Patents

Literature

49results about How to "Increase the vibration area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

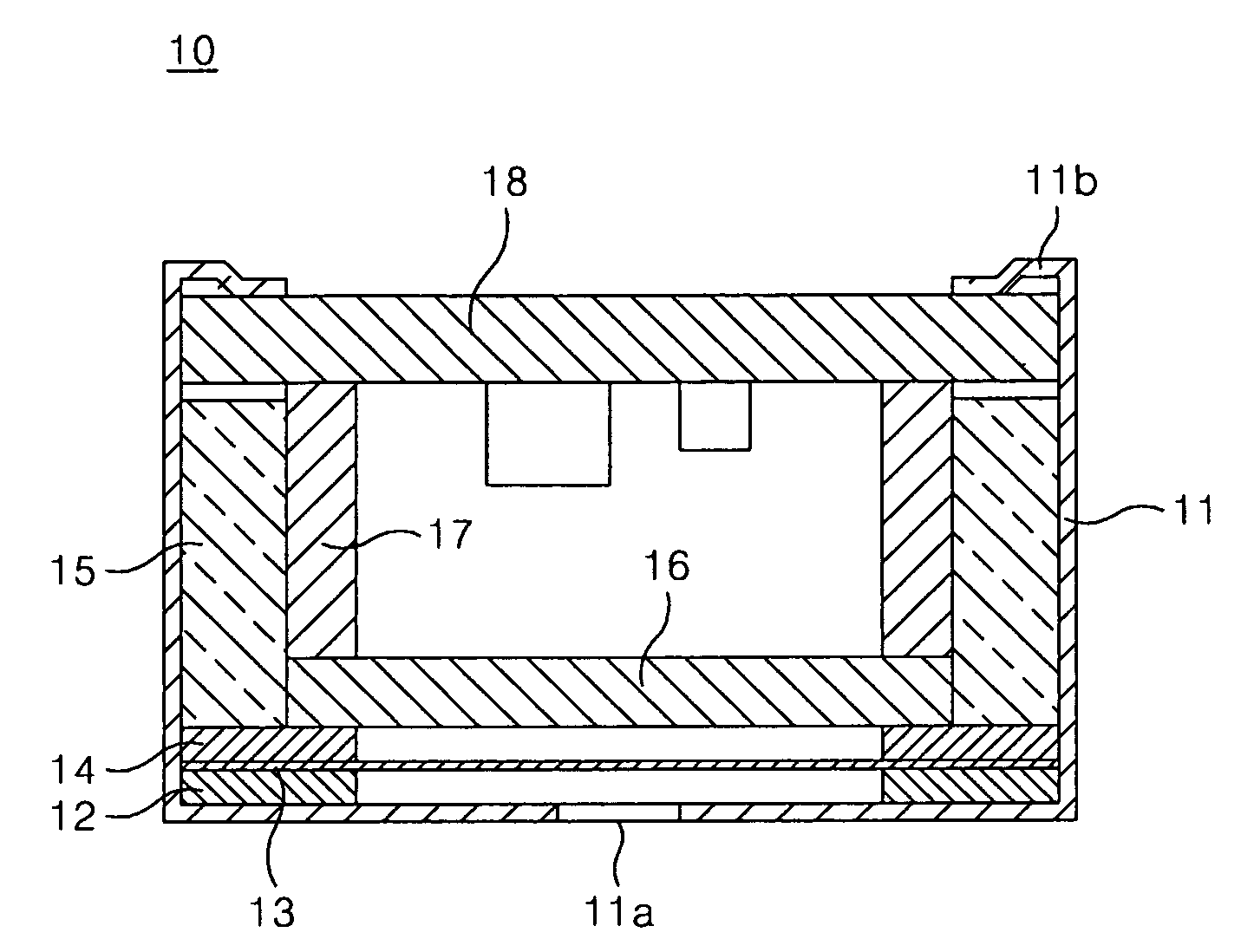

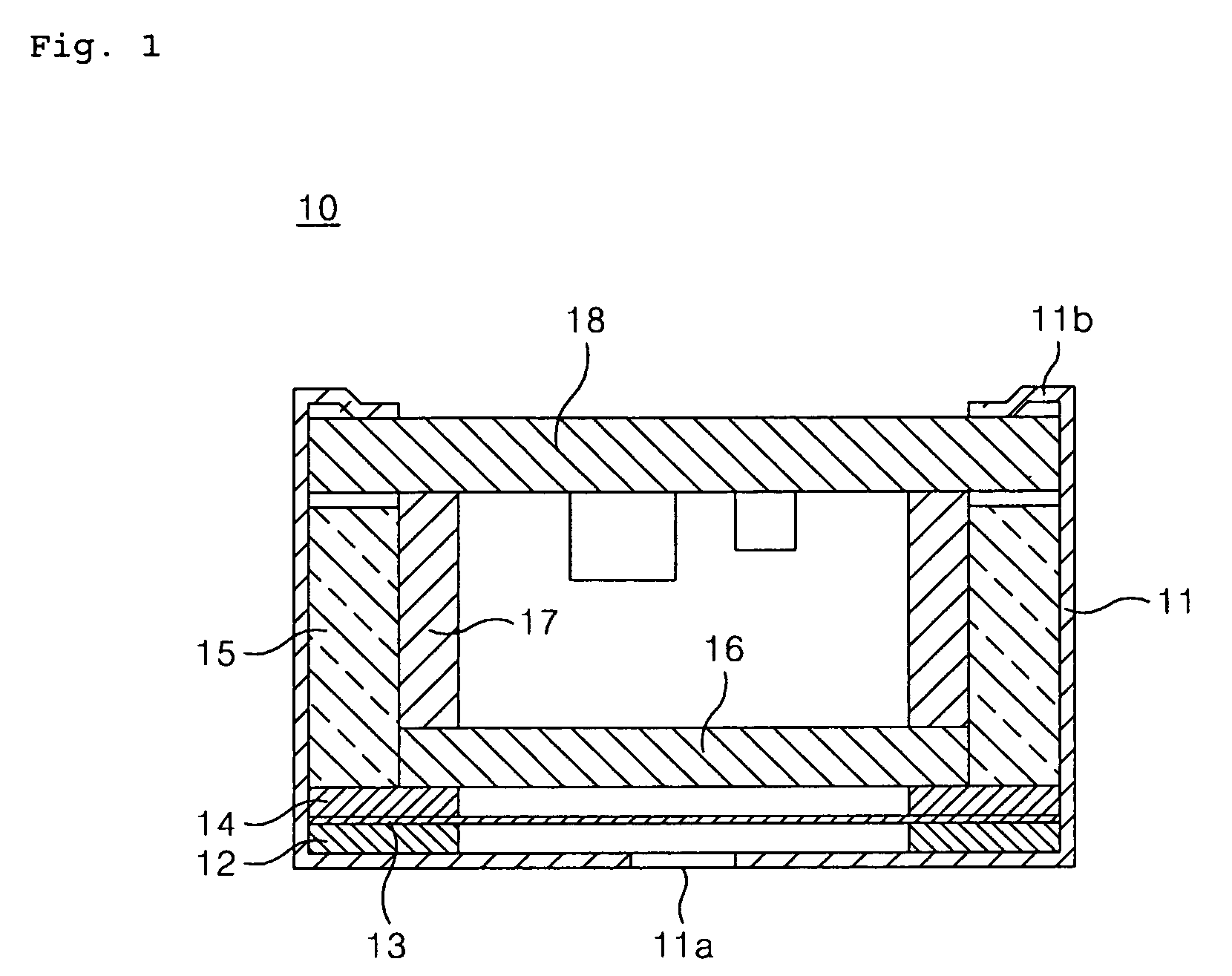

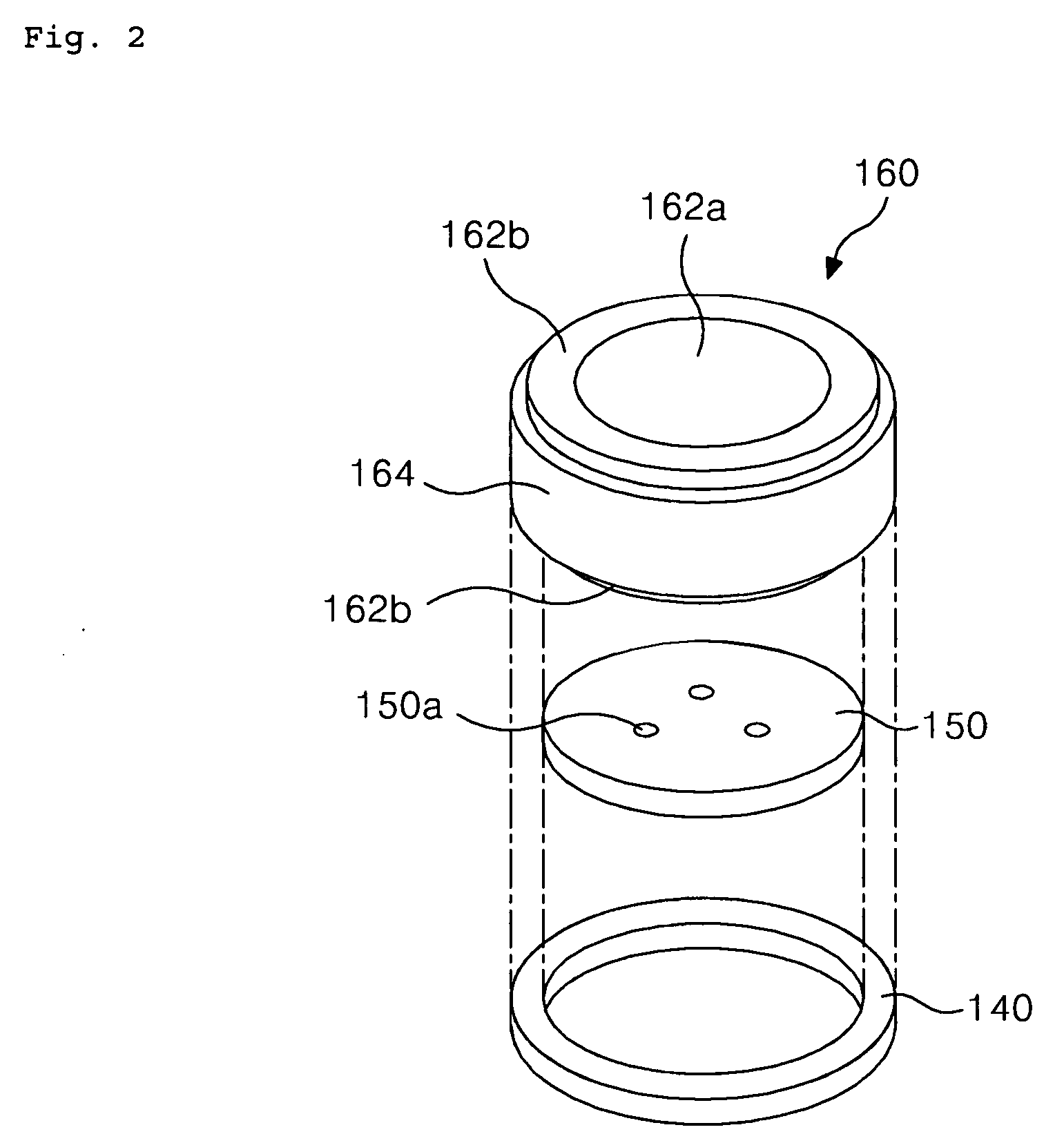

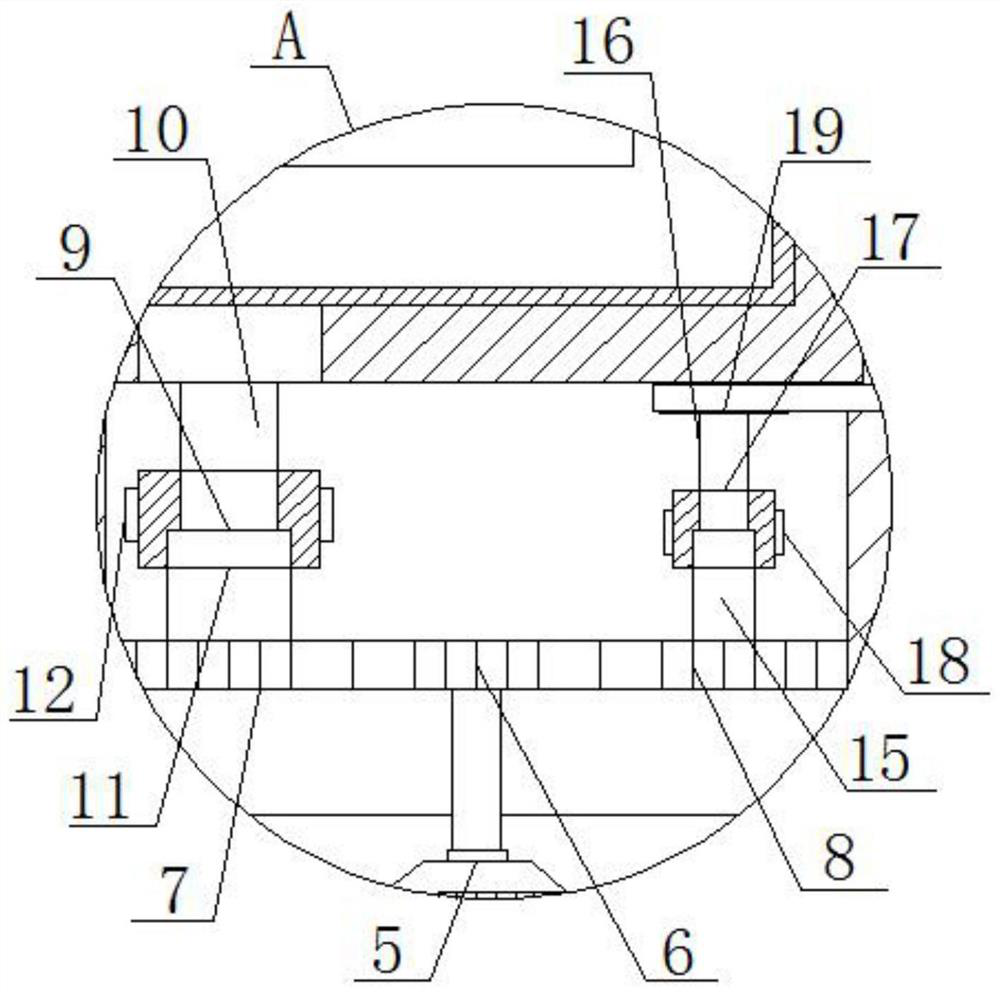

Piezoelectric device for generating acoustic signal

InactiveUS20070057601A1Optimize assembly structureEasy to assemblePiezoelectric/electrostriction/magnetostriction machinesBone conduction transducer hearing devicesDrop impactPiezoelectric actuators

There is provided a piezoelectric device for generating an acoustic signal in which an expansion mechanism expands a disposition of a laminated piezoelectric actuator by the principle of leverage. The mass of a base member placed in the expansion mechanism is larger than the mass of a vibration output member. An overall device size is small. The piezoelectric device has a pressurization structure for reducing a tractive force acting on the laminated piezoelectric actuator which is generated by the amplification. This enables provision of a piezoelectric device for generating an acoustic signal that is a small size, highly resistant to dropping impact, and has god acoustic performance with less sound leakage.

