Powder laying technology and system for ceramic substrate blank body

A technology for substrate blanks and ceramics, which is applied in the field of preparation technology of ceramic substrates, can solve the problems of difficult speed and uniformity, poor powder uniformity, and large fluctuation of powder quantity, and achieves improved dispersion uniformity and uniform powder density. The effect of improving the uniformity of powder density and improving the uniformity of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the powder coating process of the ceramic substrate blank body described in the present invention, the powder coating process of the ceramic substrate blank body described in this embodiment is a powder coating process of an alumina ceramic substrate, including the following steps:

[0032] (1), preparation of binder;

[0033] (2), forming a uniform adhesive film layer on the surface of the alumina ceramic substrate body to obtain an alumina ceramic substrate body with an adhesive film layer;

[0034] (3), on the surface of the alumina ceramic substrate green body that has adhesive film layer, form one layer to separate sticky powder layer;

[0035] (4) Drying to obtain the powder-coated alumina ceramic substrate green body.

Embodiment 2

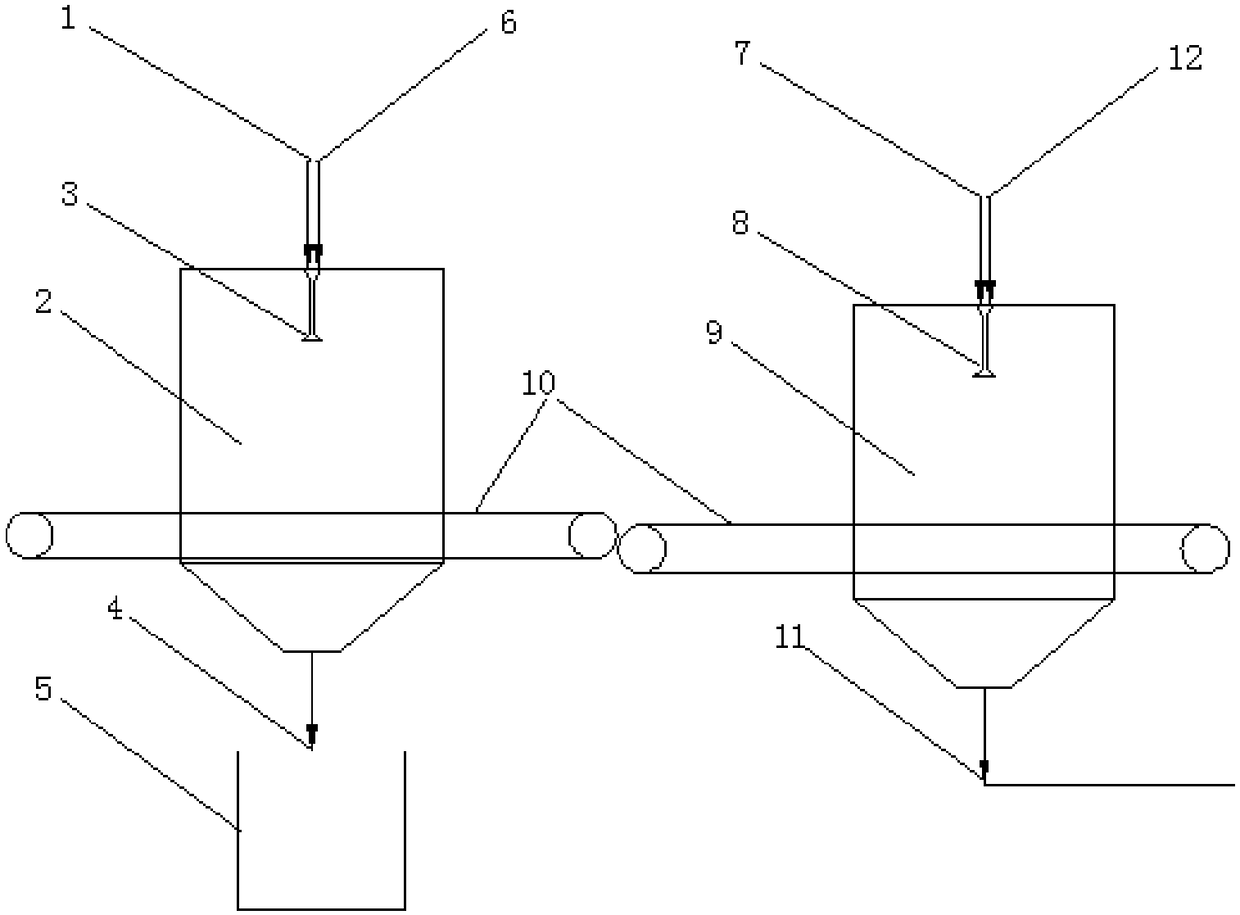

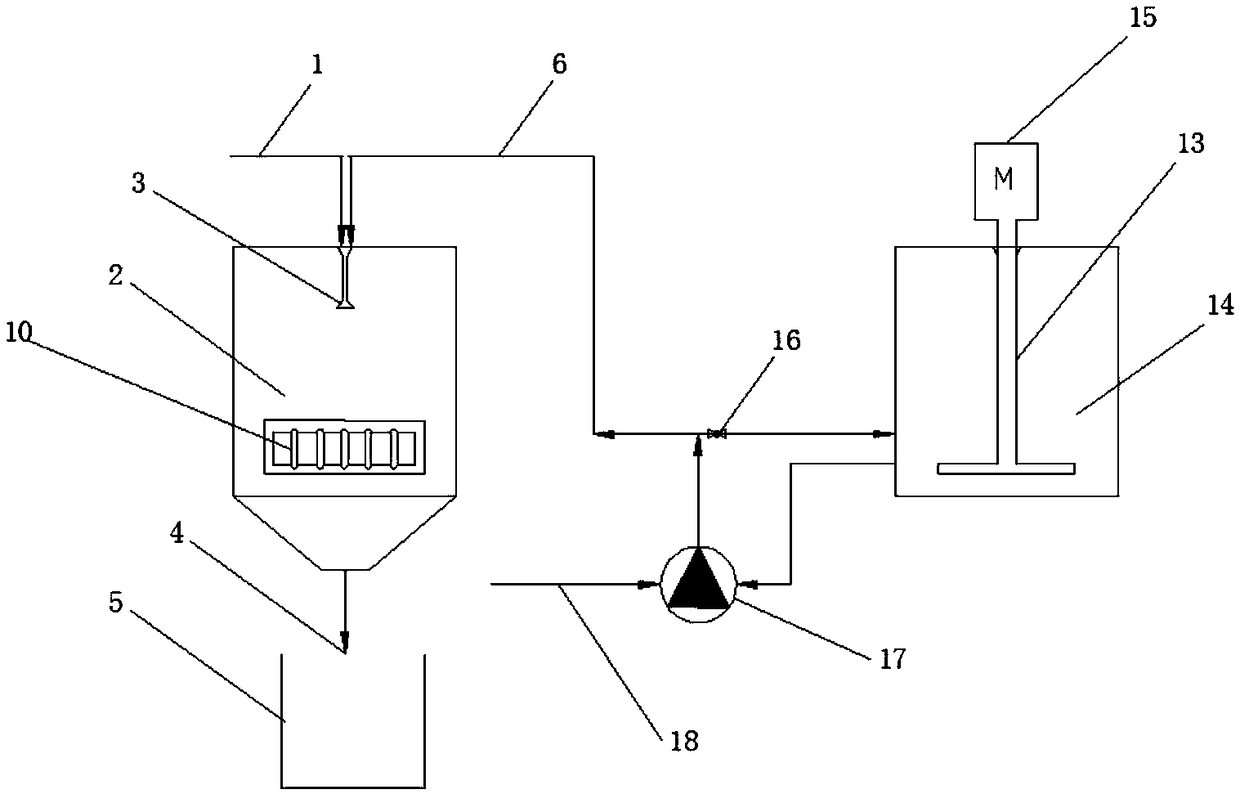

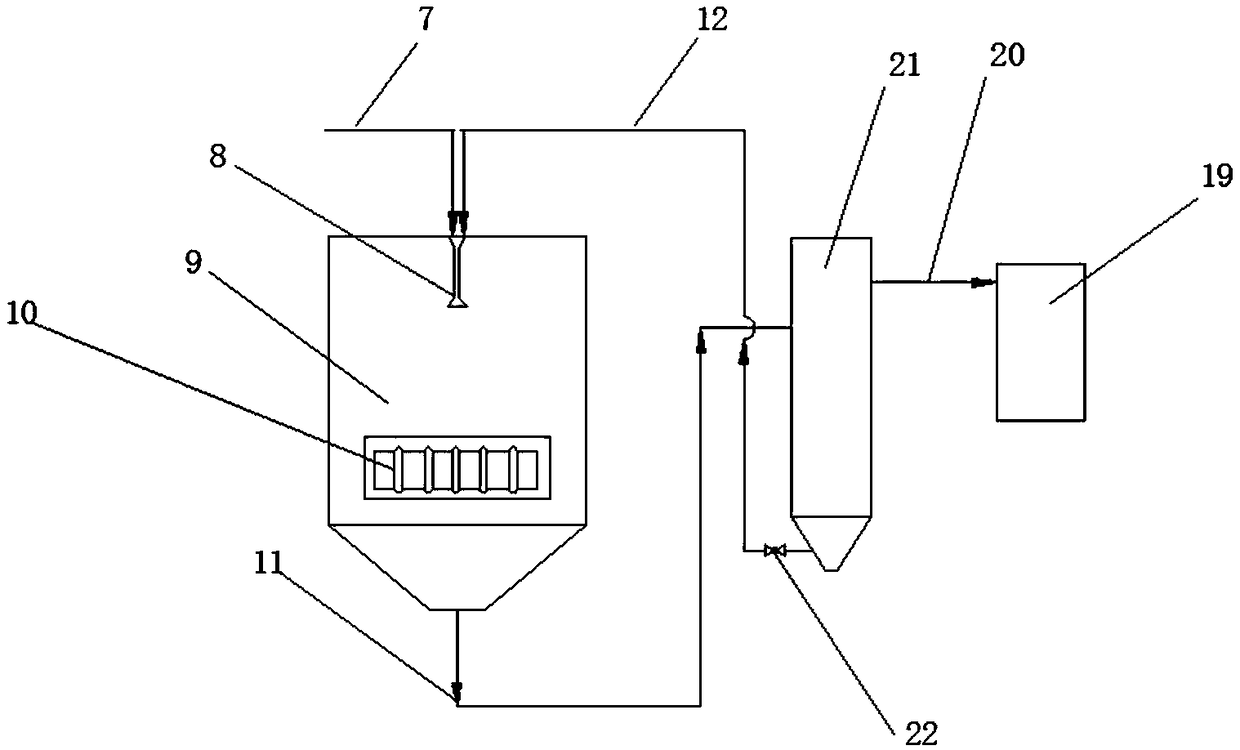

[0037] An embodiment of the powder application system of the ceramic substrate green body of the present invention, such as Figure 1~3 shown.

[0038] The powder coating system of the ceramic substrate body described in this embodiment includes a glue coating machine, a powder coating machine and a conveyor belt. 4. The colloid recovery tank 5, the rubber inlet pipe 6 and the colloid storage box 14; the colloid atomization box 2 is provided with a colloid atomizer 3; , The colloid storage box 2 is connected with the colloid atomizer 3 through the glue inlet pipe 6 .

[0039] The powder applicator includes a powder atomization box 9, a powder storage box 21 and a dust collection box 19, the powder atomization box 9 is provided with a powder atomizer 8; A powder separator (not shown in the figure) is provided; the powder storage box 21 is connected to the bottom of the powder atomization box 9 through a powder recovery pipe; The powder atomizer 8 is connected; the powder sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com