Patents

Literature

207results about How to "Easy to throw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

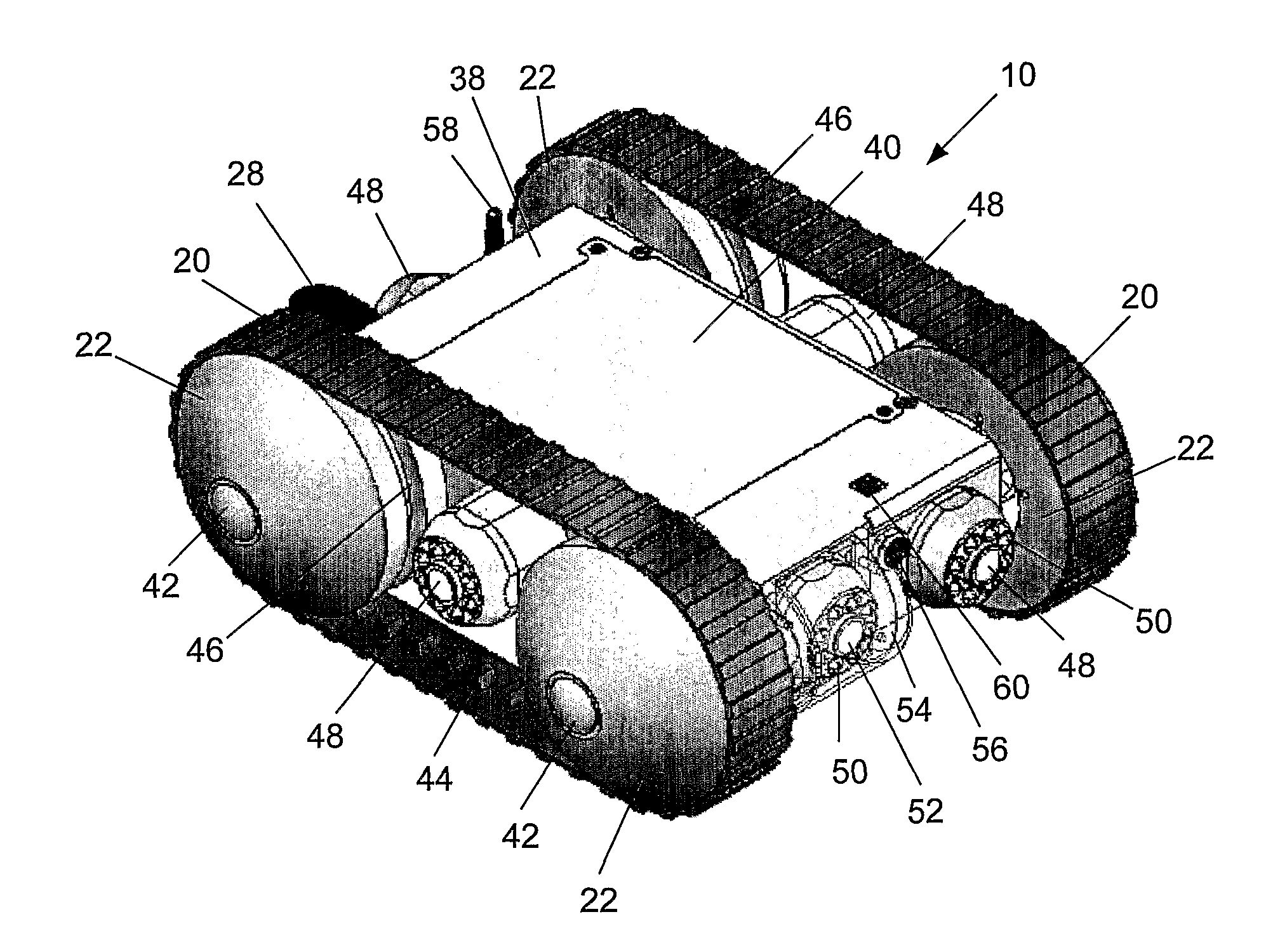

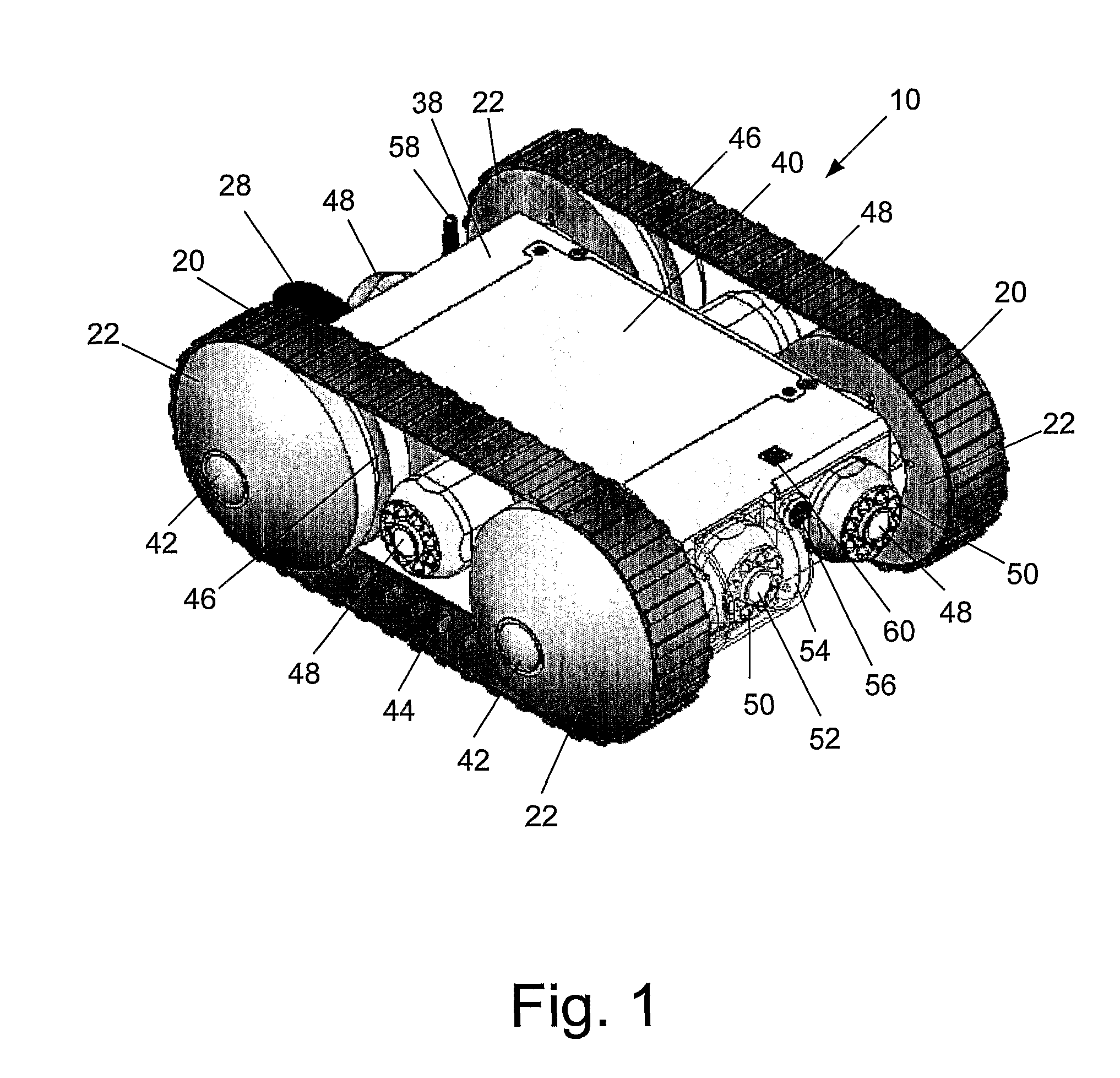

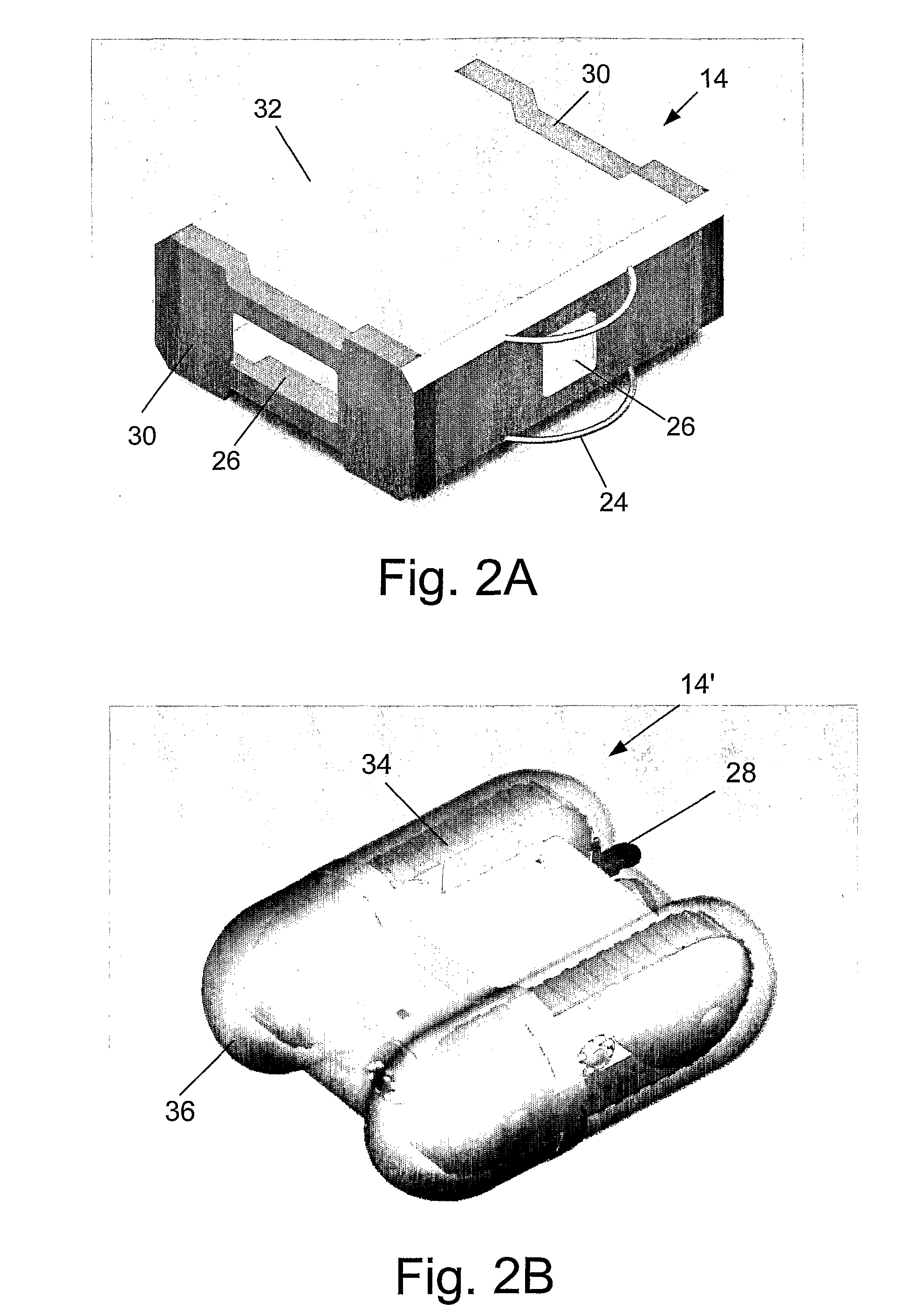

Robotic Platform

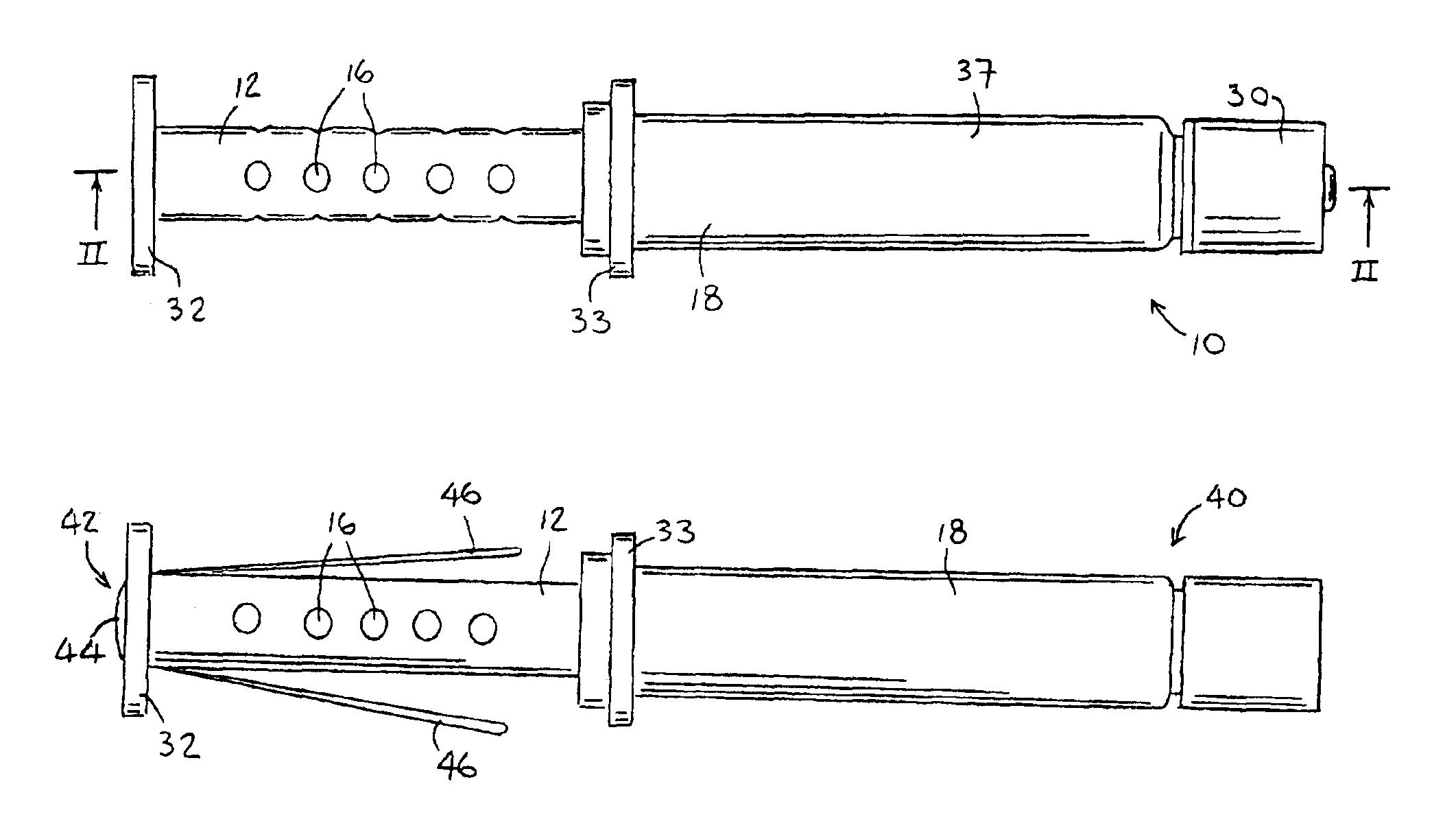

InactiveUS20100179691A1Ability to controlEasy to carryDefence devicesProgramme controlRobotic armEngineering

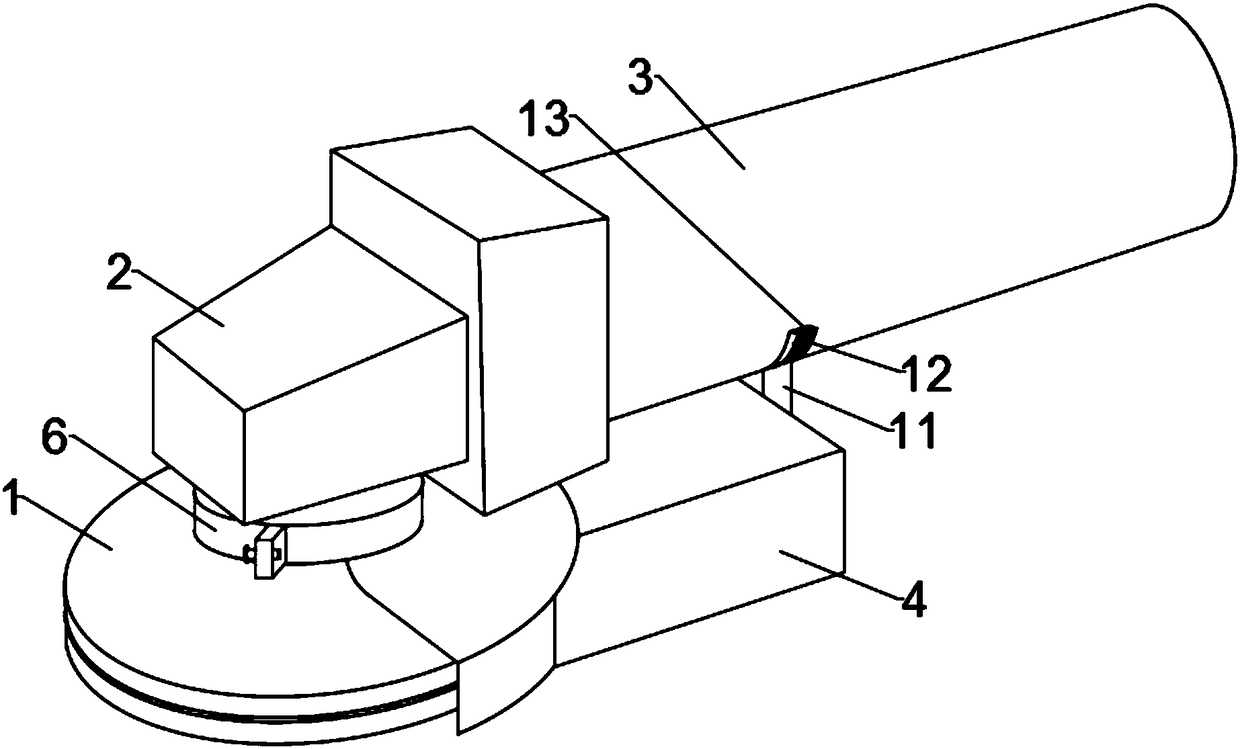

The present invention is a robotic mobile platform vehicle that can be thrown into hostile or hazardous environments for gathering information and transmitting that information to a remotely located control station and a system comprising the robotic mobile platform. The system of the invention is adapted to provide it's operator with significant information without being exposed directly to actual or potential danger. One of the key features of the invention is that at least four imaging assemblies are mounted on the robotic platform and that the system has the processing ability to stitch the views taken by the four imaging devices together into an Omni-directional image, allowing simultaneous viewing of a 360 degree field of view surrounding the mobile platform. Another feature is that the system comprises a touch screen GUI and the robotic mobile platform is equipped with processing means and appropriate software. This combination enables the user to steer the robotic platform simply by touching an object in one of the displayed images that he wants to investigate. The robotic platform can then either point its sensors towards that object or, if so instructed, compute the direction to the object and travel to it without any further input from the user.

