Patents

Literature

52results about How to "Reduce the mixing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

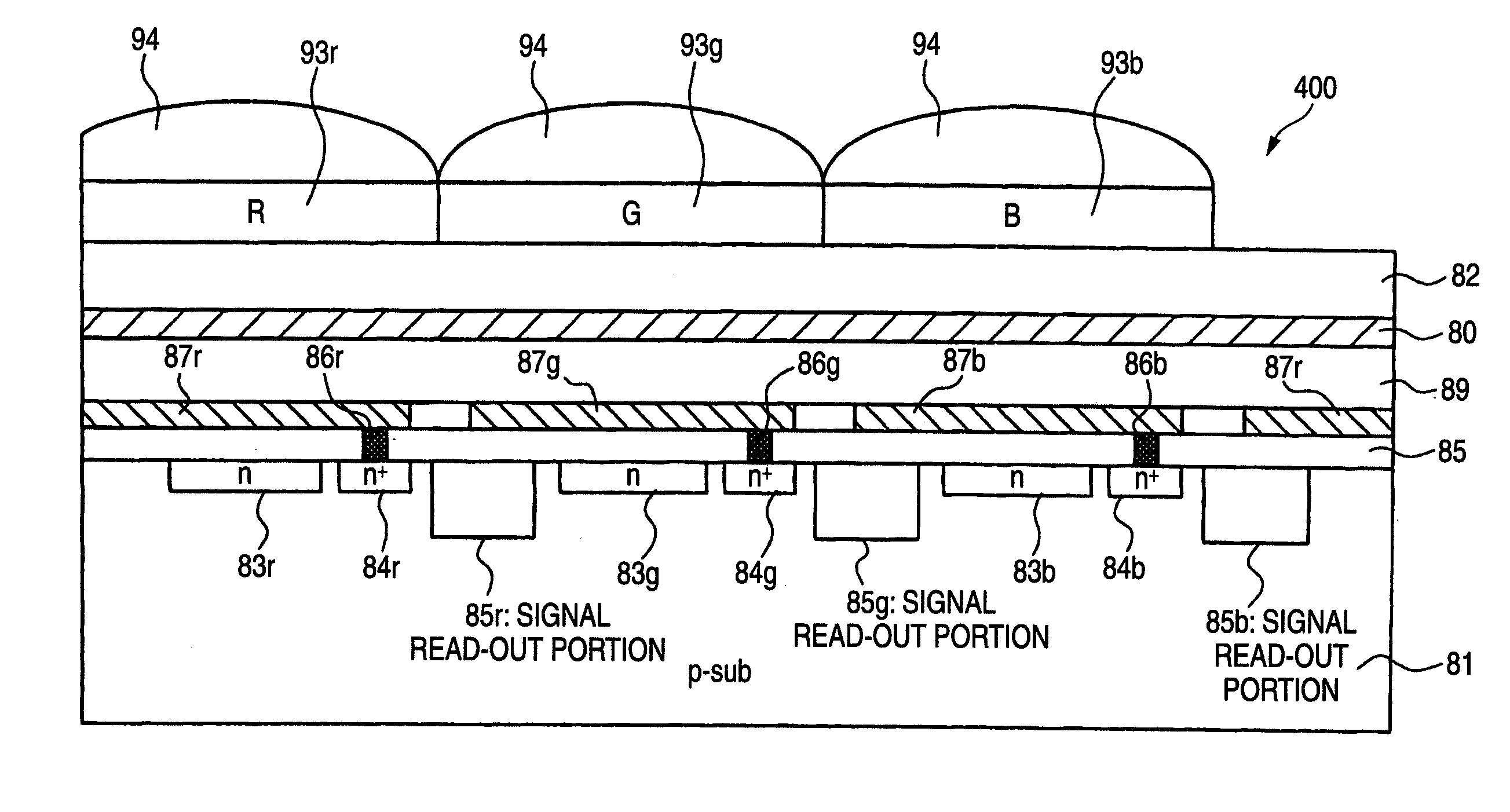

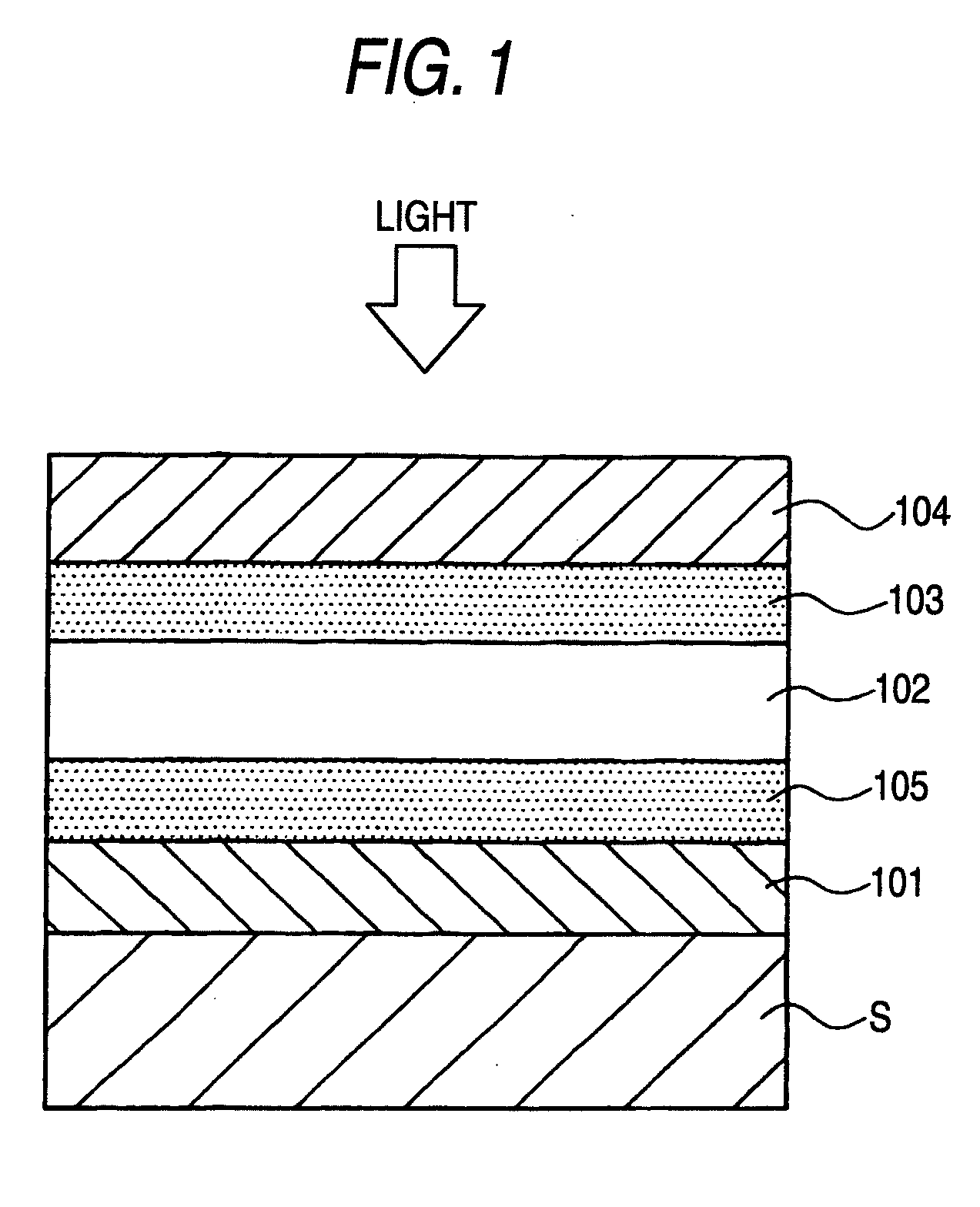

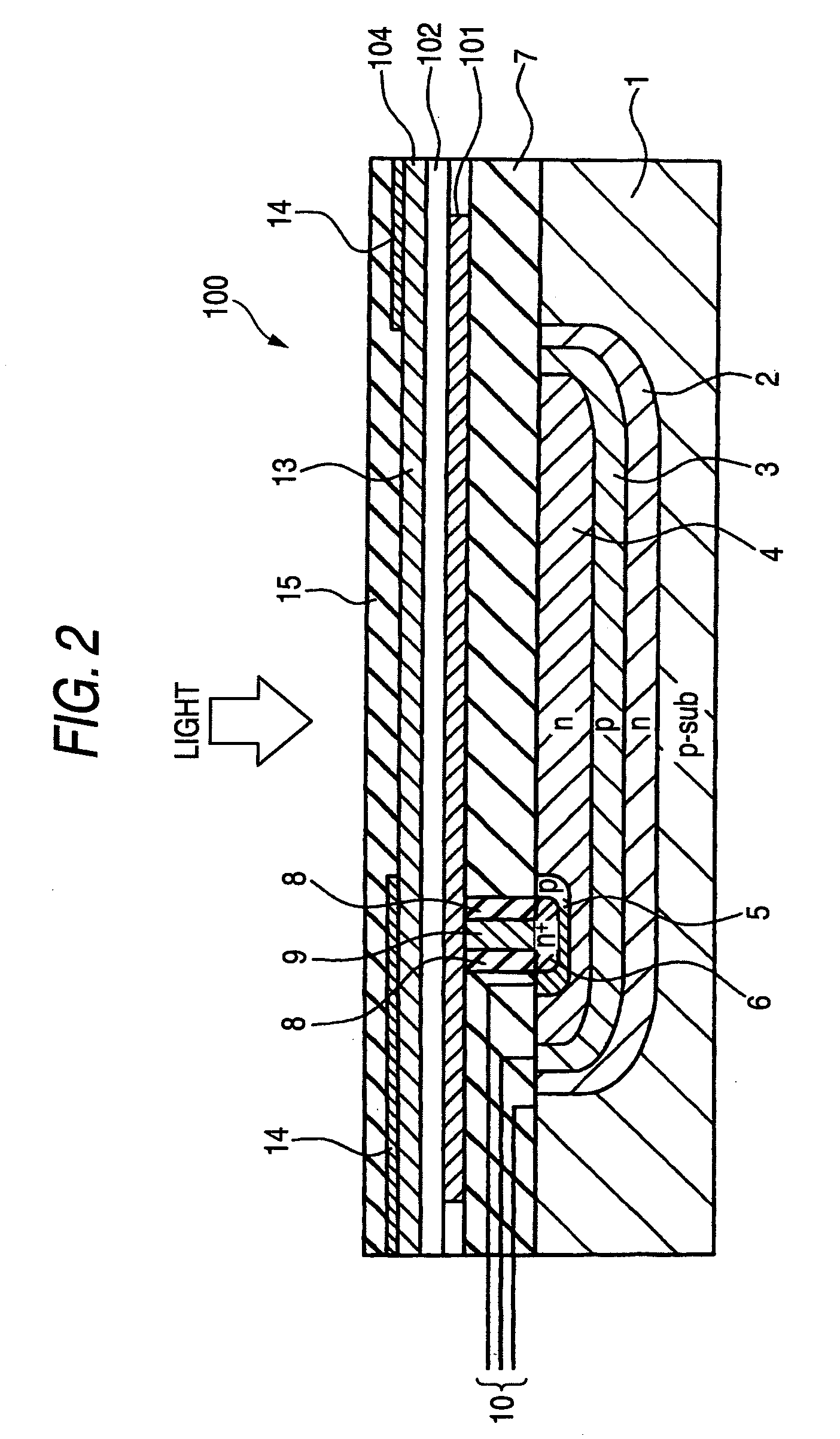

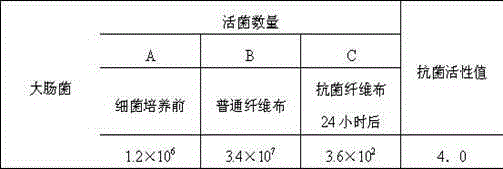

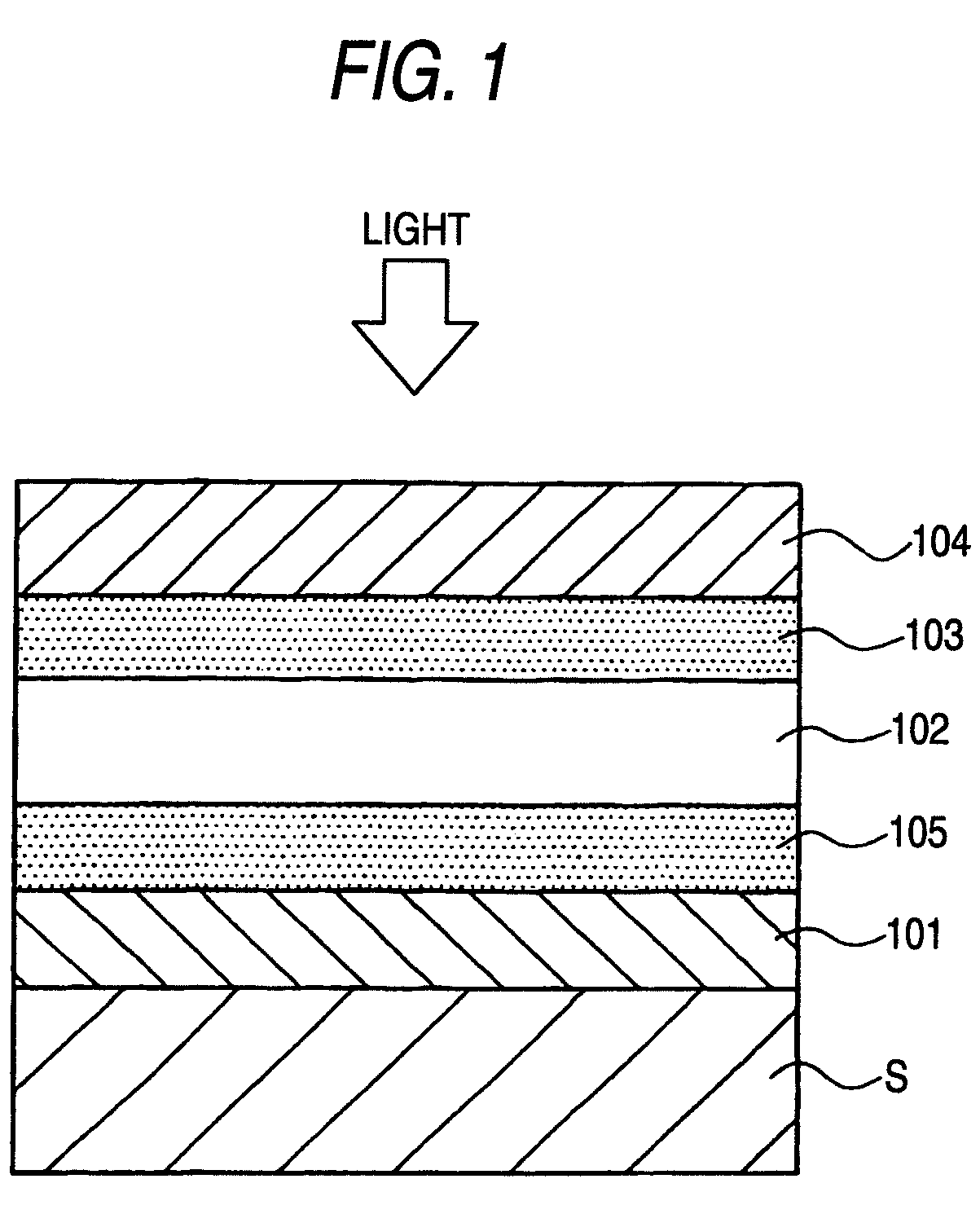

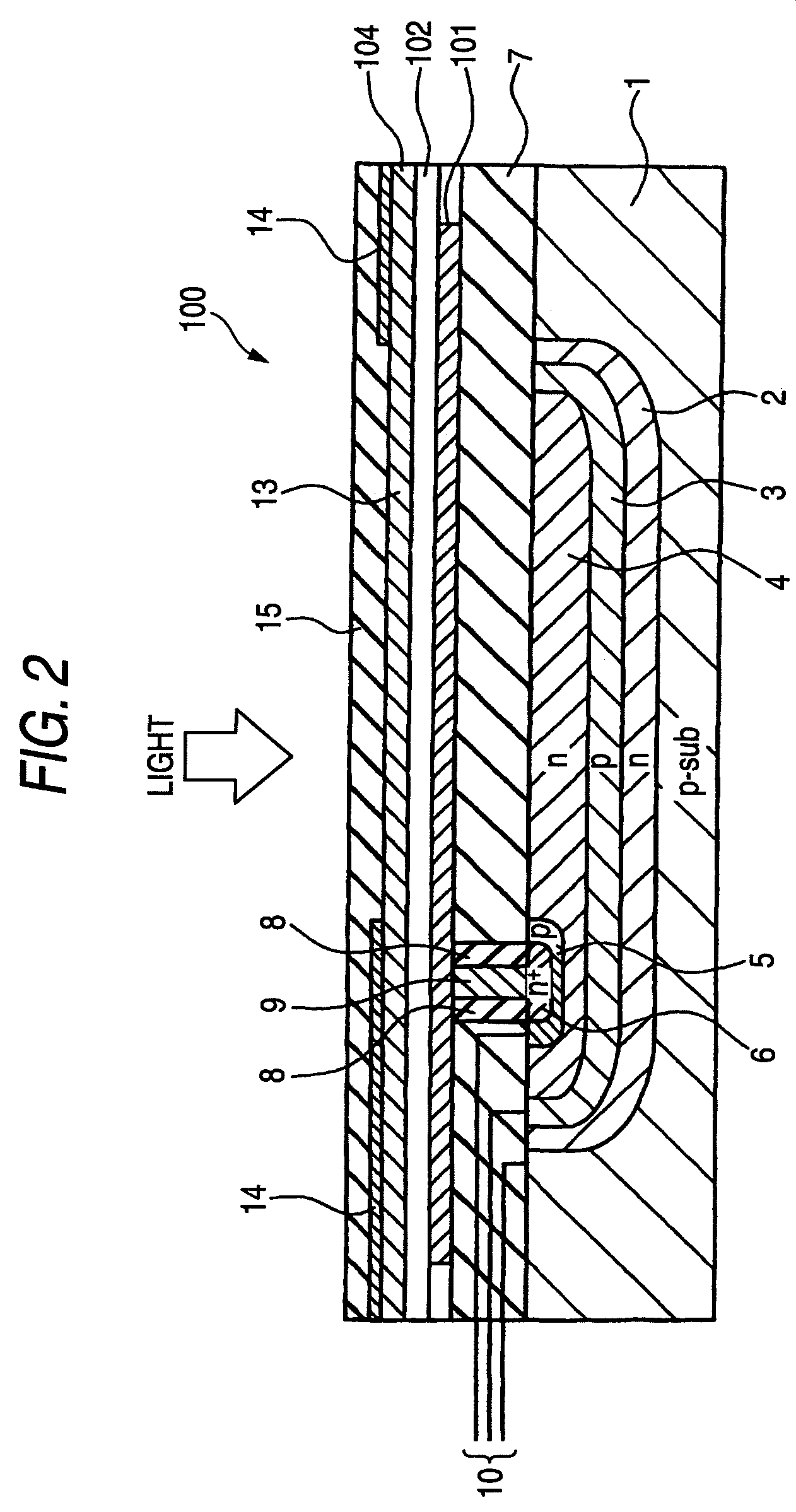

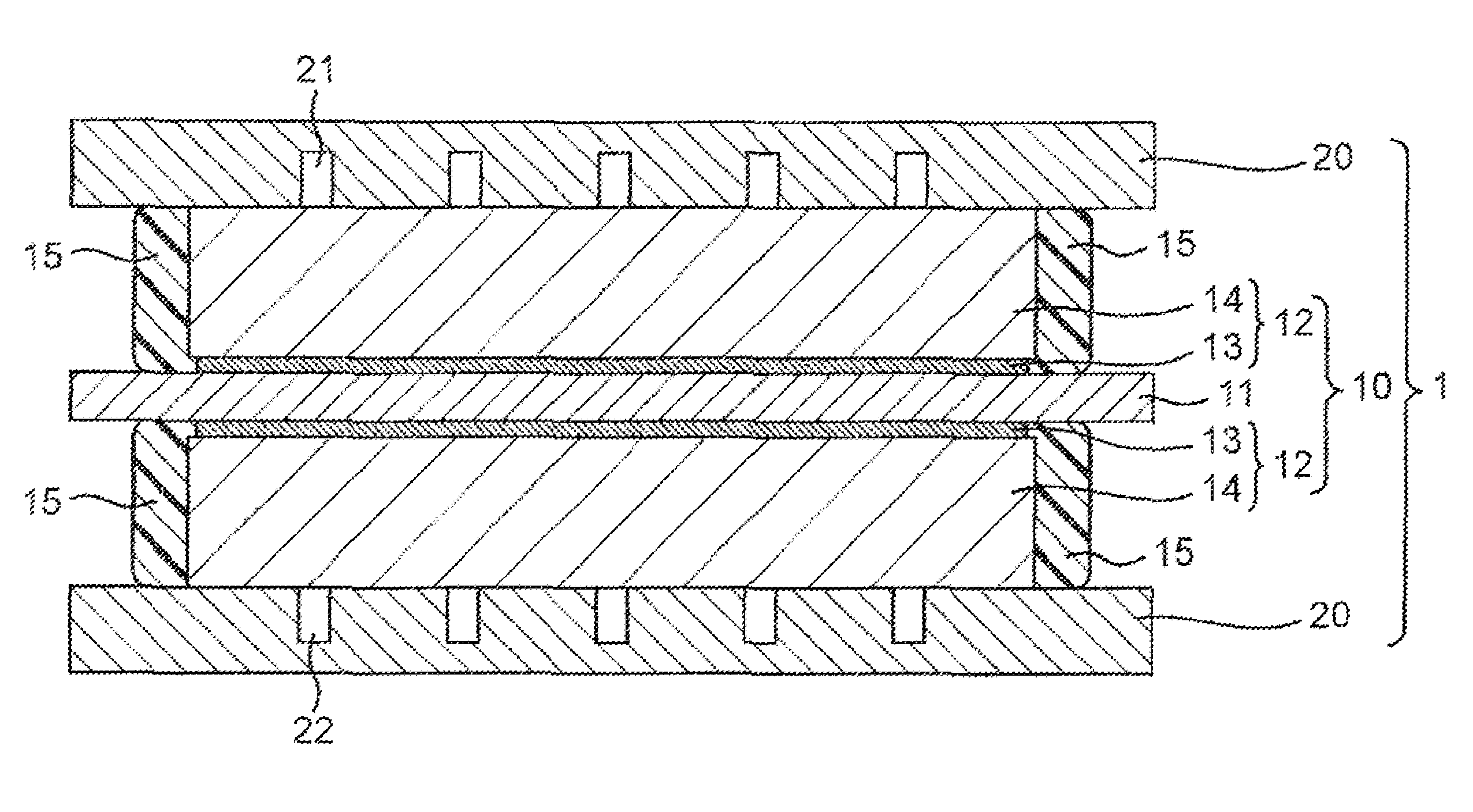

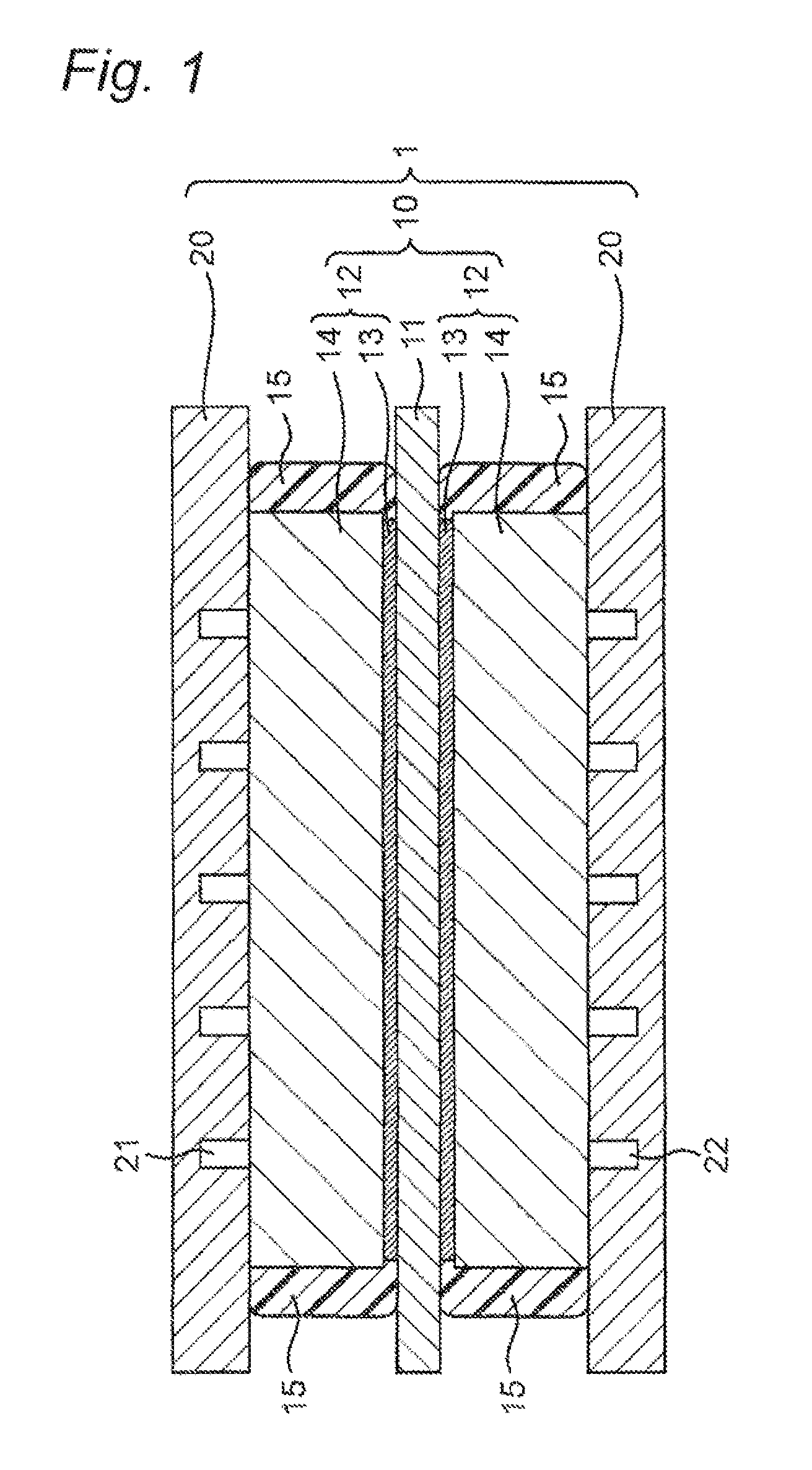

Photoelectric conversion element, method for producing photoelectric conversion element, and solid-state imaging device

ActiveUS20090050881A1Suppress generationImprove photoelectric conversion efficiencyTelevision system detailsFinal product manufactureEngineeringPhotoelectric conversion

A photoelectric conversion element is provided and includes a photoelectric conversion portion. The photoelectric conversion portion includes: a pair of electrodes; and a photoelectric conversion layer between the pair of electrodes, and at least part of the photoelectric conversion layer includes a mixed layer of a p-type organic semiconductor and a fullerene, and a mixing ratio of the fullerene to the p-type organic semiconductor in terms of thickness ratio is less than 1:1.

Owner:FUJIFILM CORP

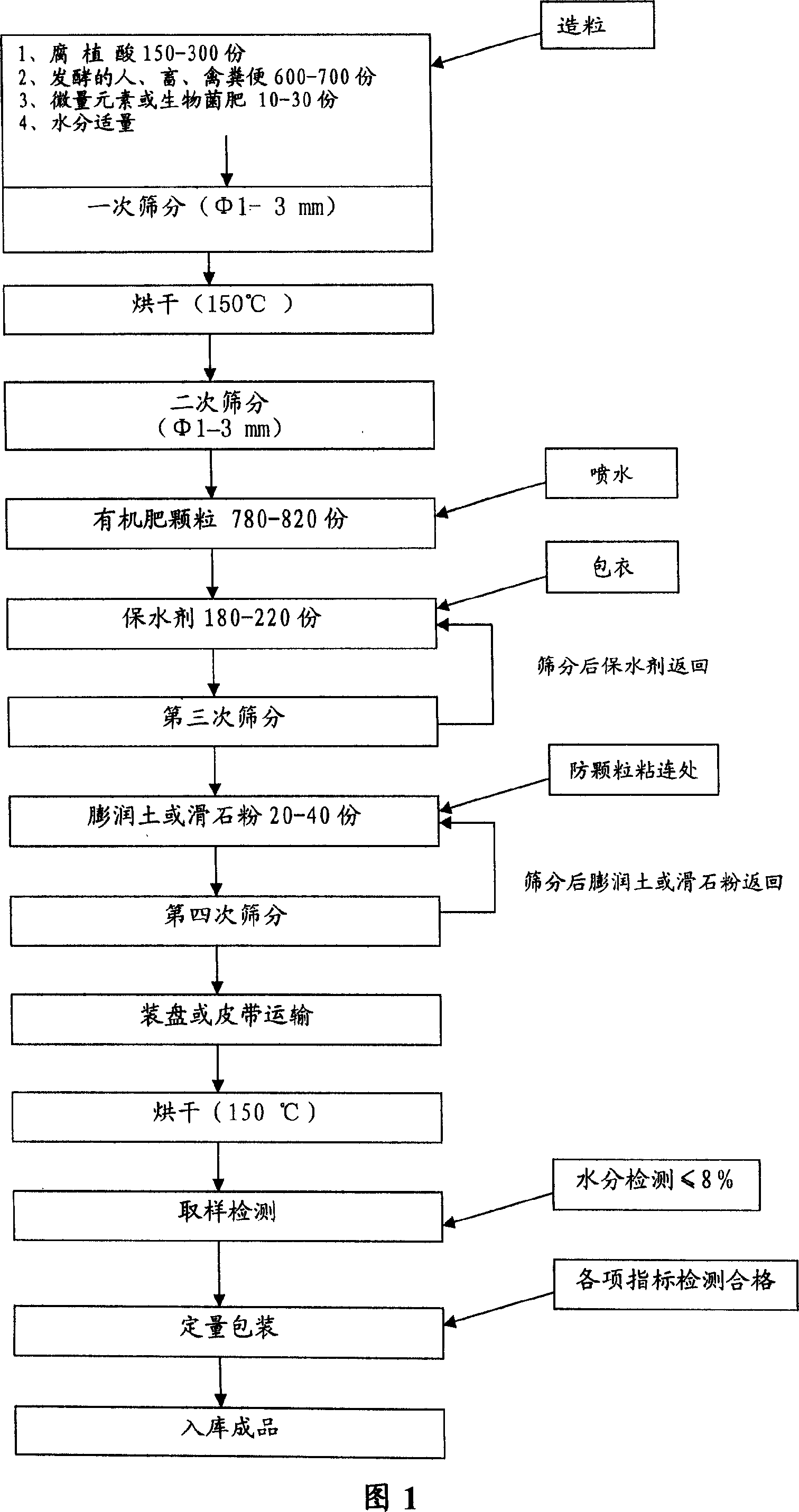

Process of producing plant water keeping organic fertilizer

InactiveCN101054317ASimple and efficient operationLess investmentClimate change adaptationExcrement fertilisersWater contentNutrient

The invention relates to a manufacturing technique of plant drought-resistant water-preserving organic fertilizer, comprises the following steps: weighing component weight parts: humic acid 150-300, microelement or biological bacterium fertilizer 10-30, fermentative excrement of human, livestock, poultry 600-700; mixing granulating and screening to get particles which phi 1-3 mm, baking, rescreening; putting 780-820 parts in a pelletizer, spraying water on particle surface when rolling, then feeding to a rotary drum with 18-22 parts of water-preserving agent, coating in the rotary drum pelletizer; feeding coated organic fertilizer in a rotary drum pelletizer with 20-40 parts of bentonite, when the bentonite separate the organic fertilizer fully, screening excess bentonite; feeding coated organic fertilizer sticking with bentonite after screening in a dryer, through sampling and detecting during drying procedure, when water content gets to less than 8%, taking out all organic fertilizer, airing to normal temperature to get products. The invention has advantages of drought-resistant and water-preserving, good nutrient preserving capability, low cost, simple and convenient application method.

Owner:孙明

A kind of sludge secondary vapor compression drying method

InactiveCN102276131AReduce energy consumptionGuaranteed cleanlinessSludge treatment by de-watering/drying/thickeningHigh energyOil sludge

The invention relates to a secondary steam compressed drying method of sludge. Present drying methods have the disadvantages of high energy consumption and low efficiency. The method of the invention comprises the following steps: uniformly mixing dewatered sludge generated in the process of sewage treatment with oil according to a weight ratio of 1-20:1 to form oil sludge, drying the oil sludge with secondary steam, carrying out oil and dry sludge separation on the dried oil sludge; reusing separated oil as a raw material of mixed oil sludge, and treating separated dry sludge as a dry finished product of sludge; and separating saturated secondary steam from the secondary steam generated in the process, compressing to superheated steam superheated steam, and sending the superheated steam which is treated as a heat source to a heating chamber of a drier. The method of the invention fully utilizes the heat energy of the secondary steam, so the energy consumption of a drying system is greatly reduced; and no dust is entrained in the drying process, so the cleaning of heat exchange surfaces of a drying device is kept, and the drying efficiency is high.

Owner:HANGZHOU DIANZI UNIV +1

Multi-stage drying method of sludge utilizing compressed secondary steam

InactiveCN102260033ATake advantage ofReduce power lossSludge treatment by de-watering/drying/thickeningDewatered sludgeThermal energy

The invention relates to a multi-stage drying method of sludge utilizing compressed secondary steam. In the existing drying methods, energy consumption is high and efficiency is low. The method provided by the invention comprises the following steps: firstly uniformly mixing dewatered sludge with oil in a weight ratio of (1-20):1 to obtain oily sludge, and then drying the oily sludge by utilizing secondary steam, separating oil and dry sludge from the dried oily sludge, and recycling the separated oil used as a raw material for the mixed oily sludge. The oily sludge is dried by a multi-stage dryer composed of 2-5 dryers connected in series; an external heat source is utilized by one of the dryers; and secondary steam is utilized by the remaining dryers, specifically saturated secondary steam is separated from the secondary steam generated in the drying process and compressed into superheated steam, and the superheated steam is introduced into heating chambers of the dryers to be used as a heat source. In the multi-stage drying method provided by the invention, the heat energy of the secondary steam is sufficiently utilized, and the energy consumption of the drying system is greatly reduced; and no dust entraining exists in the drying process, so that the heat transfer surface of the drying device is maintained clean, and the drying efficiency is high.

