Patents

Literature

64 results about "Body density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, density is defined as an object's mass divided by its volume. Body density is essentially your compactness, or how much you weigh for every square inch of space you take up.

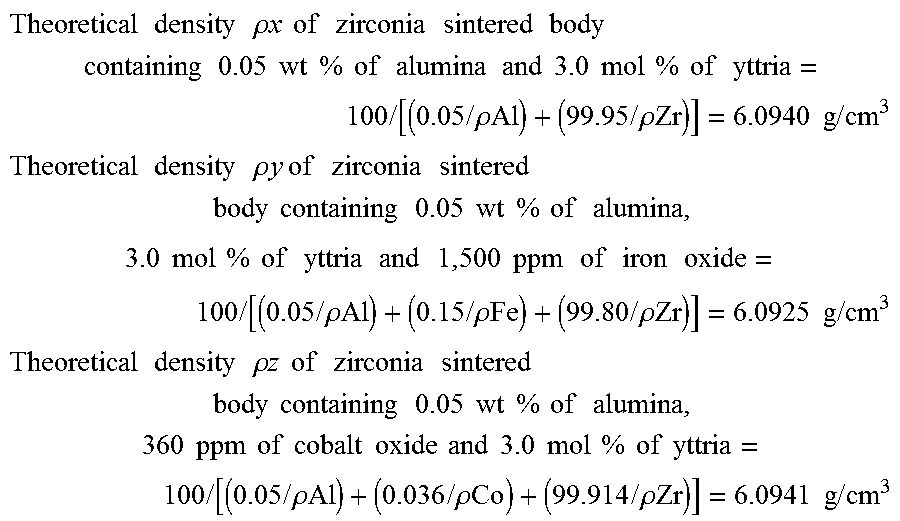

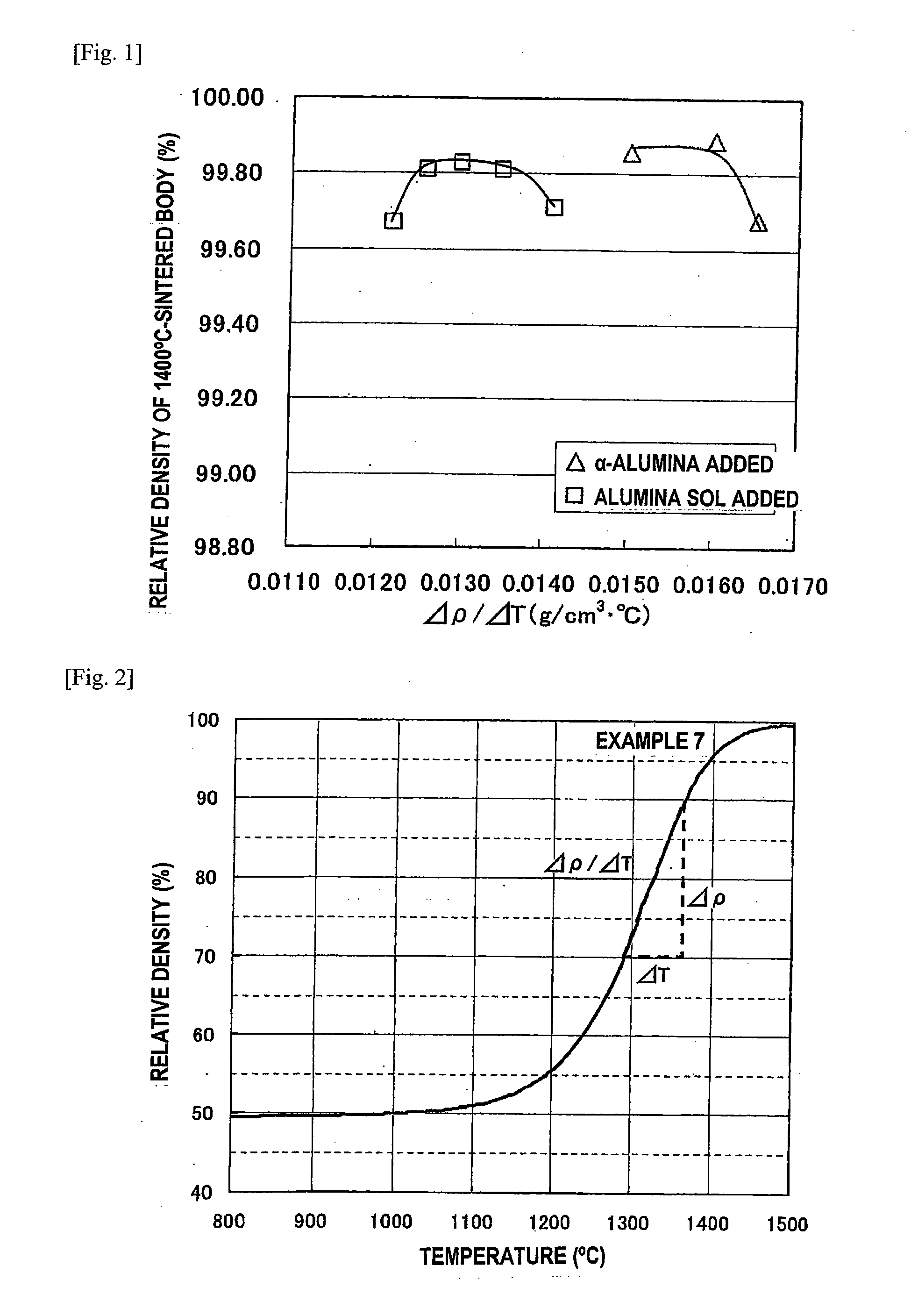

Translucent zirconia sintered body, process for producing the same, and use of the same

InactiveUS20110027742A1High densityGood light transmissionMaterial nanotechnologyDental implantsTransmittanceBody density

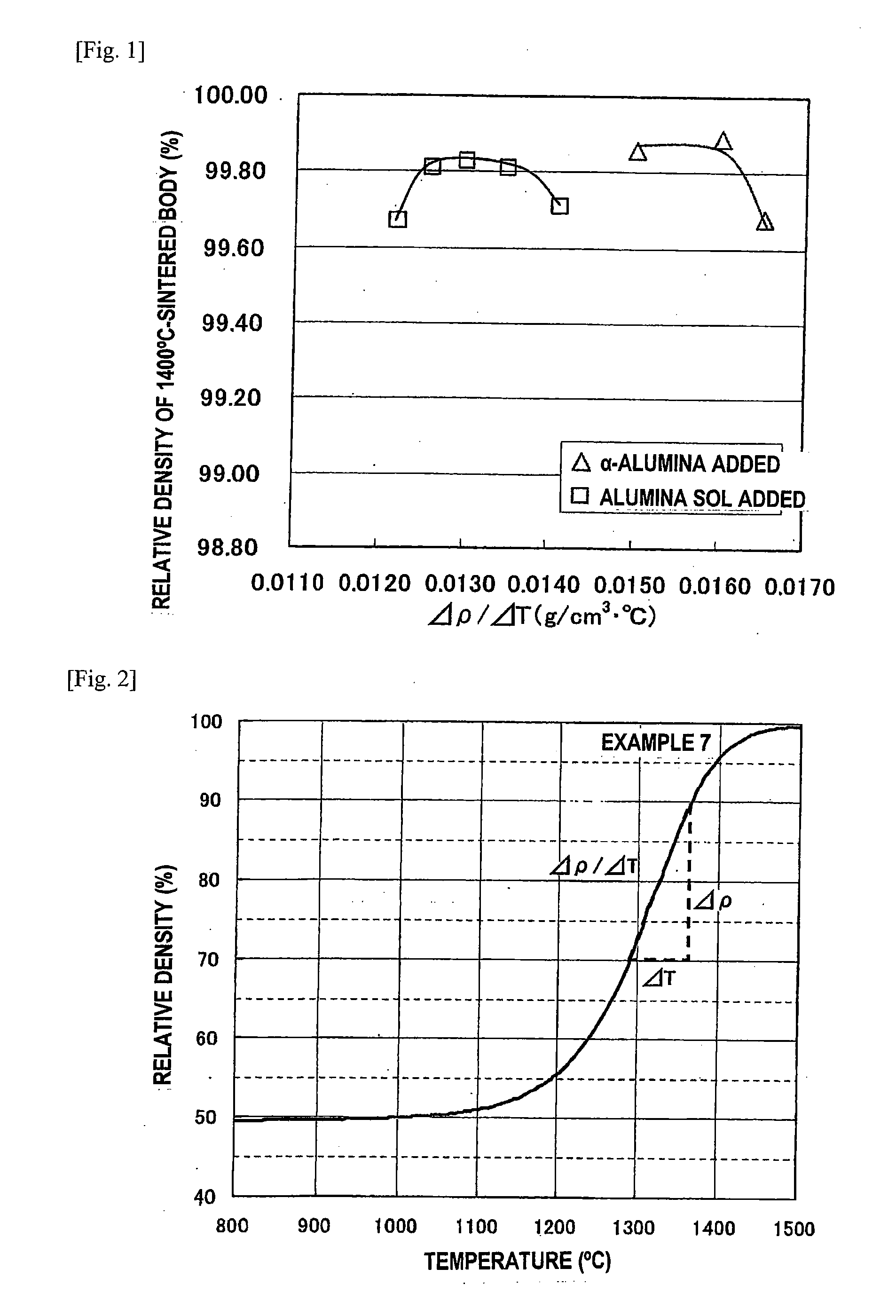

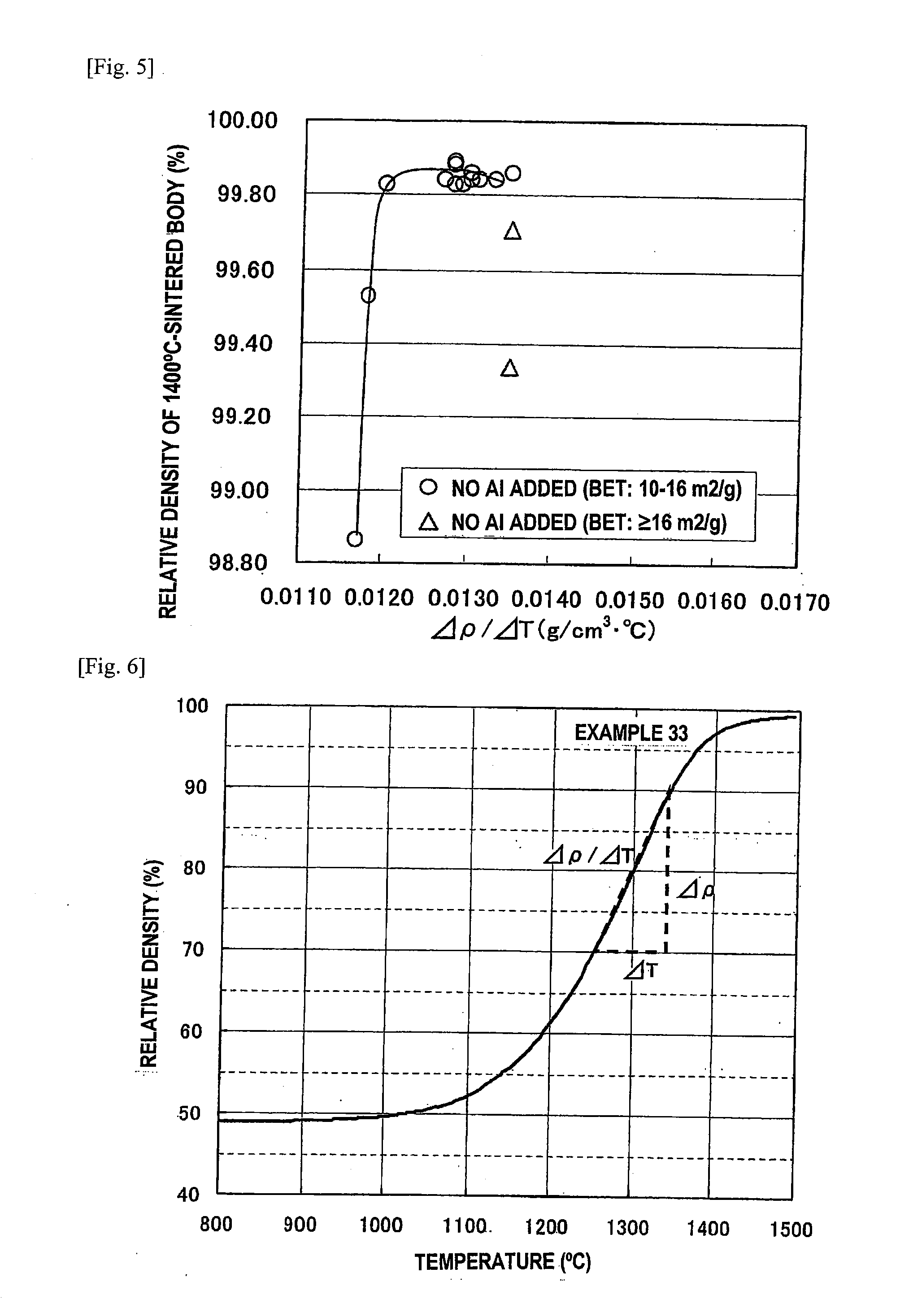

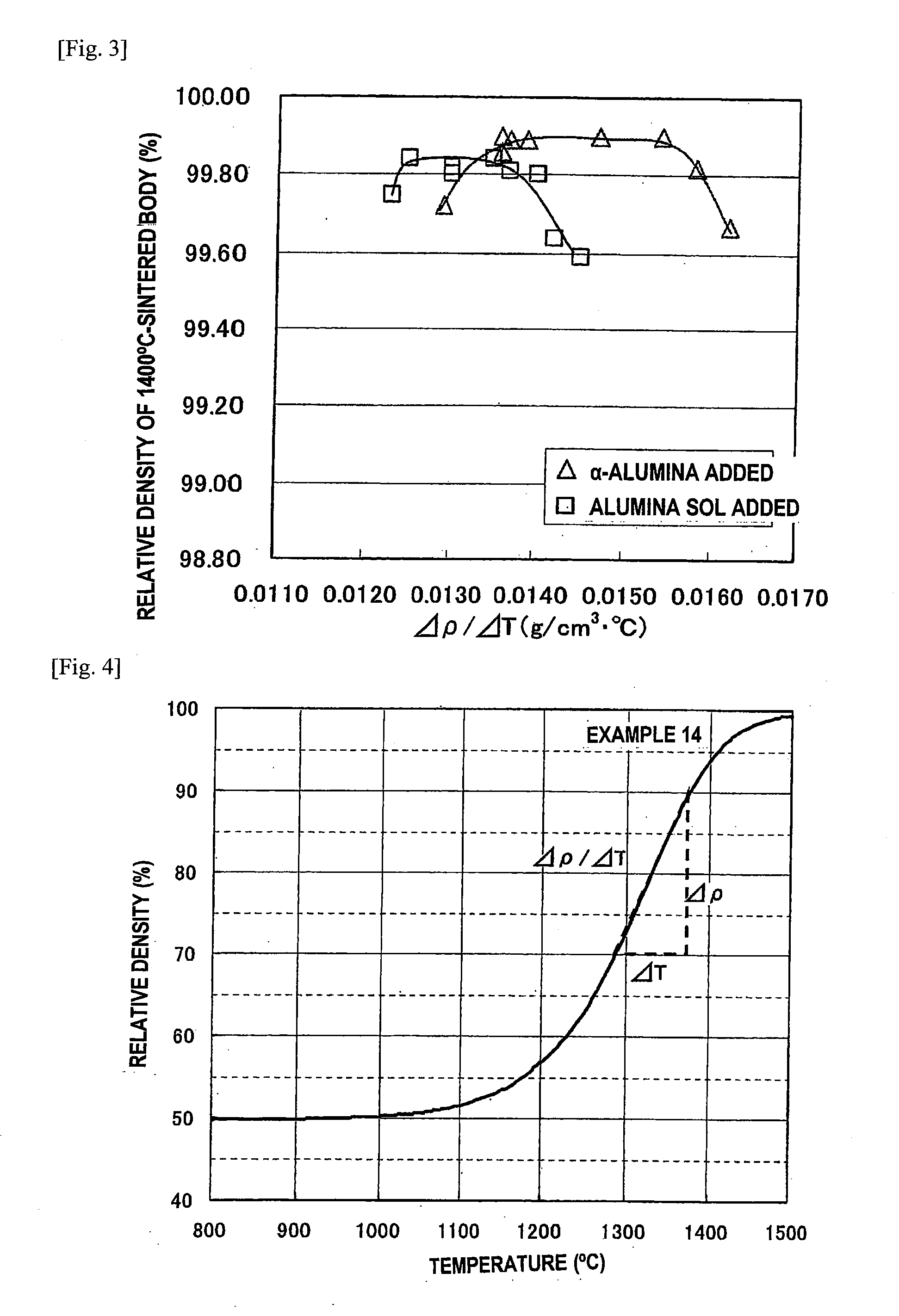

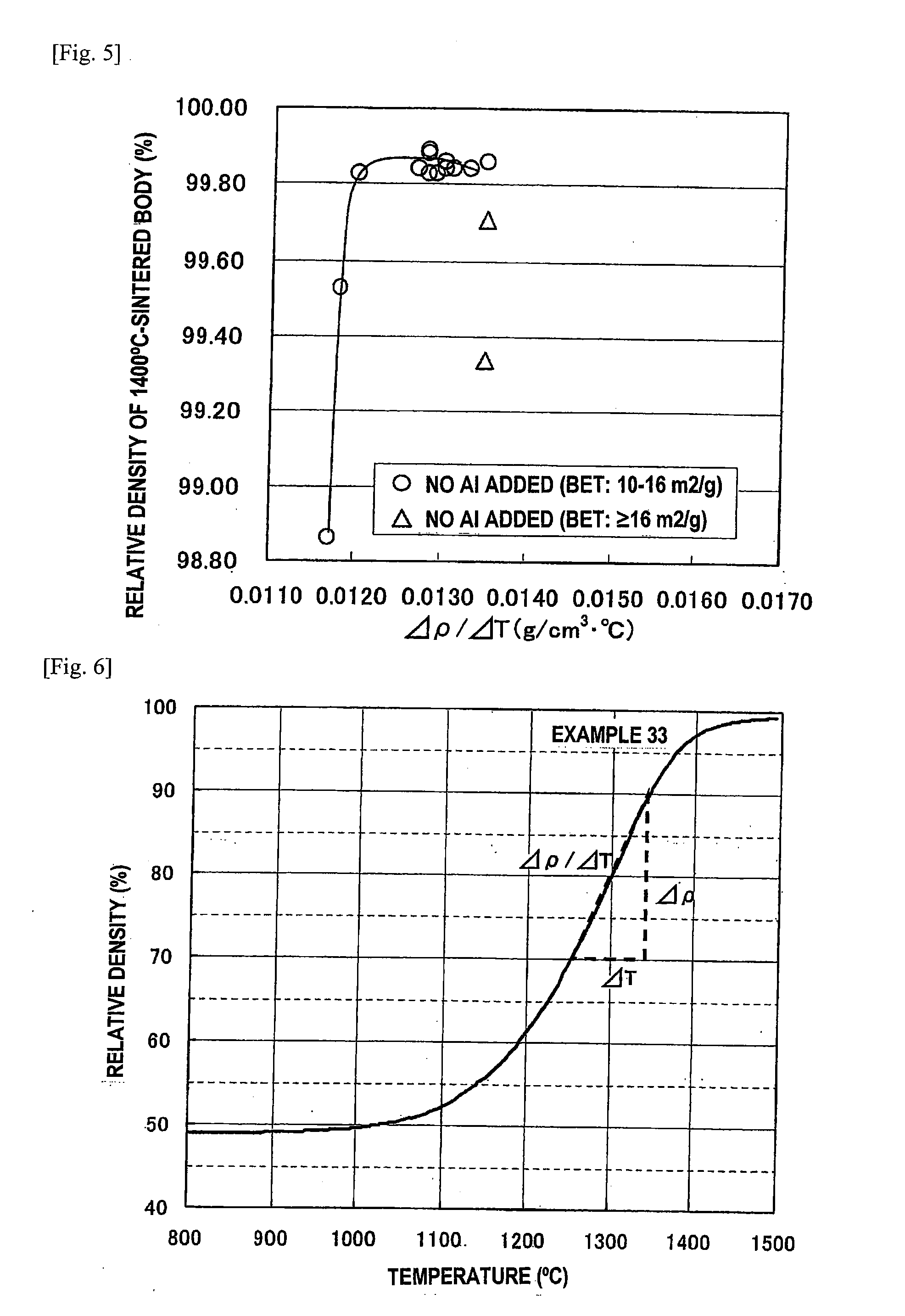

A subject of the invention relates to providing a powder for a translucent zirconia sintered body which is necessary for the production of a zirconia sintered body having a high sintered-body density and high strength and giving an excellent sense of translucency, without conducting any special sintering, such as HIP sintering. The invention relates to a technique for obtaining, through normal-pressure sintering, a translucent zirconia sintered body characterized by comprising zirconia which contains 2-4 mol % yttria as a stabilizer and has an alumina content of 0.2 wt % or lower, and by having a relative density of 99.8% or higher and a total light transmittance, as measured at a thickness of 1.0 mm, of 35% or higher. It is preferred that a powder containing 0-0.2 wt % alumina with a particle diameter of 0.01-0.5 μm, having a BET specific surface area of 5-16 m2 / g and an average particle diameter of 0.3-0.7 μm, and having a rate of sintering shrinkage in normal-pressure sintering (Δρ / ΔT; g / cm3·° C.) of 0.0125 or higher but 0.0160 or lower should be subjected to normal-pressure sintering in the atmosphere.

