Patents

Literature

146results about How to "Efficient composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

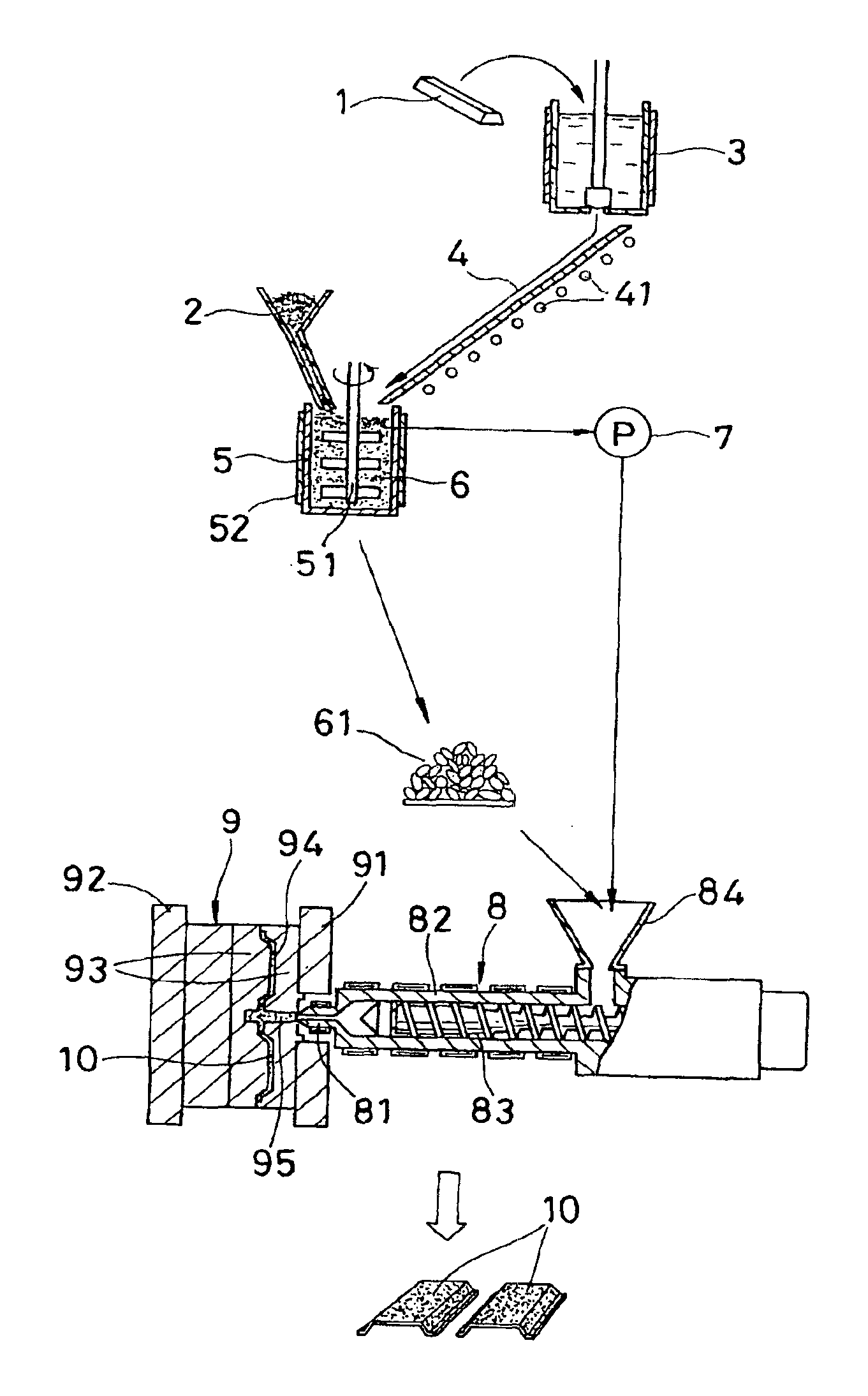

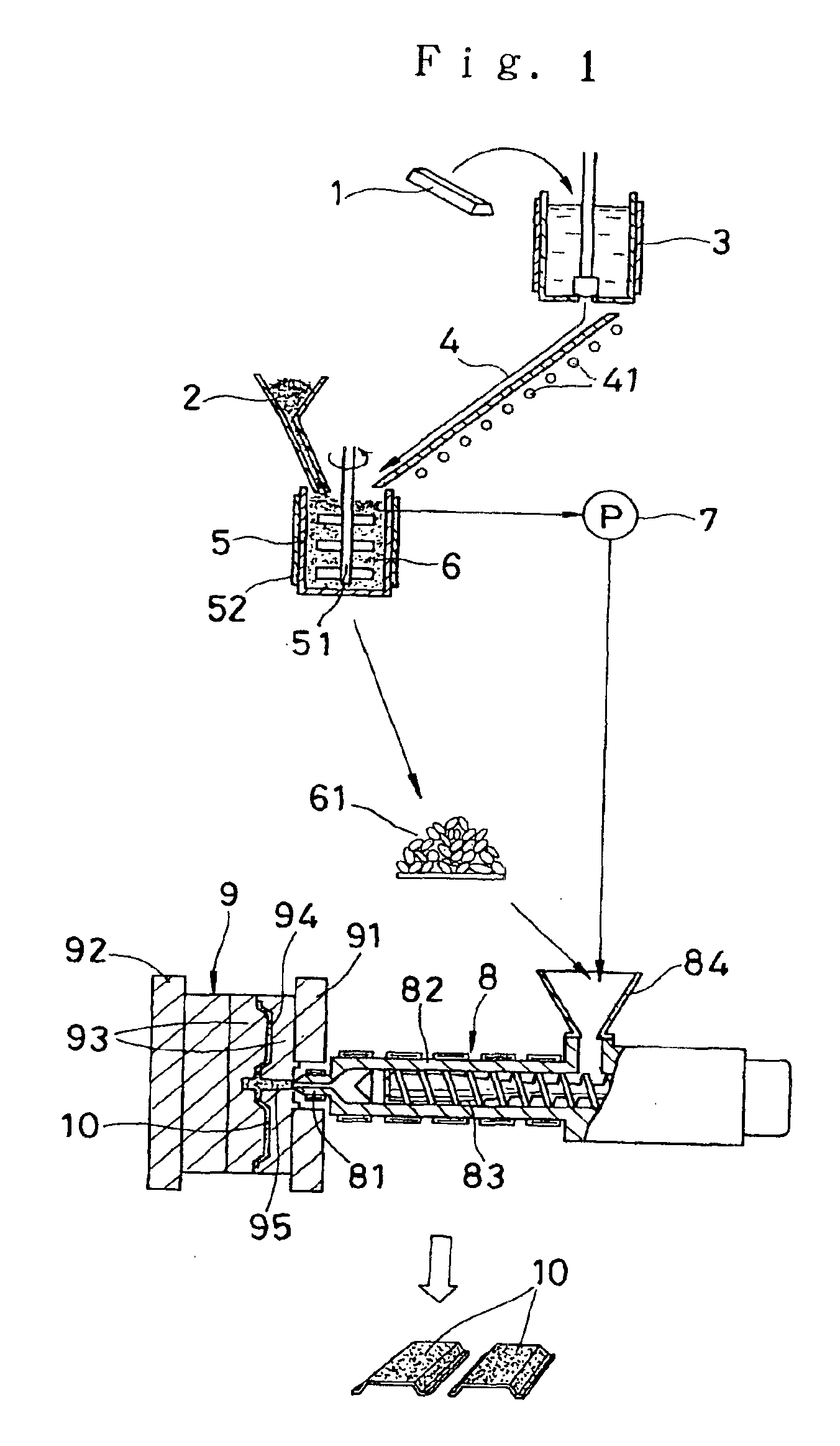

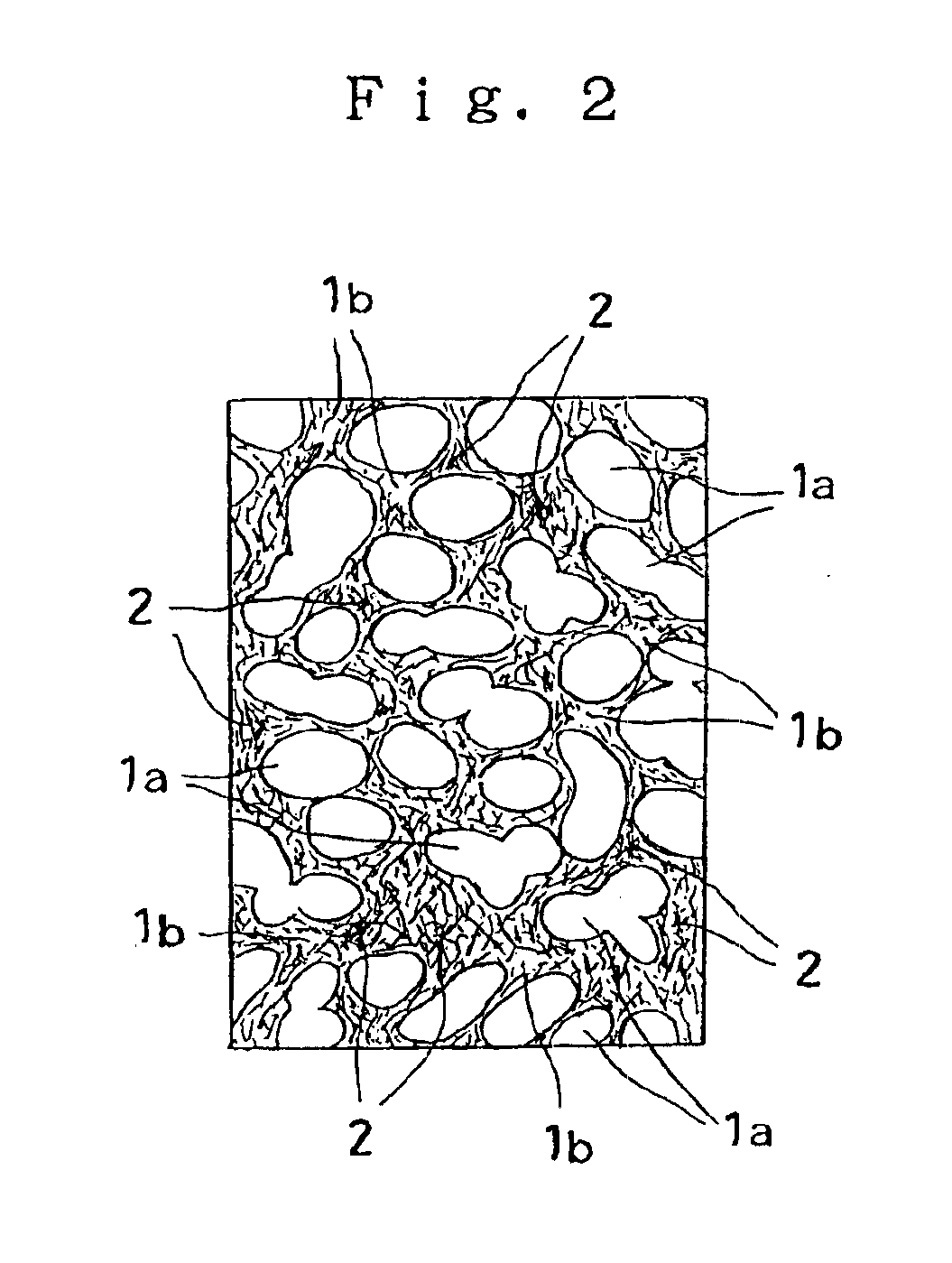

Method for producing a composite metal product

A low melting point metal material is made to a thixotropic state in which liquid phases and solid phases coexists. In the thixotropic state of the low melting point metal material, a carbon nano material is kneaded with the low melting point metal material and forms a composite material. Thus obtained composite material is supplied to a metal molding machine and injected into a mold in a thixotropic state or a completely molten state of the metal so that the composite material fills the mold, thereby the composite material is molded to a composite metal product. With the above process, it is possible to injection mold the composite metal product to which the characteristics of the carbon nano material are applied.

Owner:NISSEI PLASTIC IND CO LTD

Preparation method for graphene conductive slurry

The invention discloses a preparation method for graphene conductive slurry. The preparation method comprises the steps of dissolving a dispersing agent into a solvent firstly, and performing ultrasonic oscillation to form a uniform solution; then adding graphene and a conductive carbon material into the solution to be mixed and stirred; next, performing full dispersion through a way of ultrasonic oscillation; and finally transferring the well-dispersed slurry to a high-speed shearing emulsification homogenizing machine to be sheared and dispersed to obtain the uniform and consistent and fully-dispersed graphene conductive slurry. The preparation method is simple and easy to implement and applicable to engineering production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