Owner:MISTRAL DETECTION LTD

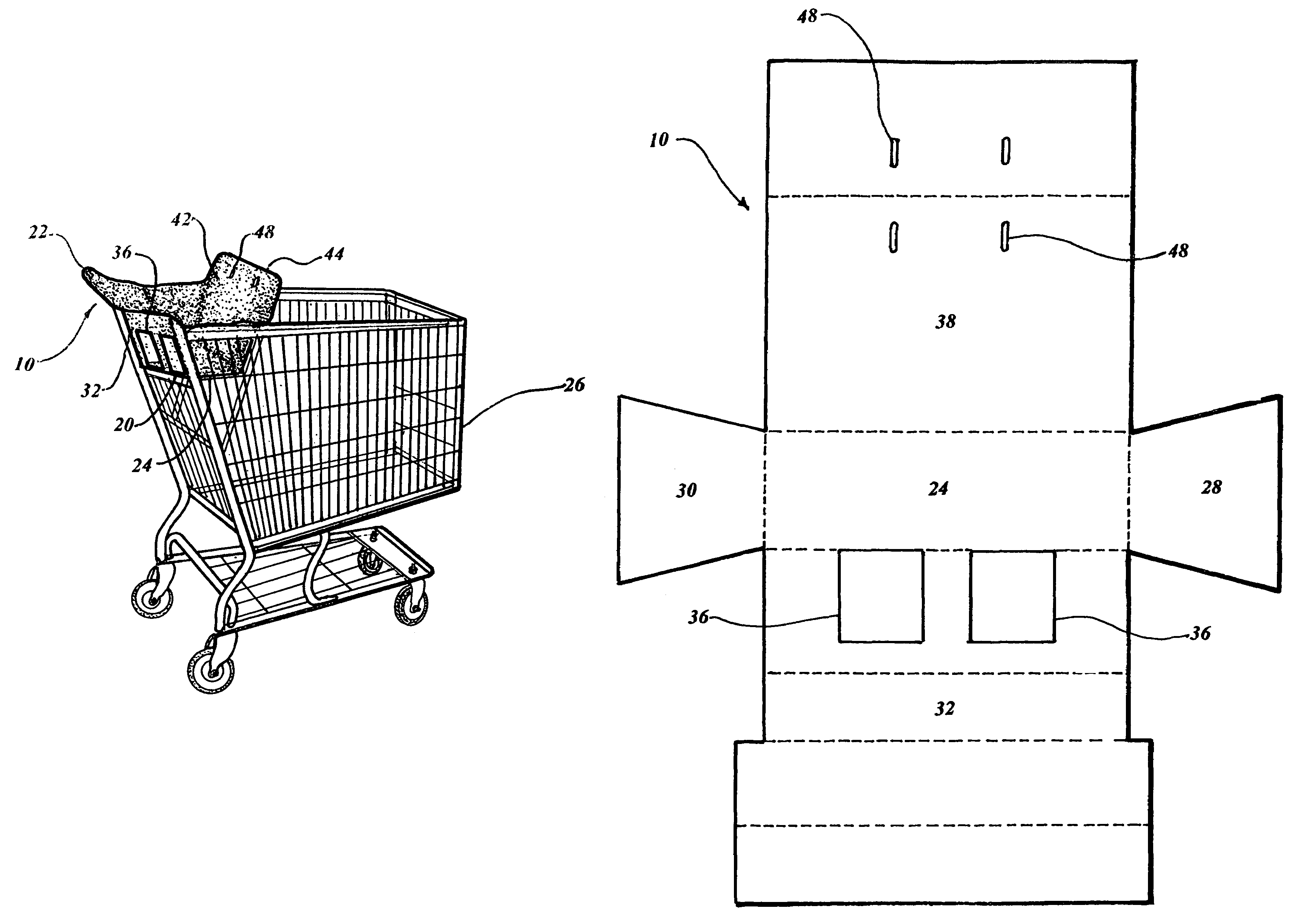

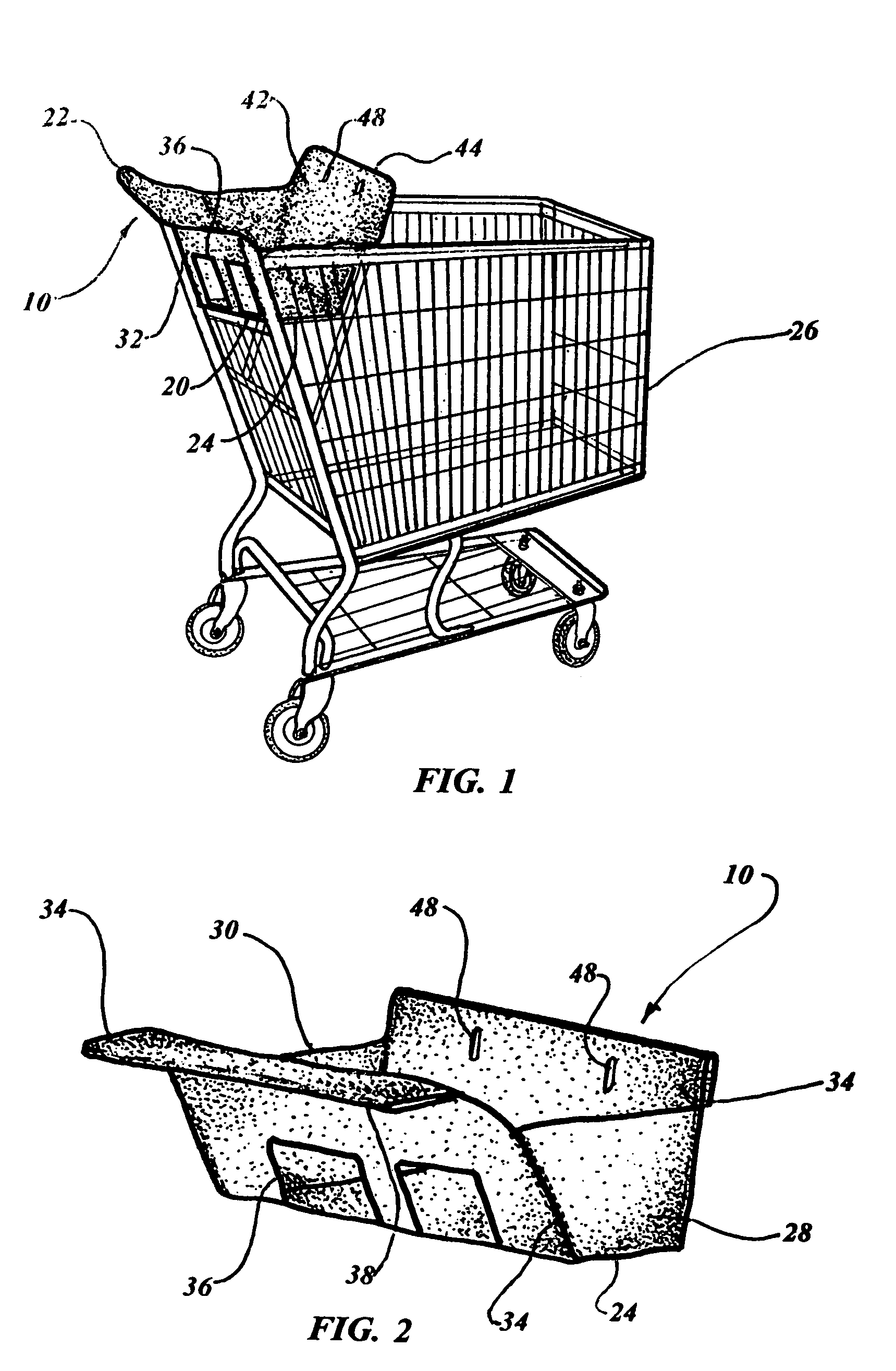

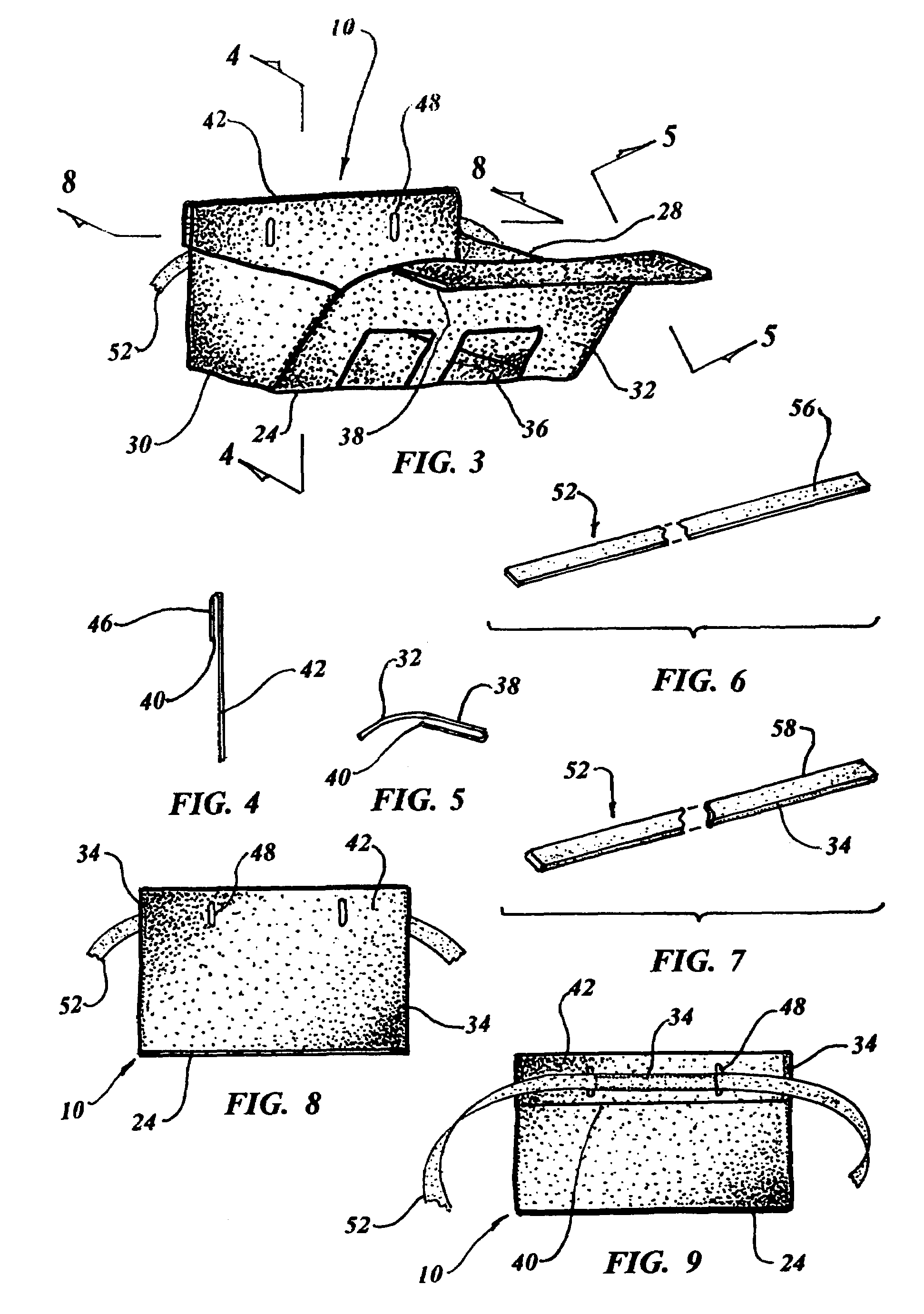

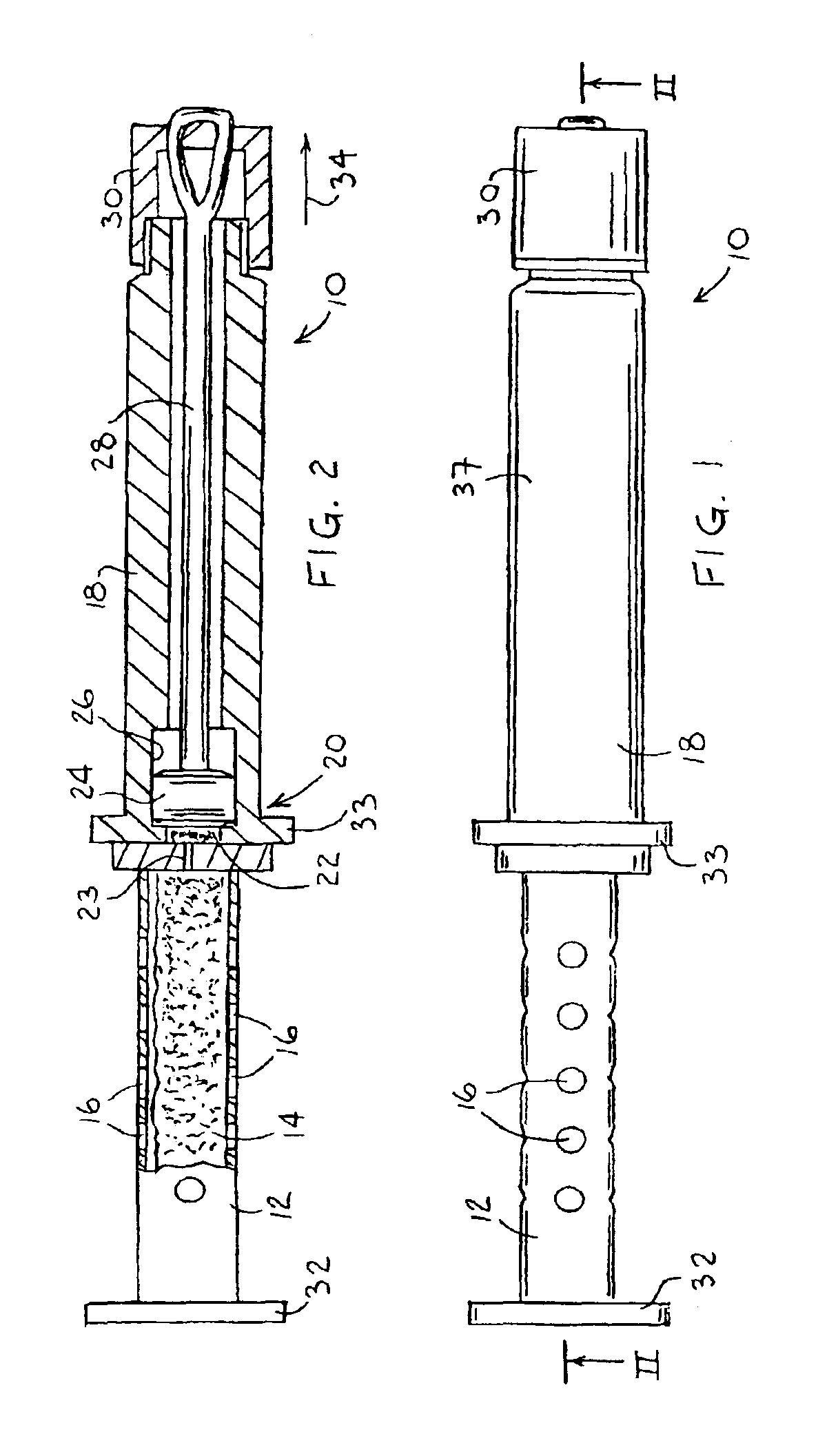

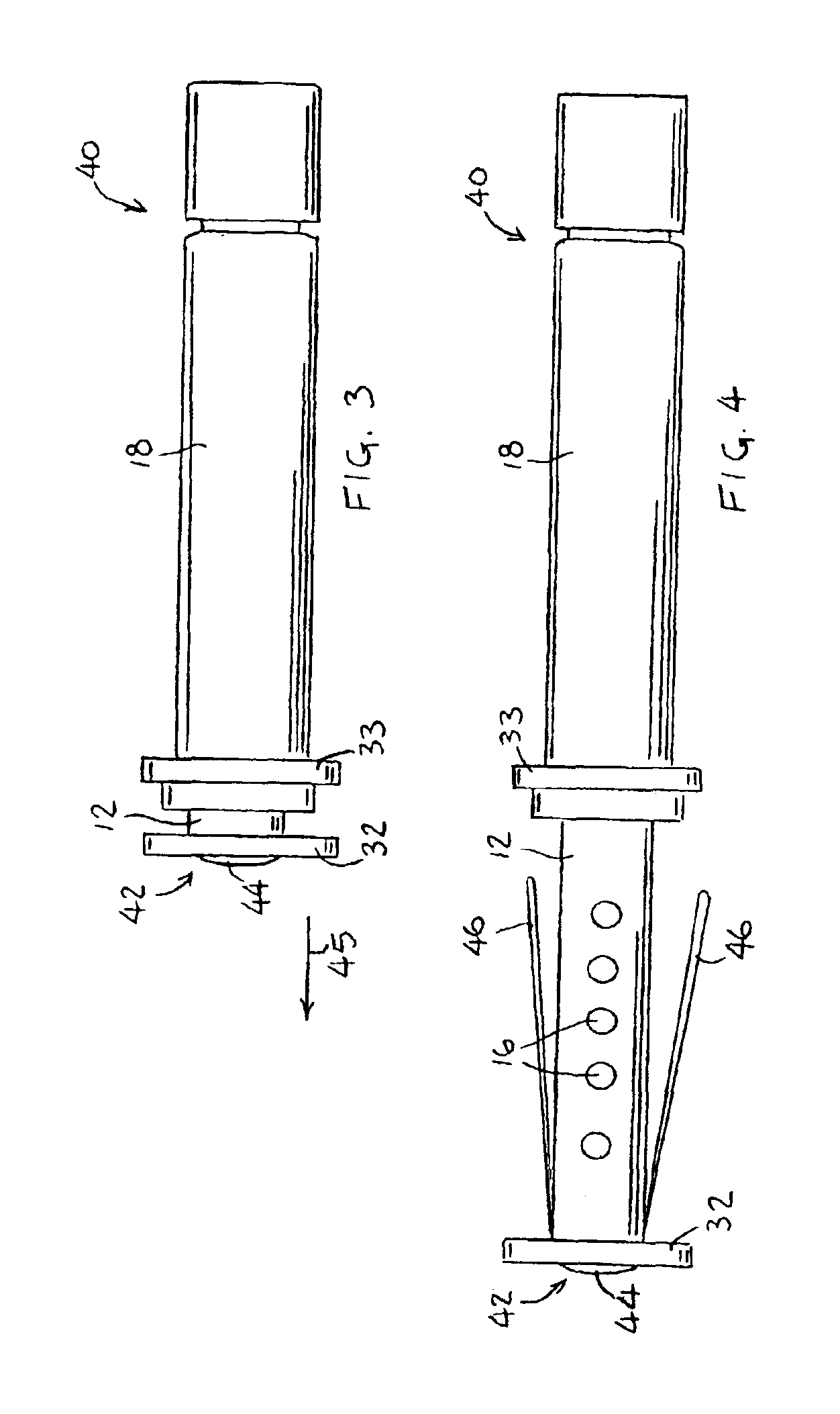

Disposable shopping cart child seat liner

InactiveUS7367621B1Easy to transportEasy to carryKids chairsHand carts with multiple axesEngineeringCart

A disposable seat liner (10) that covers a shopping cart's child seat (20) that includes a cart handle (22). The liner (10) consists of a liner seat bottom (24) configured to cover the child's seating area of a shopping cart (26). A liner right side (28) and a liner left side (30) are integrally formed with the seat bottom and folded upward. A liner handle end (32) overlaps the cart handle (22) and is also integrally formed with the liner seat bottom (24). A liner seat back (42) jointly overlaps the cart's seat and the cart's basket upper portion, and is permanently attached with heat-sealed joints (34) to the liner right side and left side on adjacent edges, thereby forming a disposable protective cover to assure isolation from microorganisms found on the shopping cart's child seat and handle.