Owner:TOSOH CORP

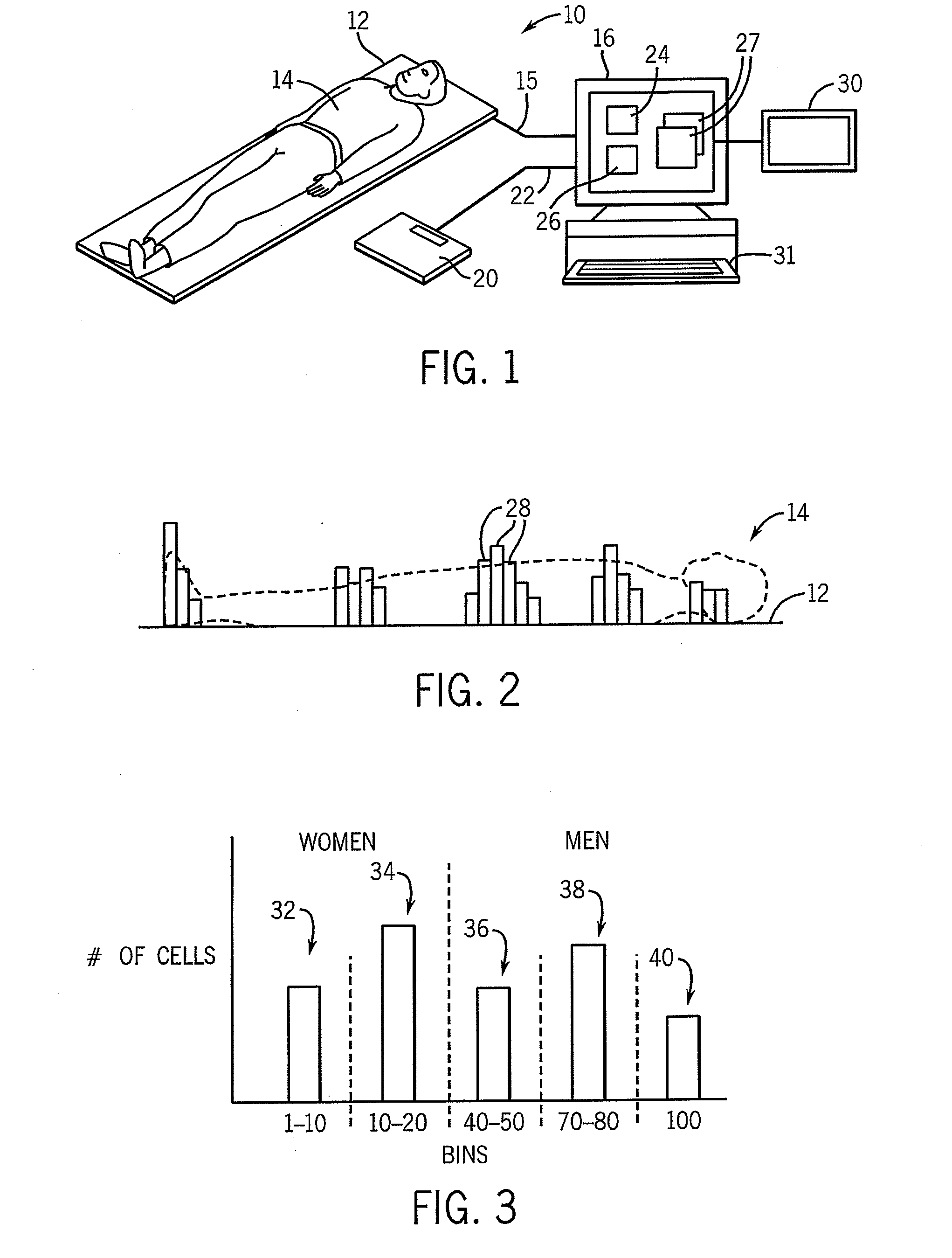

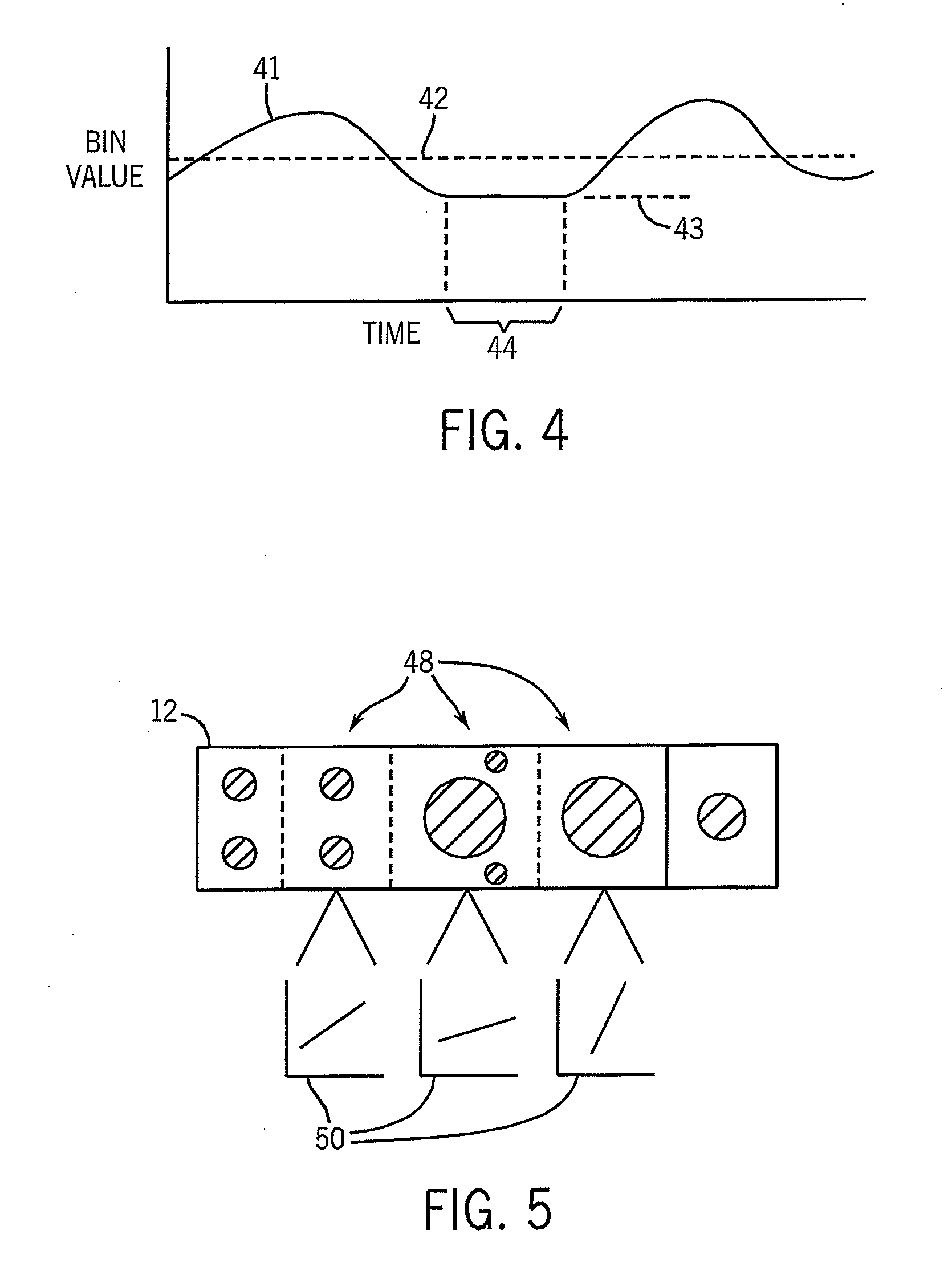

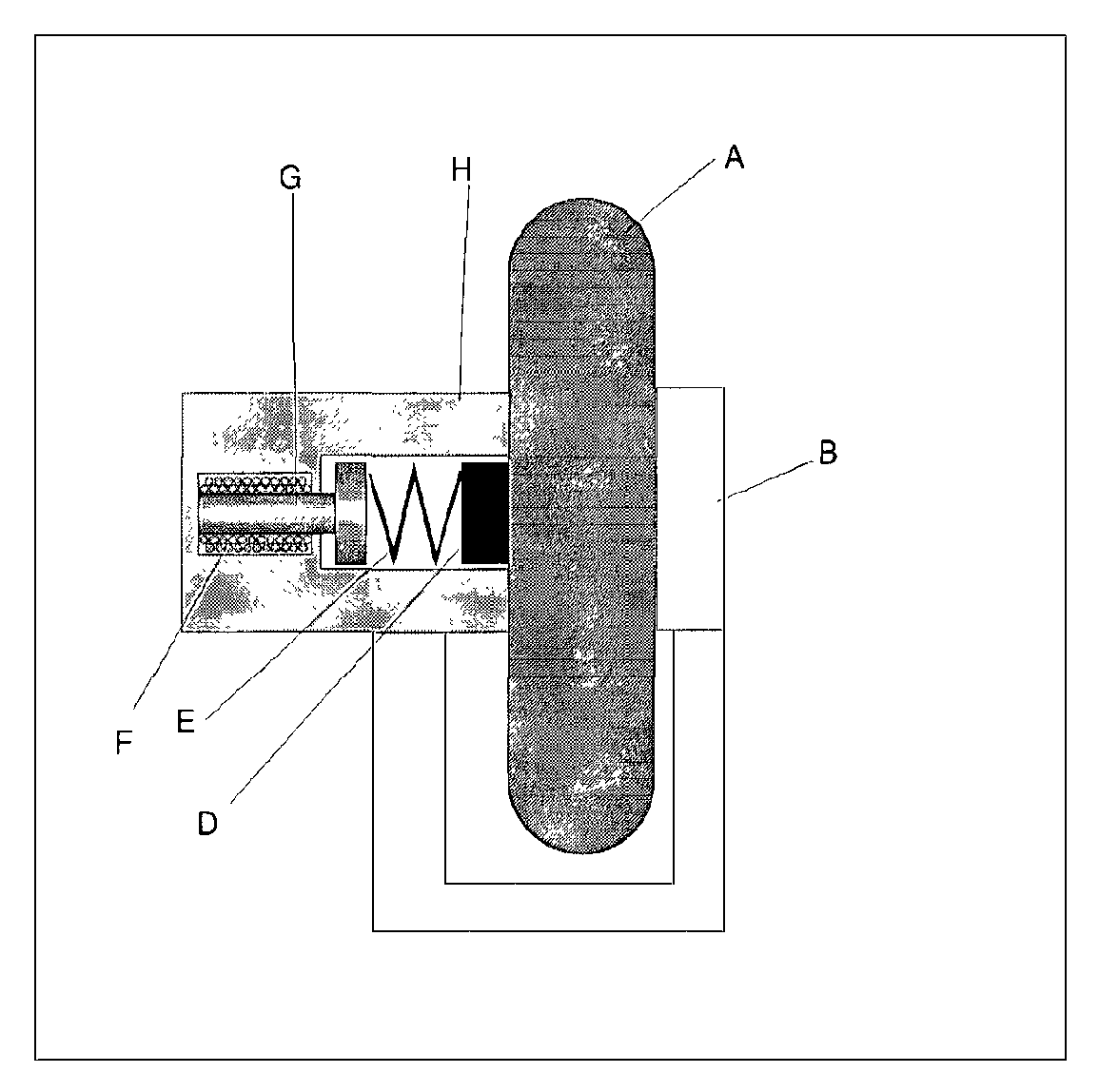

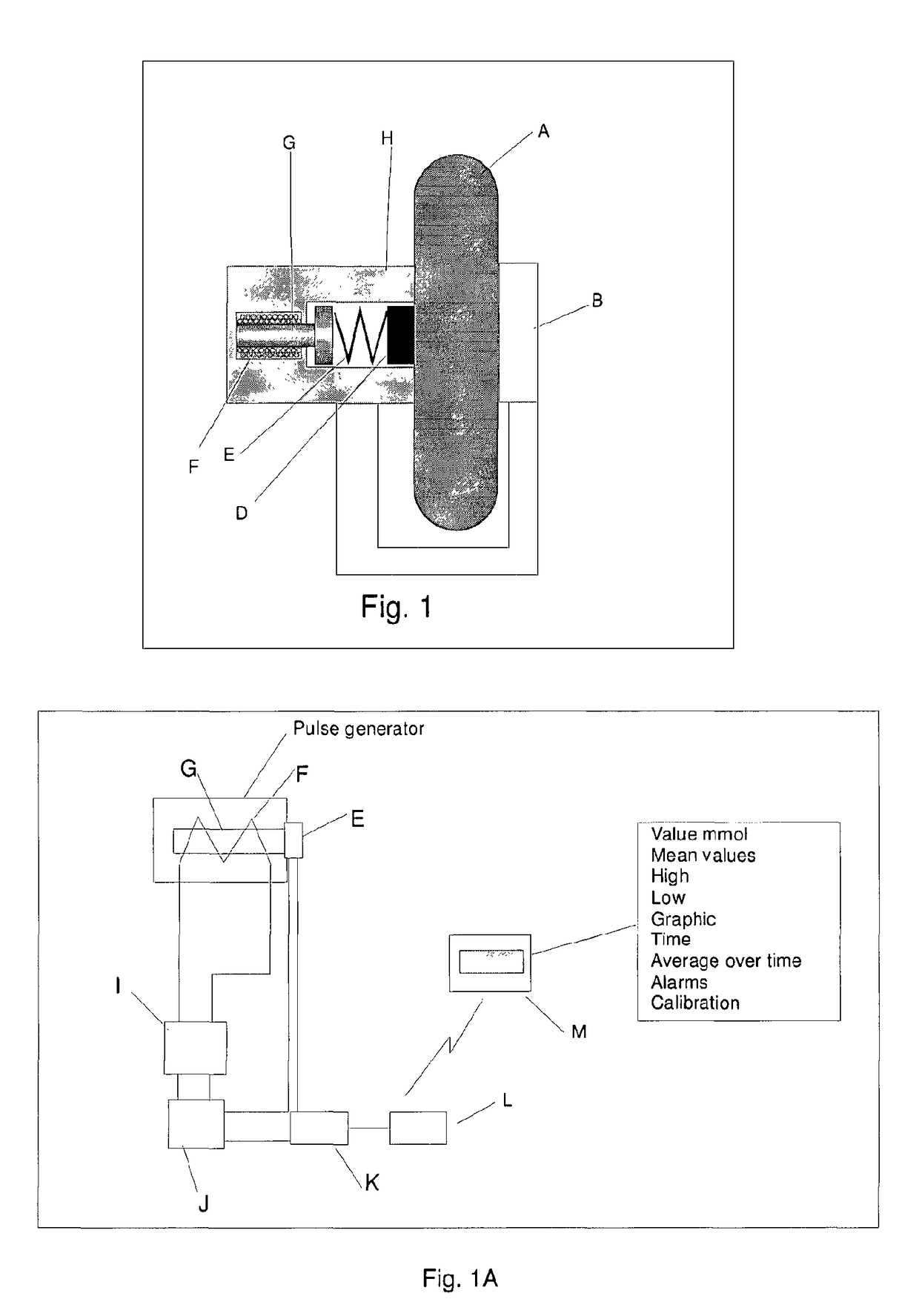

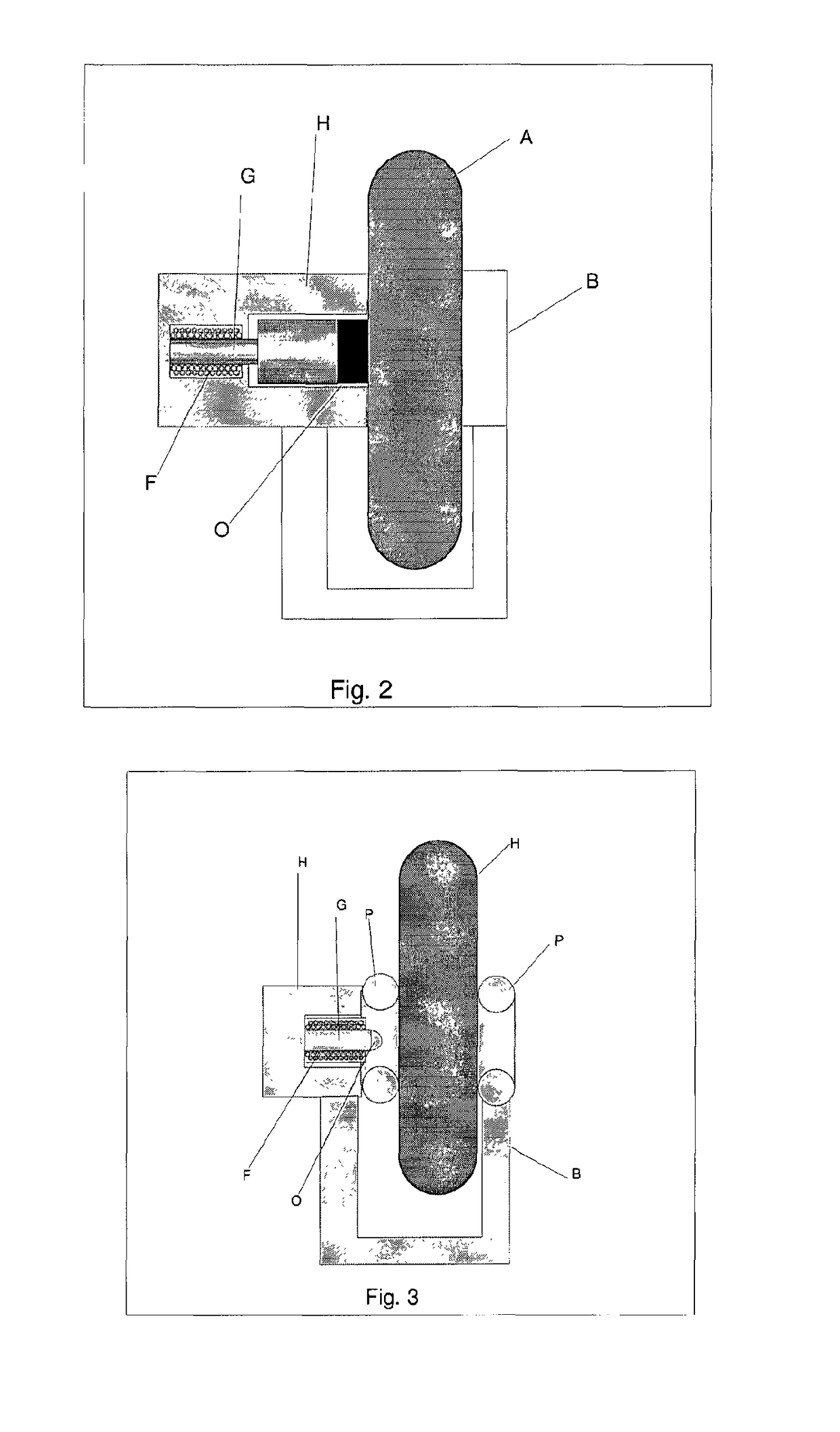

Apparatus for measurement of body composition

InactiveUS20070179360A1Accurate and precise and and timeEasy to manageDiagnostic recording/measuringPressure sensorsClinical informationWhole body

An apparatus for measurement of an individual's body composition includes a pressure mat configured to fully support an adult supine patient and to provide a series of pressure readings at a series of cells over the surface of the pressure mat and then electronically transmits the readings to a computer or the like. The pressure readings along with other relevant clinical information such as the patient's weight are then used to determine the patient's body composition such as percent body fat, body density, total body volume, fat mass and fat-free mass.