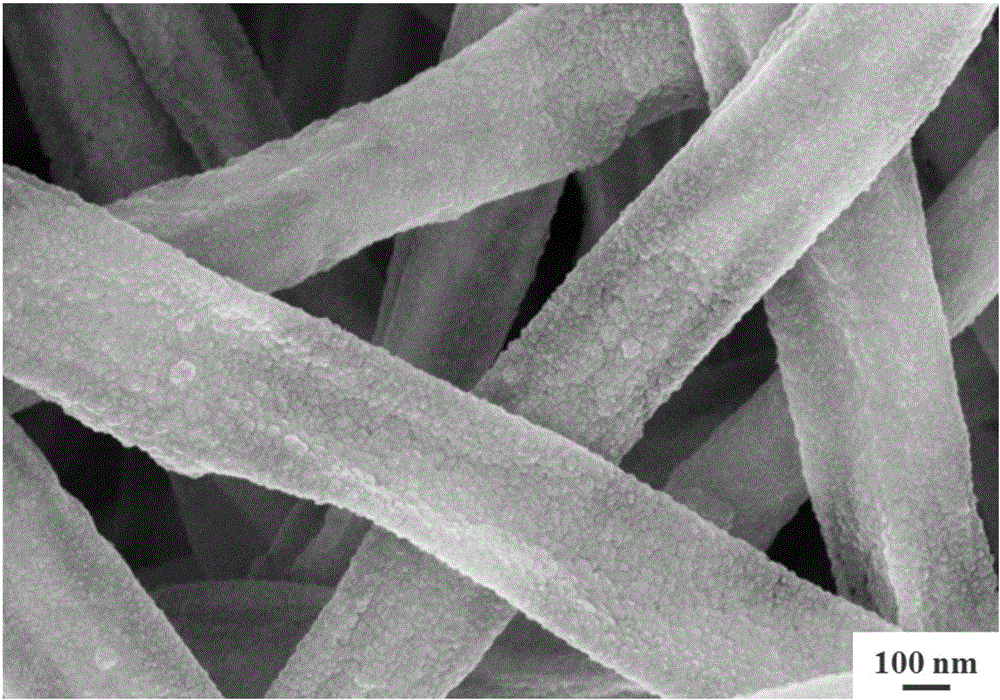

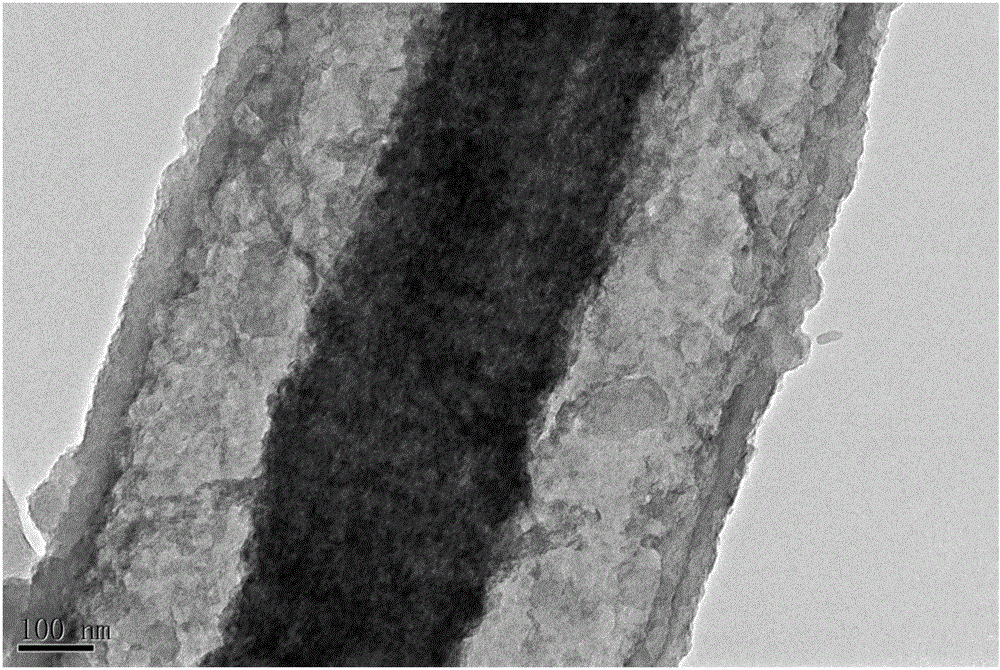

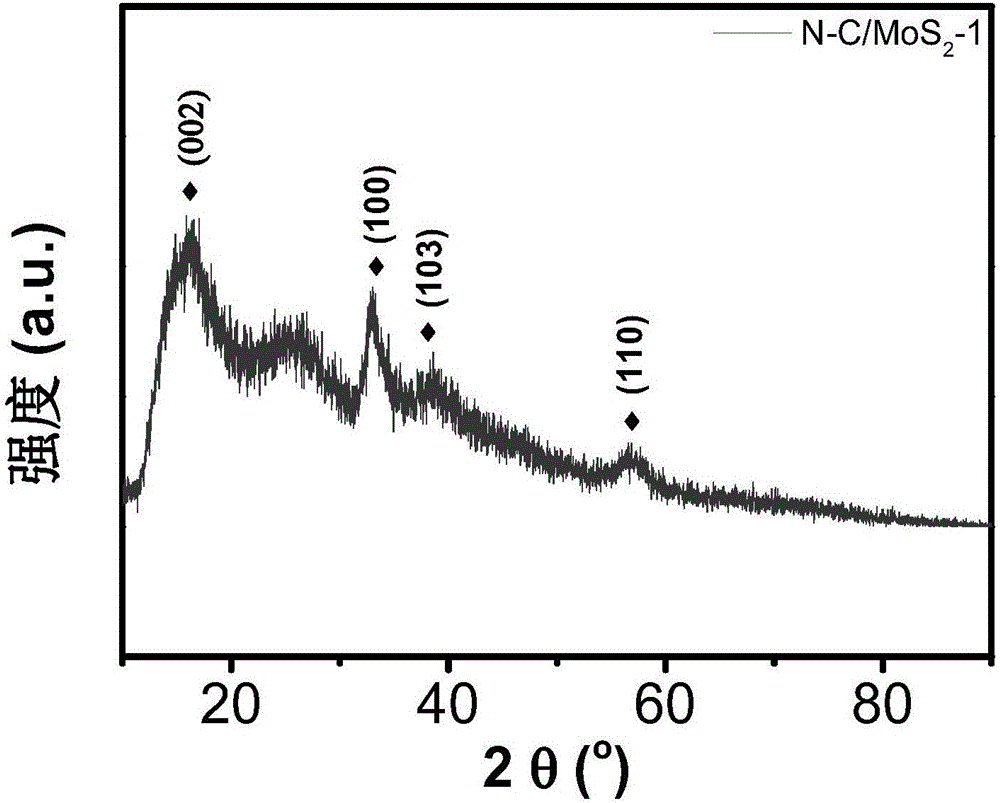

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

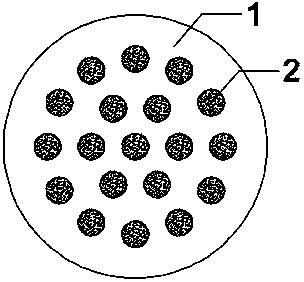

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

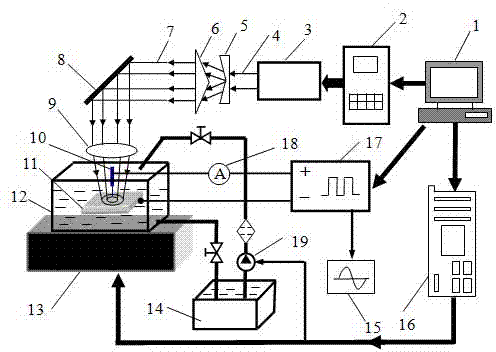

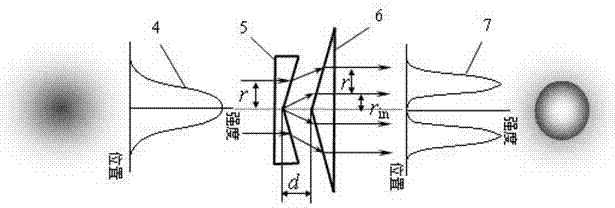

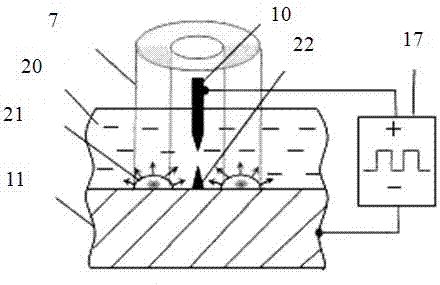

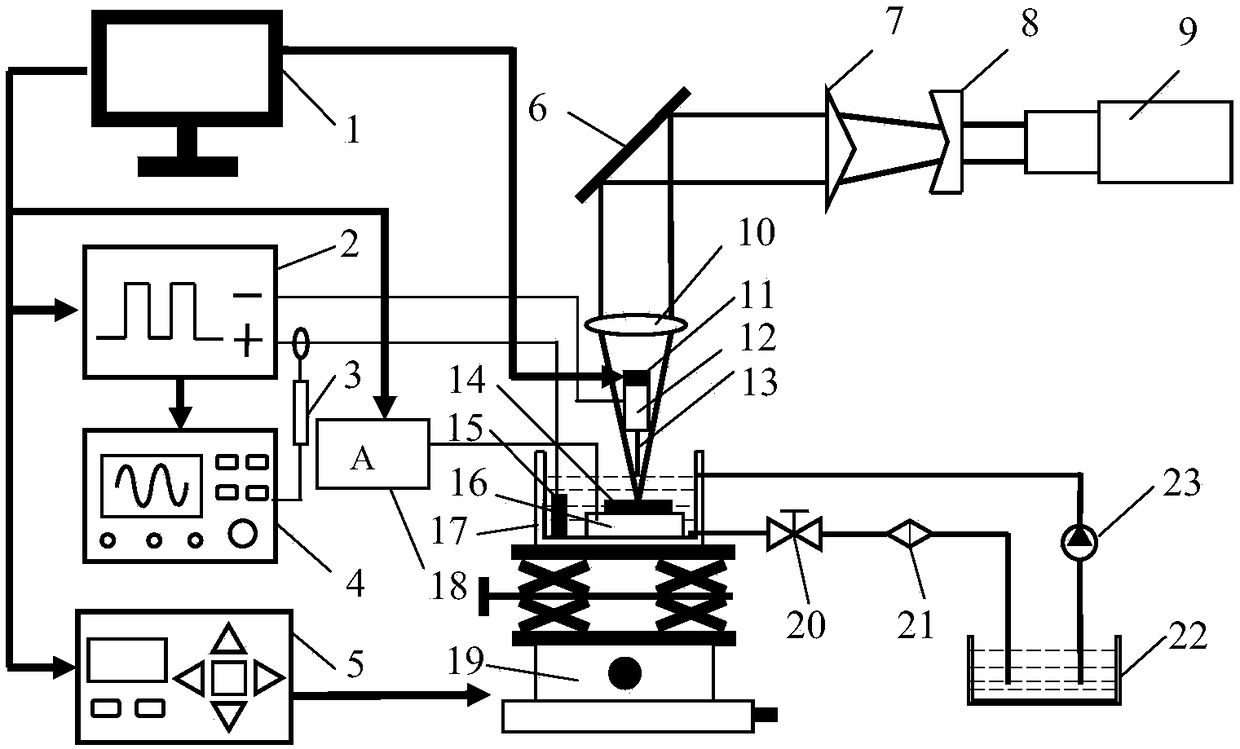

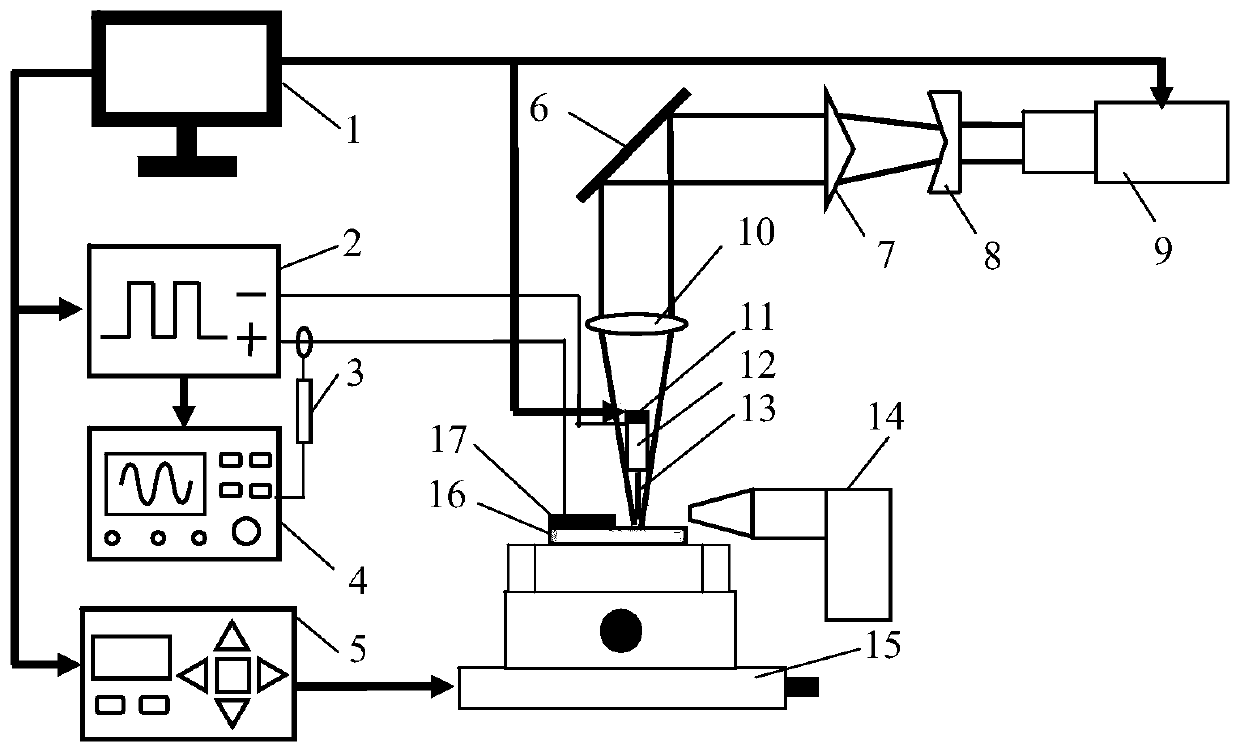

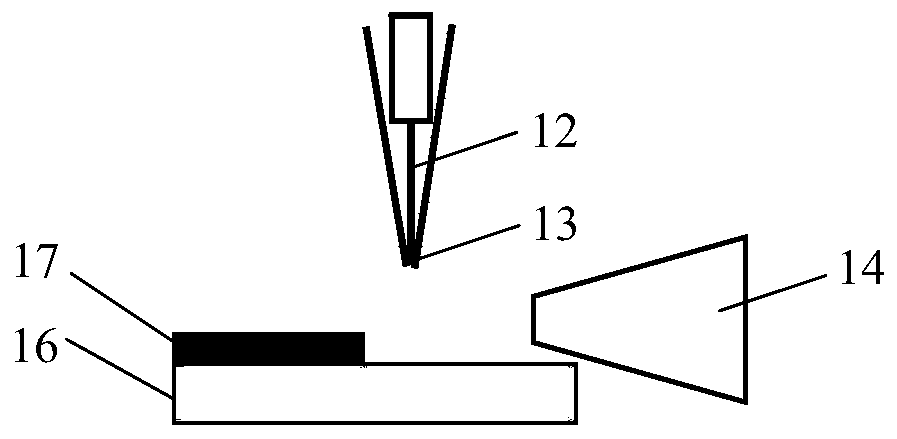

Electrochemical composite decomposition manufacturing method and device of laser light tube electrode

ActiveCN103572341ADoes not affect transmissionEfficient compositeCellsOptical elementsSolid lightDecomposition

The invention relates to an electrochemical composite decomposition manufacturing method and an electrochemical composite decomposition manufacturing device of a laser light tube electrode. Solid pulse laser is changed into an annular hollow laser beam with central light strength as zero by a light beam modulating system; compression shock is generated for electrochemical deposition in a non-solid light tube electrode by utilizing annular laser to irradiate expansion of plasma; decomposition stress is removed, a cathode reaction gas is exhausted, and material density is improved; moreover, the deposition reaction is only generated on the light beam with central laser energy as zero, so that the electrochemical composite deposition processing, repairing and surface performance strengthening which are high in quality and good in locality are realized. The electrochemical composite decomposition manufacturing method and the electrochemical composite decomposition manufacturing device disclosed by the invention are suitable for processing, repairing and surface performance strengthening of micro high-performance metal components, and belong to the field of micro quick forming and processing.

Owner:JIANGSU UNIV

Graphene/fiber fabric preparation method, graphene/fiber fabric and sensor

InactiveCN105951427AImprove mechanical propertiesEfficient compositePhysical treatmentLiquid/gas/vapor removalFiberRoom temperature

The invention relates to a graphene / fiber fabric preparation method, which is characterized by comprising the following steps of 1) immersing fiber fabric in a bovine serum albumin solution at a room temperature, drying the fiber fabric, and cleaning the fiber fabric by utilization of deionized water so as to obtain cationized fiber fabric; 2) immersing the cationized fiber fabric obtained in the step 1) into a graphene oxide solution, and drying to obtain graphene oxide / fiber fabric; 3) immersing the graphene oxide / fiber fabric obtained in the step 2) into a reducing agent, cleaning by utilization of the deionized water, and drying to obtain the graphene / fiber fabric. The preparation method provided by the invention has the advantages that the technology is simplified, the graphene / fiber fabric prepared according to the preparation method is well compounded with graphene, and the effects of stable resistance, high sensitivity, security and environmental friendliness are achieved.

