Glass bead polyurethane foam composite material and preparation method thereof

A technology of polyurethane foam and vitrified microbeads, which is applied in the field of composite materials and its preparation, can solve the problems of high cost of thermal insulation materials, difficulty in simultaneously improving flame retardancy and thermal insulation, and achieve low cost, improved thermal insulation performance, and low density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

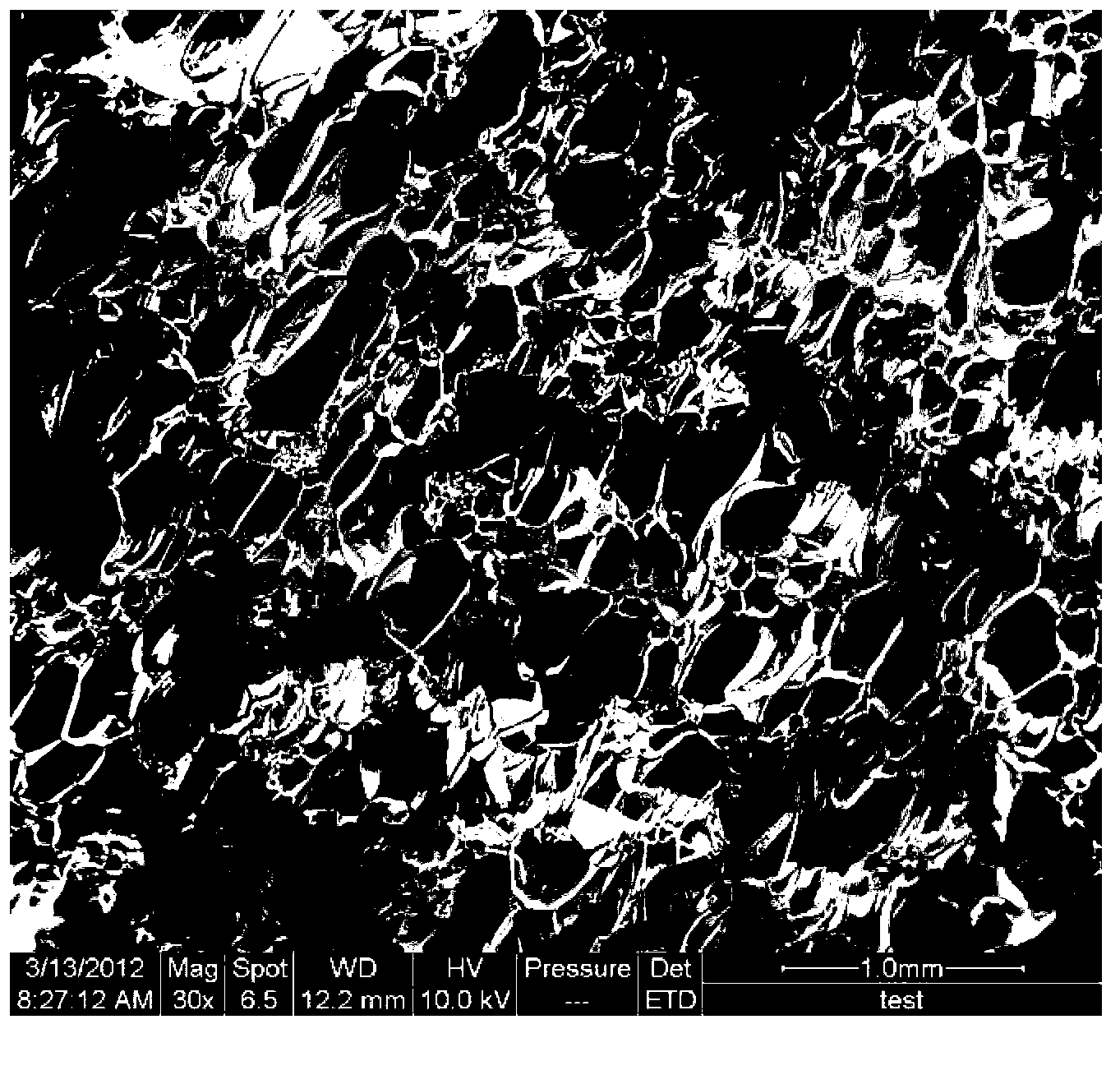

Image

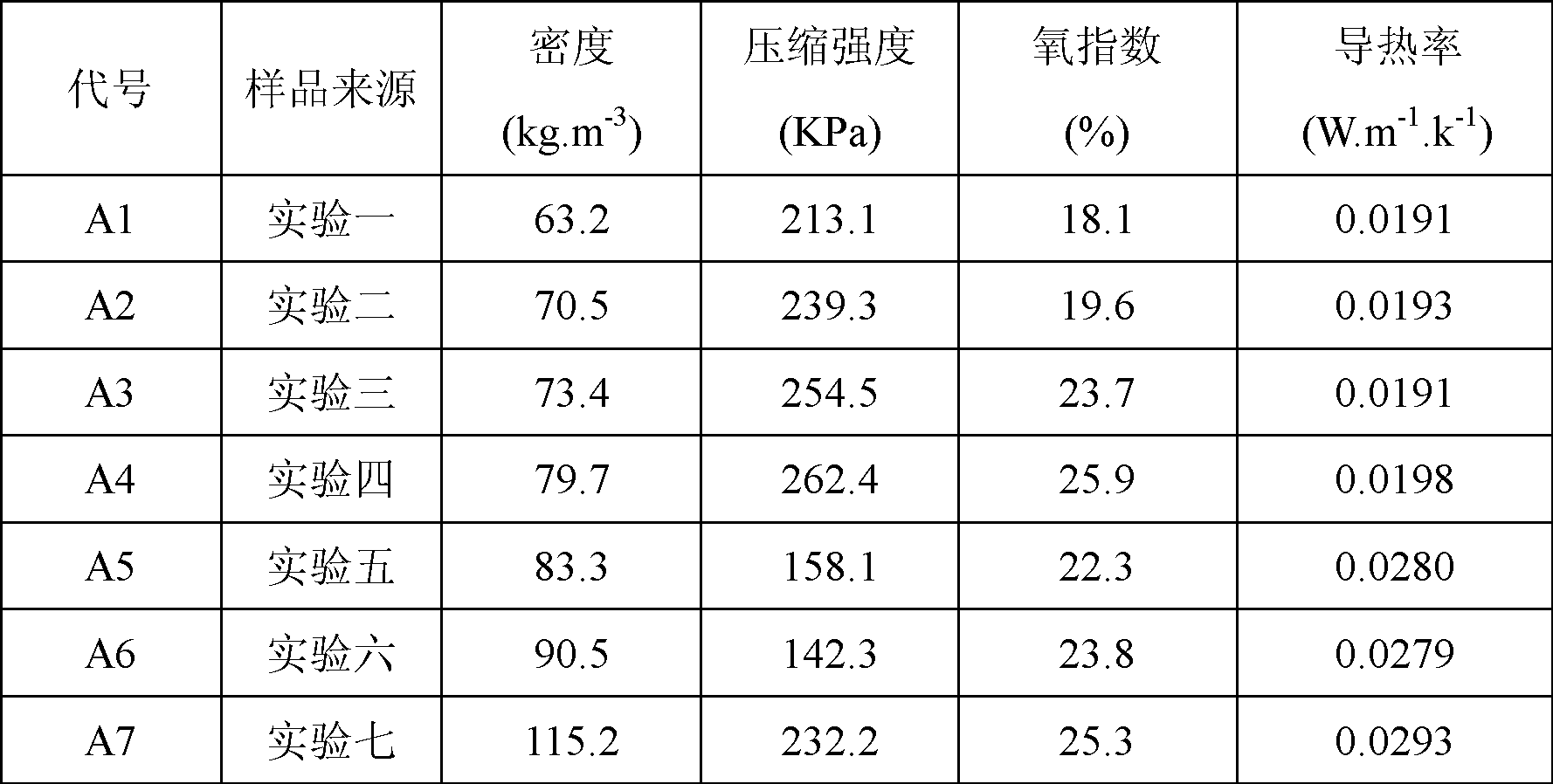

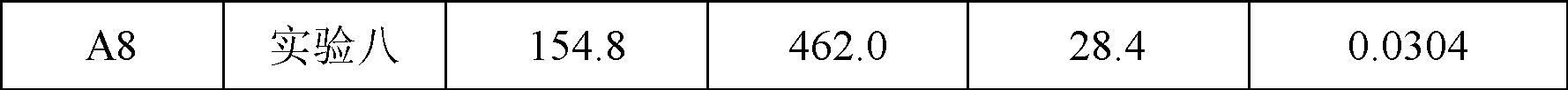

Examples

specific Embodiment approach 1

[0029] Specific implementation mode 1: The vitrified microbead polyurethane foam composite material in this embodiment consists of 200 to 270 parts by mass of pretreated vitrified microbeads with a particle size of 32 to 120 mesh, 100 parts of polyurethane white material, and 120 to 150 parts Polyurethane black material is mixed with 35-45 parts of solid flame retardant, and then it is prepared through microwave-assisted heating, foaming compounding and curing;

[0030] The polyurethane white material consists of 45-55 parts by weight of polyether 4110, 3-10 parts of polyether 403, 35-45 parts of polyether 210, 1-2 parts of catalyst, 2-5 parts of water and 5-15 parts Parts of dichlorofluoroethane;

[0031] The catalyst is a tin catalyst and / or an amine catalyst, the tin catalyst is stannous octoate, dibutyltin dilaurate, and the amine catalyst is triethylenediamine, 2,2'- Dimorpholino diethyl ether, N,N-dimethylcyclohexylamine or diethanolamine;

[0032] Described polyuretha...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the vitrified microbead polyurethane foam composite material consists of 250 parts by weight of pretreated vitrified microbeads with a particle size of 32 to 100 meshes, 100 parts of polyurethane After mixing white material, 130 parts of polyurethane black material and 40 parts of solid flame retardant, it is prepared through microwave-assisted heating, foaming compounding and curing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the polyurethane white material consists of 50 parts by weight of polyether 4110, 5 parts of polyether 403, 40 parts of polyether 210, 1.5 parts of catalyst, 3 parts by weight. Parts of water and 10 parts of dichlorofluoroethane composition. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com