La1-xAgxMnO3 perovskite type catalyst for auto tail gas purification

A perovskite type, automobile exhaust technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high price, poor anti-poisoning ability and thermal stability, limited resources, etc., and achieve low cost, Good anti-poisoning performance and wide range of temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

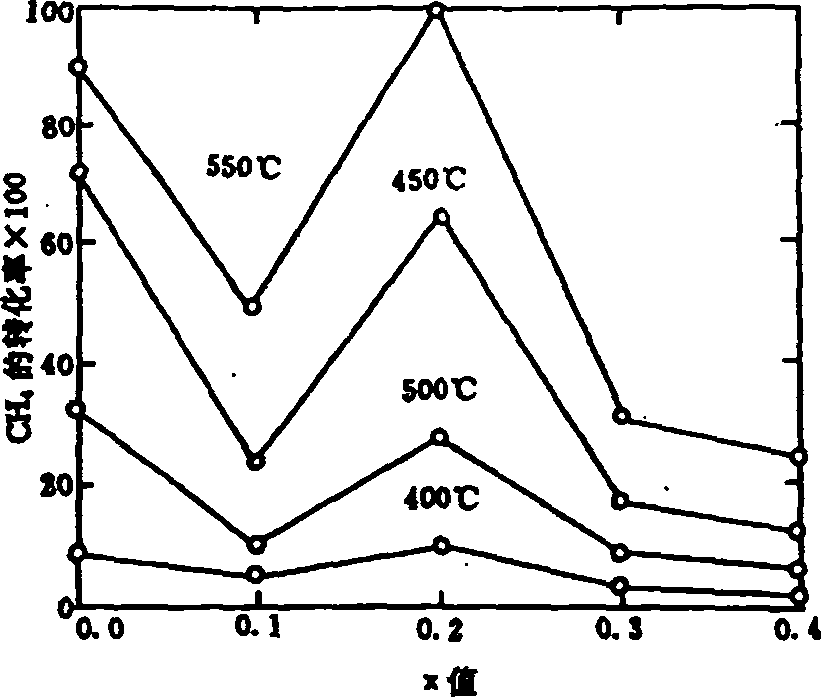

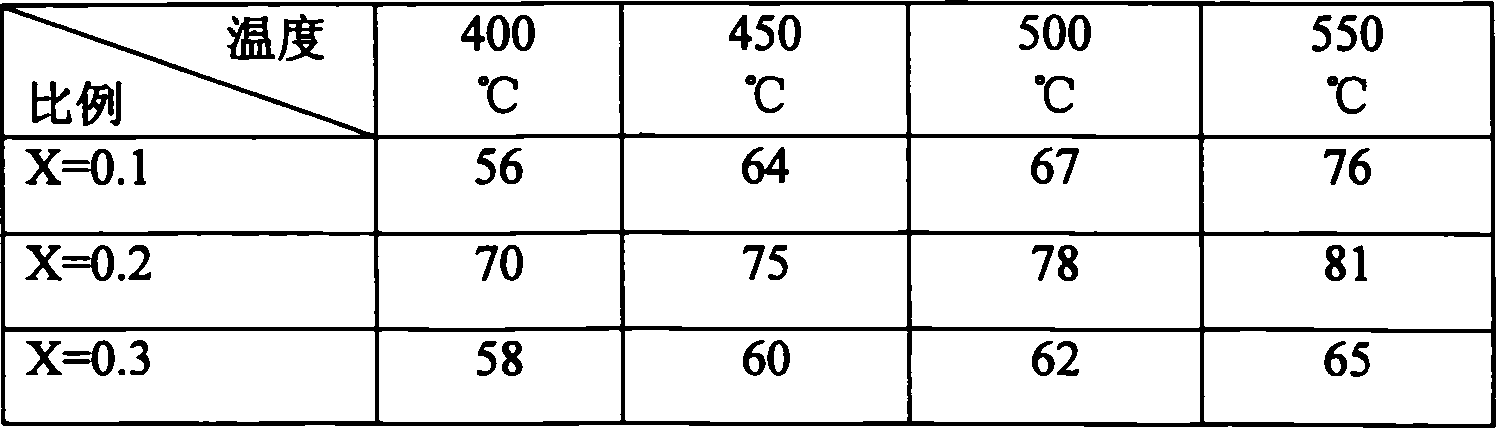

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the accompanying drawings, we have exemplified three simple values of X in the table, and other numerical values are within the scope of the present invention.

[0012] 1. Catalyst test:

[0013] CH in the test feed gas used in the present invention 4 The volume specific concentration of CO is 1.5%, the volume specific concentration of CO is 0.53%, and the rest is N 2 , the airspeed is 1.5×10 4 h -1 , various ratios of La 1-x Ag x MnO 3 The compounds were tested as catalysts, and the effects are shown in the following table and accompanying drawings.

[0014]

[0015] It can be seen from the above figure that the activity is the highest when X=0.2, and the corresponding CH 4 The oxidation temperature ranges from 400°C to 550°C, and when X+ The increase of is conducive to the improvement of catalytic activity; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com