Composite solid electrolyte and preparation method thereof

A solid electrolyte, composite technology, applied in the field of lithium ion batteries, can solve the problems of unstable metal lithium, short board of sulfide comprehensive performance, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

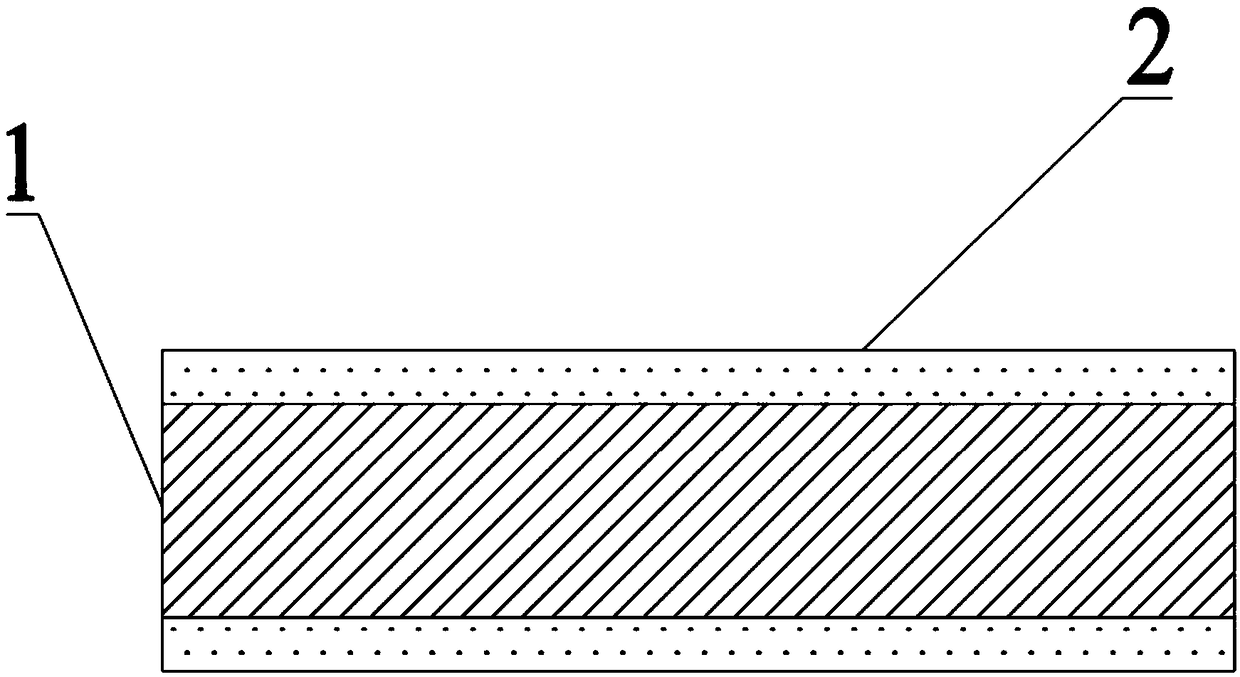

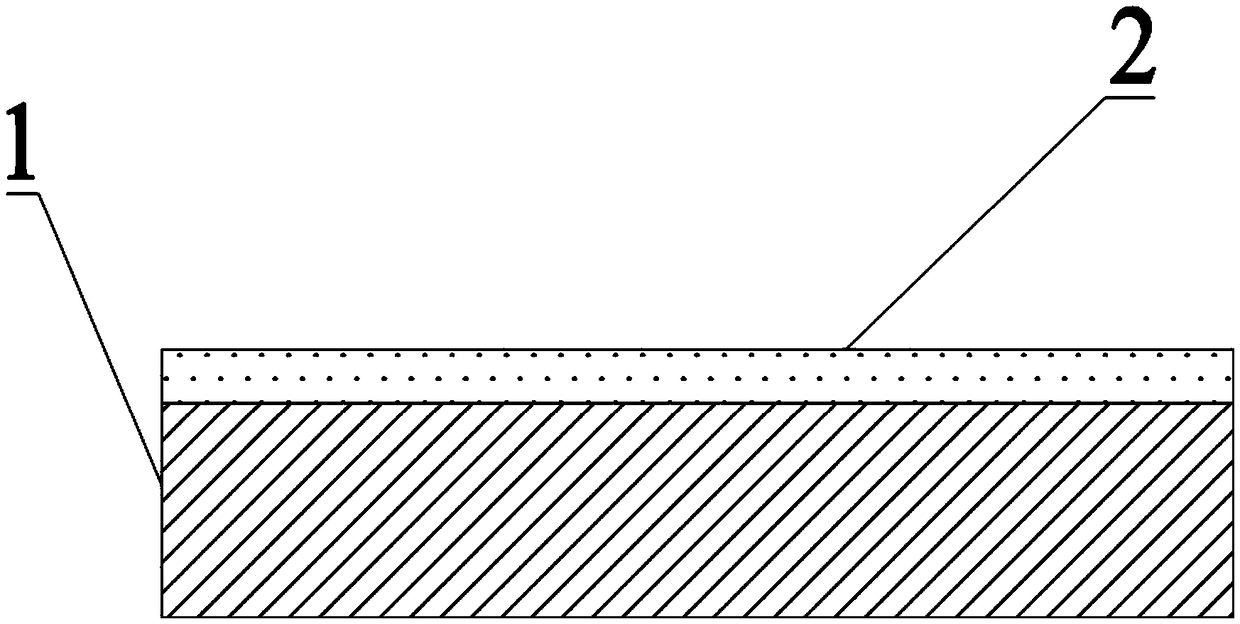

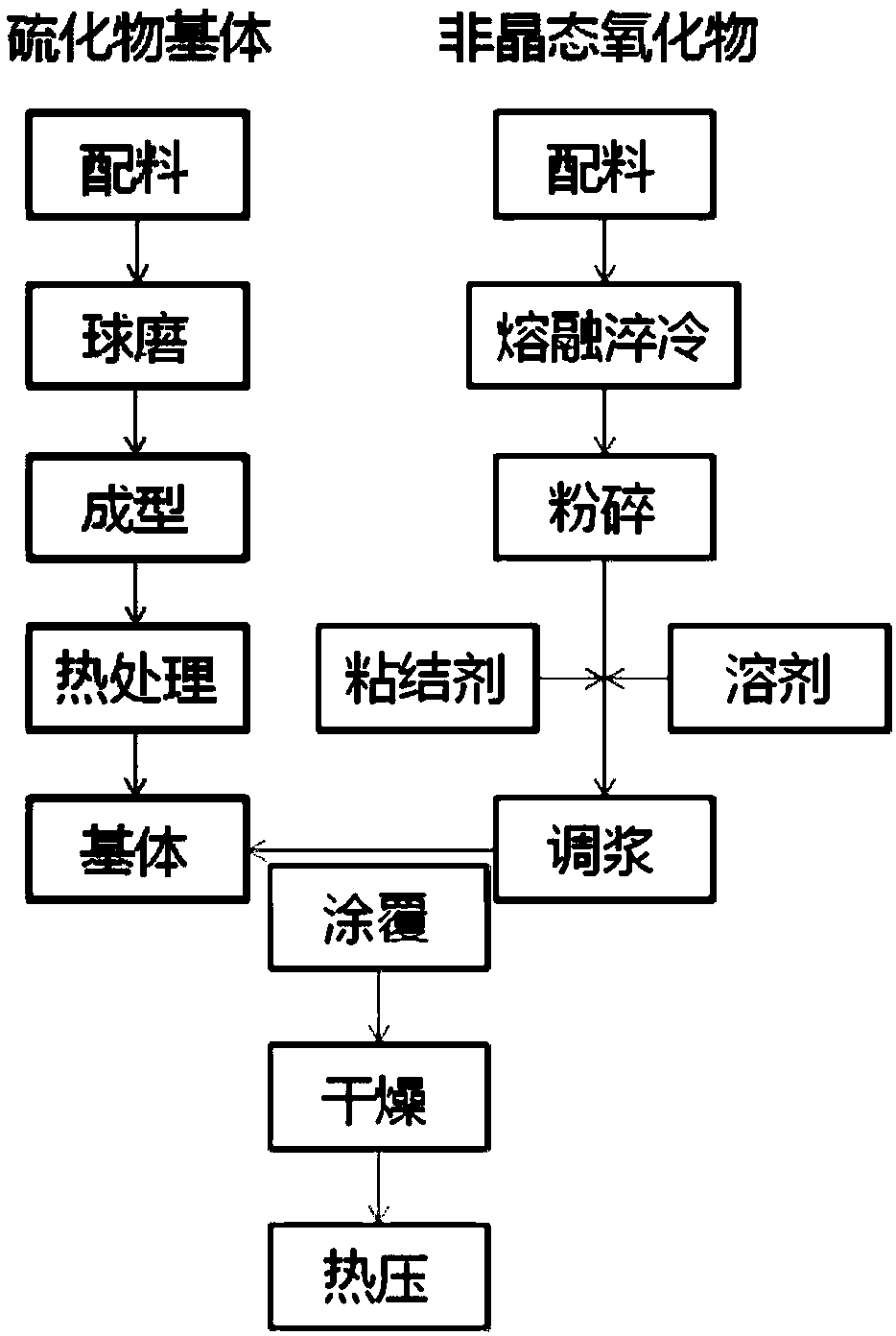

[0148] A composite solid electrolyte, the composite solid electrolyte at least includes a sulfide solid electrolyte layer 1 composed of a sulfide solid electrolyte, and an amorphous oxide solid electrolyte layer 2 composed of an amorphous oxide solid electrolyte.

[0149] In this embodiment, the interface problem between the sulfide solid electrolyte and the electrode material is improved by compounding the amorphous oxide solid electrolyte on the surface of the sulfide solid electrolyte.

Embodiment 2

[0151] This embodiment is further optimized on the basis of embodiment 1, as figure 1 As shown, the composite solid electrolyte consists of a layer of sulfide solid electrolyte layer 1 and two layers of amorphous oxide solid electrolyte layer 2; the amorphous oxide solid electrolyte layer 1 is arranged on the sulfide Solid electrolyte layer 2 on both sides.

[0152] When the positive electrode of the solid-state battery is an oxide and the negative electrode is lithium, the composite solid electrolyte with a double-layer structure described in this embodiment is used.

Embodiment 3

[0154] This embodiment is further optimized on the basis of embodiment 1, as figure 2 As shown, the composite solid electrolyte consists of a sulfide solid electrolyte layer 1 and an amorphous oxide solid electrolyte layer 2 .

[0155] When the positive electrode of the solid-state battery is sulfide, such as nickel sulfide, and the negative electrode is lithium, the single-layer structure described in this embodiment has no amorphous oxide solid electrolyte layer on the positive electrode side and an amorphous oxide solid electrolyte layer on the negative electrode side. Composite solid electrolyte; when the positive electrode of the solid-state battery is an oxide and the negative electrode is graphite, a single-layer structure with an amorphous oxide solid electrolyte layer on the positive electrode side and no amorphous oxide solid electrolyte layer on the negative electrode side as described in the embodiment is adopted Composite solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com