Owner:MIKAT RICHARD P

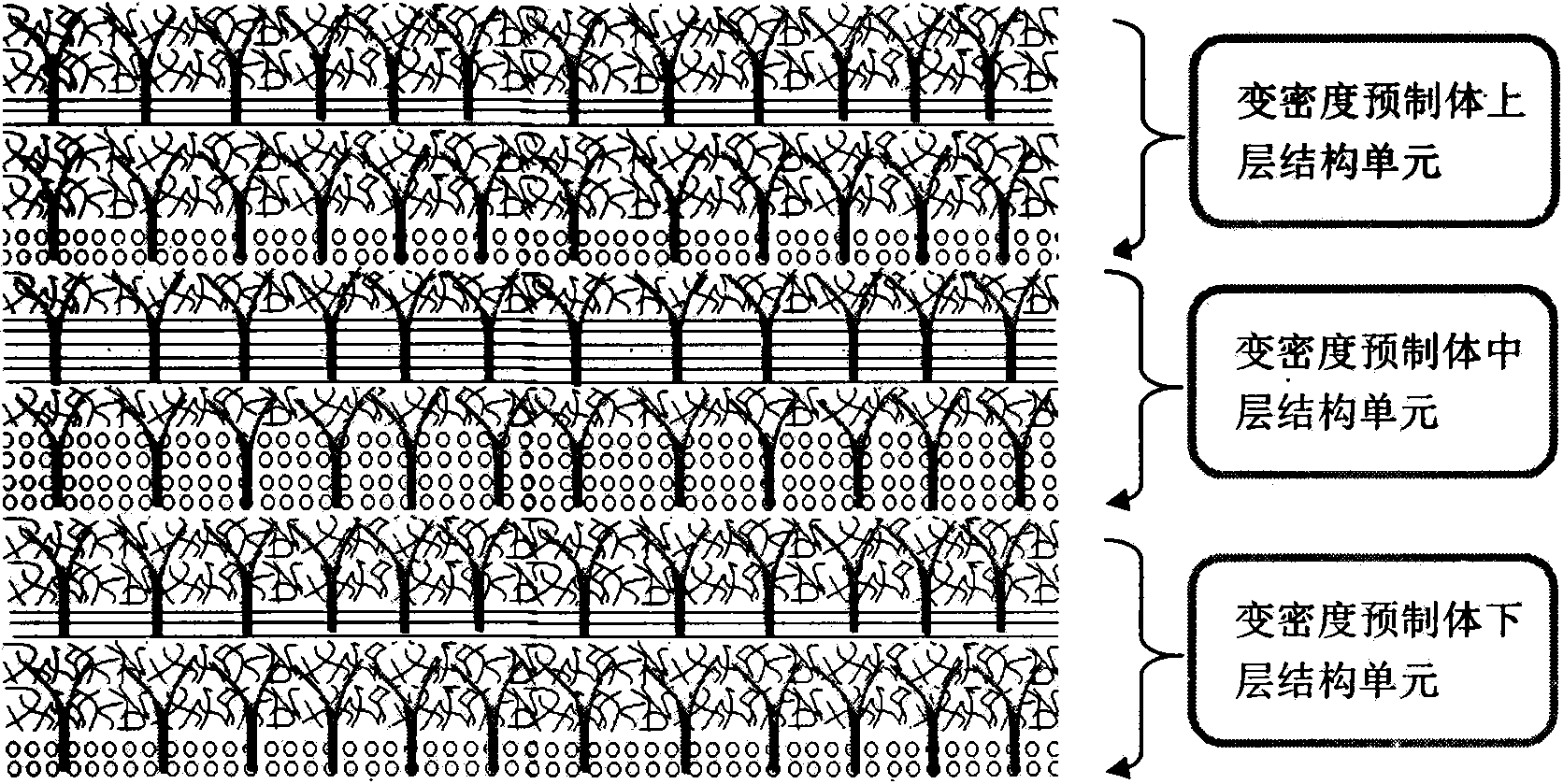

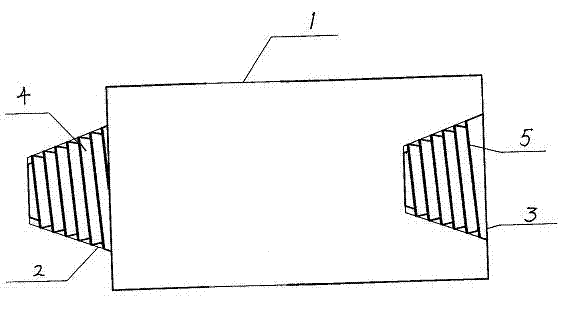

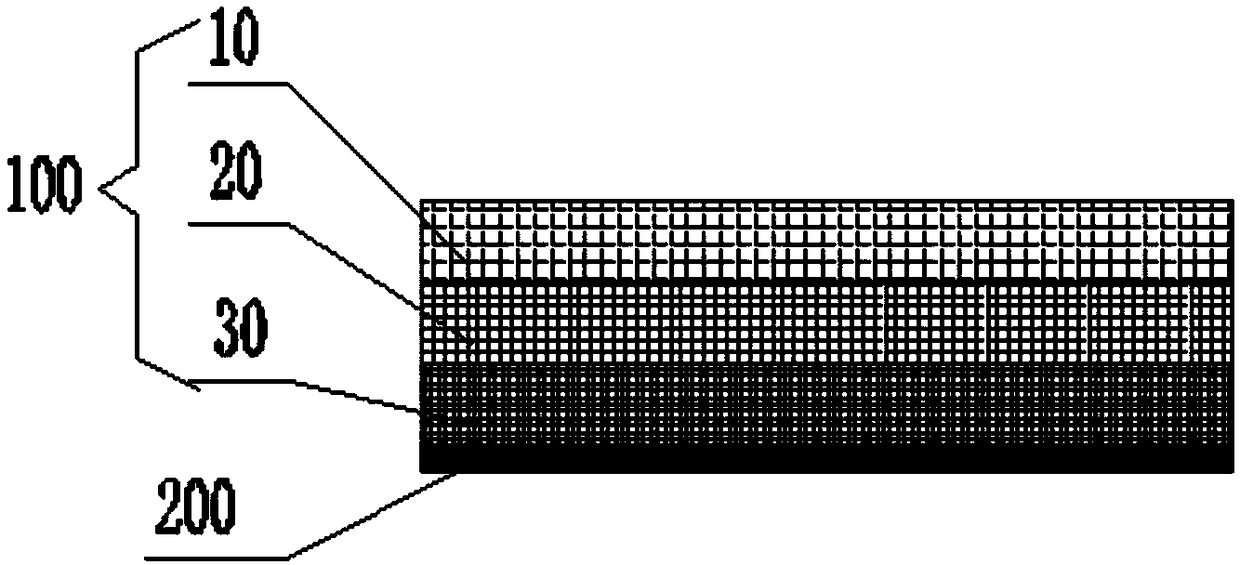

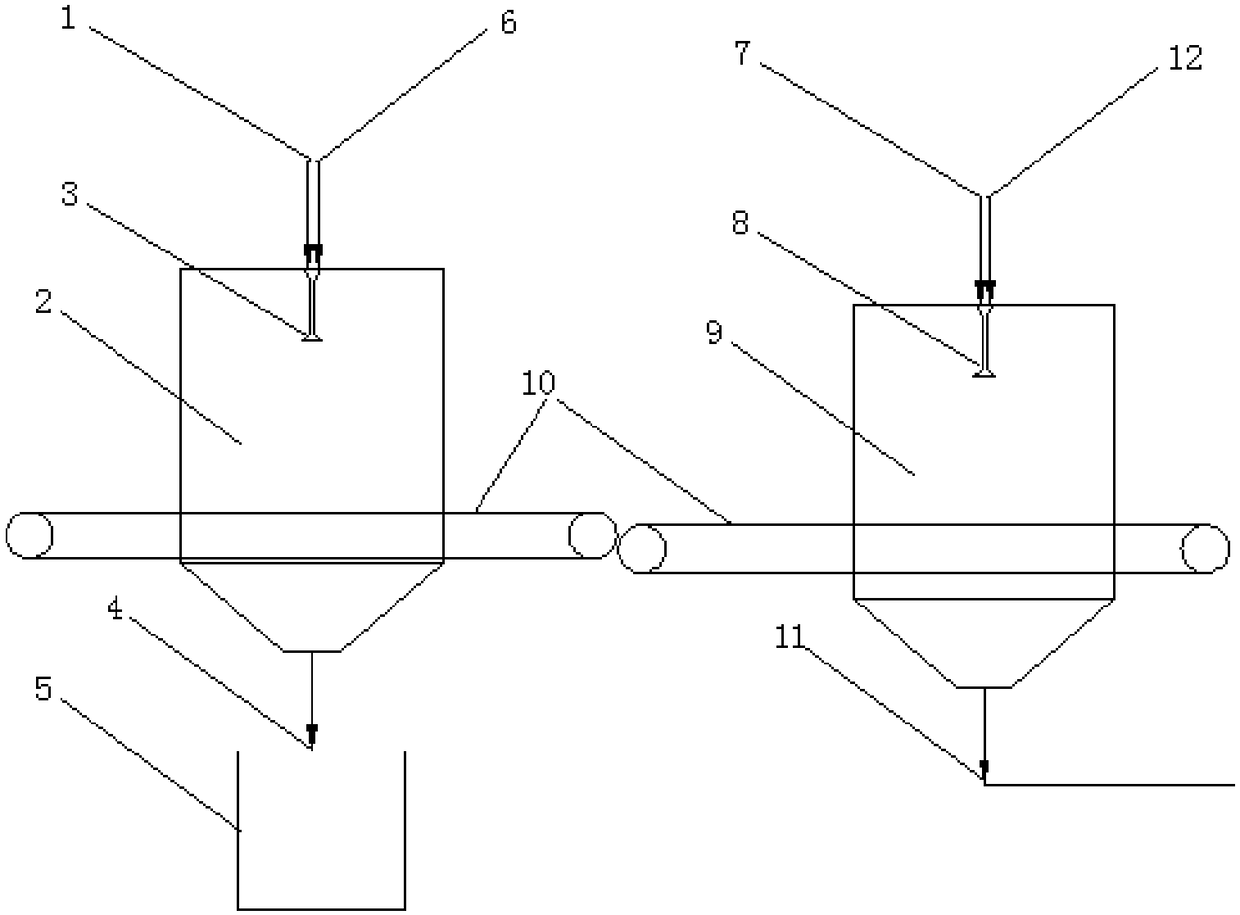

Carbon-fiber needled preformed body with gradiently-changed body density

The invention discloses a carbon-fiber needled preformed body with gradiently-changed body density. The preformed body is formed by continuously needling three layers of carbon-fiber needled preformed bodies in a multi-angle and layer-by-layer crossed manner, wherein the density of the preformed body at a middle layer is larger than the densities of the preformed bodies at an upper layer and a lower layer, and each preformed body is formed by compositing a layer of weftless carbon cloth paved in a 0-degree / 90-degree angle with a layer of mesh tire and continuously needling in the layer-by-layer manner. The preformed body has the advantages of short preparation cycle and low production cost in carbon / carbon sedimentation technological process, and a carbon / carbon composite material produced from the preformed body has excellent performances of wear resistance, high temperature resistance, low expansion coefficient, high heat conductivity, good heat shock resistance, light weight and the like. The high-performance carbon-fiber needled preformed body is a novel functional composite structure product and has wide application prospects in the fields of aviation, space flight, civil construction, military and the like due to the specific structure and advanced production process.

Owner:JIANGNAN UNIV

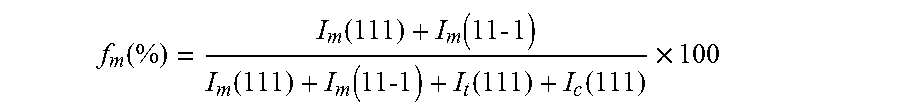

Colored translucent zirconia sintered body and its use

ActiveUS20150315086A1High densityGood light transmissionBracketsImpression capsTransmittanceBody density

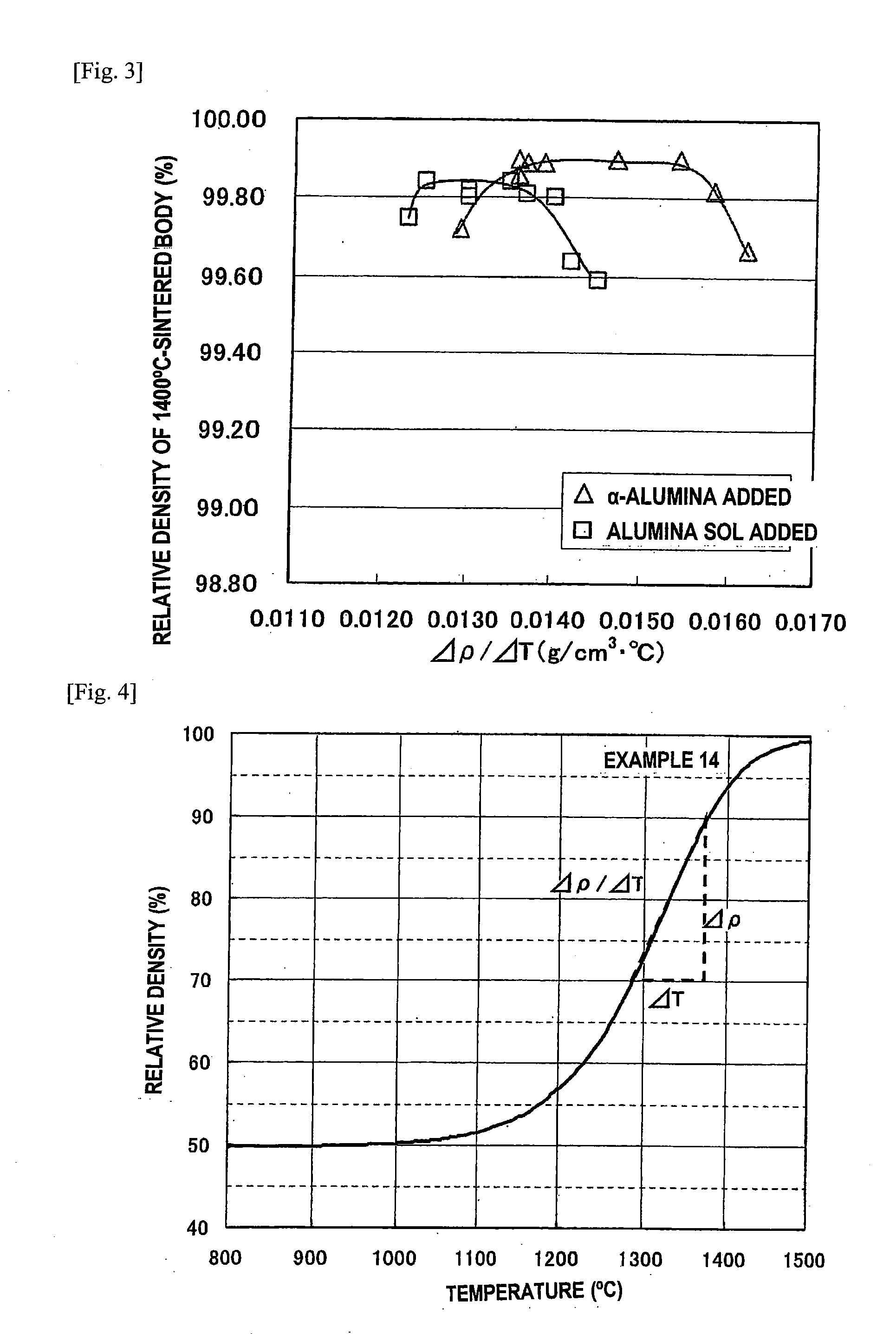

A pink-colored zirconia sintered body has a high sintered body density and strength, and a colored translucency, which has a color tone similar to teeth and excellent translucency and has high aesthetic properties. A colored translucent zirconia sintered body includes from 2 to 4 mol % of yttria, from 0.02 to 0.8 mol % of Er2O3, at least 20 and less than 2,000 ppm, as calculated as Fe2O3, of an iron compound, at least 0.005 and less than 0.2 wt % of Al2O3 and the rest being zirconia, and having a lightness L* of from 55 to 75, a* of from 0 to 10 and b* of from 0 to 30 as chromatic parameters stipulated in JIS-Z8729, has a relative density of at least 99.80% and has a total light transmittance of at least 18% and at most 40% as measured at a sample thickness of 1 mm using a D65 light source.

Owner:TOSOH CORP

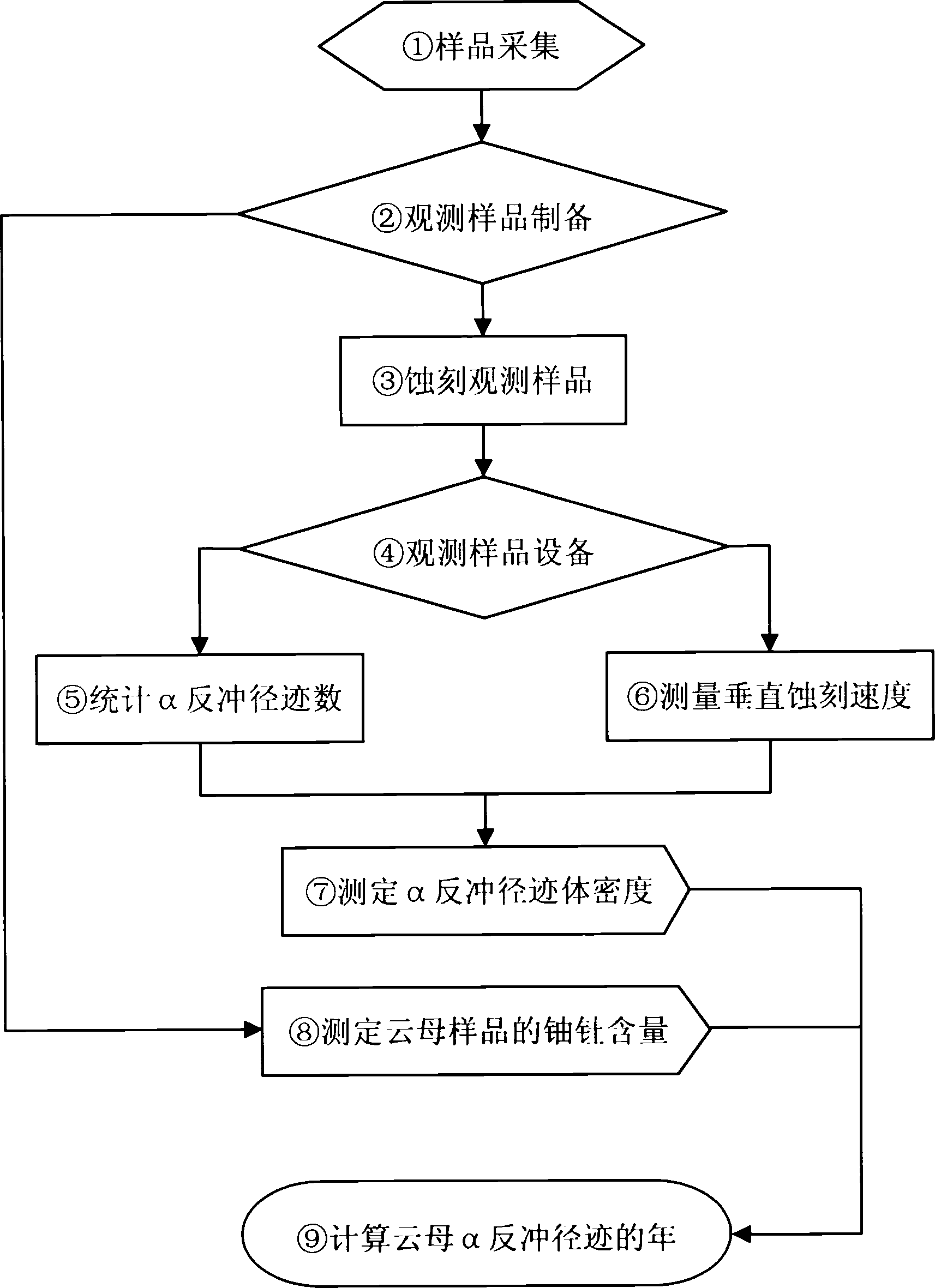

Alph recoil track dating method

The invention is concerned with chronology research determination technology field about the Quaternary epoch, geography, disaster, archeology, especially a alpha recoil track determining age method, including: a) sample collection; b) observation sample preparation; c) etch observation sample; d) observation sample equipment; e) statistic alpha recoil track value; f) measure vertical etching speed; g) determine alpha recoil track body density; h) determine the uranium thorium content of the mica sample; i) compute the alpha recoil track age of the mica.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Charcoal electrode specially used in smelting of ferroalloy and preparation method thereof

ActiveCN102355759ALow antioxidantImprove antioxidant capacityElectric discharge heatingPetroleum cokeElectron

The invention, which belongs to the charcoal electrode technology field, discloses a charcoal electrode specially used in smelting of ferroalloy and a preparation method thereof. A main technology is characterized by: screening calcined solid-raw-material electrical calcined coal, petroleum coke, graphite scraps and a secondary material of carbon black; after performing burdening through using anelectronic batching system, entering into a kneading boiler for stirring and drily mixing; then adding coal tar pitch and performing kneading; molding, roasting and machining so as to produce a charcoal electrode specially used in the smelting of ferroalloy. In the charcoal electrode specially used in the smelting of ferroalloy, volatile matter of asphalt does not exist; body density is high; an ash content is low; inoxidability is good. The volatile matter of flue gas given off by roasting during a usage process can be avoided if the charcoal electrode substitutes a self baking electrode. Electricity consumption during roasting the self baking electrode can be saved. Therefore, energy saving and environmental protection can be realized. Installation is simple. Soft breaking accident and hard breaking accident of the electrode caused by careless operation can not be generated so that safety can be substantially raised.

