Portable spontoon-type tyre breaking device

A baton-type, tire-breaking technology, applied in the direction of weapons, roads, buildings, etc., can solve the problems of reducing tire breaking accuracy, short tire breaking length, reducing tire deflation speed, etc., to improve tire breaking effect, improve longevity and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

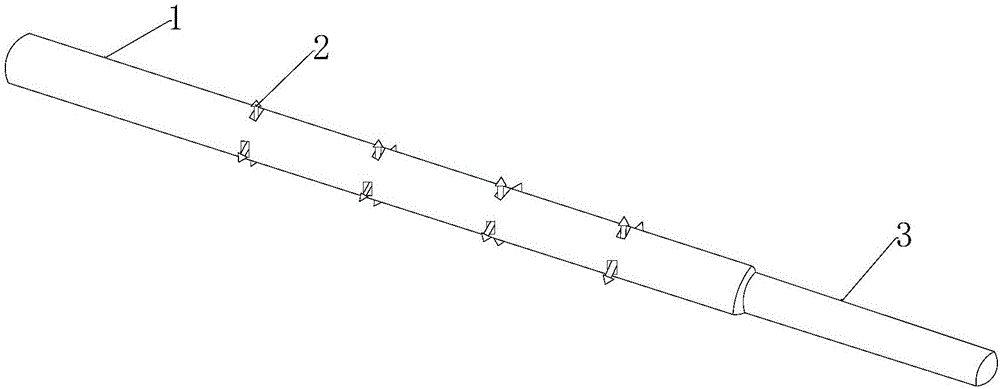

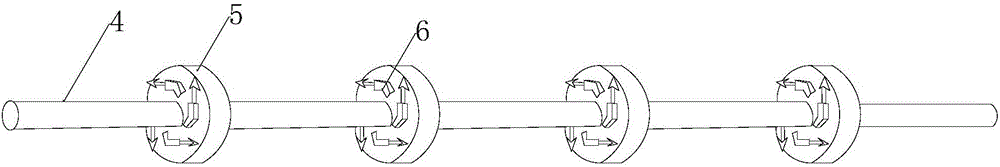

[0068] like figure 1 and figure 2 As shown, a portable baton tire breaker includes a rigid sleeve 1, an internal support core and a handle 3, wherein multiple sets of through grooves are arranged along the axial direction of the rigid sleeve, and each set of through grooves includes a a plurality of through grooves arranged circumferentially of the rigid sleeve;

[0069] The internal support core is sleeved inside the rigid sleeve and can rotate relative to the rigid sleeve 1. The internal support core includes a rotating shaft 4 and multiple sets of nailing devices 6 that are movably mounted on the rotating shaft 4 in the axial direction. The group of nailing devices 6 includes a plurality of nailing devices 6 arranged axially along the rotating shaft 4, the nailing devices 6 are arranged corresponding to the through grooves on the rigid sleeve 1, and each nailing device 6 includes a hollow nail 2 and Connecting part, one end of the connecting part is movably connected wit...

Embodiment 2

[0079] The difference with embodiment 1 is the installation structure of the nailing device 6 on the disc body 5, the structure of the present embodiment is as follows:

[0080] A protruding cylindrical shaft is provided on the disc body 5, a torsion spring is set on the shaft body, one end of the torsion spring is fixed on the disc body, and the connecting part of the nailing device is movably installed on the cylindrical shaft body. And located at the upper end of the torsion spring, a baffle is provided on the surface of the connecting part close to the disc body, and the other end of the torsion spring is clamped on the baffle.

[0081] The number of disc bodies 5 is 10, and when the number of disc bodies 5 is large, the accuracy of tire breaking can be improved.

[0082] The length of the inner support core is 600mm, the diameter of the disc body 5 is 30mm, and the length of the rigid sleeve 1 is 600mm.

[0083] The rigid sleeve 1 includes a two-layer structure from the ...

Embodiment 3

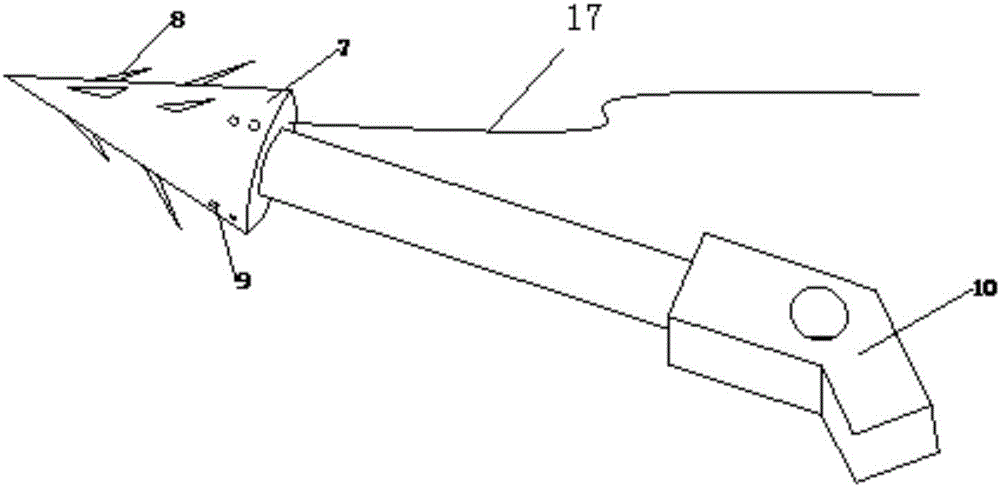

[0086] like Figure 4 As shown, the difference from Embodiment 1 is that the connection control structure includes a rod body 16 and a second torsion spring 14, one end of the rod body 16 is fixed on the inner wall of the handle 3, and the other end is inserted into the first recess at the end of the rotating shaft 4. In the groove, there is a gap between the first groove and a movable cooperation structure; a second groove is left on the rod body 16, and a return spring 15 is installed in the second groove, and the return spring 15 is connected with the control button 11;

[0087] The end of the rotating shaft 4 is provided with a protrusion 13, and the side of the control button 11 close to the rotating shaft 4 is provided with a baffle 12, and the length of the baffle 12 is greater than the distance between the protrusion 13 and the control button 11, so The second torsion spring 14 is set on the rod body 16, one end of the second torsion spring 14 is fixed on the rod body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com