Owner:HAN DRESSOR JOANNIE U +1

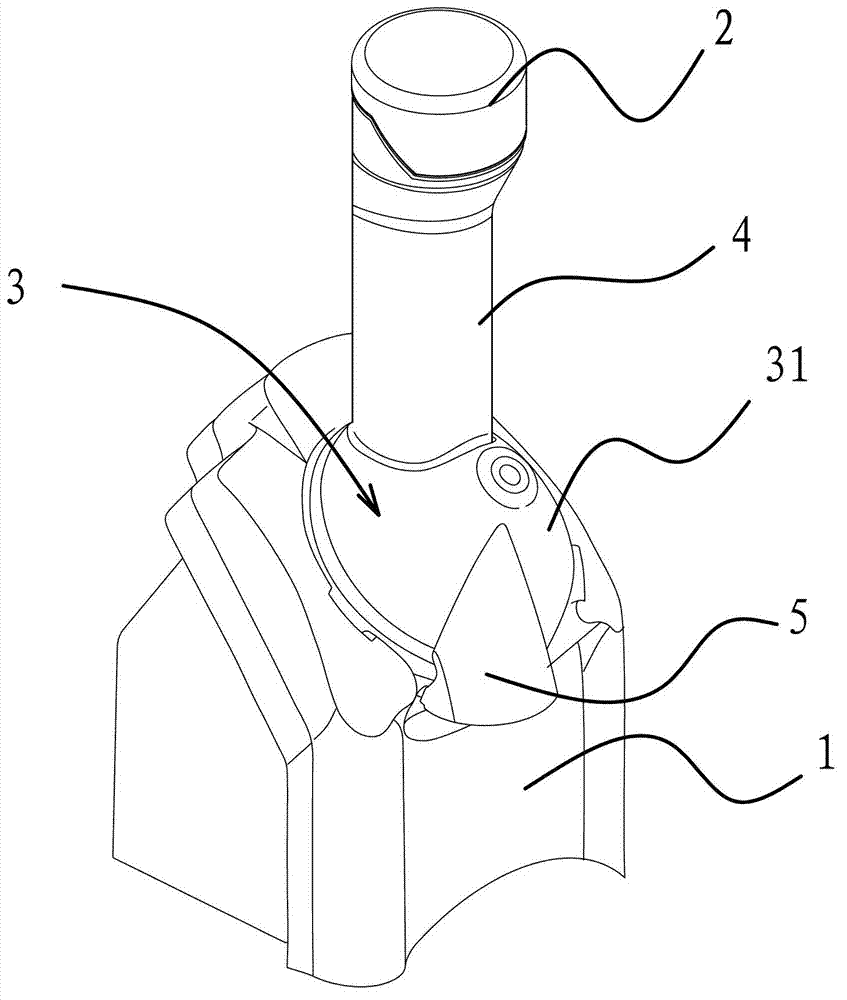

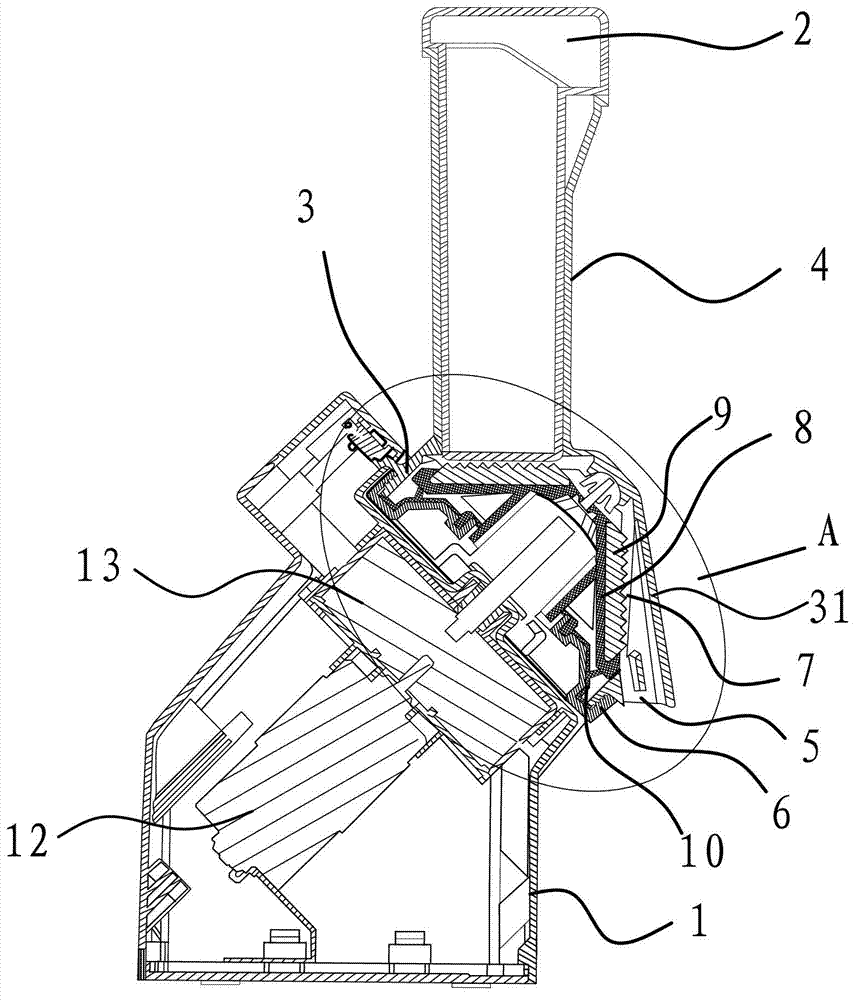

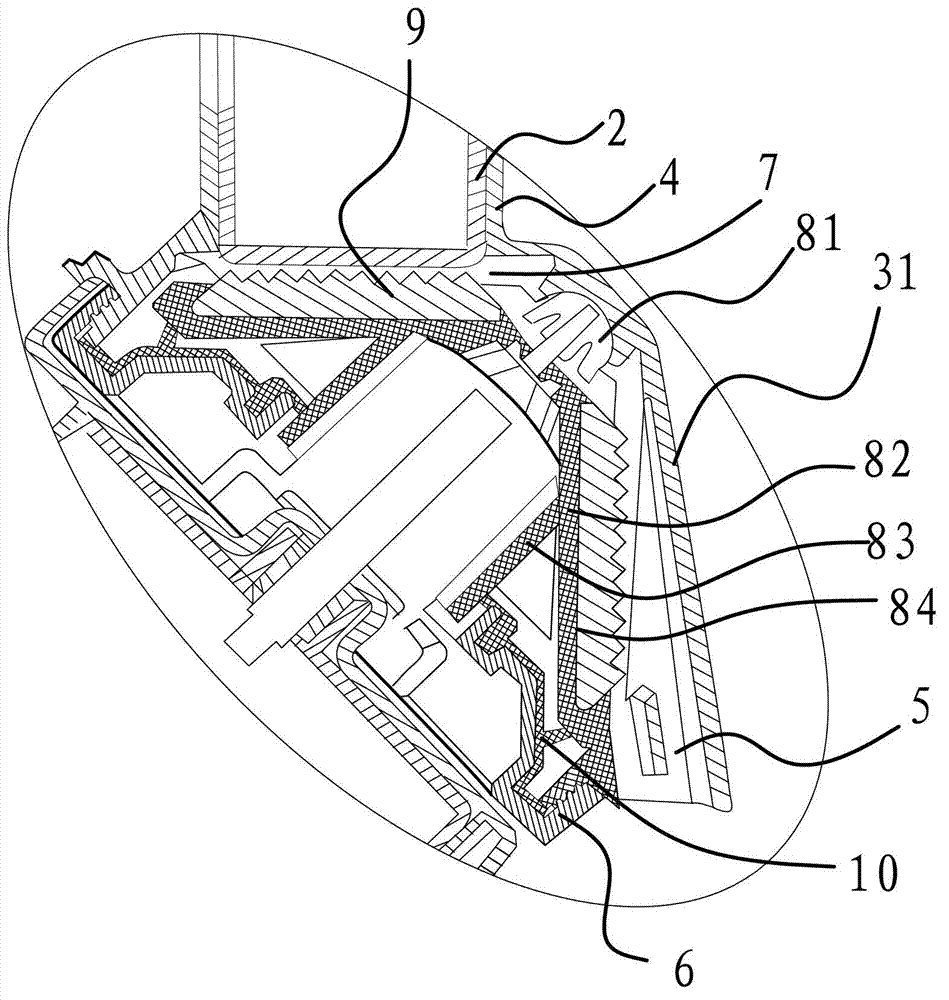

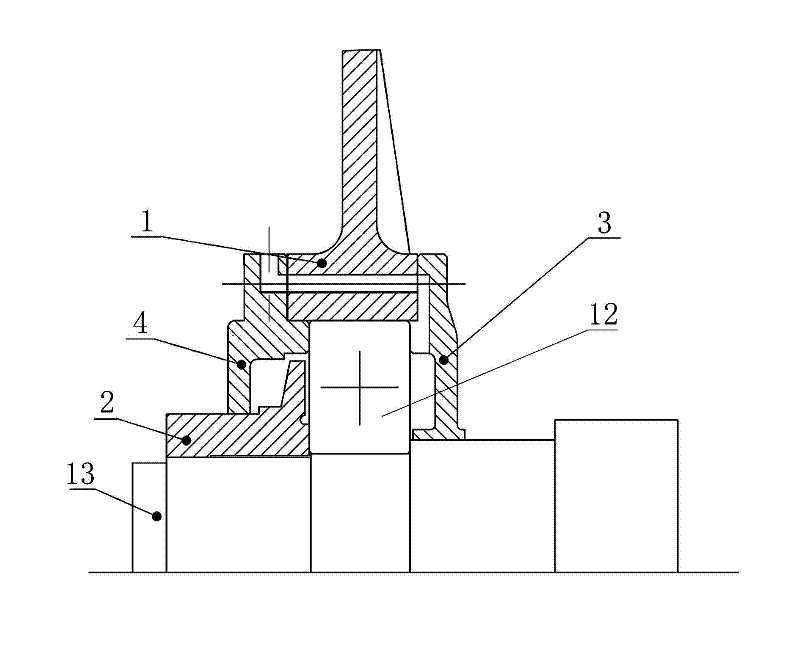

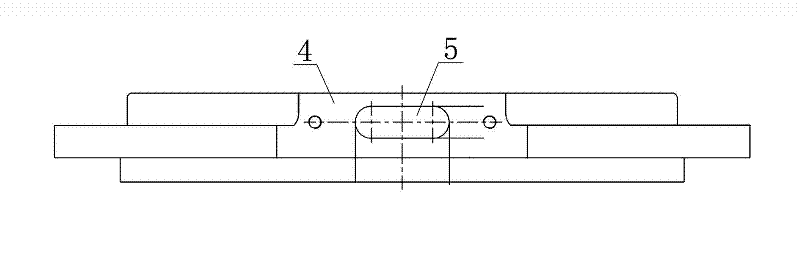

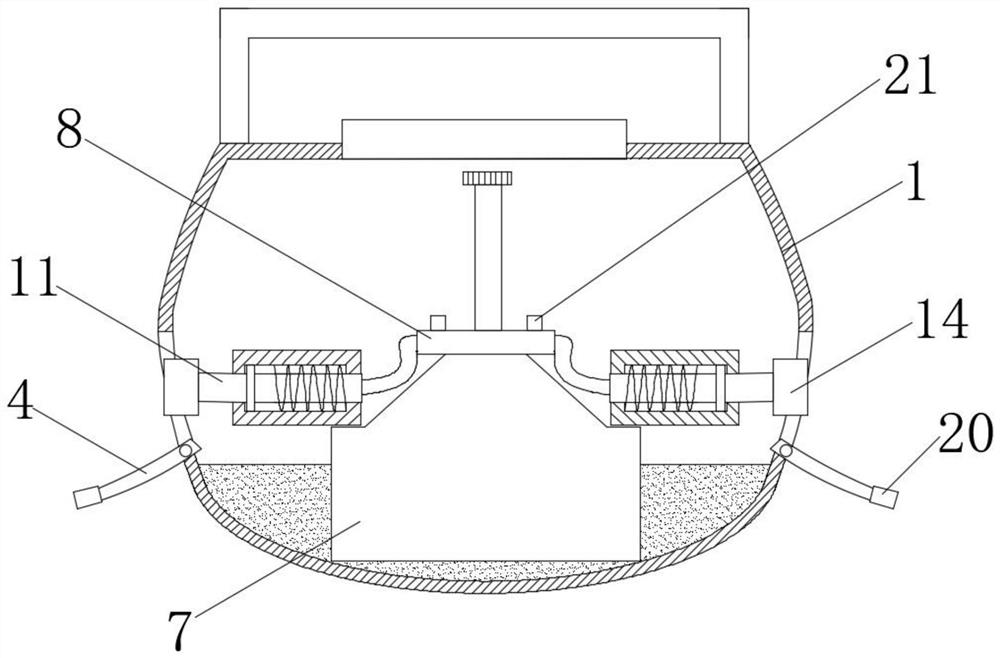

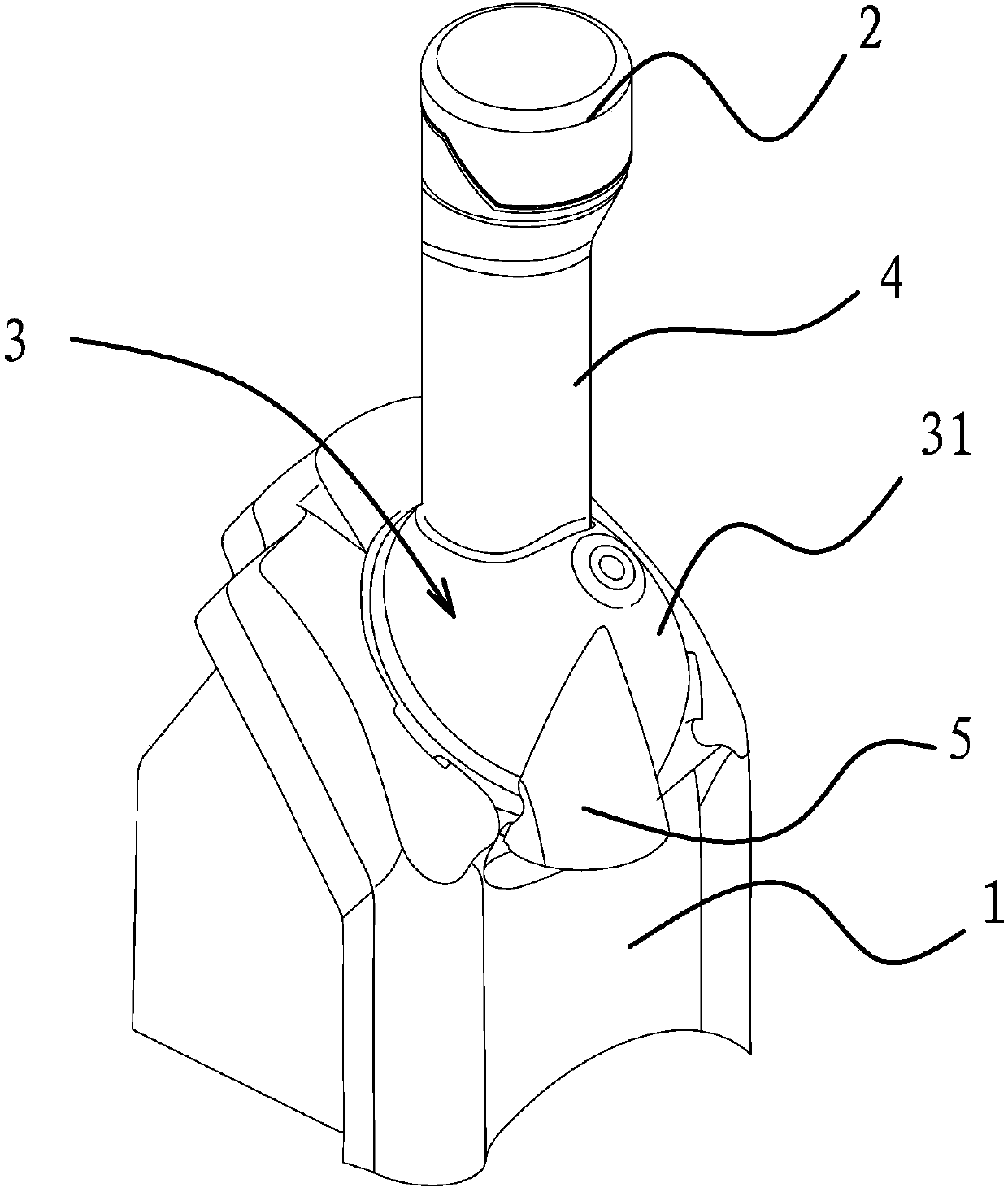

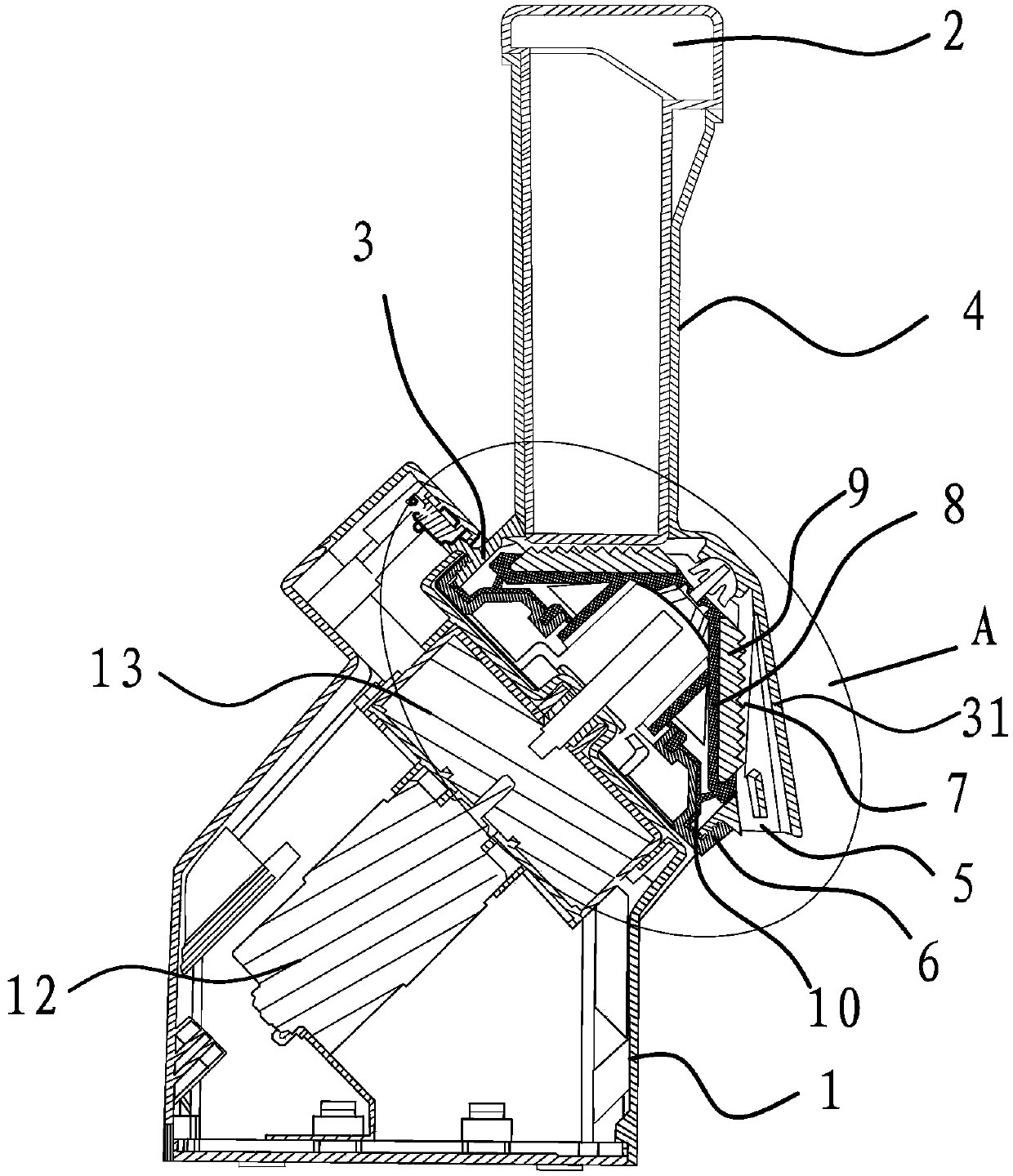

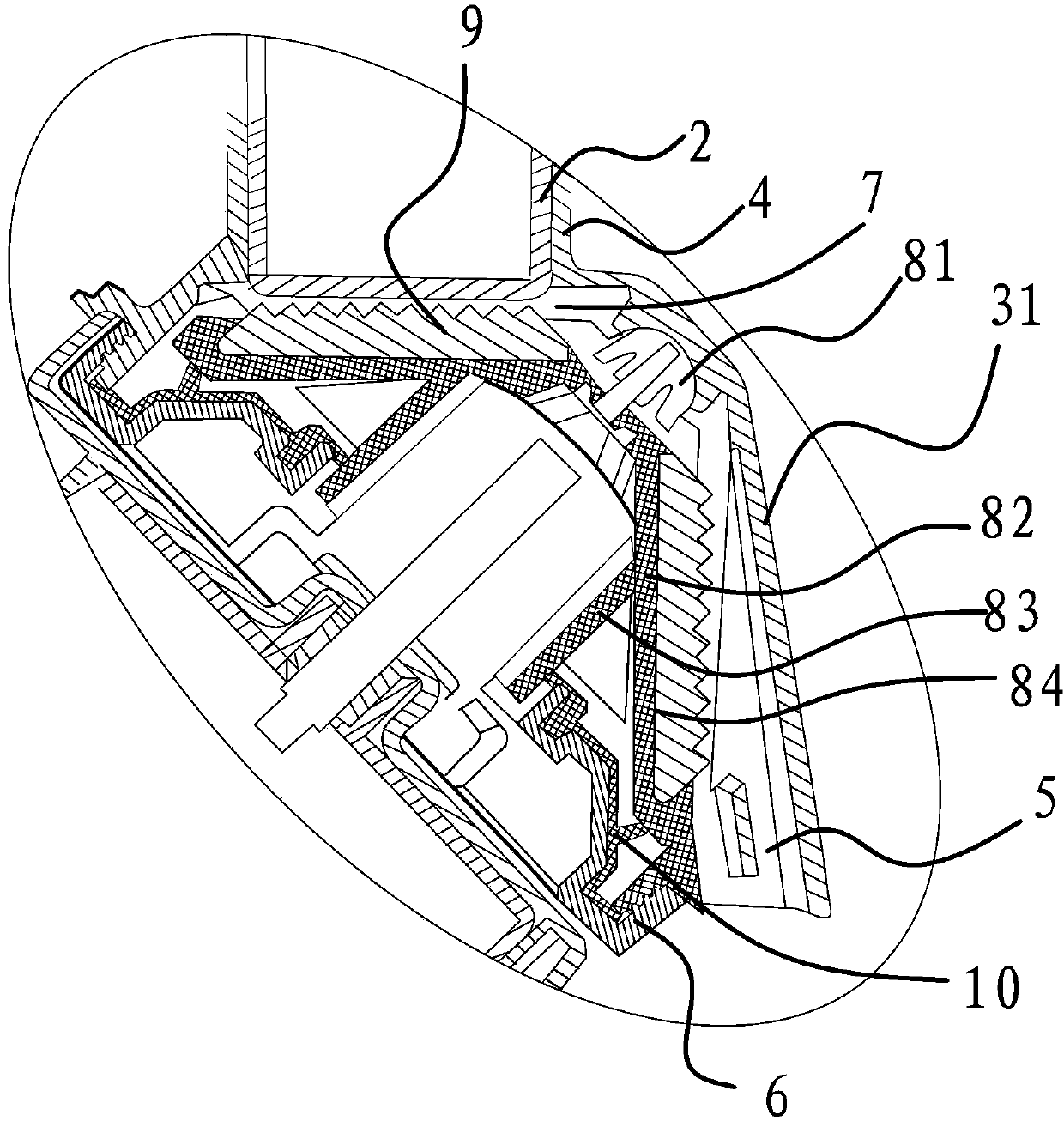

Fruit ice cream machine

InactiveCN103168908AChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

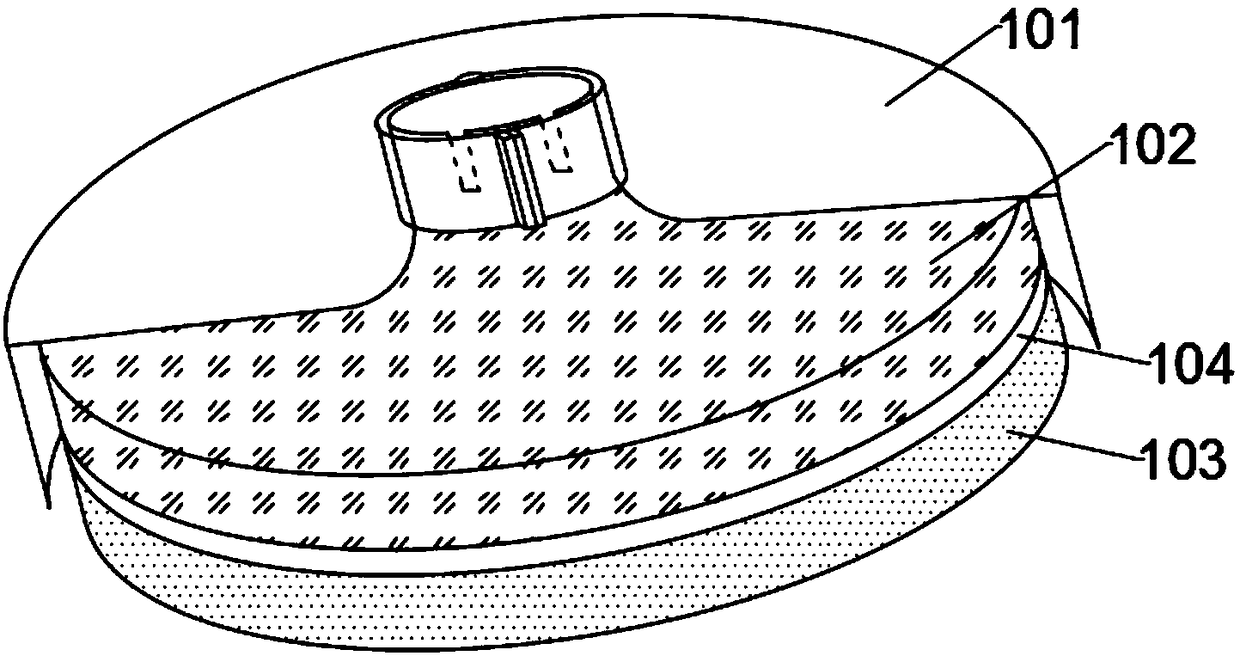

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

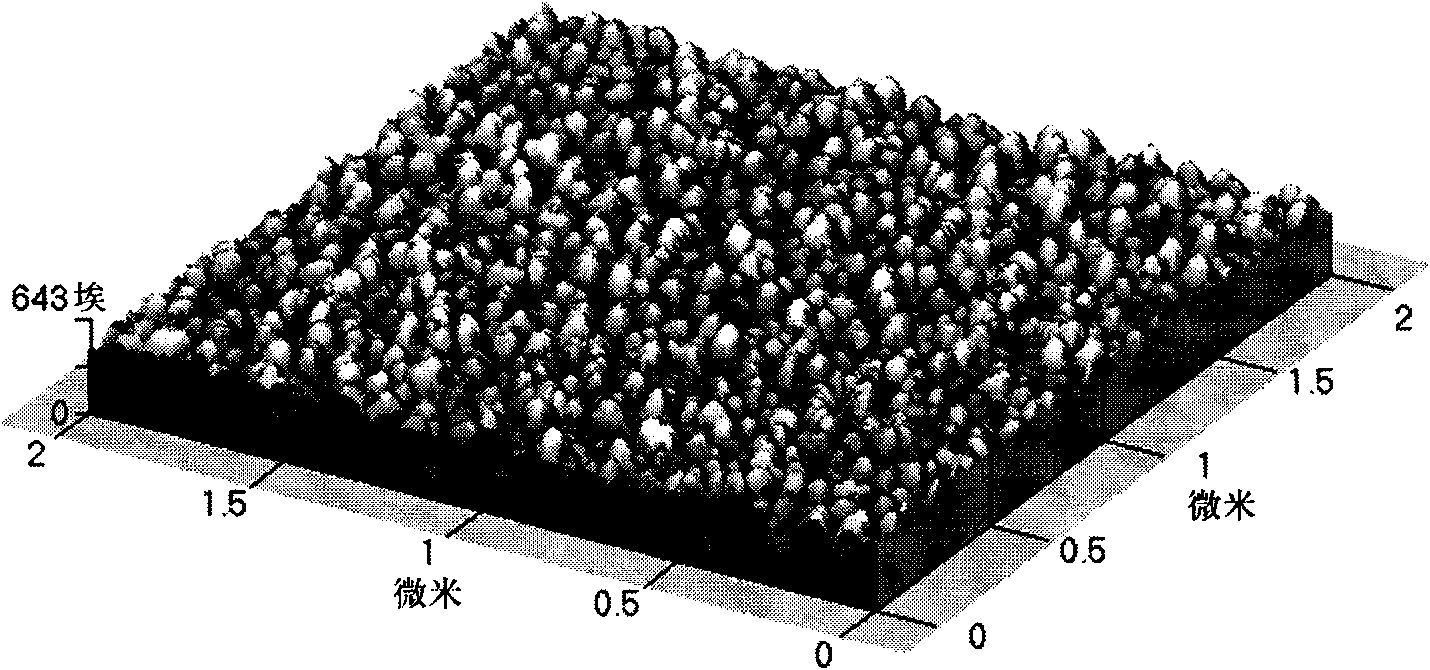

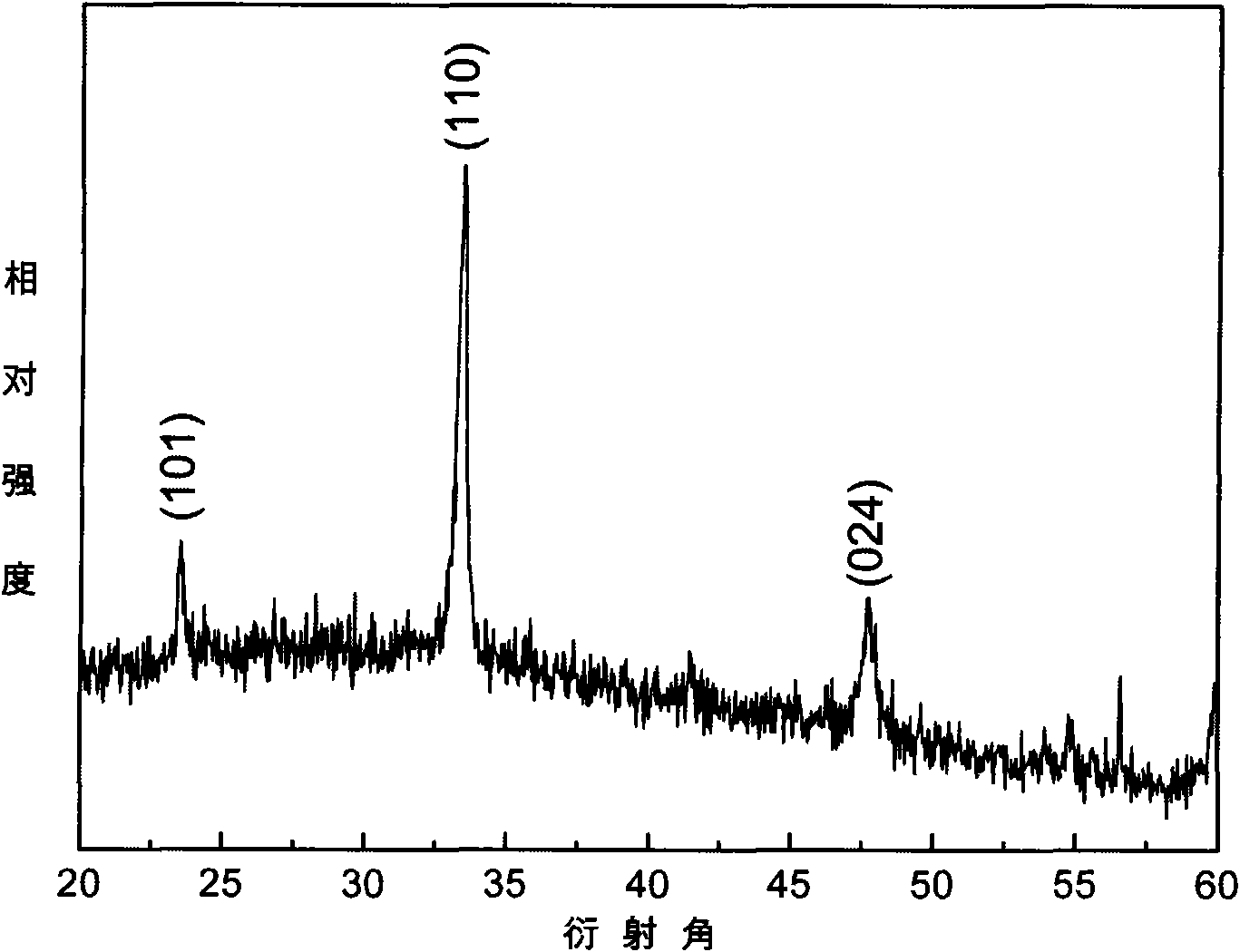

Method for preparing lanthanum nickel oxide thin-film material

InactiveCN101863679ADense shapeSmooth appearanceAfter-treatment detailsNickel compoundsAcetic acidPropanoic acid

The invention discloses a method for preparing lanthanum nickel oxide thin-film materials. The method comprises the following steps: weighing nickel acetate and lanthanum acetate according to 1:1 of molar ratio of nickel to lanthanum; respectively adding the nickel acetate and lanthanum acetate into propanoic acid which is taken as a solvent; respectively stirring for 10-30min at the temperature of 40-70 DEG C to obtain nickel acetate solution; adding lanthanum acetate to the nickel acetate solution; stirring the solution at the temperature of 40-70 DEG C; stirring to transparent state at room temperature to obtain the mixed solution; filtering the mixed solution to obtain a precursor colloid of the lanthanum nickel oxide; placing the precursor colloid of the lanthanum nickel oxide on a substrate to rotatably spray into a gel membrane, then pyrolyzing the gel membrane for 15-30min at the temperature of 300-450 DEG C; repeating the above steps until the pyrolysis membrane with needed thickness is acquired; finally, placing the pyrolysis membrane at the temperature of 600-750 DEG C for annealing for 60-240min to prepare into the lanthanum nickel oxide thin-film material with the membrane thickness of 10nm-1mu m, wherein the material has wide application prospects in the fields, such as membrane materials, information materials, superconducting materials and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

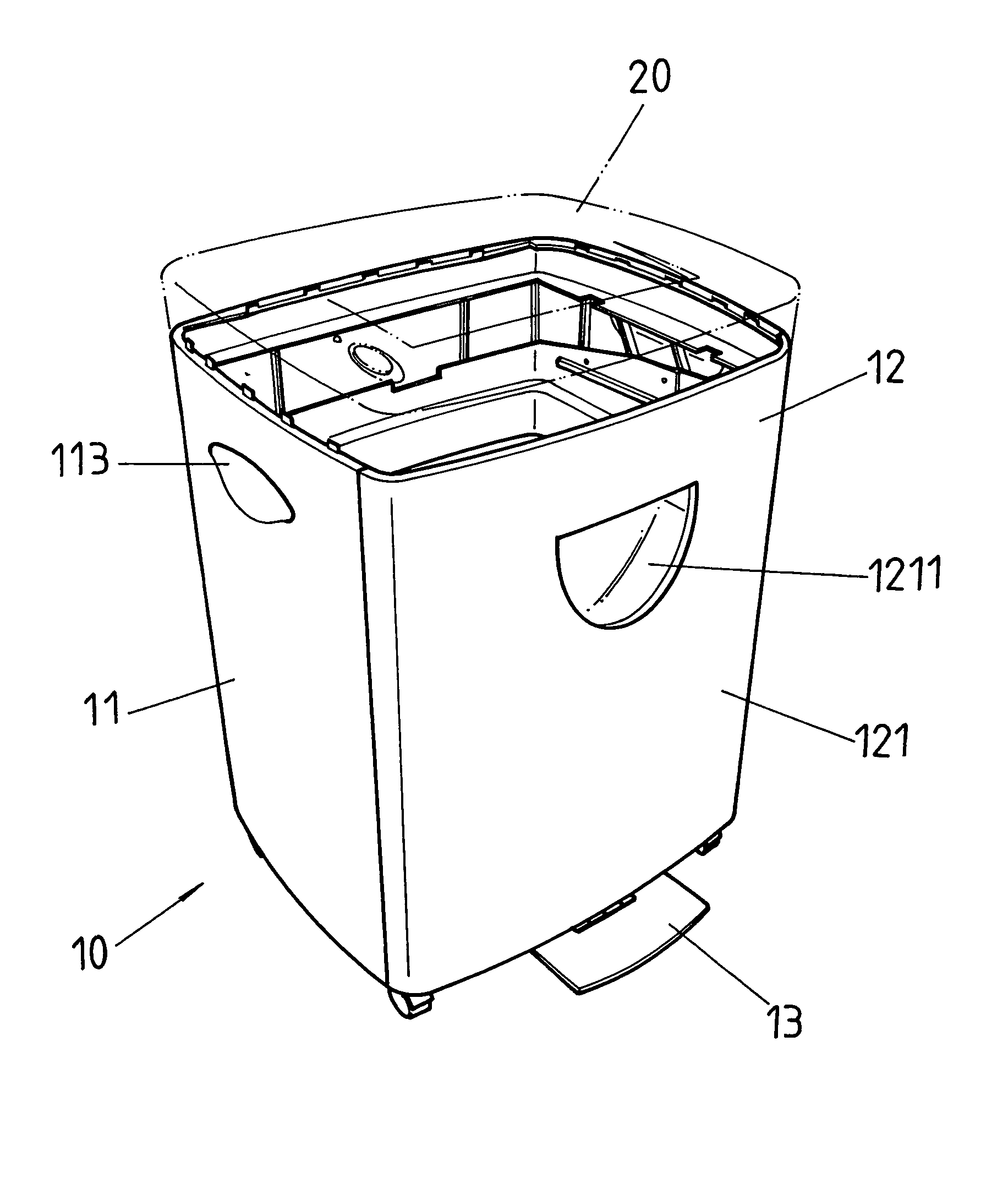

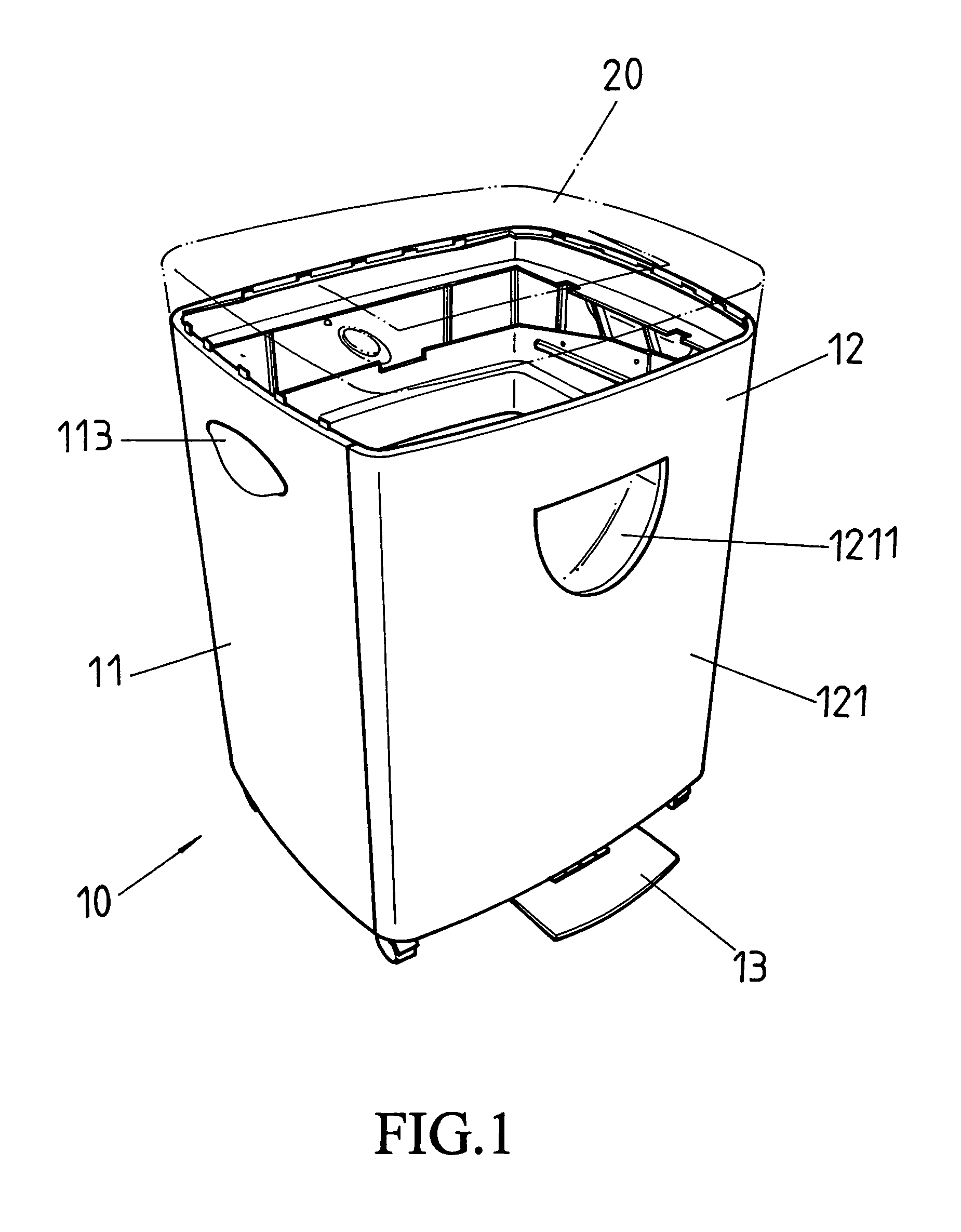

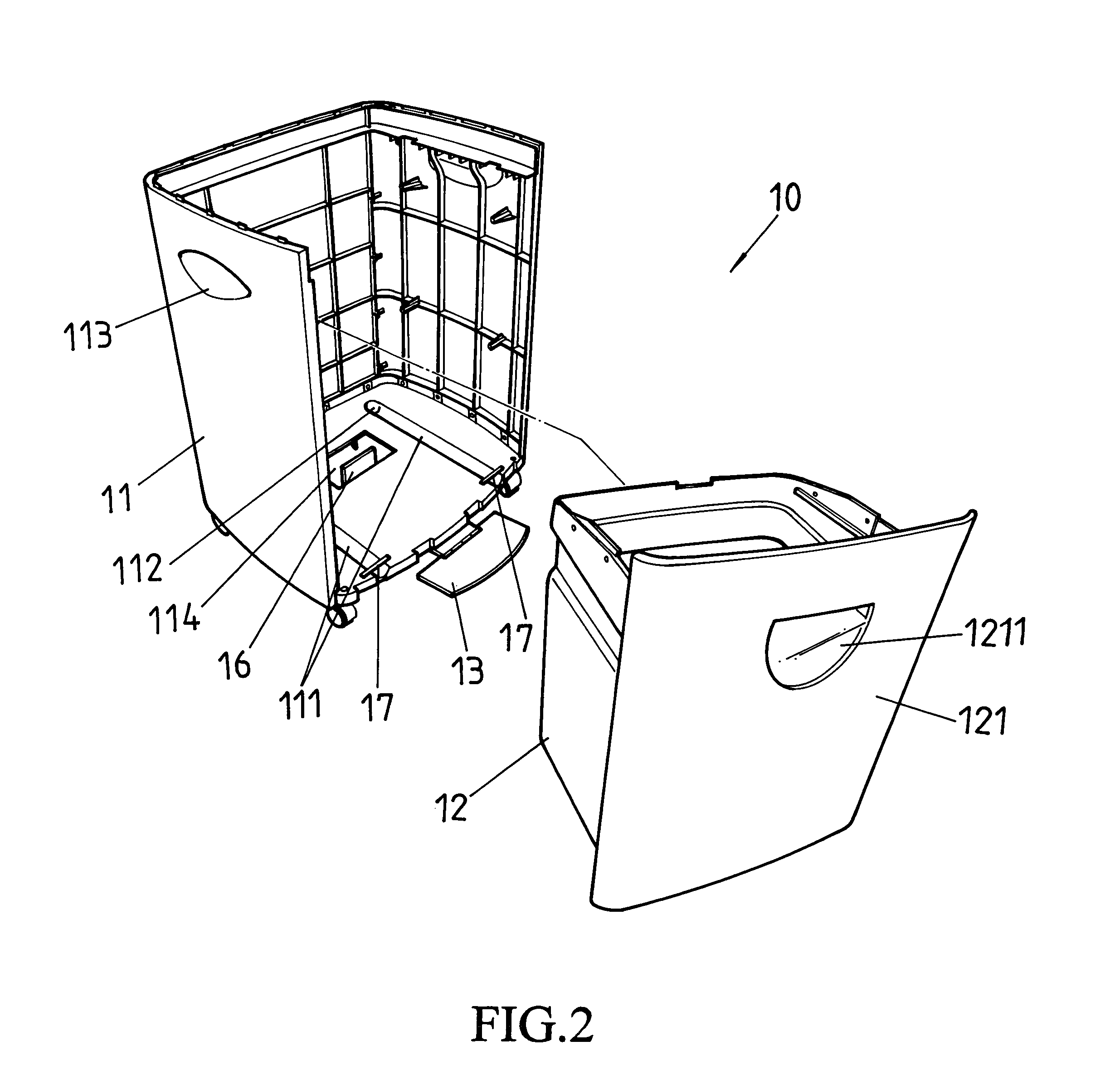

Foot-driven device for displacing a paper shredder bin

The present invention provides a foot-driven device for displacing a paper shredder bin, and is a separable paper shredder bin structured from an outer frame and an inner bin. A front edge of a bottom portion of the outer frame is provided with a foot pedal. The inner bin is caused to lean outward when a user steps on the foot pedal to facilitate throwing waste into the inner bin.