Owner:HANGZHOU DIANZI UNIV +1

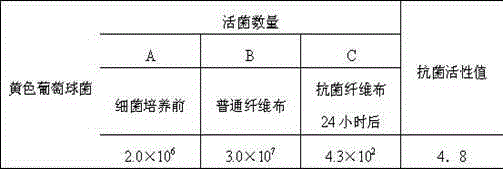

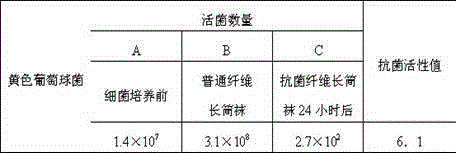

Antibacterial fiber

InactiveCN103334175ARaw material formula is reasonableWon't fall off easilyMonocomponent polyesters artificial filamentArtifical filament manufactureFiberMedical equipment

The invention discloses an antibacterial fiber. The fiber comprises following raw materials, by weight: 1 to 15% of silver oxide powder or silver nitrate powder; and one or more selected from polybutylene terephthalate, polyamide, polypropylene and polyethylene; with the balance being polyethylene glycol terephthalate. The raw materials are mixed uniformly and then the fiber is produced by melting spinning. The formula of the antibacterial fiber is reasonable; antibacterial material is embedded into the matrix material of the fiber, so that the active compounds will not fall off easily; the stability of the fiber is excellent; and the fiber is capable of preventing and killing bacterial in a long term. Antibacterial and mould-proof effects of the fiber are excellent; the fiber is capable of preventing bacterial, and also controlling and preventing fungus (mould) effectively. Blending ratio is low, and the antibacterial performance is excellent; and the fiber is capable of keeping bacterial away; so that the blending ratio is reduced, cost is saved, and antibacterial performance is enhanced. The fiber is safe to use, and can be widely applied in the field of medical equipment, medical clothes, military, household textile product, clothes, and outdoor activities.

Owner:LUMICA SPECIAL FIBER LIANYUNGANG

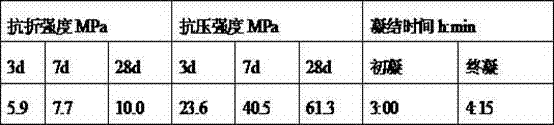

Titanium casting investment material for oral cavity and application method thereof

InactiveCN101849888AReduced responseReduce the mixing ratioImpression capsDentistry preparationsAluminiumSuperplasticizer

The invention provides a titanium casting investment material for an oral cavity and an application method thereof. A fame-proofing agent thereof adopts ZrO2 powder and Al2O3 powder; a heating expanding agent adopts metal zirconium powder or titanium powder; a bonding agent adopts pure calcium aluminate cement; a curing time modifier adopts LiCO3. The mixing liquid special for water solution with1%-5% of high performance water reducer is added to the above materials by the proportion of 100:15-25. The invention takes heat-resisting zirconia, alumina and the like as the flame-proofing agent, heat-resisting pure calcium aluminate cement as the bonding agent, metal zirconium powder or titanium powder as the heating expanding agent, lithium carbonate as the curing time modifier and water solution with high performance water reducer as the special mixing liquid of the titanium casting investment material for the first time so as to reduce the water mixing ratio and improve the compressionstrength and the heating expansibility, thereby reaching the purpose that the enough expansion volume can be generated to make up the pure titanium casting contraction under the lower temperature.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV

Cement-based wave-absorbing material prepared by compounding ferroferric oxide and fly-ash hollow microspheres and preparation method thereof

The invention belongs to the field of building materials and particularly relates to a cement-based wave-absorbing material prepared by compounding ferroferric oxide and fly-ash hollow microspheres and a preparation method thereof. The cement-based wave-absorbing material prepared by compounding ferroferric oxide and fly-ash hollow microspheres is characterized by consisting of an absorbing layer and a matching layer, wherein the matching layer is cast on the absorbing layer, the thickness of the absorbing layer is 20-30 mm, and the thickness of the matching layer is 10-15 mm. 370 kg / <3> of cement, 13 kg / <3> of expanded perlite, 1110 kg / <3> of quartz sand, 148 kg / <3> of water and 11.1-25.9 kg / <3> of wave-absorbing agent are mixed, the surface of a sample is struck off to form the absorbing layer; according to the ratio of the expanded perlite to the cement to water of 91 kg / <3> to 944 kg / <3> to 378 kg / <3>, mixing is performed and the mixture is cast on the absorbing layer during initial setting of the absorbing layer to obtain the matching layer. The volume weight of the cement-based wave-absorbing material can be remarkably reduced, and the wave-absorbing property of the cement-based material is remarkably improved, so that the cement-based material has the advantages of having wide electromagnetic wave absorbing frequency band.

Owner:WUHAN UNIV OF TECH

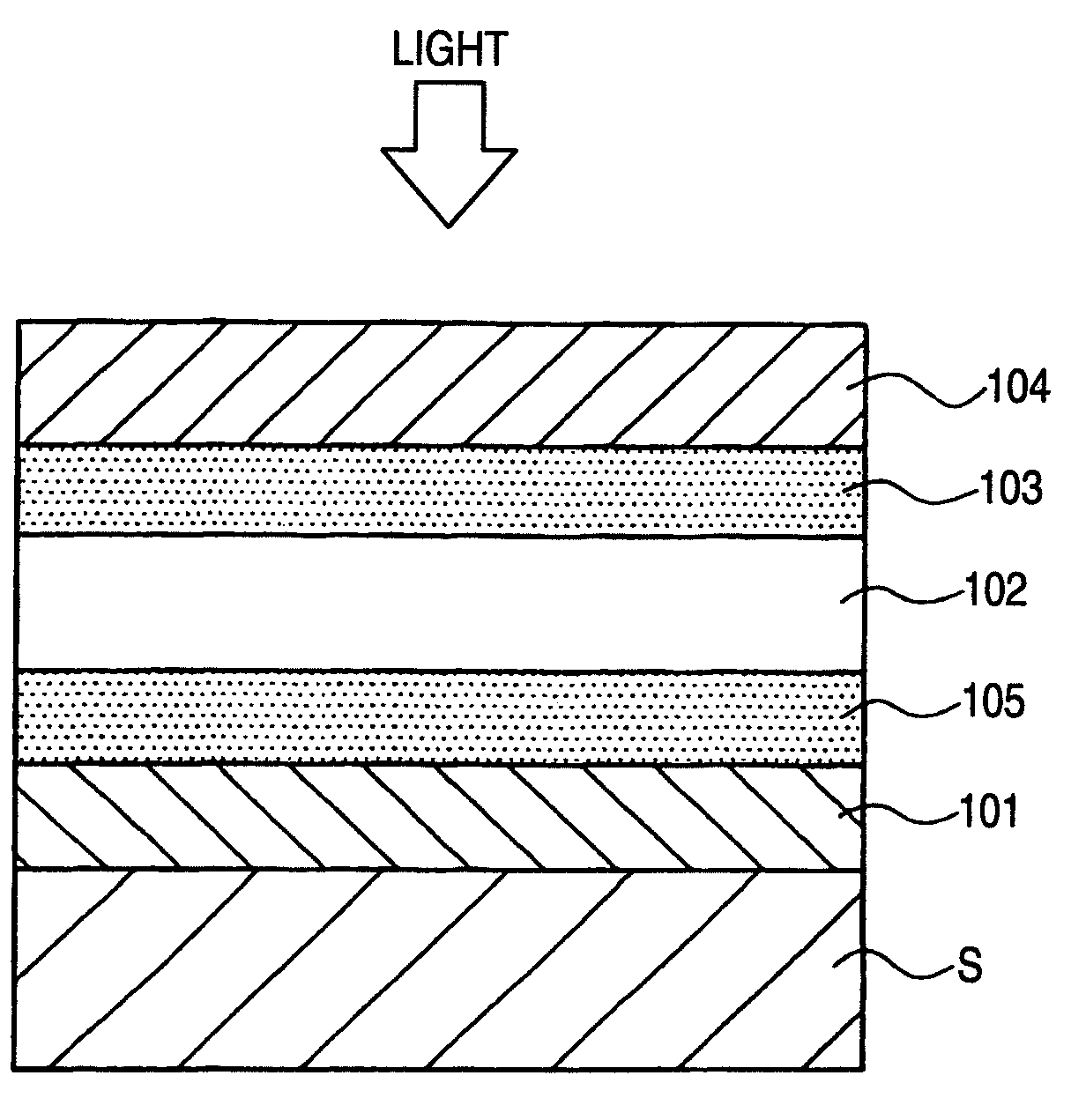

Photoelectric conversion element including a mixed layer of a P-type organic semiconductor and a fullerene, method for producing the same, and solid-state imaging device using the same

ActiveUS7863605B2Suppress generationImprove photoelectric conversion efficiencyTelevision system detailsFinal product manufacturePhotoelectric conversionOrganic semiconductor

A photoelectric conversion element is provided and includes a photoelectric conversion portion. The photoelectric conversion portion includes: a pair of electrodes; and a photoelectric conversion layer between the pair of electrodes, and at least part of the photoelectric conversion layer includes a mixed layer of a p-type organic semiconductor and a fullerene, and a mixing ratio of the fullerene to the p-type organic semiconductor in terms of thickness ratio is less than 1:1.