Owner:JIZHOU CHANGAN ELECTRODE

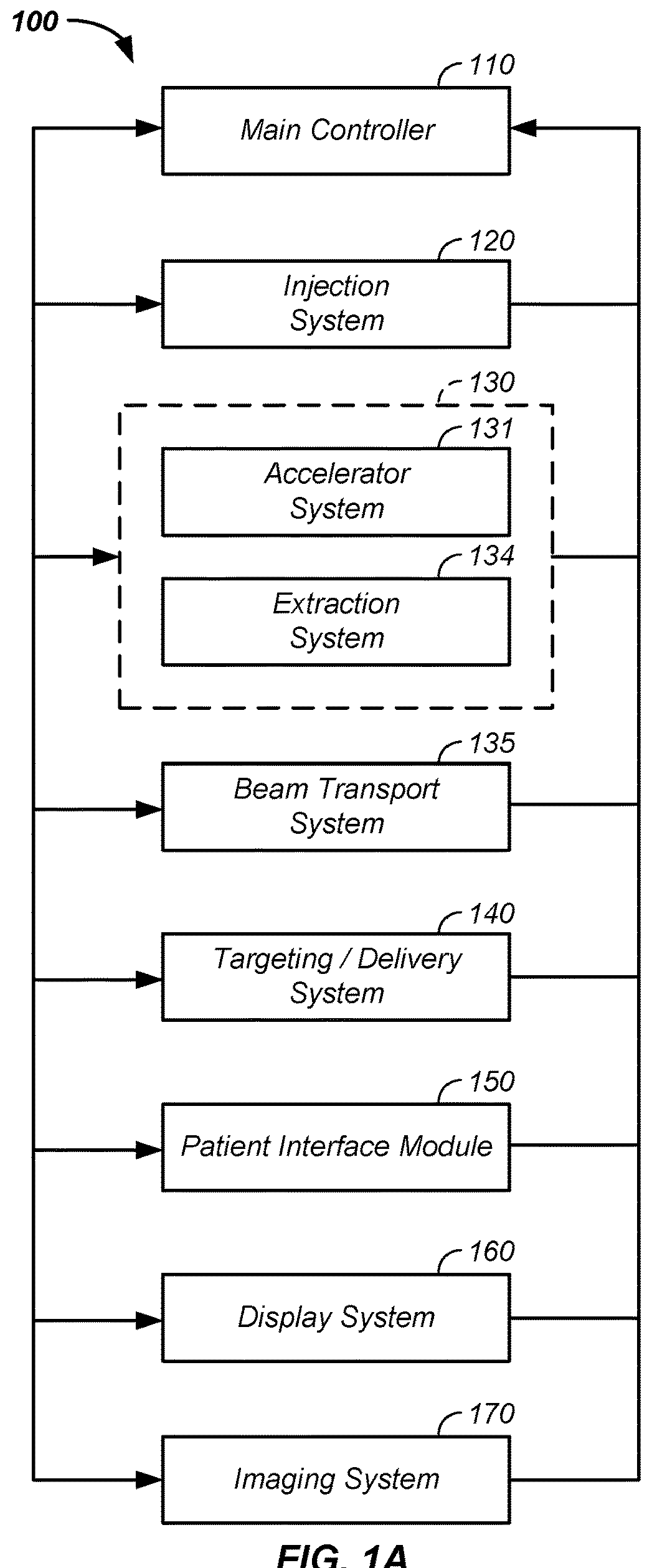

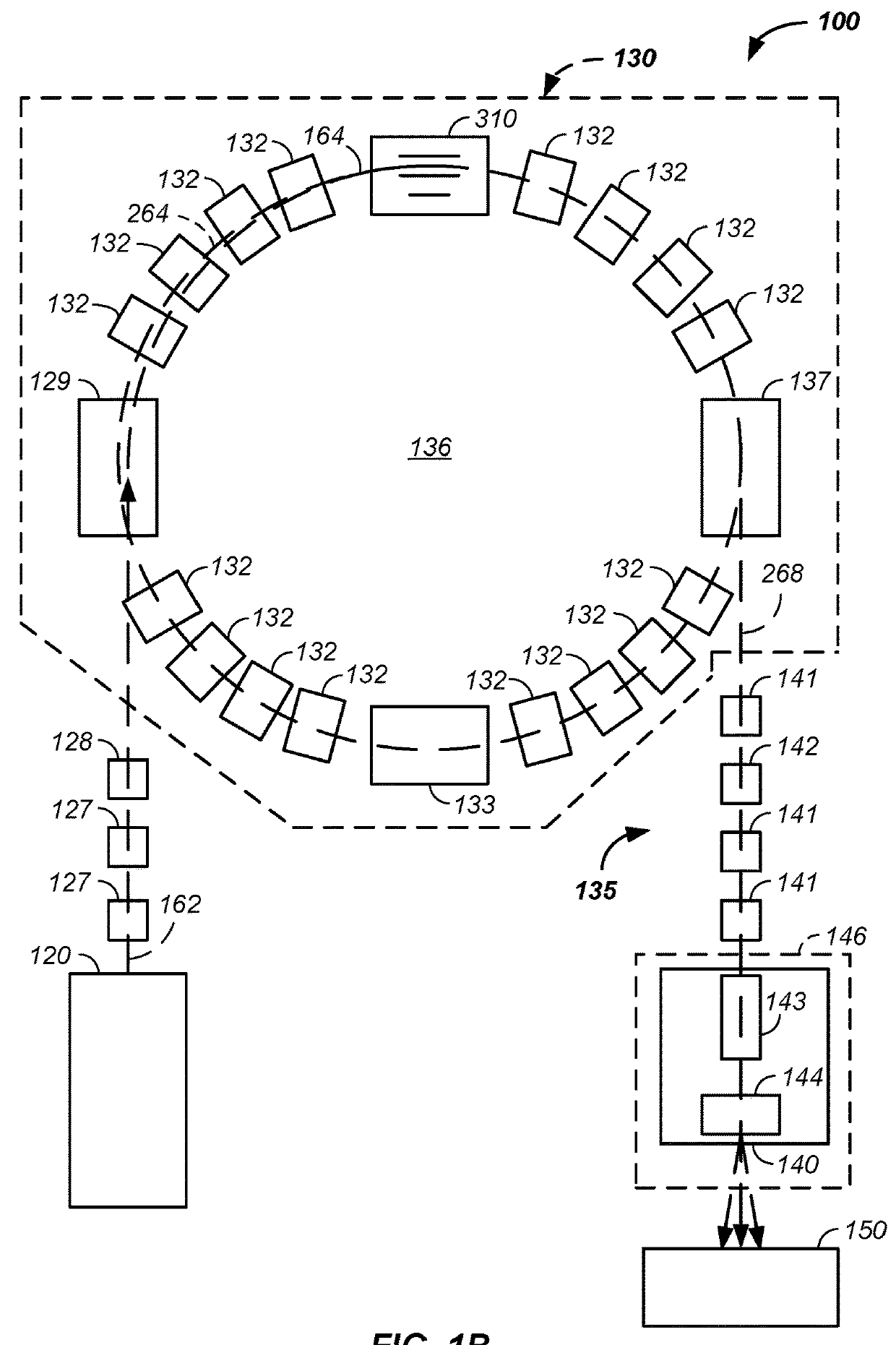

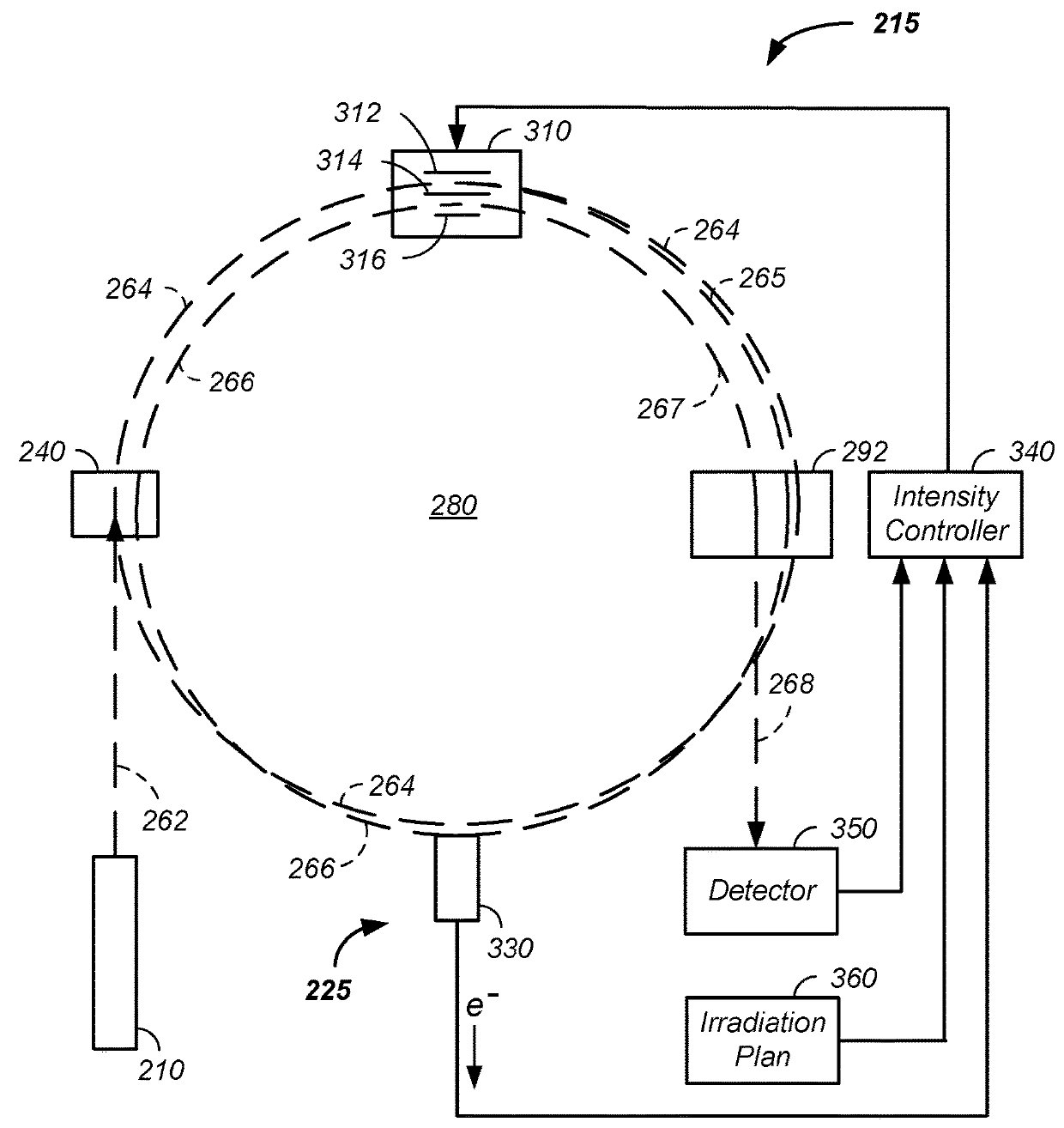

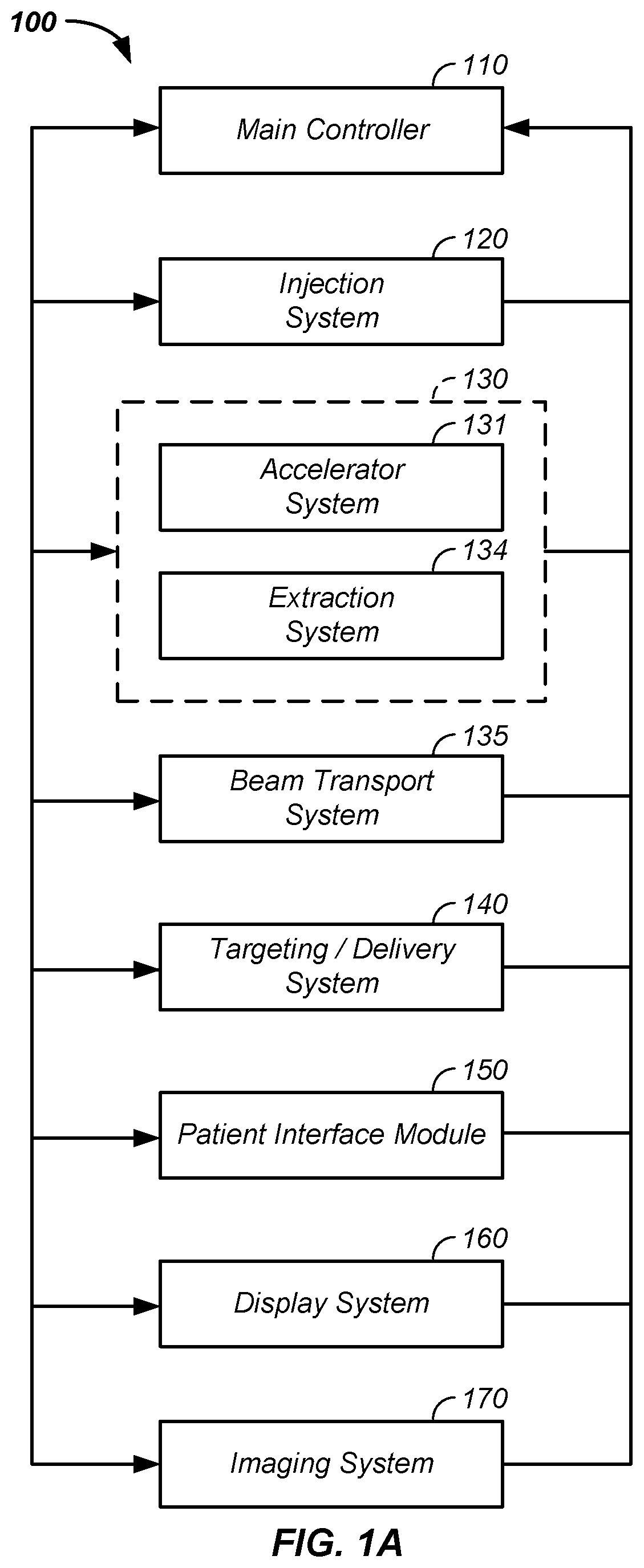

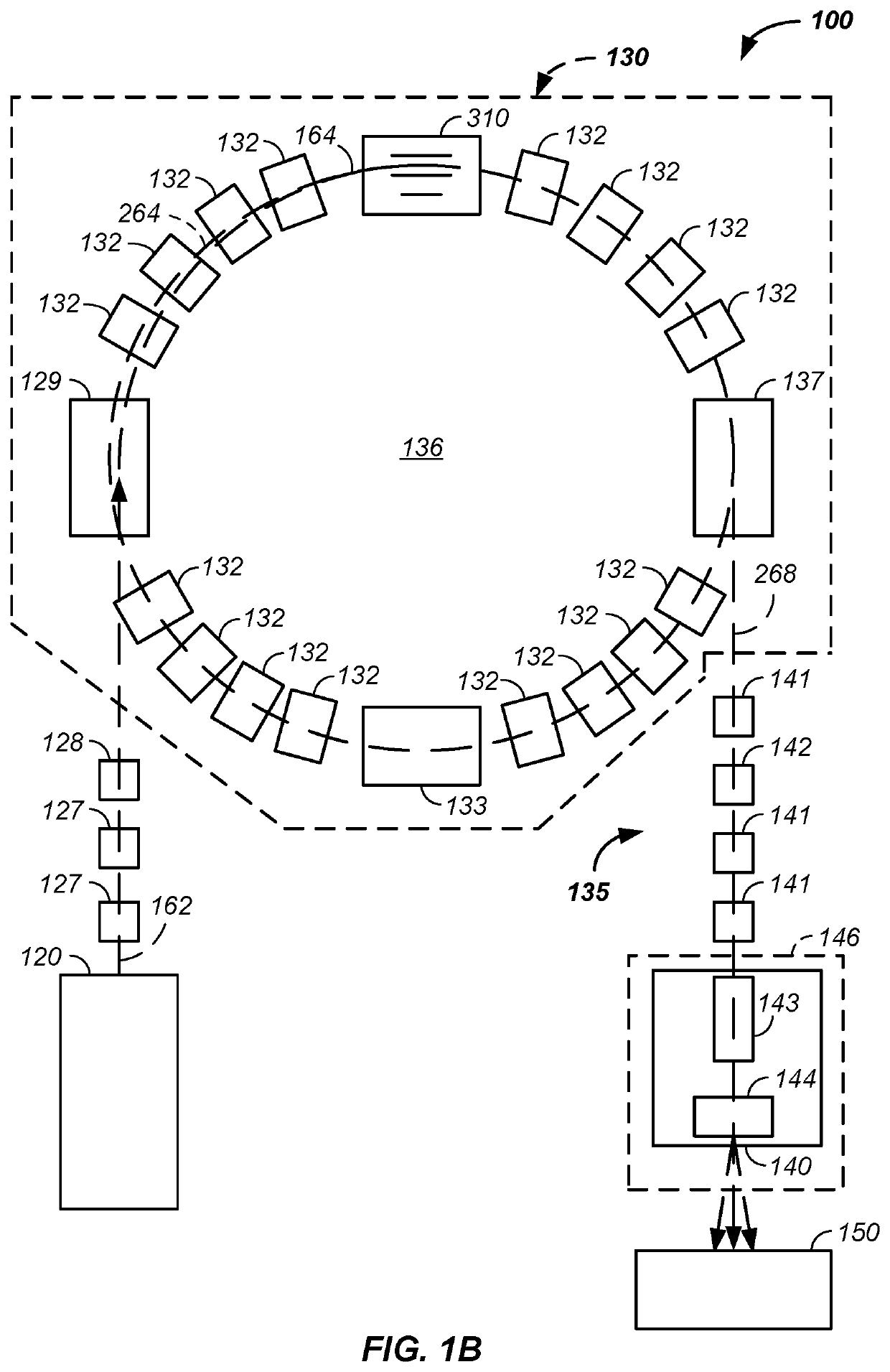

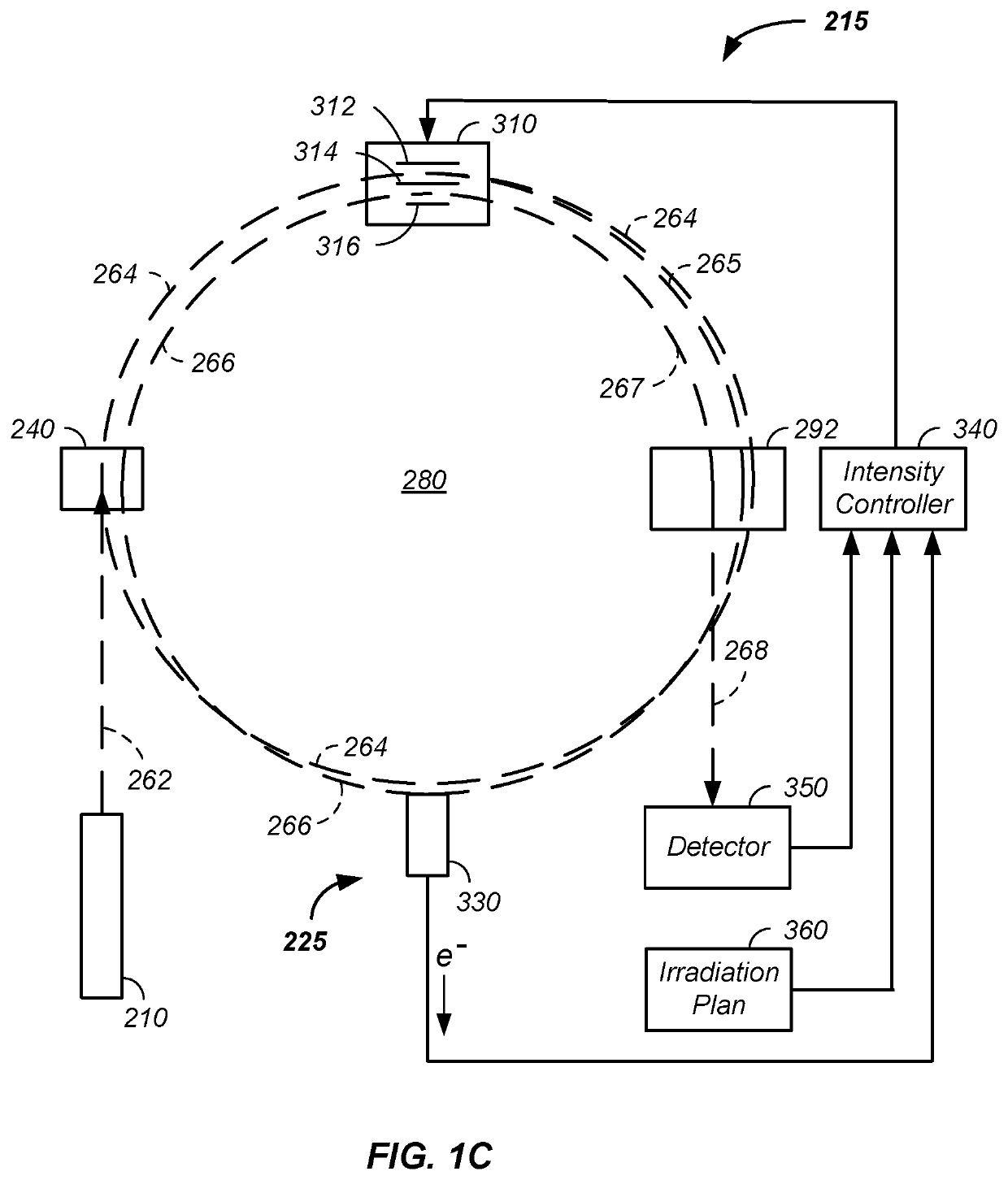

Multi-color charged particle detector apparatus and method of use thereof

ActiveUS20180178039A1Cathode ray concentrating/focusing/directingComputerised tomographsBody densityPositively charged particle

The invention comprises a method and apparatus for using a multi-layer multi-color scintillation based detector element to image a tumor of a patient using a process of determining residual energies of positively charged particles after passing through the patient, the process comprising the steps of: (1) transmitting the positively charged particles at known energies through the patient and into a multi-layer detector element; (2) detecting first and second secondary photons, resultant from passage of the positively charged particles, respectively from a first layer of a first scintillation material and a second layer of a second scintillation material at two respective layer depths, where the first wavelength range differs from the second wavelength range; (4) determining residual energies of the positively charged particles, using output from the step of detecting; and (5) relating the residual energies to body densities to generate an image.

Owner:PROTOM INT HLDG CORP

Milk white glass wine bottle

The invention relates to glass ware, in particular to a milk white glass wine bottle which is formed by components including aluminum oxide, quartz sand, feldspar powder, calcite, sodium fluosilicate, industrial sodium carbonate, zinc oxide and the like. Compared with the prior art, the milk white glass wine bottle has the advantages of being high in bottle opening size accuracy, smooth in surface and strong in bottle body density structure and anti-collision strength. Therefore, the milk white glass wine bottle better prevents wine leakage at a bottle opening, wine seepage at a bottle body, bottle oxidizing and wine volatilization, greatly satisfies reliability and safety of long-distance transportation, and greatly reduces broken percentage in the disassembly process to some extent. The wine bottle belongs to environment-friendly products, broken glass can be processed for secondary molding, and characteristics of the glass wine bottle are not changed. The milk white glass wine bottle greatly reduces waste of social resources and has no pollution to environment and social life.

Owner:黄炳炼

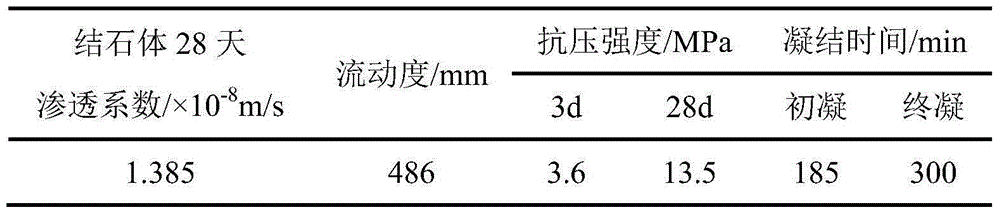

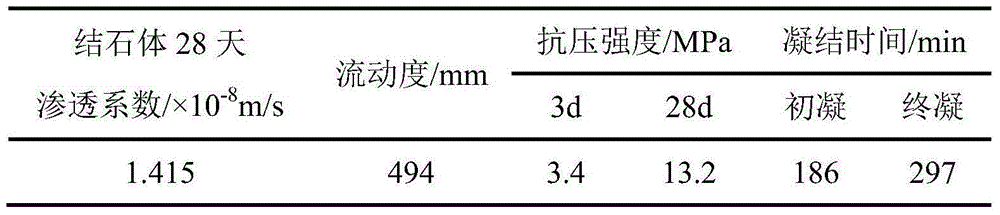

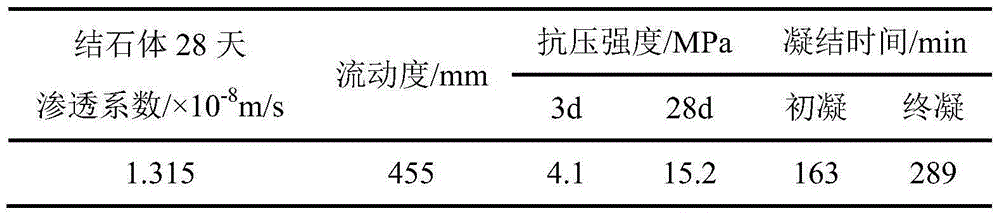

Limestone water-containing layer grouting reconstruction material suitable for superlong-distance pumping

The invention relates to a limestone water-containing layer grouting reconstruction material suitable for superlong-distance pumping, and the material is composed of, in parts by mass, 65-70 parts of burned coal gangue, 20-25 parts of sulphate aluminium cement clinker, 8-15 parts of steel slag micro powder, and 9-12 parts of an extra-additive active initiator. The active initiator comprises, in parts by mass, 13-19 parts of alum, 20-28 parts of talcum powder, 8-13 parts of guar gum, 5-8 parts of hydroxypropyl methyl cellulose, and 40-55 parts of gypsum powder. The material possesses the characteristics of being high in slurry stability, weak in environment temperature influence, suitable for long-distance pumping, good in grouting property, high in stone body density, high in impermeability, wide in raw material source, low in price, and the like.

Owner:SHANDONG UNIV +1

Translucent zirconia sintered body, process for producing the same, and use of the same

ActiveUS20140370453A1High densityGood light transmissionMaterial nanotechnologyBracketsBody densityTransmittance

