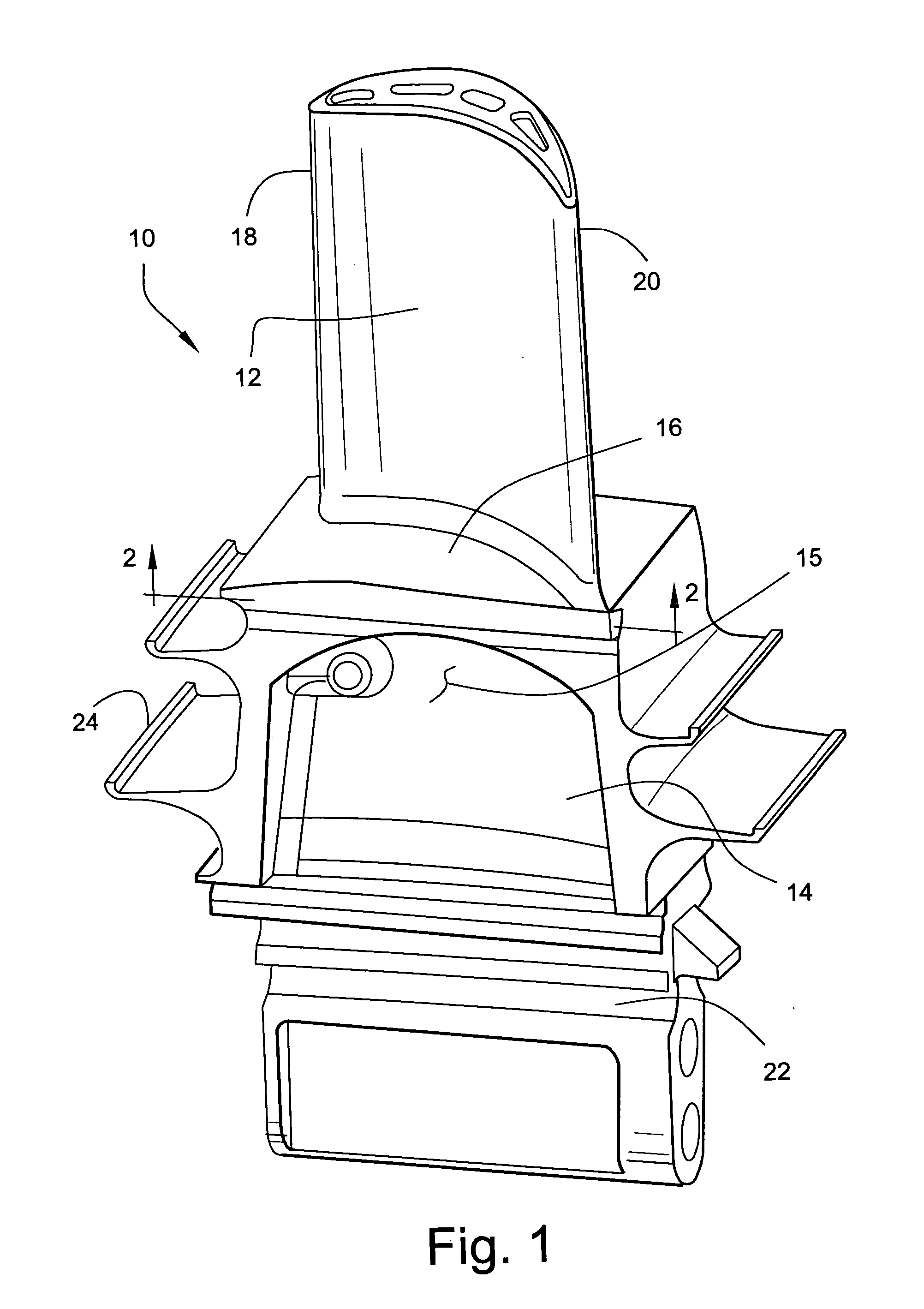

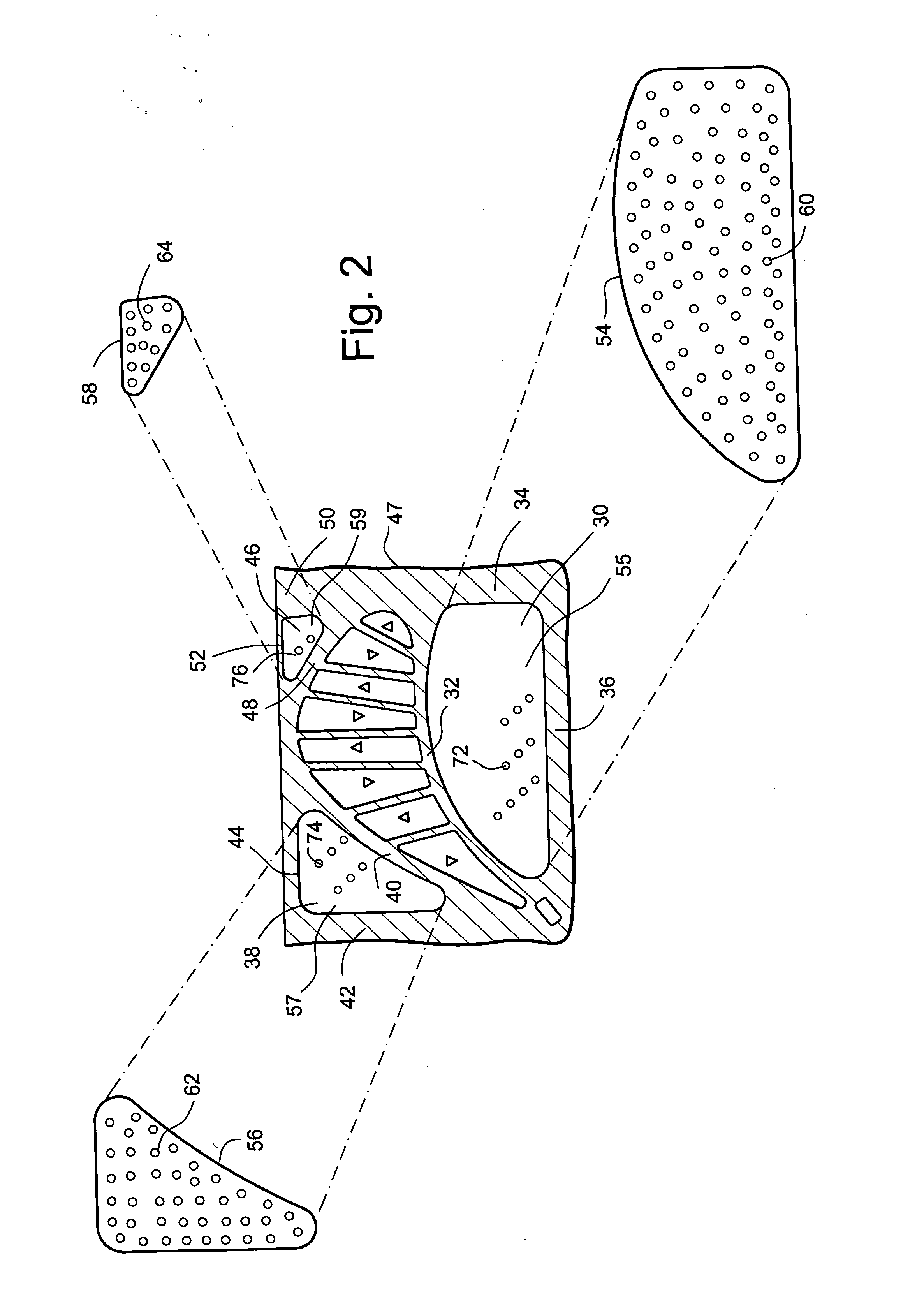

[0009] Referring to the drawings, particularly to FIG. 1, a turbine bucket, generally designated 10 includes an airfoil 12 and a shank 14 with a platform 16 interfaced between the airfoil 12 and shank 14. The airfoil 12, of course, extends radially outwardly from the platform 16 and includes leading and trailing edges 18 and 20, respectively. Below the shank 14 is a dovetail 22 forming part of the base of the bucket. It will be appreciated that the buckets 10 are arranged in a circumferentially spaced array thereof in generally correspondingly shaped dovetail grooves in the rim of a turbine rotor wheel, not shown. So-called angel wing seals 24 are provided on the forward and aft faces of the shank 14 of the bucket 10 for sealing purposes as is conventional. Typically, a cooling medium, e.g., compressor discharge air, is provided in the base of the bucket and circulated along the bucket shank and through the airfoil to cool the airfoil. The cooling medium typically discharges into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com