Owner:FUJIFILM CORP

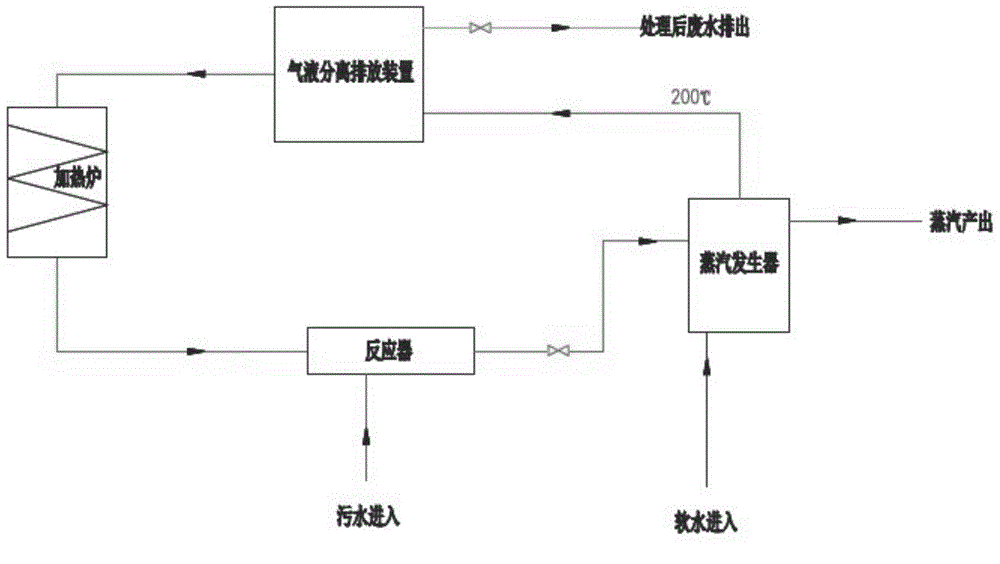

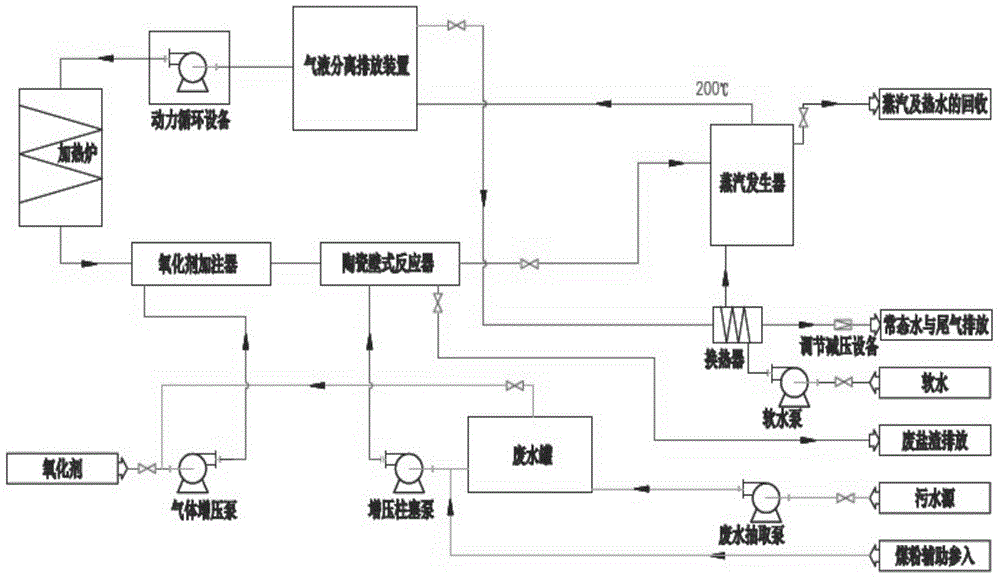

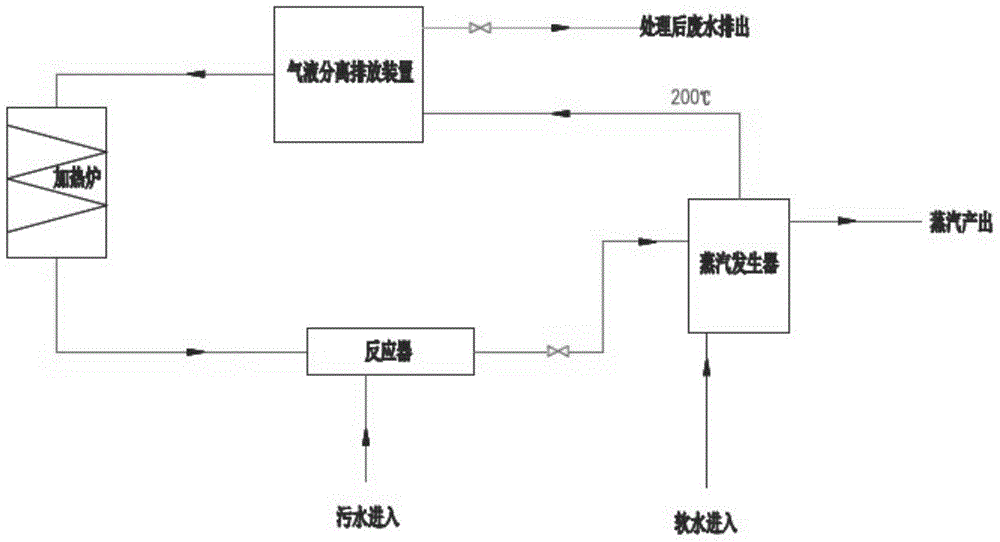

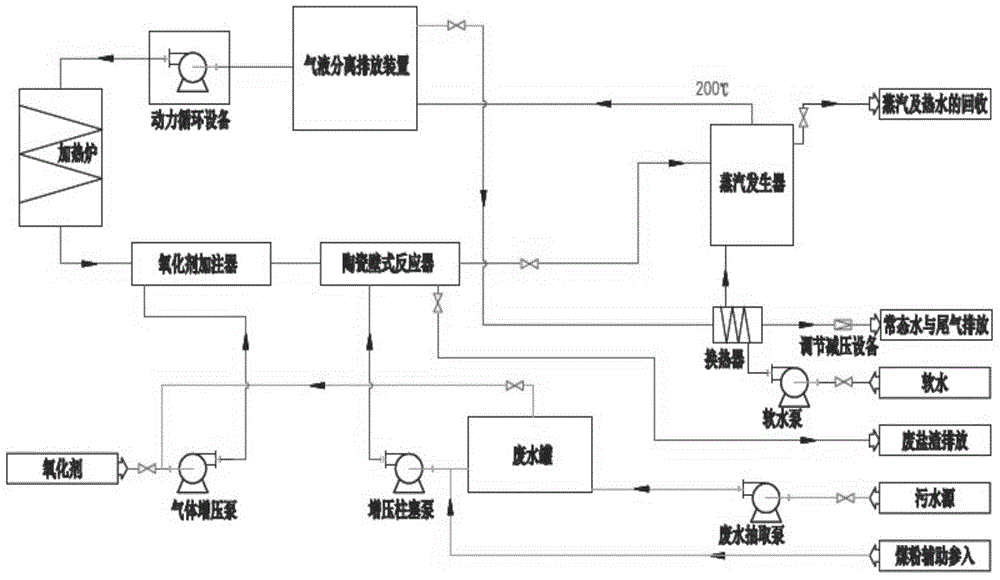

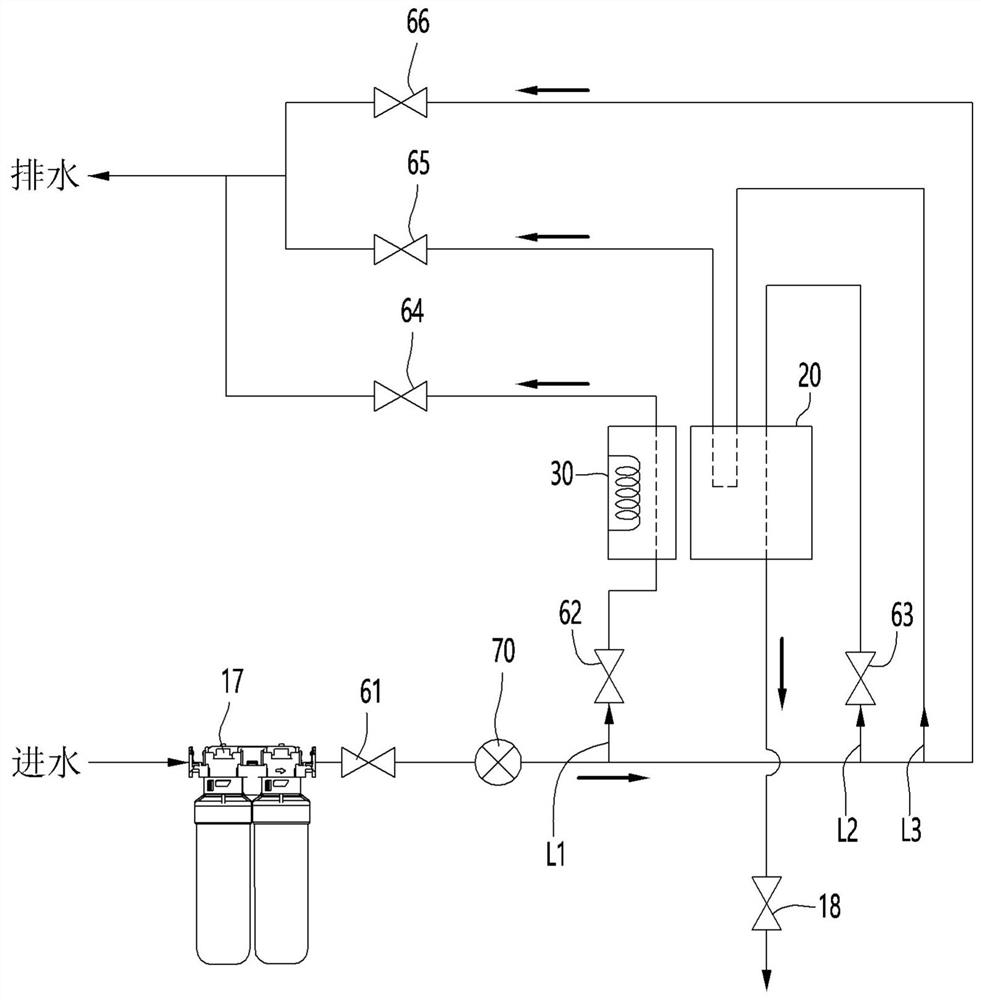

Process for waste oxidation treatment and steam co-production by using supercritical circulating water

ActiveCN103553202AReduce excess spaceShorten the timeSteam generation using hot heat carriersWater/sewage treatment by oxidationInorganic saltsChemical oxygen demand

The invention provides a process for waste oxidation treatment and steam co-production by using supercritical circulating water. A treatment system is a circulating treatment system. The process comprises the steps of filling circulating water into a supercritical circulating water oxidation treatment system, heating the circulating water in a heating device, driving the circulating water to circularly operate in the system, and controlling the temperature to be raised to 395-450 DEG C and the pressure to be higher than 22.1Mpa; inputting sewage and an oxidizing agent to a reactor, and enabling the sewage and the oxidizing agent to react in a supercritical state; enabling the water after reacting to enter a steam generator for heat recovery, and outputting steam; carrying out gas-liquid separation on the water subjected to heat exchange through the steam generator, and discharging inorganic salt gas and a part of water; inputting the other part of water after gas-liquid separation as the circulating water to the heating device. In the process, the sewage is up to the supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

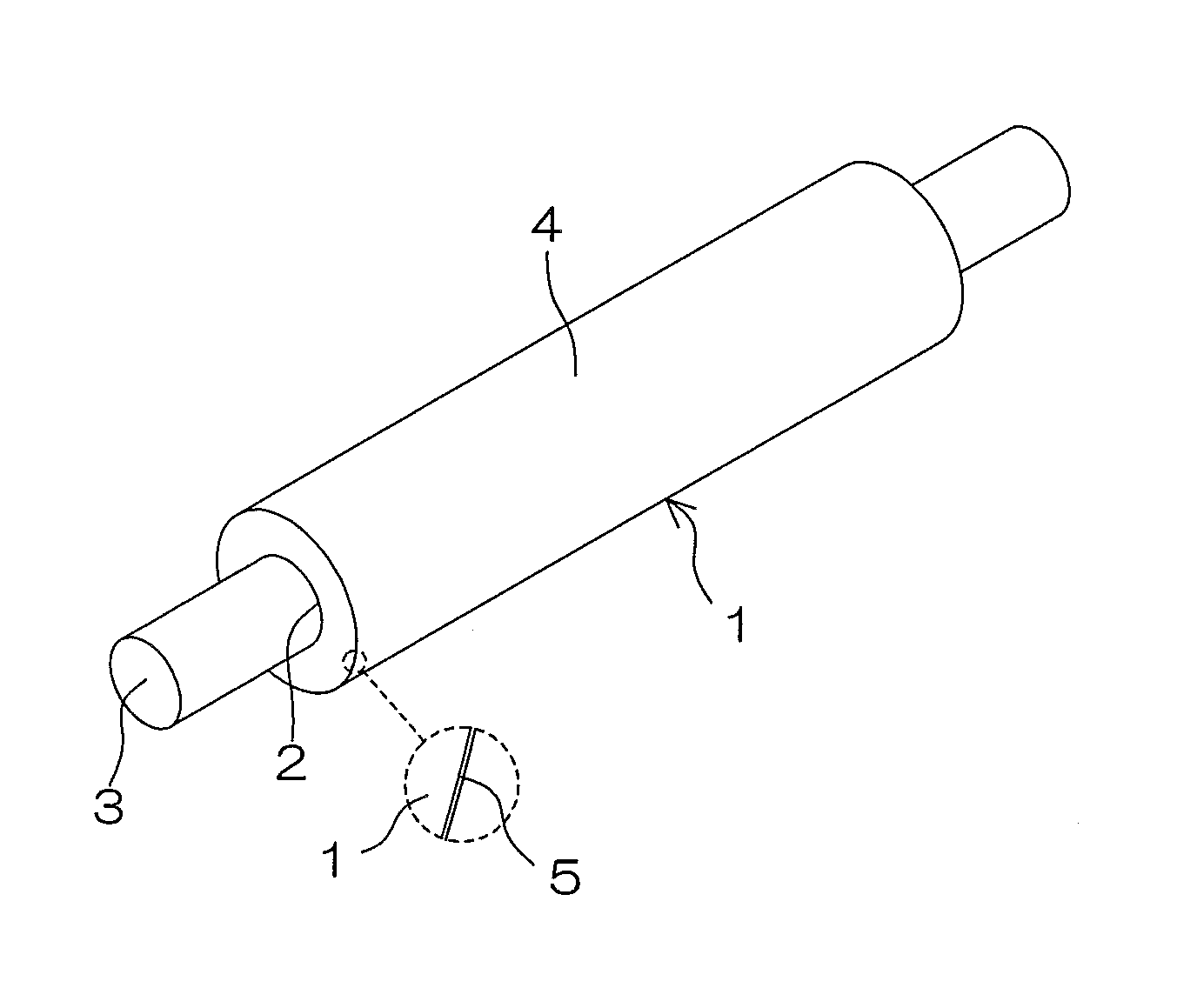

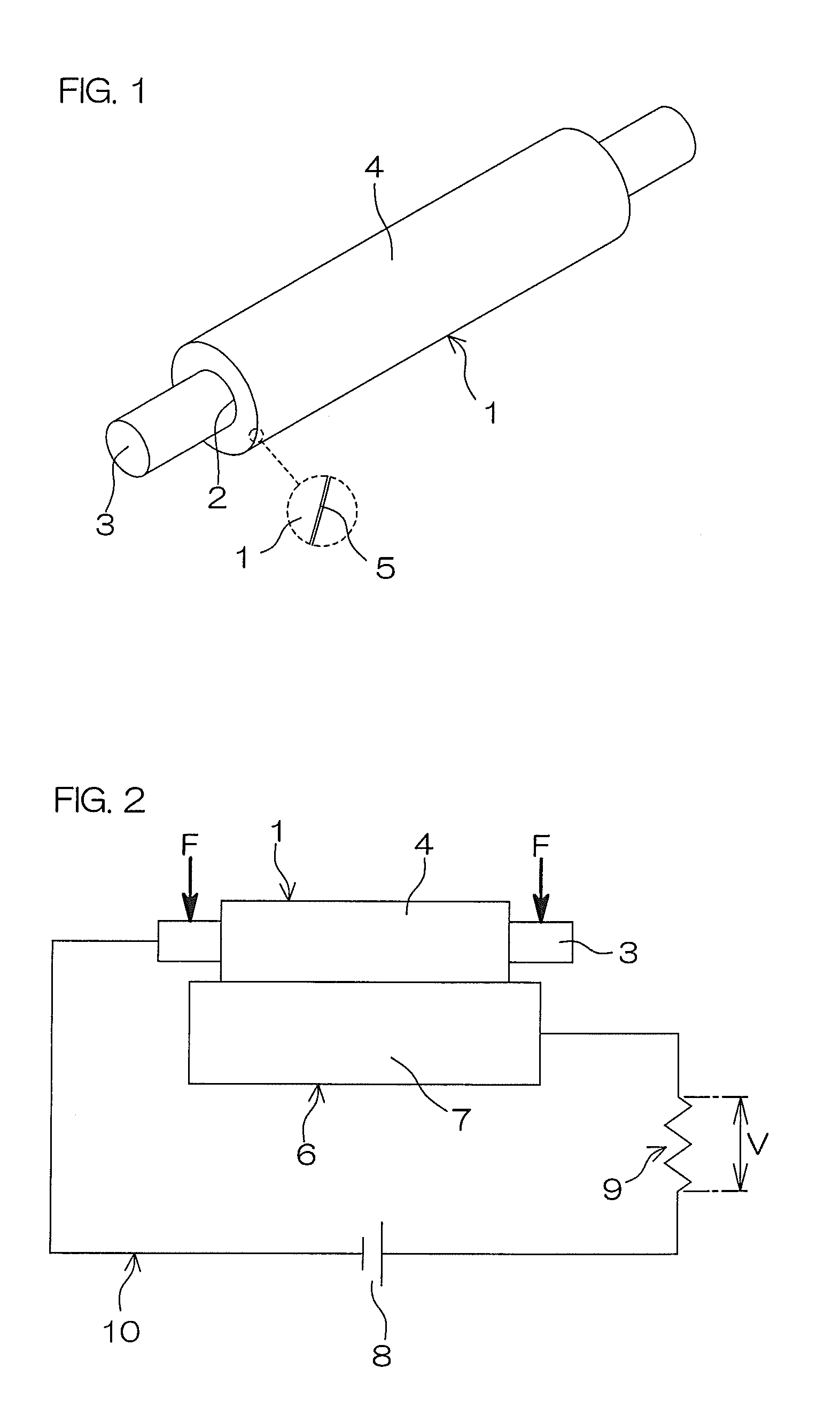

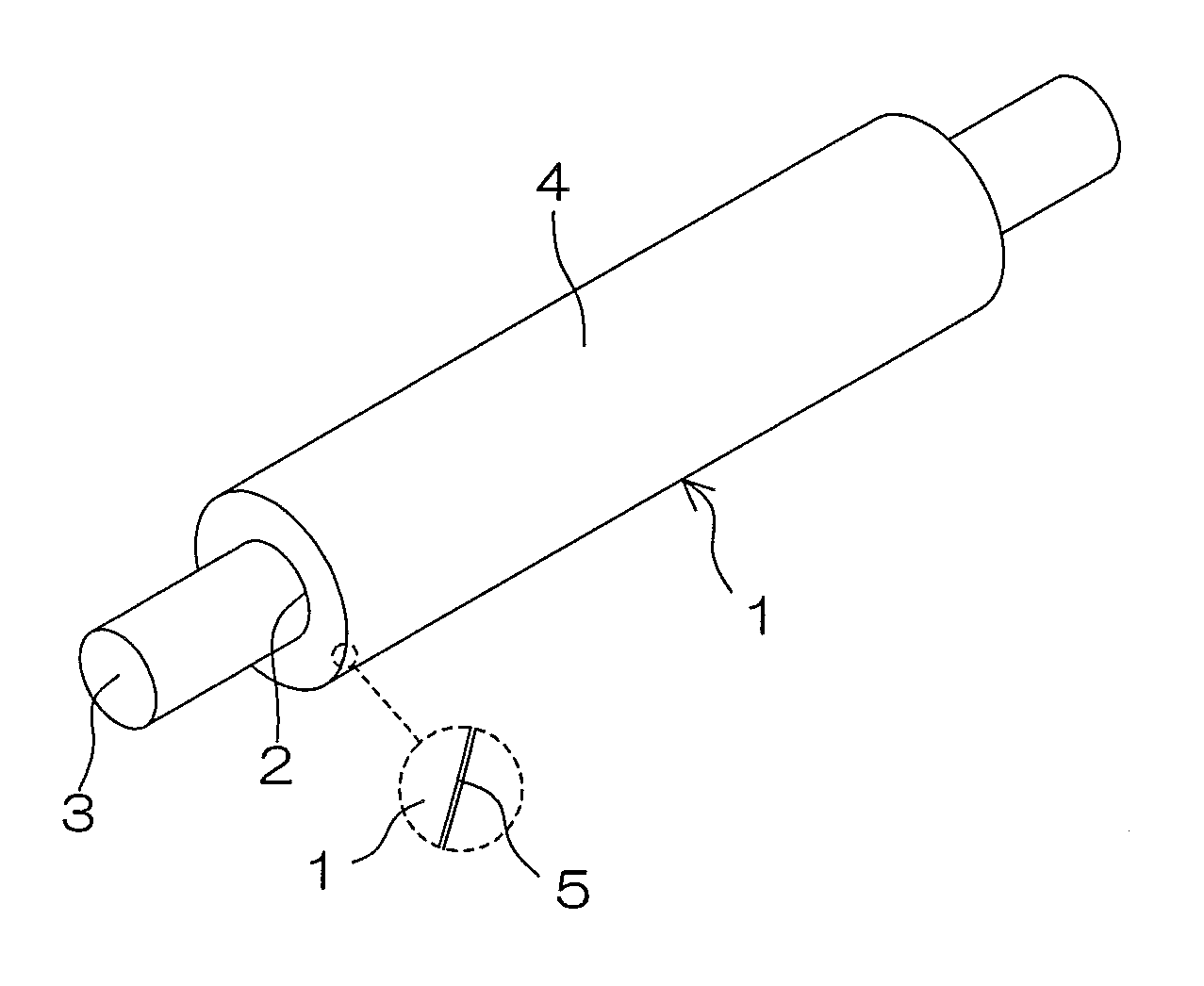

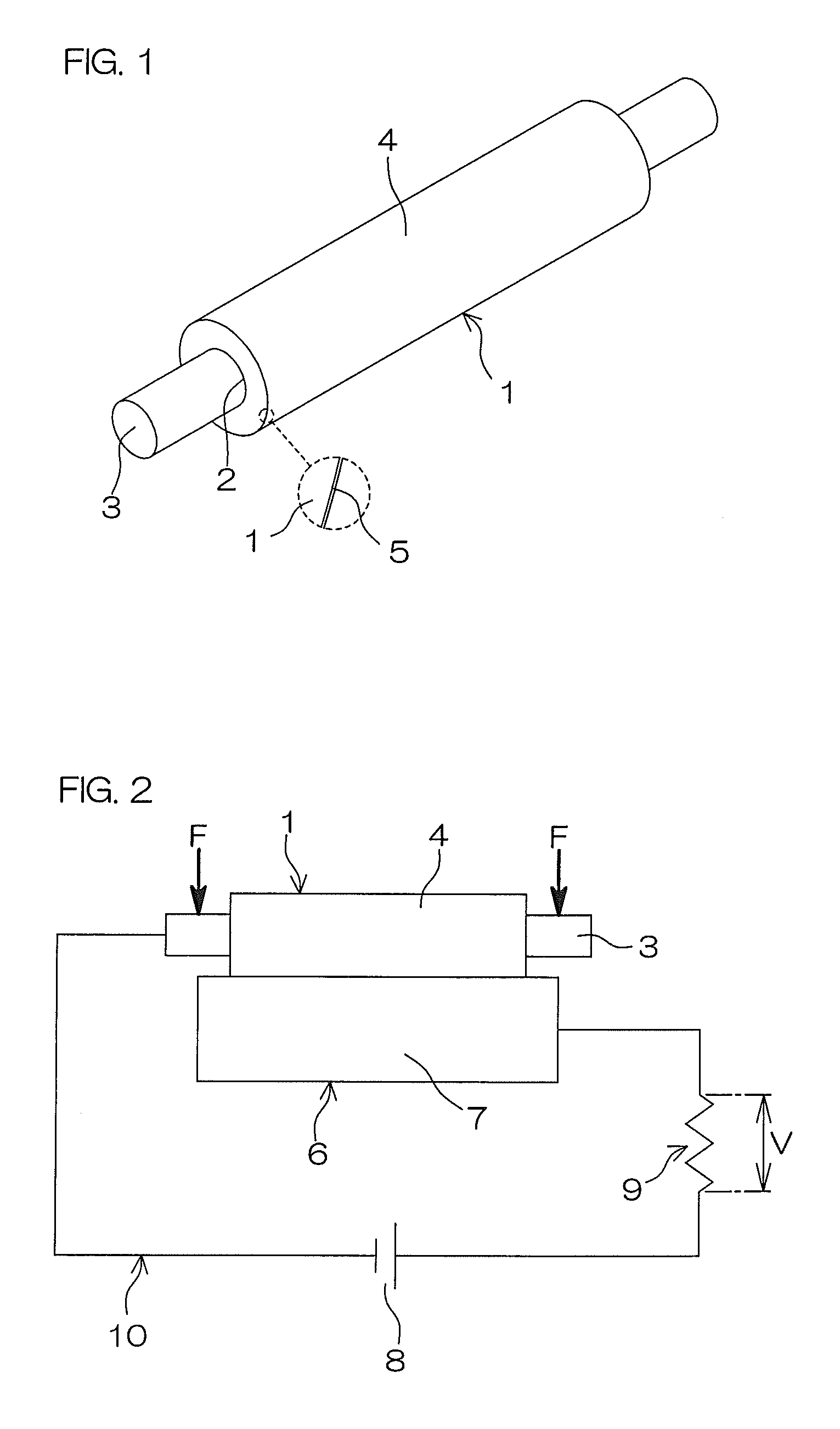

Semiconductive roller

ActiveUS20150355571A1Electrically conductive be reduceReduce image qualitySynthetic resin layered productsConductive materialButadiene-styrene rubberSulfonyl

A semiconductive roller (1) according to the present invention has a nonporous single-layer structure formed from a rubber composition which includes: a rubber component including a styrene butadiene rubber and an epichlorohydrin rubber; and a salt of an anion having a fluoro group and a sulfonyl group in its molecule; the salt being present in the rubber composition in a proportion of 0.05 to 5 parts by mass based on 100 parts by mass of the overall rubber component.