Owner:LO EMILY

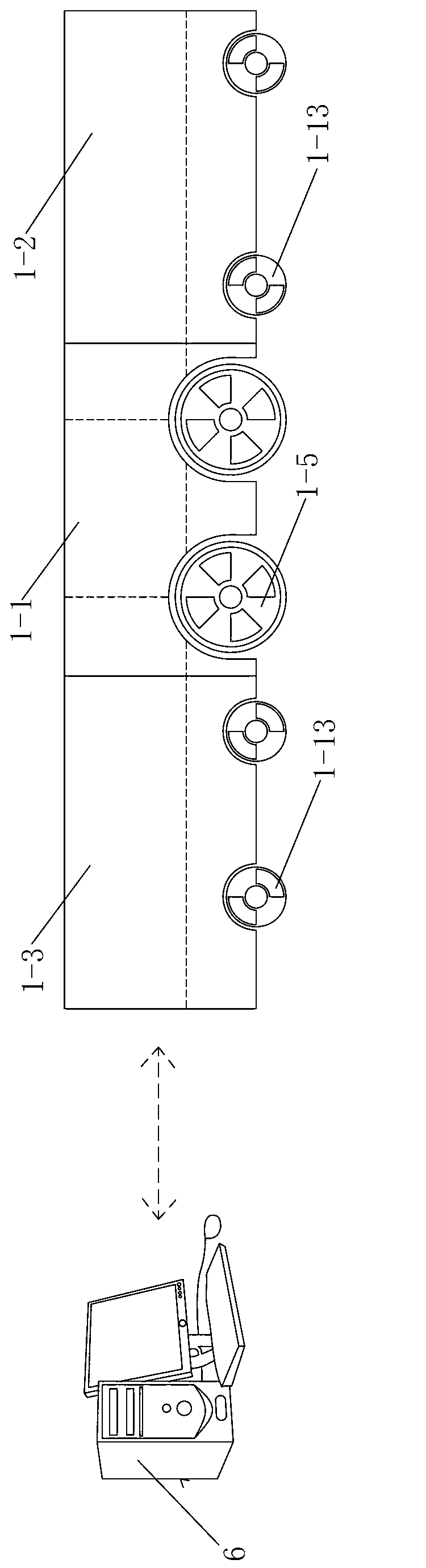

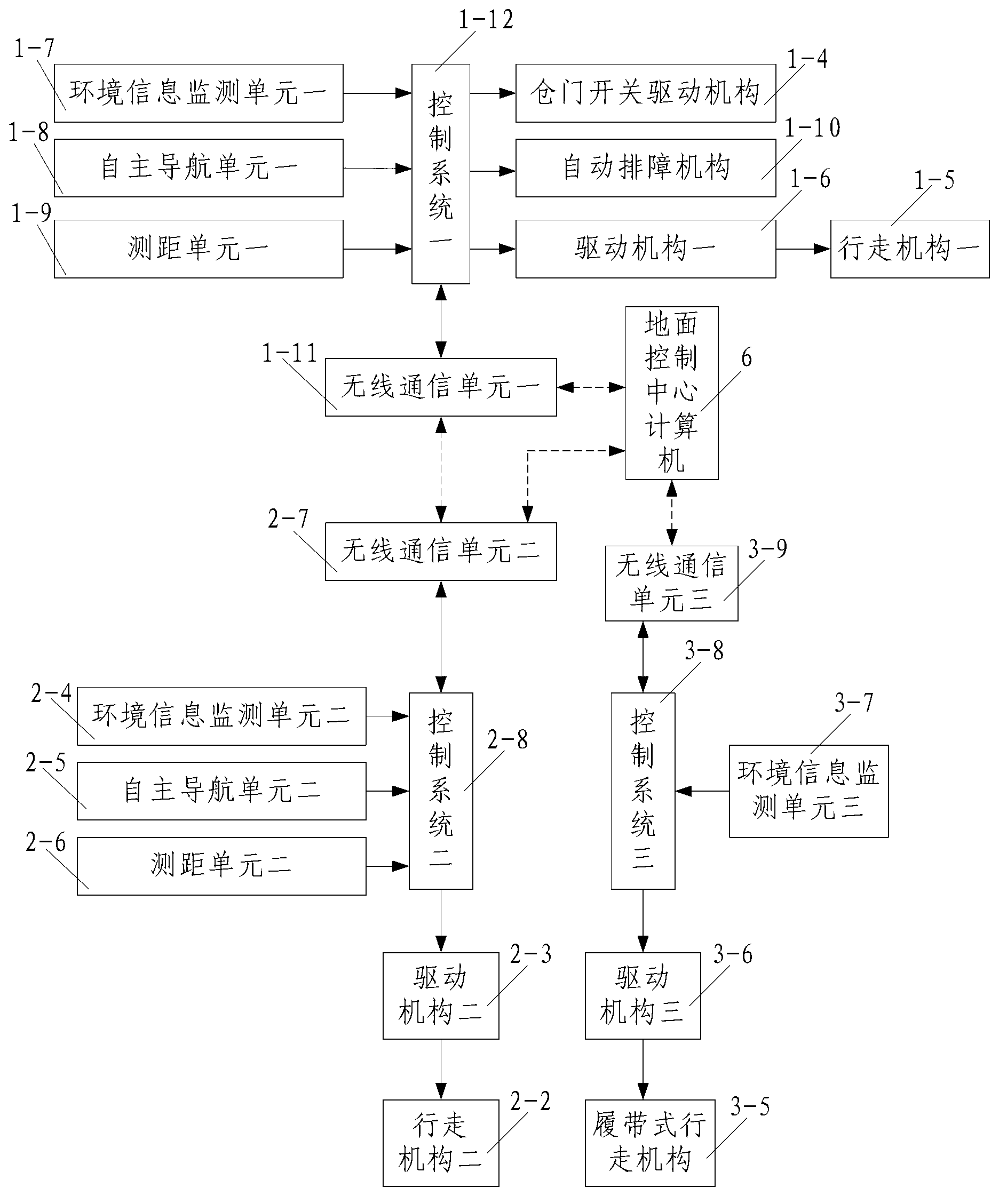

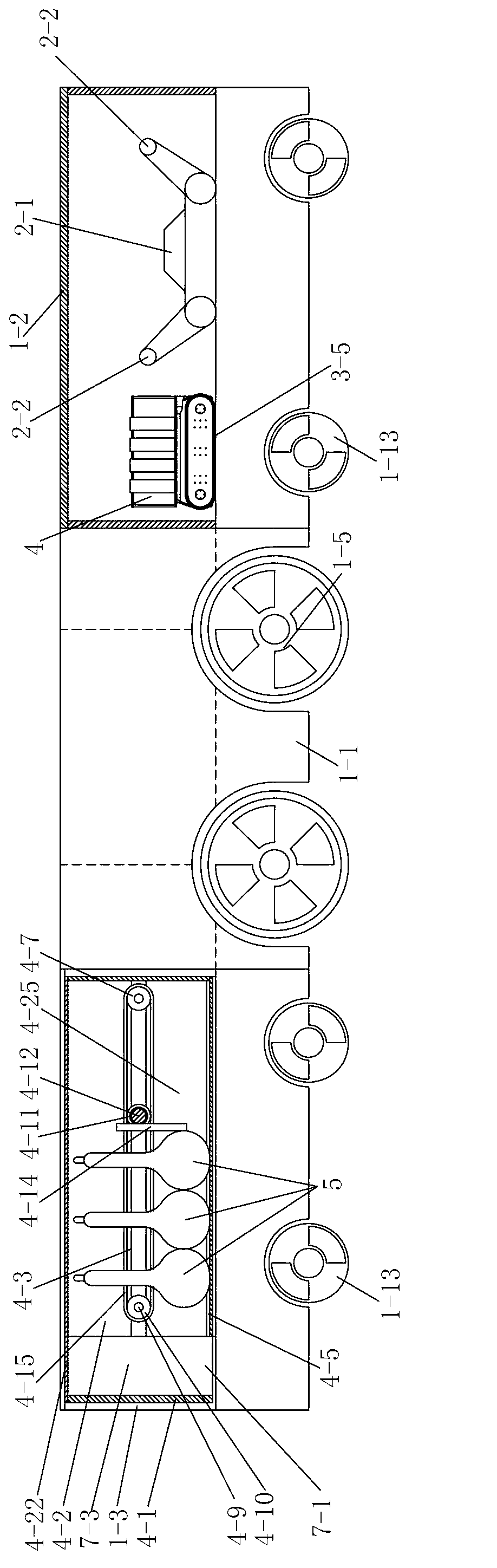

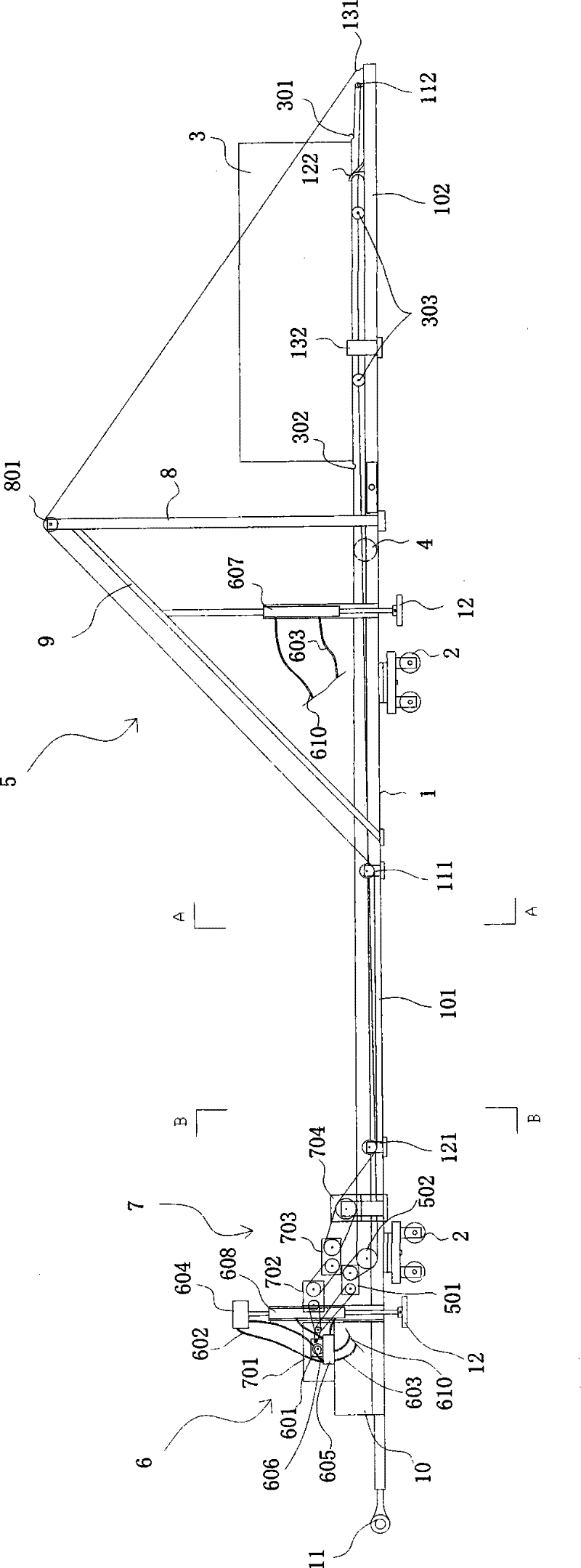

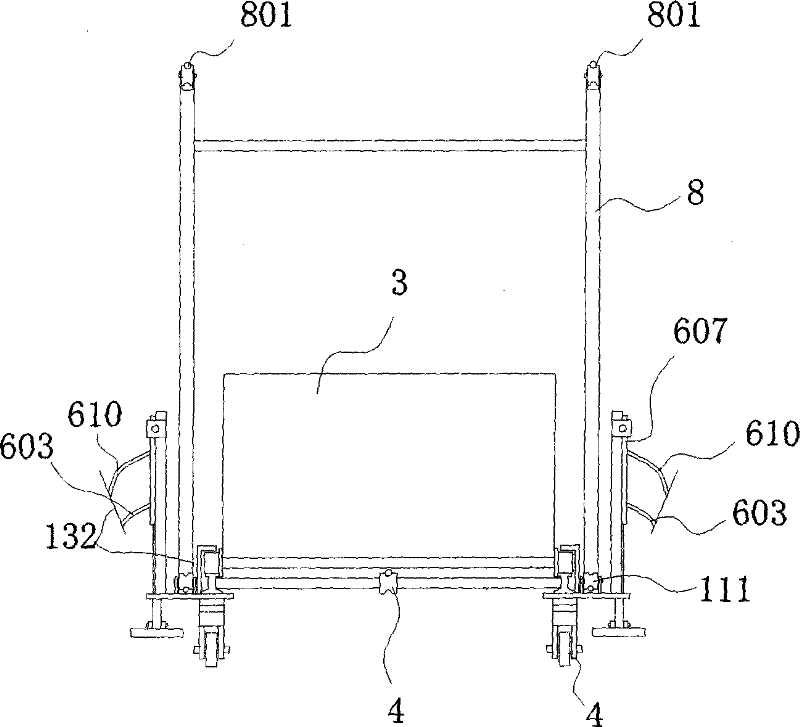

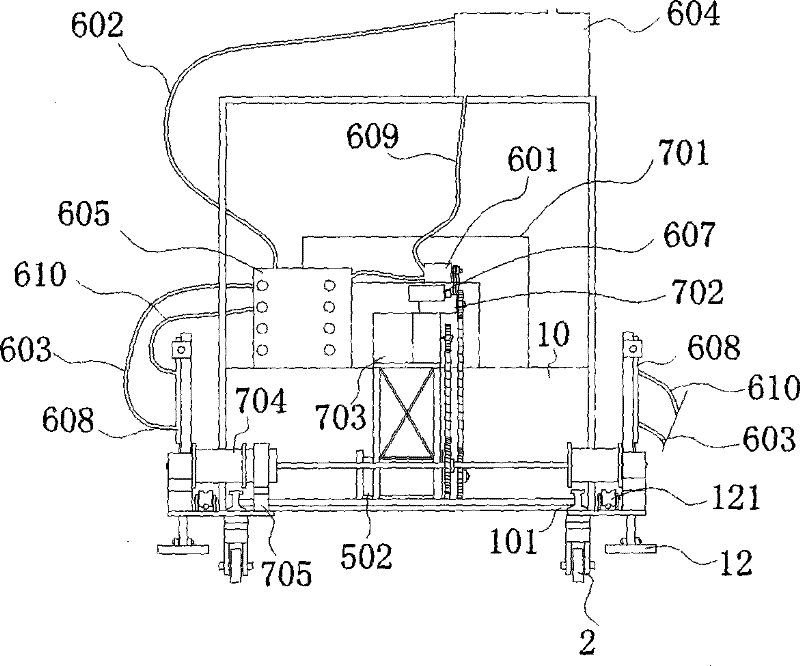

Building system and method of wireless communication network for emergency rescue in underground coal mine

ActiveCN103072600ANovel and reasonable designEasy to implementRailway traffic control systemsRescue robotNetwork link

The invention discloses a building system and method of a wireless communication network for emergency rescue in an underground coal mine. The system comprises a rescue commanding center computer and a rescue robot system. The rescue robot system comprises a carrying robot, a probe robot placed in a robot storage cabin, and a wireless communication relay placing system which places a communication network robot and is placed in a placing system storage cabin. The wireless communication relay placing system comprises a wireless communication relay placing device and a wireless communication relay. The method comprises the steps that first, the carrying robot detects and processes signals, the placing device in the placing system storage cabin casts the wireless communication relay and draws an emergency rescue wireless communication network link map; then, the communication network robot is placed to detect and process the signals and the wireless communication relay is cast to update the map till the underground emergency wireless communication network is built. The system and the method are reasonable in design, strong in practicality and high in popularization and application value.

Owner:XIAN UNIV OF SCI & TECH

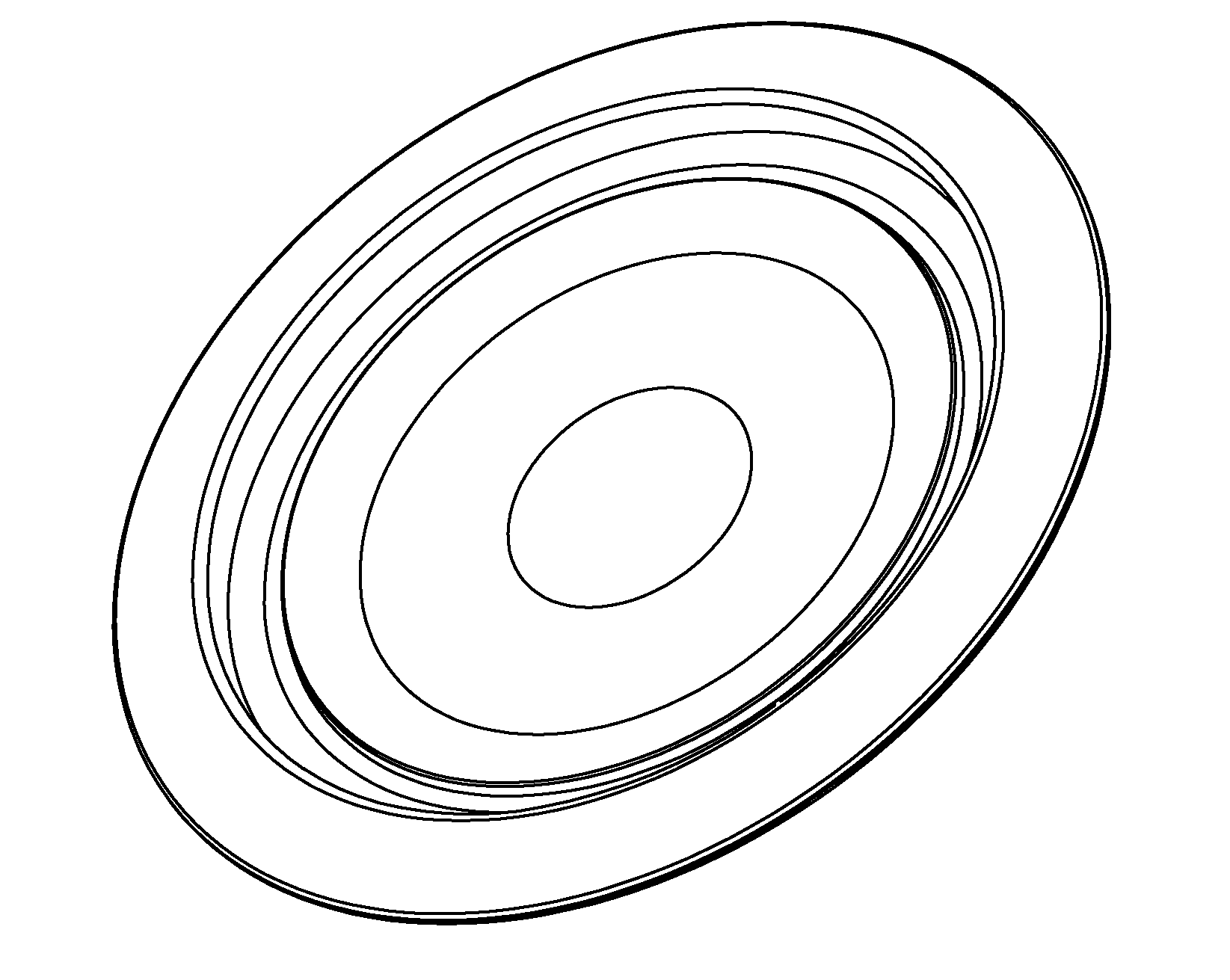

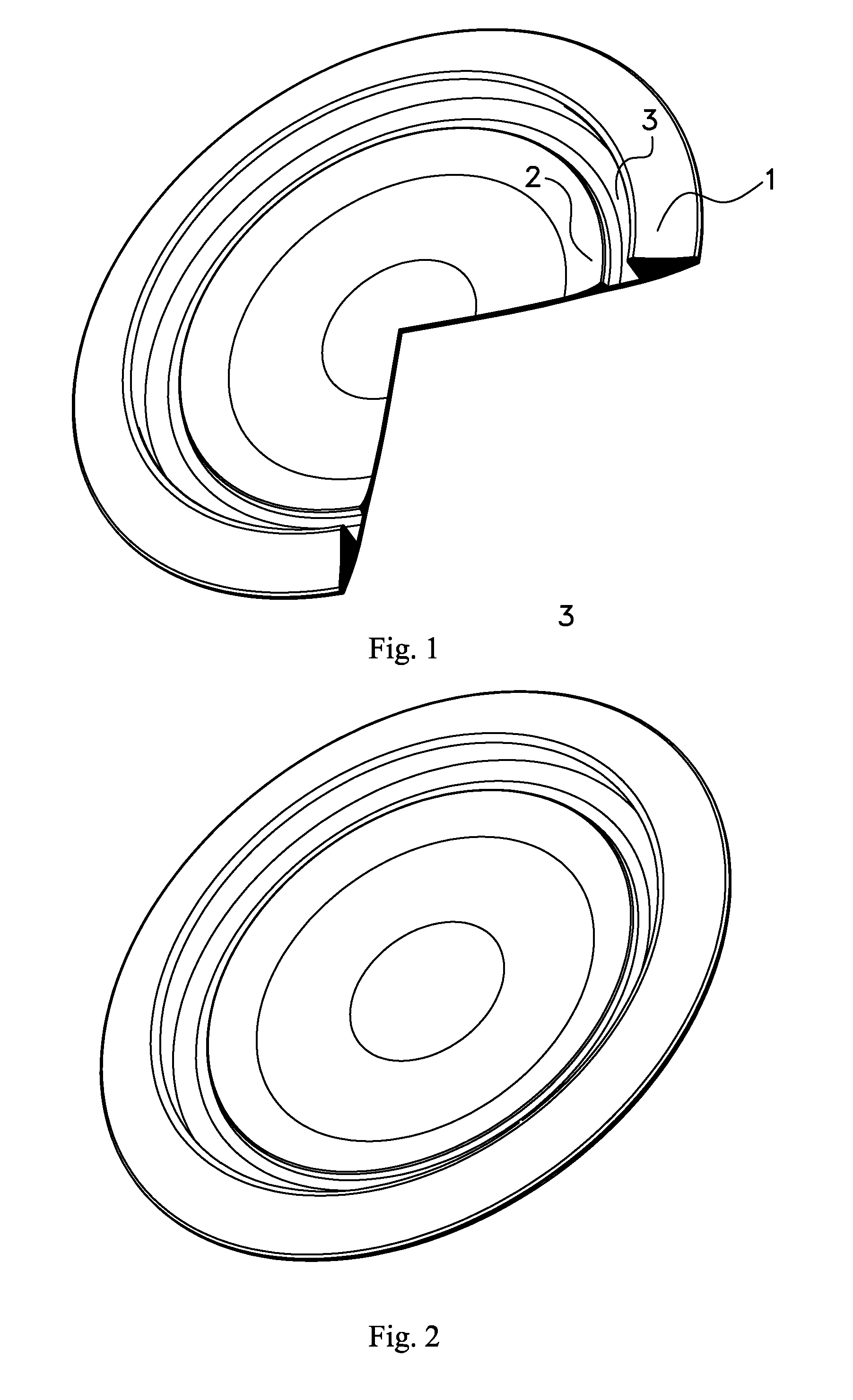

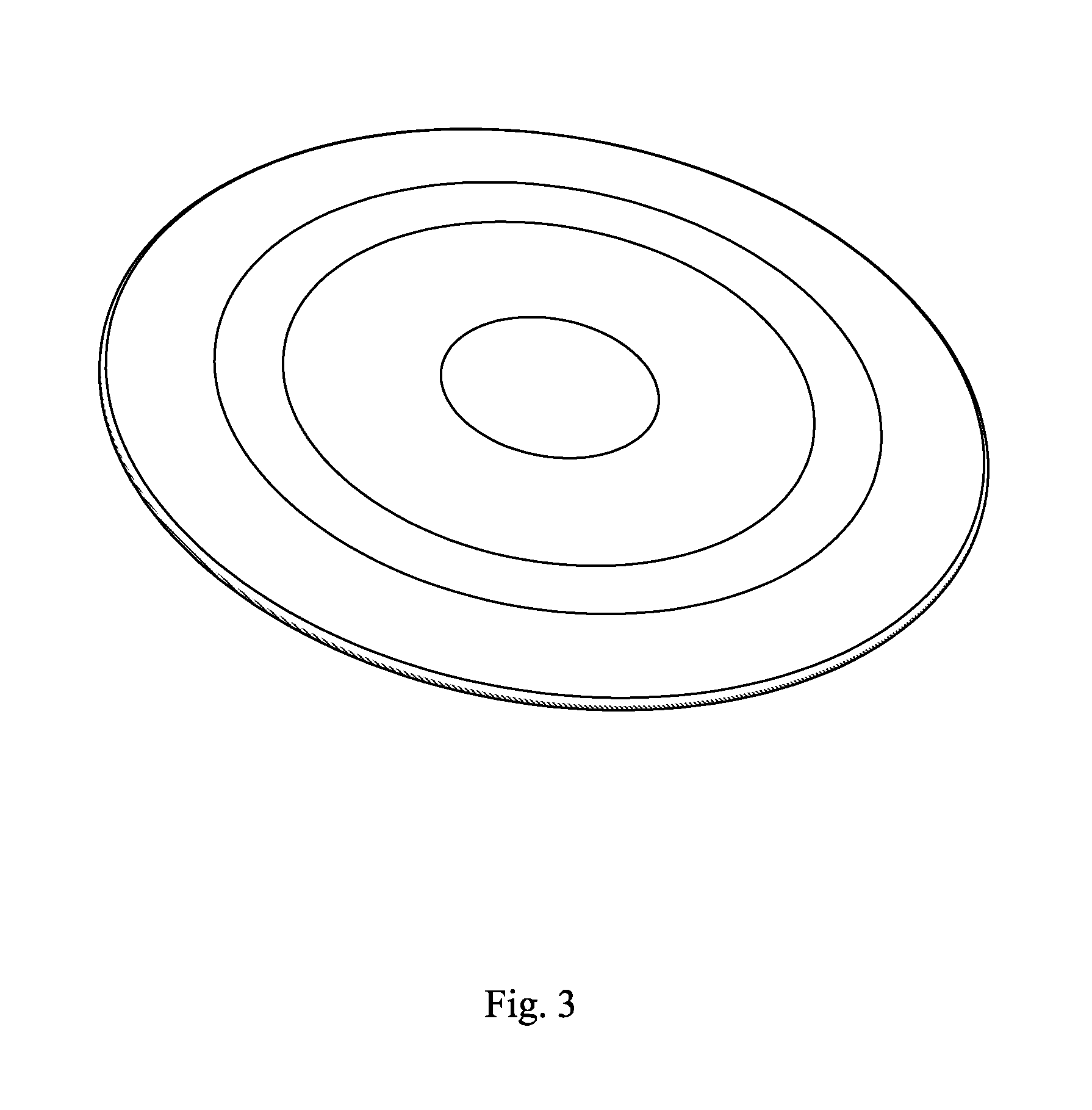

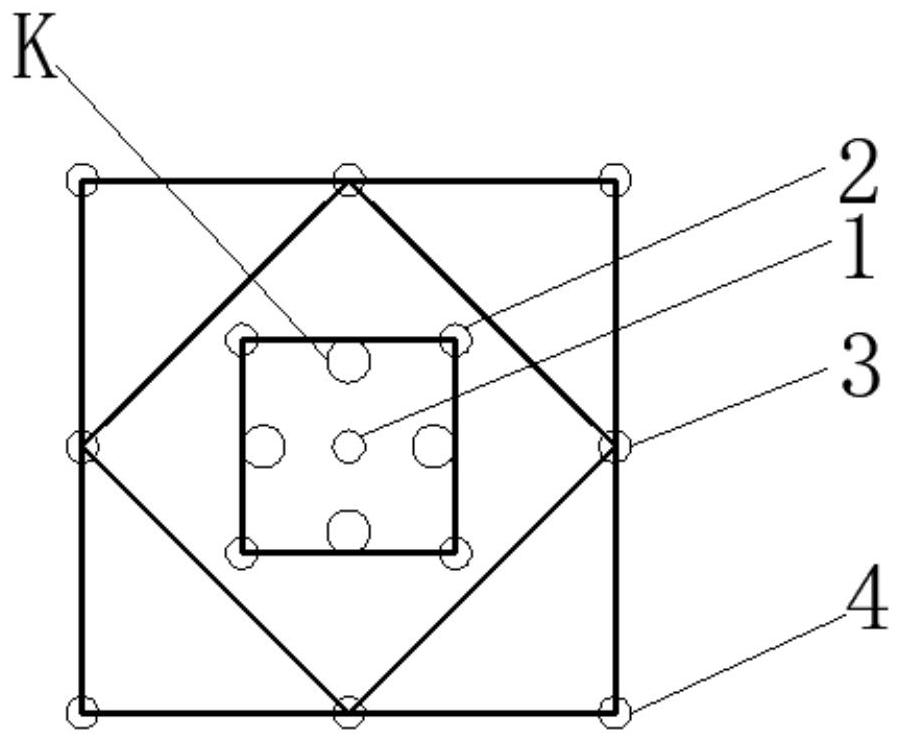

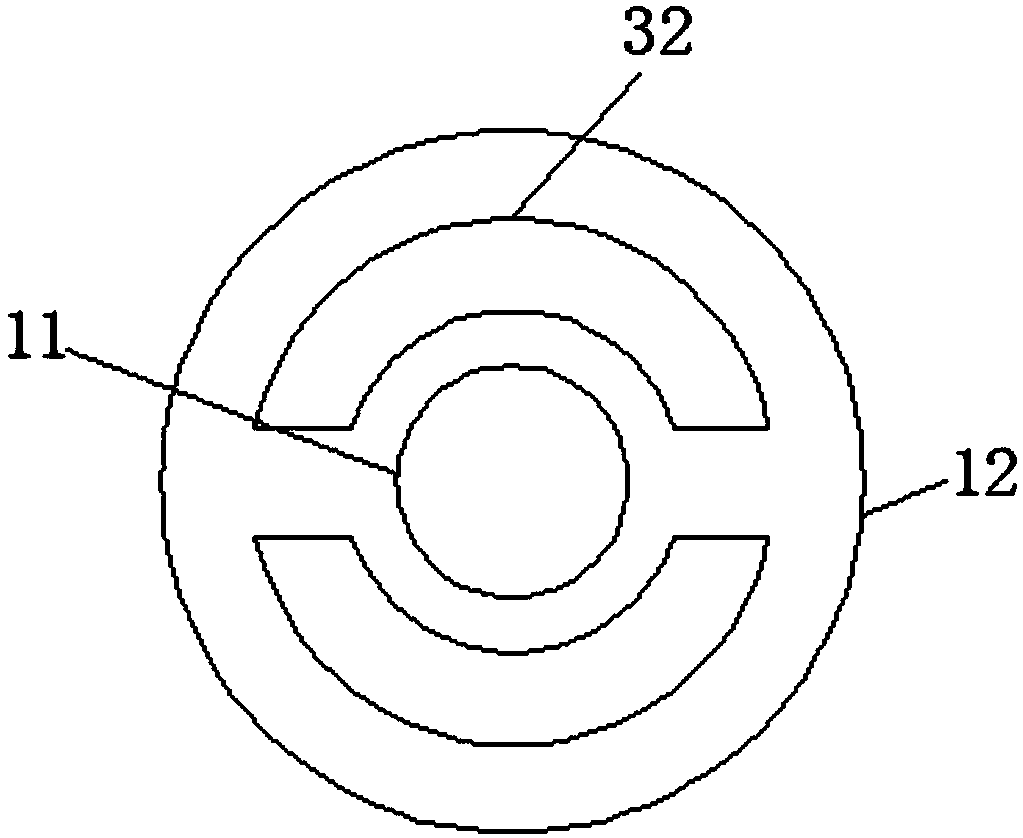

Flying disc

The invention relates to a flying disc constituted as a disc with a first and a second side. The second side has a central portion that is concave and the central portion is surrounded by an innermost rim (2) and an outermost rim (1) extending to the disc's periphery. The innermost rim (2) is separated from the outermost rim (1) by a circularly symmetrical depression (3). This depression gives the disc superior aero dynamical properties, allowing it to glide further in the air than corresponding prior art discs.In one embodiment, the face of the outermost rim (1) nearest the centre of the disc extends essentially in parallel to the centre axis of the disc. This makes it particularly easy to grasp the disc and facilitates throwing the disc.In another embodiment, the concave central portion of the second side extends along a virtual concave surface to the innermost rim, where the virtual concave surface further extends essentially to the part of the outer rim that extend the furthest from the first side of the disc. This further optimizes the aero dynamical properties of the disc.Typically, the outermost rim (1) has a face on the second side of the disc, which is concave, and the first side of the disc is convex.