Owner:SHENZHEN MICRO & NANO INTEGRATED CIRCUITS & SYST RES INST

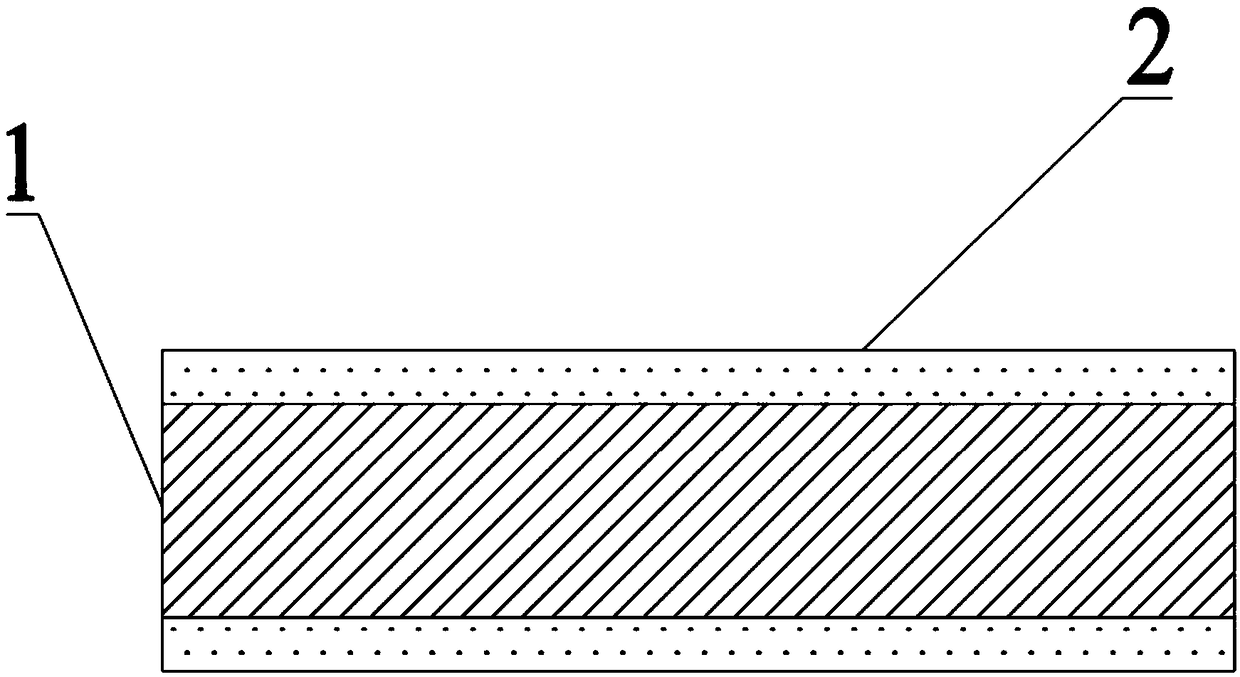

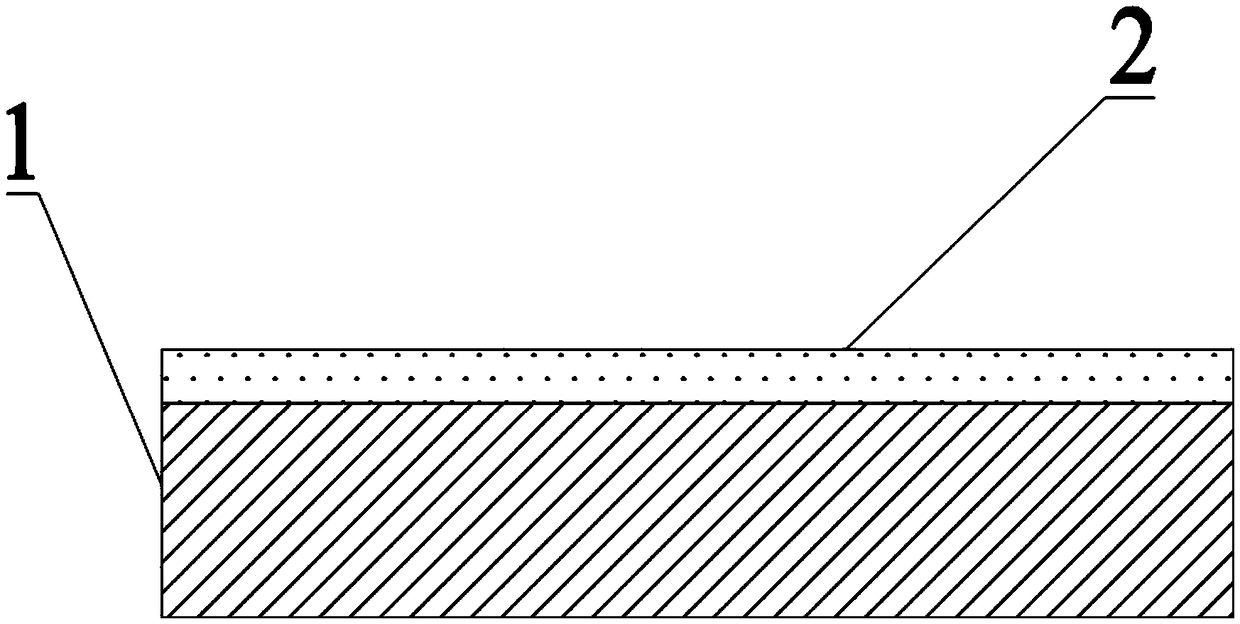

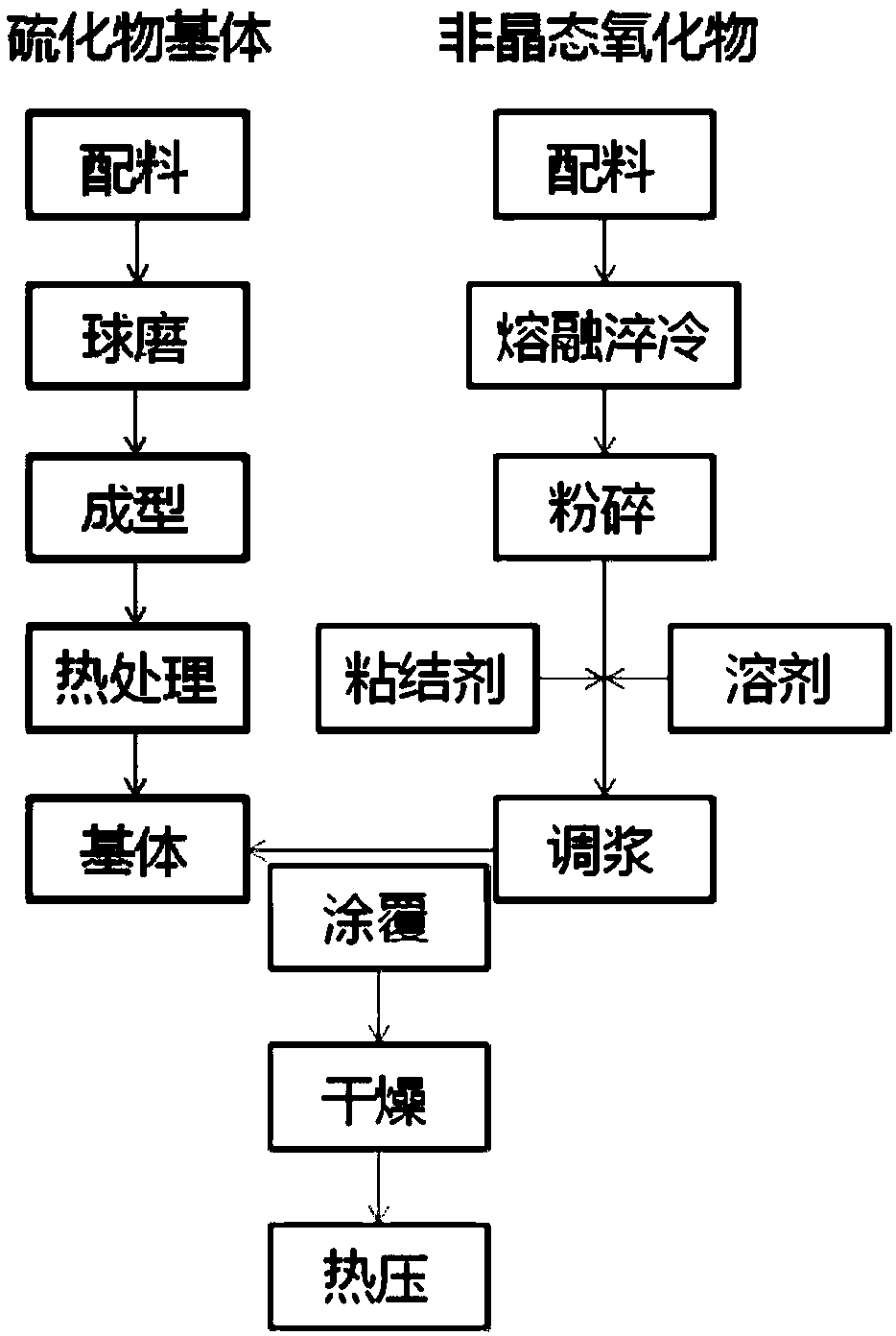

Composite solid electrolyte and preparation method thereof

PendingCN109509910APromote growthGrowth inhibitionSolid electrolytesSecondary cellsSolid state electrolyteSulfide

The invention discloses a composite solid electrolyte and a preparation method thereof. The composite solid electrolyte is at least prepared from a sulfide solid electrolyte layer and an amorphous oxide solid electrolyte layer. By adopting the composite solid electrolyte, the amorphous oxide solid electrode is compounded on the surface of the sulfide solid electrolyte layer, so that the interfaceproblem between the sulfide solid electrolyte and an electrode material is solved. Meanwhile, a hot-press molding manner is adopted to ensure a good compounding effect on an heterogeneous interface (oxide / sulfide interface).

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Method for preparing lithium ion battery positive electrode material

ActiveCN106784671AIncrease coverageImprove cycle performanceCell electrodesSecondary cellsSlurryGraphene

The invention discloses a method for preparing a lithium ion battery positive electrode material. The method comprises the following steps: preparing a monodisperse graphene solution with consistent flake diameter size and good dispersion in an ultrasonic oscillation manner; and transferring the graphene solution into a high-shear emulsifying homogenizer for performing shearing dispersion, and filling the sheared graphene solution and a positive active material into a zirconia ball milling tank together for performing ball milling and mixing. The graphene solution is mixed with the positive active material in a mechanical ball milling manner, so that the graphene can be inlaid into or coated with positive active material granules, an excellent bonding interface can be formed, and the positive active material granules are refined; and therefore, the material is uniform, and the rate capability and consistency of the material are improved. Finally, the positive slurry subjected to ball milling is dried, ground and screened so as to obtain the positive electrode material powder.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

