Preparation method of carbon fiber reinforced nylon composite micro-powder for selective laser sintering

A technology of laser sintering and carbon fiber powder, which is applied in the field of preparation of carbon fiber reinforced nylon composite micropowder for selective laser sintering, can solve the problems affecting the performance of parts, uneven composition, different shapes, etc. The effect of increasing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

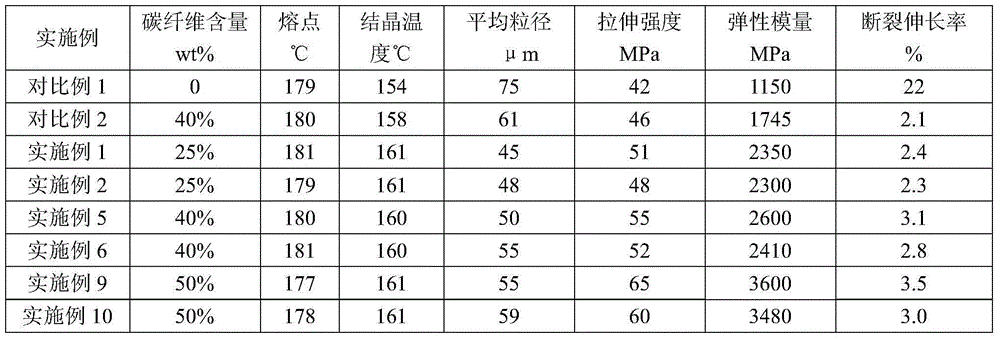

Examples

Embodiment 1

[0038] (1) Extract 1.5 kg of commercially available carbon fiber powder with acetone in a Soxhlet extractor for 48 h, add 1.0 L of nitric acid with a concentration of 14 mol / L after vacuum drying, and oxidize under reflux for 5 h. Dilute with distilled water, vacuum filter, wash until neutral, dry, and pass through a 300-mesh sieve.

[0039] (2) Add 1kg of carbon fiber powder treated in step (1), 3kg of nylon 12 pellets, and 2kg of polyvinylpyrrolidone into 15L of formic acid, heat and stir at 80°C for 2 hours to fully dissolve the nylon 12 pellets.

[0040] (3) While vigorously stirring, add 10 L of absolute ethanol to step (2), and precipitate out after standing still. After suction filtration, washing with ethanol, and drying, sieve with a 200-mesh sieve.

[0041](4) Take step (3) gained carbon fiber-nylon powder 4kg, and flow aid nano silicon dioxide 20g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol ) 10 g, stirred and mixed for 1 h in a vertical mixer to ...

Embodiment 2

[0043] (1) Commercially available 1.5kg carbon fiber powder was extracted with acetone in a Soxhlet extractor for 48 hours, vacuum-dried, added to a toluene solution to stir and disperse, added an ethanol solution of silane coupling agent KH550, ventilated with nitrogen, heated to reflux for 1 hour, and vacuumed Filter, wash, dry, and pass through a 300-mesh sieve.

[0044] (2) Add 1kg of carbon fiber powder treated in step (1), 3kg of nylon 12 pellets, and 2kg of polyvinylpyrrolidone into 15L of formic acid, heat and stir at 80°C for 2 hours to fully dissolve the nylon 12 pellets.

[0045] (3) While vigorously stirring, add 10 L of absolute ethanol to step (2), and precipitate out after standing still. After suction filtration, washing with ethanol, and drying, sieve with a 200-mesh sieve.

[0046] (4) Take step (3) gained carbon fiber-nylon powder 4kg, and flow aid nano silicon dioxide 20g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol ) 10 g, stirred and mix...

Embodiment 3

[0048] (1) Commercially available 1.5kg carbon fiber powder was extracted with acetone for 48 hours in a Soxhlet extractor, dried in a vacuum, added to 14 mol / L nitric acid, heated to reflux for 5 hours for oxidation. Dilute with distilled water, vacuum filter, wash until neutral, dry, and pass through a 300-mesh sieve.

[0049] (2) Add 1kg of carbon fiber powder treated in step (1), 3kg of nylon 66 pellets, and 2kg of polyvinylpyrrolidone into 18L of acetic acid, heat and stir at 100°C for 2 hours to fully dissolve the nylon 66 pellets.

[0050] (3) While vigorously stirring, add 10 L of absolute ethanol to step (2), and precipitate out after standing still. After suction filtration, washing with ethanol, and drying, sieve with a 200-mesh sieve.

[0051] (4) Take step (3) gained carbon fiber-nylon powder 4kg, and flow aid nano silicon dioxide 20g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol ) 10 g, stirred and mixed for 1 h in a vertical mixer to obtain carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com