Owner:TOKIN CORP

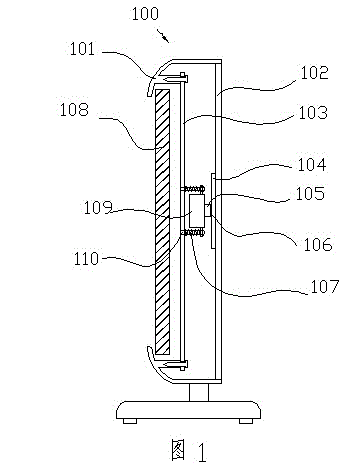

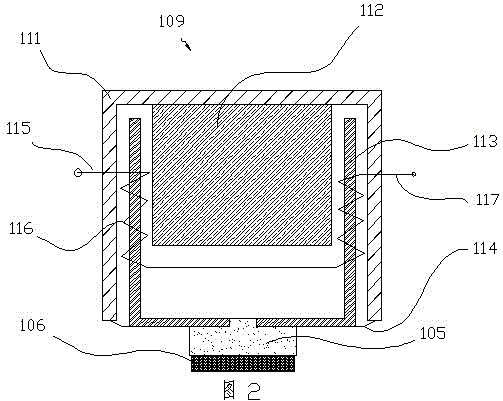

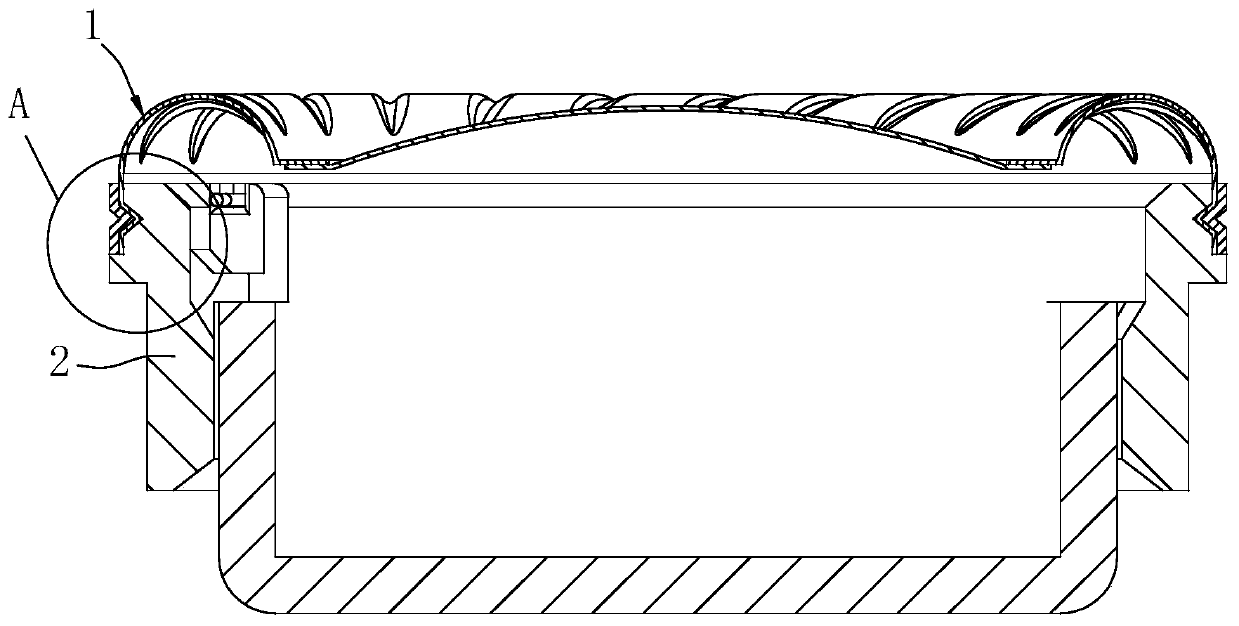

Liquid crystal television bass boost system

InactiveCN102946577AGood bassSmall volumeTelevision system detailsColor television detailsEngineeringLCD television

A liquid crystal television bass boost system comprises a front frame, a rear cover, a screen and a vibration speaker, wherein the vibration speaker is fixed to the front frame through a speaker support, the vibration speaker and the speaker support are fixedly connected through a spring cushion, an elastic cushion is installed on an vibration head of the vibration speaker, a metal plate is arranged between the rear cover and the vibration speaker and is fixed to the rear cover, and the metal plate and the vibration head of the vibration speaker are connected tightly through the elastic cushion. By the aid of the system, a flat television has good bass effect under the condition that the thickness of a mainframe is not changed.

