Powder billet forming device and method thereof

A blank forming and powder technology, which is applied in the field of powder blank forming devices, can solve problems such as unevenness, uneven density gradient, and limited pressure capacity of transducers, so as to increase the density of the blank, increase the contact area, and increase the The effect of vibration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

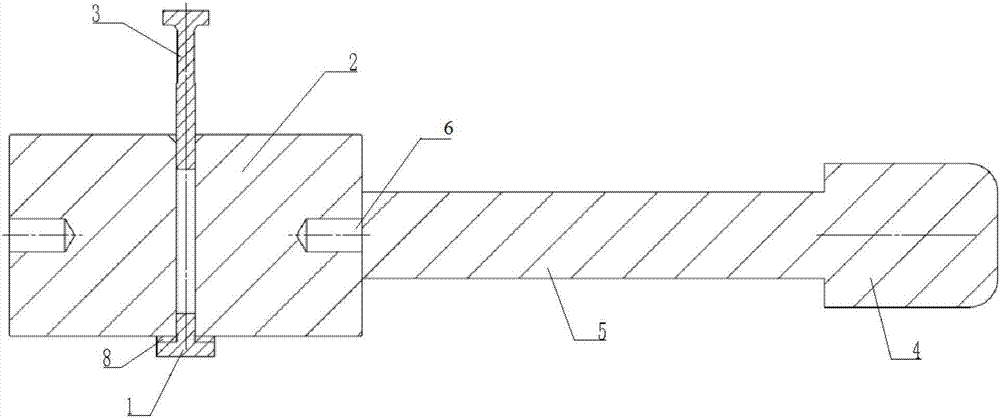

[0026] figure 1 Schematically shows the first embodiment of the structure of the powder blank forming device of the present invention, as figure 1 As shown, the powder billet molding device provided by the present invention includes: a bottom bracket 1, a mold 2, an extrusion rod 3, a transducer 4 and a horn 5, wherein the bottom bracket 1 and The molds 2 are flexibly connected by a rubber pad 8, and the bottom bracket 1 and the mold 2 form a mold cavity, and the rubber pad is provided to make the mold cavity more airtight; one end of the horn 5 and the mold 2 are connected through a bolt 6 Fixed connection, the other end of the horn 5 is bolted to the transducer 4; while the extrusion rod 3 exerts axial pressure on the powder, the transducer 4 receives the signal generated by the ultrasonic generator and converts electrical energy into mechanical energy. The vibration drives the horn 5, and the horn 5 drives the overall vibration of the mold 2, and the mold 2 evenly applies ...

Embodiment 2

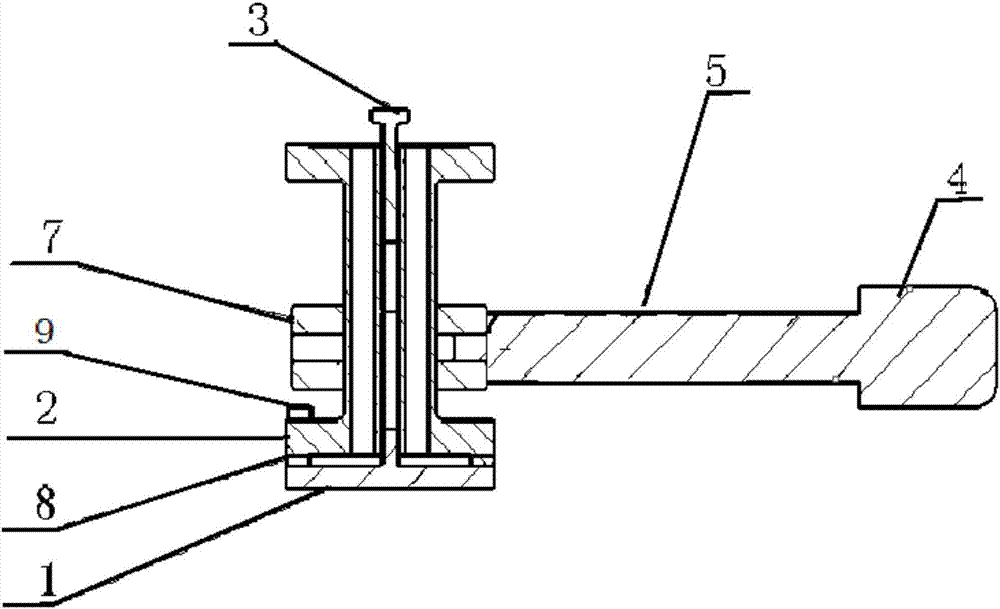

[0036] figure 2 Schematically shows the second embodiment of the structure of the powder blank forming device of the present invention, as figure 2As shown, the powder billet molding device provided by the present invention includes: a bottom bracket 1, a mold 2, an extrusion rod 3, a transducer 4, a horn 5, and the outer wall of the mold 2 The clamping device 7 on the top, the mold 2 and the horn 5 are indirectly connected through the clamping device 7; between the clamping device 7 and the horn 5 and between the horn 5 and the transducer 4 Both are connected by bolts; preferably, the clamping device 7 can be a clamp or the like.

[0037] Preferably, this embodiment is applicable to the case where the mold 2 is hollow and thin-walled. Since the thin-walled structure of the mold 2 itself is easily deformed by excitation, this embodiment drives the mold 2 to generate multiple shapes by combining the horn 5 and the clamping device. Modal compound vibration.

[0038] The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com