Owner:SUMITOMO RUBBER IND LTD

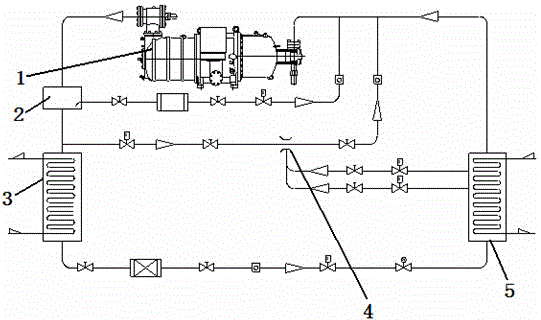

System for wastewater oxidation treatment by using supercritical circulating water

InactiveCN103553254AReduce excess spaceShorten the timeMultistage water/sewage treatmentChemical oxygen demandSewage

The invention provides a system for wastewater oxidation treatment by using supercritical circulating water. The system comprises a heating device, a reactor, a steam generator and a gas-liquid separation device which are sequentially connected end to end through pipelines to form a circulating treatment system, wherein the heating device is used for heating circulating water. In the system, the heating device is used for heating the circulating water to promote the whole treatment process to operate, sewage is up to a supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

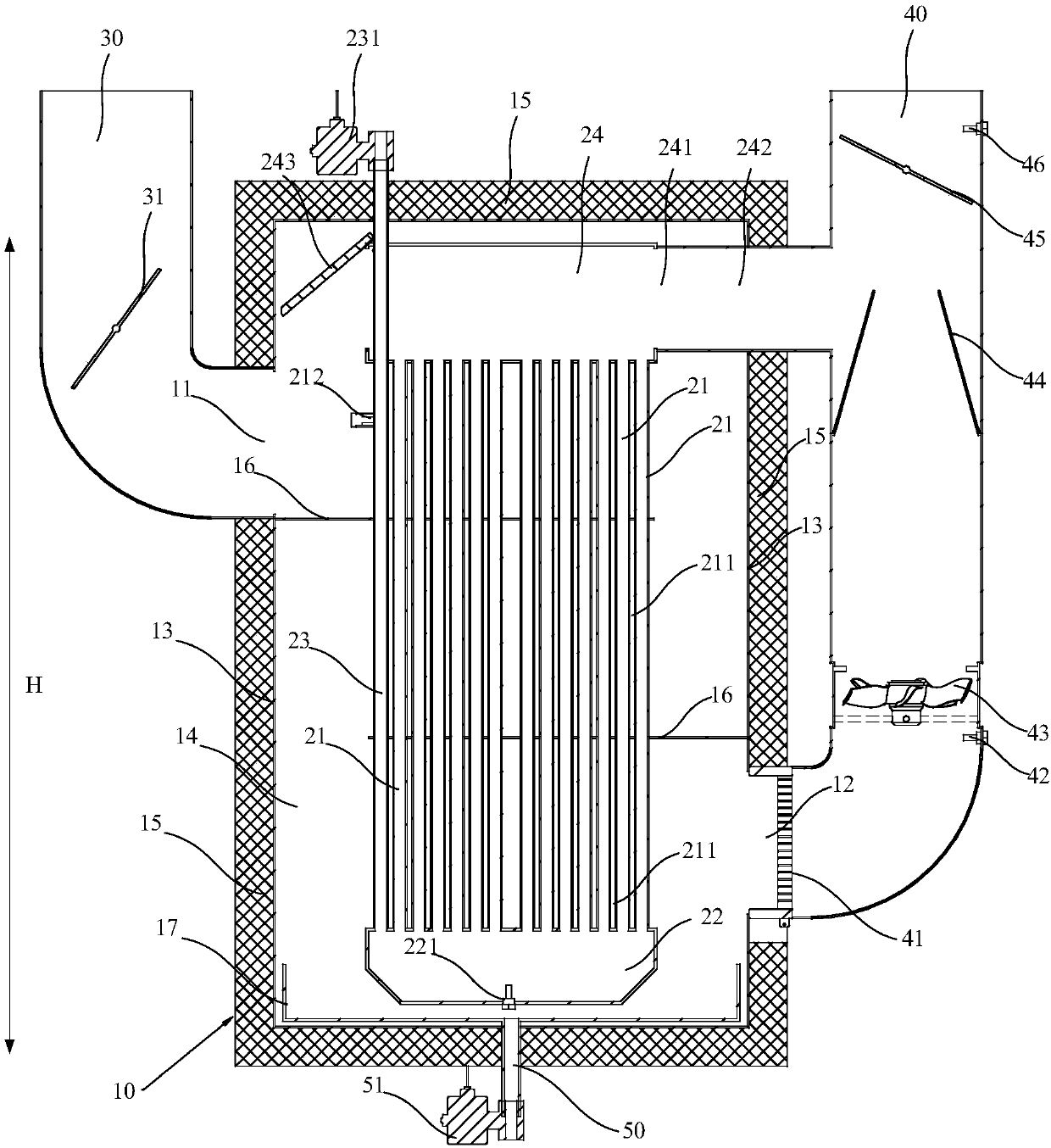

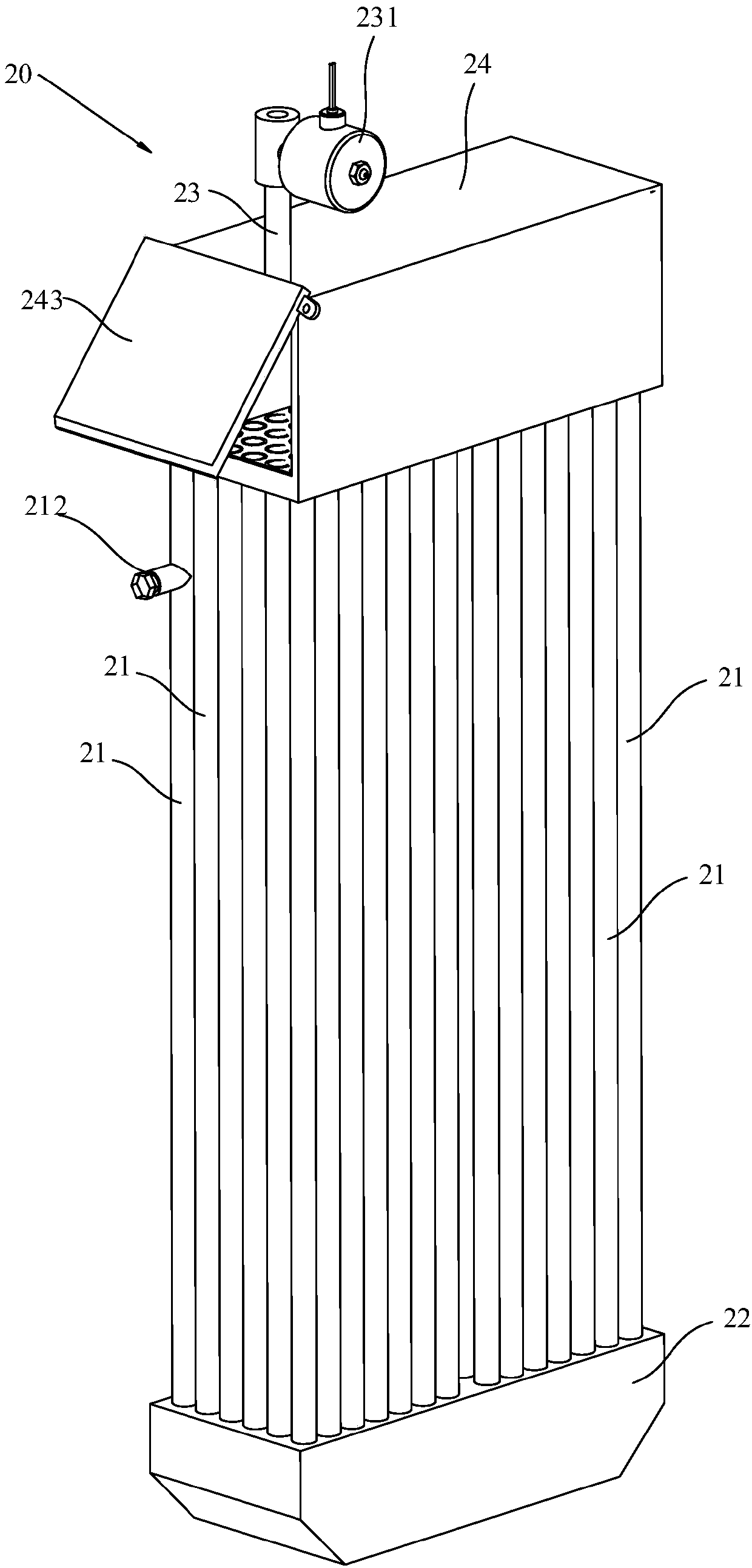

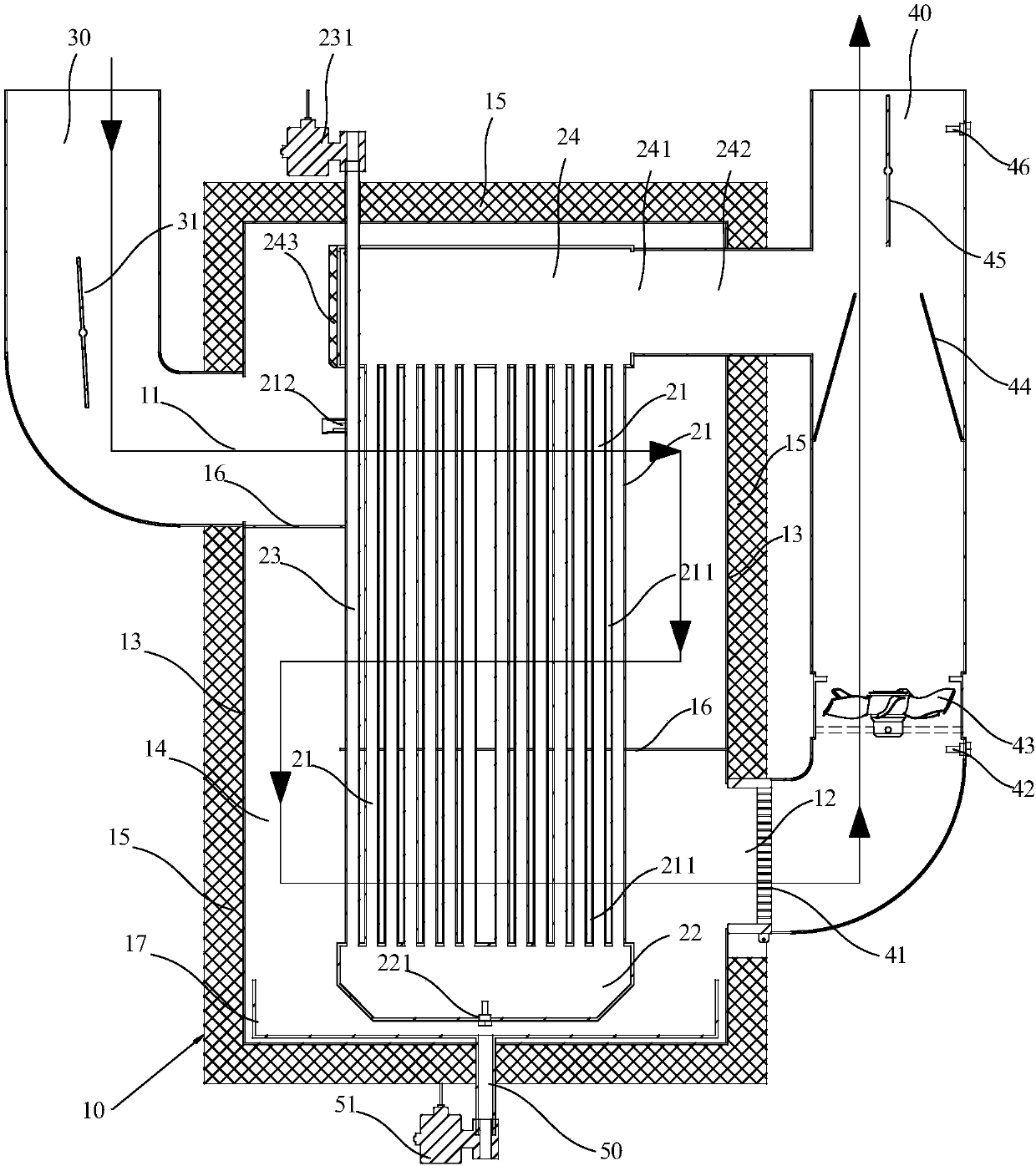

Liquid nitrogen cooling dehumidification device

PendingCN107940574ACompact layoutSimple structureMechanical apparatusSpace heating and ventilation safety systemsEngineeringNitrogen gas

The invention provides a liquid nitrogen cooling dehumidification device. The liquid nitrogen cooling dehumidification device comprises a heat exchanger, a liquid-collecting chamber and a liquid nitrogen liquid inlet pipe, wherein the heat exchanger includes a plurality of liquid nitrogen heat exchanging pipes, and a gap is formed between every two adjacent liquid nitrogen heat exchanging pipes; the liquid-collecting chamber communicates with the multiple liquid nitrogen heat exchanging pipes and is arranged at the bottoms of the multiple liquid nitrogen heat exchanging pipes; and the liquid nitrogen liquid inlet pipe communicates with the liquid-collecting chamber. The liquid nitrogen cooling dehumidification device is compact in layout and simple in structure and has no complex parts; the heat exchanging temperature of the liquid nitrogen cooling dehumidification device is low, air can be made to reach a very low dew point, and the dehumidification effect is good; nitrogen produced after liquid nitrogen is evaporated further dilutes water vapor in the dry air, and the mixing ratio of the water vapor is further reduced; and the temperature of the dry air sent back to a room can becontrolled, and requirements of different conditions are met accordingly.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

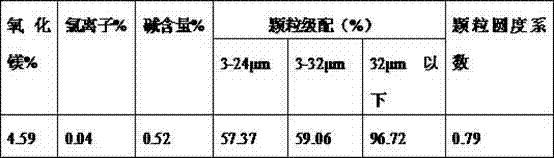

Special composite cementitious material for high-grade concrete of bridge expansion joints and thin-shell structures

The invention provides a special composite cementitious material for the high-grade concrete of bridge expansion joints and thin-shell structures. The invention aims to solve the problems that as the mixing amount of the admixture material of the common Portland cement is little and the corrosion resistance is poor, and the concrete of highways and railway bridge expansion joints is damaged. The key points of the material are as follows: the cementitious material mainly comprises ground general Portland cement clinker, fly ash, slag powder, volcanic ash, silicon ash and gypsum, which are homogenized and mixed to obtain the cementitious material, wherein the total weight of fly ash, slag powder, volcanic ash and silicon ash accounts for 50-60% of the total weight of the cementitious material. The invention has the following positive effects that: the mixing amount of the admixture material is increased, and the components of the cementitious material are changed while the performances are obviously increased.

Owner:DANDONG HAIGONG CEMENT

Anticoagulant for prolonging external hemolymph cell life and its application method

InactiveCN1411818AIncrease contentReduce contentMammal material medical ingredientsDead animal preservationMedicineHemolymph

Each 100 ml of blood anticoagulant contains trisodium citrate 3.31-3.32g, citric acid 0.01-0.05g, glucose 2.45-3.37g and the rest is water. The tests show that after the external blood is undergone the process of anticoagulation treatment it can prolong the stroage life of lymphocyte to 48-72 hr. from original 4-6 hr. Said invention also provides its application method.

Owner:SHANGHAI BLOOD CENT

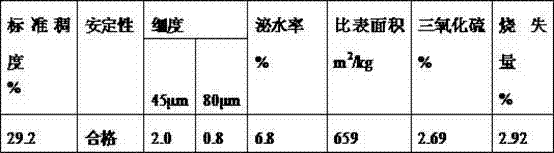

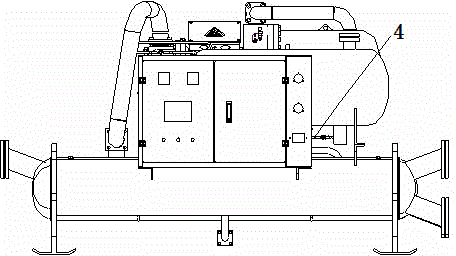

Water source heat pump unit system for low temperature water source

InactiveCN104676978AReduce freezingPrevent freezingHeat pumpsEvaporators/condensersWater source heat pumpWater source

The invention relates to an air conditioning unit device, in particular to a water source heat pump unit system for a low temperature water source. The system comprises a compressor, an oil separator, a condenser, a oil return injecting device and an evaporator; the evaporator is in a falling film type structure, a liquid distributor is arranged in the upper portion of the evaporator, the top of the evaporator is provided with a liquid incoming pipe, the port of the liquid incoming pipe contacts with the surface of the liquid distributor, the top of the evaporator is provided with an exhaust pipe, the bottom of the evaporator is provided with a discharge pipe, and heat exchange pipe beams are arranged below the liquid distributor. According to the system, water is distributed to the surface of the heat exchange pipes evenly through the liquid distributor, the heat exchange effect is fine, the refrigerant can be evaporated fully, the refrigerant storage amount is reduced, and the heat exchange pipes are prevented from freezing; meanwhile, since the level of the evaporator is low, the mixing ratio of lubrication oil is decreased, the lubrication oil can be injected to the compressor through the oil return injecting device, and the fine oil returning effect is achieved.

Owner:SHANDONG YUGIA FUERDA AIR CONDITIONER EQUIP

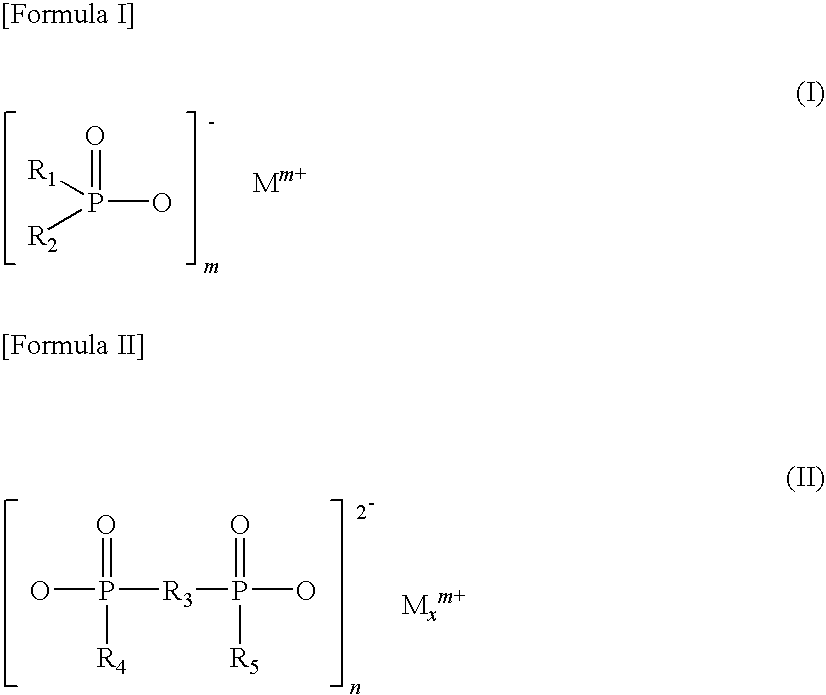

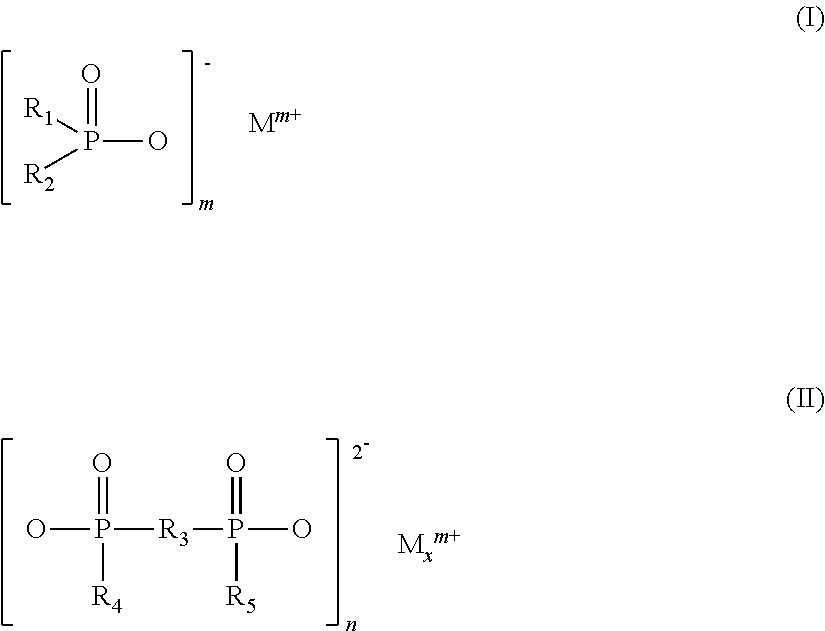

Flame-retardant glass fiber-reinforced polyamide resin composition

InactiveUS8193263B2Reduce the mixing ratioImprove suppression propertiesGroup 5/15 element organic compoundsGlass fiberHalogen

A flame-retardant glass fiber-reinforced polyamide resin composition, containing:100 parts by mass of a flame-retardant resin composition consisting of(A) 60 to 90 percent by mass of a polyamide resin, and(B) 40 to 10 percent by mass of a flame retardant containing no halogen atom,(A)+(B) being 100 percent by mass; and60 to 210 parts by mass of a flattened glass fiber (C) having a flat section of 1.5-10 in a ratio of major axis / minor axis,wherein the polyamide resin (A) contains a crystalline polyamide resin (a1) and an amorphous polyamide resin (a2),the flame retardant containing no halogen atom (B) contains a phosphinate (b1) and / or a diphosphinate (b2), anda blending ratio of the amorphous polyamide resin (a2) in the polyamide resin (A) is 0.1≦(a2) / (A)≦0.5.