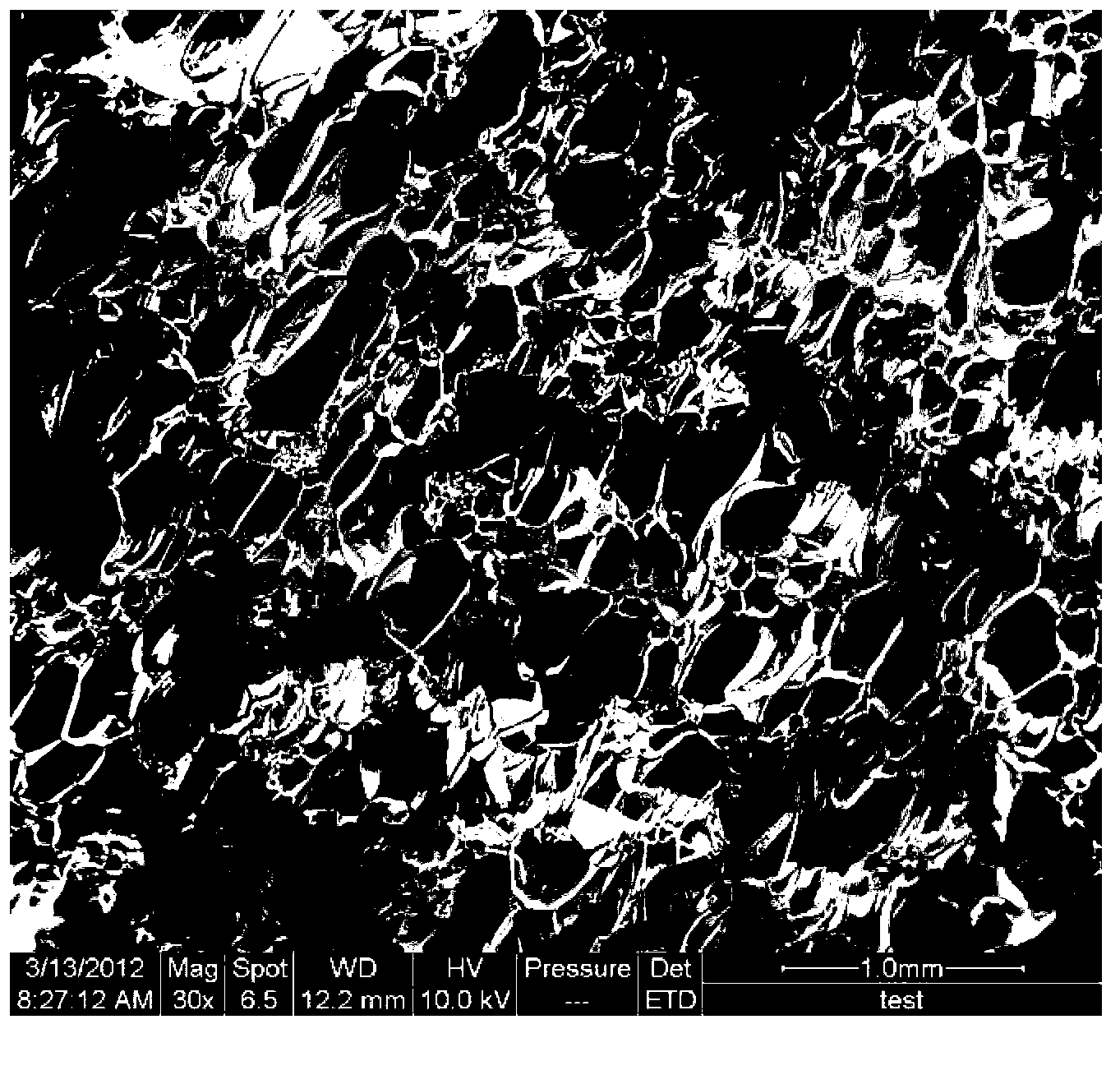

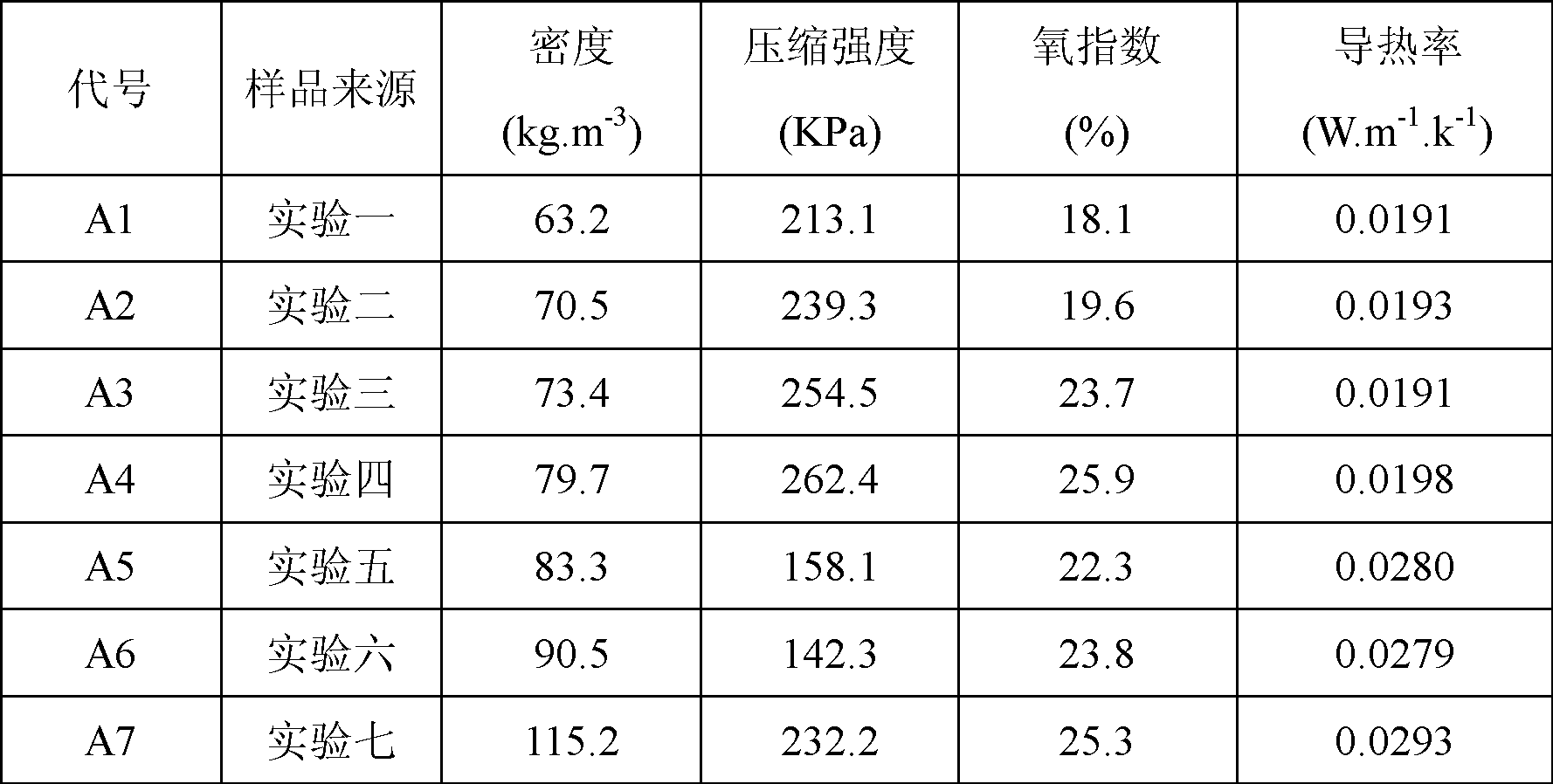

Glass bead polyurethane foam composite material and preparation method thereof

The invention discloses a glass bead polyurethane foam composite material and a preparation method thereof, relating to a composite material and a preparation method thereof. Through the invention, the technical problems that the existing thermal insulation material is high in cost and the flame retardance and heat retaining property are hard to improve synchronously are solved. The glass bead polyurethane foam composite material is prepared by mixing the pretreated glass bead, polyurethane white material, polyurethane black material and solid flame retardant and then performing microwave auxiliary heating, foaming compounding and curing. The method comprises the following steps of: (I) glass bead pretreatment; (II) weighing; (III) mixture preparation; (IV) microwave auxiliary heating and foaming compounding; and (V) curing. The glass bead polyurethane foam composite material disclosed by the invention has low density (90-120kg / m<2>), high strength (144-320KPa), high flame retardance (the limiting oxygen index can reach 34.7%), and lower cost (the raw material cost is reduced by about 37.5% in comparison with the flame-retardant hard polyurethane foam with the same density).

Owner:NORTHEAST FORESTRY UNIVERSITY +1

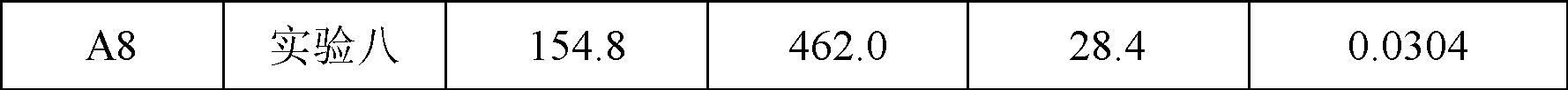

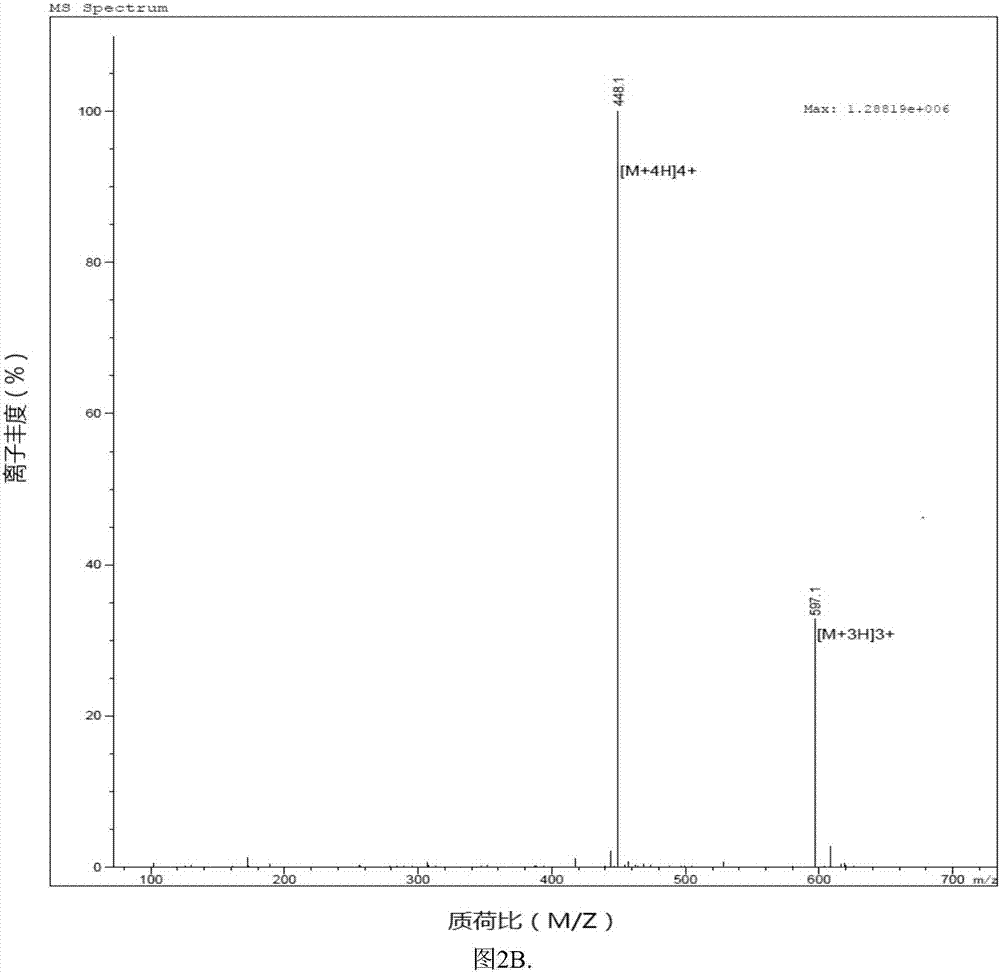

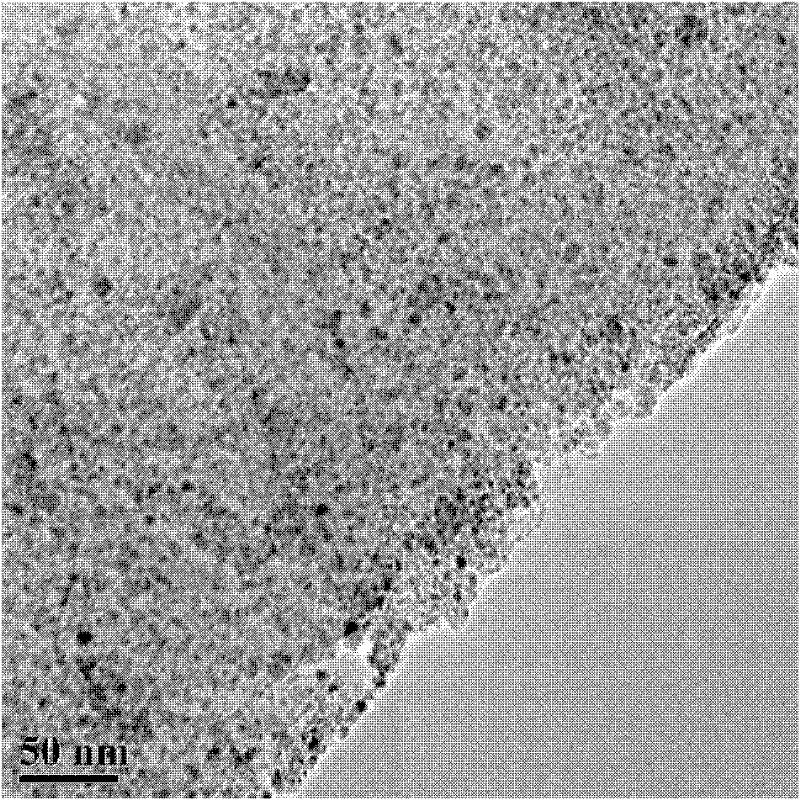

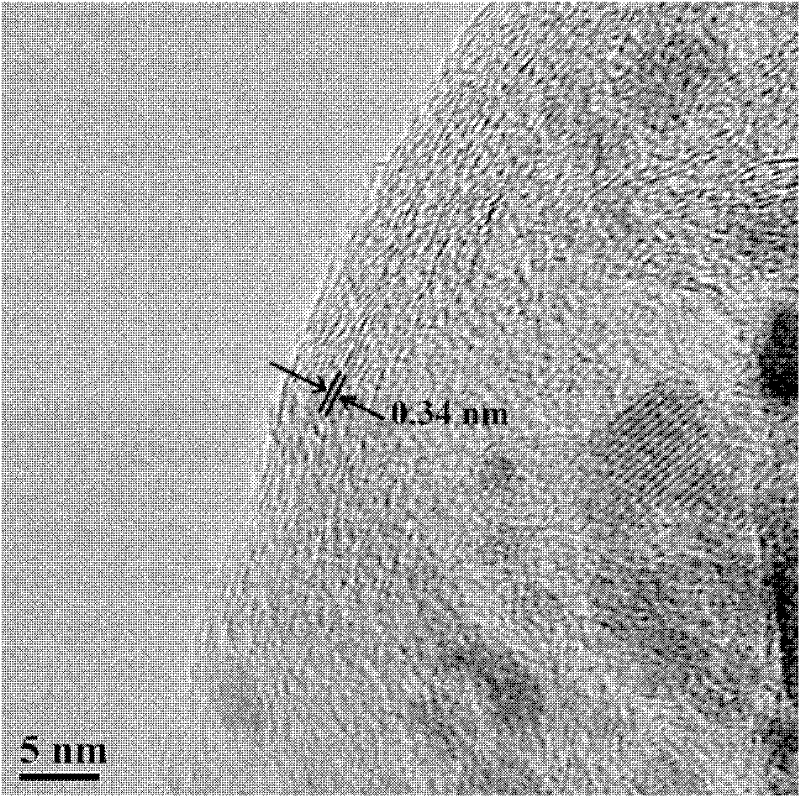

Antibacterial peptide derivate and application thereof

ActiveCN107446019ASmall molecular weightGood monodispersityAntibacterial agentsOrganic active ingredientsNucleic acid transportChemical synthesis

The invention belongs to the field of biological medicines, mainly relates to an antibacterial peptide derivate and the application thereof, in particular to a hydrophobic modified antibacterial peptide DP7 derivate and the application thereof. The hydrophobic modified antibacterial peptide is characterized in that a hydrophobic fragment is coupled to nitrogen terminal of the antibacterial peptide to realize the hydrophobic modification. The invention also provides a micelle which is prepared through the hydrophobic modified antibacterial peptide, and the application of the hydrophobic modified antibacterial peptide and the micelle in preparation of antibacterial medicines, preparation of a nucleic acid transporter and the preparation of an immunologic adjuvant. The antibacterial peptide is small in molecular weight and can be conveniently synthesized through an Fmoc solid-phase multi-peptide synthesis method; the hydrophobic fragment based chemical synthesizing coupling method is simple and easy to carry out.

Owner:SICHUAN UNIV

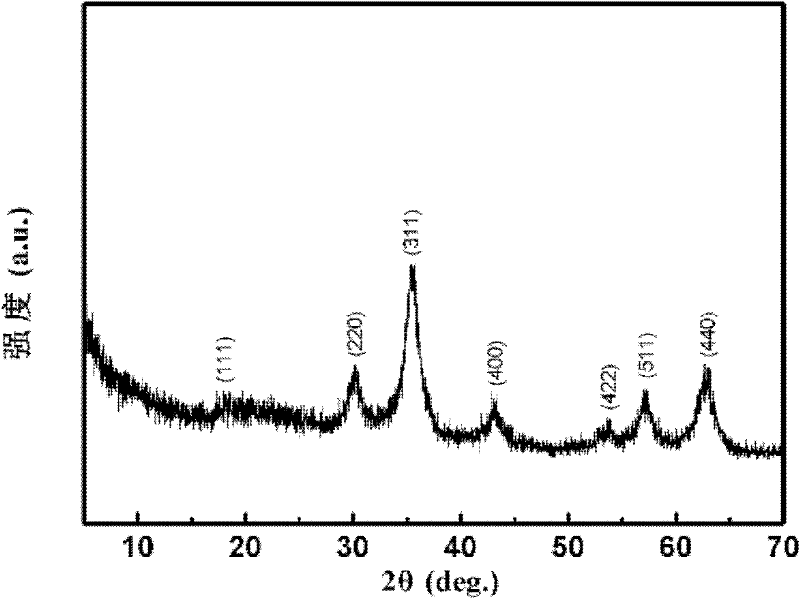

Preparation method of water-dispersible graphene/ferroferric oxide (Fe3O4) composite powder

InactiveCN102173411AEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesWater dispersibleFerrous salts

The invention relates to a preparation method of water-dispersible graphene / ferroferric oxide (Fe3O4) composite powder. The method comprises the following steps of: (1) ultrasonically dispersing graphite oxide and sodium polystyrene sulfonate into water at room temperature to form reaction liquid, raising a temperature to 90 to 110 DEG C, and reacting for 8 to 16 hours; (2) adding ferric salt and ferrous salt into the reaction liquid under the protection of nitrogen atmosphere at room temperature, adding ammonia water, reducing the temperature to 70 to 90 DEG C, reacting for 20 to 40 minutes, and then adding an oleic acid for continuous reaction; and (3) cooling to room temperature, collecting the graphene / Fe3O4 composite powder by using a magnet, washing and drying to obtain the finished product. The method is simple and easy for industrial production; Fe3O4 in the prepared composite powder has pure crystalline phase; the Fe3O4 is well combined with the graphene; the Fe3O4 has good dispersibility on a surface of the graphene and in a layer of the graphene; the composite powder is low in resistivity, high in magnetic intensity and good in underwater dispersibility and has a good application prospect.

