Process for preparing predispersed masterbatch of polyolefin and nano calcium carbonate

A technology of nano-calcium carbonate and polyolefin, which is applied in the field of preparation of polyolefin/nano-calcium carbonate pre-dispersed masterbatch, can solve the problems of poor macroscopic uniformity of mechanical mixing, poor modification effect, dust pollution, etc., and achieve the best results Significant, avoid high energy consumption, improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

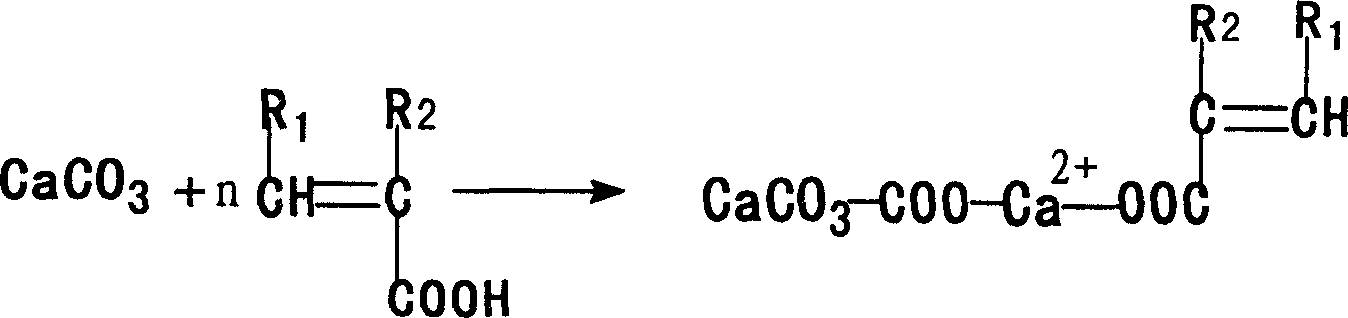

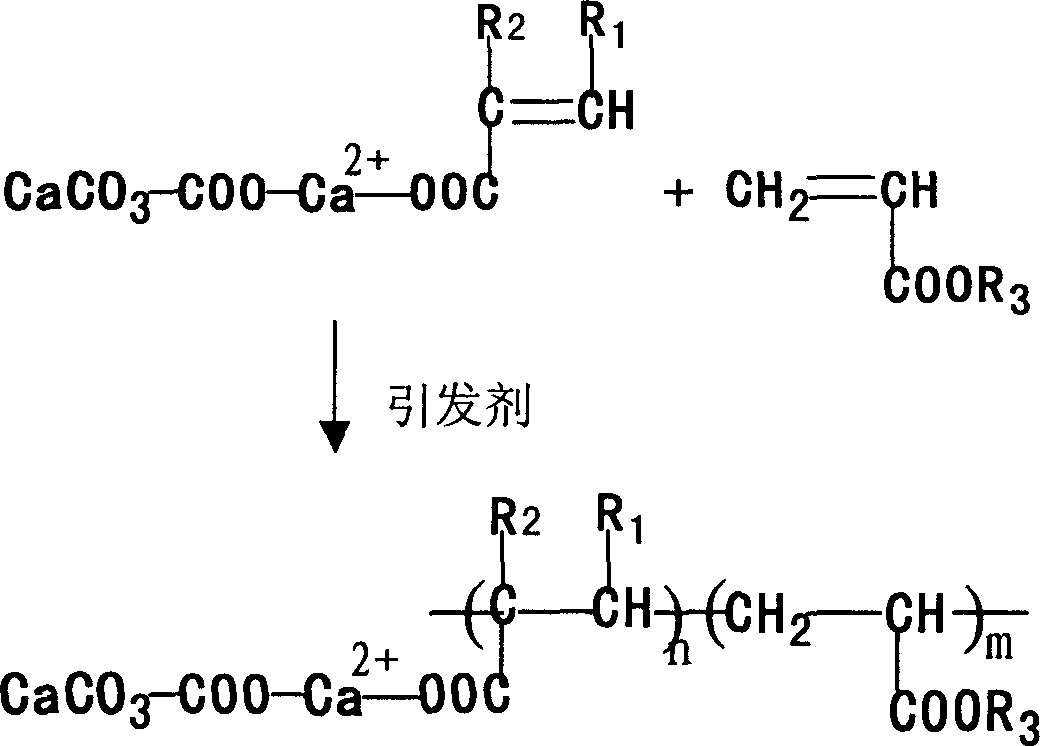

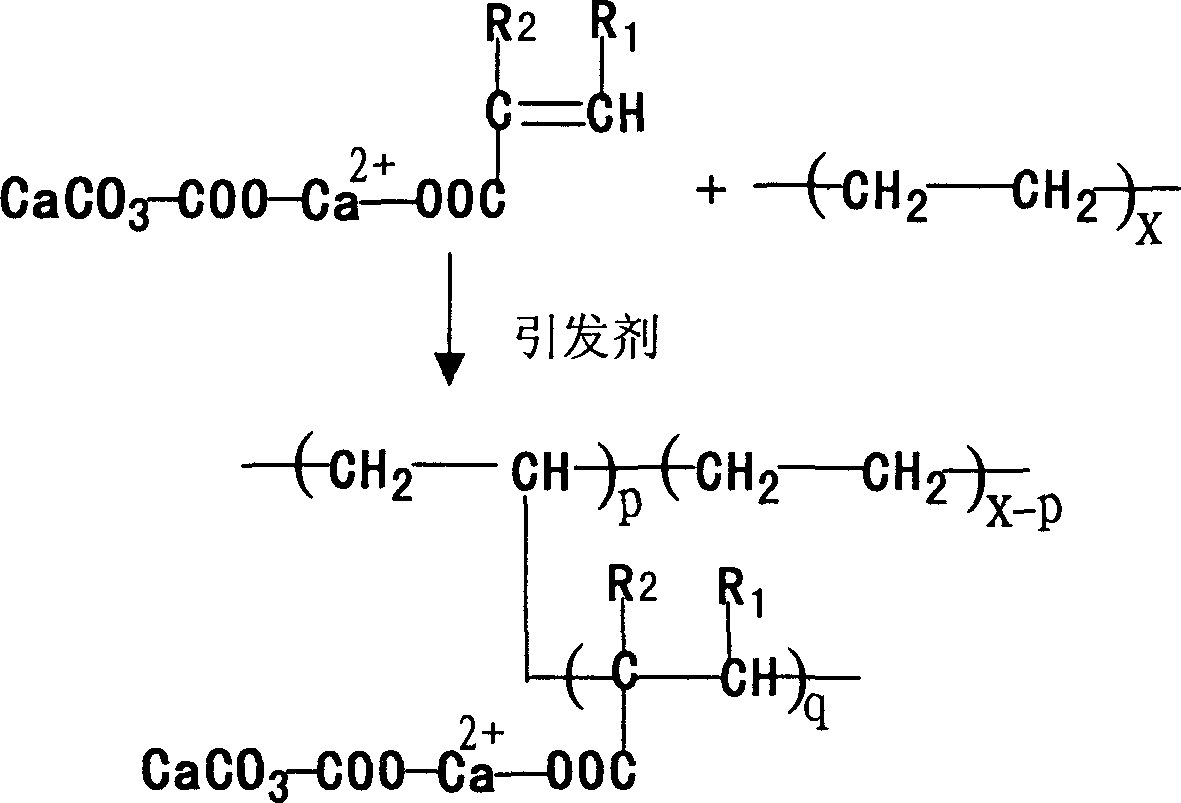

Method used

Image

Examples

Embodiment 1

[0047] In a 200-liter kneader, according to the formula of Table 1 Example 1, add 80 kilograms of nano-calcium carbonate (particle diameter is 30-65 nanometers), add 0.8 kilograms of methacrylic acid, 0.8 kilograms of methacrylic acid in sequence under low speed stirring Stearyl methacrylate, 0.008 kg of di-tert-butyl peroxide, 1 kg of sodium cetyloxypolyoxyethylene ether sulfonate (the degree of polymerization of polyoxyethylene ether is 20), 3 kg of Anhydride grafted linear low density polyethylene (grafting ratio 1.2 mmol / 100 gram) and 14.4 kilograms of linear low density polyethylene (melt flow rate is 17g / 10min), after adding, high-speed stirring 1 minute, obtains mixture.

[0048] Add the mixture into the feed hopper of the twin-screw extruder, extrude and pelletize in a twin-screw extruder with a length-to-diameter ratio of 48:1 and a screw diameter of 75 mm with 5 sections of mixing elements added to the screw. The speed of the main engine of the twin-screw extruder i...

Embodiment 2

[0051] The preparation of predispersed masterbatch refers to the formula of Example 2 in Table 1, and the preparation process conditions are the same as Example 1. The application formula is according to the formula of Example 2 in Table 2, and the mechanical properties and heat distortion temperature of the obtained NCM-2 filled polypropylene are shown in Table 4.

[0052] Example 1

[0053] Example 1

[0054] project

Embodiment 3

[0056] Press the prescription of table 1 embodiment 3, the difference of preparation process condition and embodiment 1 is: the host speed of twin-screw extruder is 280 rev / mins, and feeding speed is 40 revs / mins, each section of extruder (comprising extruder) There are 6 sections in the first section) the temperature is 180°C, 200°C, 200°C, 195°C, 195°C, 190°C in sequence. The application formula is according to Example 3 in Table 2, and the mechanical properties and heat deflection temperature of the obtained NCM-3 filled polypropylene are shown in Table 4.

[0057] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com