Processing device and method for laser and spray electrochemical discharge compounding

A processing device and electrochemical technology, which is applied in the laser and spray electrochemical discharge composite processing device, the micro-processing and manufacturing of insulating hard and brittle materials, can solve the problems of not suitable for etching and processing of insulating hard and brittle materials, and save energy Electrochemical energy consumption, high processing efficiency, and the effect of improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

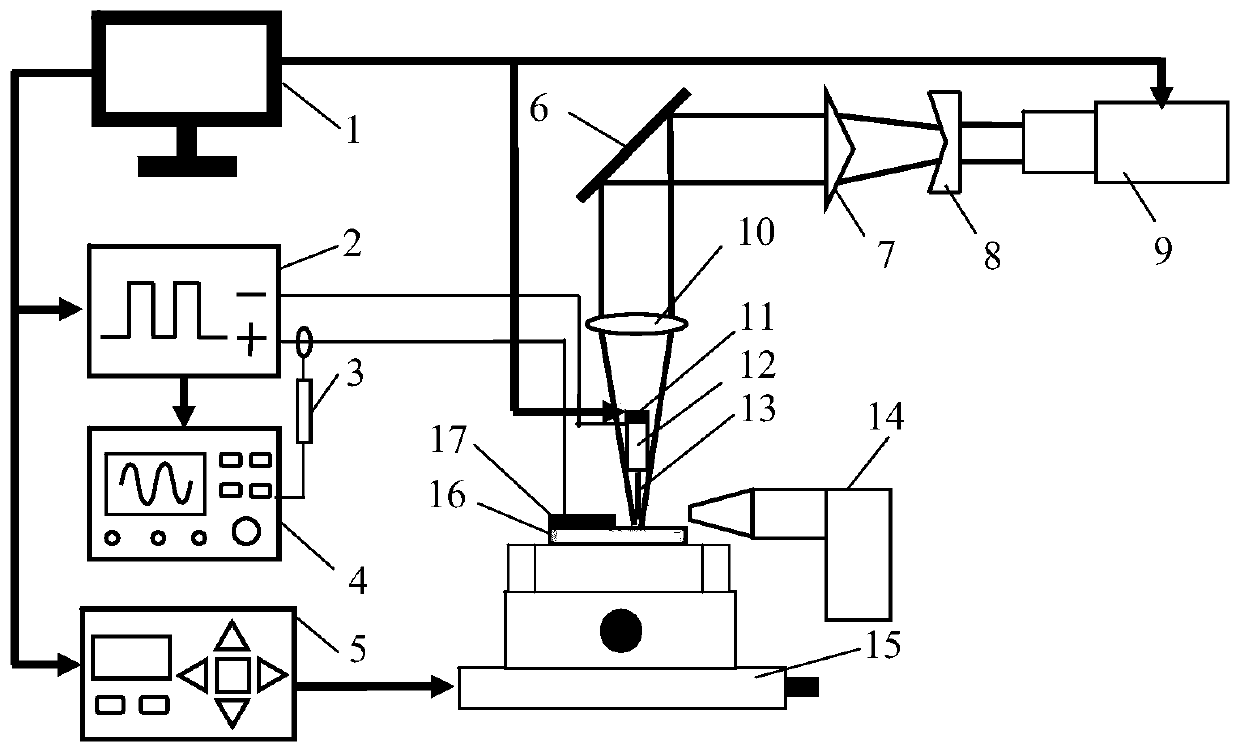

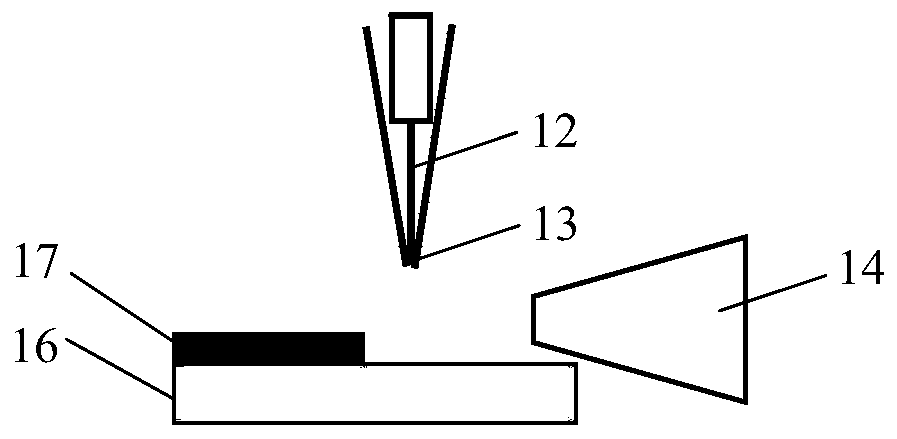

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0043] Such as figure 1 As shown, a laser and spray electrochemical discharge composite processing device includes a hollow laser irradiation system, a spray electrochemical processing system and a motion control system; the hollow laser irradiation system includes a pulse laser 9, a positive prism 7, and a negative prism 8 , mirror 6 and focusing lens 10, the pulsed laser light sent by pulse laser 9 is modulated into hollow laser through negative prism 8 and positive prism 7 in turn, the optical path is changed by reflecting mirror 6, and finally focused by focusing lens 10.

[0044] The spray electrochemical machining system includes a DC pulse power supply 2, a current probe 3, an oscilloscope 4, an electrode fixture 12, a tool electrode 13, a fine atomizer 14, an x-y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com