Owner:DONGHUA UNIV

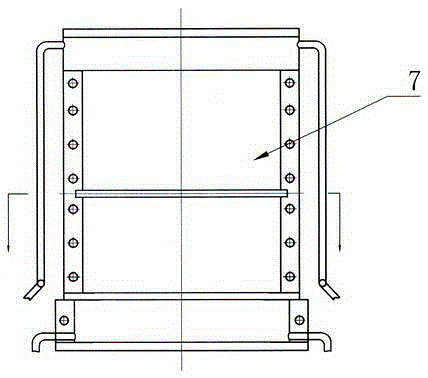

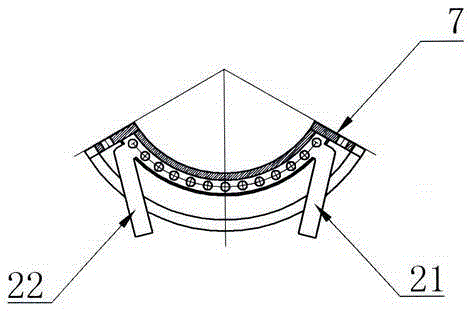

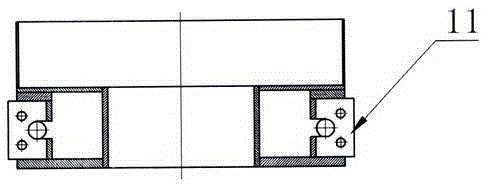

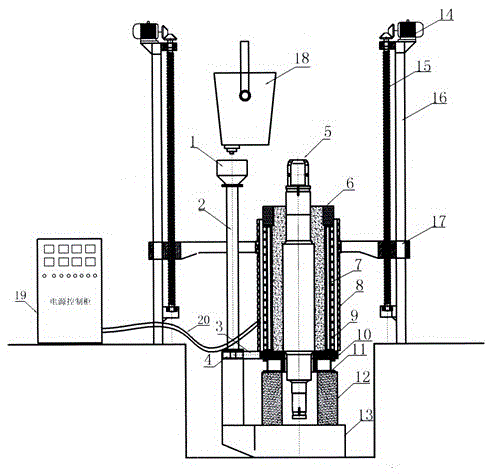

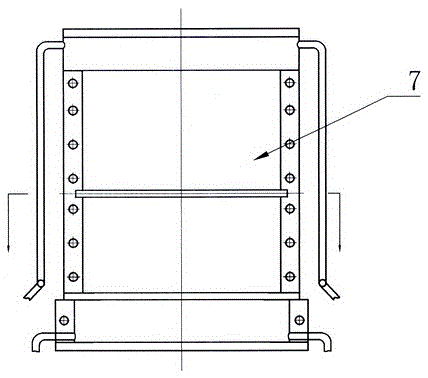

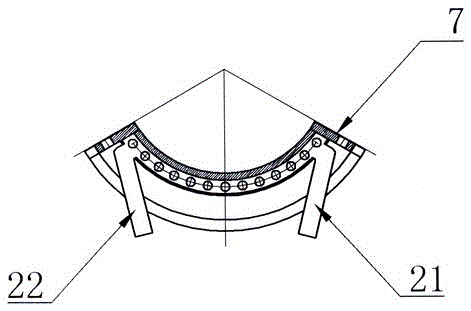

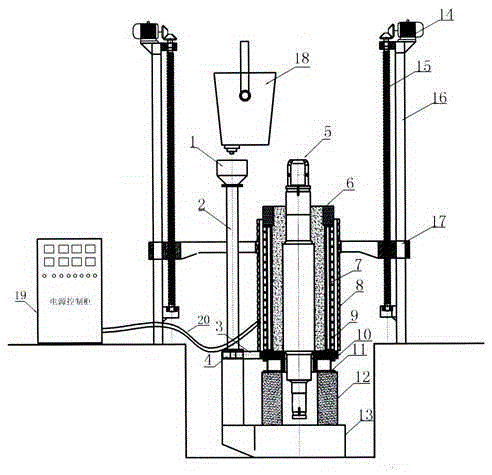

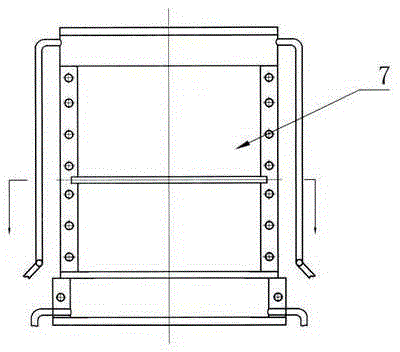

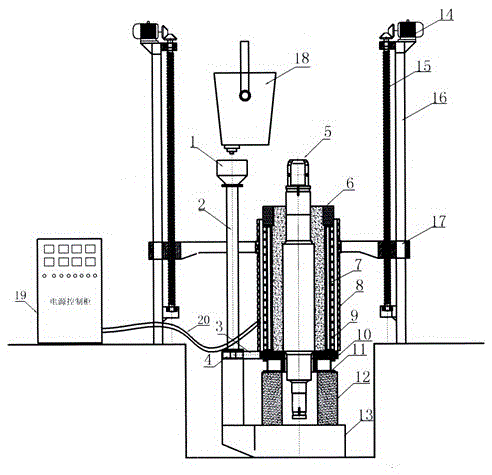

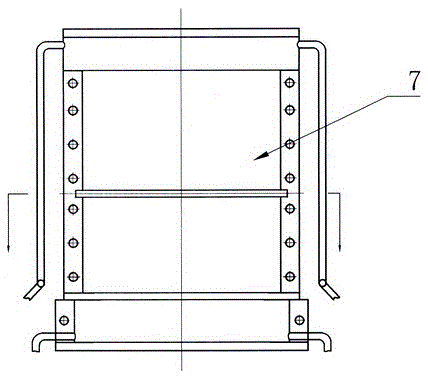

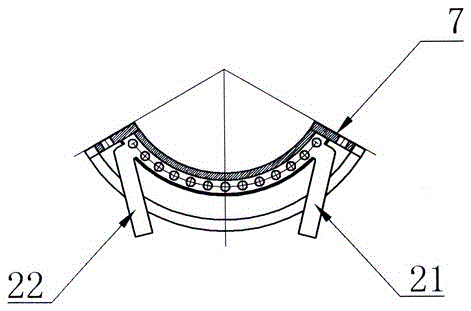

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

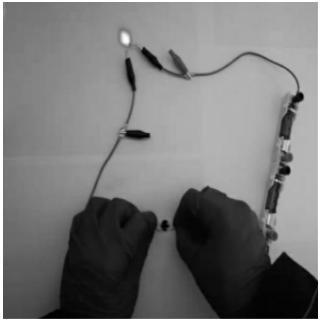

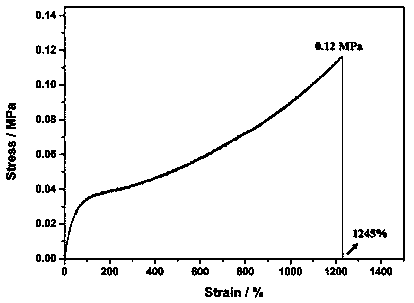

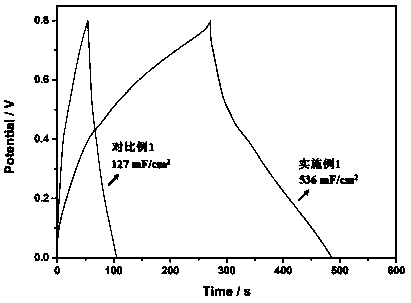

Preparation method of high-stretchability polyaniline-based flexible electrically conductive hydrogel

ActiveCN110157013AEfficient compositeImprove mechanical propertiesFreeze thawingIn situ polymerization

The invention belongs to the field of flexible electronic material, and more specifically relates to a preparation method of a high-stretchability polyaniline-based flexible electrically conductive hydrogel. The preparation method comprises following steps: firstly, acrylamide and acrylic acid at an appropriate neutralization degree are taken as monomers, ammonium persulfate and N, N'-methylene-bisacrylamide are added, and synthesis of poly(acrylamide-co-sodium acrylate)copolymer hydrogel (ASH) is carried out; then swelling-freeze thawing processing is adopted to prepare porous ASH, aniline monomer immersion is carried out, and in-situ polymerization is carried out to obtain a finished product. The flexible electrically conductive hydrogel preparation process is simple; operation is convenient; aniline permeability problem is solved without introducing any template into hydrogel medium; hydrogel pH responsiveness is capable of improving product electrochemical performance greatly; theobtained flexible electrically conductive hydrogel possesses excellent electric conductivity and electrochemical performance, and excellent stretchability, and can be widely used in manufacturing of wearable flexible electronic devices.

Owner:FUZHOU UNIV

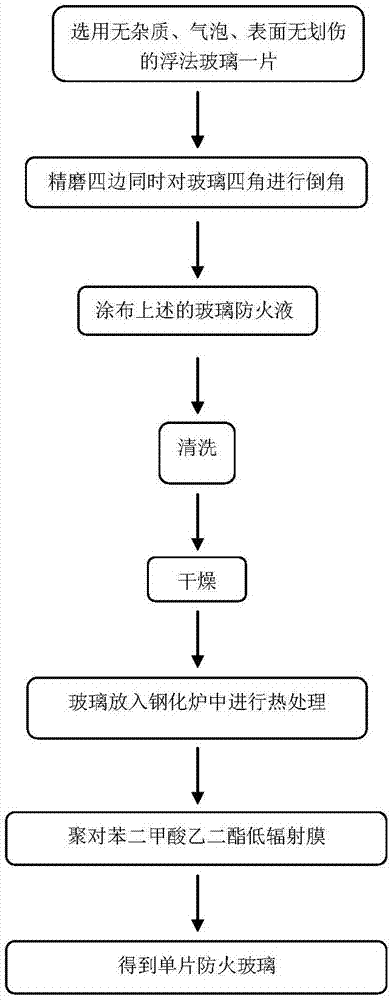

Glass fireproof liquid and application thereof

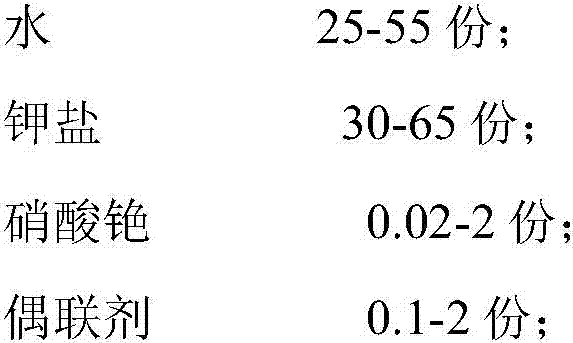

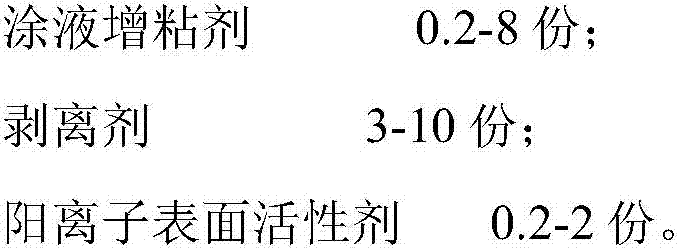

InactiveCN107954610AImprove fitImprove fire performanceSynthetic resin layered productsGlass/slag layered productsNitrateSURFACTANT BLEND

The invention discloses a glass fireproof liquid. The glass fireproof liquid comprises the following components in parts by weight: 25-55 parts of water, 30-65 parts of a potassium salt, 0.02-2 partsof cesium nitrate, 0.1-2 parts of a coupling agent, 0.2-8 parts of a masking liquid tackifier, 3-10 parts of a stripping agent and 0.2-2 parts of a cationic surfactant. The glass fireproof liquid hasgood anti-release, anti-aging and fireproof performance.

Owner:北京华城耀强玻璃科技有限公司

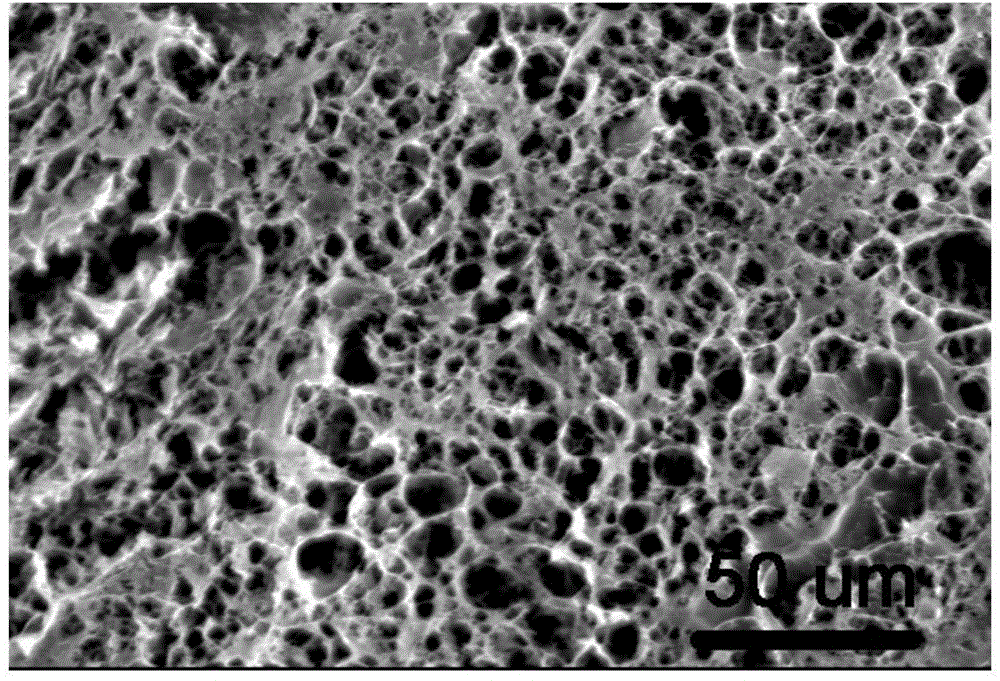

Cellulose-based composite material with three-dimensional porous structure and preparation method of cellulose-based composite material

The invention relates to a cellulose-based composite material with a three-dimensional porous structure. The cellulose-based composite material comprises the following components in percentage by mass: 0.01-99.99% of graphene oxide and 0.01-99.99% of cellulose, wherein an oxygen-containing group in the graphene oxide and hydroxyl in cellulose form a hydrogen bond, and the cellulose is natural or regenerated cellulose with molecular weight smaller than or equal to 4*10<5>. The invention further relates to a preparation method of the cellulose-based composite material with the three-dimensional porous structure. The cellulose-based composite material with the three-dimensional porous structure disclosed by the invention has the advantages of graphene oxide and cellulose, is adjustable in structural performance and wide in application. The preparation method of the cellulose-based composite material has the advantages of cheap and rich raw materials, a simple process and easy industrialization.