Owner:UNITIKA LTD

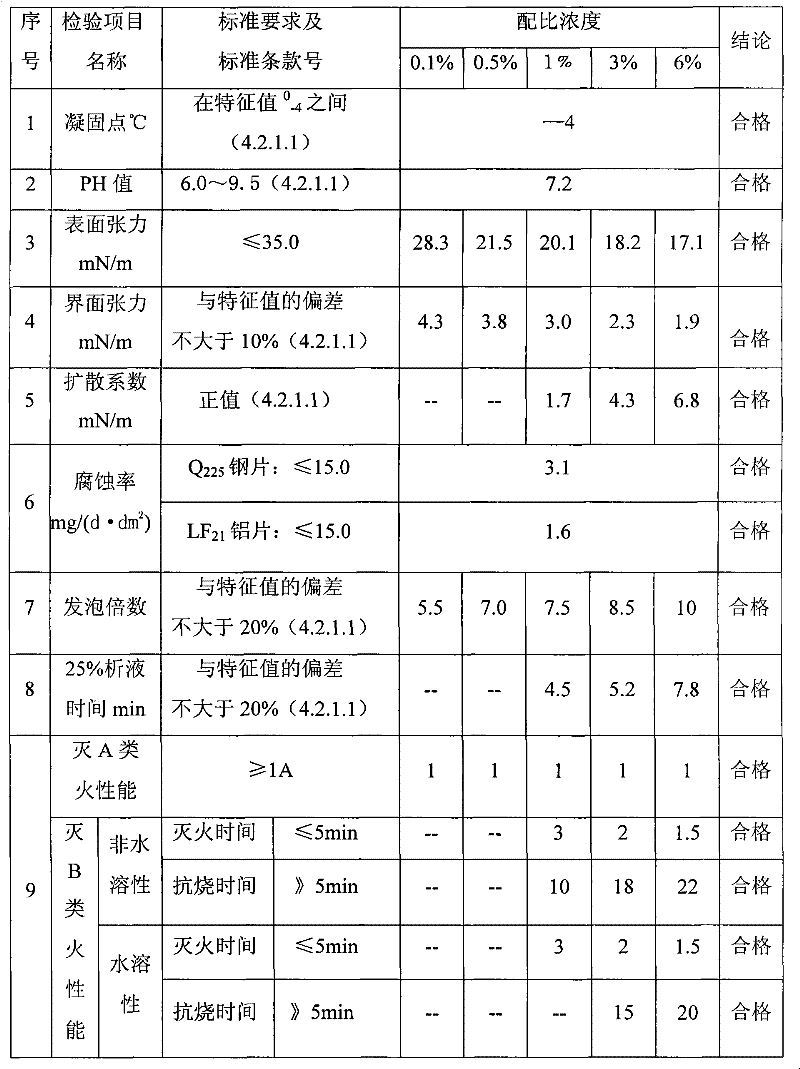

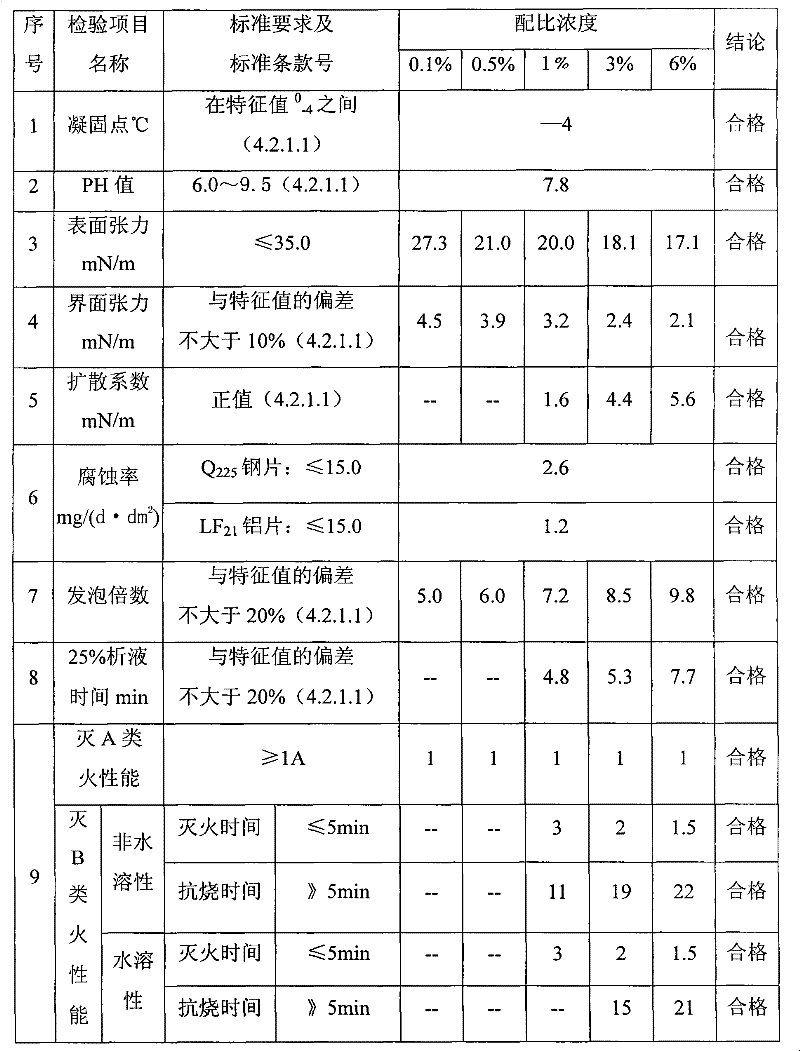

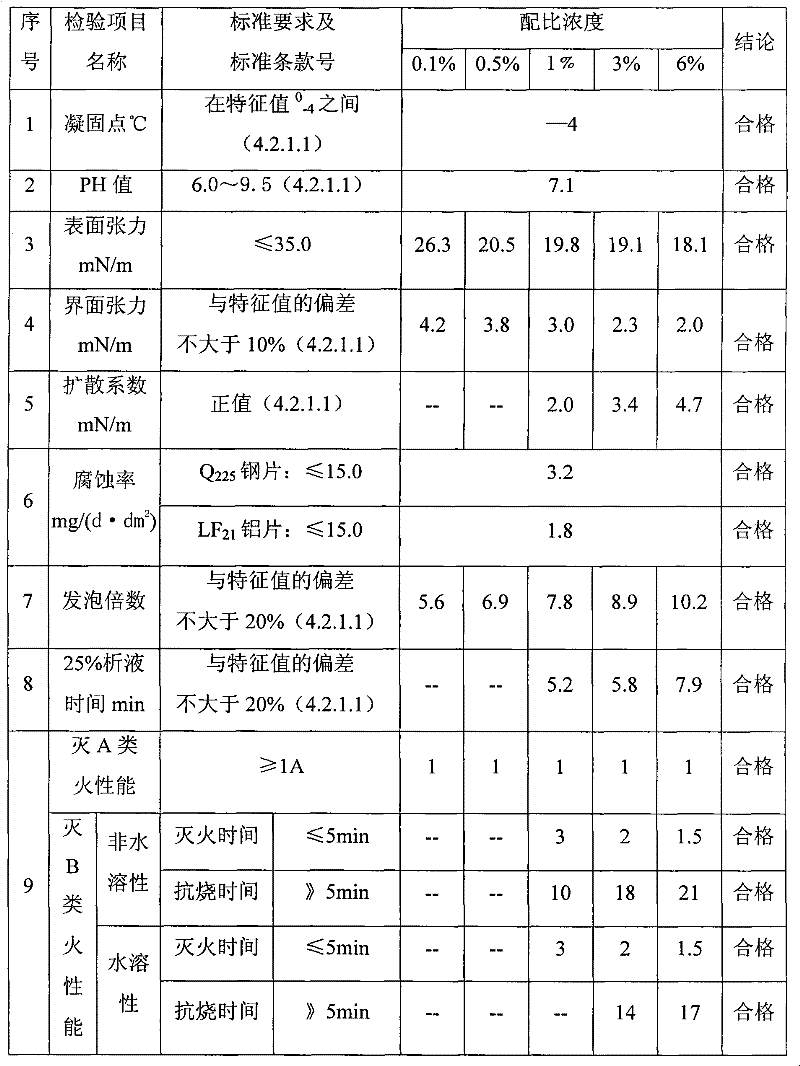

Additive for firefighting water

The invention discloses an additive for firefighting water, which is formed by the following raw materials by weight percent in a mixing way: 5-10 percent of fluorocarbon surfactant, 40-50 percent of foaming agent, 3-10 percent of penetrating agent, 5-10 percent of fire retardant, 3-5 percent of burn-resistant agent, 5-10 percent of antifreeze agent, 3-5 percent of booster solvent, 0.3-2 percent of pH regulating agent and the remaining percent of purified water. The highly-enriched water additive can be mixed with water by any proportion within 0.1-6 percent, and is suitable for the existing firefighting trucks in the market, novel firefighting trucks and water-based firefighting systems. When in extinguishing Class A fires, only 0.1-0.5 percent of additive is added and good permeability and abundant foam can be produced. Moreover, the additive is suitable for foaming systems and spray equipment. For non-water-soluble Class B fires, the required concentration of the used additive is only one percent and good effect can be reached. For water-soluble Class B fires, the concentration of the used additive is 3-6 percent. The used additive causes no environmental pollution and thereby the additive is environment-friendly.

Owner:EASTEX XIAMEN FIRETEC

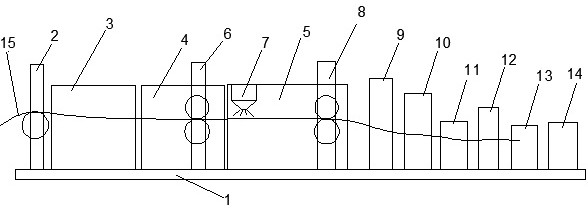

EP composite ultra-short curl-free fiber post-treatment production method and device

PendingCN112553703ACortical melting point depressionReduce the mixing ratioArtificial thread manufacturing machinesArtificial filament washing/dryingYarnNonwoven fabric

The invention discloses an EP composite ultra-short curl-free fiber post-treatment production method and device. The production method comprises the steps of pre-spinning protofilament bundling, dipping bath, primary tow stretching, secondary tow stretching, tow curling, tow laying, tow loosening and shaping, tow cutting, packaging and the like. The corresponding post-treatment device comprises abundling frame, a dipping bath tank, a water bath tank, a steam drafting box, an oiling machine, a yarn stacking machine, a curling machine, a drying setting machine, a cutting machine and a packagingmachine which are sequentially arranged on a workbench from left to right. According to the EP composite ultra-short curl-free fiber post-treatment production method and device, through specific post-treatment methods such as dipping bath, drafting, curling, shaping and cutting, the melting point of the skin layer of the prepared EP composite ultra-short curl-free fiber can be reduced, the bonding strength of non-woven fabric is improved, the doping proportion of the fiber is reduced, and the downstream production cost is reduced.

Owner:扬州石化有限责任公司

Semiconductive roller

ActiveUS9443637B2Reduce resistanceReduce the mixing ratioConductive materialOrganic conductorsPolymer scienceEpichlorohydrin

A semiconductive roller (1) according to the present invention has a nonporous single-layer structure formed from a rubber composition which includes: a rubber component including a styrene butadiene rubber and an epichlorohydrin rubber; and a salt of an anion having a fluoro group and a sulfonyl group in its molecule; the salt being present in the rubber composition in a proportion of 0.05 to 5 parts by mass based on 100 parts by mass of the overall rubber component.

Owner:SUMITOMO RUBBER IND LTD

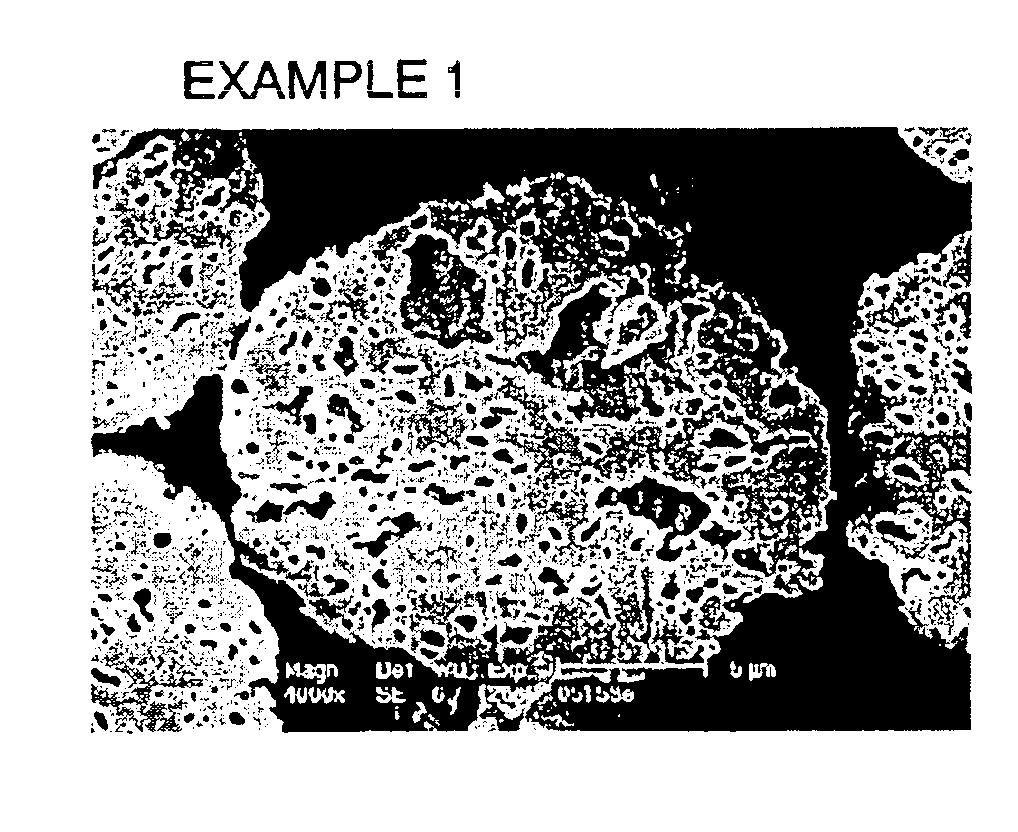

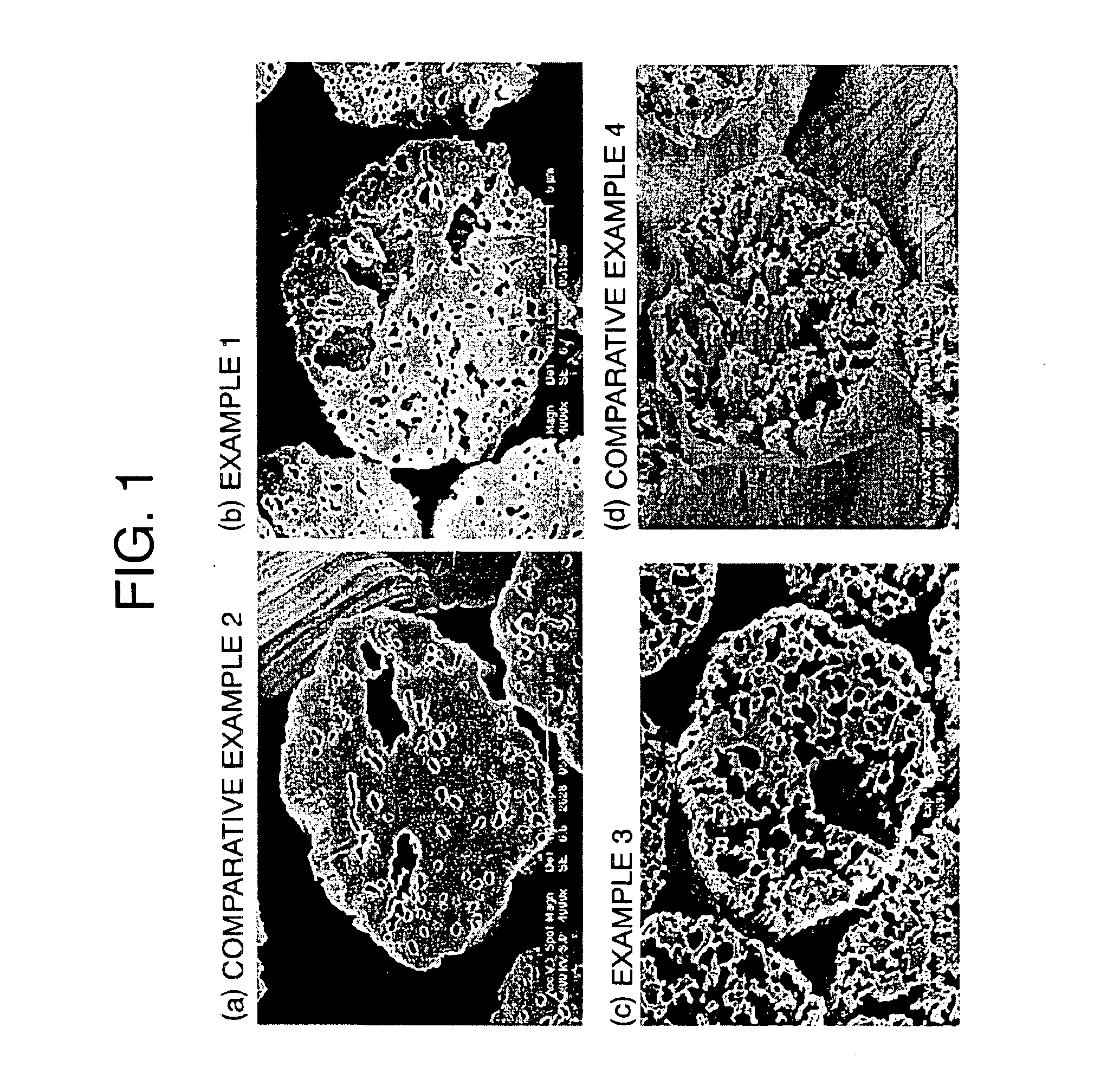

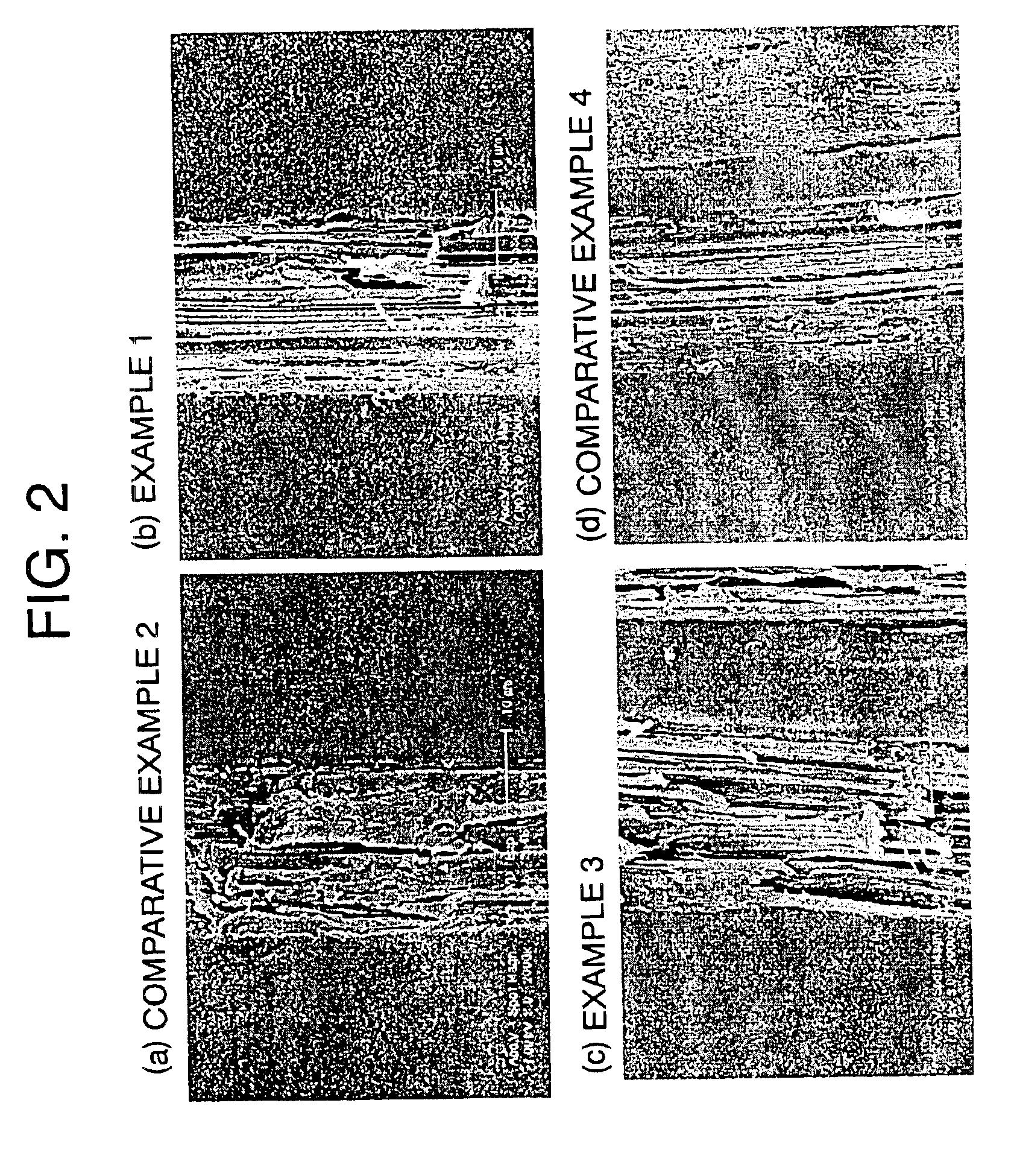

Acrylic based composite fiber and method for production thereof, and fiber composite using the same

InactiveUS6866931B2Improve deodorization functionEfficient compositeCellulosic plastic layered productsMonocomponent synthetic polymer artificial filamentYarnCellulose acetate

An object of this invention is to provide an acrylonitrile based composite fiber having a new feeling different from that of an ordinary cellulose acetate fiber, cellulose fiber and acrylic fiber, excellent spinability, fiber properties and process ability of yarn spinning, and excellent functions, in particular, a deodorizing function and a moisture absorbing and retaining property.The composite fiber is comprised of 10 to 40% by weight of cellulose acetate and / or cellulose and 60 to 90% by weight of an acrylonitrile based polymer, and has a structure with the cellulose acetate and / or cellulose forming an island component in a cross section perpendicular to a fiber axis and the acrylonitrile based polymer forming a sea component. Preferably, the cellulose acetate and / or cellulose as the island component communicate with another island component in the fiber axis direction, a vacant hole is provided inside the fiber, or a ratio of the longest diameter and the shortest diameter of the fiber cross section is 2 or less, and 5 or more recess parts of 0.3 μm or more and 3 μm or less width and 0.3 μm or more and 3 μm or less depth are provided in a fiber cross section outer circumferential part. Further preferably, by applying a heat treatment under alkali in a production stage, the moisture absorbing and retaining property can be improved.

