Ceramic basic glaze with health maintenance function and environment-friendly function and use method thereof

A functional glaze technology, applied in the field of ceramic basic glaze, can solve the problems that hinder the application of negative ion material technology, and achieve the effect of improving the quality of wine, good process applicability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Implementation column one:

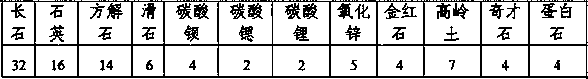

[0016] The composition of the prepared functional glaze materials is as follows: Unit: wt%

[0017]

[0018] First, carry out mixing, ball milling, and passing through a 325 mesh sieve according to the composition in the above table to obtain a basic glaze with a moisture content of 50%;

[0019] Then apply the prepared glaze to the interior and surface of the ceramic body, the thickness of the glaze layer is 0.3mm, and after drying, it is fired in a kiln at 1180°C to obtain the health-preserving and environmental-friendly functional glaze of the present invention. Negative ion emission is 1500 / cm 3 .

[0020] Implementation column two:

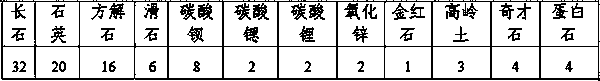

[0021] The composition of the prepared functional glaze materials is as follows: Unit: wt%

[0022]

[0023] First, carry out mixing, ball milling, and passing through a 325 mesh sieve according to the composition in the above table to obtain a basic glaze with a moisture content of 50%;

[0024]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com