Owner:LINDBERG JONAS

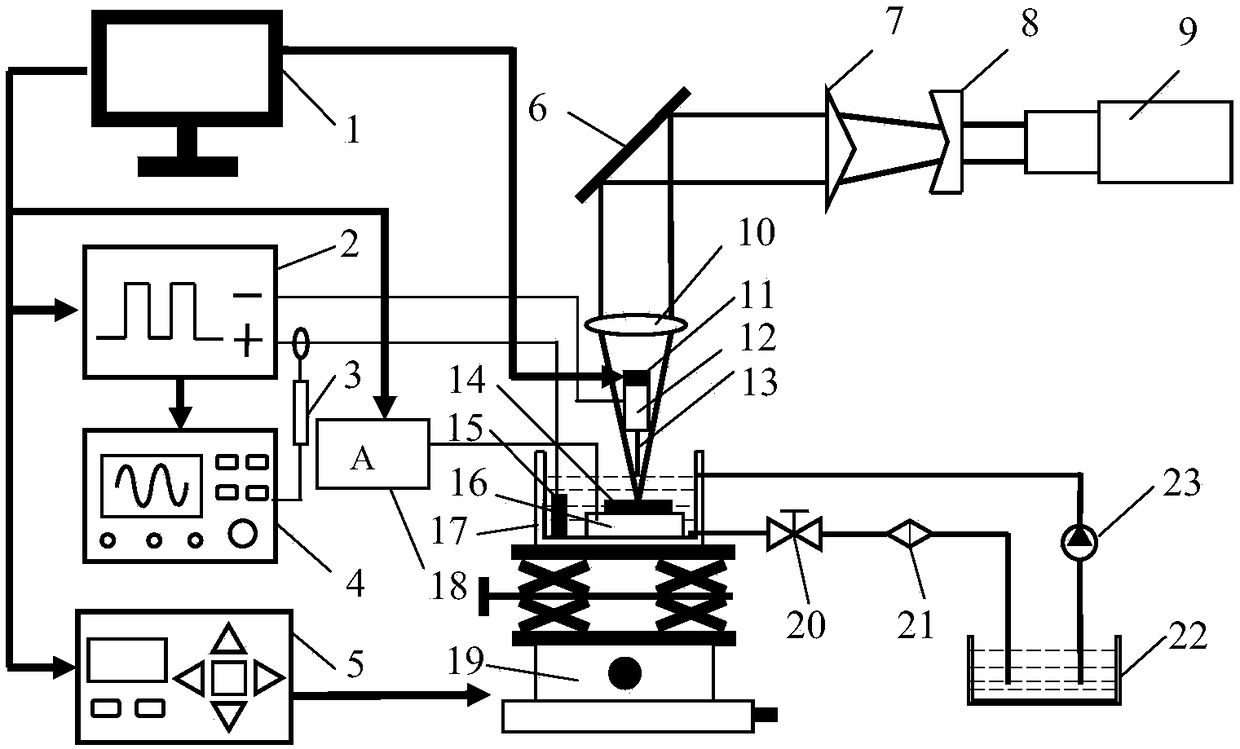

Machining device and method for synchronizing piezoelectric ceramic vibration and electrochemistry discharging

InactiveCN108655521AEasy to throwEasy to updateLaser beam welding apparatusElectrical-based auxillary apparatusElectricityPower flow

The invention provides a machining device and method for synchronizing piezoelectric ceramic vibration and electrochemistry discharging and belongs to the field of special composite machining. When anelectrochemistry power source outputs pulse currents, a piezoelectric ceramic power source outputs forward voltage excitation signals synchronously, piezoelectric ceramic is bent upwards, and a gap between a workpiece and a tool electrode becomes smaller; during pulse intermittence of the electrochemistry power source, when no glass workpiece is subjected to discharging machining, the piezoelectric ceramic power source outputs negative voltage excitation signals, the piezoelectric ceramic is bent downwards, and the gap between the workpiece and the tool electrode becomes large. The electrochemistry power source and the piezoelectric ceramic power source carry out discharging synchronously to enable the machining gap during the discharging stage to be reduced, the utilization efficiency ofthe discharging energy is improved, and the machining locality is enhanced; and during discharging stop intermittence, the machining gap becomes large, which is beneficial for throwing out corrosiveimpurities and updating electrolyte.

Owner:JIANGSU UNIV

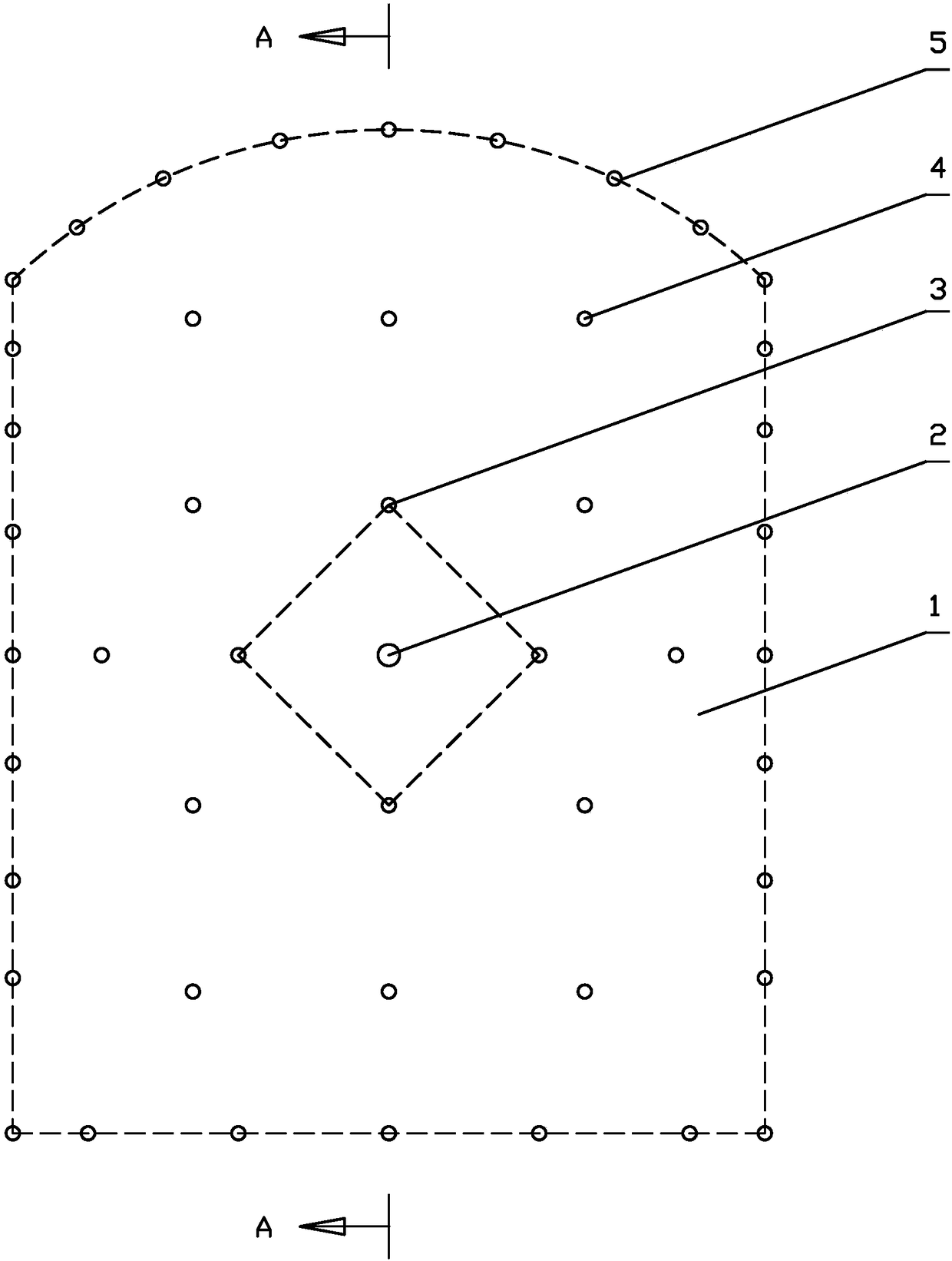

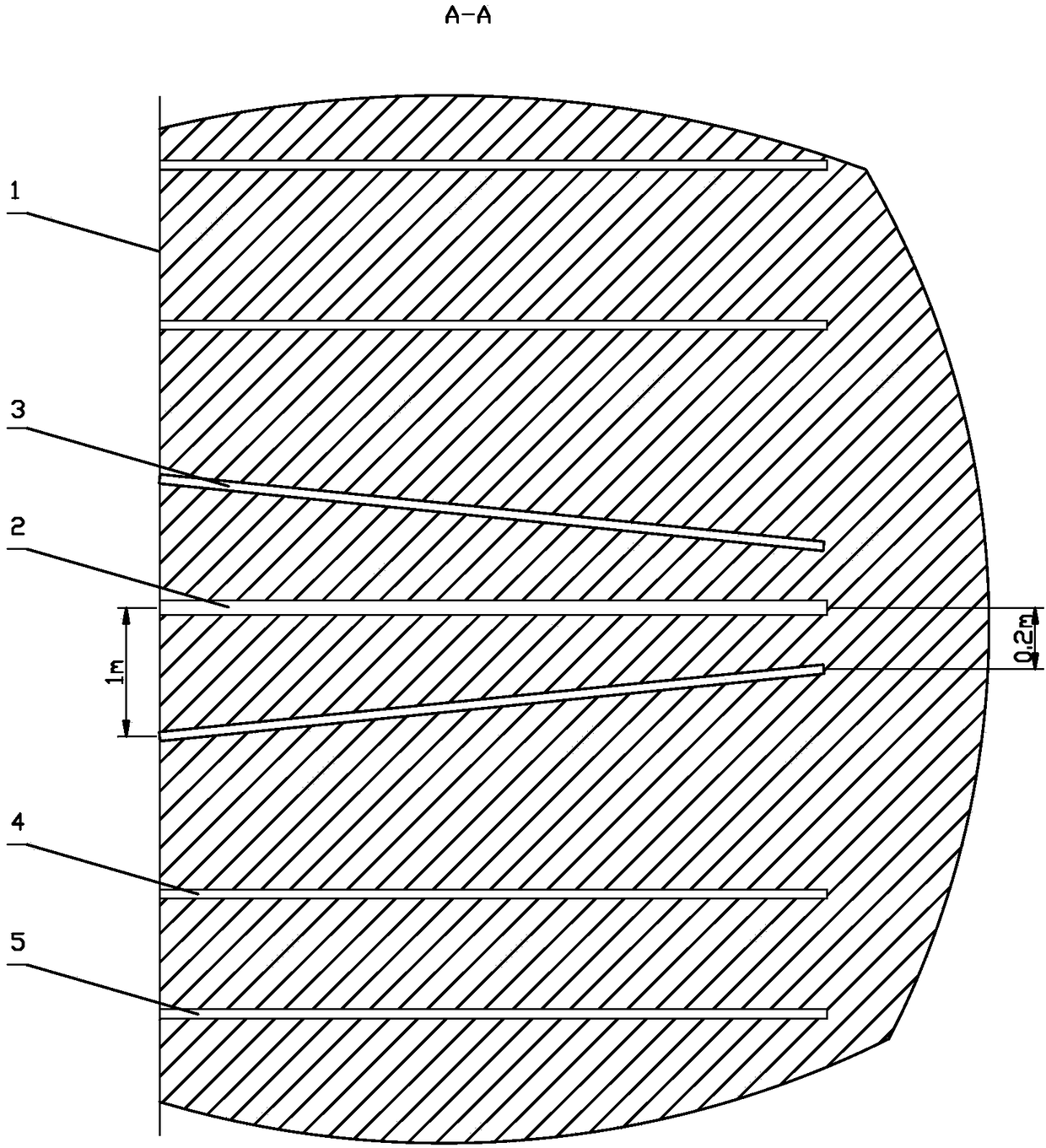

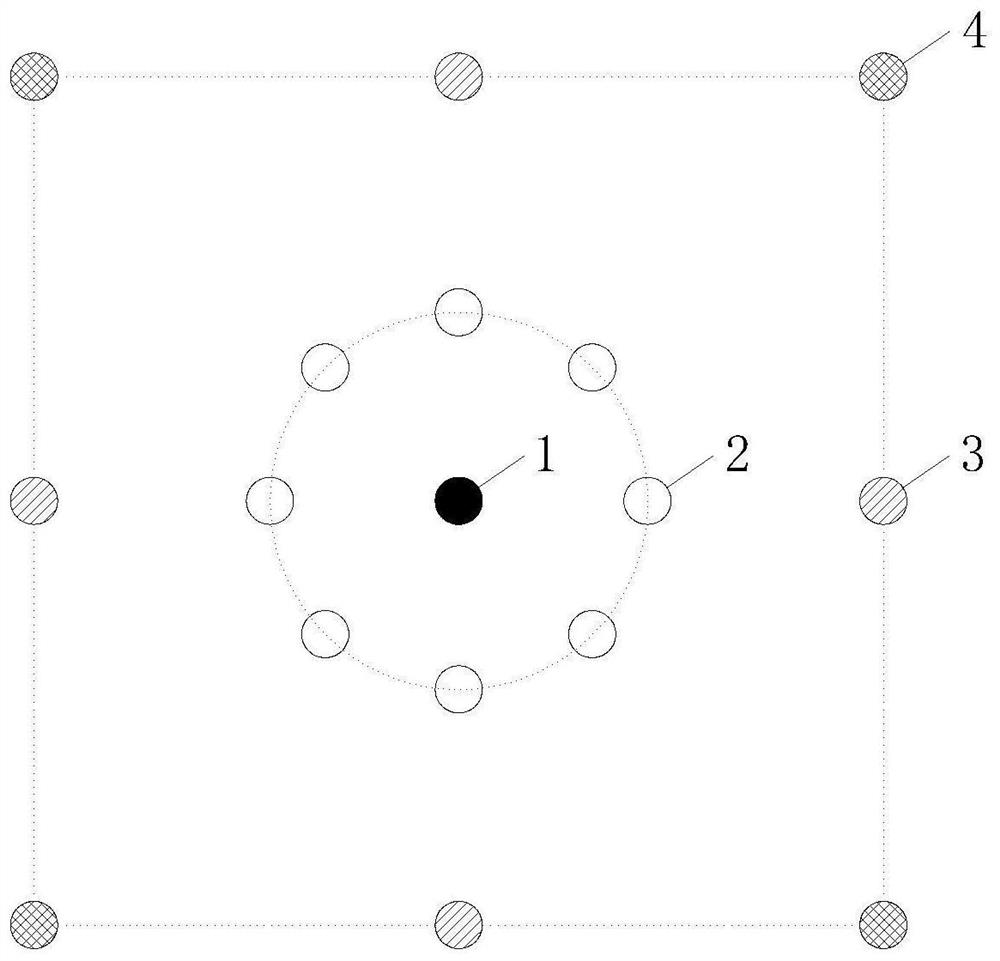

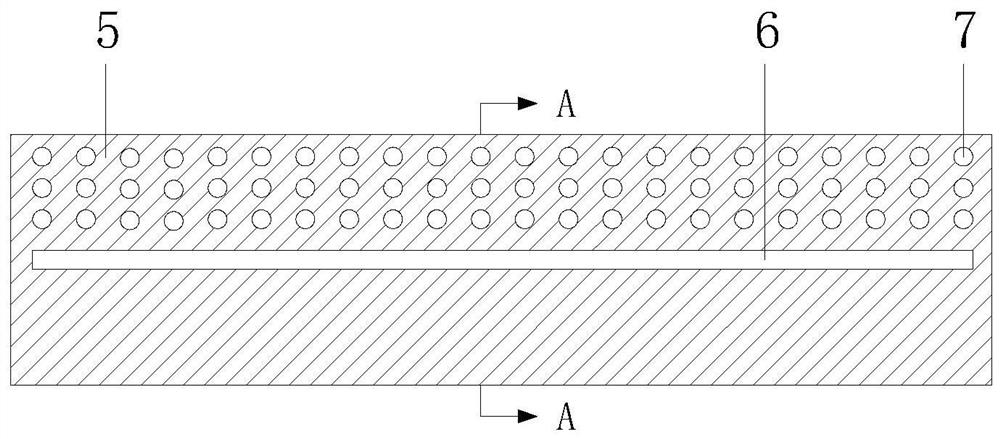

Blast hole forming structure for cutting blasting of small section roadway

The invention discloses a blast hole forming structure for cutting blasting of a small section roadway. The blast hole forming structure comprises a center hole formed in the center of a roadway driving working face and cutting blasting holes formed around the center hole. Auxiliary holes are formed in the peripheries of the cutting blasting holes. Peripheral holes are formed in the edge of the design section of the roadway driving working face. The axial directions of the auxiliary holes and the peripheral holes and the hole direction of the center hole are the same as the cutting blasting driving direction of the roadway. The cutting blasting holes are concentrated gradually towards the center hole from a hole opening to the hole bottom. According to the blast hole forming structure forcutting blasting of the small section roadway, the scheme that the hole bottoms of the cutting blasting holes are concentrated to the position near the center hole, and concentrated charging and detonating together are implemented is adopted, the number of drilled holes is small, the consumption amount of explosive is low, the center hole serves as the auxiliary free surface during charging blasthole blasting and a compensation space of a broken body, the broken body is thrown out advantageously, and the cutting blasting effect is good.

Owner:内蒙古康宁爆破有限责任公司

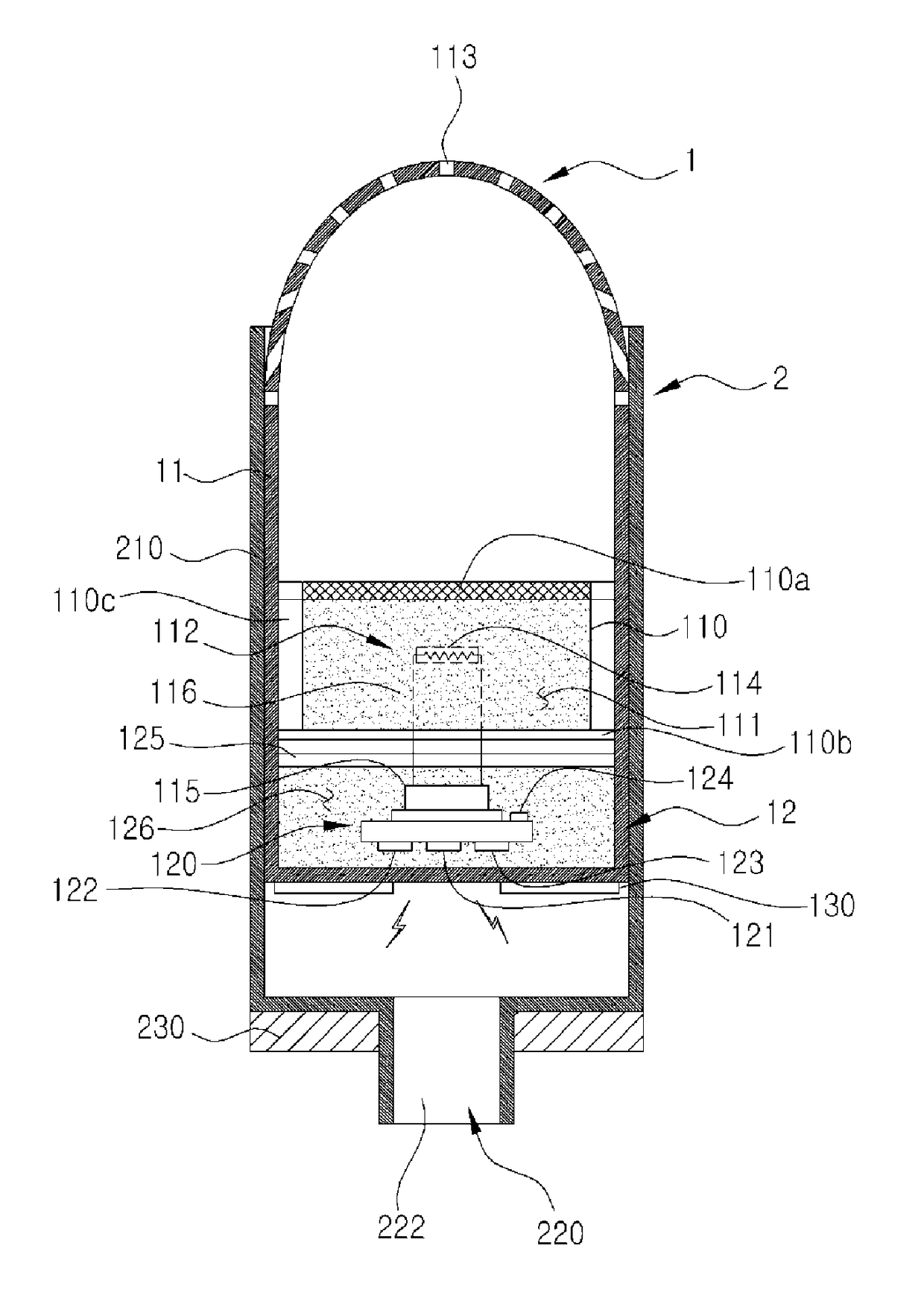

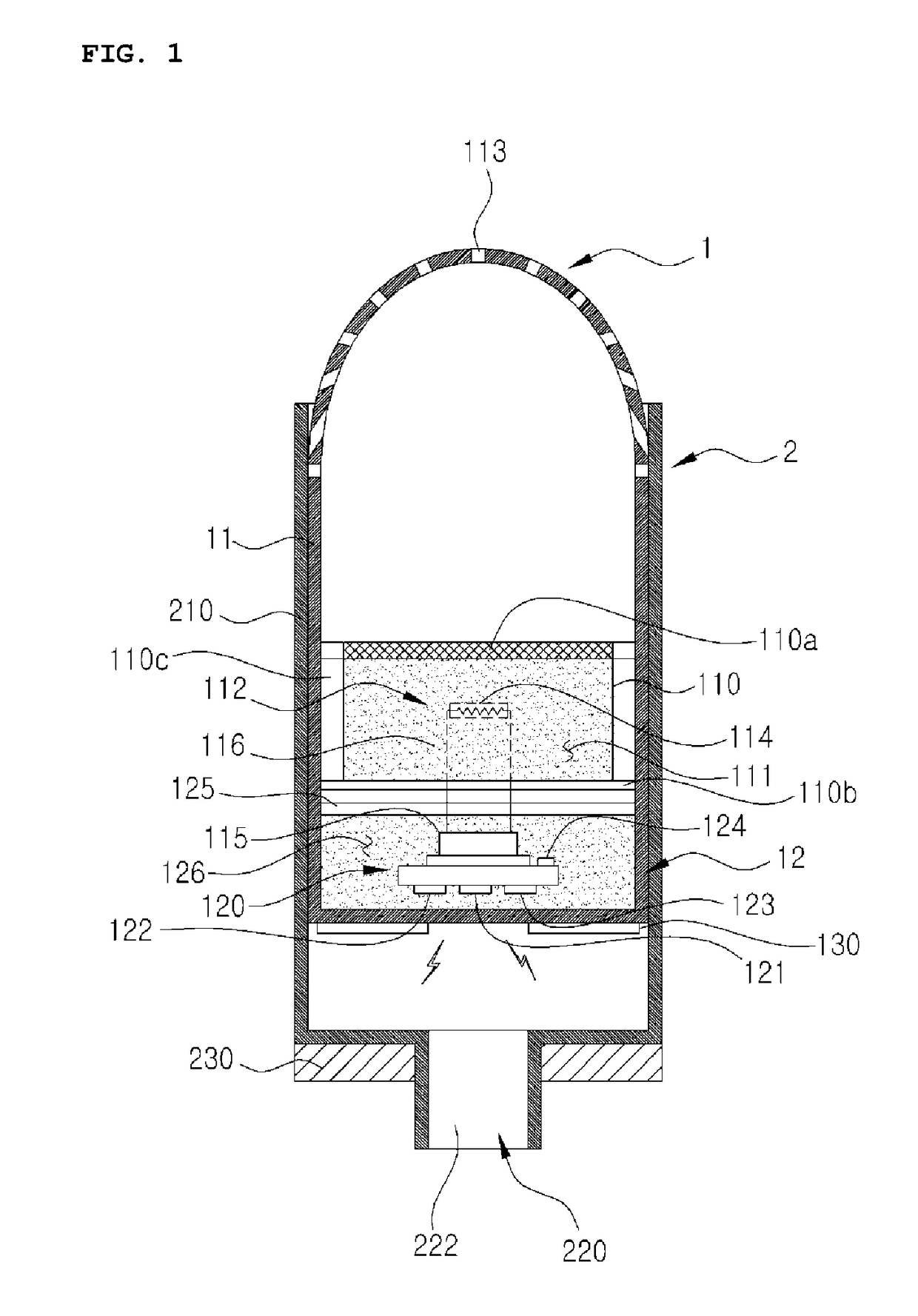

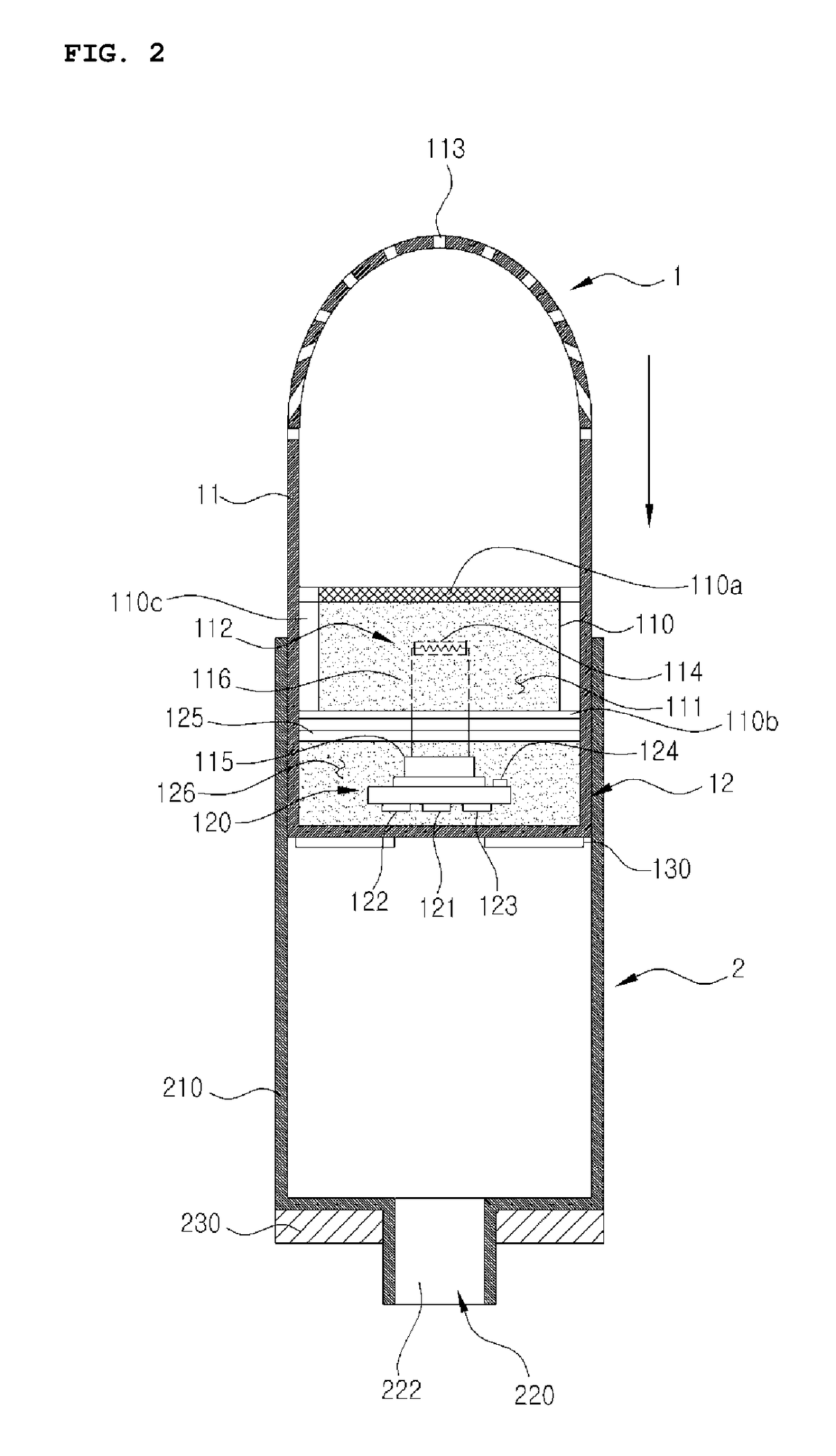

Fire extinguishing bullet system for launching

ActiveUS9671203B1Easy to throwSimply kept and usedAmmunition projectilesFire rescueEngineeringProjectile

Disclosed herein is a fire extinguishing bullet system for launching, which is capable of effectively extinguishing a fire generated at a place that is difficult to access by a person by loading a fire extinguishing bullet that generates a fire extinguishing gas having a fire extinguishing effect onto a projectile, throwing the fire extinguishing bullet loaded at a long distance from a firing point to a specific distance, and discharging the fire extinguishing gas after the fire extinguishing bullet reaches the firing point.