Owner:TOSOH CORP

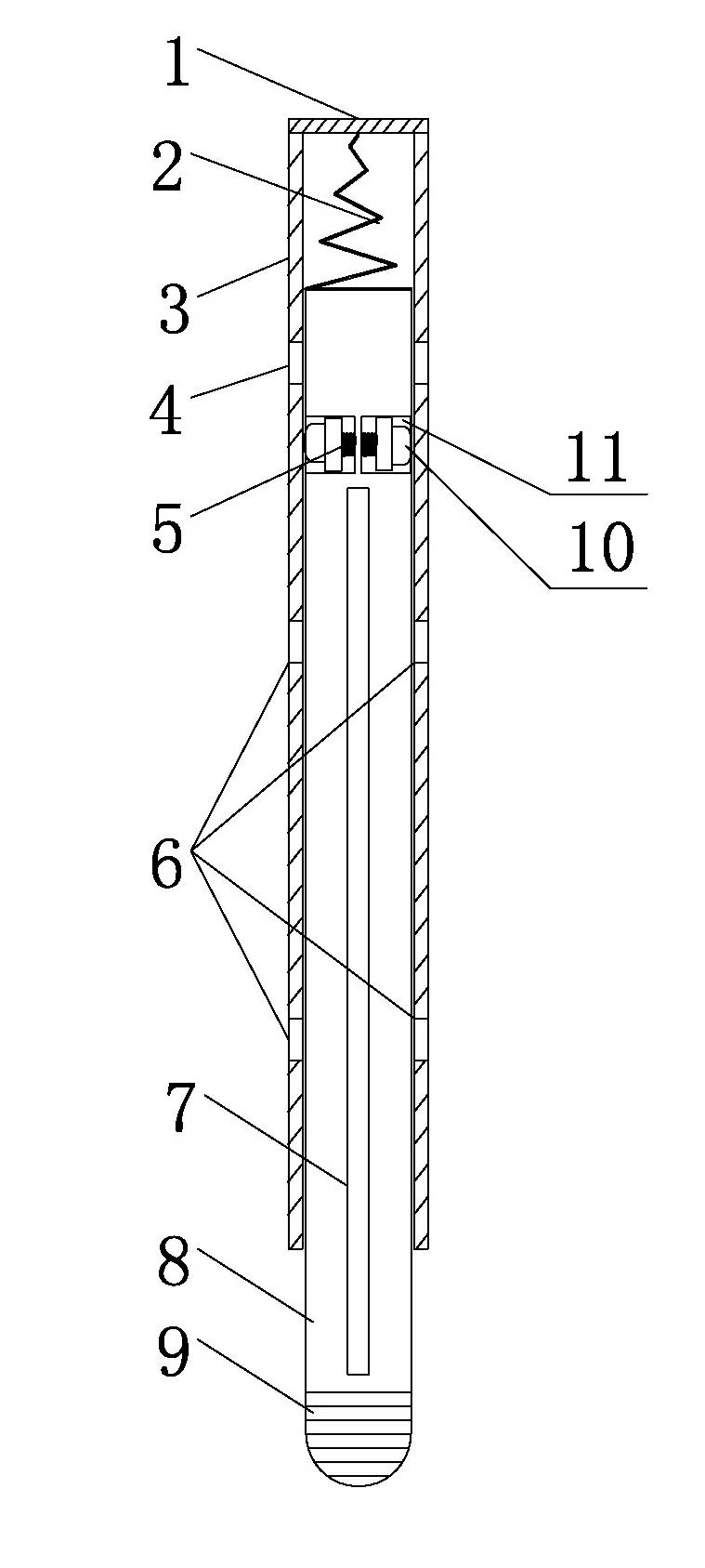

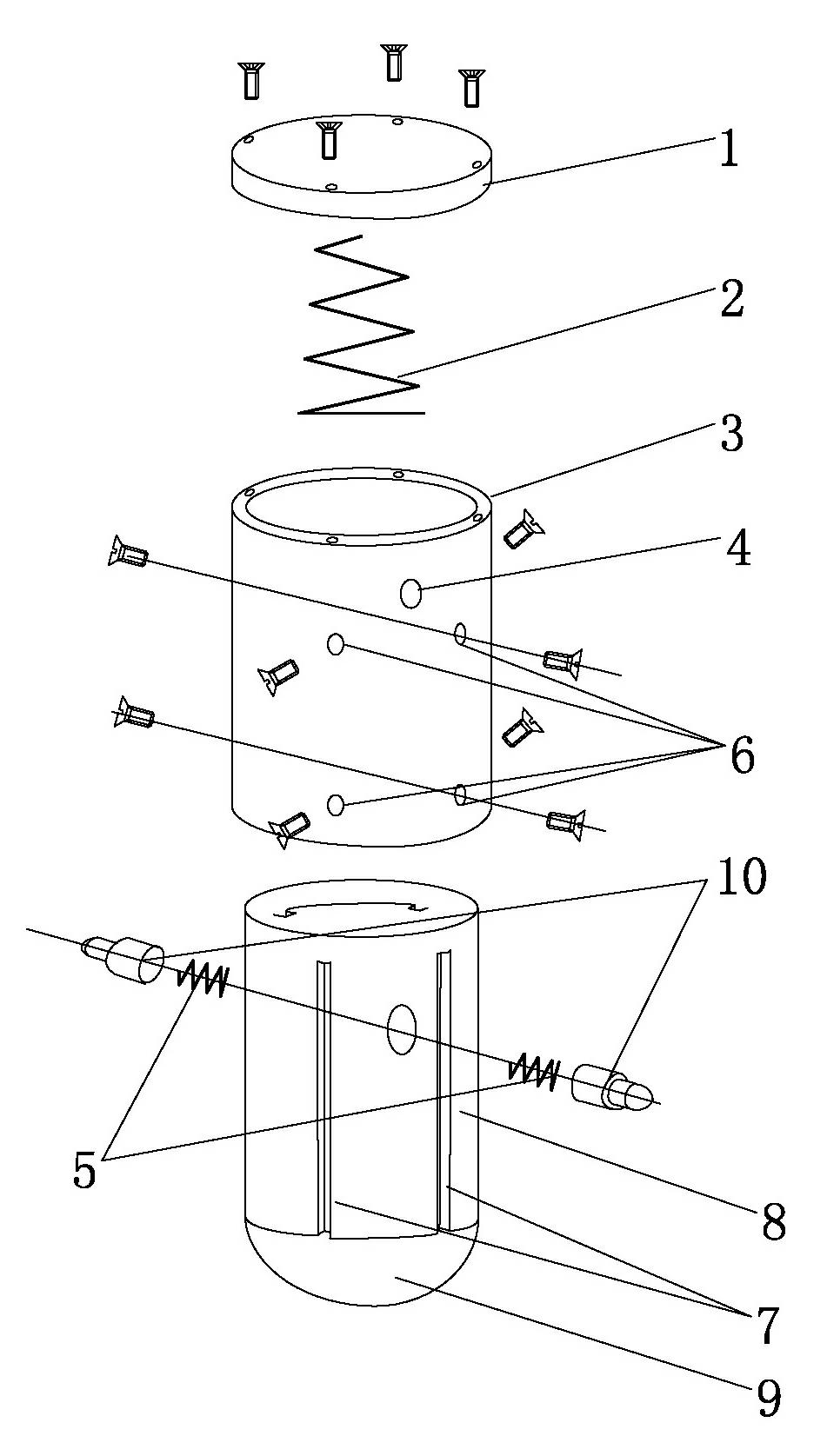

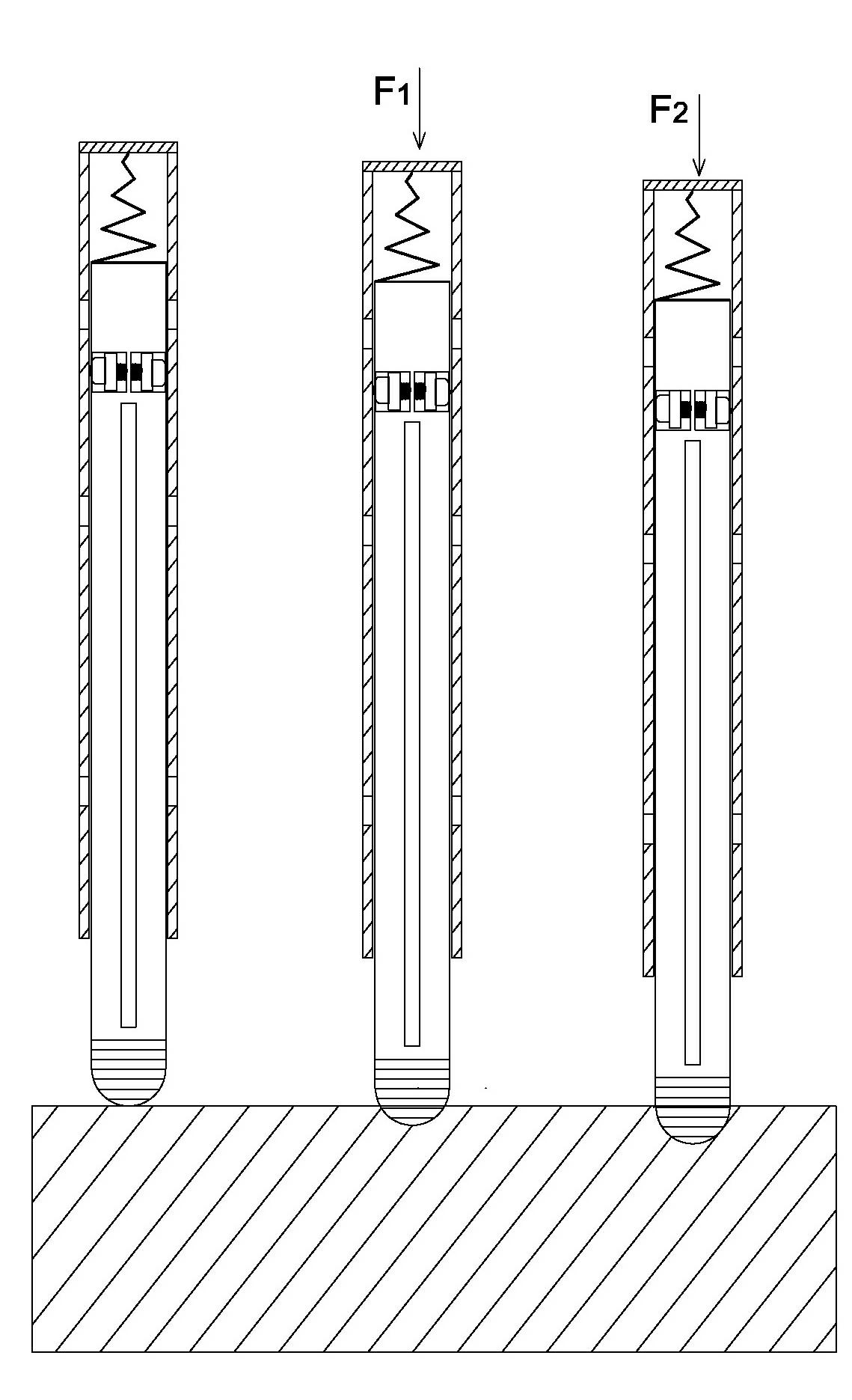

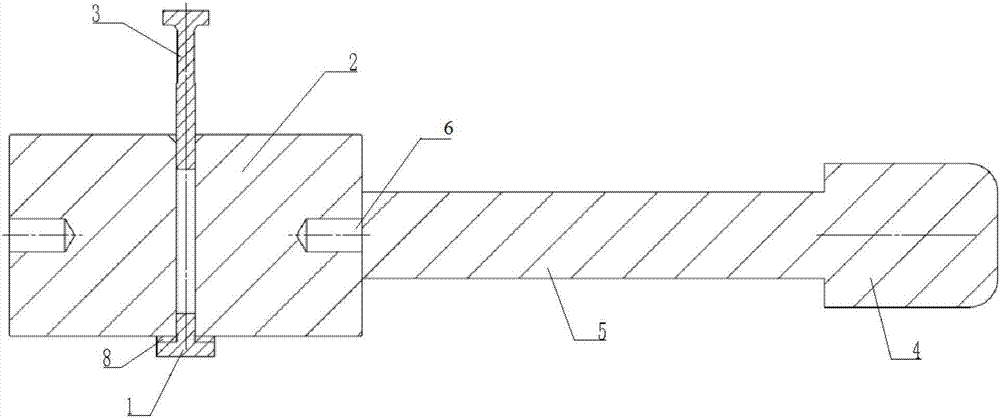

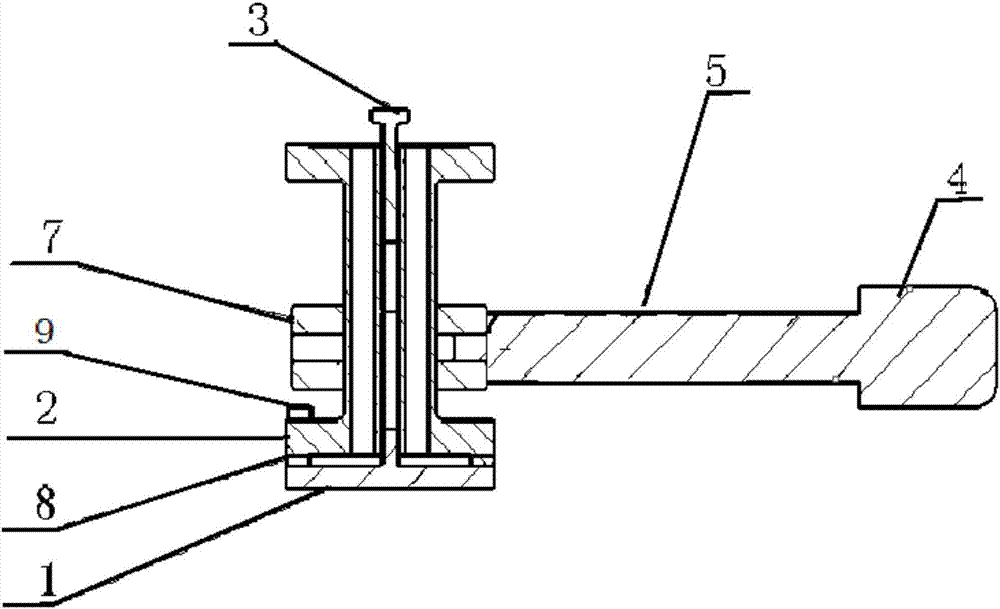

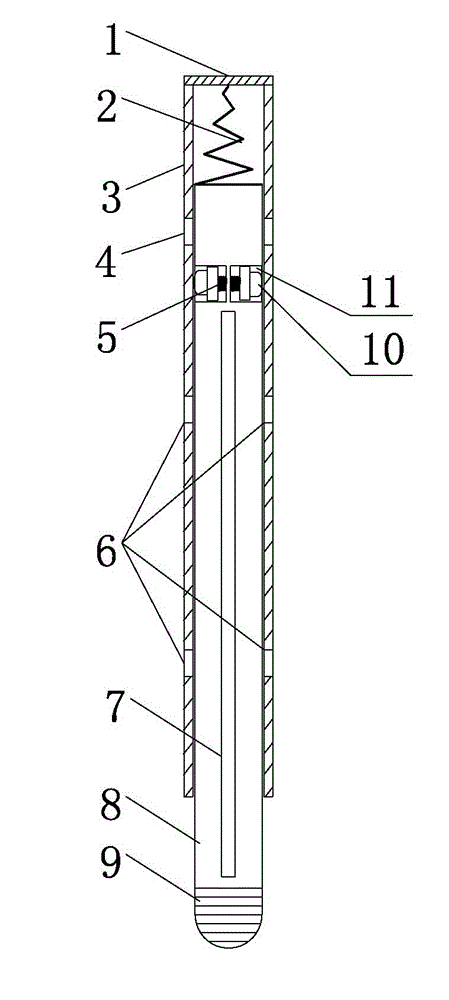

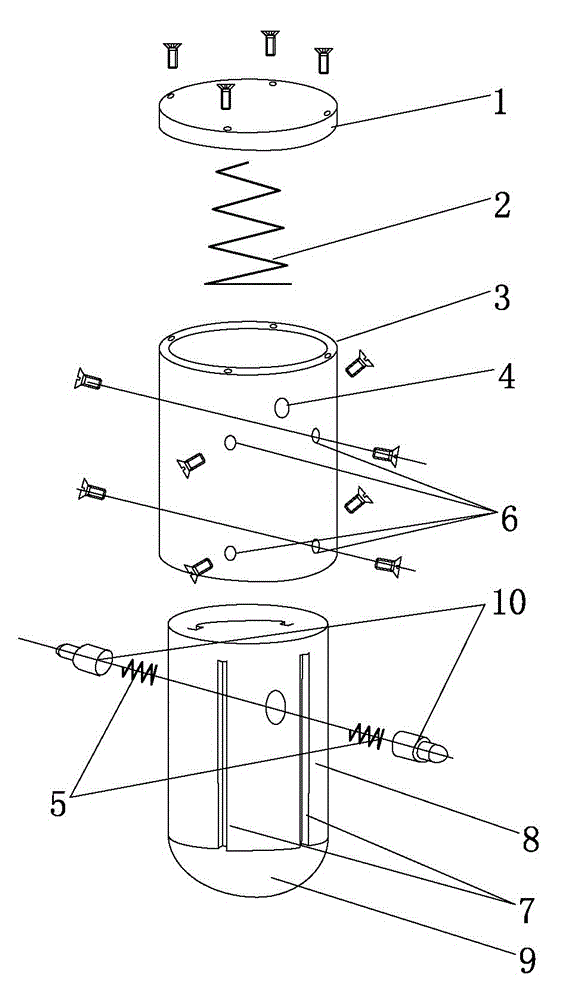

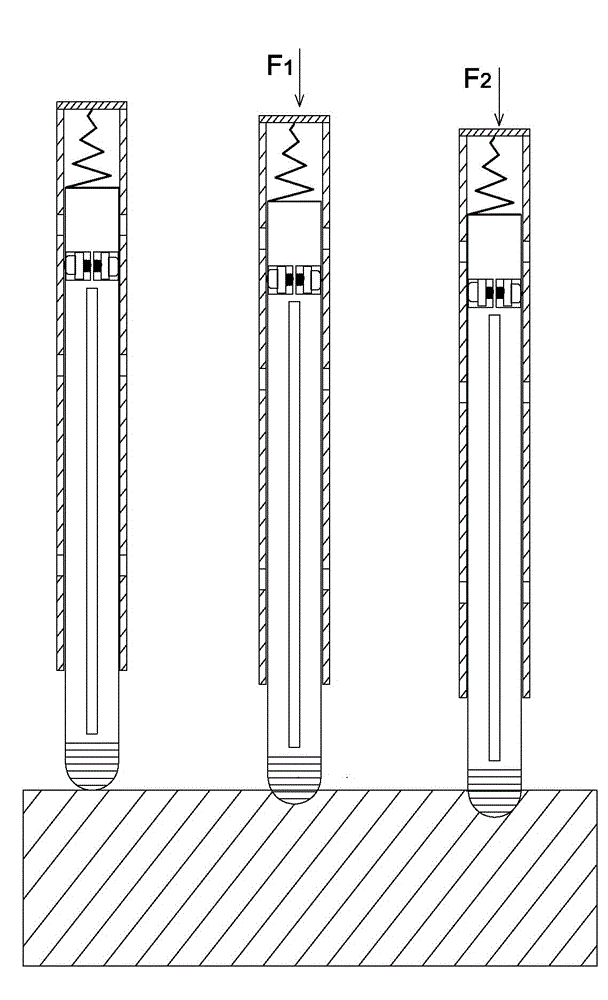

Hand-held soil body density detection device

InactiveCN102109438ASimple structureReduce volumeMaterial strength using tensile/compressive forcesBody densityHand held

The invention relates to a hand-held soil body density detection device, comprising an outer cylinder and a detection rod arranged in the outer cylinder, wherein a first spring is arranged between the top part of the detection rod and the outer cylinder; a limiting pin groove is arranged on the upper part of the detection rod; limiting pins are symmetrically arranged on the outer side of the limiting pin groove; a second spring matched with the limiting pin is arranged in the inner side of the limiting pin groove; the second spring presses a positioning pin against the internal wall of the outer cylinder; a limiting pin hole matched with the limiting pin is arranged on the upper part of the outer cylinder; and a contact probe with a scale is arranged at the bottom of the detection rod. The hand-held soil body density detection device is simple in structure, small in volume, light in weight, low in cost, easy to operate, and suitable for being applied to rock soil body stabilization and tunnel simulating tunneling experiments.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

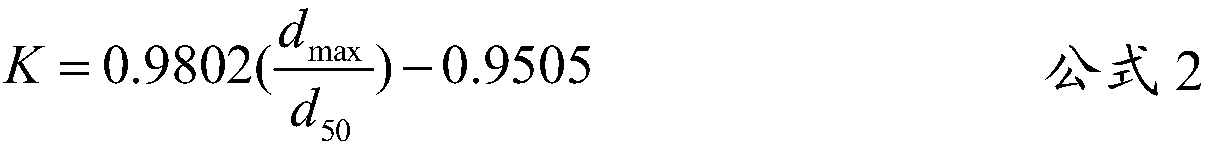

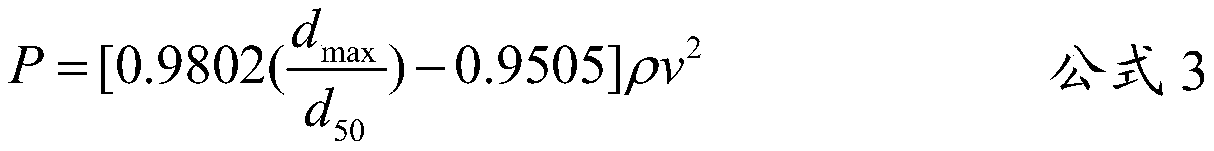

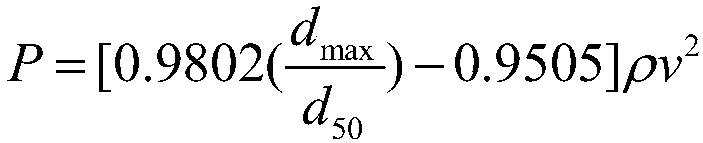

Impact force calculation method for viscous debris flow, and application thereof

InactiveCN108563807AEasy accessCalculation results are accurate and reasonableDesign optimisation/simulationSpecial data processing applicationsBody densityDebris flow

The invention discloses an impact force calculation method for a viscous debris flow, and application thereof. The calculation method comprises the following steps that: firstly, through sample experiment screening, determining a maximum particle size and a median particle size in a debris flow body, then, through sampling actual measurement, determining debris flow body density and debris flow kinematic velocity, and finally, carrying out calculation to obtain the impact force of the viscous debris flow. By use of the method, the influence of viscous debris flow particle graduation is comprehensively considered, the empirical coefficient of a dynamic pressure impact force calculation formula is corrected through a flume experiment, parameters required by calculation can be obtained through field survey, sampling and experiment analysis, the impact force of viscous debris flow motion can be reasonably determined, a basis is provided for viscous debris flow prevention and treatment engineering, and the method is suitable for the practical engineering design requirements of the viscous debris flow.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

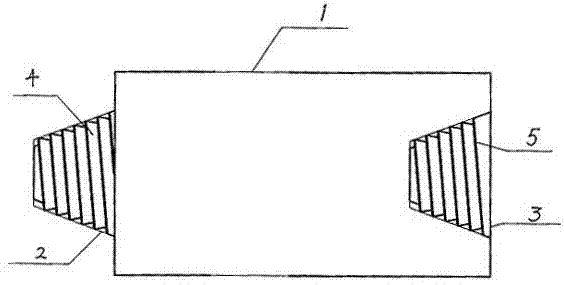

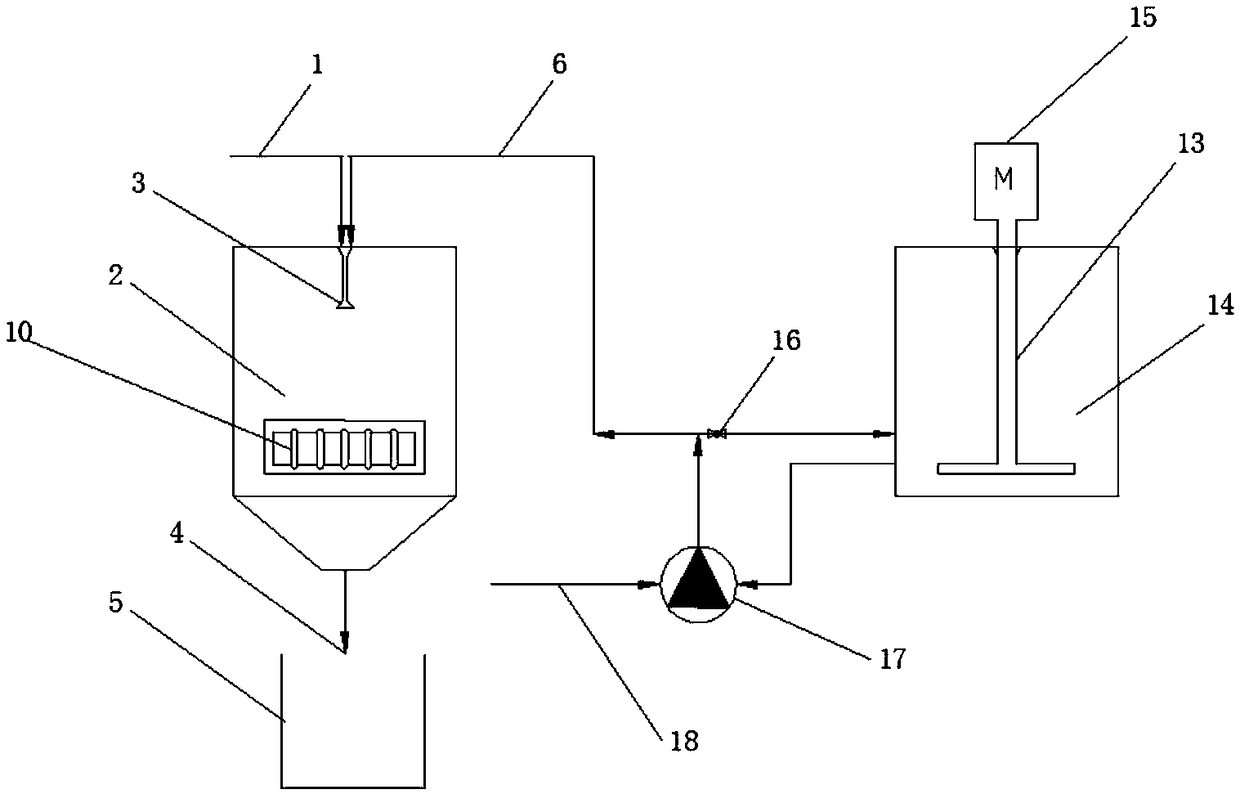

Powder billet forming device and method thereof

The invention discloses a powder billet forming device. The powder billet forming device comprises a die, an extruding rod, an amplitude-change pole and an energy converter, wherein the extruding rod is axially mounted in the die; one end of the amplitude-change pole is radially connected with the die, and the other end of the amplitude-change pole is connected with the energy converter; the electricity energy can be converted into mechanical vibration for driving the amplitude-change pole through the energy converter while axial pressure is applied to powder in the die through the extruding rod, and the die is driven to vibrate to apply radial pressure to the powder through the amplitude-change pole. The device is simple in structure, reliable in performance, and capable of quickly releasing the die; the powder is driven to vibrate through the die, so that the powder vibrating area is increased, and the powder can be uniformly vibrated, and as a result, the formed body density is improved, and the stress of the body is uniformly distributed. In addition, the invention also discloses a powder billet forming method.