Owner:MITSUBISHI CHEM CORP

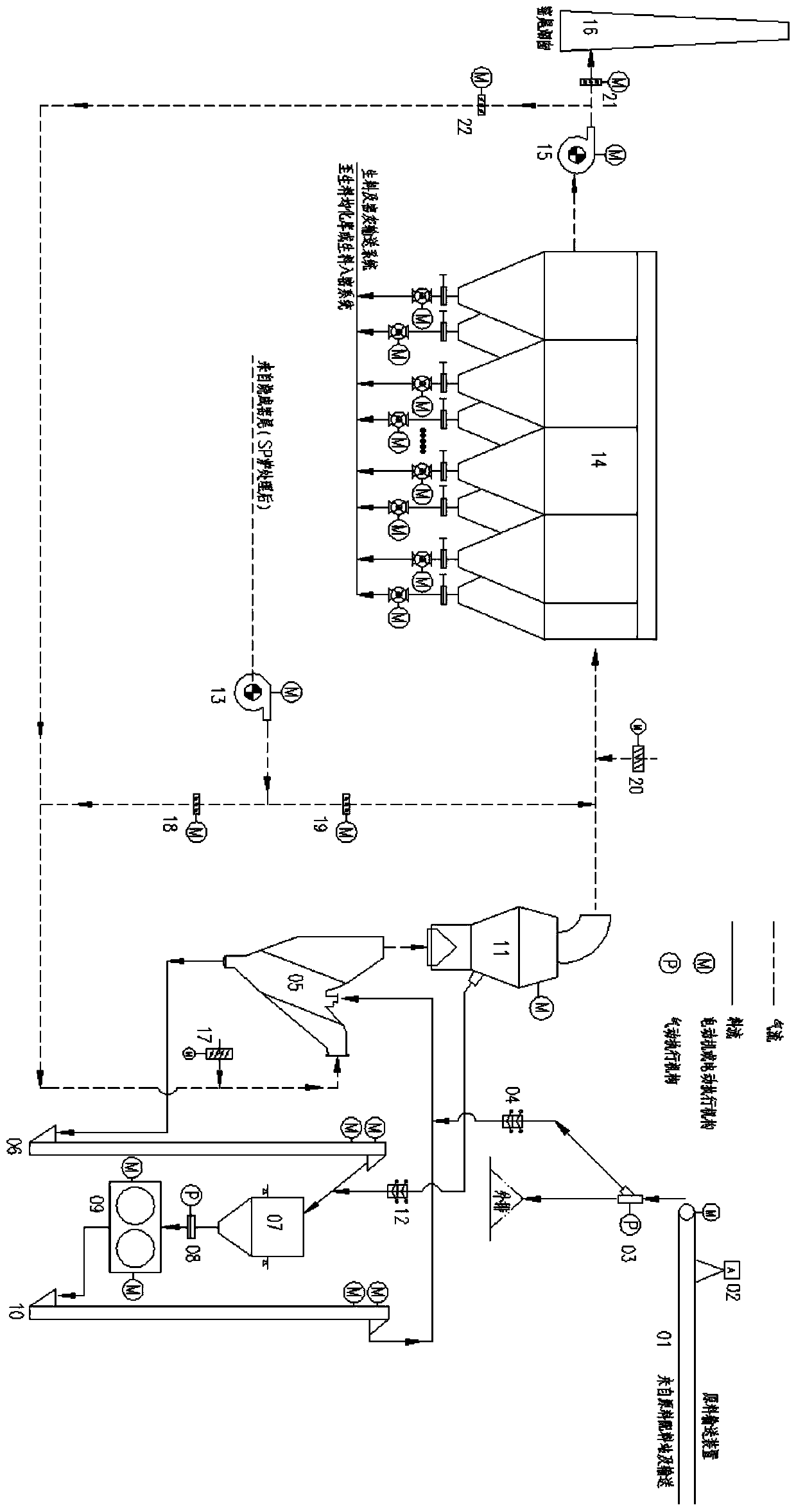

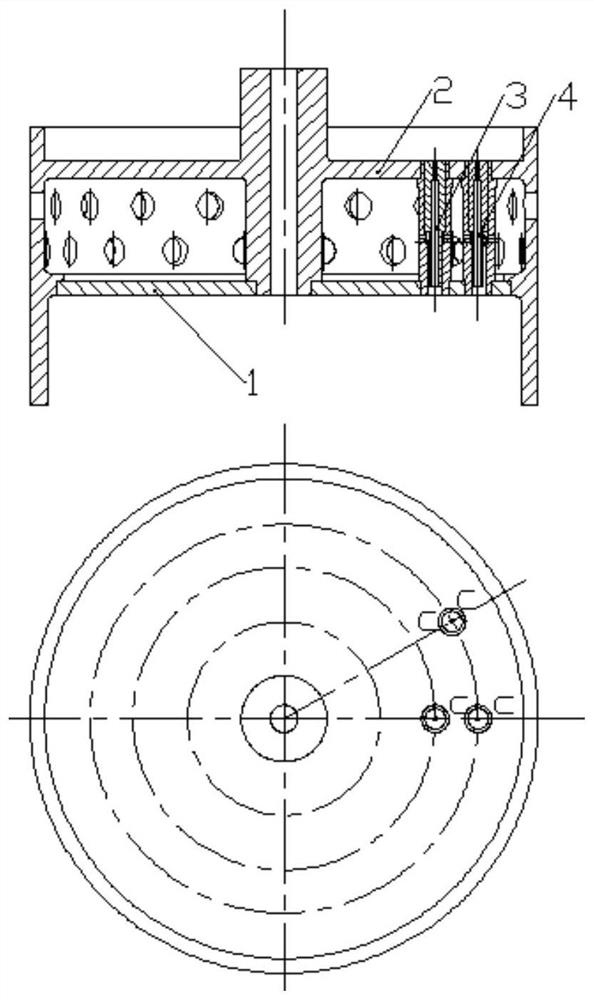

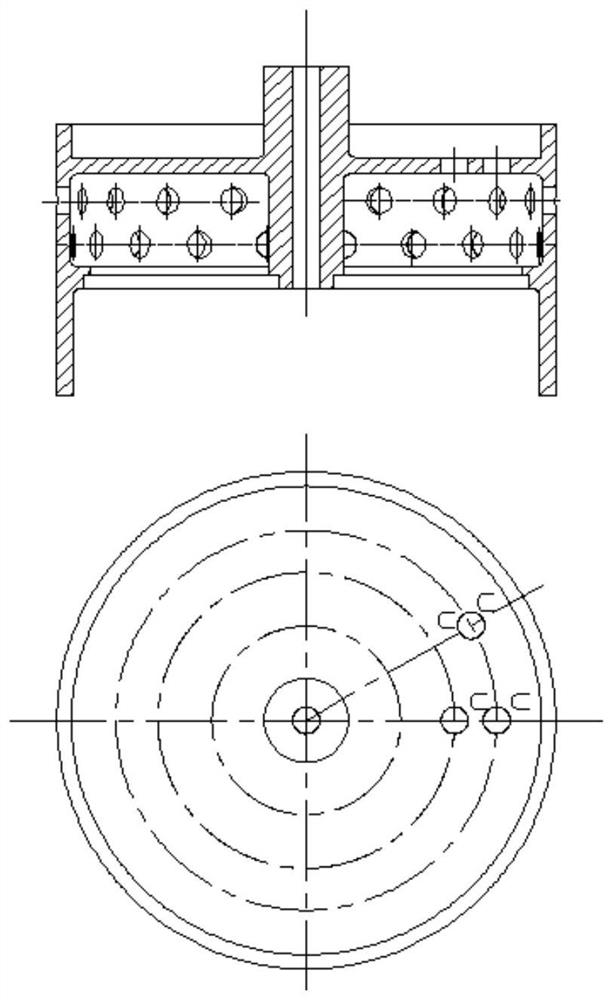

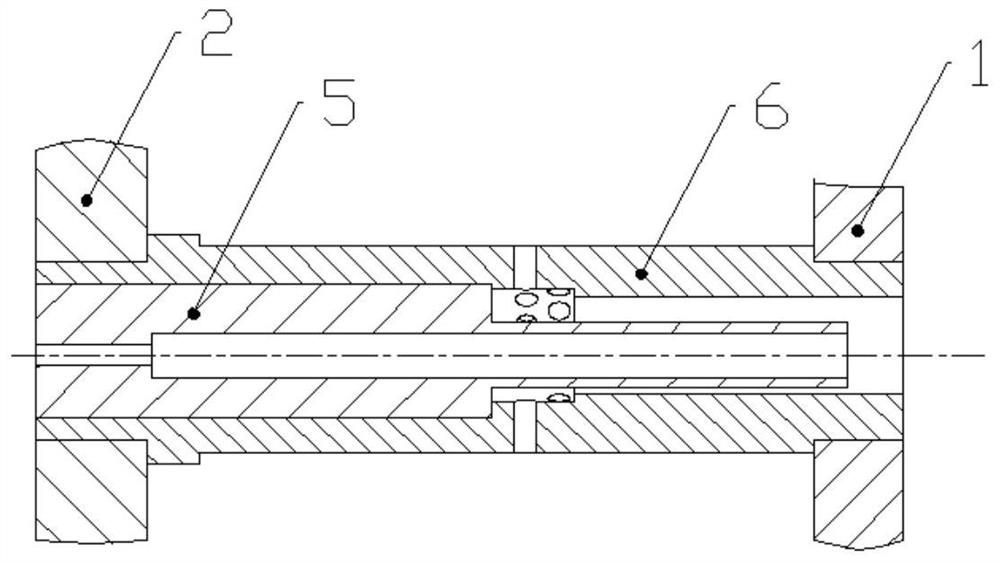

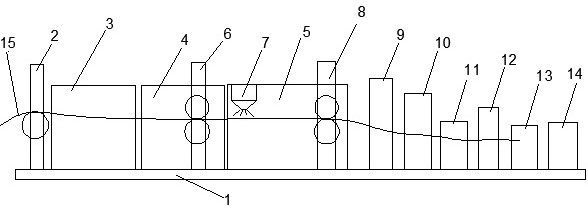

Final powder grinding double-fan system for raw material roller press and rolling method

PendingCN111569994AReduce the mixing ratioSimple processGrain treatmentsProcess engineeringMechanical engineering

The invention discloses a final powder grinding double-fan system for a raw material roller press. The system comprises a kiln tail high-temperature fan and a kiln tail exhaust fan. An air outlet of the kiln tail high-temperature fan is connected with an air inlet of a V-shaped powder selecting machine and an air inlet of a kiln tail bag dust collector. An air outlet of the V-shaped powder selecting machine is connected with an air inlet of a dynamic powder selecting machine. An air outlet of the dynamic powder selecting machine is connected with the air inlet of the kiln tail bag dust collector. An air outlet of the kiln tail bag dust collector is connected with an air inlet of the kiln tail exhaust fan. An air outlet of the kiln tail exhaust fan is connected with the air inlet of the V-shaped powder selecting machine and a kiln tail chimney. The invention further provides a rolling method based on the system. By the adoption of the final powder grinding double-fan system and the rolling method, a circulating fan of a powder grinding system in a traditional system is omitted, the flow is simplified, the system resistance is reduced, the equipment fault point is reduced, the capital construction investment can be effectively reduced, the power consumption of the system is reduced, and the maintenance workload of equipment is reduced.

Owner:SINOMA INT ENG

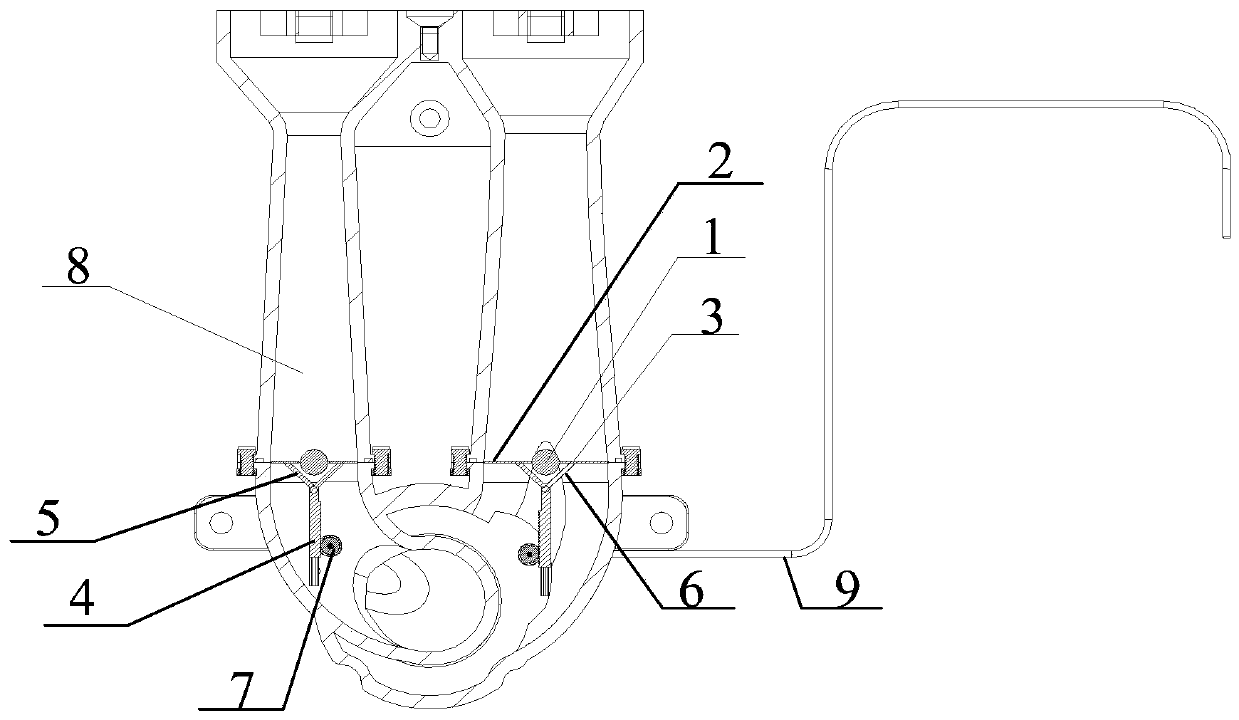

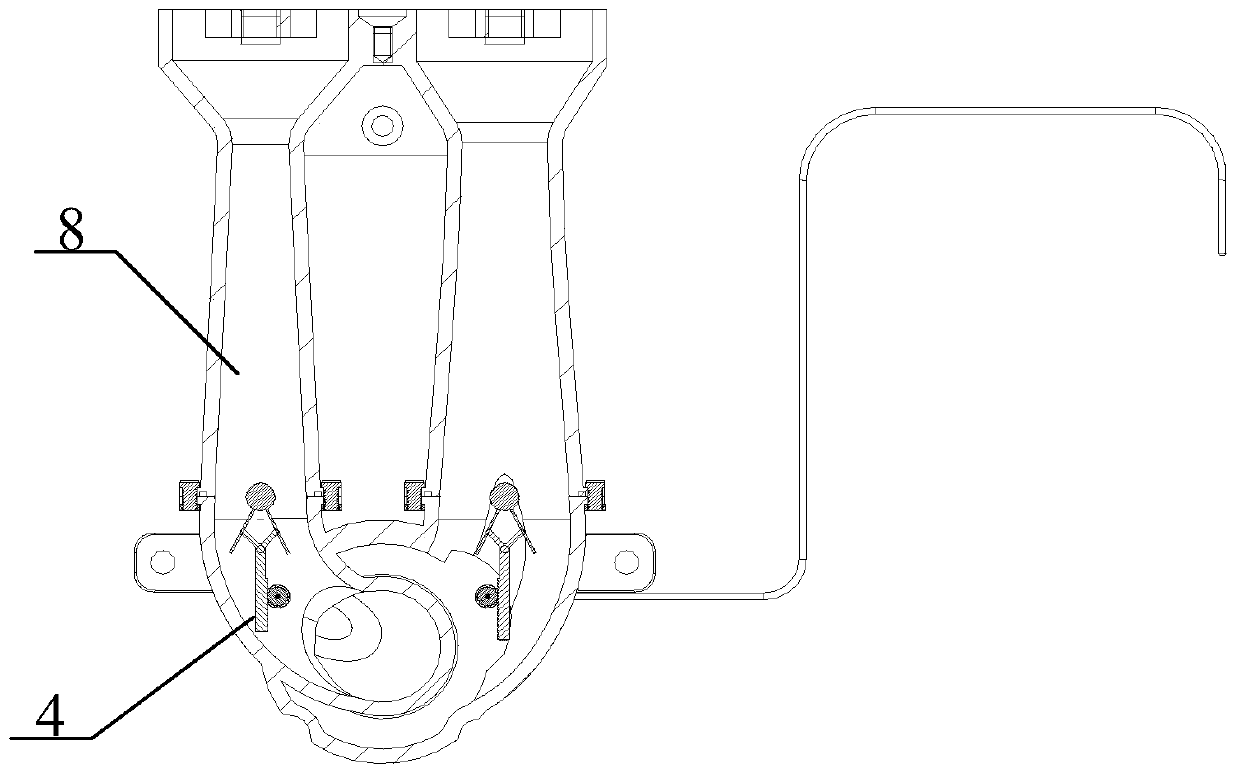

Injector structure capable of preventing body from being overheated

ActiveCN114165359AReduce the mixing ratioAchieving operational reliabilityInternal combustion piston enginesRocket engine plantsEngineeringLiquid hydrogen

A combined design scheme of an eccentric injection unit and a coaxial injection unit is adopted, the mixing ratio of the near wall face side of a fuel gas generator is reduced, the problem that the wall face of the fuel gas generator is prone to ablation and bluing is solved, the injector structure can adapt to the extremely severe environment of high temperature and high pressure, and the service life of the fuel gas generator is prolonged. And the working reliability of the fuel gas generator with the single-wall non-cooling structure is realized. The invention has already been applied to a certain liquid hydrogen and liquid oxygen rocket engine, can also be applied to various fields such as liquid oxygen methane rocket engines, aero-engines and oil burning boilers, and is simple in structure, easy to popularize and low in cost.

Owner:BEIJING AEROSPACE PROPULSION INST

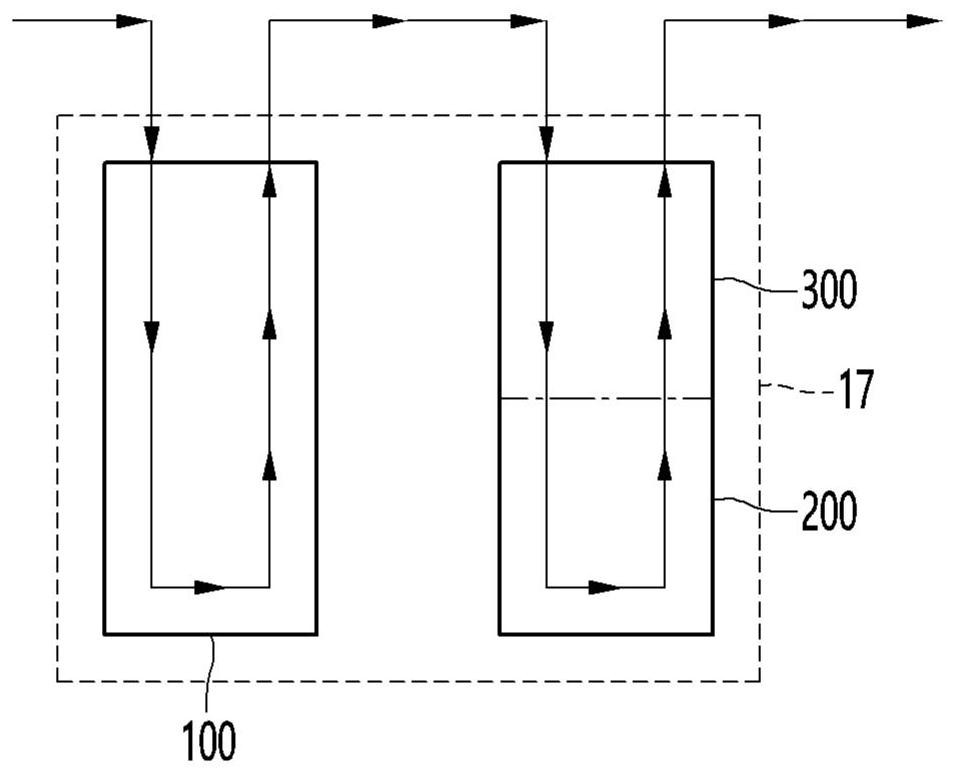

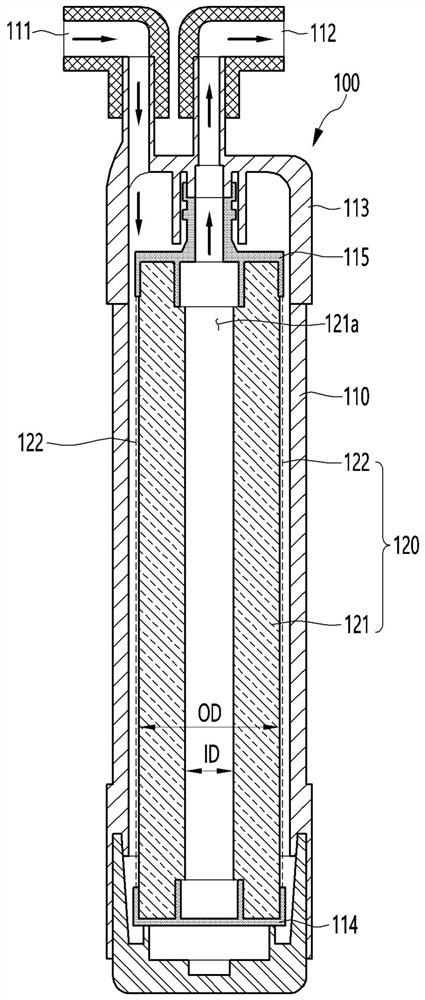

Filter for water-purification device and water-purification device including the same

PendingCN113620455AReduce the numberReduce manufacturing costWater contaminantsTreatment involving filtrationActivated carbonEnvironmental engineering

The invention relates to a filter for a water-purification device and the water-purification device including the filter. Disclosed is a filter for a water-purification device, the filter including a filter housing having a water inlet and a water outlet defined therein; and a filter member disposed in the filter housing to purify water introduced through the inlet and supply the purified water to the outlet, wherein the filter member includes a carbon block produced by mixing 40 to 50% by weight of titanium oxide, 30 to 40% by weight of activated carbon, and 18 to 23% by weight of binder with each other. Further, a water-purification device including the filter is disclosed.