Owner:CHANG SUNG CO LTD

Environmentally friendly snow melting agent and preparation method thereof

The invention relates to an environmentally friendly snow melting agent which comprises the following components in percentage by weight: 90-110 percent of calcium chloride, 15-25 percent of urea, 15-25 percent of sodium nitrite, 10-15 percent of potassium sulphate, 22-30 percent of sodium metasilicate and 50-90 percent of carbon black. The environmentally friendly snow melting agent can be used for effectively solving the problems of the traditional snow melting agent used in China on corrosion to metal and cement concrete, damage to plant growth, and the like. The snow melting agent product does not contain sodium chloride, thereby reducing the influences and the damages to roads and environment of ordinary snow melting agents, and has the advantages of high snow melting speed, no corrosion, small feed dose, economy, environmental protection, and the like. Products after melting can be used for promoting the growth of plants, and compared with the traditional products, the snow melting agent has micro corrosion to the metal and the cement concrete and also has safety and reliability; the residual products after snow melting can be used for promoting the growth of the plants so as to realize reutilization; and the snow melting agent is easy to deliquesce, has certain effects of stabilizing soil and controlling dust and good flowability and is easy to scatter and mechanically spread.

Owner:赵欣

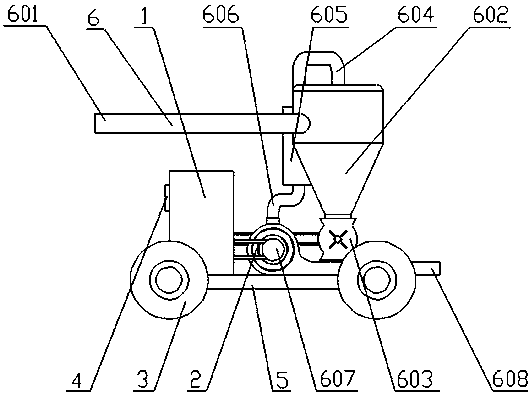

Movable type sandy-soil-throwing fire extinguishing device

The invention discloses a movable type sandy-soil-throwing fire extinguishing device comprising a movable vehicle body, a sandy soil conveying mechanism and a control system. The control system and the sandy soil conveying mechanism are installed on the movable vehicle body. The sandy soil conveying mechanism comprises a feeding pipe, a discharging pipe, a material separator, an airlock and a draught fan. The material separator comprises a feeding opening, a discharging opening and an air outlet. The feeding opening communicates with the feeding pipe. The discharging opening communicates withthe discharging pipe through the airlock. The air outlet communicates with the air inlet of the draught fan. The control system comprises a controller, a vehicle body movement driving mechanism and asandy soil conveyance driving mechanism. The controller controls the movable vehicle body to move through the vehicle body movement driving mechanism. The controller controls the airlock and the draught fan in the sandy soil conveying mechanism to operate through the sandy soil conveyance driving mechanism, sandy soil materials are made to enter the movable type sandy-soil-throwing fire extinguishing device via the feeding pipe, sequentially pass through the material separator and the airlock and then flow out from the discharging pipe. The movable type sandy-soil-throwing fire extinguishing device can move, suck the sandy soil at a sand pile and blow out the sandy soil to cover a fire site, the fire extinguishing efficiency is high, and the safety of rescue workers can be guaranteed.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Cutting blasting method based on pre-blasting

The invention relates to a cutting blasting method based on pre-blasting. The cutting blasting method comprises the following steps: (1) a center charge hole is drilled in the center of a cut area, acircle of empty holes are drilled in the periphery of the center charge hole, main cutting holes and compensation cutting holes are drilled in the peripheries of the empty holes, and auxiliary holes,breaking holes and peripheral holes are sequentially drilled in the outer sides of the cutting holes; (2) the center charge hole is continuously filled with an explosive, the main cutting holes and the compensation cutting holes are continuously filled with 1 / 2 cumulative charge and 1 / 4 cumulative charge correspondingly, the auxiliary holes, the breaking holes and the peripheral holes are continuously filled with explosives, and blast holes are blocked by stemming; (3) the center charge hole is separately initiated to form a pre-blasted area; and (4) the remaining blast holes adopt micro-delayinitiation to achieve full-face one-time blasting. A large free face and rock breaking expansion space can be provided for cutting blasting, the surrounding rock clamping effect is overcome, the cutting effect is improved, and the overall blast hole utilization rate is increased.

Owner:ANHUI UNIV OF SCI & TECH

Explosion simulator

InactiveUS6845715B2Easy to throwSlow onsetAmmunition projectilesFirework simulationsEngineeringMechanical engineering

Owner:SANSOLO ARIE

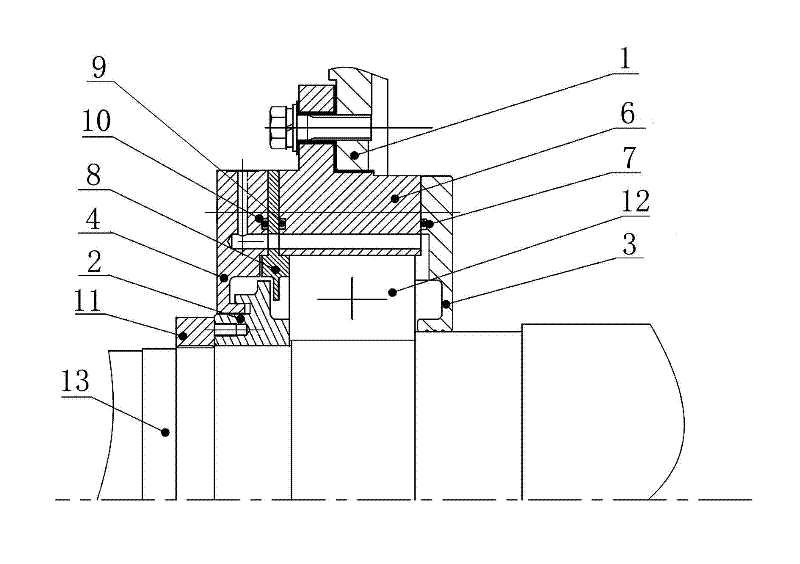

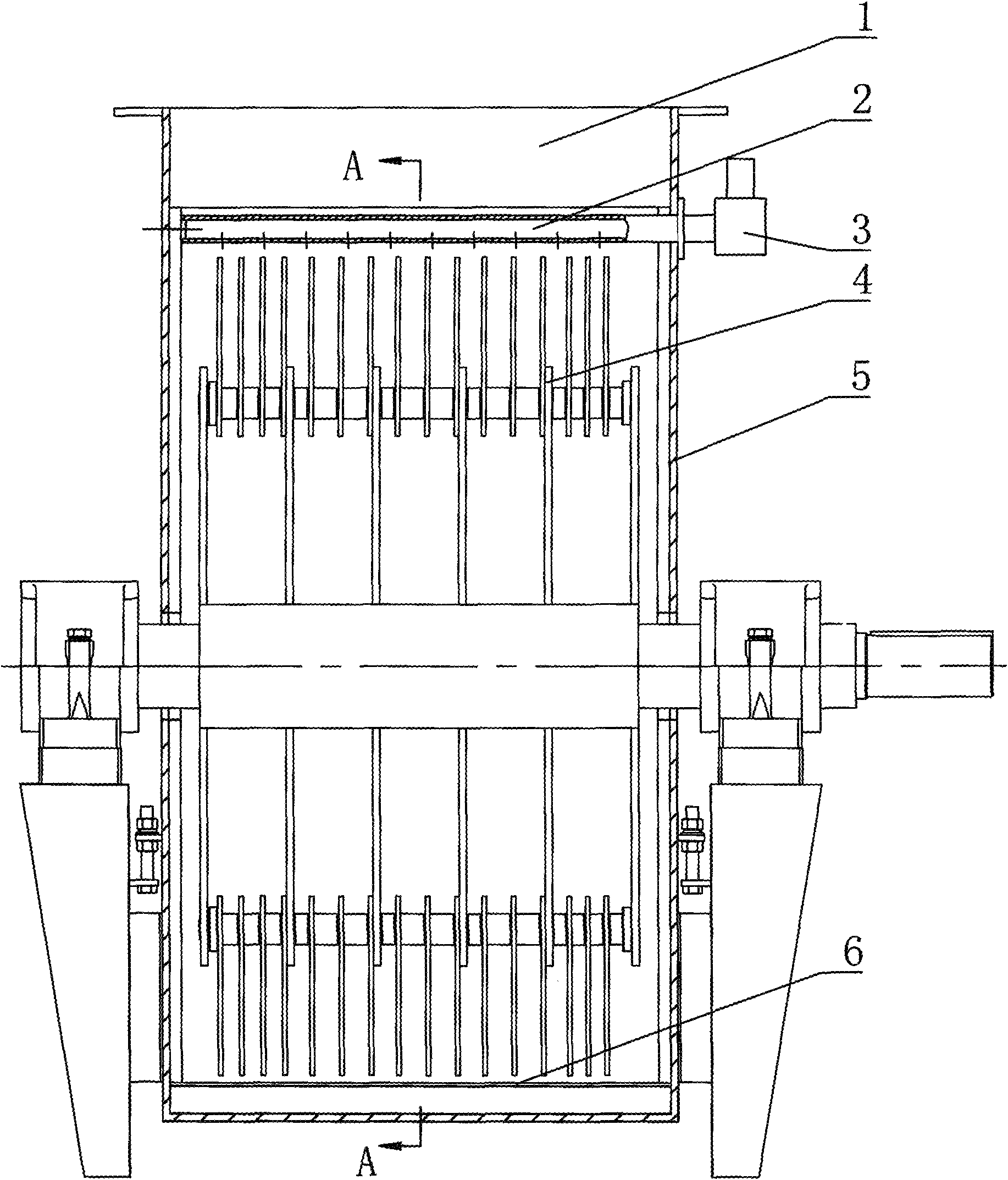

Motor bearing lubrication system

ActiveCN102510160APrevent leakagePrevent throwingSupports/enclosures/casingsForeign matterEngineering

The invention relates to a motor bearing lubrication structure, in particular to a motor bearing lubrication system. The motor bearing lubrication system solves the problem that lubricating grease always leaks and throws out, and is always accumulated in an outer bearing cover and external foreign matters are easy to enter the bearing when the traditional motor bearing lubrication structure is used. The motor bearing lubrication system comprises an end cover, a sealing ring, an inner bearing cover and an outer bearing cover, wherein the outer bearing cover is provided with a grease discharging hole; the inner side of the end cover is sheathed with a bearing chamber; the end surface of the outer side of the bearing chamber is provided with an oil deflector ring; a second O-shaped seal ringis installed between the end surface of the inner side of the oil deflector ring and the end surface of the outer side of the bearing chamber; and a labyrinth seal is arranged between the end surfaceof the outer side of the seal ring and the end surface of the inner side of the outer baring cover. According to the motor bearing lubrication system, the problem that the lubricating grease always leaks and throws out, and is always accumulated in the outer bearing cover and the external foreign matters are easy to enter the bearing when the traditional motor bearing lubrication structure is used can be effectively solved, and the motor bearing lubrication system is suitable for the motor bearing lubrication.

Owner:CRRC YONGJI ELECTRIC CO LTD

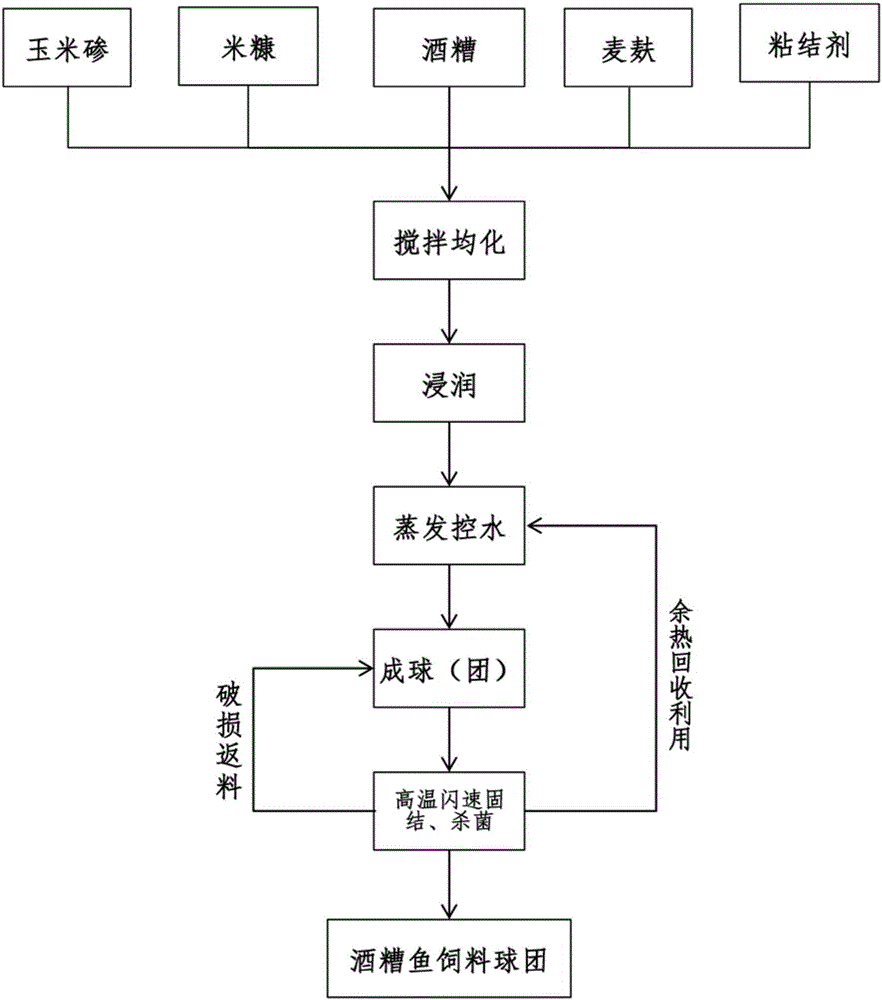

Method for preparing fish feed and fish attracting bait from distillers' grains

InactiveCN106036194AImprove resource utilizationEasy to fillFood processingClimate change adaptationEvaporationFresh water

The invention relates to a method for preparing a fish feed and a fish attracting bait from distillers' grains. The method comprises the following steps of stirring the distillers' grains, wheat bran, rice bran, corn grits and a binder, performing homogenization, performing soaking, performing evaporation for controlling moisture, forming balls / pellets, performing high-temperature flash consolidation and performing sterilizing. The distillers' grain fish feed pellets prepared by the method are dissolved and dispersed when being in contact with water, the wheat bran, the rice bran and part of tiny distillers' grains float in a water body, and large distillers' grains and the corn grits settle down into water, so that three-dimensional feeds are obtained, and self adult fish and adult fish in different water layers can effortlessly suck the feed. The distillers' grains, the wheat bran and the rice bran are recycled, waste is turned into wealth, and flash-drying and sterilizing are performed at high temperature; and residual heat is recycled, the heat utilization efficiency is high, discharge of three industrial wastes does not exist, the utilization way of the distillers' grains is extended, and superior cheap feeds are provided for large-scale freshwater fish and fish attracting baits for large fish are provided for vast fishermen.

Owner:黄钰雪

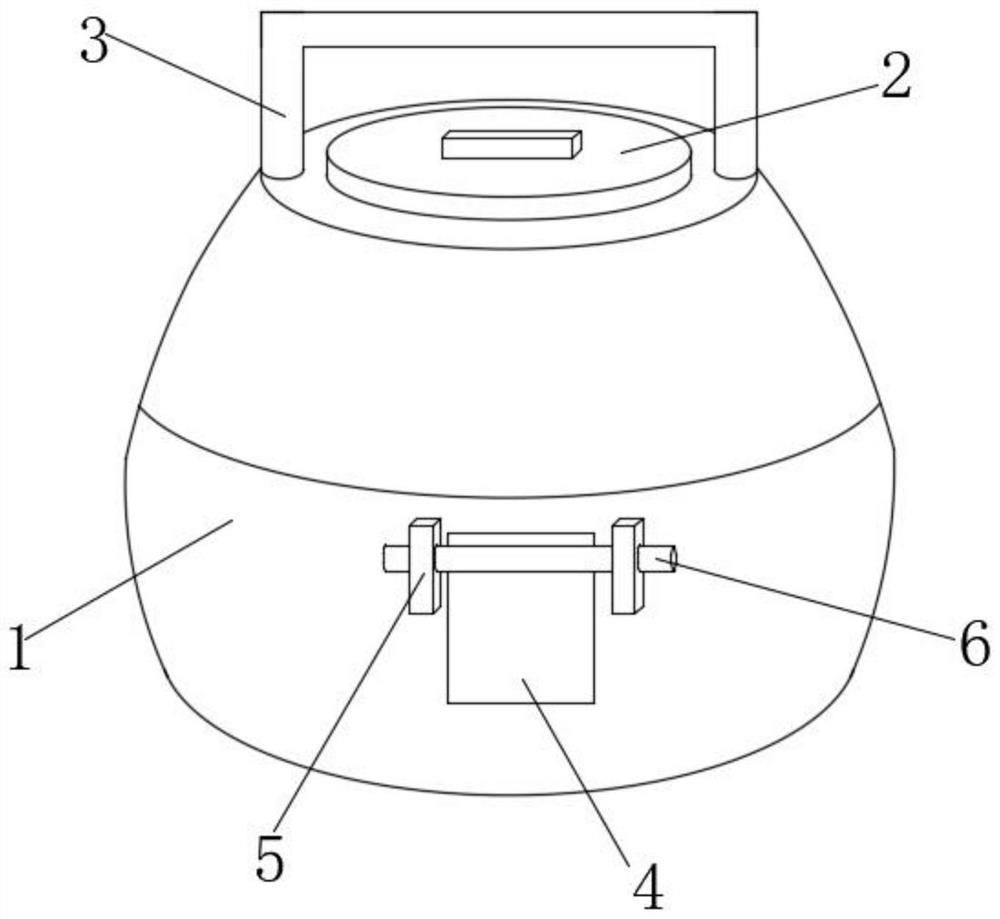

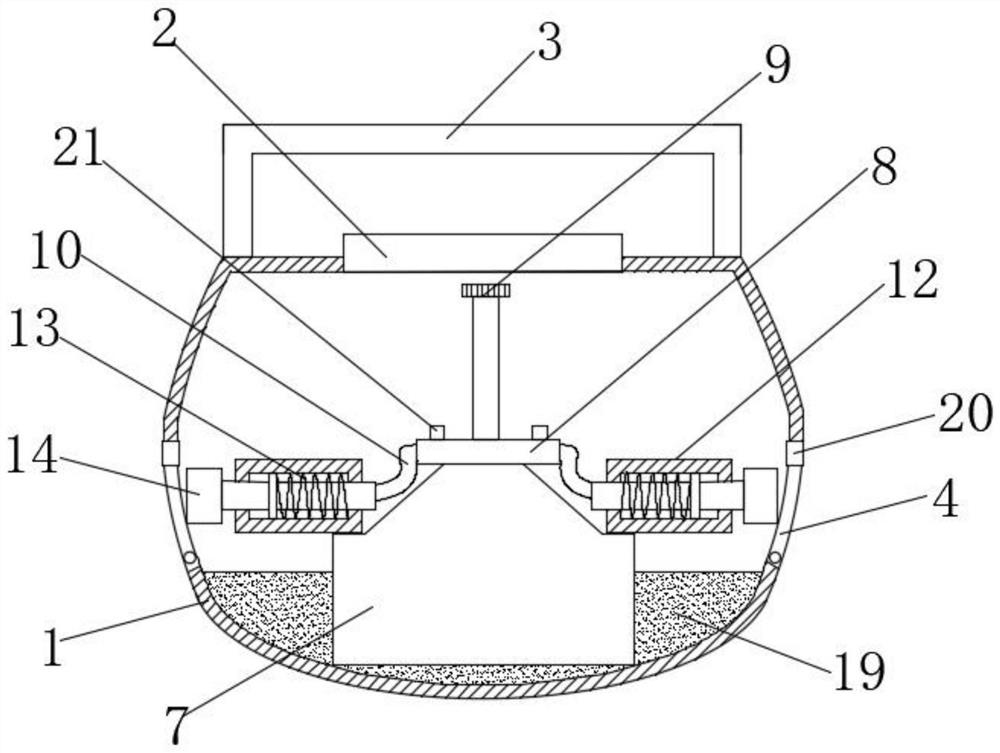

Novel throwing type fire extinguisher convenient to use

The invention discloses a novel throwing type fire extinguisher convenient to use. The novel throwing type fire extinguisher comprises a fireproof shell, a top cover is fixedly connected with the topend of the fireproof shell, and a grip is fixedly connected with the position, located above the top cover, of the top end of the fireproof shell. By arranging the fireproof shell and the grip, a fireextinguishing tank body is protected through the fireproof shell, explosion caused by burning of the fire extinguishing tank body is prevented, the safety of a fire scene is higher, moreover, the fireproof shell can be thrown conveniently through the grip, therefore the fire extinguisher can extinguish fire through throwing in the using process, the situation that an operator continuously controls the fire extinguisher to get close to a fire source in the fire extinguishing process is avoided, the effect of convenient use is achieved, the psychological burden of people during fire fighting isrelieved, the practicability of the fire extinguisher is improved, fire fighting personnel can be far away from the fire source for throwing, and the danger caused by a fire disaster to the fire fighting personnel is reduced; and the fire extinguisher can sense temperature and automatically trigger release of pressure in the tank, on one hand, fire-baking explosion is avoided, and on the other hand, fire behavior development can be actively inhibited.

