Preparation method of water-dispersible graphene/ferroferric oxide (Fe3O4) composite powder

A composite powder, graphene technology, applied in ferrous oxide, iron oxide/iron hydroxide and other directions, can solve the problems of limiting the application field of composite materials, poor dispersion of the composite, and many process steps, etc. Achieving good application prospects, easy industrial production, and good compounding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

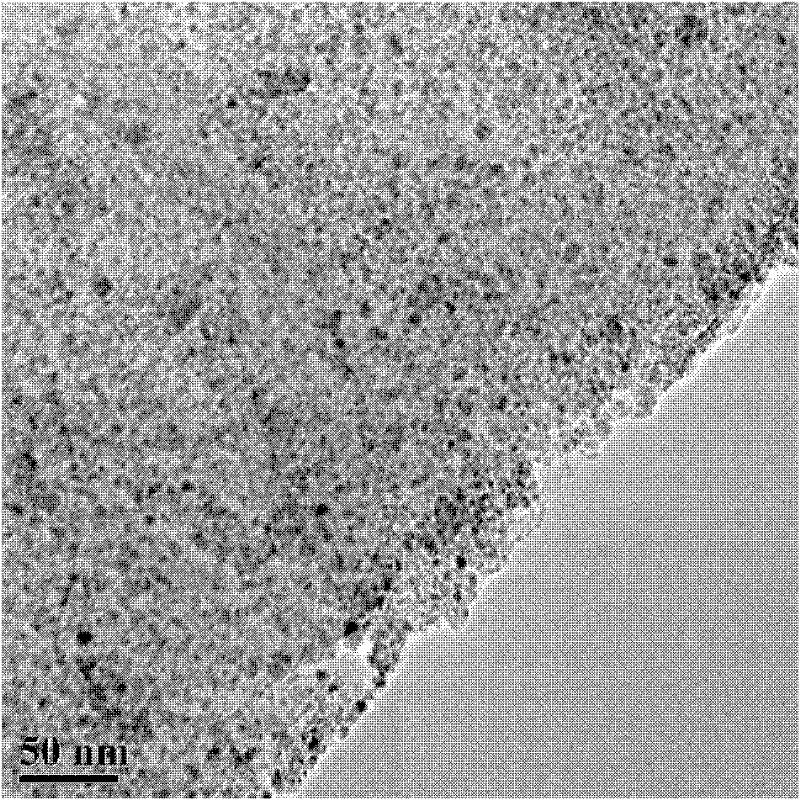

[0026] Weigh 100mg of graphite oxide and 1g of sodium polystyrene sulfonate into a beaker, then add 100ml of deionized water, and disperse ultrasonically for 45min at a power of 300W. After the dispersion is uniform, pour the above dispersion into a three-necked flask and heat up To 100°C, react for 12h. Weigh 366mg of ferric chloride hexahydrate and 134mg of ferrous chloride tetrahydrate into the above reaction solution under the protection of nitrogen atmosphere, then add 1ml of ammonia water, cool down to 80°C for 30min, then add 0.0752g of oleic acid to continue the reaction for 90min. At the end of the reaction, the graphene / Fe is collected with a magnet 3 o 4 The composite powder was washed with deionized water, and then the product was dried at 60 °C for 18 h. figure 1 For the transmission electron microscope photo of the synthetic powder of this embodiment, it can be seen that: Fe 3 o 4 Nanoparticles are uniformly attached to the surface and interlayer of graphene,...

