A Neutron Poison Sandwich Structure with Open Pores in a Continuous Dissolver

A sandwich structure and dissolver technology, which is applied in the field of critical safety control, can solve problems such as complex structures, and achieve the effects of improving processing capacity, increasing neutron absorption effects, and reducing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

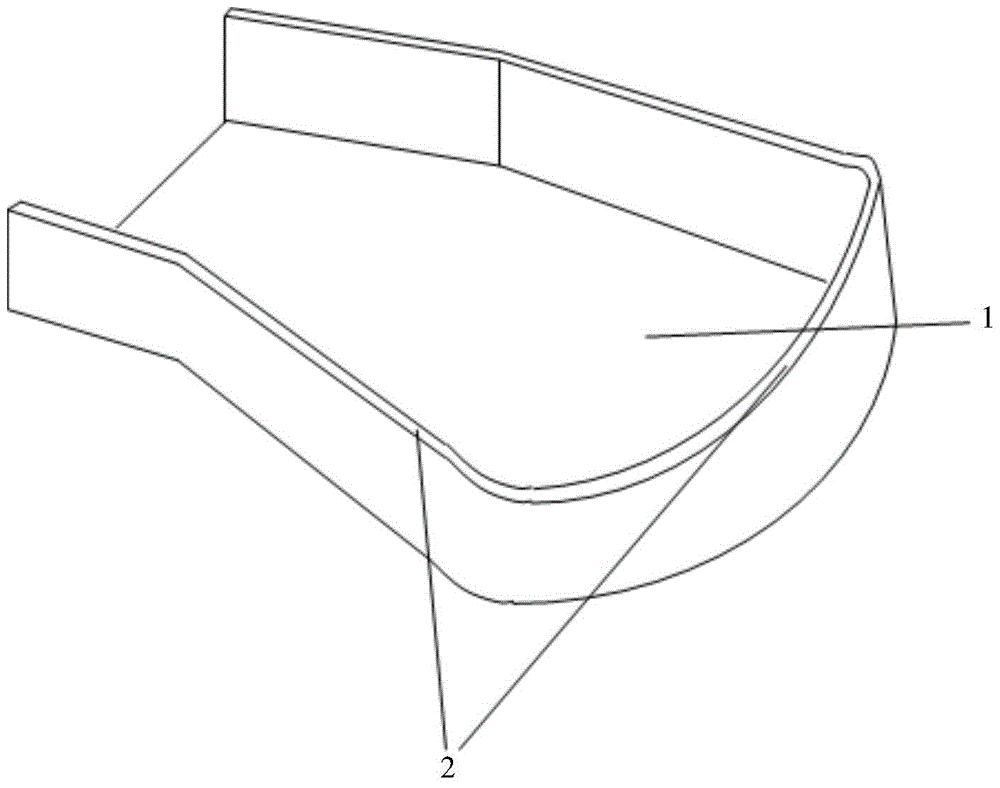

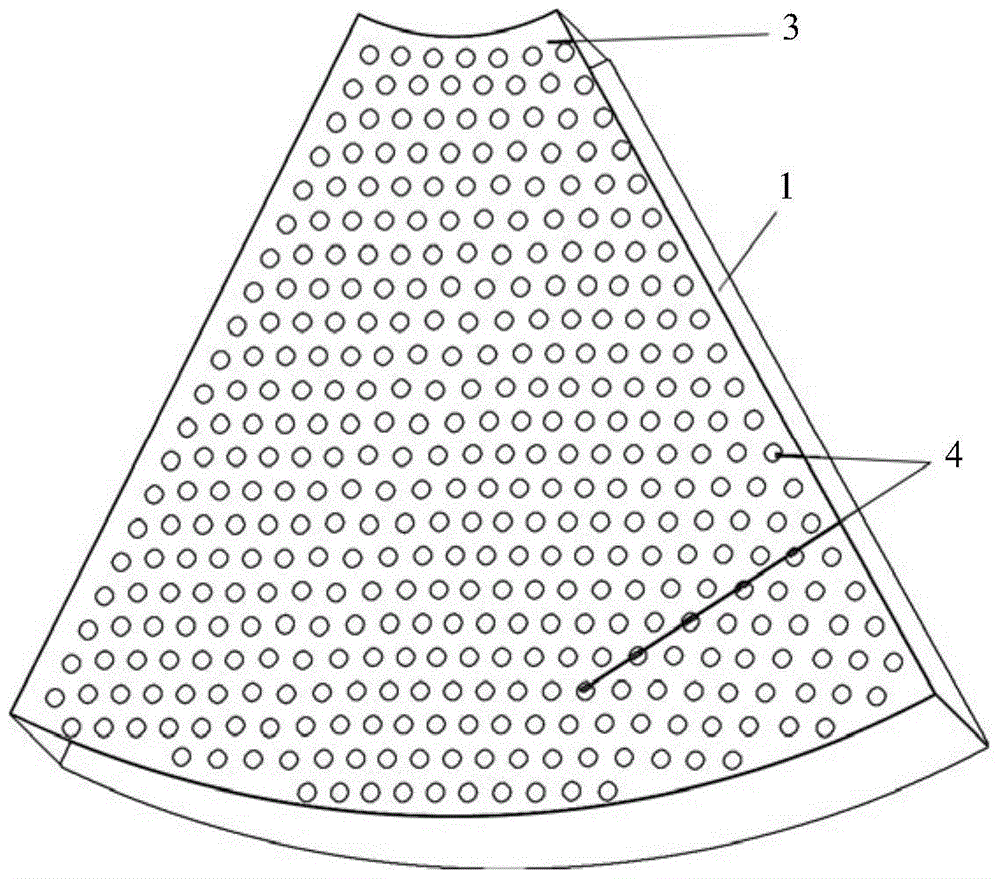

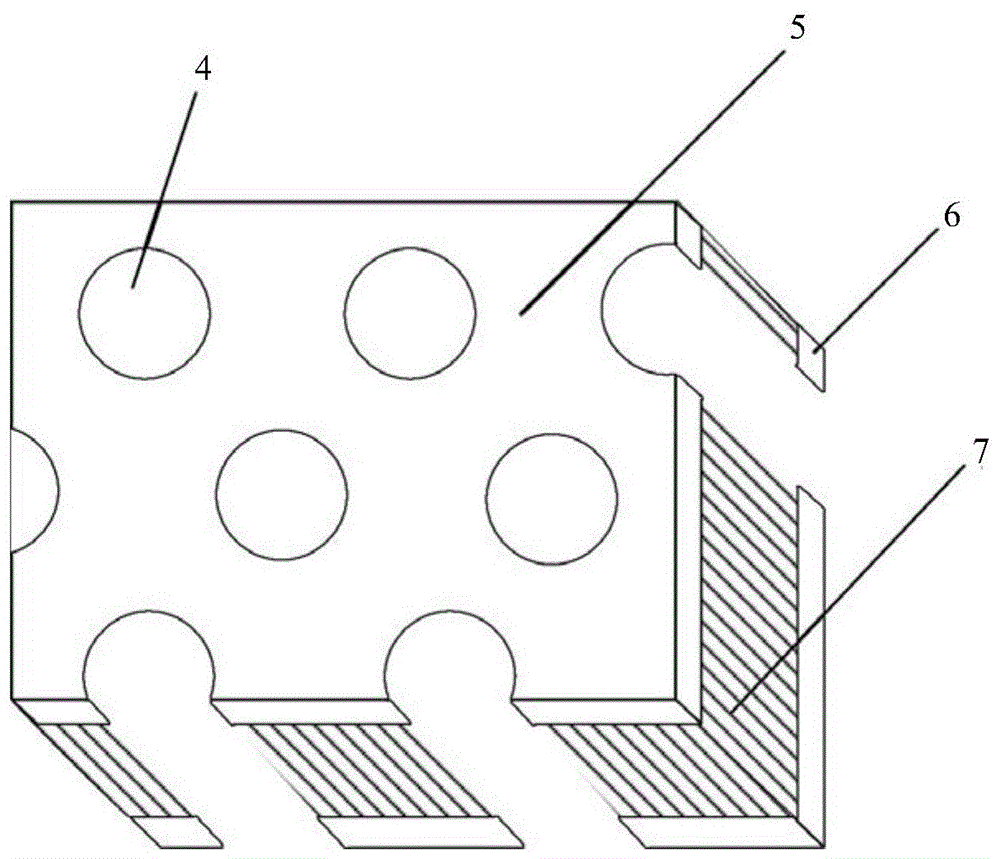

[0015] The structure of the container part in the continuous dissolver that directly contacts the pellets is as follows: figure 1 As shown, the structure of the dissolving container (hereinafter referred to as the bucket) is similar to a fan-shaped body with a certain thickness, which is used to load the spent fuel pellets to be dissolved, and is placed in another flat tank container for dissolving spent fuel craft. figure 1 The bottom wall 1 and the side wall 2 of the bucket are marked in the figure, and the top wall of the container is not shown. In order to ensure the exchange of the solution in the bucket and the solution outside the bucket when dissolving, there are openings 4 on the top and bottom container walls 3,1 of the container, such as figure 2 shown.

[0016] In the entire dissolving device, the bucket has a small thickness and is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com