Self-adaptive zirconium oxide tundish nozzle

A zirconia and tundish technology, applied in the field of refractory materials, can solve problems such as short service life, and achieve the effects of reducing energy consumption, uniform material and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

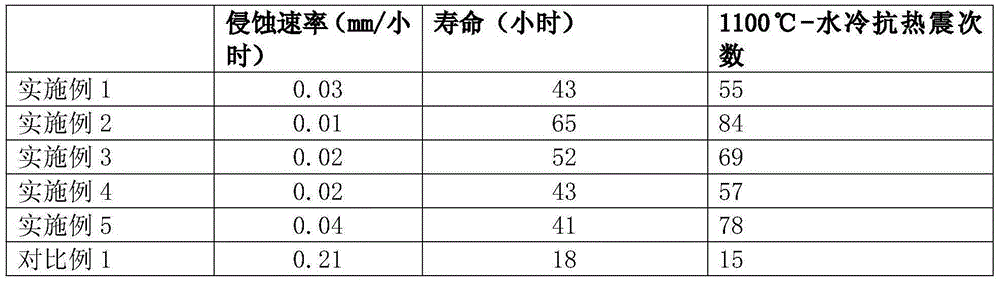

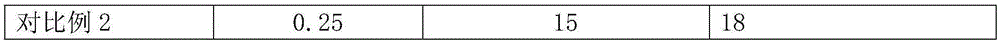

Examples

Embodiment 1

[0018] Adaptive zirconia tundish nozzle, prepared by the following method:

[0019] (1) equipped with raw materials:

[0020] According to parts by weight, 40 parts of 50% stabilization rate partial magnesium oxide stabilized zirconia, 10 parts of particle size is 52nm superfine aluminum-rich desilication monoclinic zirconia powder, 20 parts of monoclinic zirconia with 2UM particle size, 3 parts One part of ultrafine activated magnesia with a particle size of 10 μm, and one part with a particle size of 20 μm yttrium oxide fine powder.

[0021] Wherein, the semi-stable zirconia is matched according to the quantity ratio, D10:D20:D30:D50:D90 according to 1:1:2:3:1.5;

[0022] (2) Granulation:

[0023] According to the formula, the raw materials are granulated, first pressed with a four-column press, and then the pressed product is vacuumized, put into an isostatic press, and kept under pressure for 5 minutes under a pressure of 120 MPa for further molding. The uniformity of th...

Embodiment 2

[0025] Adaptive zirconia tundish nozzle, prepared by the following method:

[0026] (1) equipped with raw materials:

[0027] According to parts by weight, 60 parts of 30% stabilization rate partial magnesia stabilized zirconia, 20 parts of particle size is 35nm superfine aluminum-rich desilication monoclinic zirconia powder, 30 parts of monoclinic zirconia with 2UM particle size, 2 A particle size of 10 μm ultrafine activated magnesia, 2 parts particle size of 16 μm yttrium oxide fine powder.

[0028] Wherein, the semi-stable zirconia is matched according to the quantity ratio, D10:D20:D30:D50:D90 according to 1:1:2:3:1.5;

[0029] (2) Granulation:

[0030] According to the formula, the raw materials are granulated, first pressed with a four-column press, and then the pressed product is vacuumized, put into an isostatic press, and kept under pressure for 5 minutes under a pressure of 120 MPa for further molding. The uniformity of the product The performance is the same, pu...

Embodiment 3

[0032] Adaptive zirconia tundish nozzle, prepared by the following method:

[0033] (1) equipped with raw materials:

[0034] According to parts by weight, 50 parts of 40% stabilization rate partial magnesia stabilized zirconia, 13 parts of particle size is 45nm superfine aluminum-rich desilication monoclinic zirconia powder, 28 parts of monoclinic zirconia with 2UM particle size, 3 parts One part of ultrafine activated magnesia with a particle size of 10 μm, and one part with a particle size of 19 μm yttrium oxide fine powder.

[0035] Wherein, the semi-stable zirconia is matched according to the quantity ratio, D10:D20:D30:D50:D90 according to 1:1:2:3:1.5;

[0036] (2) Granulation:

[0037] According to the formula, the raw materials are granulated, first pressed with a four-column press, and then the pressed product is vacuumized, put into an isostatic press, and kept under pressure for 5 minutes under a pressure of 120 MPa for further molding. The uniformity of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com