Owner:BOZHOU TEACHERS COLLEGE

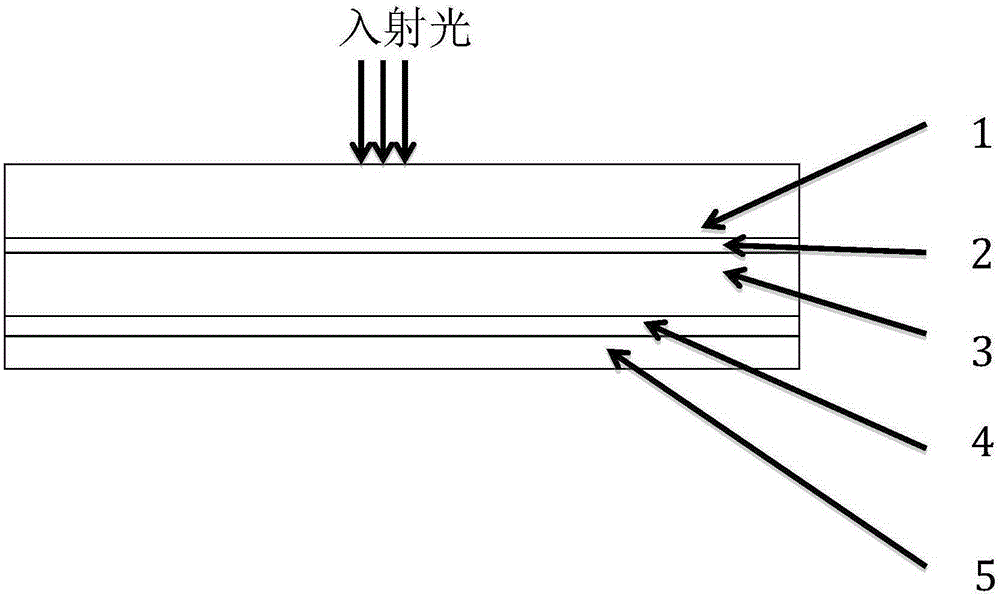

Thin film crystalline silicon perovskite heterojunction solar battery and preparation method thereof

ActiveCN105226187AOvercome the disadvantage of low light absorption coefficientReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionHole transport layer

The invention relates to a thin film crystalline silicon perovskite heterojunction solar battery and a preparation method thereof, and relates to a semiconductor device for converting luminous energy into electric energy. The thin film crystalline silicon perovskite heterojunction solar battery includes a transparent conductive substrate, a P-type thin film crystalline silicon hole transport layer, a perovskite light absorption layer, an electron transport layer formed by compact titanium dioxide, and a back electrode, wherein the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer have matched energy levels. The configuration pattern: the P-type thin film crystalline silicon hole transport layer is arranged on the transparent conductive substrate; the perovskite light absorption layer is arranged on the P-type thin film crystalline silicon hole transport layer; the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer form a thin film crystalline silicon perovskite heterojunction; the electron transport layer formed by the compact titanium dioxide is arranged on the perovskite light absorption layer; the back electrode is arranged on the electron transport layer formed by the compact titanium dioxide. According to the invention, the defects that the existing perovskite solar battery is low in stability and high in preparation cost, and a mass of silicon materials are used can be overcame.

Owner:HEBEI UNIV OF TECH

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

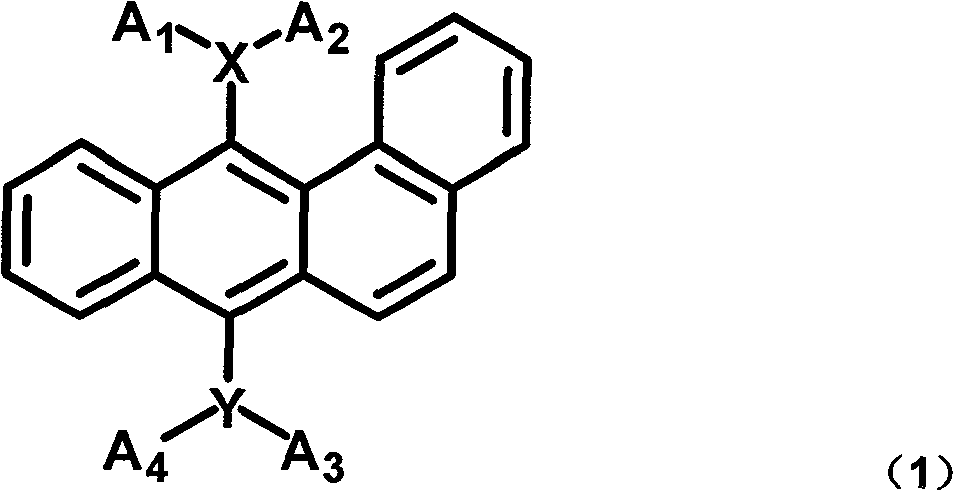

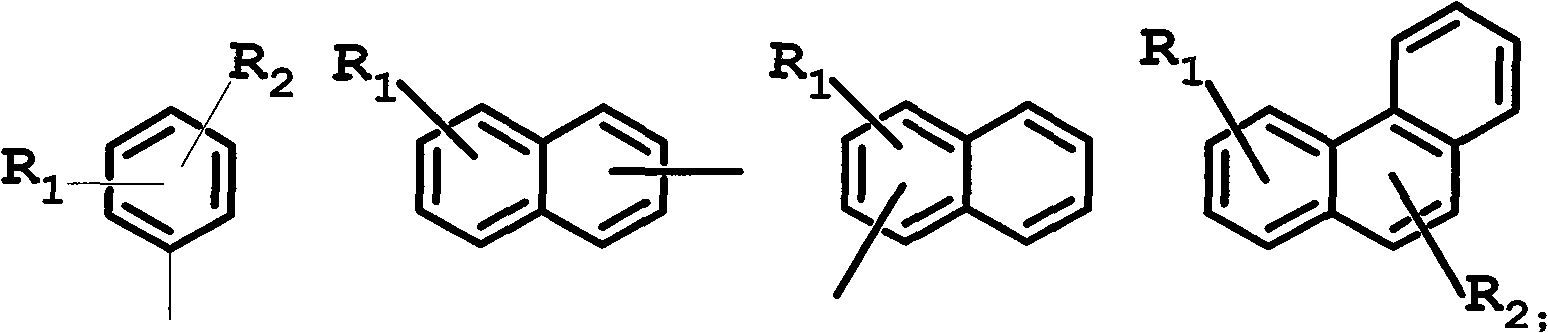

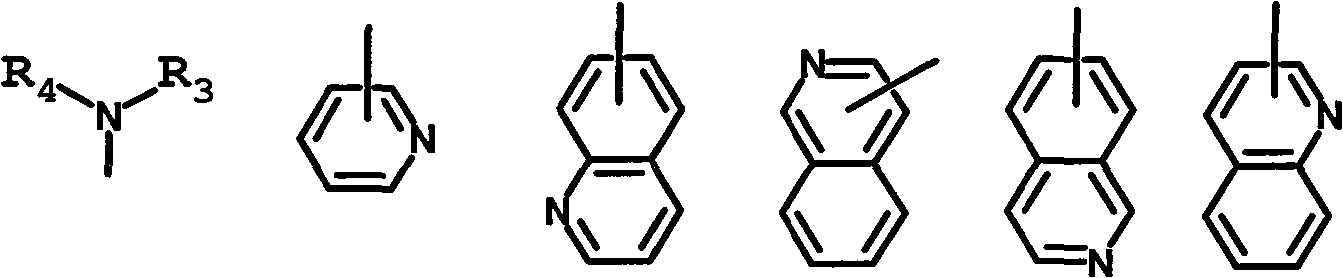

Organic electroluminescence device

InactiveCN101540375AIncrease brightnessImprove efficiencyOrganic chemistrySolid-state devicesHydrogenHydrogen atom

The invention relates to an organic electroluminescence device with the new structure, which comprises a first electrode, a second electrode, an organic layer positioned between the two electrodes and comprising a luminous layer. The device is characterized in that the luminous layer at least comprises a benzanthracene derivative selected from the general expression such as right; wherein X and Y are separately selected from cyclization aromatic groups of four to twenty atomic carbon atoms or replaced cyclization aromatic groups of four to twenty atomic carbon atoms; A1, A2, A3 and A4 are separately selected from hydrogen atoms, ethylene, aromatic amino, carbazyl or aromatic heterocyclic radical and are selected from the hydrogen atoms at different times. The device uses the benzanthracene derivative as luminescent dye, thus being capable of obtaining devices with high brightness, high efficiency and excellent emitting colors.

