Molded coal and manufacturing method therefor

A technology of briquette and preparation equipment, which is applied in the field of briquette and its preparation, can solve the problems such as the inability to control the quality of briquette and the decline of briquette quality, and achieve the effects of improving fuel efficiency, reducing reactivity, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

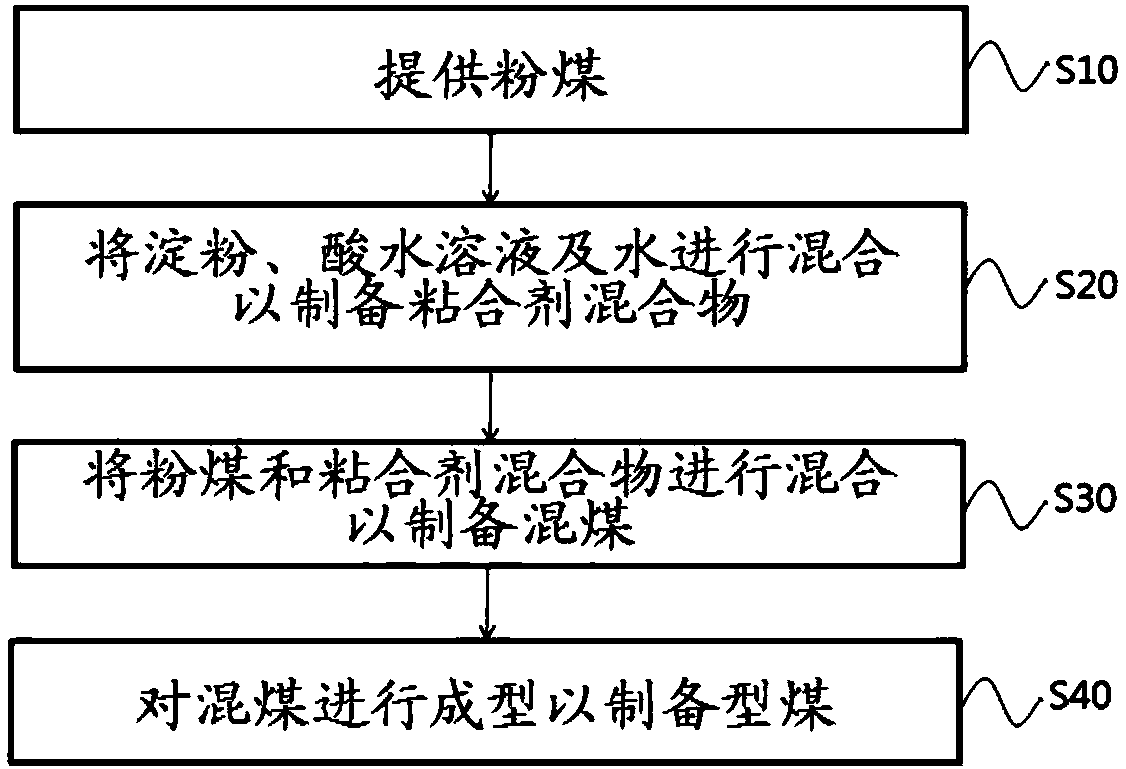

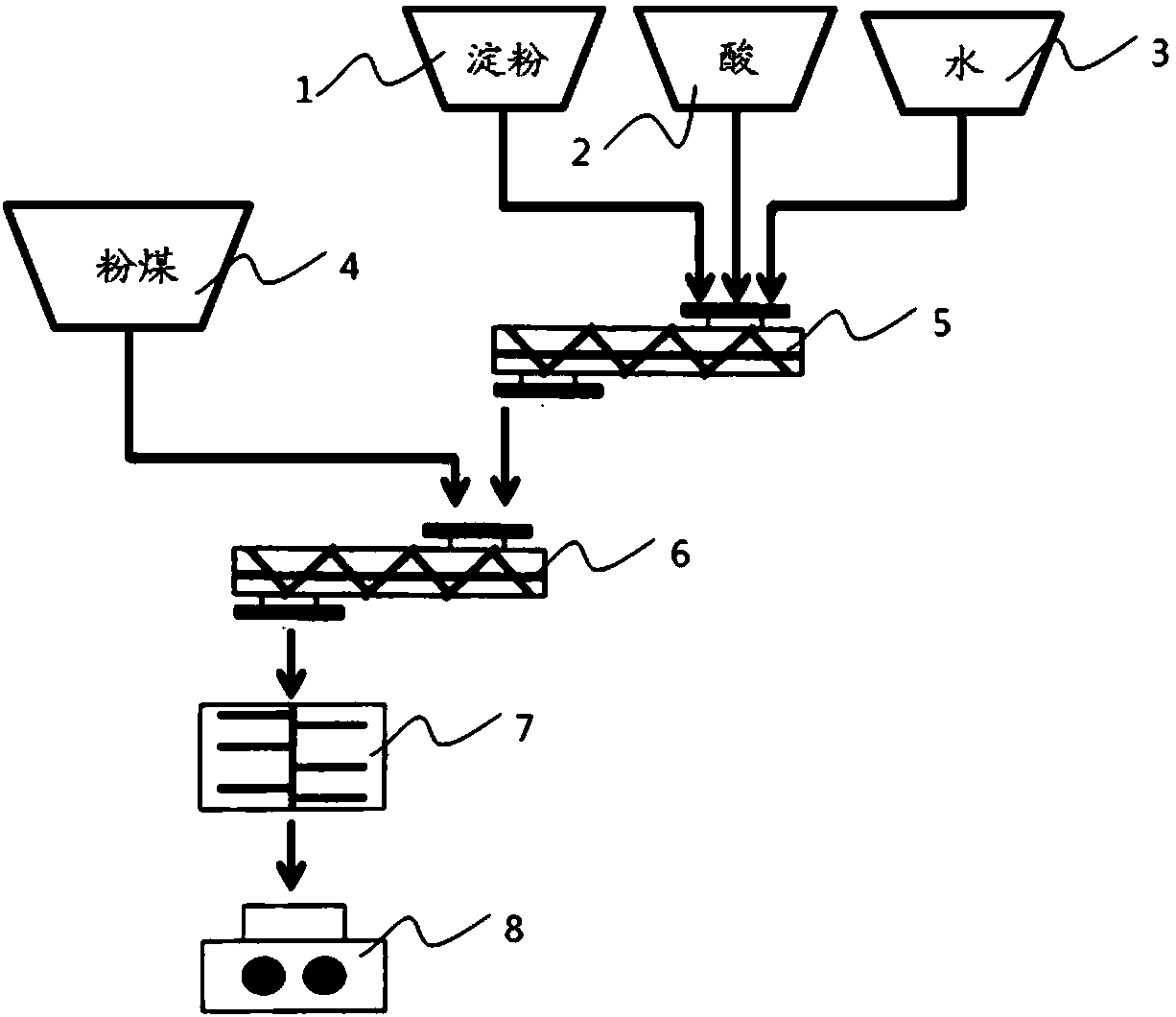

[0036] Such as figure 1 As shown, the briquette preparation method includes: step S10 of providing pulverized coal; step S20 of mixing starch, acid aqueous solution and water to prepare a binder mixture; mixing pulverized coal and binder mixture to prepare a mixed coal Step S30; and the step S40 of molding the mixed coal to prepare coal briquettes. In addition, the briquette preparation method may also include other steps as required.

[0037] First, pulverized coal is provided in step S10. Pulverized coal is pulverized coal. Generally, coal is divided into peat with a carbon content of about 60%, wood coal and lignite with a carbon content of about 70%, sub-bituminous coal with a carbon content of about 70% to 80%, and subbituminous coal with a carbon content of about 80% to 80%. 90% bituminous coal, more than 90% anthracite. The type of coal used is not particularly limited, and a single type of coal or various types of coal may be used in combination. In order to reduce...

Embodiment 1

[0079] Example 1: Viscoelastic testing of pH-based bioplastics

[0080] 704 g of starch, 793 g of water, and 70.4 g of an aqueous solution of 5 wt % acid (acetic acid) were mixed to prepare binder mixtures with pHs of 3.0, 4.0, 5.0, and 6.0. For comparison, an adhesive mixture with a pH of 7.0 in aqueous solution without mixing acid was also prepared. Then, the binder mixture was heated to 70°C to prepare the bioplastic.

[0081] The storage modulus G' (storage modulus) and loss modulus G" (loss modulus) of each bioplastic were measured according to the pH of the binder mixture and are shown in Image 6 middle.

Embodiment 2

[0082] Example 2: Viscoelasticity Tests of Bioplastics Based on Acid Species

[0083] The same test as in Example 1 was carried out by substituting the kind of acid for citric acid, lactic acid, malic acid, tartaric acid, and ascorbic acid.

[0084] Calculate the complex viscosity (|η*| 10 ) and shown in Figure 7 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com