Owner:周鹏

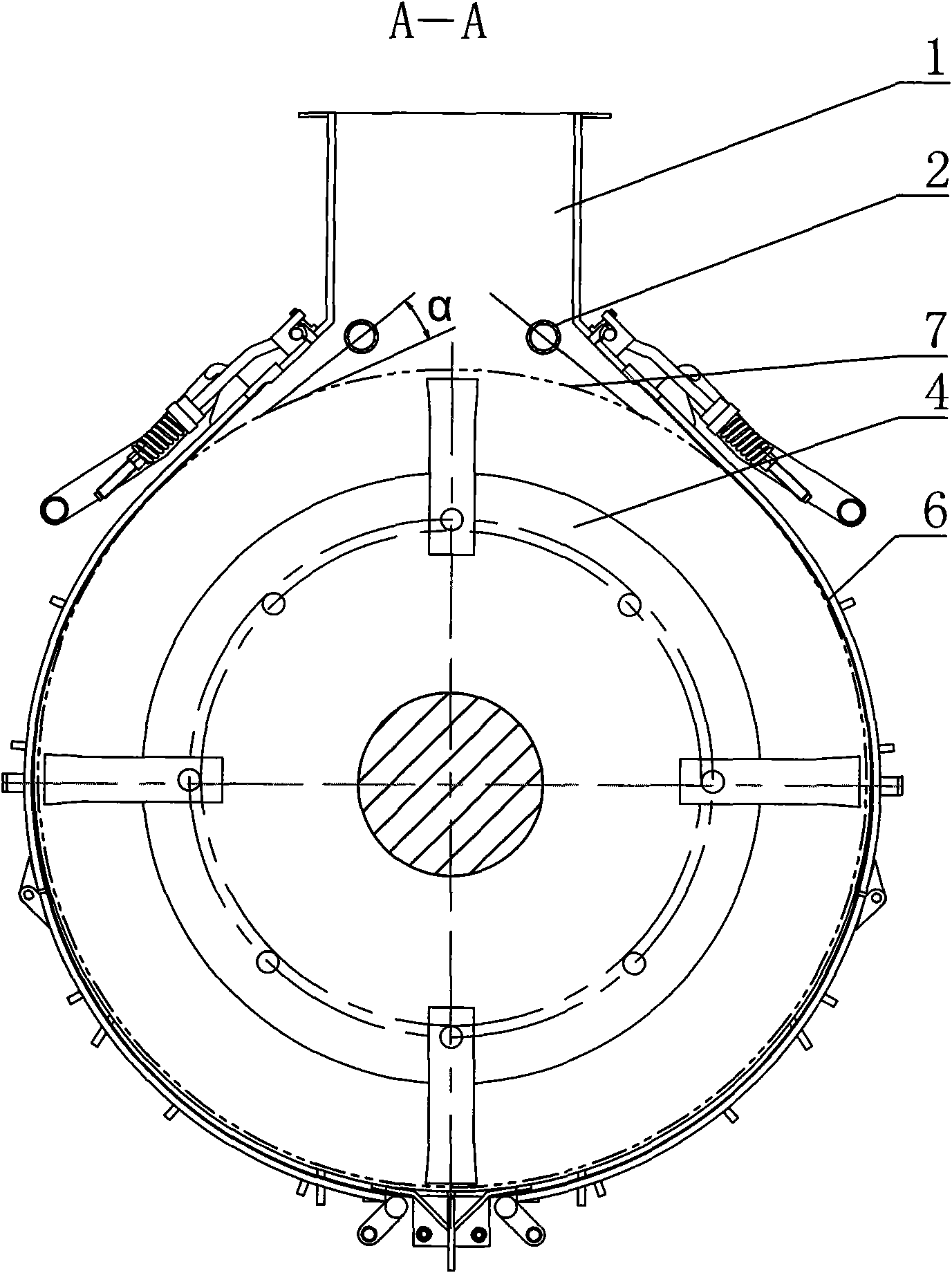

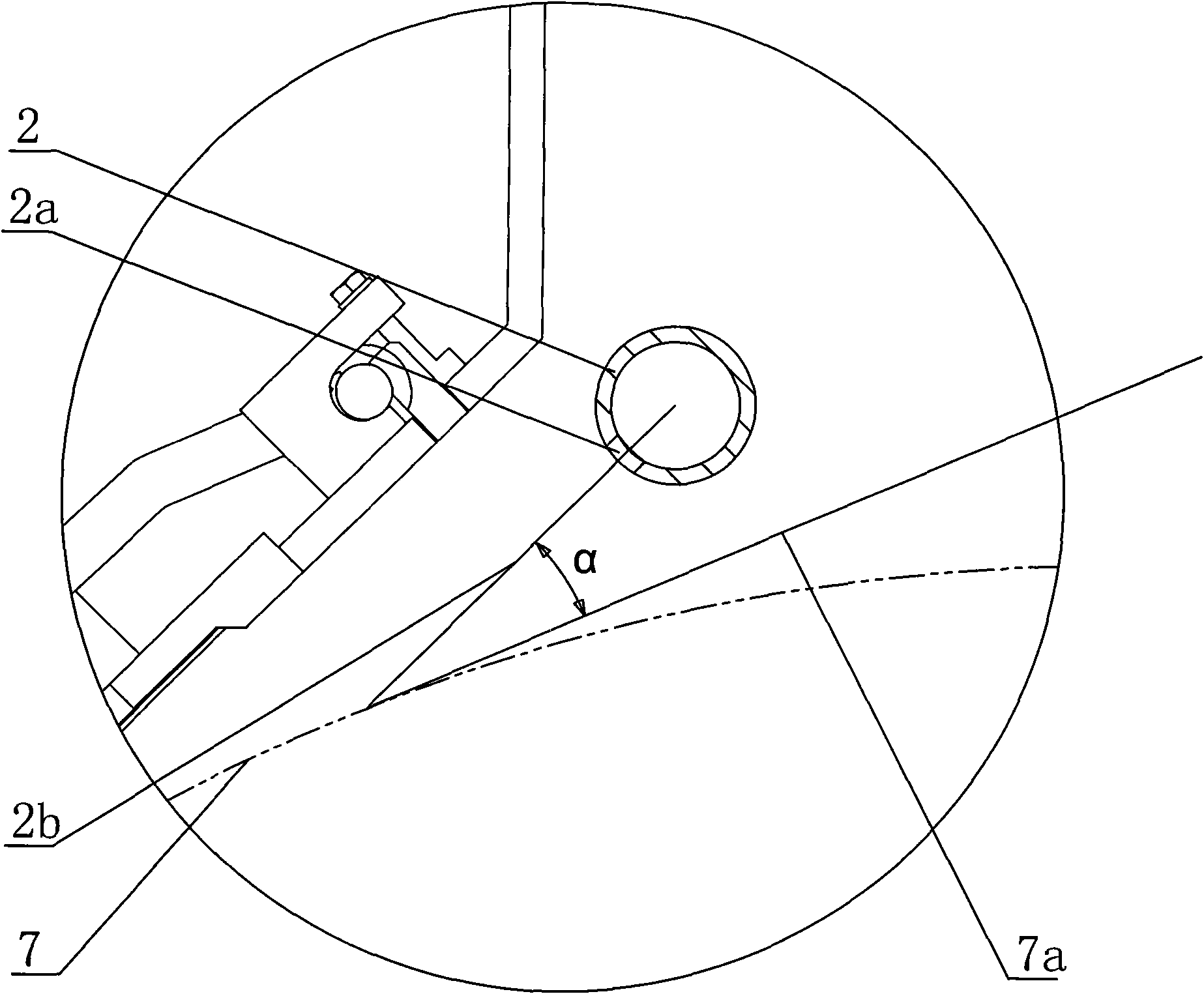

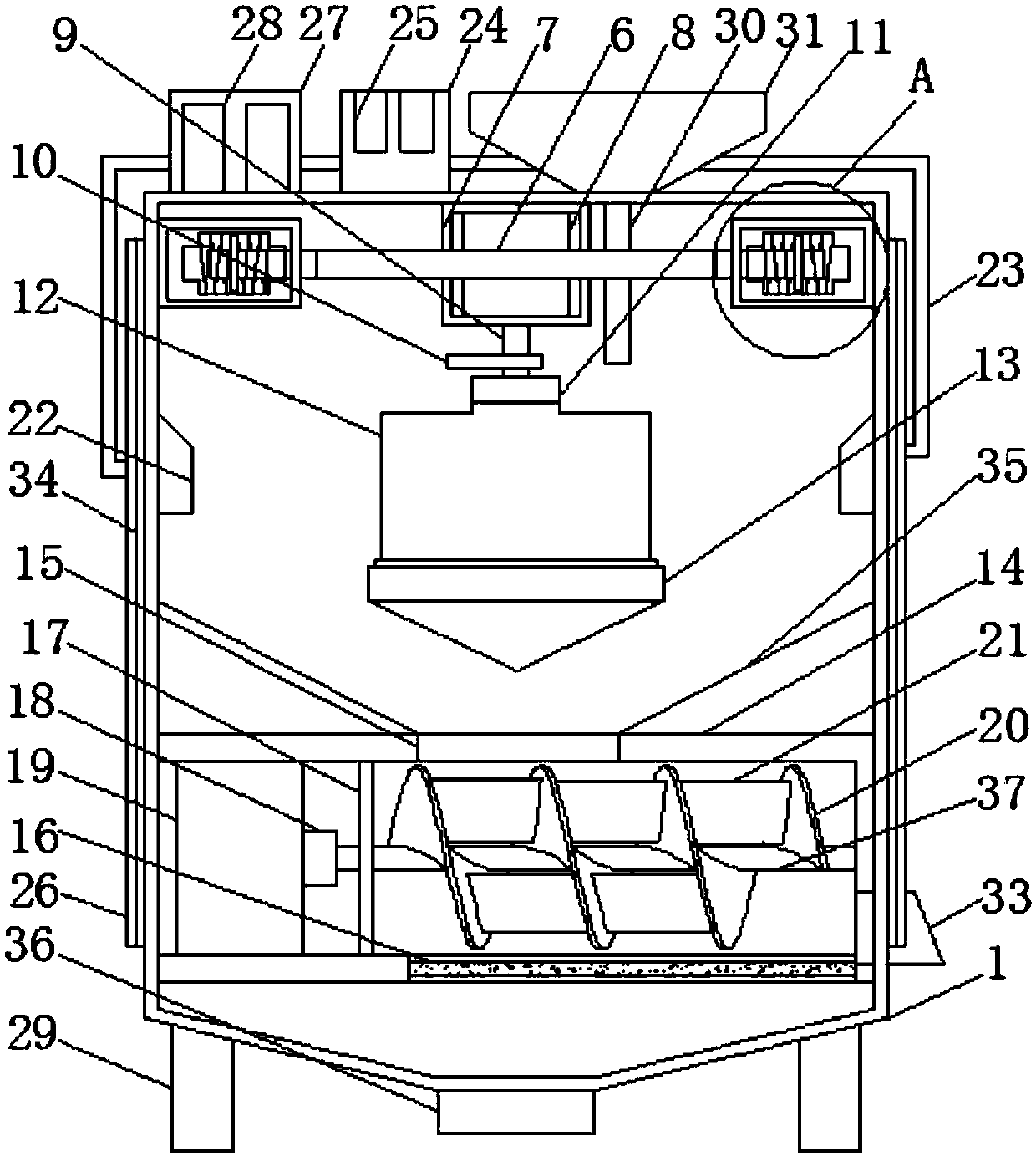

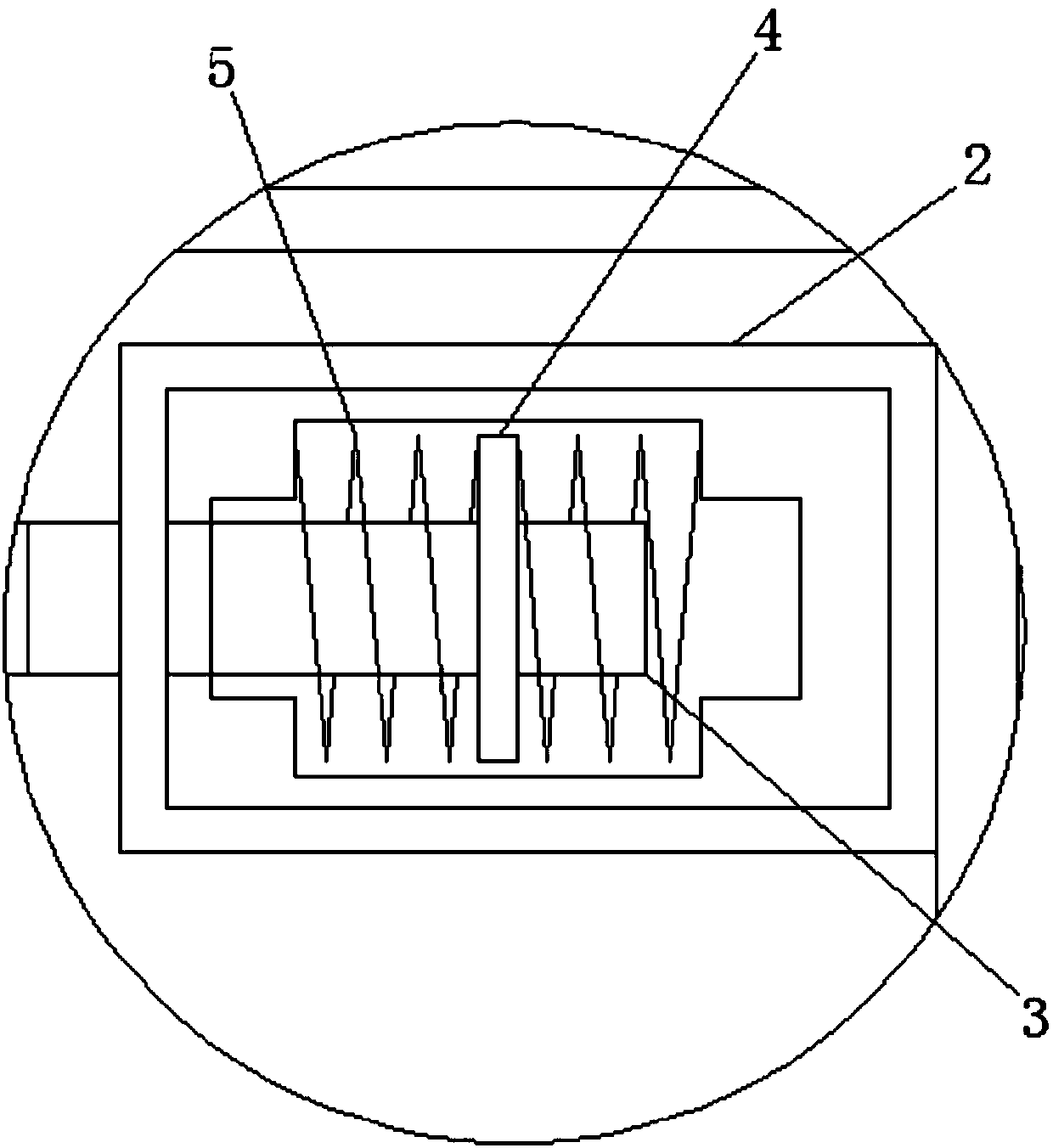

Fruit ice cream machine

InactiveCN103168908BChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

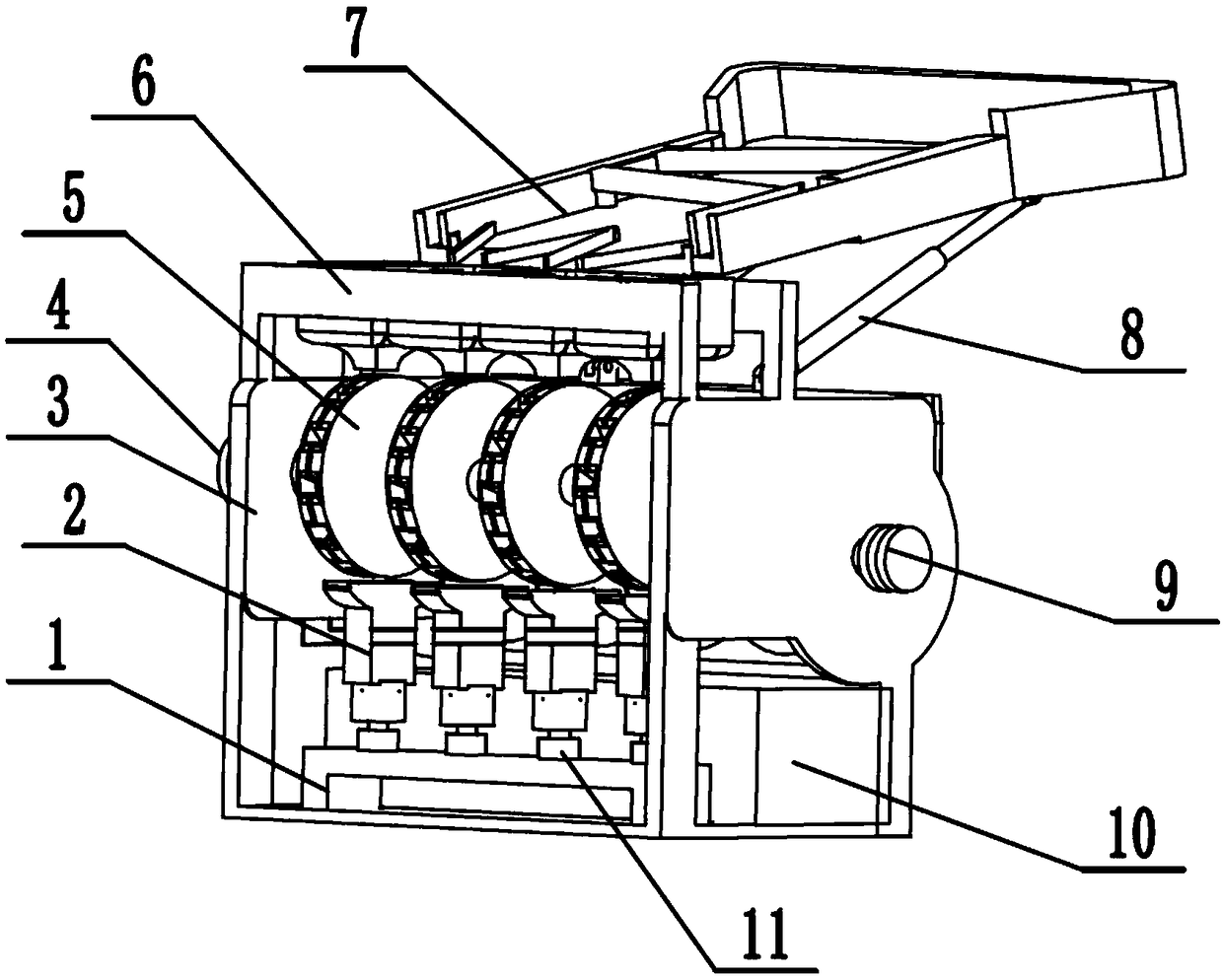

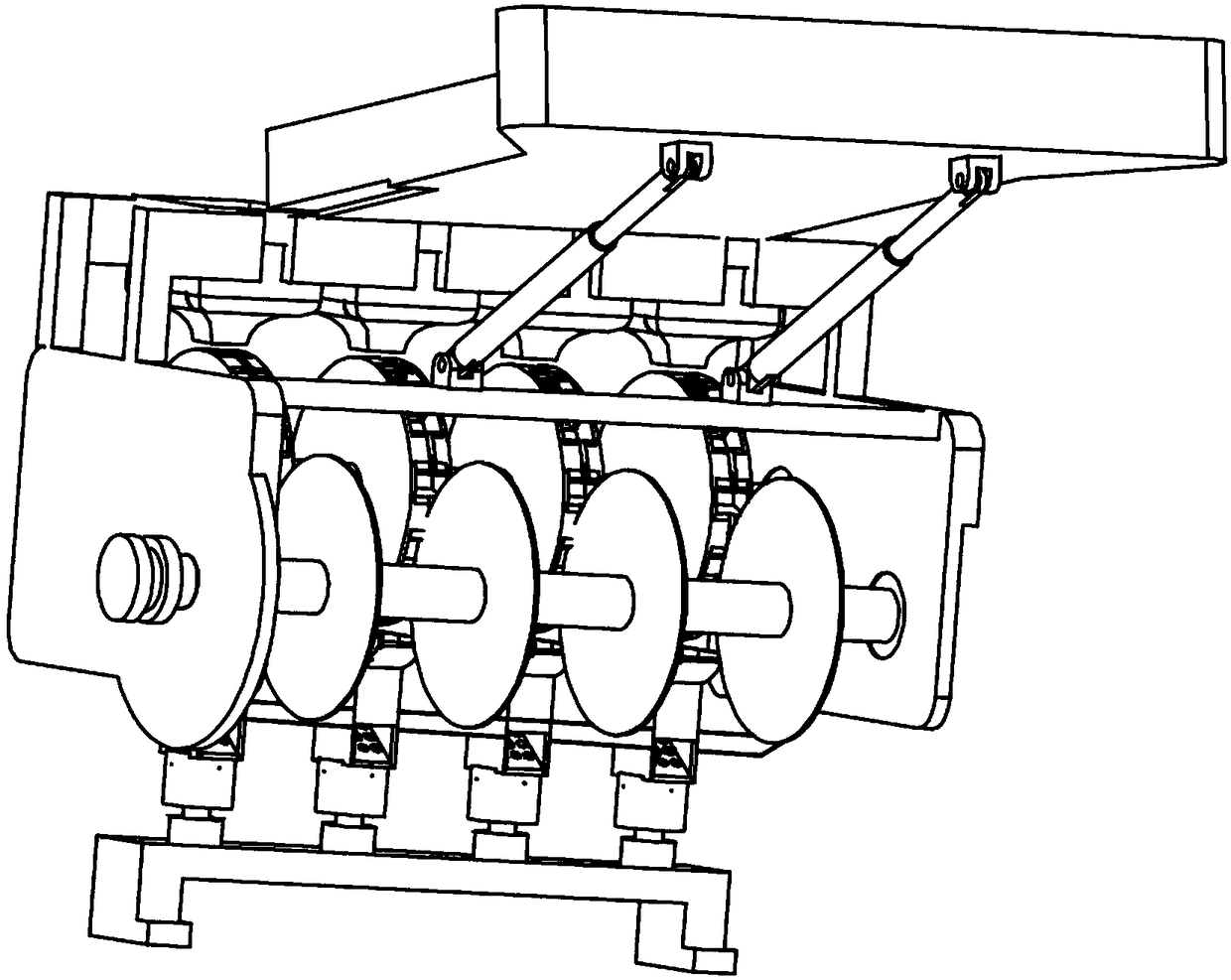

Opening device capable of automatically separating large macadamia nuts from small macadamia nuts

ActiveCN109329962AIncrease scrollingIncrease frictionHuskingHullingEngineeringMechanical engineering

The invention provides an opening device capable of automatically separating large macadamia nuts from small macadamia nuts, belongs to the field of nut processing equipment, and particularly relatesto a device which adopts rotating wheels having a special structure and a large and small macadamia nut separating device and cooperates with cutting knives to perform subpacking and cutting for opening the macadamia nuts. The opening device consists of a fan mounting frame, collectors, a mounting frame, a rotating wheel belt wheel, rotating wheels, a feeding box mounting frame, a macadamia nut separating machine, hydraulic pressure rods, a cutting knife belt wheel, a collecting box, fans, cutting knives, cutting knife shafts, a rotating wheel shaft and a feeding box. According to the openingdevice disclosed by the invention, macadamia nuts of different specifications are separated, and a manner of p opening the single macadamia nut is adopted, so that the opening efficiency of the macadamia nuts is greatly improved, and the cost is saved.

Owner:绍兴米苏机械设备有限公司

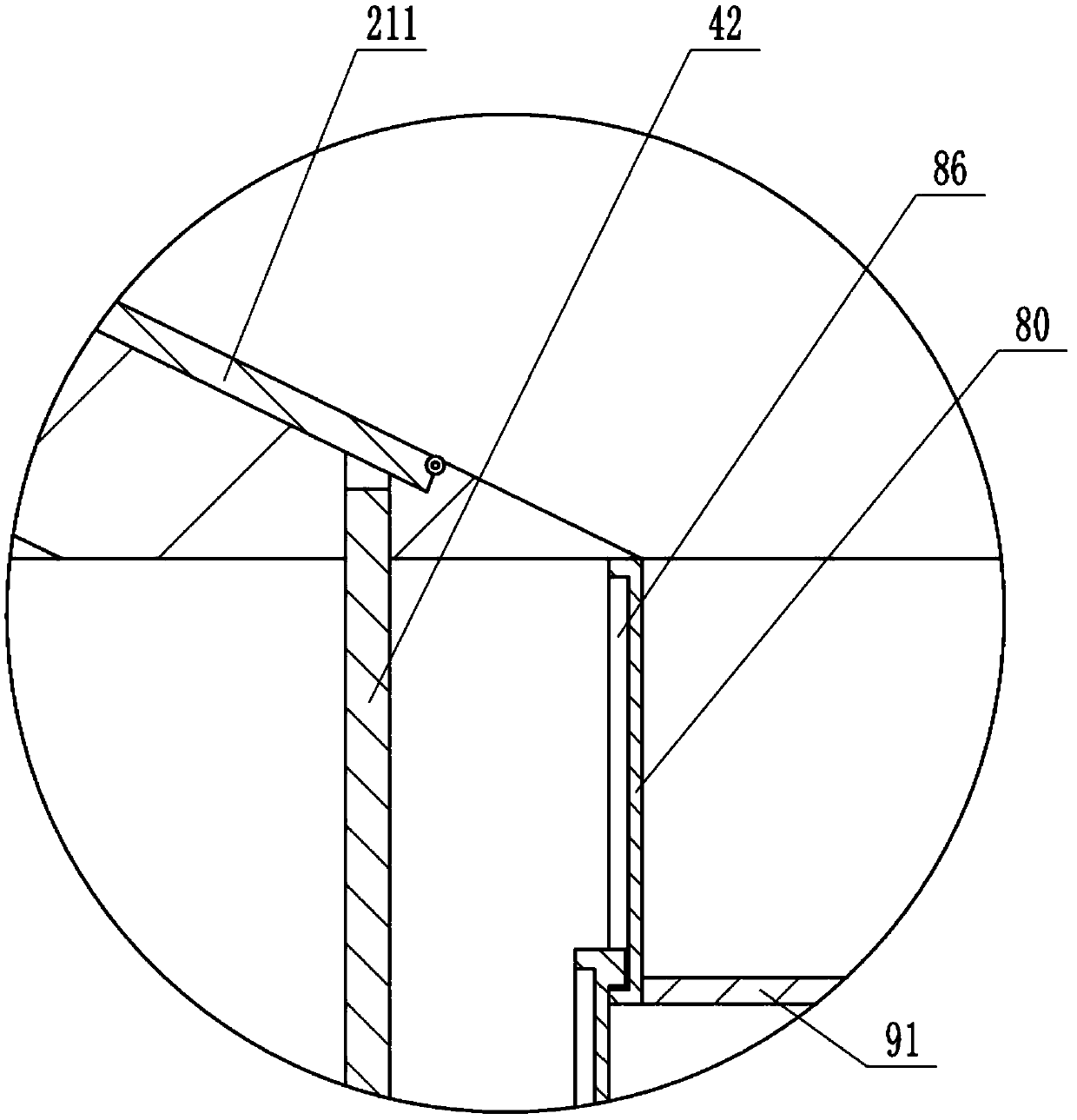

Slag discharge structure of secondary combustor

The invention belongs to the technical field of incinerator supporting equipment and particularly discloses a slag discharge structure of a secondary combustor. The slag discharge structure comprisesa melting unit arranged at the lower end of the secondary combustor; the melting unit includes an insulation base and a melting chamber arranged in the insulation base; a combustion mechanism to meltslag is arranged in the melting chamber; a slag discharge mechanism is connected to the lower end of the melting chamber. The the slag discharge structure herein helps effectively remove the slag generated during operating of the secondary combustor; slag discharging is convenient and reliable; the existing application needs can be effectively met.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

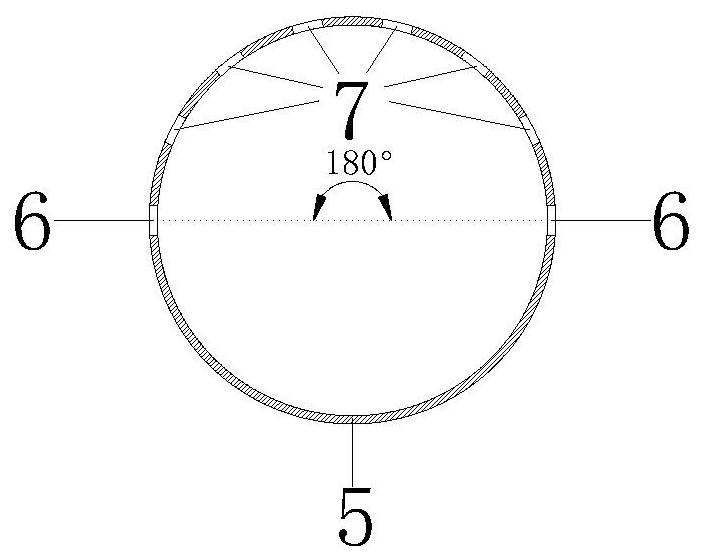

Smooth blasting method for tunnel weak surrounding rock

The invention discloses a smooth blasting method for tunnel weak surrounding rock. The blasting method comprises the steps that a large-diameter auxiliary slotting hole is formed, the bottom of the hole is filled with a cartridge, a water bag is arranged on the upper portion of the cartridge, and a hole opening is blocked by a water sandbag; or the blasting method adopts an energy-gathered water pressure peripheral hole blasting mode, blasting shock waves are released and transmitted to the rock wall through kerfs of an energy-gathered pipe to form cracks, which are communicated with one another, and finally a complete surrounding rock loose circle is formed. Energy loss caused by plastic deformation in ore rock can be reduced or eliminated, so that the utilization rate of explosives can be greatly improved, and the utilization rate of shot holes is greatly improved. The damage of blasting to the rock is further enhanced, the blasting area is increased, and the blasting footage is increased.

Owner:CHINA COMM NORTH ROAD & BRIDGE +2

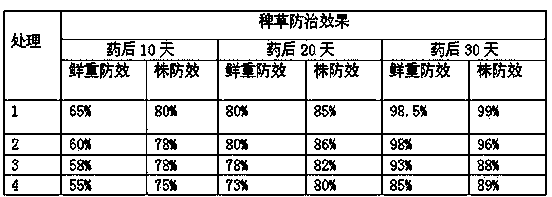

Environment-friendly type wettable powder capable of being directly applied to rice field

InactiveCN103444707AReduce pollutionAvoid pollutionBiocideFungicidesPhysical chemistryEnvironmental engineering

The invention relates to an environment-friendly type wettable powder capable of being directly applied to a rice field. The environment-friendly type wettable powder comprises the components by weight percent: 0.1-90% of effective components, 1-5% of wetting agent, 1-10% of dispersing agent, 0.1-5% of diffusion agent, the balance of filler and water-soluble packaging film material. The auxiliary agents with different components and the diffusion agent are added into the wettable powder, and the wettable powder is packed in the water-soluble packaging material, so that the wettable powder has the advantages of being high in content of active components, low in environmental pollution, more uniform in spraying, more convenient in application, good in dispersing performance, stable in heat storage performance and the like; when being used, the environment-friendly type wettable powder is high in controlling efficiency and free from dust and liquid medicine drift when being applied, and enables people not to be contacted with the drug, thus being good in safety.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Pulse crusher

InactiveCN101574676AImprove work efficiencyIncrease the sieving speedGrain treatmentsEngineeringCrusher

The invention discloses a pulse crusher in the field of material crushing devices, which comprises a shell, wherein the upper part of the shell is provided with a feed opening, a rotor is arranged in the shell, a sieving plate is arranged on the periphery of the rotor in a half surrounded mode to form a crushing room, and the upper part of the sieving plate is connected with the lower side of the feed opening transitionally; and the upper side of the extended periphery of the sieving plate in the feed opening is provided with a plurality of nozzles blowing towards a circulation layer directly. When the pulse crusher works, pulse airflow can generate instant impact force to impact large particles directly so that the large particles get into a beating area of the rotor, and small particle materials have more sifting opportunities; and the pulse airflow can improve the sifting speed of the materials, and the pulse air flow is ensured to have excellent impact effect. The pulse crusher breaks through the inherent prejudice in the prior art and breaks the circulation layer in the feed opening, and the breaking effect is more direct and efficient, thus the pulse crusher can promote the sifting of the small particle materials and the re-striking and the re-crushing of the large particle materials, and improve the working efficiency of the crusher.

Owner:JIANGSU MUYANG GRP CO LTD

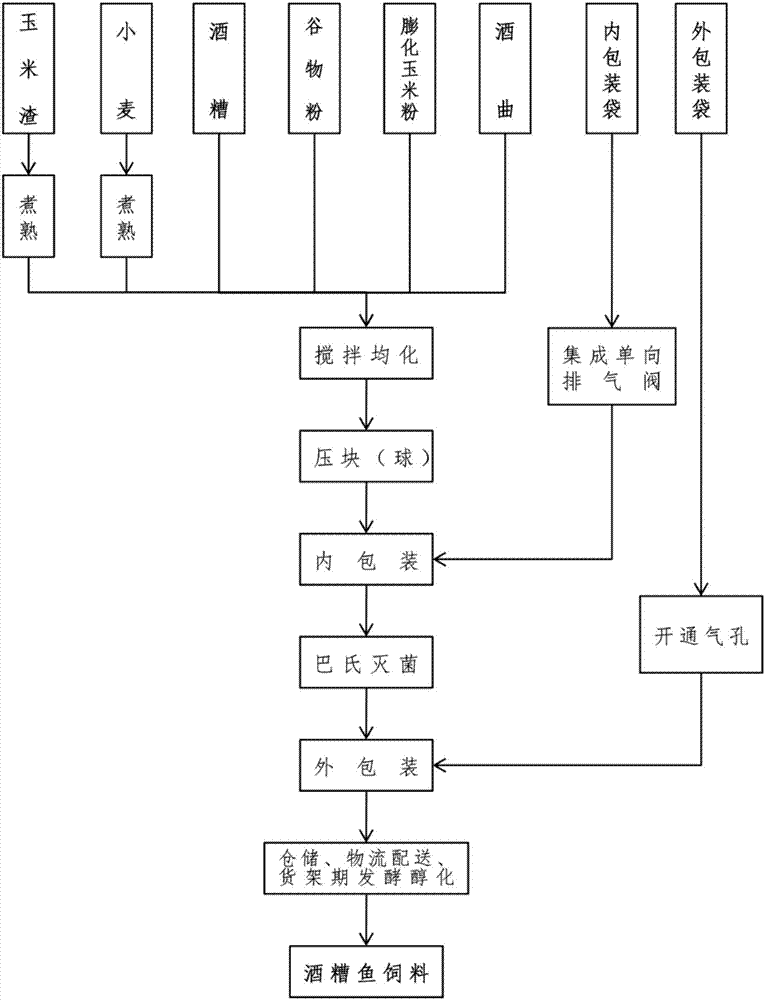

Method for preparing fish feed from vinasse

InactiveCN106912749ALess investmentIncrease attractivenessClimate change adaptationAnimal feeding stuffYeastCorn flour

The invention relates to a method for preparing a fish feed of vinasse. The method comprises the following steps: respectively thoroughly boiling corn grit and wheat; uniformly mixing vinasse having a vinasse liquid with the cooked corn grit, the cooked wheat, cereal flour, puffed corn flour and distiller's yeast in proportion, and compacting the obtained mixture to form a vinasse fish feed blank; integrating a one-way exhaust valve on an inner packaging bag, and arranging a ventilating hole in an outer packaging bag; and filling the inner packaging bag with the vinasse fish feed, carrying out hot pressing sealing by a vacuum packaging machine, pasteurizing the feed blank, packaging the inner packaging bag in the outer packaging bag, sealing the outer packaging bag, and carrying out storage, logistic delivery and shelf life fermentation alcoholization to obtain the high-protein vinasse fish feed. The fermentation alcoholization process of the vinasse fish feed is set in the storage, logistic delivery and shelf life stage, and the inner and outer packaging bags are packaging bags and also are small production devices, so the production cycle is shortened, the capital construction investment is saved, the production cost is reduced, the mellowness and the attractiveness to fish of the above product are improved, and the product can be used as a fish luring material and an explosive bait for general fishers to fish large fish.