Owner:TSINGHUA UNIV +2

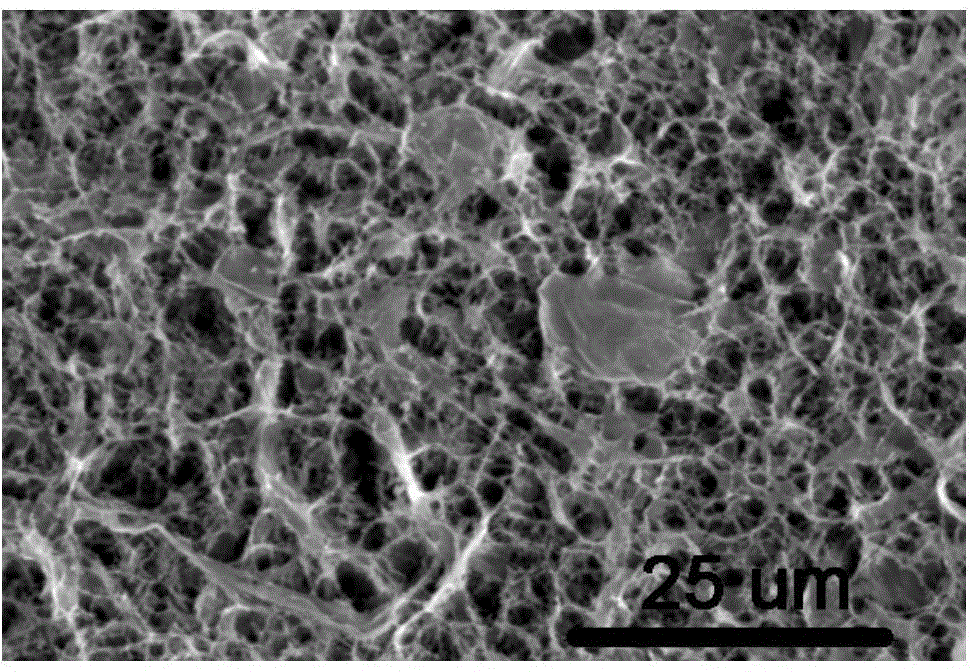

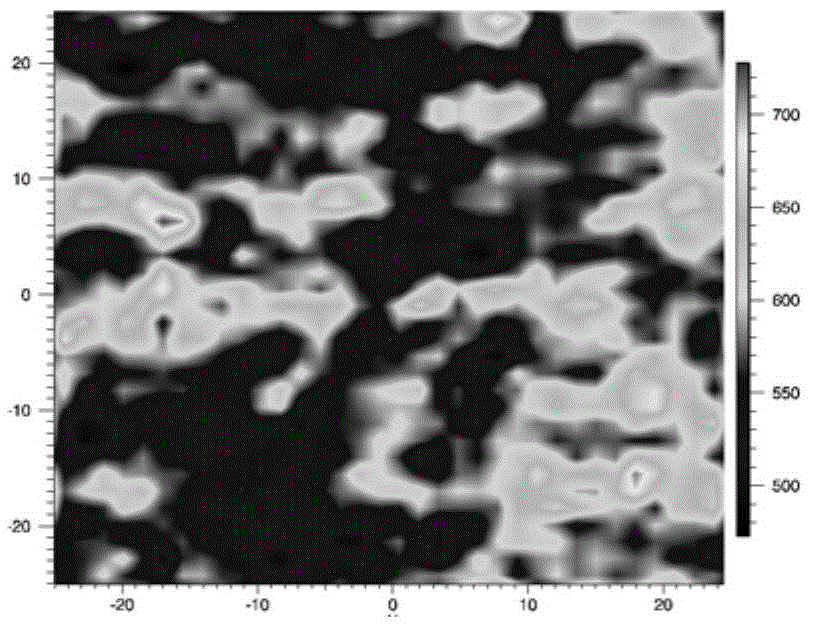

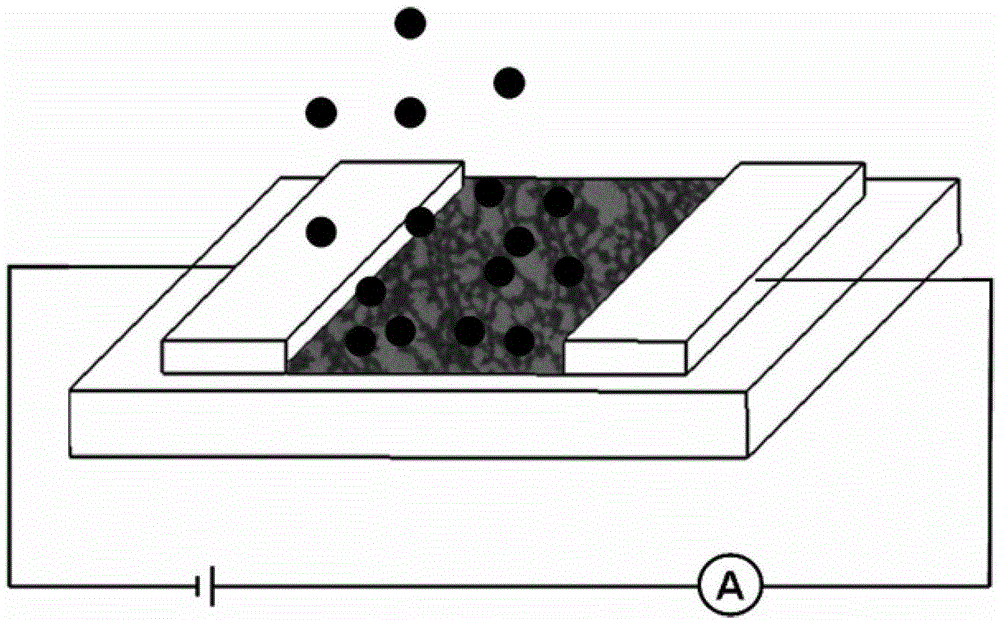

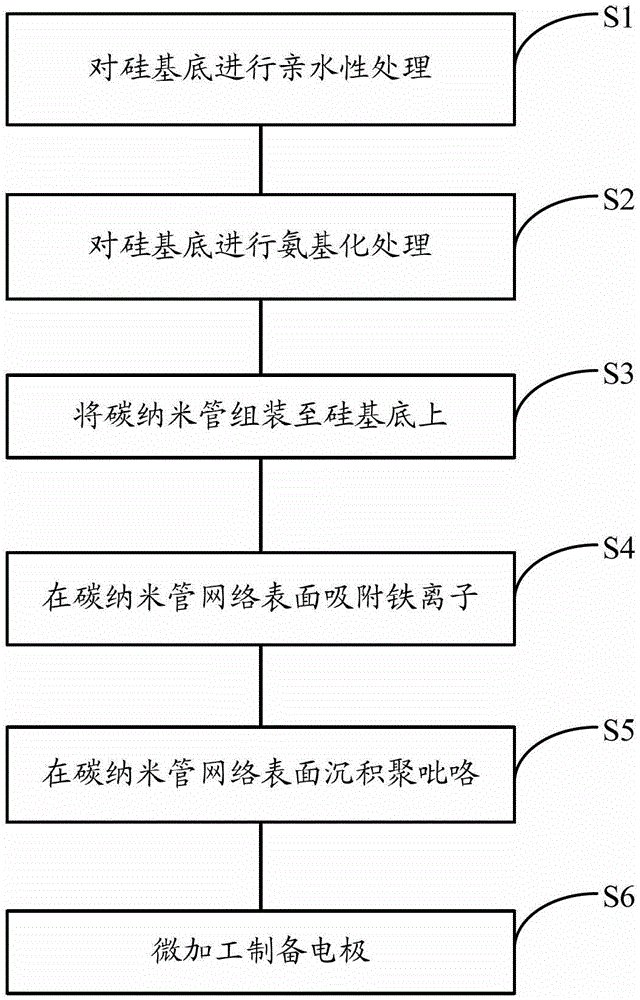

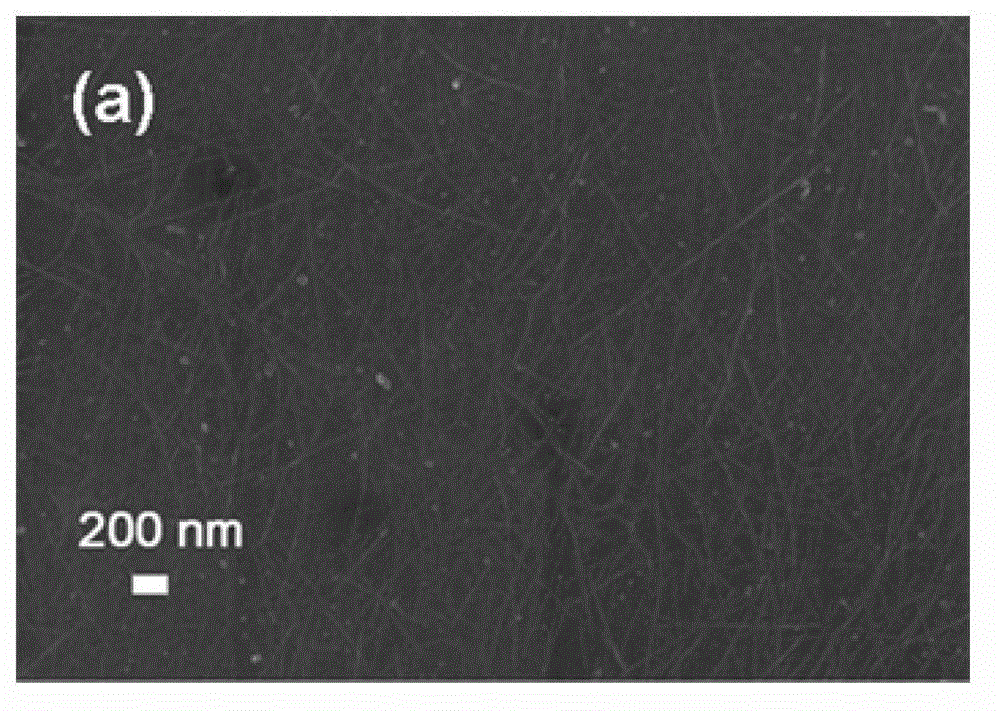

Preparation method of gas sensitive sensor based on carbon nano tube-polypyrrole complex network structure

InactiveCN103336032AEvenly distributedEfficient compositeMaterial analysis by electric/magnetic meansPolypyrroleCarbon nanotube

The invention discloses a preparation method of a gas sensitive sensor based on a carbon nano tube-polypyrrole complex network structure. The preparation method comprises the following steps of: carrying out hydrophilic treatment on a silicon base; carrying out amination treatment on the silicon base; assembling a carbon nano tube on the silicon base; adsorbing iron ions on the surface of a carbon nano tube network; depositing polypyrrole on the surface of the carbon nano tube network; and micromachining to prepare an electrode. The gas sensitive sensor based on the carbon nano tube-polypyrrole complex network structure obtained by the preparation method disclosed by the invention realizes the purpose that an ammonia response performance is greatly improved; the preparation method is simple in process and is suitable for large-scale preparation of the sensors.

Owner:SUZHOU UNIV

Machining device and method for synchronizing piezoelectric ceramic vibration and electrochemistry discharging

InactiveCN108655521AEasy to throwEasy to updateLaser beam welding apparatusElectrical-based auxillary apparatusElectricityPower flow

The invention provides a machining device and method for synchronizing piezoelectric ceramic vibration and electrochemistry discharging and belongs to the field of special composite machining. When anelectrochemistry power source outputs pulse currents, a piezoelectric ceramic power source outputs forward voltage excitation signals synchronously, piezoelectric ceramic is bent upwards, and a gap between a workpiece and a tool electrode becomes smaller; during pulse intermittence of the electrochemistry power source, when no glass workpiece is subjected to discharging machining, the piezoelectric ceramic power source outputs negative voltage excitation signals, the piezoelectric ceramic is bent downwards, and the gap between the workpiece and the tool electrode becomes large. The electrochemistry power source and the piezoelectric ceramic power source carry out discharging synchronously to enable the machining gap during the discharging stage to be reduced, the utilization efficiency ofthe discharging energy is improved, and the machining locality is enhanced; and during discharging stop intermittence, the machining gap becomes large, which is beneficial for throwing out corrosiveimpurities and updating electrolyte.

Owner:JIANGSU UNIV

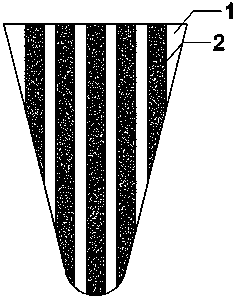

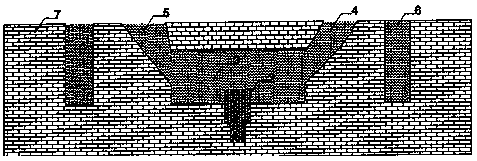

Ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and manufacturing method thereof

ActiveCN108380850AFacilitate compounding processEfficient feedingBallastwayTransportation and packagingManufacturing technologyWear resistant

The invention discloses a ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and a manufacturing method of the ceramic particle multi-scale reinforced metalbase composite wear-resistant raking tooth head, and belongs to the field of part manufacturing. According to the manufacturing method, ceramic particles and alloy powder are compacted and sintered tomanufacture rod-shaped composite materials, the rod-shaped composite materials are embedded into a metal base through the combination of the powder metallurgy technology and the embedment casting technology, and the purpose that the metal base covers the uniformly-distributed rod-shaped composite materials is achieved. The ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head solves the problems that an ordinary raking tooth is prone to being worn, and a homogeneous composite wear-resistant part is poor in toughness, brittle and low in impact resistance. Compared with overall metallurgical sintering, the manufacturing method has the advantages that by means of the technology of combination of powder metallurgy and embedment casting, the dimensionalaccuracy of parts is guaranteed, the requirements of specific parts for using performance are met, the assembling working procedure is omitted, the manufacturing technology is simplified to a certainextent, the part manufacturing cost is greatly reduced, the organization is compact, the metallurgical bonding is good, and the ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head can be applied to cleaning and screening vehicles for railway maintenance and parts of raking teeth of scraper loaders.

Owner:KUNMING UNIV OF SCI & TECH

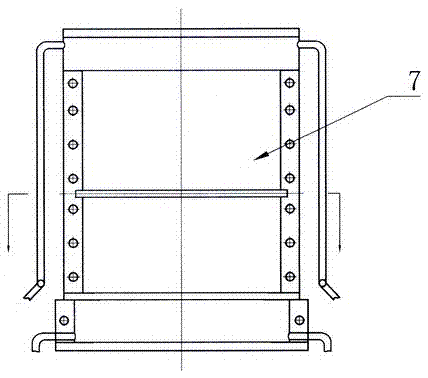

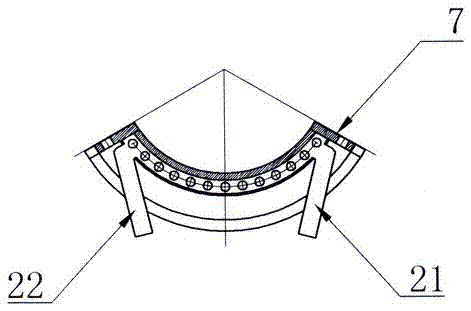

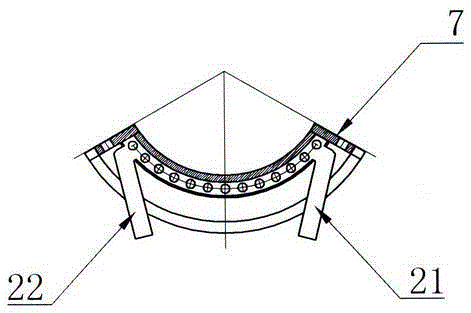

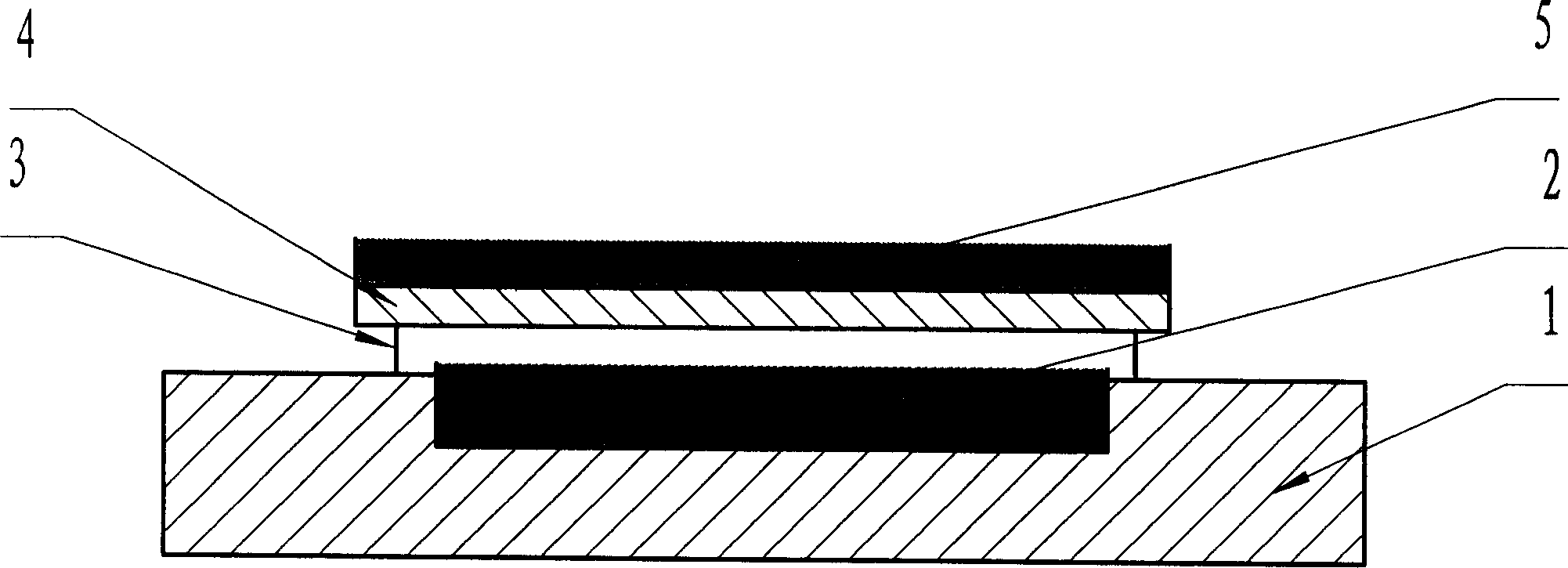

Manufacturing technique and equipment for high-performance composite roller shaft

The invention discloses a manufacturing technique and equipment for a high-performance composite roller shaft. The manufacturing technique comprises the steps that a mandril installed in a combined water-cooling crystallizer is integrally heated to 840-1100 DEG C through an induction heater; molten liquid of a working layer of the roller shaft is poured into the mandril, and then the mandril is continued to be heated for 10-50 minutes; a lifting device is stared so as to lift the heater at a certain speed for 5-15 minutes, and the heater is stopped in the position of a heat-insulating ring; and heating is continued for 10-50 minutes, feeding is conducted on a dead head, and after heating is stopped, cooling is conducted for 30 minutes to 24 hours through water. When the composite roller shaft is manufactured through the manufacturing technique, the number of controllable technological parameters is small, the interface of a composite layer is easy to control, the technique is simple, the efficiency is high, the power consumption is low, the cost is low, the composite layer is free of composition segregation, and the service life of the roller shaft is long; the defect of a centrifugation method that structure segregation is prone to occurring is overcome, and the problems of a CPC method and an ESR method that the production technique is complex, and the cost is high are solved.

Owner:丹阳恒庆复合材料科技有限公司

Preparation method of biological ink material for 3D printing

InactiveCN107744602AGood biocompatibilityGood hemostatic effectAdditive manufacturing apparatusSurgical adhesivesCross-linkBiocompatibility Testing

The invention discloses a preparation method of a biological ink material for 3D printing. The preparation method mainly comprises preparing modified sodium alginate, and preparing a biological ink material. According to the present invention, the materials used by the preparation method comprise active cells, a cell culture medium, a photoinitiator, modified sodium alginate and antioxidant enzyme; sodium alginate is modified through light curing, such that the modified sodium alginate can retain the original good biocompatibility and the original good hemostasis of the sodium alginate, and can further has double cross-linking property due to the linking of the light-curable group to the molecule chain of the sodium alginate, such that the rapid curing molding can be achieved; the biological material has good biocompatibility with active cells so as to achieve active printing; and the hydrogel formed through the curing molding of the biological ink material has advantages of good mechanical property, healing promoting, bleeding stopping and good biocompatibility.

Owner:GUANGDONG TAIBAO MEDICAL DEVICE TECH RES INST CO LTD

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Explosion cladding process of steel bond hard alloy and carbon steel

InactiveCN1789494AEfficient compositeImprove wear resistanceMetallic material coating processesShock waveHigh intensity

The invention relates material composite technology. The explosion cladding technology of steel bonded alloy and carbon steel is synthesized by steel bonded alloy powder and carbon steel base body, comprising the following steps: using the shock wave caused by explosion to form the alloy powder, then using the liquid phase sintering to make the powder and carbon steel compound, finally carrying out heat treatment to get the complex of steel bonded alloy and carbon steel. The explosion cladding technology makes the steel bonded alloy and carbon steel well combine. So the complex possesses the high intensity, abrasive resistance and tenacity, overcomes the problem that it is difficult to synthesize compound the steel bonded alloy and carbon steel, and can take place the complex of tool steel and carbon steel.