Owner:LG ELECTRONICS INC

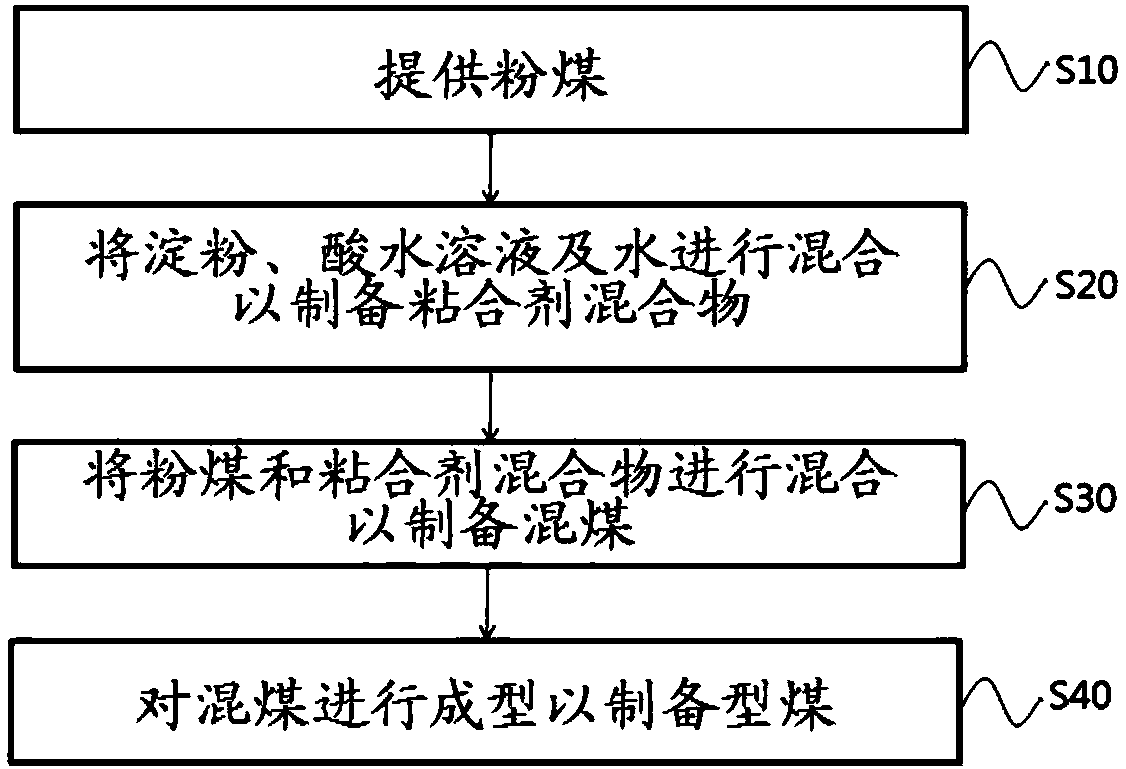

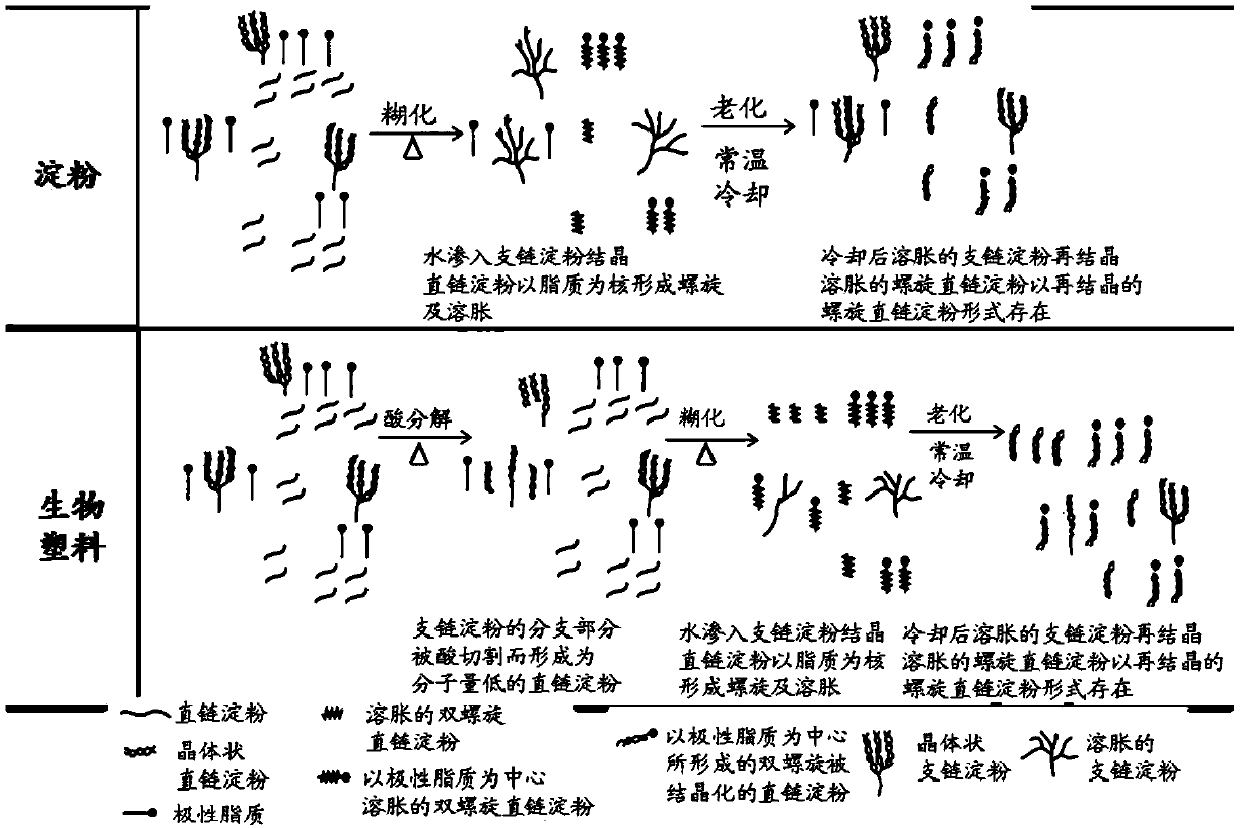

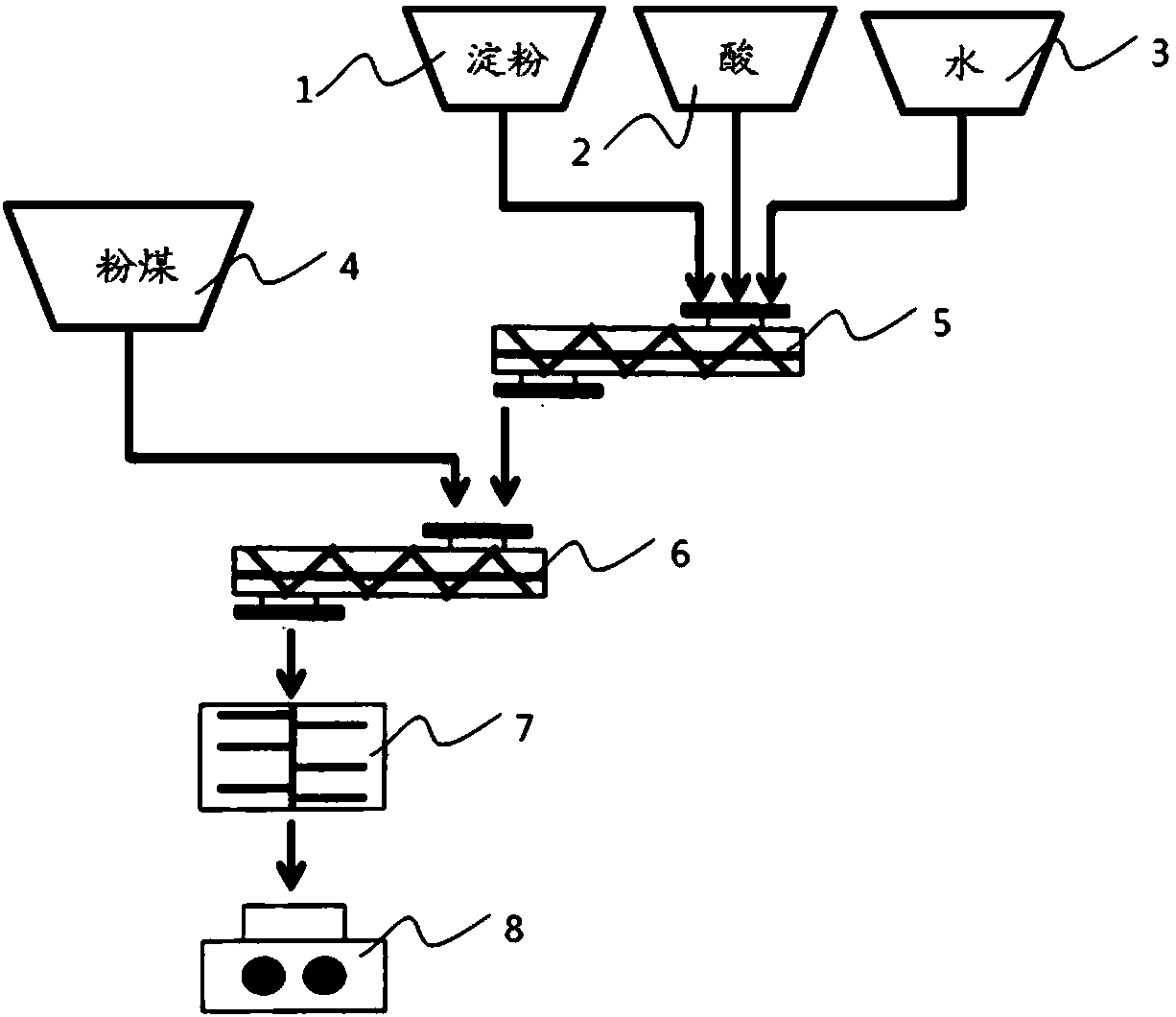

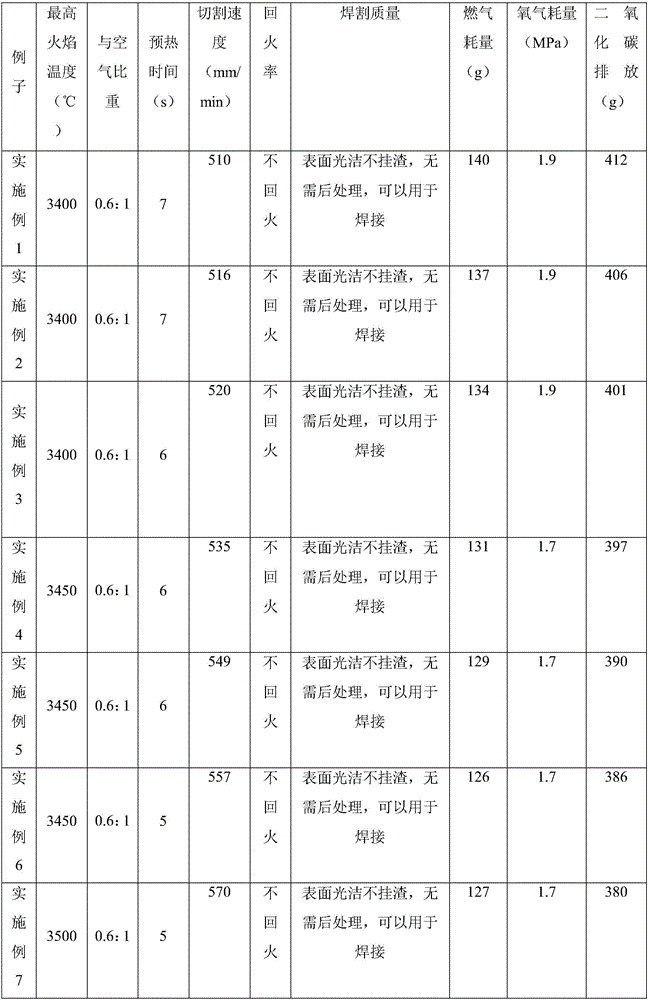

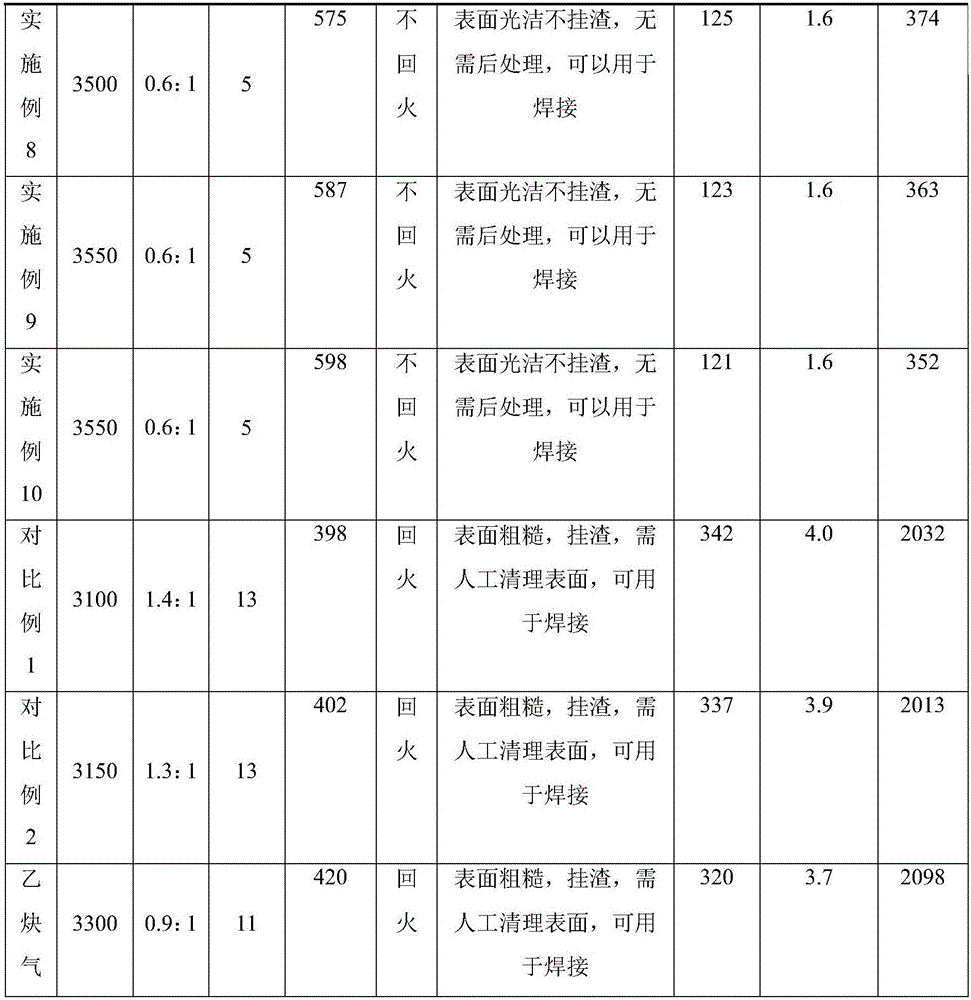

Molded coal and manufacturing method therefor

InactiveCN108026462ADecreased reactivityImprove fuel efficiencyBiofuelsSolid fuelsBriquetteAqueous solution

Provided are: molded coal to be rapidly heated by being charged in a dome part of a melting gasification furnace in an apparatus for manufacturing molten iron, the apparatus comprising the melting gasification furnace in which reduced iron is to be charged, and a reduction furnace connected to the melting gasification furnace and providing reduced iron; and a manufacturing method therefor. The method for manufacturing molded coal comprises the steps of: providing fine coal; preparing a binder mixture by mixing starch, an acid aqueous solution and water; preparing a coal blend by mixing the fine powder and the binder mixture; and manufacturing molded coal by molding the coal blend.

Owner:POHANG IRON & STEEL CO LTD

Gas synergist and application method thereof

InactiveCN106701226AImprove performanceIncrease combustion temperature and calorific valueGaseous fuelsChemistryEther

The invention relates to the technical field of industrial combustion gas synergists and particularly relates to a pentane combustion synergist for metal cutting and welding and an application method thereof. The gas synergist comprises the following ingredients in parts by weight: 30-50 parts of methanol, 10-20 parts of acetone, 10-20 parts of ethylbenzene, 15-25 parts of xylene, 1-3 parts of biferrocene ether, 20-30 parts of turpentine, 3-5 parts of solubilizer and 2-5 parts of dispersant. The gas synergist is capable of obviously improving the combustion temperature, combustion heat, combustion velocity and combustion efficiency of pentane, improving the total available energy of the pentane, improving the flame temperature, improving combustion product ingredients, and achieving the technical effects of reducing energy consumption, reducing pollution, reducing the production cost of using institutions, improving the production efficiency and the like.