Owner:沈阳赫声装备科技有限公司

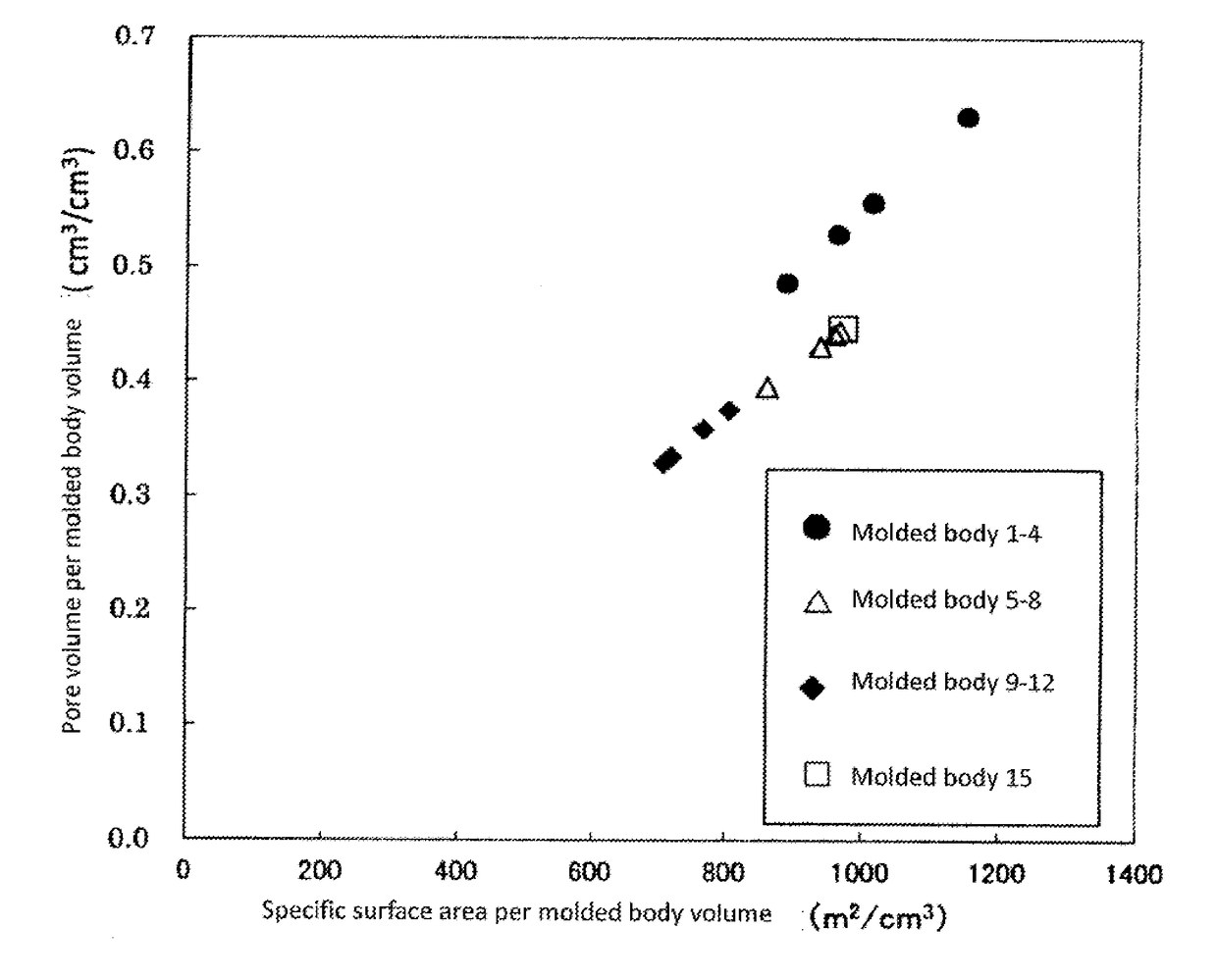

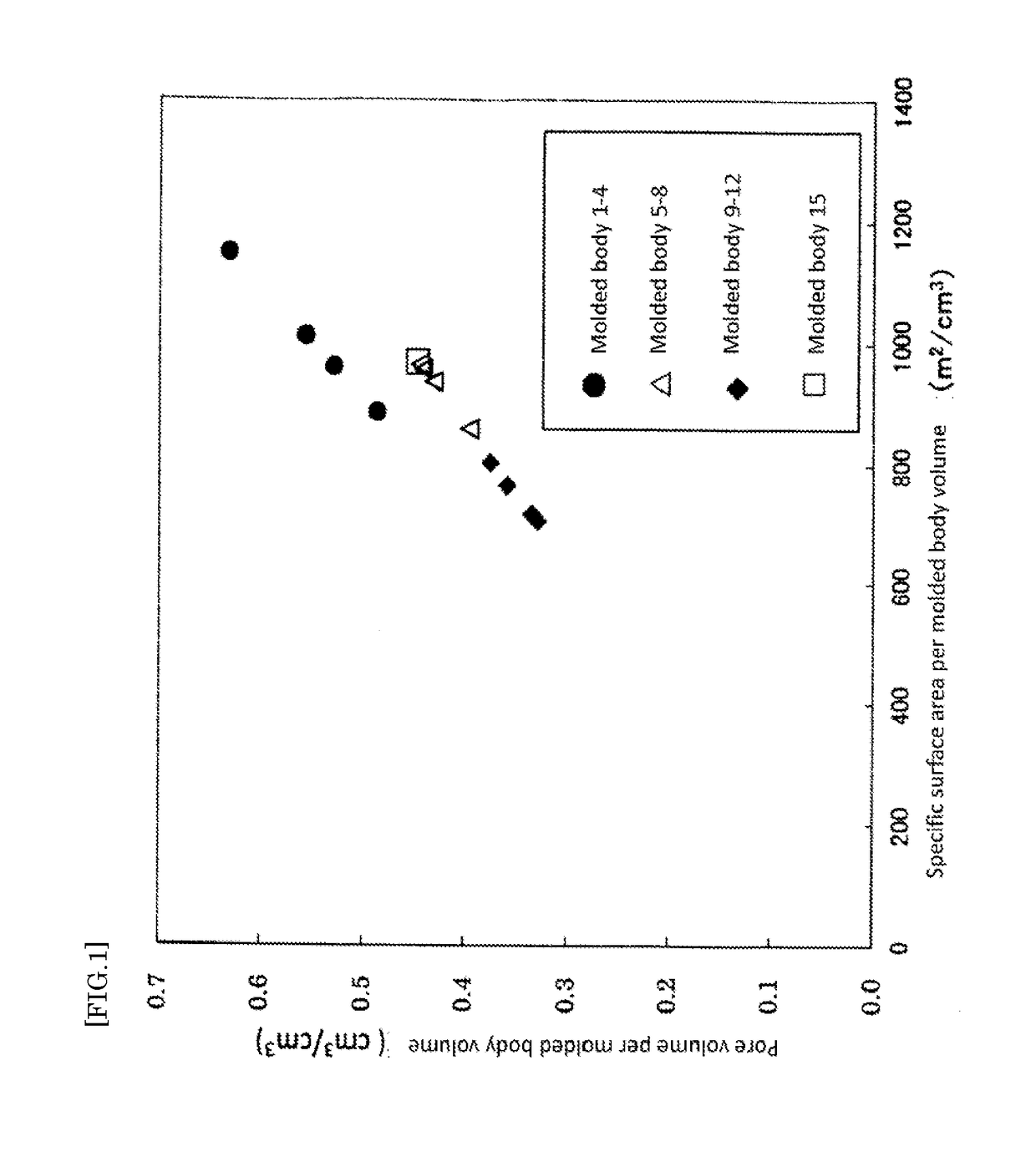

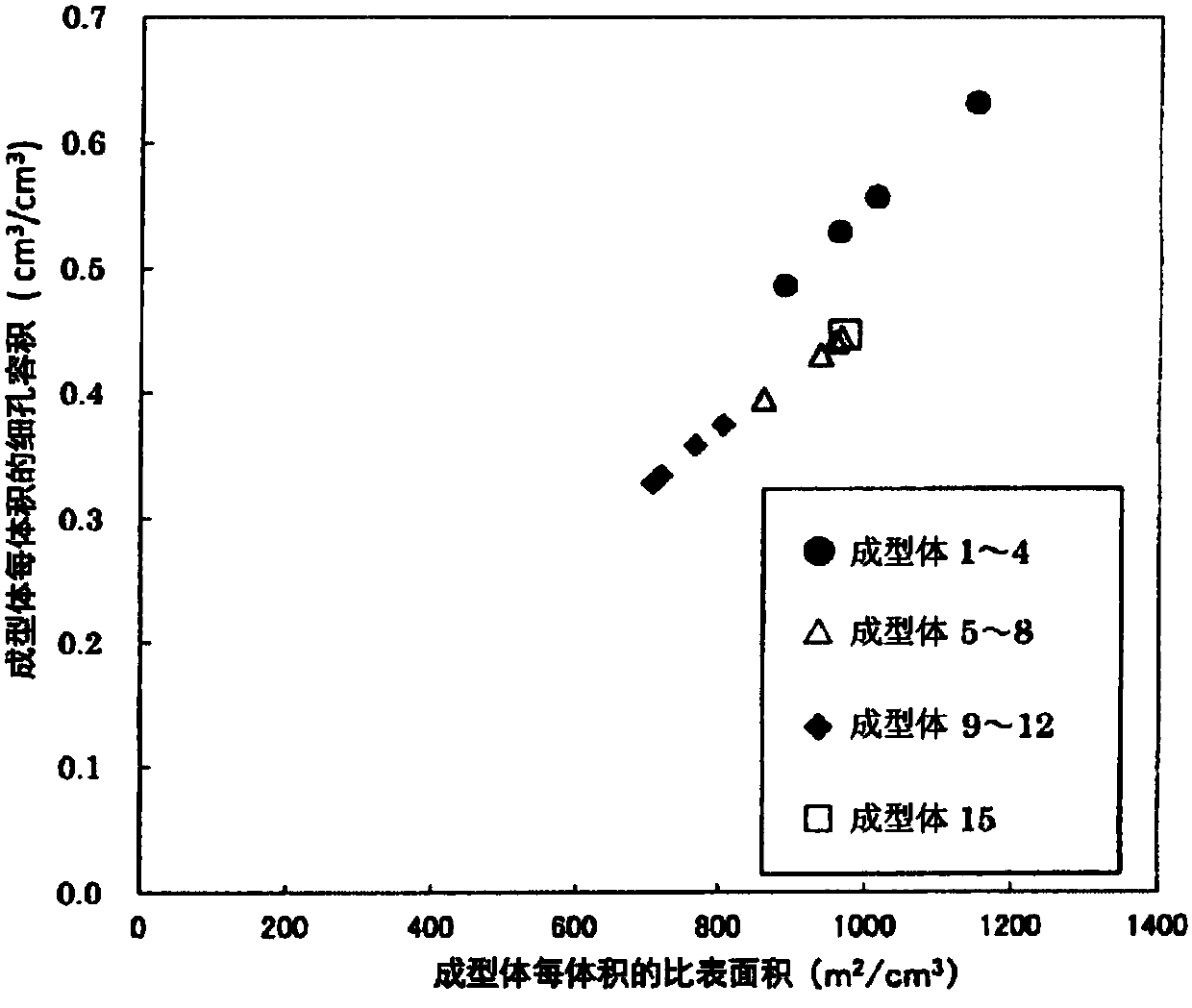

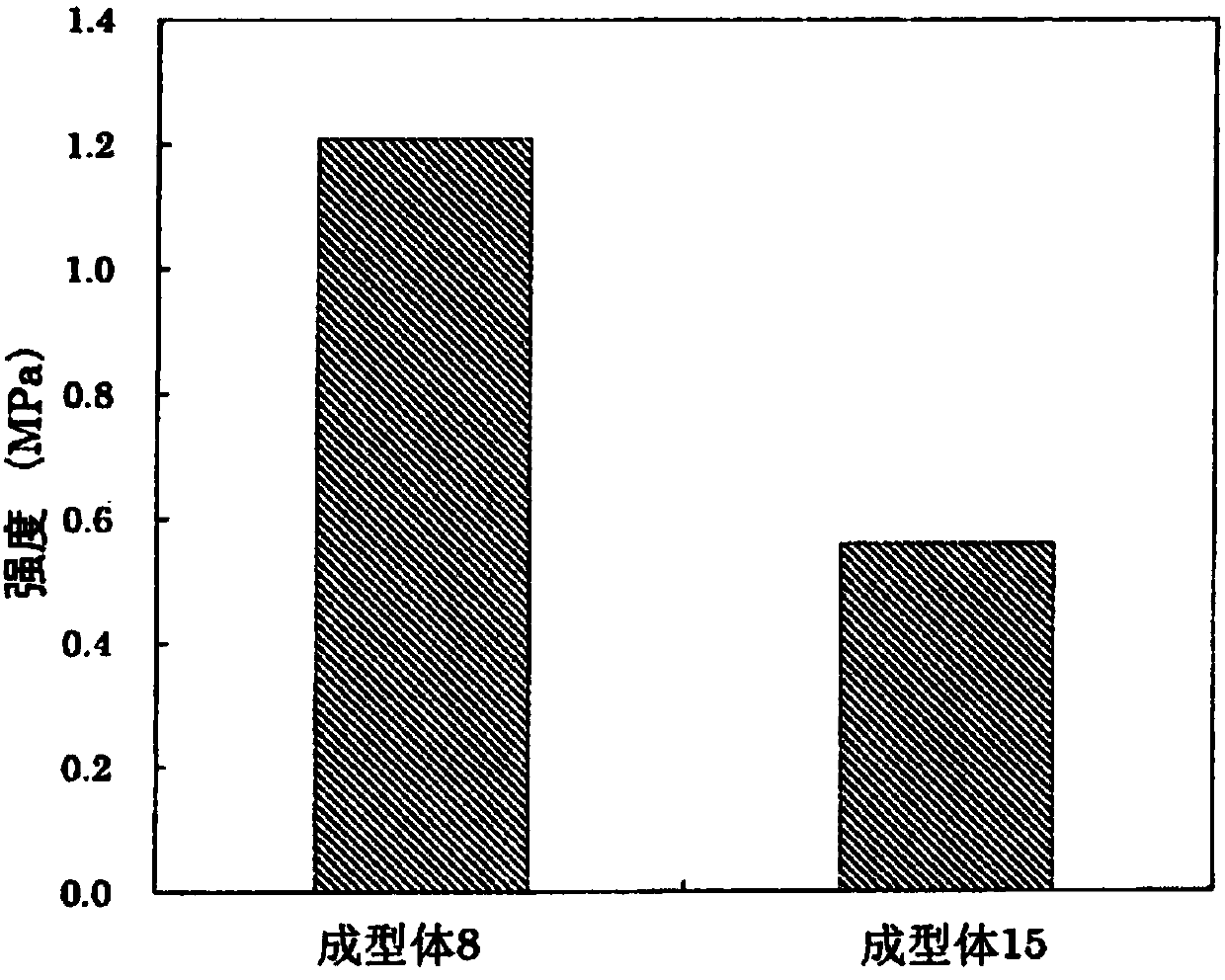

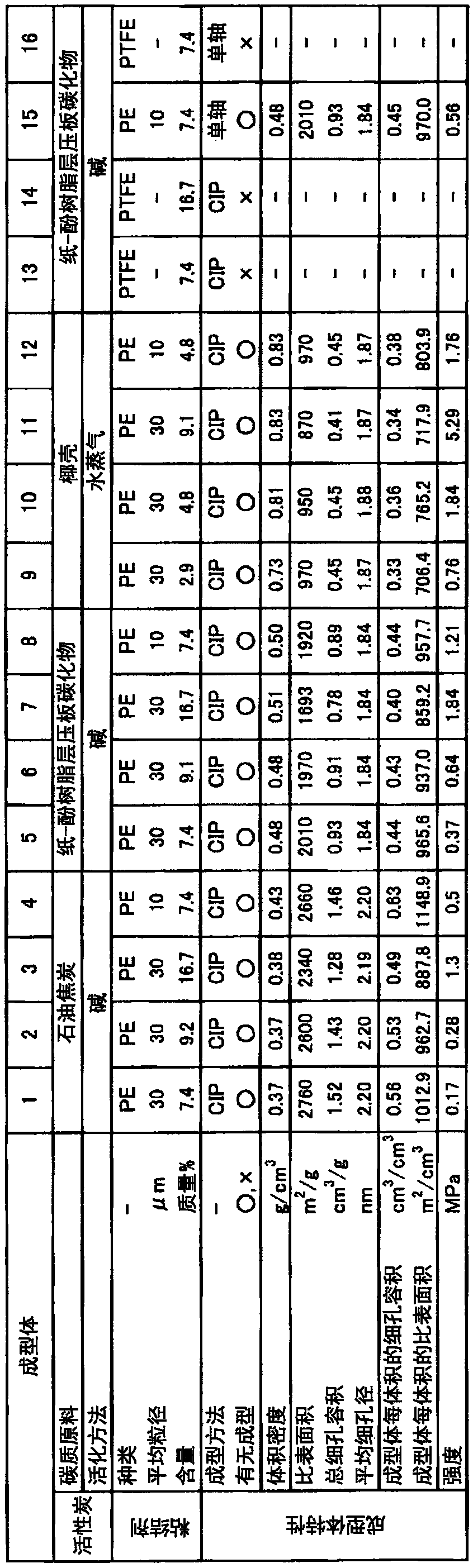

Activated carbon molded body, method for manufacturing activated carbon molded body, and absorbent material and storage material using activated carbon molded body

InactiveUS20180170760A1Large hole volumeImprove adsorption capacityCarbon compoundsOther chemical processesActivated carbonBody density

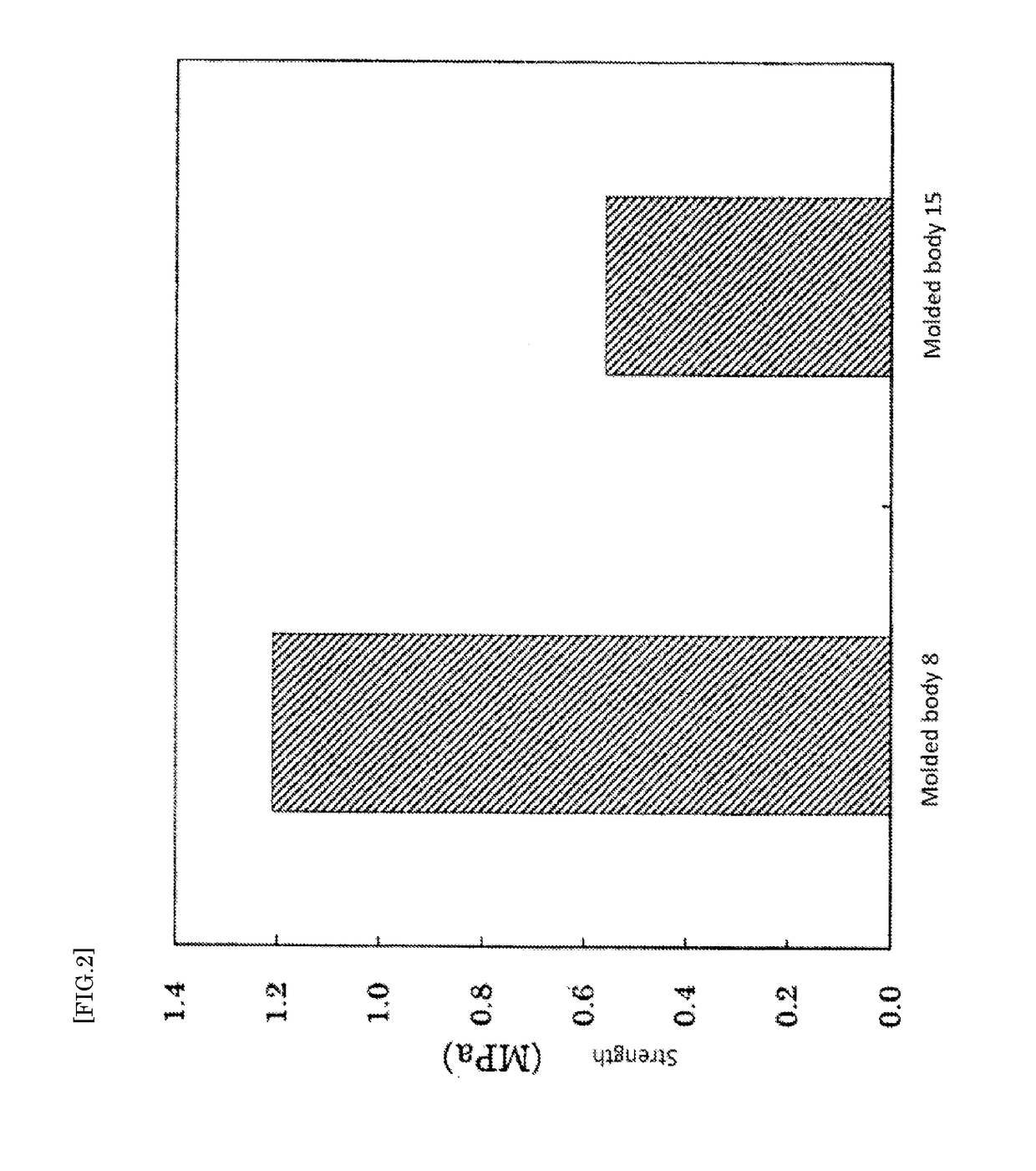

Provided are: an activated carbon molded body which has a large pore volume and has the strength to allow a desired shape to be molded therefrom; and a method for manufacturing the same. This activated carbon molded body has a pore volume per molded body volume (cm3 / cm3) obtained from the product of the total pore volume (cm3 / g) of the activated carbon molded body and the molded body density (g / cm3) of 0.39 cm3 / cm3 or greater, and a strength of 0.1 MPa or greater.