Owner:四川新磷环保技术有限公司

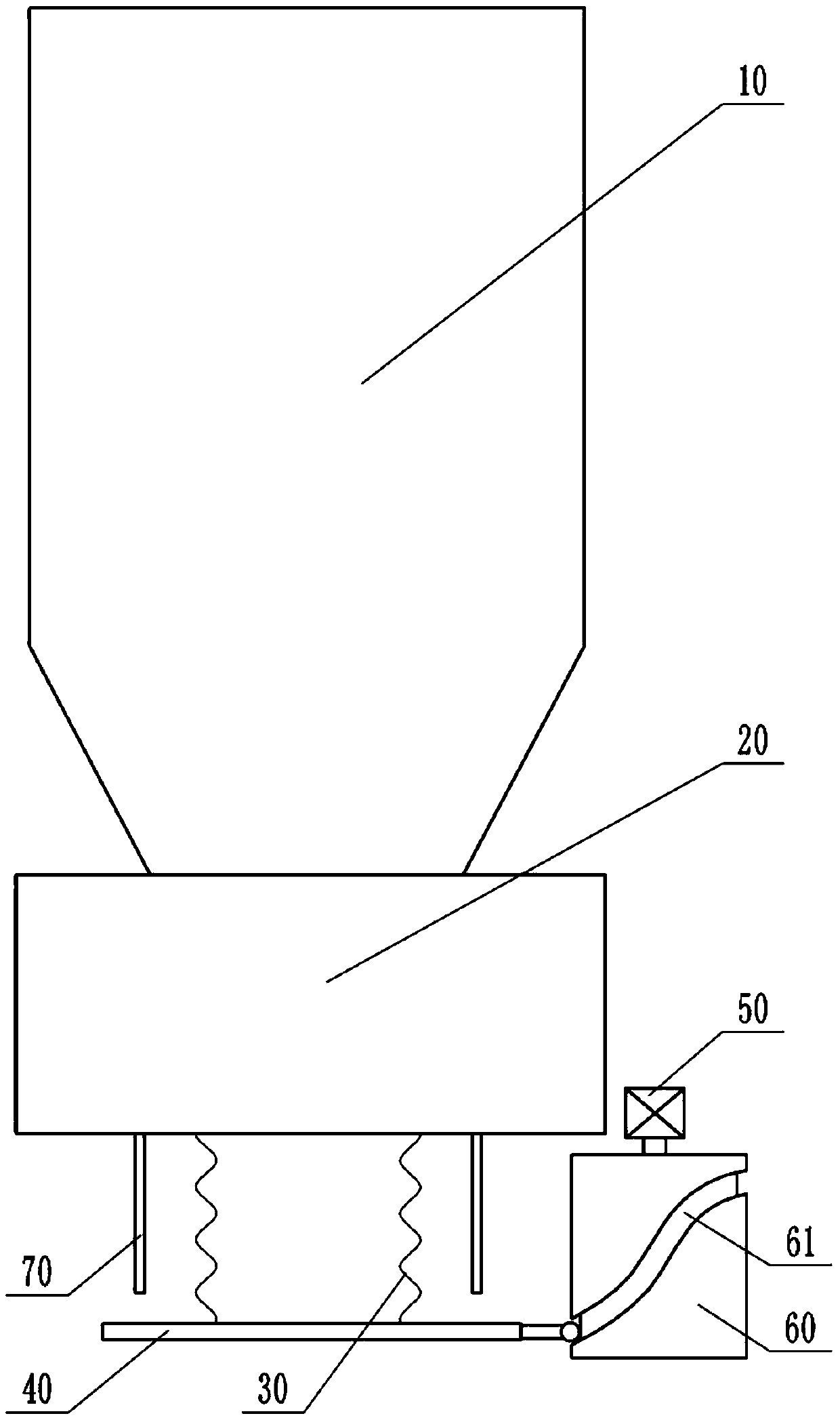

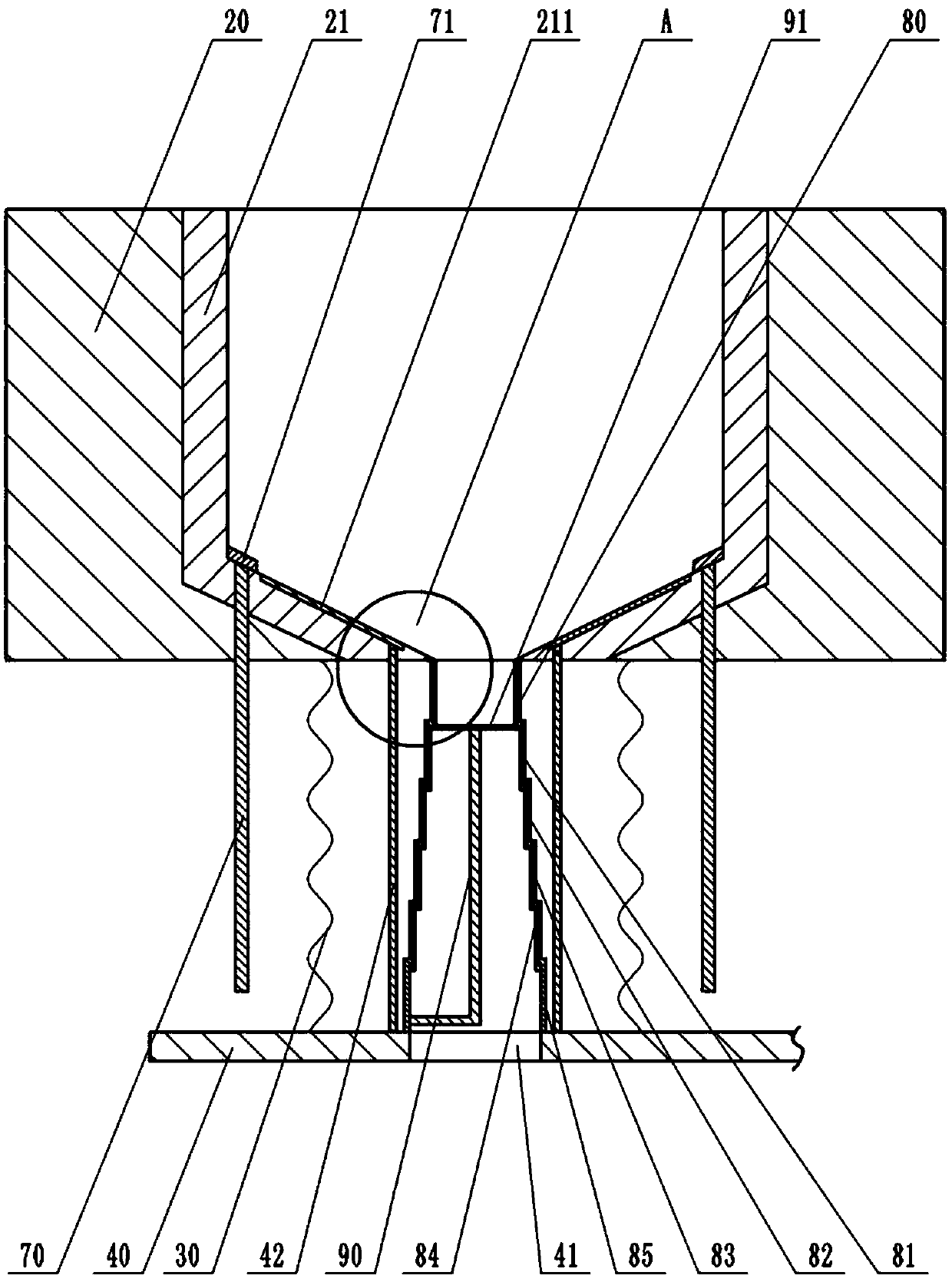

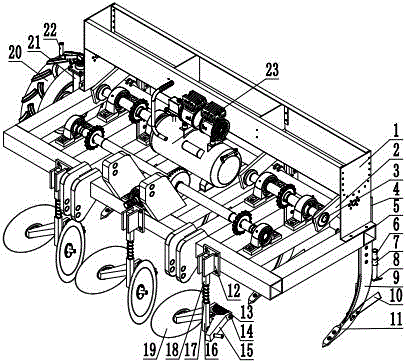

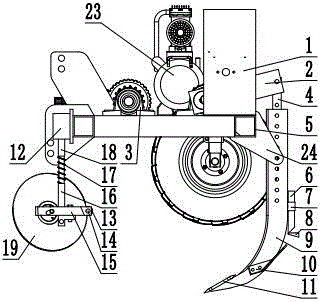

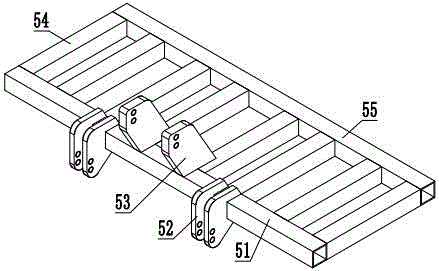

Forced vibrating, air-pressure deep loosening, weeding and fertilizing machine

InactiveCN105900546ARealize vibration subsoiling operationAchieve the effect of reducing drag and reducing consumptionSoil lifting machinesSpadesAgricultural engineeringAtmospheric pressure

The invention relates to a forced vibrating, air-pressure deep loosening, weeding and fertilizing machine which is characterized by comprising a machine frame, a weeding device, a forced vibrating device, a deep loosening device, a high-pressure air pump, a fertilizing device and deep control devices; the weeding device is arranged under a front beam; the forced vibrating device, the high-pressure air pump and the fertilizing device are arranged on a cross beam; the deep loosening device is arranged under a rear beam; one deep control device is arranged on each of the two sides of the cross beam. According to the forced vibrating, air-pressure deep loosening, weeding and fertilizing machine provided by the invention, firstly, a deep loosening shovel is forced to vibrate through the forced vibrating device so as to realize deep loosening operation of soil; on the other hand, high-pressure air is injected into the deep loosening shovel through the high-pressure air pump, so that soil can be broken through air pressure, and meanwhile, an air film is formed on a shovel tip and jointly plays a role of resistance reduction with the vibration. In a word, the invention provides the forced vibrating, air-pressure deep loosening, weeding and fertilizing machine which can reduce the traction resistance, reduce the energy consumption and finish weeding, deep loosening, fertilization and other operations at a time and of which parts are convenient to disassemble, and the tilling width is adjustable.

Owner:SHIHEZI UNIVERSITY

Polishing machine of 3D printed product

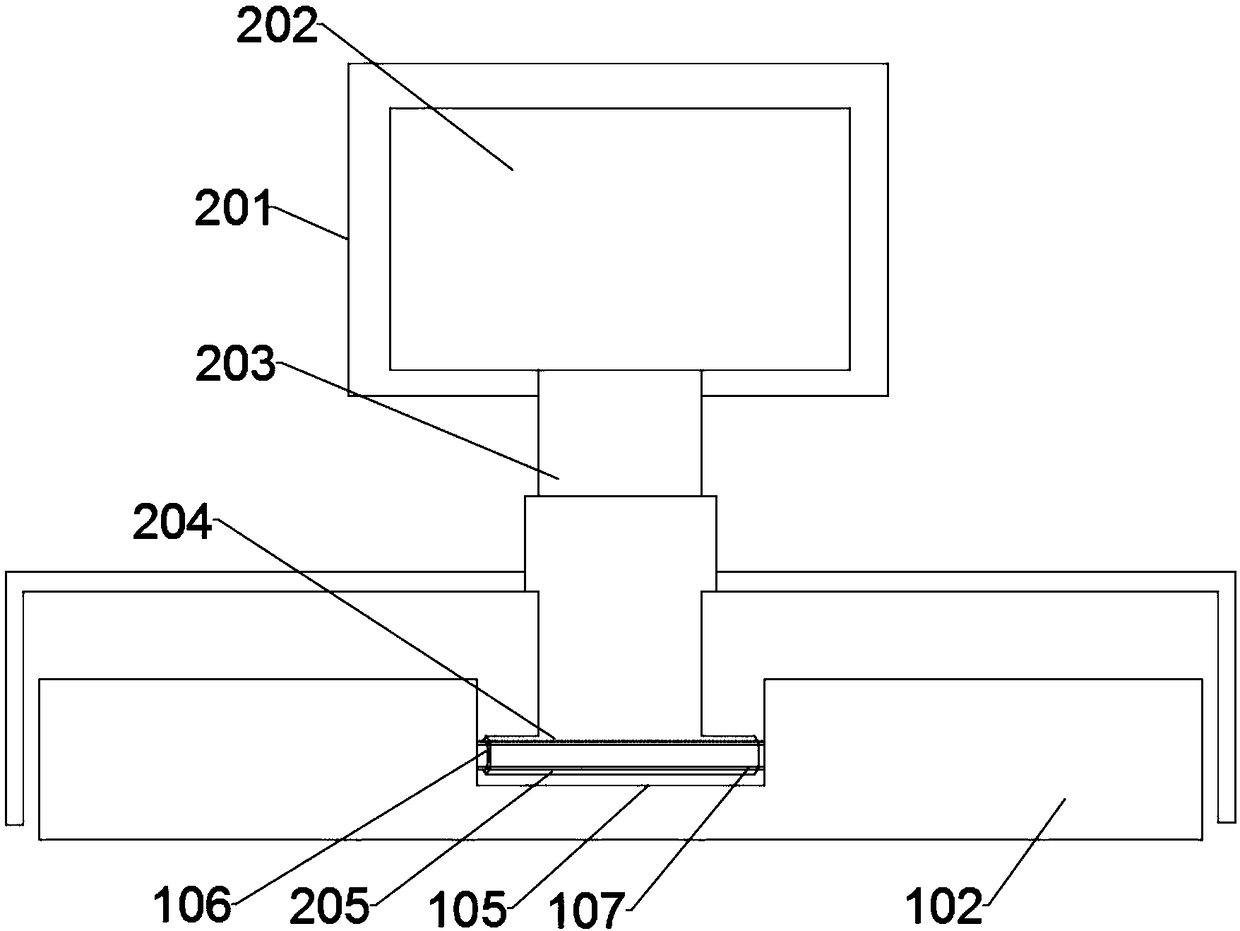

ActiveCN108453596AEasy and fast conversionImprove grinding and smoothing precisionPortable grinding machinesGrinding/polishing safety devices3d printMotor protection

The invention discloses a polishing machine of a 3D printed product. The polishing machine comprises a grinding mechanism and a drive mechanism connected with the grinding mechanism. The drive mechanism is connected with a handheld handle. A dust collection shell is arranged below the grinding mechanism. The drive mechanism comprises a motor protection shell and a variable frequency motor. The variable frequency motor is connected with a drive rotating rod. The tail end of the drive rotating rod is provided with a cavity clamping cylinder. The grinding mechanism comprises a polishing disk protection shell and grinding disks. The grinding disks include a coarse grinding disk and a fine grinding disk which are fixed together through a powerful bonding layer. The center position of the coarsegrinding disk and the center position of the fine grinding disk are both provided with fixing grooves. The fixing grooves are internally provided with grabbing rods. The drive rotating rod penetratesthe polishing disk protection shell, and the outer side of the grabbing rod is sleeved with the cavity clamping cylinder. By means of the scheme, the maximum polishing rate can be increased, the changing frequency of the grinding disks is reduced, and the using convenience is further improved; and the protection shell is convenient to demount, the maintaining and polishing efficiency of the polishing machine is improved, and therefore the polishing working efficiency is improved.

Owner:亳州易泽信息科技有限公司

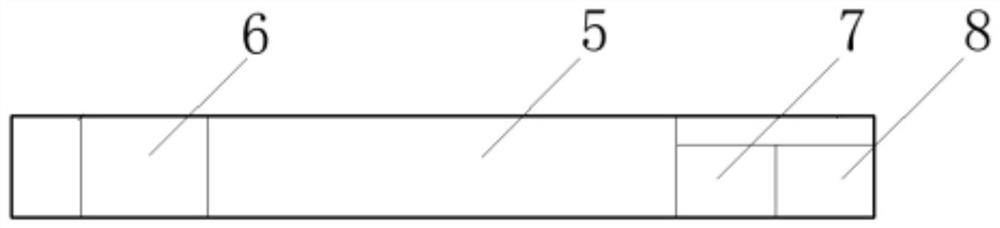

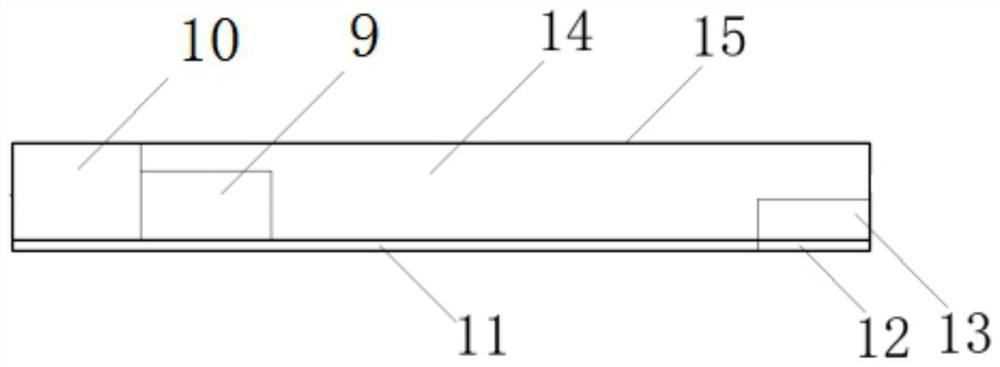

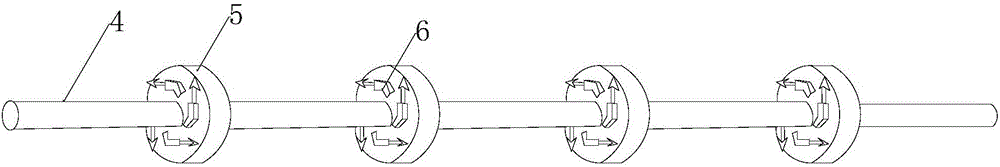

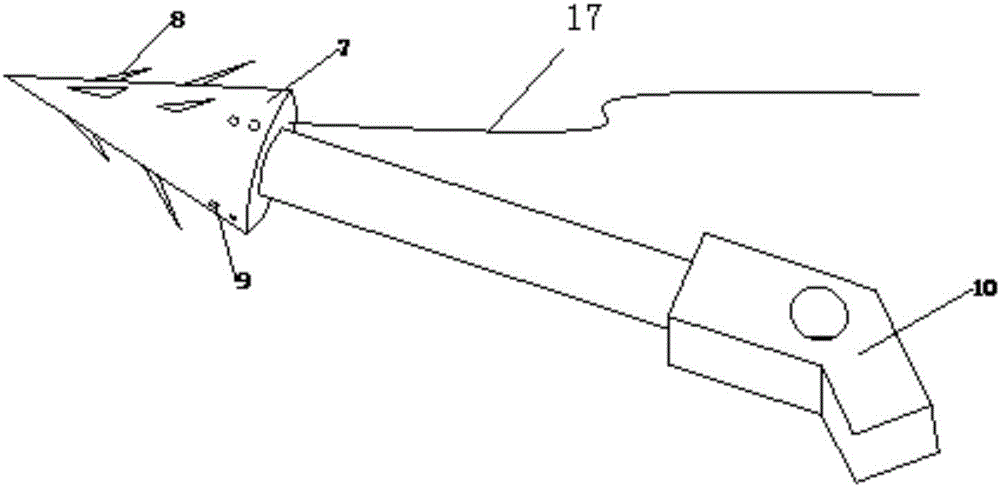

Portable spontoon-type tyre breaking device

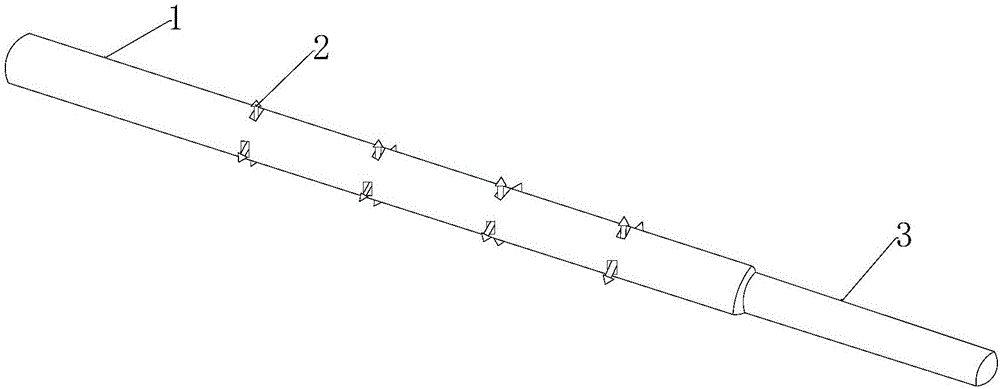

ActiveCN106381824AEasy to throwImprove accuracyWeapons typesTraffic restrictionsEngineeringConnection control

The invention discloses a portable spontoon-type tyre breaking device, which comprises a rigid sleeve, an inner supporting core and a handle, wherein multiple groups of troughs are arranged along the axial direction of the rigid sleeve, and each group of troughs comprises a plurality of troughs which are arranged along the circumference of the rigid sleeve; the inner supporting core is sheathed by the rigid sleeve; the inner supporting core comprises a rotation shaft and multiple groups of barbed nail devices which are movably installed on the rotation shaft along the axial direction; each group of barbed nail device comprises a plurality of barbed nail devices which are arranged along the axial direction of the rotation shaft; the barbed nail devices and the troughs on the rigid sleeve are correspondingly arranged; each barbed nail device comprises a barbed nail and a connection part; one end of the connection part is movably connected with the rotation shaft; the barbed nail is installed on the other end of the connection part; the handle is clamped and installed on one end of the rigid sleeve and can rotate relative to the rigid sleeve; the handle is provided with a control button; one end of the rotation shaft is movably cooperated with the rigid sleeve, and the other end of the rotation shaft is cooperated with the control button on the handle through a connection control mechanism.

Owner:SHANDONG UNIV

Sand screener

The invention discloses a sand screening machine. Strong springs are fixedly connected to both sides of the block, a convex block is sleeved on the lower part of the outer side of the first machine shaft, and a screen bucket is fixedly connected to the bottom of the connection block. , the bottom of the sieve barrel is threadedly connected with a mesh sleeve, the right side of the bottom of the sieve column is connected with a sieve plate, and the right side of the rotating roller is sleeved with a spiral blade through the partition plate, and between the spiral blades There are five sweeping plates connected at equal distances, fans are fixedly connected on both sides of the inner cavity of the rack, heating blocks are fixedly connected on both sides of the top of the drying inner cavity, and solar energy is installed on the outside of the rack. The battery plate is overlapped with batteries on both sides of the inner cavity of the power box. Through the use of the first motor, the sieve barrel and the mesh sleeve, the bump, the telescopic column, the strong spring, the heating block, the fan, the spiral blade, the sweeping plate, the sieve plate, the solar cell panel and the battery, the sand sieving machine can be Strong practicality.

Owner:赵顺豪

A kind of rescue stone throwing machine

InactiveCN102296614AProblems overcoming serious lossesEasy to throwFoundation engineeringEmergency rescueEngineering

The emergency rock-throwing machine provided by the present invention includes two parts of track, a track wheel arranged at the lower part of the track, a feeding hopper arranged at the upper part of the track, and a middle wheel arranged at the front end of the track. It is characterized in that: the rock-throwing machine also includes a feeding System, hydraulic system, transmission system for controlling the feeding system and hydraulic system. The emergency riprap machine provided by the invention can not only complete the traditional emergency riprap, but also use it to throw other fillers that it thought could not be used for emergency rescue in the past as emergency materials, which can save emergency costs and improve emergency efficiency. It can also widely use other alternative materials for emergency rescue, and can easily solve the problem of difficult throwing of large volumes; its simple structure can be used as power by agricultural diesel engines, and the road transportation of the whole equipment is also very easy, and it can be used on the front of a four-wheel vehicle You can walk on the road by pulling it.

Owner:纪龙彪

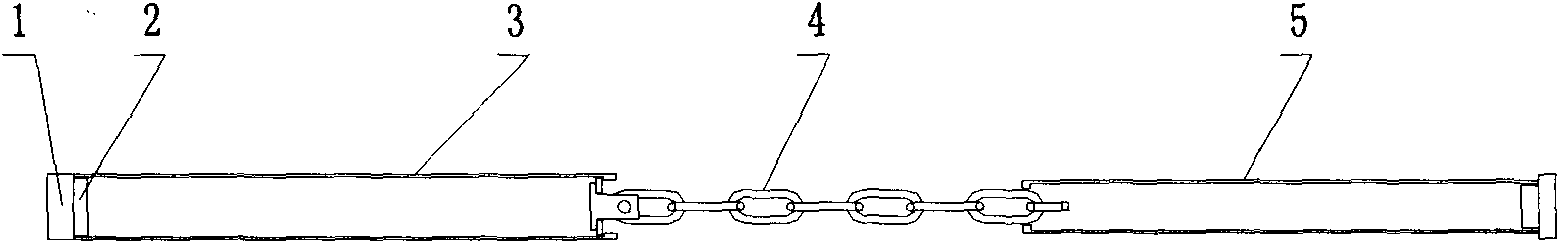

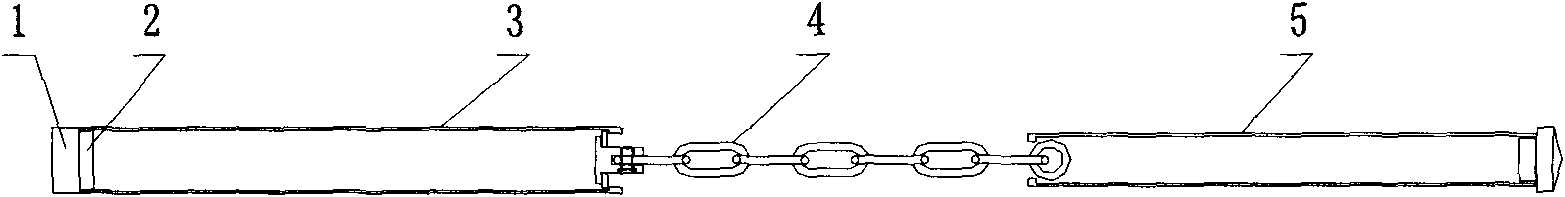

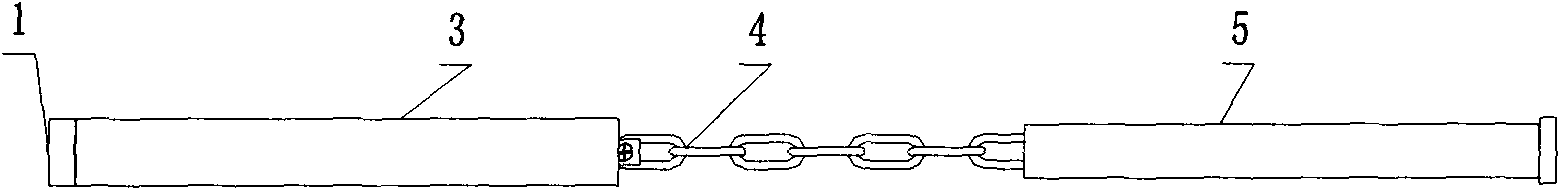

Telescopic nunchakus

The invention relates to telescopic nunchakus. The telescopic nunchakus comprises a nunchakus body A, a nunchakus body B and a chain connecting the nunchakus body A with the nunchakus body B, wherein the nunchakus body A is of a hollow structure, the inner diameter of the nunchakus body A meets the requirement that the nunchakus body B can be contained and fixed in the nunchakus body A, and the connecting end of the nunchakus body A and the chain is positioned in the nunchakus body A and is free connection. The telescopic nunchakus has the advantages that 1) the nunchakus body B is contained in the nunchakus body A, and when the nunchakus is stretched, the chain and the nunchakus body B are both contained in the nunchakus body A, the whole length of the nunchakus is the length of the nunchakus body A, and compared with a conventional telescopic nunchakus structure, the telescopic nunchakus has a more precise and compact structure; 2) the nunchakus body B is fixed by adopting a strong magnet, the structural form is simple, and the nunchakus body B is thrown out; and 3) a tail cover is arranged at the tail end of the nunchakus body A and is provided with the strong magnet, so that the absorption between the strong magnet and the inner wall of the nunchakus body A can be avoided, and meanwhile, when the magnetism of the strong magnetic is not enough, the strong magnet can be replaced easily, and the stretching of the nunchakus can not be affected.

Owner:YANGZHOU LINGZI SPORTS GOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com