Embodiment 2

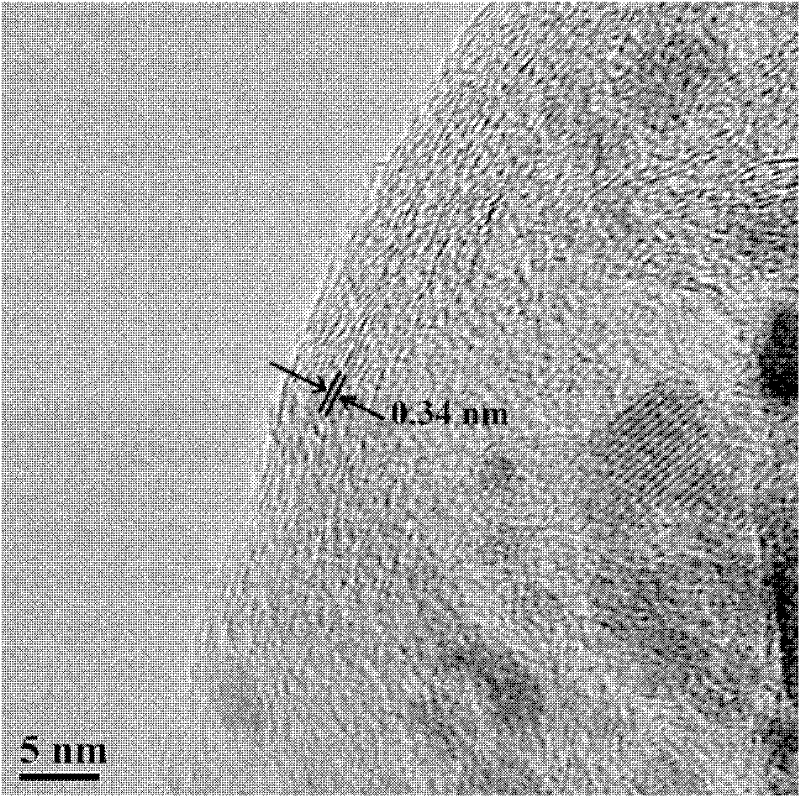

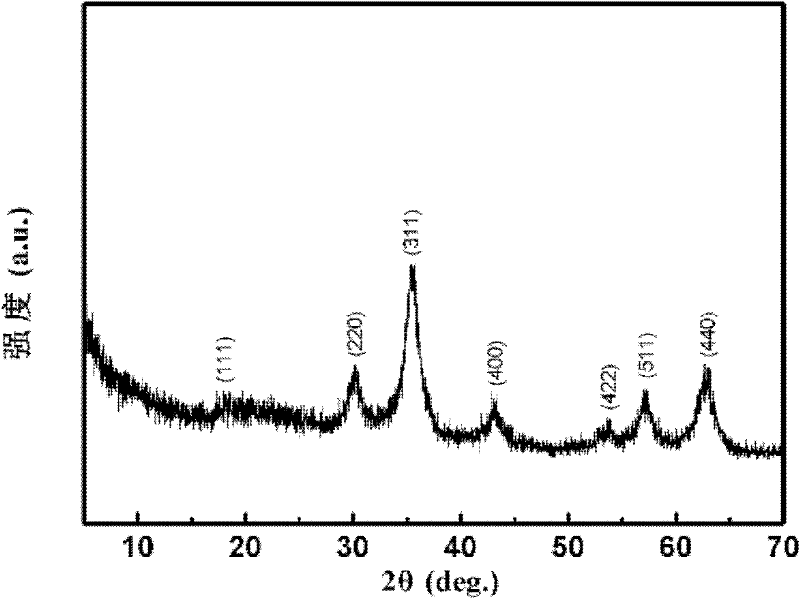

[0028]Weigh 50mg of graphite oxide and 1g of sodium polystyrene sulfonate into a beaker, then add 100ml of deionized water, and disperse ultrasonically for 60min at a power of 200W. To 110°C, react for 8h. Weigh 110mg of ferric chloride hexahydrate and 40mg of ferrous chloride tetrahydrate into the above reaction solution under the protection of nitrogen atmosphere, then add 0.3ml of ammonia water, cool down to 70°C for 40min, then add 0.0226g of oleic acid to continue the reaction for 80min. At the end of the reaction, the graphene / Fe is collected with a magnet 3 o 4 The composite powder was washed with deionized water, and then the product was dried at 40 °C for 24 h. Transmission electron microscopy observations showed that: Fe 3 o 4 The particle size of the nanoparticles is about 5nm, and they are well compounded with graphene. Observation by high-resolution transmission electron microscopy shows that: the Fe in the composite powder 3 o 4 Nanoparticles, graphene she...

Embodiment 3

[0030] Weigh 200mg of graphite oxide and 1g of sodium polystyrene sulfonate into a beaker, then add 100ml of deionized water, and disperse ultrasonically for 30min at a power of 400W. After the dispersion is uniform, pour the above dispersion into a three-necked flask and heat up To 90°C, react for 16h. Weigh 146mg of ferric chloride hexahydrate and 54mg of ferrous chloride tetrahydrate into the above reaction solution under the protection of nitrogen atmosphere, then add 0.4ml of ammonia water, cool down to 90°C for 20min, then add 0.032g of oleic acid to continue the reaction for 100min. At the end of the reaction, the graphene / Fe is collected with a magnet 3 o 4 The composite powder was washed with deionized water, and then the product was dried at 80 °C for 12 h. Transmission electron microscopy observations showed that: Fe 3 o 4 The particle size of the nanoparticles is about 5nm, and they are well compounded with graphene. Observation by high-resolution transmission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com