Owner:HENAN UNIV OF SCI & TECH

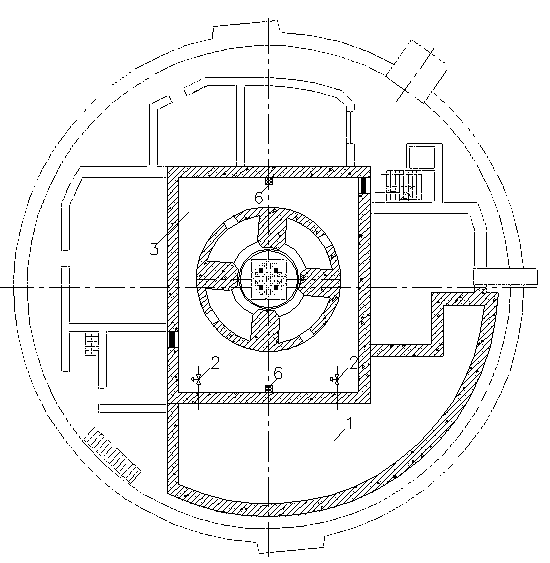

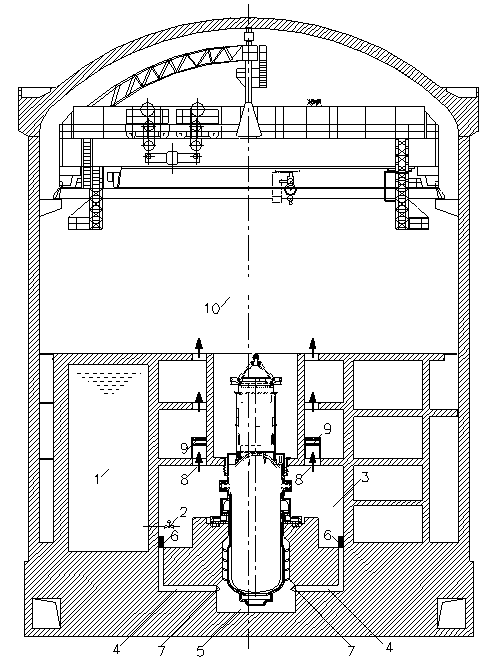

Integral reactor passive reactor cavity runner system and application method thereof

ActiveCN103390436ARelieve pressureReduce hydrogen concentrationNuclear energy generationEmergency protection arrangementsReactor pressure vesselPressure vessel

The invention discloses an integral reactor passive reactor cavity runner system and an application method thereof. The integral reactor passive reactor cavity runner system comprises a reactor cavity and a reactor pit as well as an annular main shield wall positioned between the reactor cavity and the reactor pit, wherein the reactor pit is formed below the main shield wall, and the reactor cavity is positioned above the main shield wall; the reactor cavity and the reactor pit are communicated through an L-type runner; one end, close to a reactor pit, of the runner is provided with a wind shield, and the top of the reactor cavity is provided with two gas releasing holes. The integral reactor passive reactor cavity runner system and the application method thereof provided by the invention have the advantages that a passive reactor cavity runner structure can submerge the reactor cavity and the reactor pit of an integral reactor in a passive manner, cool a reactor pressure vessel, maintain the integrity of the reactor pressure vessel, prevent the reactor pressure vessel from being melted out through a reactor core melt, provide the injection flow for cooling a reactor core of the reactor for a long time, and prevent risks of the overpressure and hydrogen gathering explosive of the reactor cavity of the integral reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Aramid fiber surface modification method

InactiveCN105568672AGood mechanical propertiesEfficient compositeFibre typesUltrasonic/sonic fibre treatmentAlcoholSilanes

The invention relates to the technical field of aramid fiber surface modification, in particular to an aramid fiber surface modification method. The aramid fiber surface modification method comprises the following steps that 1, surface treatment is performed on aramid fibers to be modified through ultrasonic waves; 2, the aramid fibers treated through the step 1 are dried; 3, the aramid fibers treated through the step 2 are placed in a hydrogen peroxide solution to be soaked; 4, the aramid fibers treated through the step 3 are placed in a buffer solution in which a compound with an o-hydroxy group is dissolved to be soaked; 5, the aramid fibers treated through the step 4 are washed and then dried; 6, the aramid fibers treated through the step 5 are placed in a solution prepared from ethyl alcohol and silane to be soaked; 7, the aramid fibers treated through the step 6 are treated through drip washing and then dried. The aramid fibers modified through the method are high in tensile strength and compositing viscosity with rubber.

Owner:NINGBO UNIV

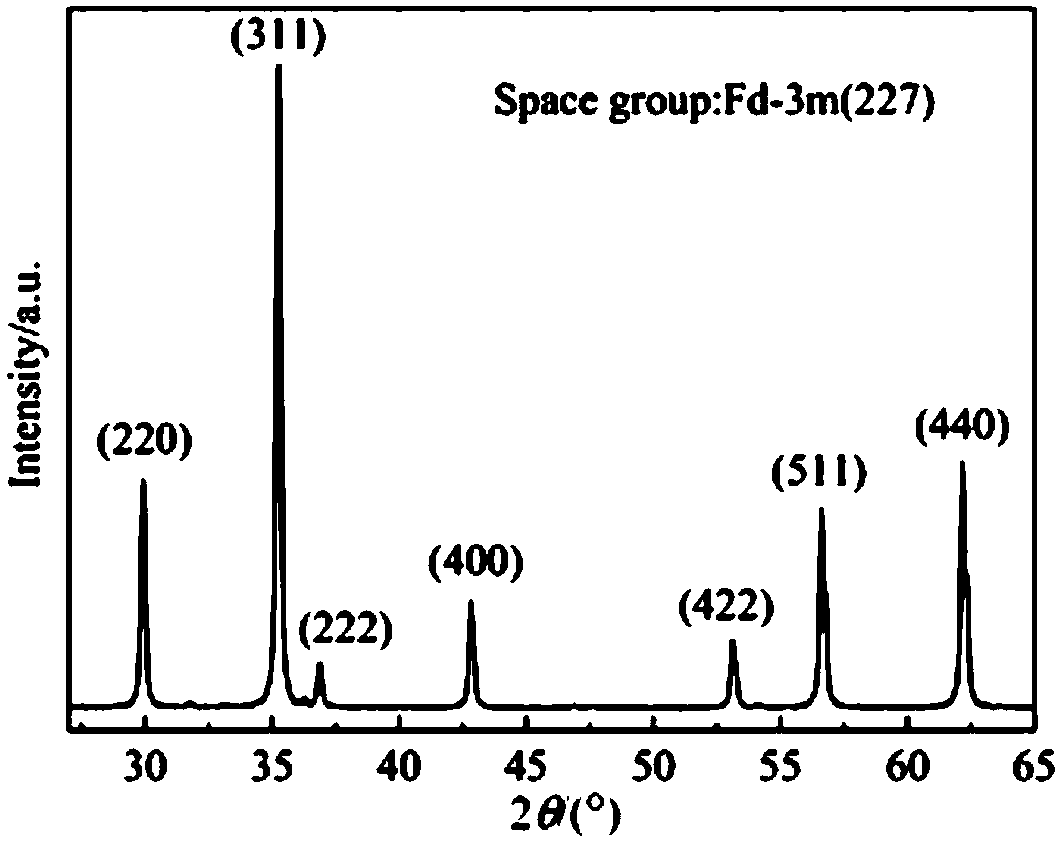

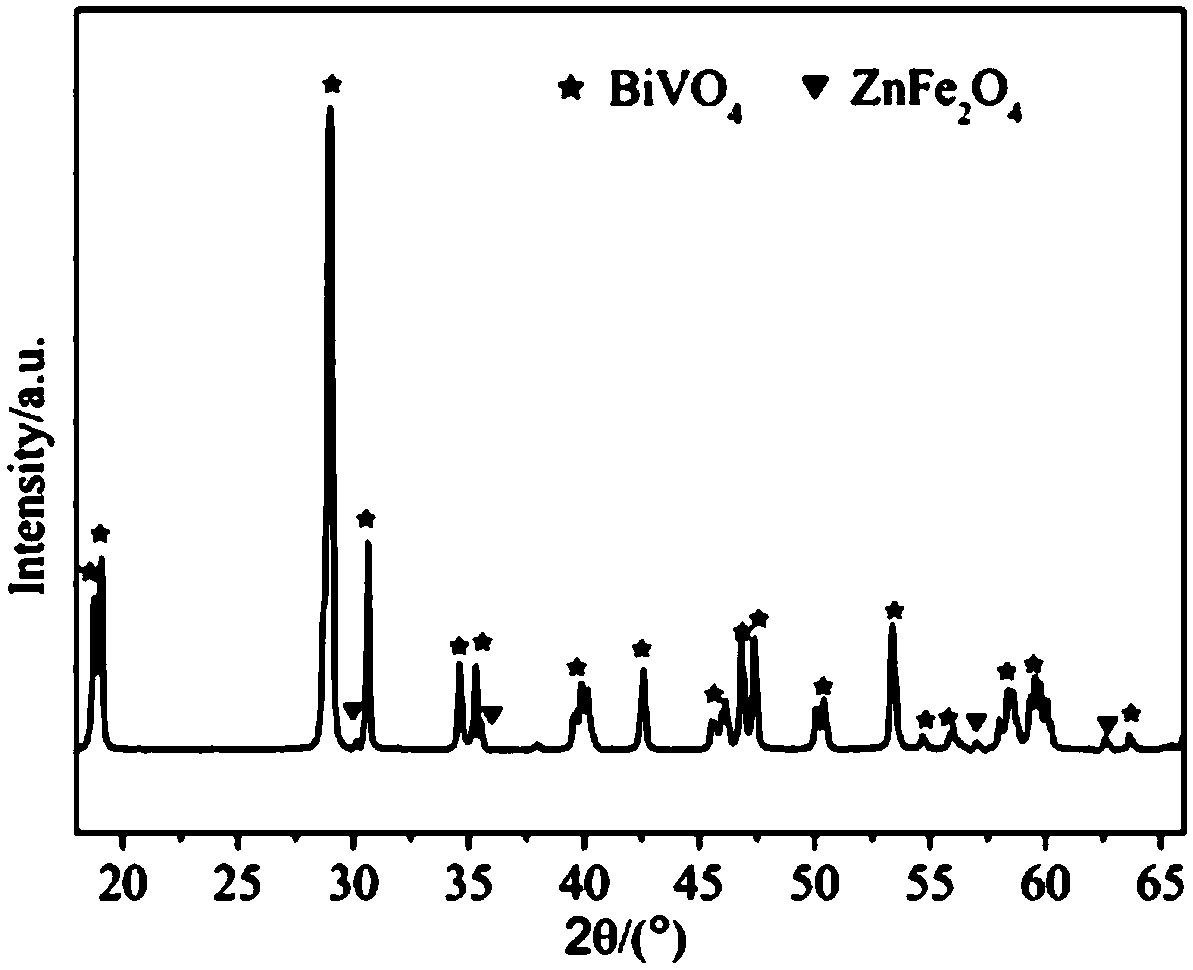

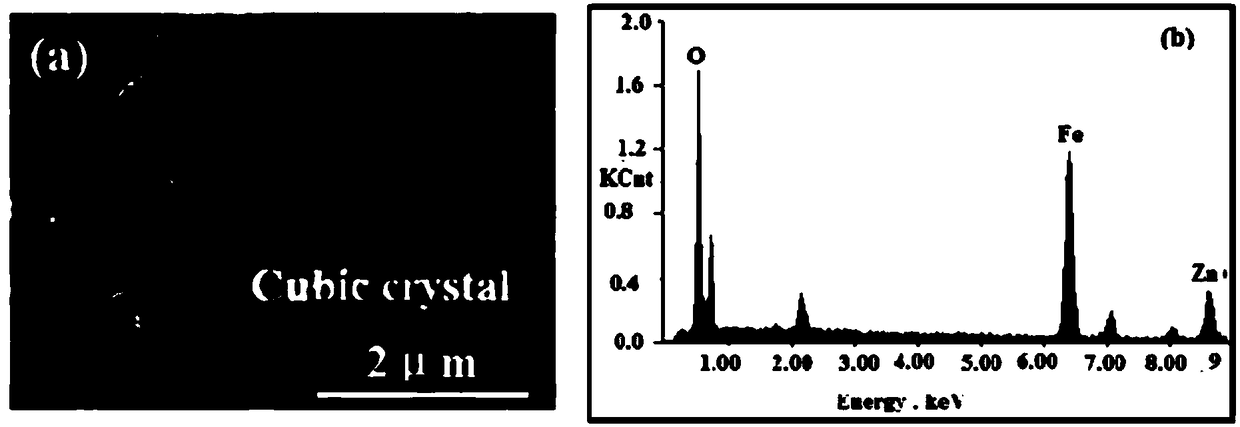

Bismuth vanadate-franklinite composite photocatalyst, and preparation method and application thereof

InactiveCN108636420AImprove performanceEasy to separate and recycleWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionBismuth vanadate

The invention discloses a bismuth vanadate-franklinite composite photocatalyst, and a preparation method and application thereof. The photocatalyst comprises an m-BiVO4 substrate, wherein ZnFe2O4 is dispersed on the surface of the m-BiVO4 substrate, and a mass ratio of the ZnFe2O4 to the m-BiVO4 substrate is (5-20): (95-80). A monoclinic bismuth vanadate-franklinite composite photocatalysis material is prepared by using a low-temperature self-propagating sol-gel method and a calcination method; the photocatalytic properties of the prepared material are tested by using simulated visible light;and the superior photocatalytic properties of the material are proved by degradation of the non-biodegradable organic pollutant methylene orange. The material belongs to inorganic photocatalysis materials, and has high photocatalytic activity and good application prospects in environmental protection. The preparation method has the advantages of controllable morphology of monoclinic bismuth vanadate, good compounding between franklinite and monoclinic bismuth vanadate, uniform dispersion and formation of effective p-n heterojunctions.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Technique and equipment for forged steel roll neck high-chrome cast iron composite roller

The invention discloses a technique and equipment for a forged steel roll neck high-chrome cast iron composite roller. Materials comprise, by mass, 2.4-3.3% of C, 0.60-1.0% of Si, 0.50-1.20% of Mn, 0.8-1.2% of Ni, 15-20.0% of Cr, 0.80-2.2% of Mo, 0.5-1% of W, 0-0.05% of P, 0-0.03% of S, 1-3% of Sb, 0.02-0.18% of N, 0.1-0.3% of Y, and the balance Fe and inevitable trace elements. The rare earth Y and silicon iron are adopted for composite inoculation; grain refinement treatment is conducted by adding the Sb and the N, so that the mechanical properties of the roller are improved; the strength of the roller is improved by the adoption of a forged steel roll neck; integral in-mold heating and casting are conducted on a mandril through an induction heater, and a water-cooling crystallizer is used for formation. The interface of a composite layer can be dynamically controlled, the technique is simple, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

A graphene positive electrode slurry and an efficient controllable preparation method thereof

InactiveCN109244464AEfficient compositeViscosity is easy to controlCell electrodesSecondary cellsElectrochemistryTransport network

The invention relates to a graphene positive electrode slurry and an efficient controllable preparation method thereof. A graphene positive electrode slurry is prepared from positive electrode activematerial, graphene and other conductive carbon materials, binder (PVDF), N-Methyl pyrrolidone (NMP) composites. the method includes adding a proper amount of positive active material dry powder and PVDF dry powder into a double-planet stirrer and disperser, and slowly stirring for a certain time. Then adding proper amount of conductive slurry in batches, stirring, dispersing, wetting, kneading andwet mixing; At last, an appropriate amount of NMP solvent is added to adjust that viscosity of the slurry, and the slurry is quickly stirred and dispersed for a long time to obtain the final slurry.The graphene in the graphene positive electrode slurry is well dispersed and can form a good coating effect on the particles of the positive electrode active material, and can form a high-efficiency charge transport network in the electrode, thereby accelerating the diffusion speed of electrons, reducing the polarization of the battery, and improving the electrochemical performance of the battery.The slurry viscosity of the method has high controllability and better stability and rheological properties.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Processing device and method for laser and spray electrochemical discharge compounding

ActiveCN110614428AReduce absorptionRaise the ratioOther manufacturing equipments/toolsLaser beam welding apparatusElectricityEtching

The invention discloses a processing device and method for laser and spray electrochemical discharge compounding, and relates to the field of composite micro processing in special processing technology. The device comprises a hollow laser irradiation system, an electrochemical spray processing system and a motion control system; the two kinds of energy synergistically act on the surface of an insulating high-hard brittle material, an electrochemical discharge loop is formed in an electrolyte through an auxiliary electrode and a tool electrode, meanwhile, a laser light beam generates focus on the surface of a sample, the processing efficiency is improved under the condition of not generating hot etching and fusing, and the processing and sizing property is improved. Compared with a traditional electrochemical discharge processing method, the atomization of the electrolyte can effectively reduce the absorption of electrolyte on discharge energy, thereby saving the electrochemical energyconsumption required by gas film formation and increasing the proportion of spark discharge energy. Meanwhile, the flowing electrolyte can take away the impurities generated by the material etching intime, so that the good micro processing quality is obtained.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com