Owner:KANSAI COKE & CHEM

Light grouting material for grouting treatment of highway goaf and preparation method of light grouting material

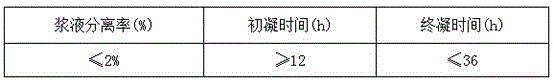

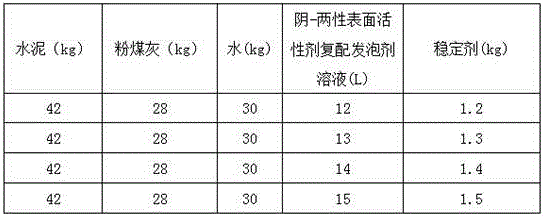

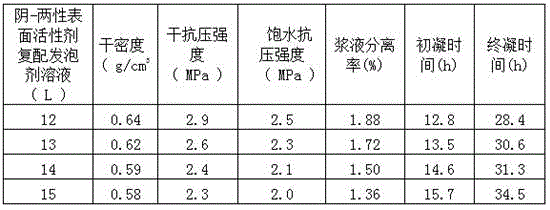

The invention relates to a light grouting material for grouting treatment of a highway goaf and a preparation method of the light grouting material. An existing under-highway goaf grouting treatment technology has the defects of being high in grout water content and large in unit weight. Cement, coal ash and water are mixed and evenly stirred to obtain cement and coal ash slurry; a negative and positive zwitter ion surface active agent is added to water to be evenly stirred to obtain a surface active agent solution, a stabilizer is added to the surface active agent solution to obtain a negative and positive zwitter surface active agent compound foaming agent solution; cement and coal ash slurry is doped with the negative and positive zwitter surface active agent compound foaming agent solution to be stirred to obtain the light grouting material. The prepared light grouting material is small in stone body density, large in intensity, good in construction performance, little in grouting and much in filling, and capable of overcoming the defects of the prior art.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

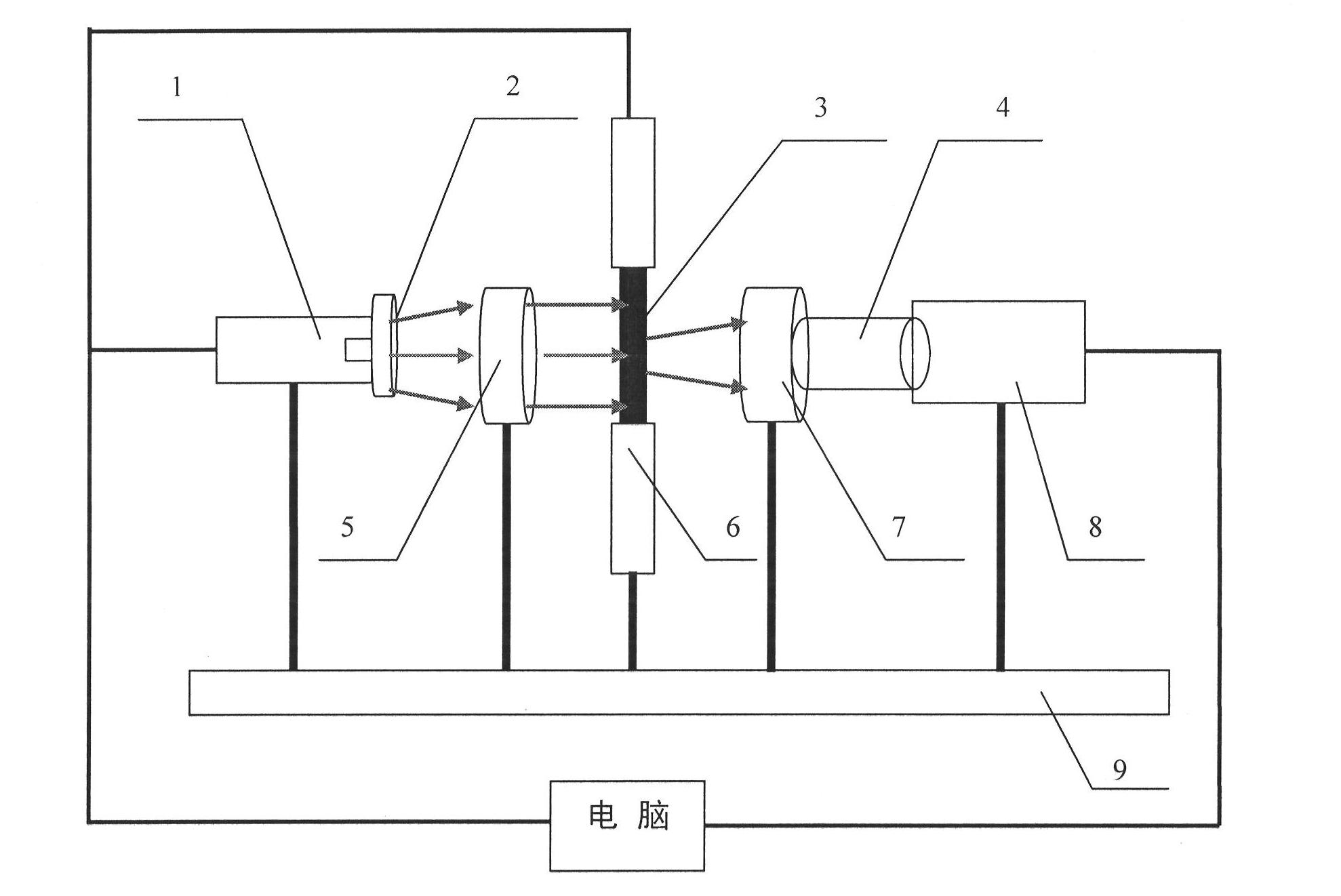

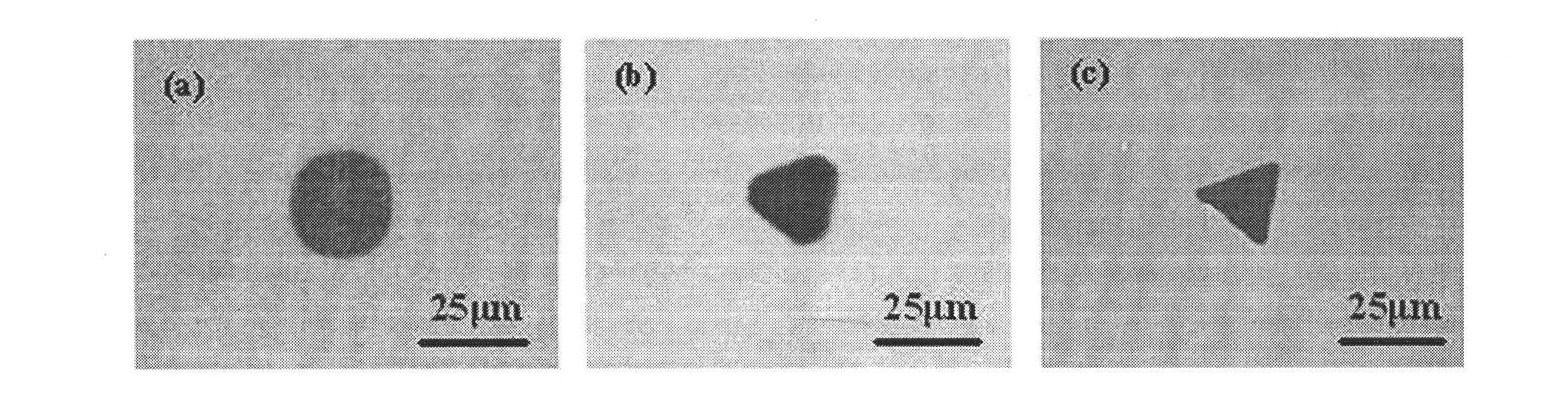

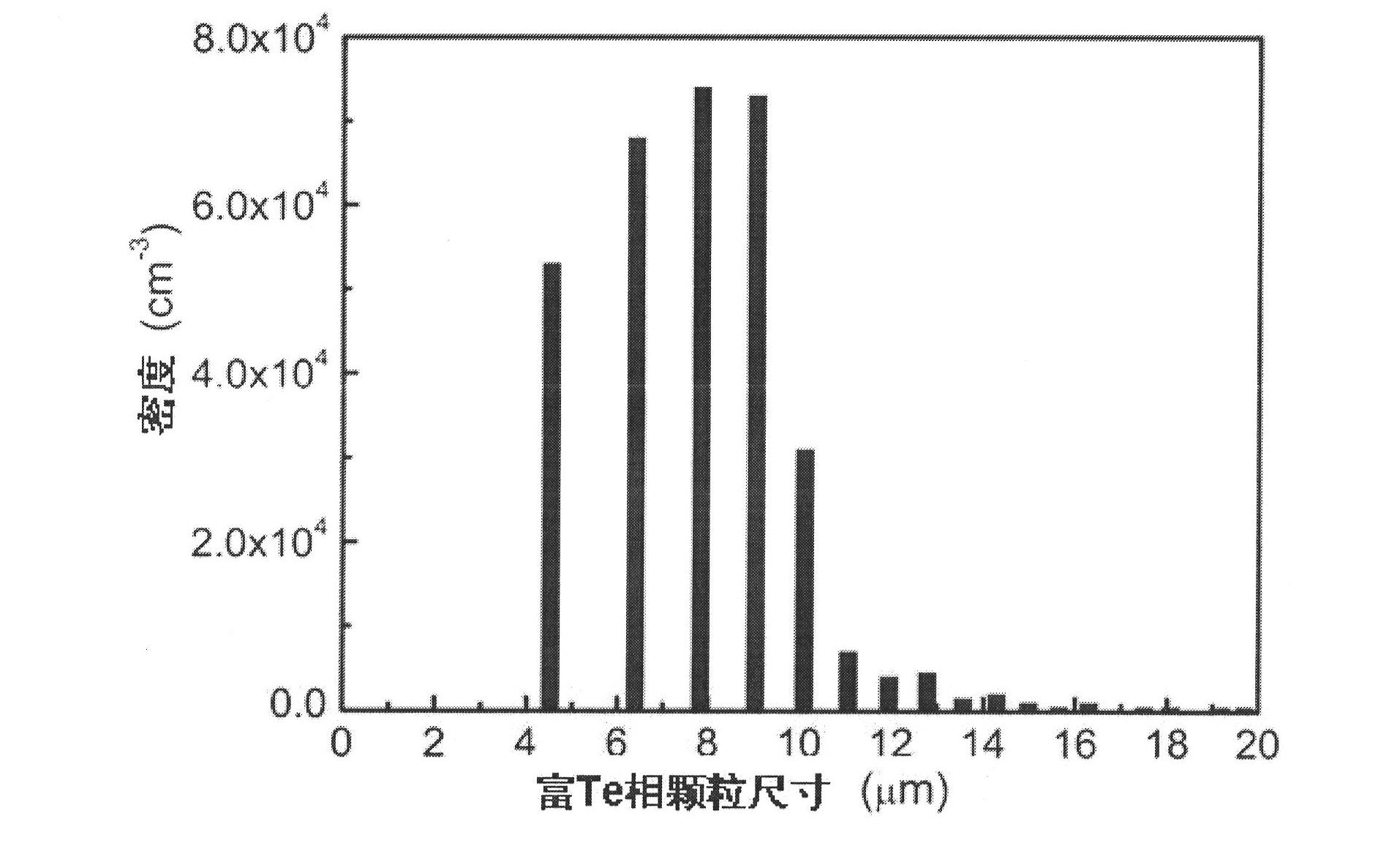

Device and method for detecting rich-Te phase in telluride semiconductor crystal

ActiveCN102169076ARealize 3D observationOvercoming two-dimensional distributionParticle size analysisSpecific gravity measurementVisual field lossBody density

The invention discloses a device and a method for detecting a rich-Te phase in a telluride semiconductor crystal. By the device and the method, the technical problems that the conventional device for detecting the rich-Te phase in the telluride semiconductor crystal cannot obtain a larger-size visual field and realize focused imaging of a layered domain in the thickness direction of the crystal can be solved. The technical scheme is that: the visual field can be adjusted by changing the magnifying power of a zoom lens barrel; meanwhile, by adoption of a high-precision four-coordinate three-dimensional automatic translational table, the body density of the rich-Te phase can be observed. By the method for detecting the rich-Te phase in the telluride semiconductor crystal by using the detecting device, the focused imaging of the layered domain is realized by adjusting the position in the thickness direction, so the form of the rich-Te phase in the crystal can be observed; and a Labview-based image collection and processing system is used for splicing every collected independent picture into a whole large image at first, counting different gray scale regions of the spliced image and analyzing the distribution of the rich-Te phase in the crystal.

Owner:IMDETEK

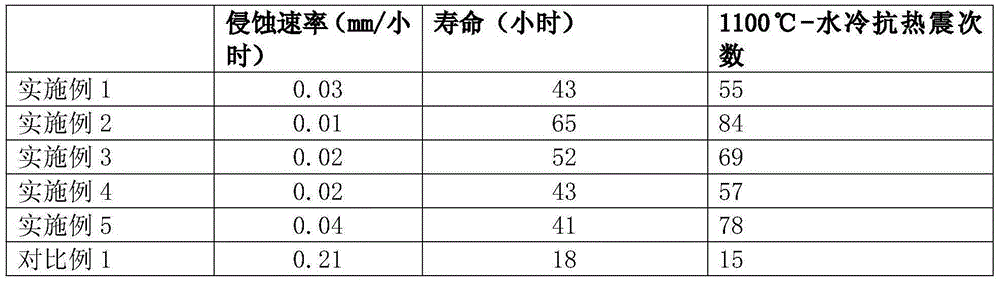

Self-adaptive zirconium oxide tundish nozzle

The invention discloses a self-adaptive zirconium oxide tundish nozzle. Serving as functional fireproof materials, most of sizing nozzles have relatively short service life because of the problems of erosion resistance and hole shrinkage. According to the invention, in the research direction, by researching the crystalline phase, particle size distribution and firing process of zirconium oxide, on the premise that the thermal shock stability and erosion resistance of products are ensured, in the process of eroding a zirconium core in molten steel, a second sintering shrinkage phenomenon is caused, thereby achieving the dynamic change of pore sizes; and tracking is carried out aiming at the special service environment of a steel mill, thereby controlling the initial air hole and body density so as to achieve the dynamic balance of nozzle pore sizes. In the aspect of hole shrinkage, Al2O3 nodulation is mainly prevented. Therefore, in the invention, argon blowing-free materials are used for preventing blockage, partial aluminum-rich desiliconized monoclinic zirconium oxide is added, surface sintering of the products is promoted, and smooth surfaces are not favorable for attachment of aluminum oxide.

Owner:ZHEJIANG IRON LION HIGH TEMPERATURE MATERIALS CO LTD

Preparation method of radon-proof radiation-proof plate

ActiveCN103042585BHigh radon radiation protection performanceCeramic shaping apparatusBody densitySlurry

The invention discloses a preparation method of a radon-proof radiation-proof plate. The method includes the following steps: a) preparing gypsum slurry containing gypsum powder, water and radon-proof radiation-proof mineral powder with zeolite powder; b) pouring 1 / 3-2 / 3 of total gypsum slurry into a lower mould coated with a release agent and arranging a radiation-proof metal net on the surface of the slurry; c) pouring surplus gypsum slurry into the place above the radiation-proof metal net, covering an upper mould plate coated with the release agent and compacting the slurry by vibration to conduct molding; and d) conducting demoulding to conduct natural airing to obtain the radon-proof radiation-prof plate. By means of the preparation method of the radon-proof radiation-proof plate, wall body density is reduced, and danger caused by wall body deformation is reduced. In addition, the radon-proof radiation-proof plate has excellent radon-proof radiation-proof performance due to the added radon-proof radiation-proof plate.

Owner:国能朗新明环保科技有限公司

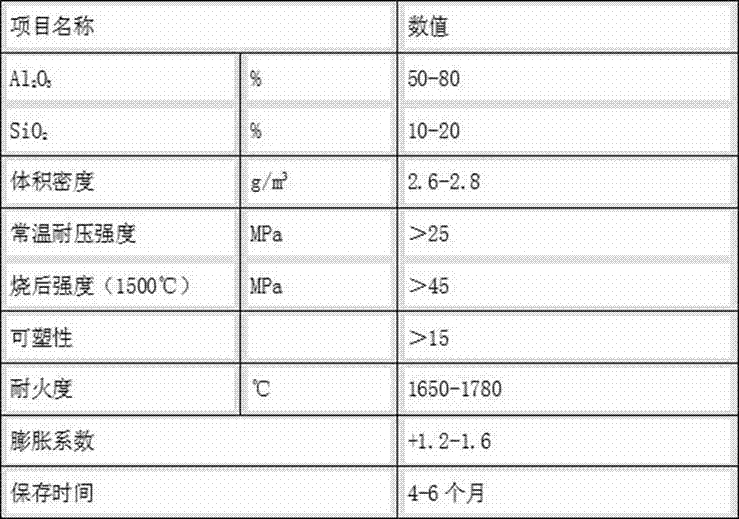

Smoke-free environment-friendly stemming and preparation method

The invention discloses smoke-free environment-friendly stemming. The smoke-free environment-friendly stemming is prepared from the following component in percentage by mass: 50 to 60 percent of high-aluminum aggregate, 10 to 20 percent of Guangxi white clay, 5 to 10 percent of kyanite, 3 to 8 percent of sericite, 3 to 5 percent of bentonite, 10 to 20 percent of high-aluminum refractory fine powder, 8 to 15 percent of binding agent, 0.2 to 0.5 percent of moisturizer and 0.1 to 0.3 percent of plasticizer. Meanwhile, the invention also discloses a preparation method of the smoke-free environment-friendly stemming. Compared with the prior art, the smoke-free environment-friendly stemming disclosed by the invention has the advantages that a production technology is simple and moderate in cost; in addition, no smoke is released in the use process, so better environment-friendly performance is realized; the smoke-free environment-friendly stemming is good in flushing resistance, good in plasticity and proper in body density, is not easy to broach and is easy to open and block; the phenomena of including iron, breaking iron notches and the like are avoided; besides, the smoke-free environment-friendly stemming can be directly installed for using without baking, and is short in heated hardening time; stemming removal can be realized by blocking for 5 minutes; the smoke-free environment-friendly stemming is more convenient to operate and excellent in slag-resistant performance, so that comprehensive energy consumption is greatly reduced and the working environment is greatly improved.

Owner:JIANGSU JIANGNENG NEW MATERIAL TECH

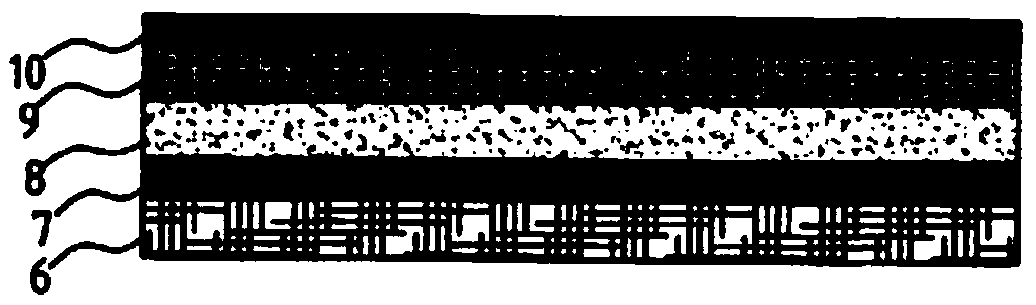

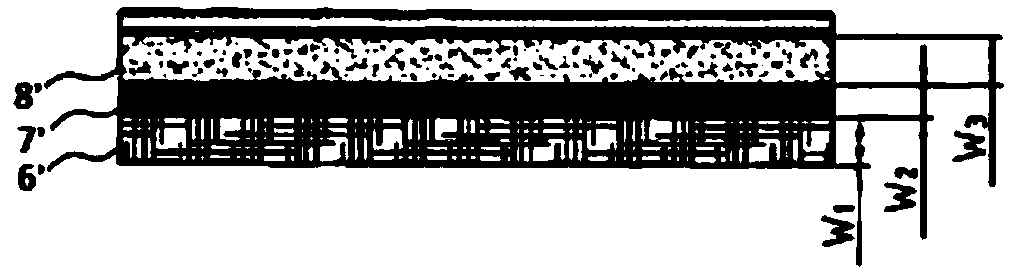

Sound insulation cotton with multi-layer sound absorbing materials and compressor

PendingCN109210757AWide variety of sourcesSimple structurePositive displacement pump componentsNoise suppressionPorosityBody density

The invention belongs to the technical field of noise reduction and discloses a sound insulation cotton with multi-layer sound absorbing materials and a compressor. The sound insulation cotton includes an inner sound absorbing material layer and an outer sound insulation material layer, wherein the sound absorbing material layer includes at least two layers of sound absorbing materials of the samematerial or different materials with the body density increasing layer by layer or the porosity decreasing layer by layer or the flow resistance increasing layer by layer or the structure factor increasing layer by layer from the inside to the outside, the sound insulation material layer includes a layer of sound insulation materials, the sound absorbing material layer is made by stitching all the sound absorbing materials with sutures, and the layer with the largest density or the smallest porosity, the largest flow resistance or the largest structural factor of the sound absorbing materiallayer is cemented with the sound insulation material layer. The sound insulation cotton is advantaged in that the sound insulation cotton has a wide range of sources, simple structure, easy processingand wide applicability, has a higher sound absorption coefficient, is more conducive to noise absorption, especially for noise with a wide frequency band.

Owner:GREE ELECTRIC APPLIANCES INC

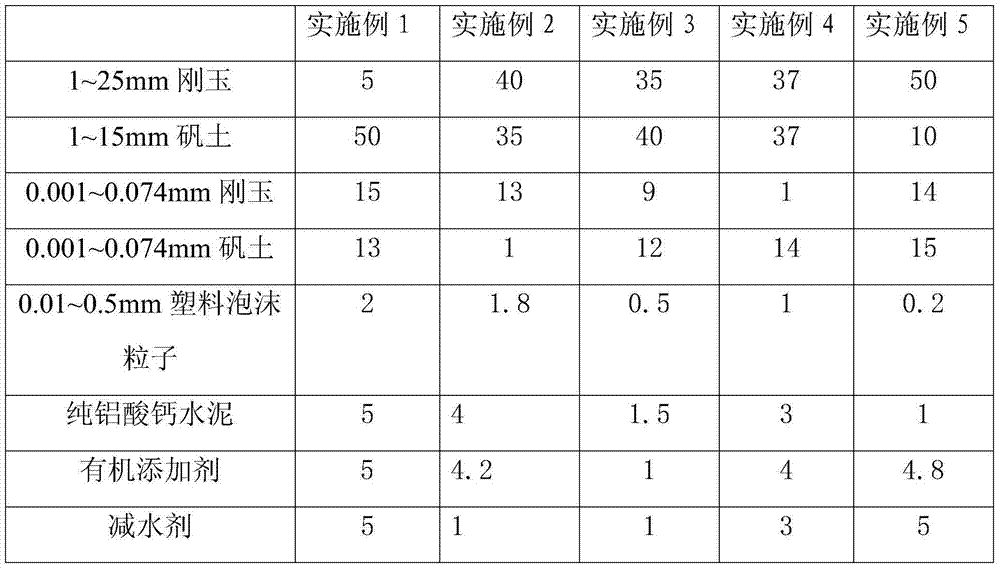

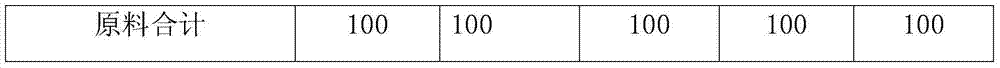

Light steel ladle permanent layer castable

InactiveCN104119093AReduce body densityNo change in high temperature performanceCeramicwareBody densityMolten steel

The invention discloses light steel ladle permanent layer castable. The castable comprises the following components in percentage by weight: 5-50% of 1-25mm corundum, 10-50% of 1-15mm alumina, 1-15% of 0.001-0.074mm corundum, 1-15% of 0.001-0.074mm alumina, 0.5-2% of 0.01-0.5mm plastic foam particle, 1-5% of pure calcium aluminate cement, 1-5% of organic additives and 1-5% of a water reducer. The plastic foam particle is added in the light steel ladle permanent layer castable and uniformly-distributed cavities below 0.5mm are formed in the castable after the plastic foam particle is heated and molten at high temperature, so that the body density of the steel ladle permanent layer castable is reduced and the effect of preserving the temperature of molten steel is realized.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

