Pulse crusher

A pulverizer and pulse technology, which is applied in the field of mechanical devices, can solve the problems of reducing the effect of pulse air flow, low injection efficiency, poor effect of destroying the circulation layer, etc., and achieves the effect of improving screening efficiency, improving work efficiency and direct destruction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

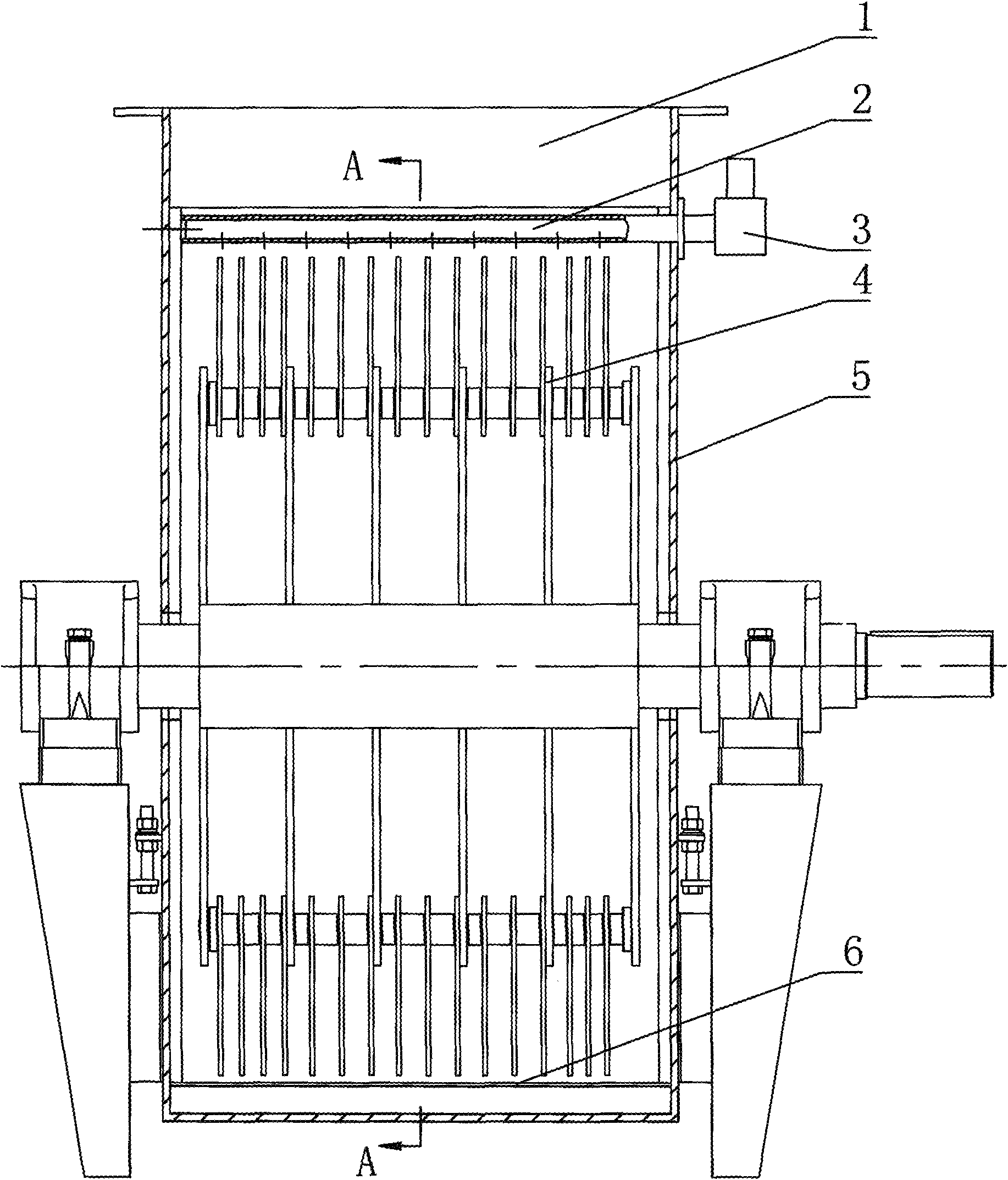

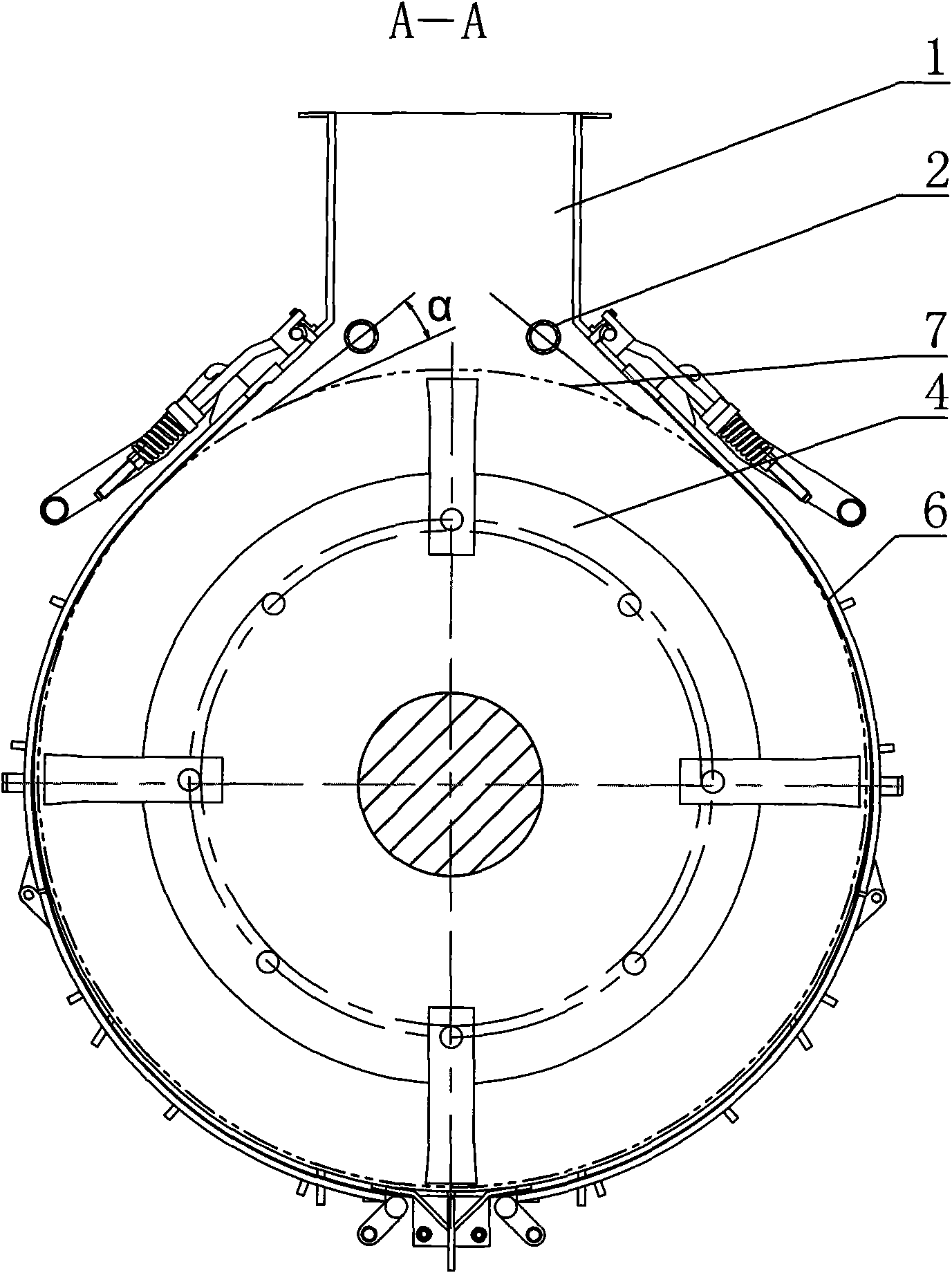

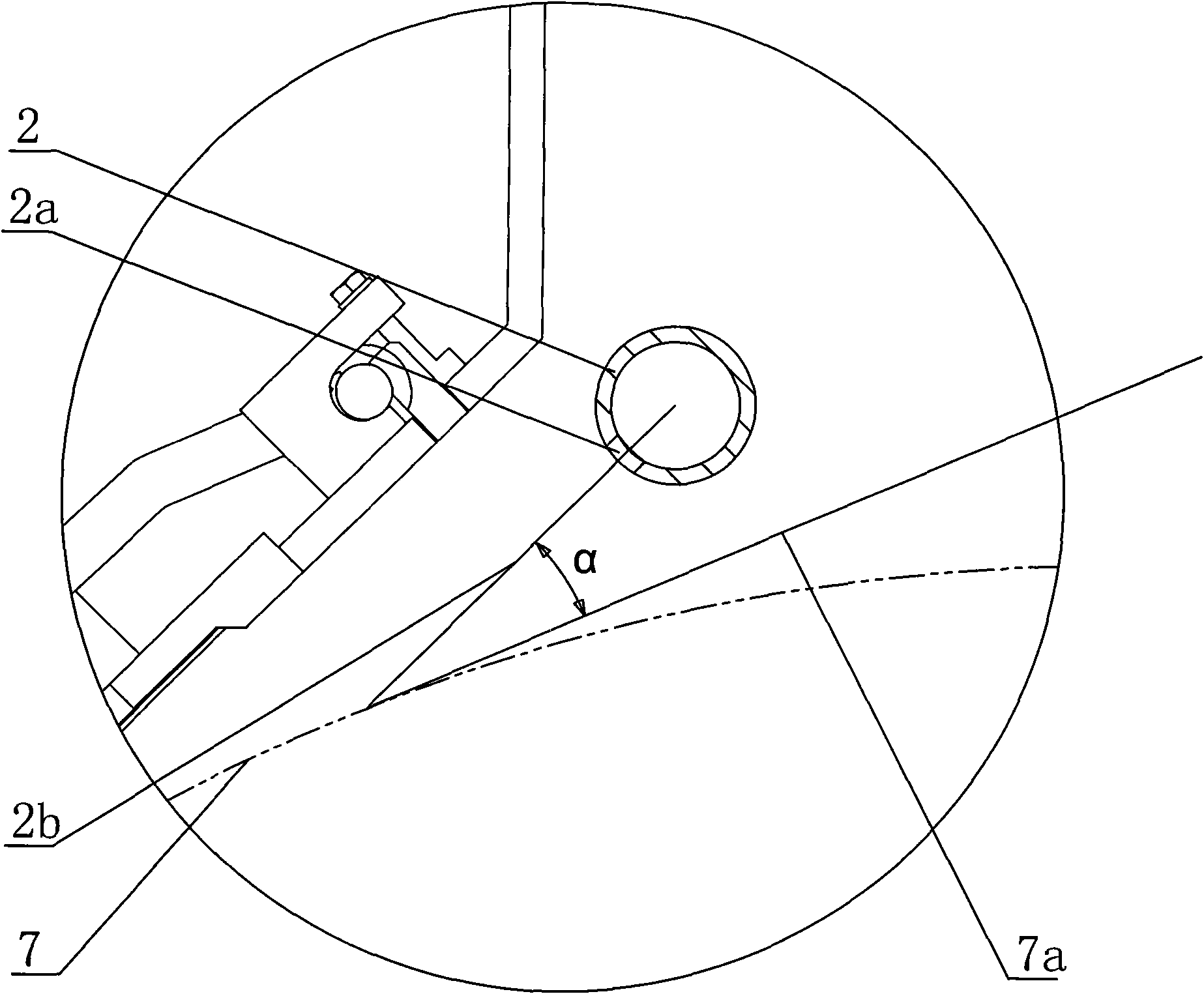

[0013] As shown in the figure, it is a pulse pulverizer, which includes a housing 5, a feed inlet 1 is opened on the upper part of the housing 5, a rotor 4 is arranged inside the housing 5, and a sieve 6 is provided around the outer half of the rotor 4, forming In the crushing chamber, the upper part of the sieve 6 is transitionally connected with the lower side of the feed port 1; in the feed port 1, an air inlet pipe 2 is arranged horizontally on the upper side of the extension circle 7 of the sieve sheet, and the air inlet pipe 2 is connected to the solenoid valve 3, and the air inlet pipe 2 2. A number of nozzles 2a are arranged at intervals. The nozzles 2a face the upper side of the screen extension circle 7 and can directly blow the airflow to the circulation layer; the distance between the air inlet pipe 2 and the screen extension circle 7 is 10-30mm, which can be 10mm , 20mm, 30mm; the angle between the injection axis 2b of the nozzle 2a and the tangent 7a of the sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com