Owner:巨烃新能源技术有限公司

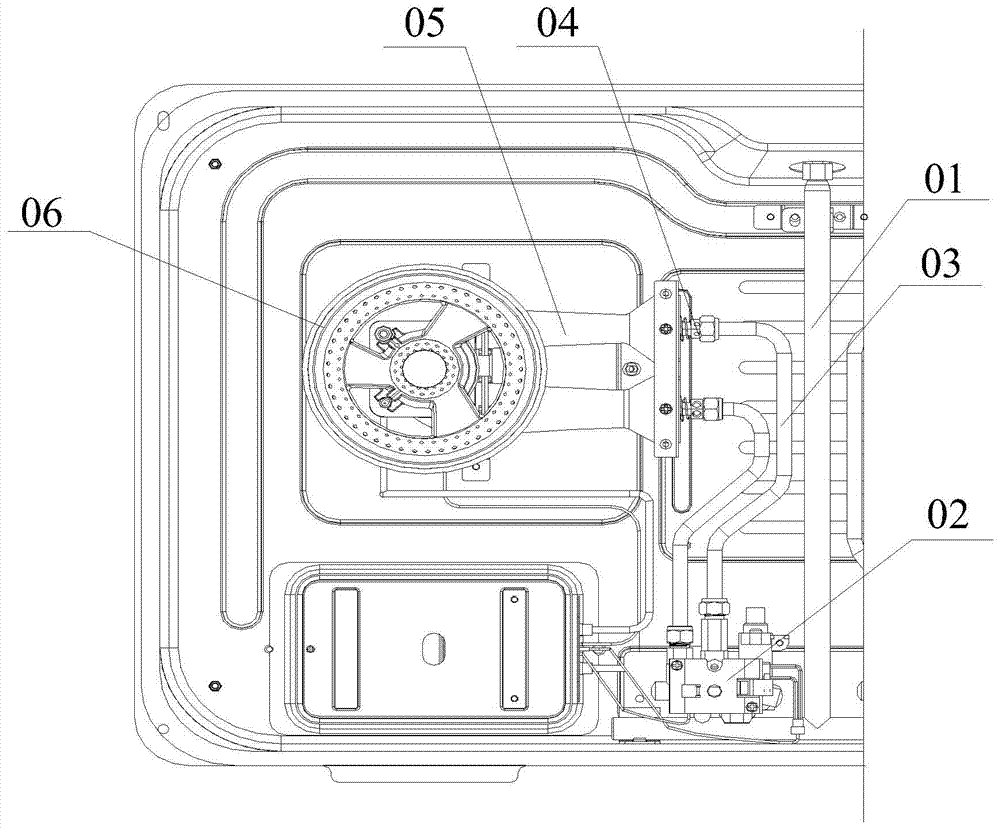

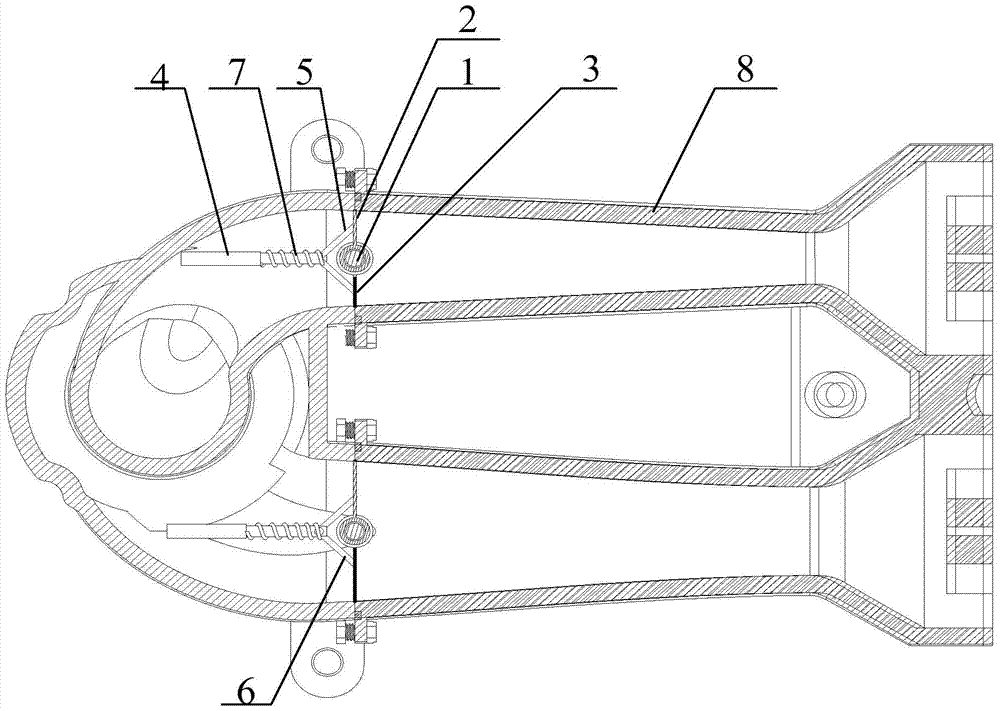

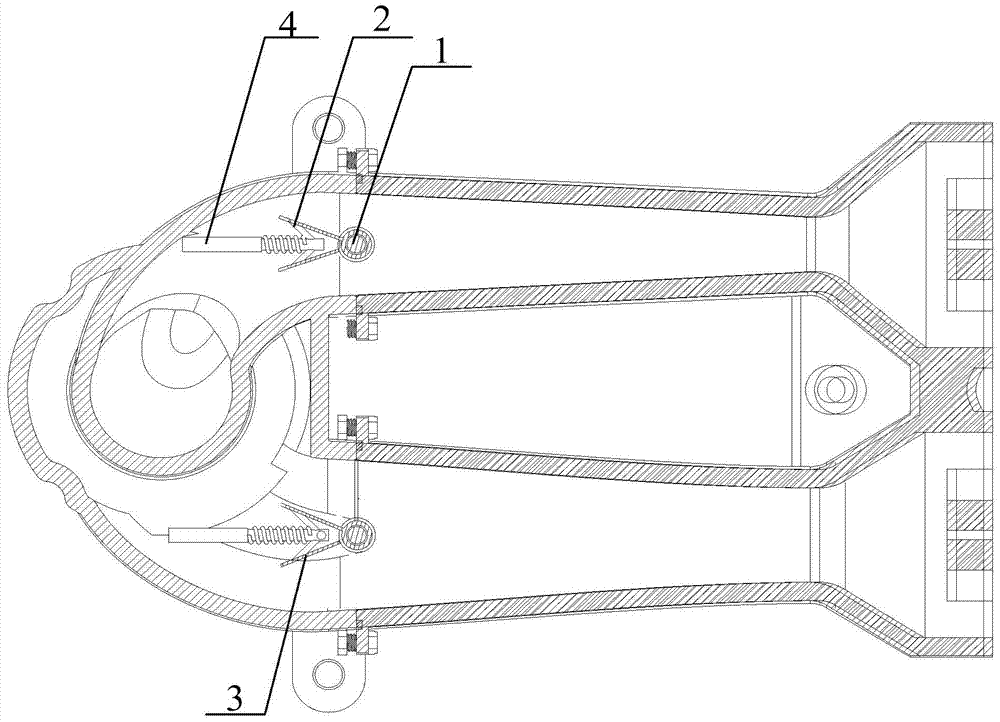

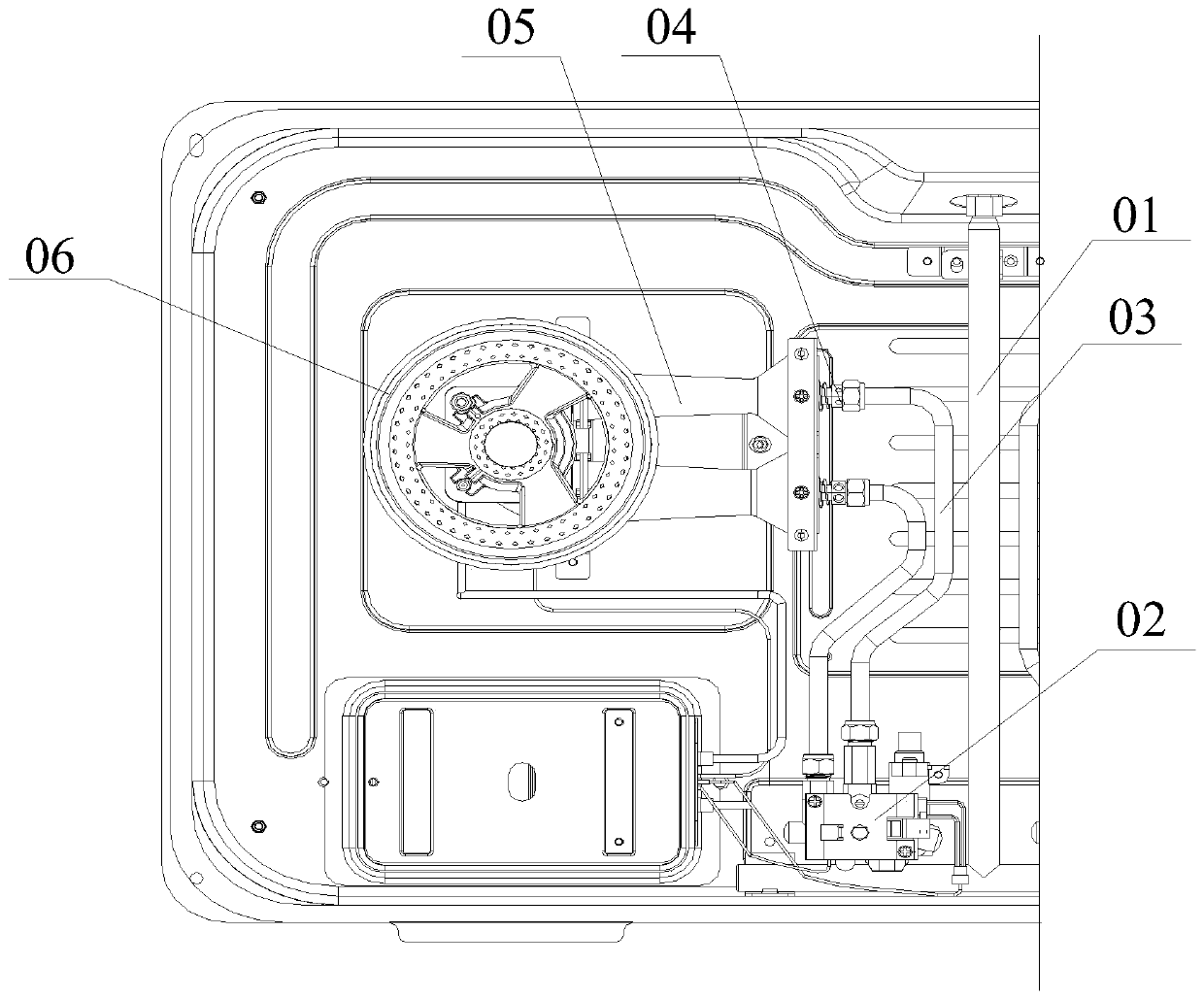

An anti backfire gas stove

ActiveCN104976647BGuaranteed circulationReduce the mixing ratioDomestic stoves or rangesLighting and heating apparatusCombustorSpray nozzle

The invention relates to an anti-flareback gas stove. The anti-flareback gas stove comprises a spray nozzle, a furnace end and a burner which are connected in sequence and further comprises a switch mechanism which is arranged in the furnace end and capable of blocking and unblocking a gas channel in the furnace end. The switch mechanism comprises a supporting shaft arranged in the radial direction of the furnace end and fixed to the furnace end, a first blade, a second blade, a self-restoration assembly and a limiting part, wherein the first blade and the second blade are hinged to the supporting shaft and form a blocking plate used for blocking the gas channel in the furnace end after being expanded, and the gas channel in the furnace end is totally unblocked after the first blade and the second blade are attached to each other; the self-restoration assembly is used for driving the first blade and the second blade to be kept expanded, the force of gas on the first blade and the second blade is larger than the restoration force of the self-restoration assembly when a valve assembly of the gas stove is opened, and the limiting part is arranged in the furnace end and used for preventing the first blade and the second blade from being expanded too much. By the adoption of the anti-flareback gas stove, flareback can be effectively reduced or even avoided, and parts of the gas stove are protected against damage.

Owner:GREE ELECTRIC APPLIANCES INC

PE/PET composite ultra-short non-crimp fiber post-treatment production method and device

PendingCN112695397ACortical melting point depressionReduce the mixing ratioArtificial thread manufacturing machinesArtificial filament washing/dryingWoven fabricYarn

The invention discloses a PE / PET composite ultra-short non-crimp fiber post-treatment production method and device. The production method comprises the steps of pre-spinning precursor bundling, dipping bath, primary tow stretching, secondary tow stretching, tow crimping, tow laying, tow loosening and shaping, tow cutting, packaging and the like. The corresponding post-treatment device comprises a bundling frame, a dipping bath tank, a water bath tank, a steam drafting box, an oiling machine, a yarn stacking machine, a crimping machine, a drying setting machine, a cutting machine and a packaging machine which are sequentially arranged on a workbench from left to right. Through specific post-treatment method including dipping bath, drafting, crimping, shaping and cutting, the melting point of the skin layer of the prepared PE / PET composite ultra-short non-crimp fiber can be reduced, the bonding strength of non-woven fabric is improved, the doping proportion of the fiber is reduced, and the downstream production cost is reduced.

Owner:扬州石化有限责任公司

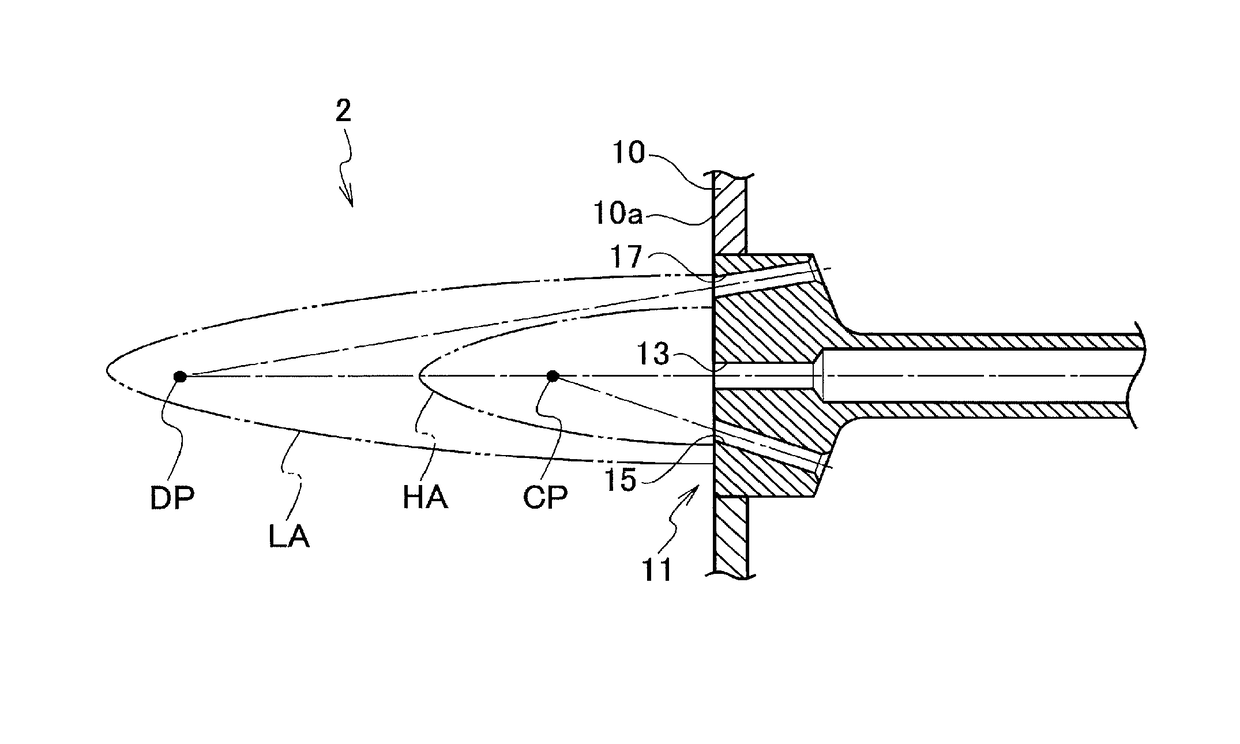

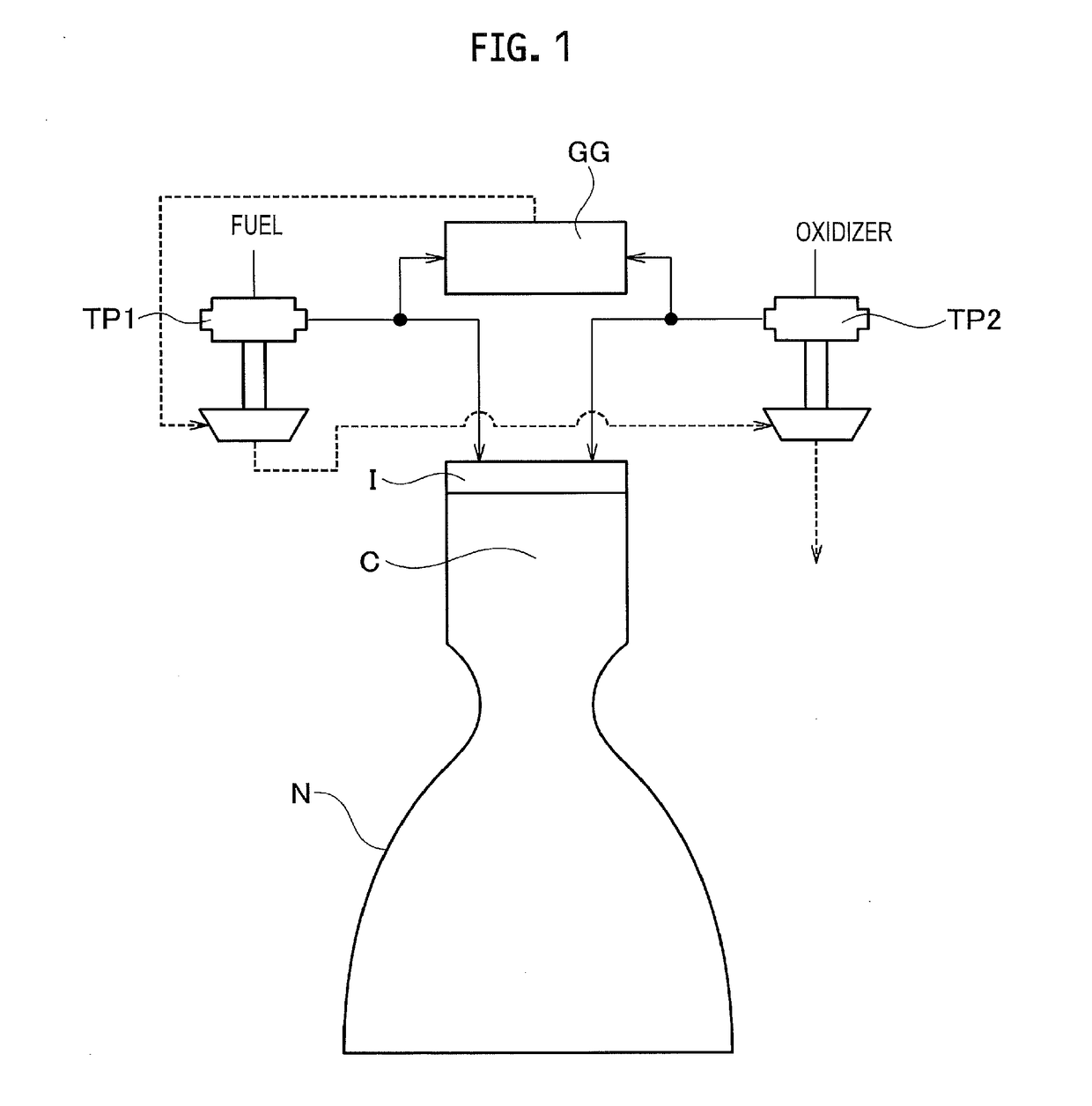

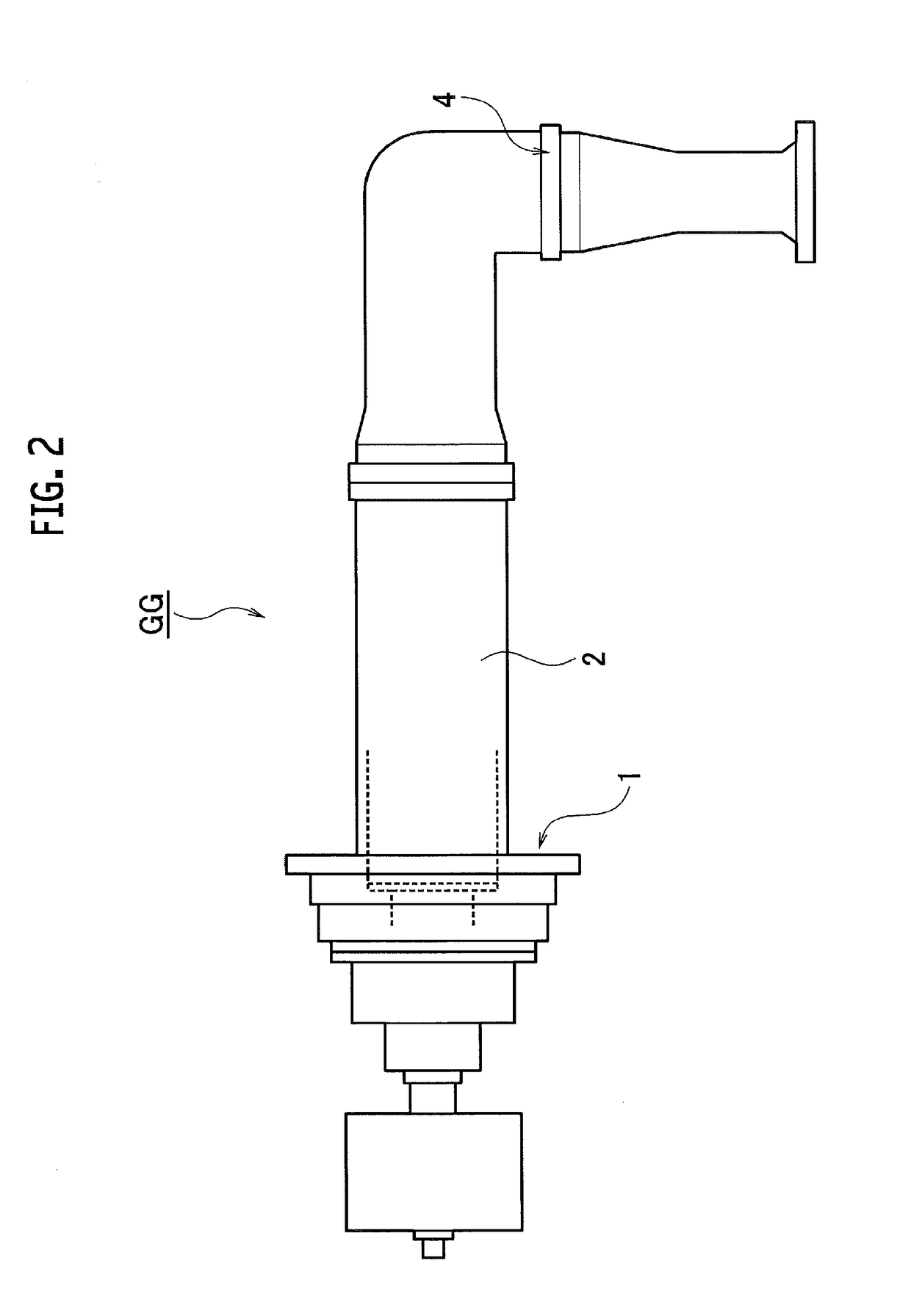

Gas generator

ActiveUS10072611B2Reduce the temperatureReduce the mixing ratioTurbine/propulsion fuel flow conduitsGas turbine plantsCombustorEngineering

A gas generator includes an injector that injects a fuel and an oxidizer, and a combustor that mixes and burns the fuel and the oxidizer injected from the injector. The injector includes a plurality of injection elements arranged on a face plate. Each of the injection elements includes unlike-impingement type injection nozzles that inject the fuel and the oxidizer toward a combustion point in front of the face plate, and injection nozzles that inject fuel for dilution to a dilution point DP forward further than the combustion point.

Owner:IHI CORP

Anti-tempering gas stove

ActiveCN104949165BReduce the mixing ratioSo as not to damageDomestic stoves or rangesLighting and heating apparatusCombustorFlameout

The invention relates to an anti-backfire gas stove. The anti-backfire gas stove comprises a nozzle, a furnace end and a burner which are sequentially connected. The anti-backfire gas stove further comprises a switching mechanism which is arranged inside the furnace end and can block and open a gas channel inside the furnace end. When the gas stove is closed, the switching mechanism can block the gas channel inside the furnace end. Due to the fact that the switching mechanism is arranged inside the furnace end, the furnace end is directly connected with the burner, the residual gas volume is greatly lowered, the probability that mixing ratio of gas to air is within the explosion limit is greatly lowered, a small amount of gas remained in the furnace end and the burner can be burned by a flame, the flame cannot be spread towards the furnace end or farther, the continuous flameout noise and even the explosive sound due to the fact that the flame is spread for the long time are avoided, and parts of the gas stove is effectively protected from being damaged.

Owner:GREE ELECTRIC APPLIANCES INC

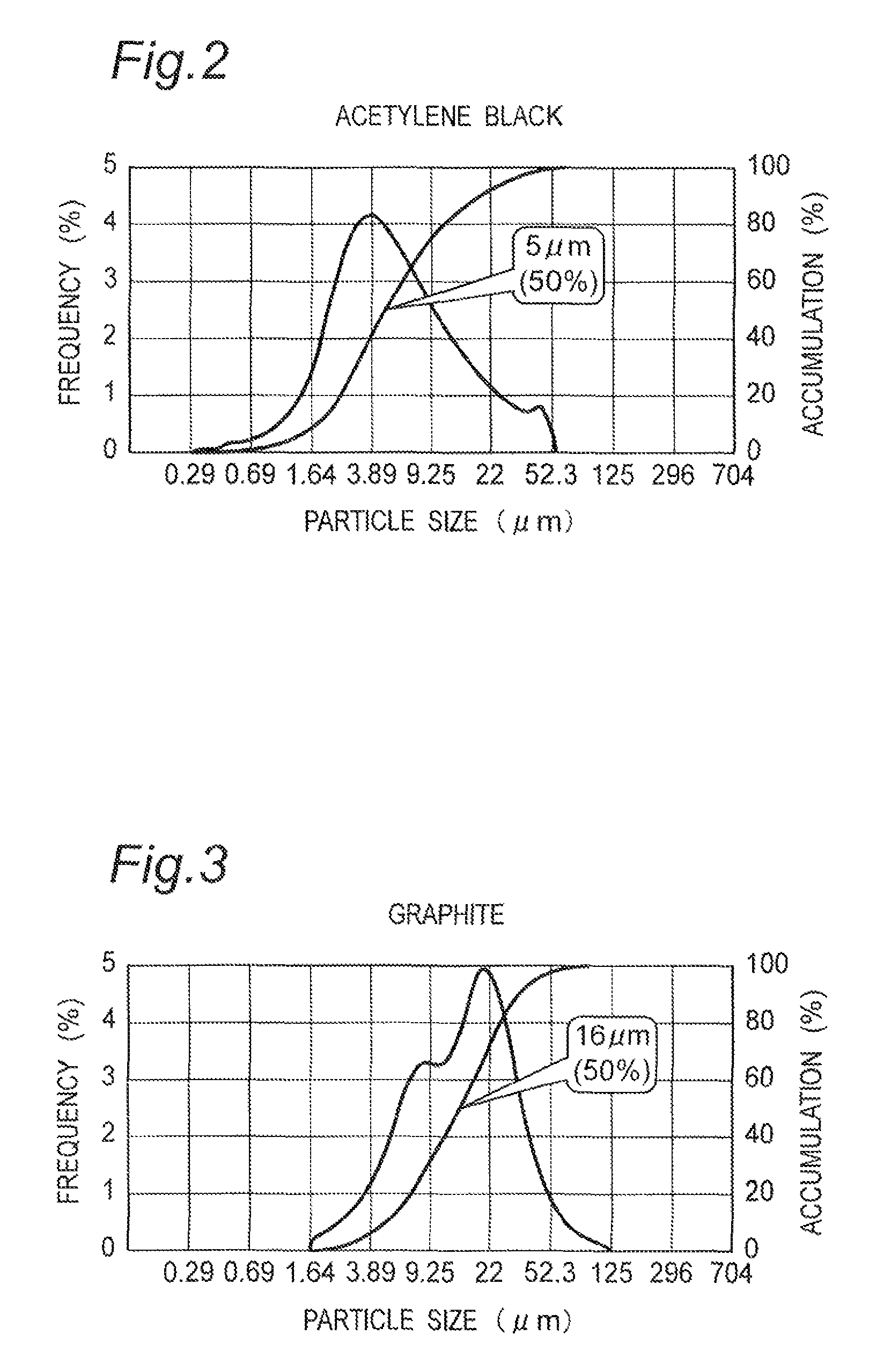

Gas diffusion layer for fuel cell, manufacturing method therefor, membrane electrode assembly, and fuel cell

ActiveUS8999603B2Low costIncrease power generation capacityFinal product manufactureFuel cell auxillariesFuel cellsPolymer resin

A gas diffusion layer for fuel cell of the present invention is structured with a porous member mainly comprised of conductive particles such as acetylene black, graphite and a polymer resin such as PTFE. This makes it possible to achieve both an improvement in power generation performance of the fuel cell and a reduction in costs.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com