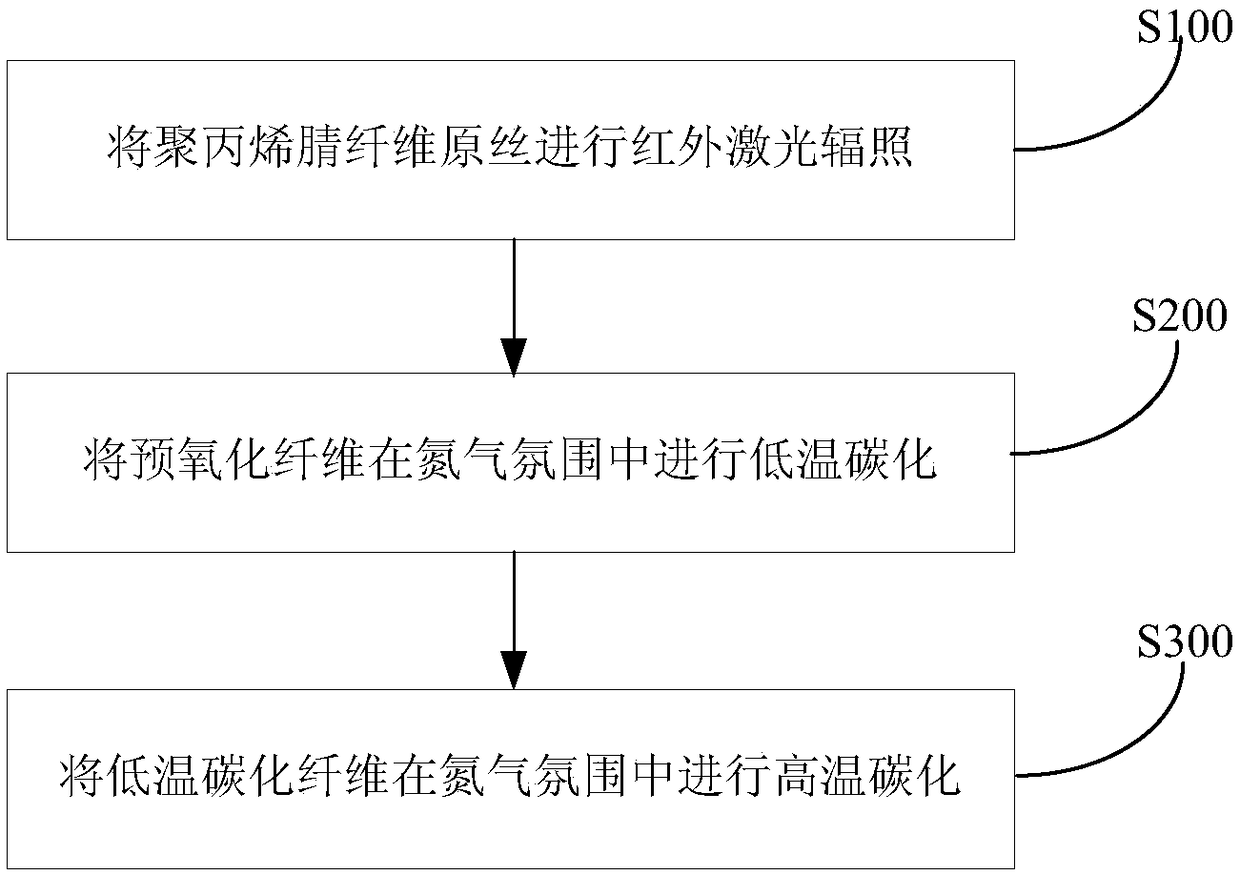

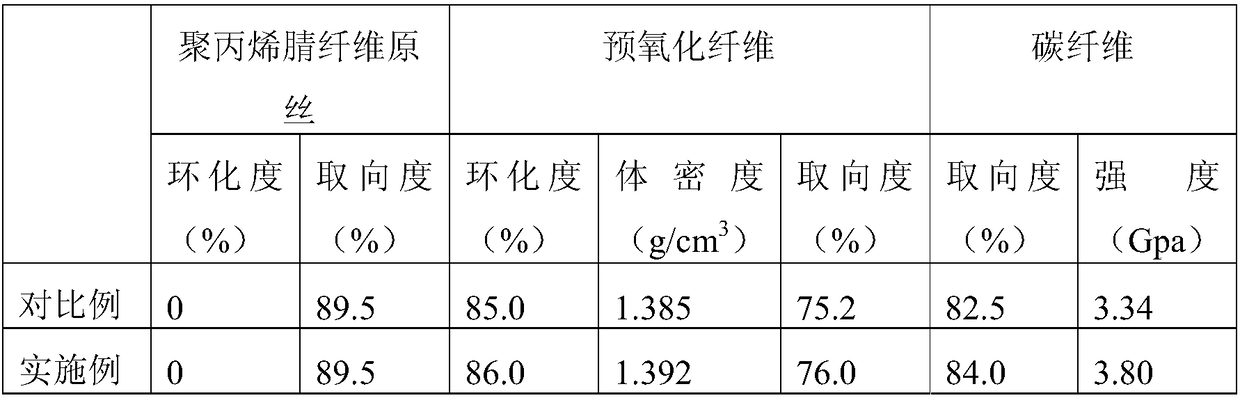

Method for preparing polyacrylonitrile carbon fibers

InactiveCN109306553AHigh strengthGood orientationFibre chemical featuresPolymer scienceCarbon fibers

The invention discloses a method for preparing polyacrylonitrile carbon fibers. The method is realized through the following steps: (1) carrying out infrared laser irradiation on polyacrylonitrile fiber protofilaments to obtain pre-oxidized fibers; (2) carrying out low-temprature carbonization on the pre-oxidized fibers in a nitrogen gas atmosphere to obtain low-temprature carbonized fibers; (3) carrying out high-temprature carbonization on the low-temprature carbonized fibers to obtain the polyacrylonitrile carbon fibers. According to the method disclosed by the invention, the polyacrylonitrile fiber protofilaments are subjected to pre-oxidization treatment through the infrared laser irradiation and rapid heating can be realized; the thermal stabilization time is shortened and the pre-oxidized fibers with suitable cyclization degree, orientation density and body density can be obtained; the pre-oxidized fibers are subjected to low-temprature carbonization and high-temprature carbonization treatment, so that the obtained carbon fibers have relatively high strength and orientation degree. The polyacrylonitrile fiber protofilaments are treated by adopting the infrared laser irradiation, so that the production efficiency of the carbon fibers is remarkably improved and the production cost of the carbon fibers is further reduced; furthermore, the commoditization of the production ofthe carbon fibers is easy to realize and the high-performance carbon fibers are obtained.

Owner:BEIJING UNIV OF CHEM TECH

Multi-color charged particle detector apparatus and method of use thereof

ActiveUS20190366125A1Radiation/particle handlingCathode ray concentrating/focusing/directingBody densityPositively charged particle

The invention comprises a method and apparatus for using a multi-layer multi-color scintillation based detector element to image a tumor of a patient using a process of determining residual energies of positively charged particles after passing through the patient, the process comprising the steps of: (1) transmitting the positively charged particles at known energies through the patient and into a multi-layer detector element; (2) detecting first and second secondary photons, resultant from passage of the positively charged particles, respectively from a first layer of a first scintillation material and a second layer of a second scintillation material at two respective layer depths, where the first wavelength range differs from the second wavelength range; (4) determining residual energies of the positively charged particles, using output from the step of detecting; and (5) relating the residual energies to body densities to generate an image.

Owner:PROTOM INT HLDG CORP

Radon-proof radiation-proof plate

The invention discloses a radon-proof radiation-proof plate which comprises a gypsum substrate and a radiation-proof metal net arranged in the gypsum substrate. Radon-proof radiation-proof mineral powder is scattered in the gypsum substrate, and radon-proof radiation-proof mineral powder contains zeolite powder. The radon-proof radiation-proof plate adopts the radiation-proof metal net is embedded in the radon-proof radiation-proof plate, so that composite wall body structure can be conducted on the radiation-proof metal net or the metal plate on a construction site, wall body density is reduced, and danger caused by wall body deformation is reduced. In addition, the radon-proof radiation-proof plate has excellent radon-proof radiation-proof performance due to the added radon-proof radiation-proof mineral powder.

Owner:国能朗新明环保科技有限公司

Hand-held soil body density detection device

InactiveCN102109438BSimple structureReduce volumeMaterial strength using tensile/compressive forcesBody densityHand held

The invention relates to a hand-held soil body density detection device, comprising an outer cylinder and a detection rod arranged in the outer cylinder, wherein a first spring is arranged between the top part of the detection rod and the outer cylinder; a limiting pin groove is arranged on the upper part of the detection rod; limiting pins are symmetrically arranged on the outer side of the limiting pin groove; a second spring matched with the limiting pin is arranged in the inner side of the limiting pin groove; the second spring presses a positioning pin against the internal wall of the outer cylinder; a limiting pin hole matched with the limiting pin is arranged on the upper part of the outer cylinder; and a contact probe with a scale is arranged at the bottom of the detection rod. The hand-held soil body density detection device is simple in structure, small in volume, light in weight, low in cost, easy to operate, and suitable for being applied to rock soil body stabilization and tunnel simulating tunneling experiments.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Activated Carbon Molded Body, Method For Manufacturing Activated Carbon Molded Body, And Absorbent Material And Storage Material Using Activated Carbon Molded Body

PendingCN107683254ALarge pore volumeEasy to manufactureOther chemical processesCarbon compoundsActivated carbonBody density

Owner:KANSAI COKE & CHEM

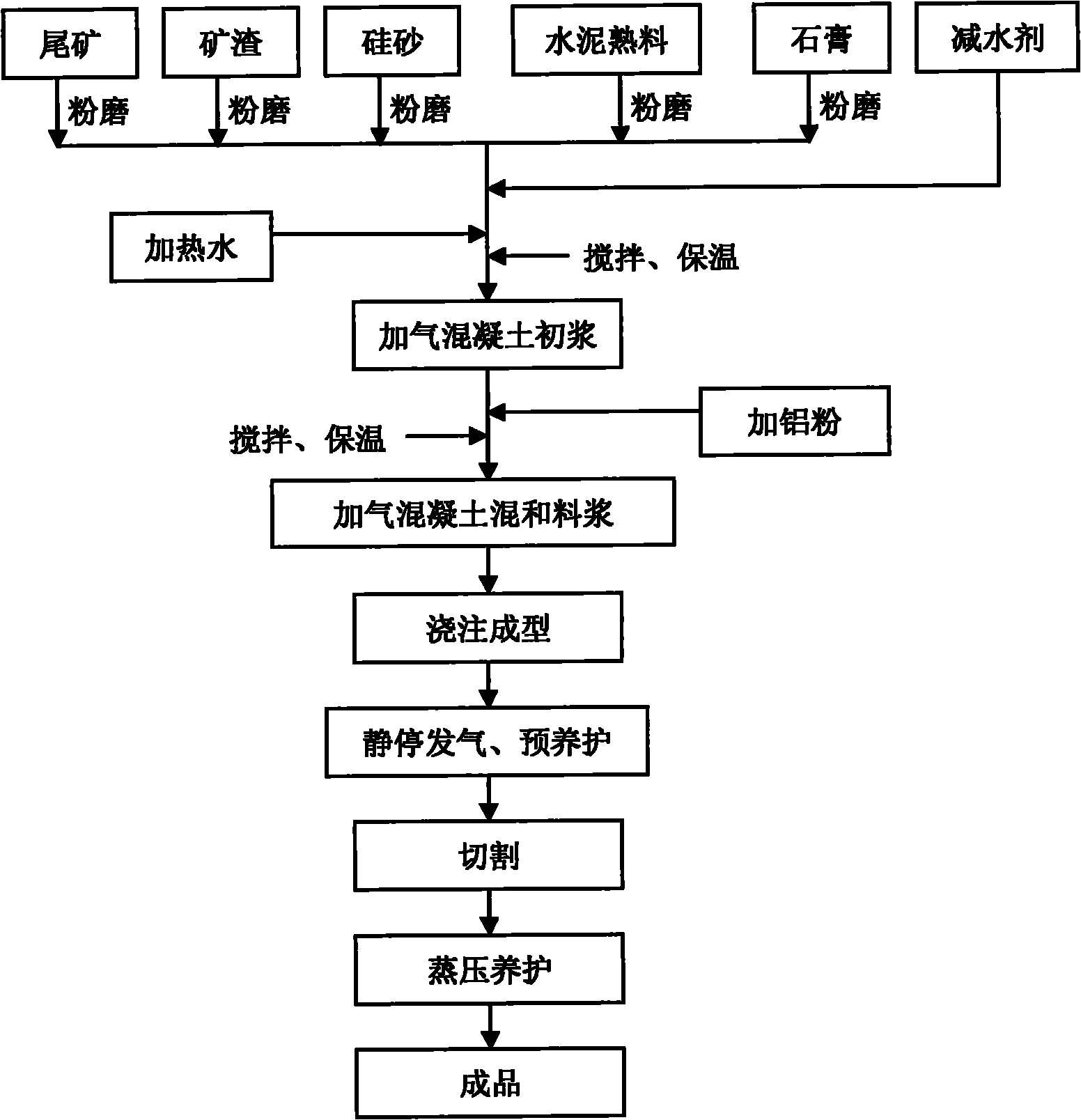

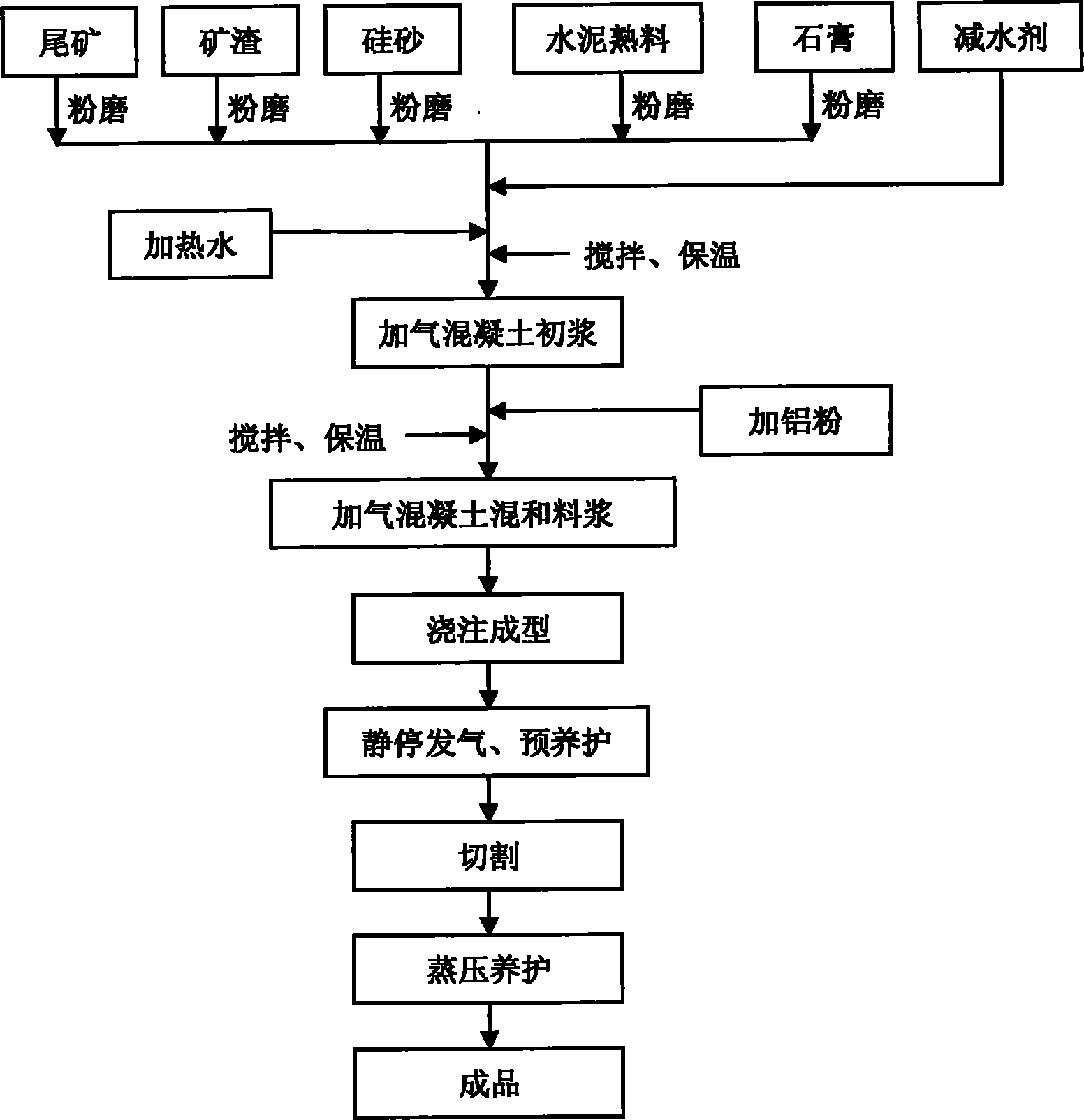

Method for preparing steaming pressure aeroconcrete by skarn type mine tailings

InactiveCN101870568ASolve difficult problems that are not easy to comprehensively utilizeReduce management costsSolid waste managementCeramicwareSteam pressureWarm water

The invention relates to a method for preparing steaming pressure aeroconcrete by skarn type mine tailings, which belongs to the field of ore mine environment protection and the field of building materials and comprises following ingredients in percentage by weight: 25 to 45 percent of skarn type mine tailings, 25 to 35 percent of water quenching blast furnace slag, 15 to 30 percent of silica sand, 6 to 12 percent of cement clinker, 3 to 6 percent of natural gypsum, water reducing agents accounting for 0.6 to 0.9 percent of the total mass of the mixed dry materials, 0.06 to 0.12 percent of aluminum powder and 35 to 45 percent of warm water at the temperature between 48 and 55 DEG C. The aeroconcrete prepared by the invention has the moisture pressure-resistance intensity higher than 3.5 MPa, the absolute dry pressure-resistance intensity higher than 5 MPa and the dry body density between 550 kg / m<3> and 650 kg / m<3>, the requirement of the national standard on the performance indexes of the steaming pressure aeroconcrete can be met, and the invention provides a novel utilization path for the skarn type mine tailing resources with difficult utilization, and is favorable for solving the problems of ground resource occupation and environment pollution of the piling storage of the skarn type mine tailings.

Owner:UNIV OF SCI & TECH BEIJING

Sensor device for sensing body fluid density and/or membrane resistance

ActiveUS9888883B2Diagnostics using vibrationsSpecific gravity by measuring pressure differencesElectrical resistance and conductanceBody density

Owner:MECSENSE

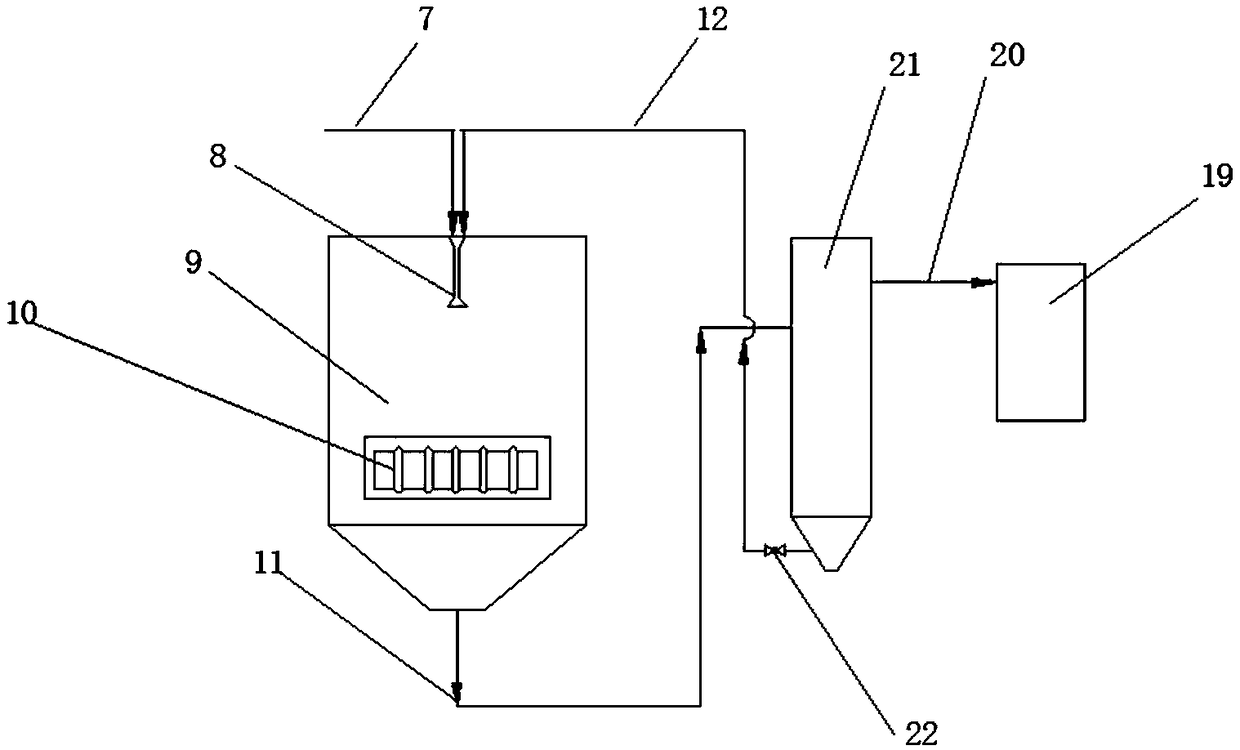

Powder laying technology and system for ceramic substrate blank body

ActiveCN108058264AImprove dispersion uniformityIncrease profitAuxillary shaping apparatusMetallurgyBody density

The invention discloses a powder laying technology for a ceramic substrate blank body and further discloses a powder laying system for the ceramic substrate blank body. The powder laying technology comprises the following steps that (1), a uniform adhesion agent film layer is formed on the surface of the ceramic substrate blank body, and a ceramic substrate blank body with the adhesion agent filmlayer is obtained; and (2), an adhesion preventing powder layer is formed on the surface of the ceramic substrate blank body with the adhesion agent film layer, and then a ceramic substrate blank bodysubjected to powder laying is obtained. According to the powder laying technology, an adhesion agent and adhesion preventing powder are implemented independently in two steps, and the situation thatthe adhesion agent forms liquid beads on the surface of the blank body under the effect of tension and thus the adhesion preventing powder is gathered on the surface of the blank body is effectively avoided; the adhesion preventing powder dispersion uniformity and the powder body density uniformity are improved; and meanwhile the adhesion preventing powder which is not laid on the surface of the blank body can be directly recovered for reutilizing, the utilizing rate of the adhesion preventing powder is remarkably increased, and the recovery difficulty of the adhesion preventing powder is reduced. Through the powder laying system, it can be ensured that a powder body on the surface of the ceramic substrate blank body is uniform.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

Process for producing oxide magnetic material based permanent magnet

ActiveCN1757078AInorganic material magnetismInductances/transformers/magnets manufactureWaxMagnetization

A process for producing an oxide magnetic material based permanent magnet, comprising a binder addition step of adding a binder and a molding auxiliary to raw material powder containing an oxide magnetic material and mixing the same; a moisture regulation step of regulating the moisture of the resultant molding mixture containing the raw material powder, binder and molding auxiliary; an in-magnetic-field dry molding step of charging the molding mixture after moisture regulation into a metal mold and pressing the mold in an applied magnetic field so as to align the easy magnetization directions of the oxide magnetic material powder; and a firing step of firing the thus molded item, wherein the binder added in the binder addition step is a fatty acid ester wax, while the molding auxiliary added in the binder addition step is a stearic acid salt having such a property that it is melted at 90 DEG C or below in relation to the fatty acid ester wax as the binder (90 DEG C melting characteristic). By this process, at low cost, there can be obtained an oxide magnetic material based permanent magnet of enhanced alignment and sintered body density excelling in magnetic characteristics.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com