Owner:宁波市环球宇斯浦电器有限公司

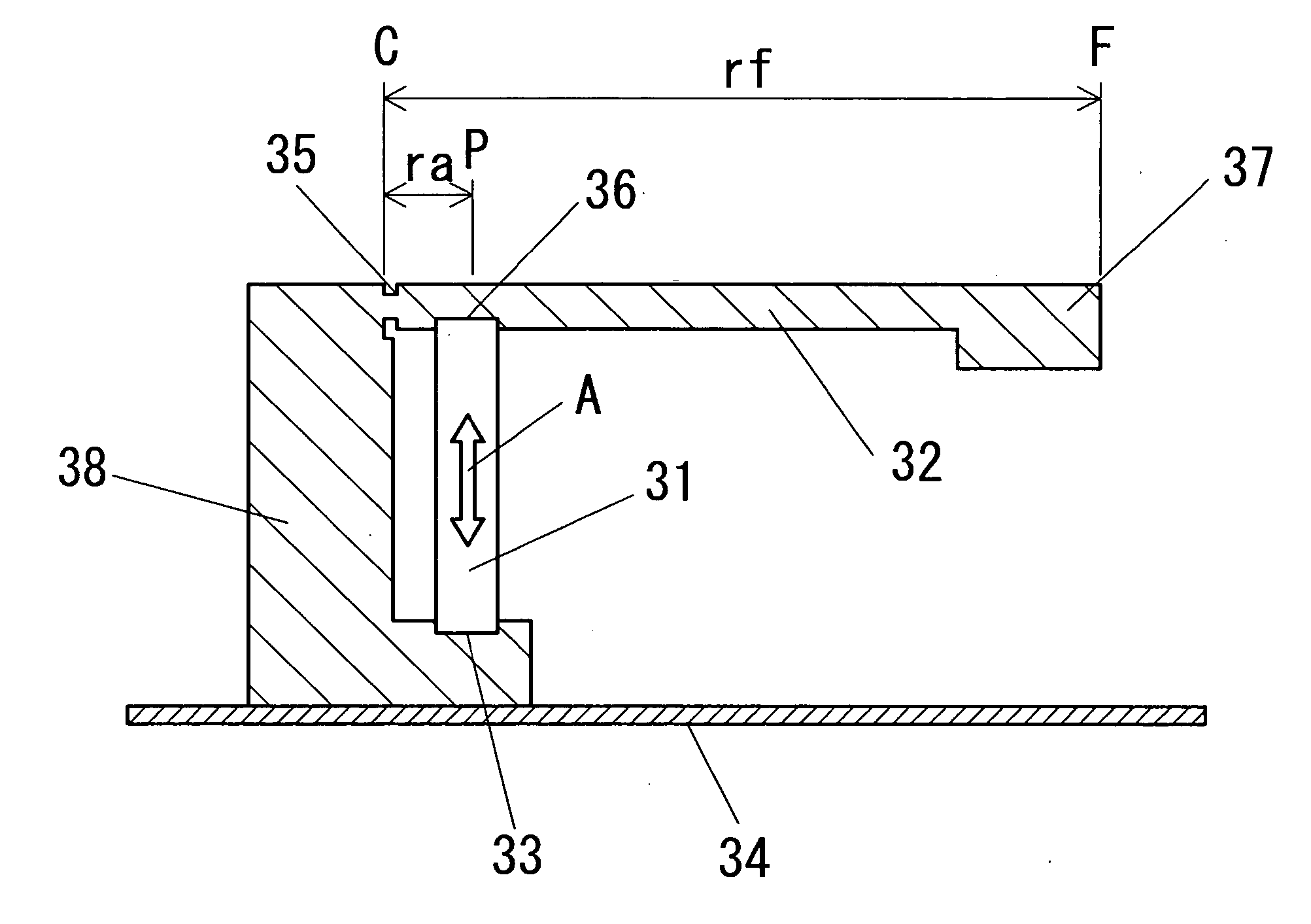

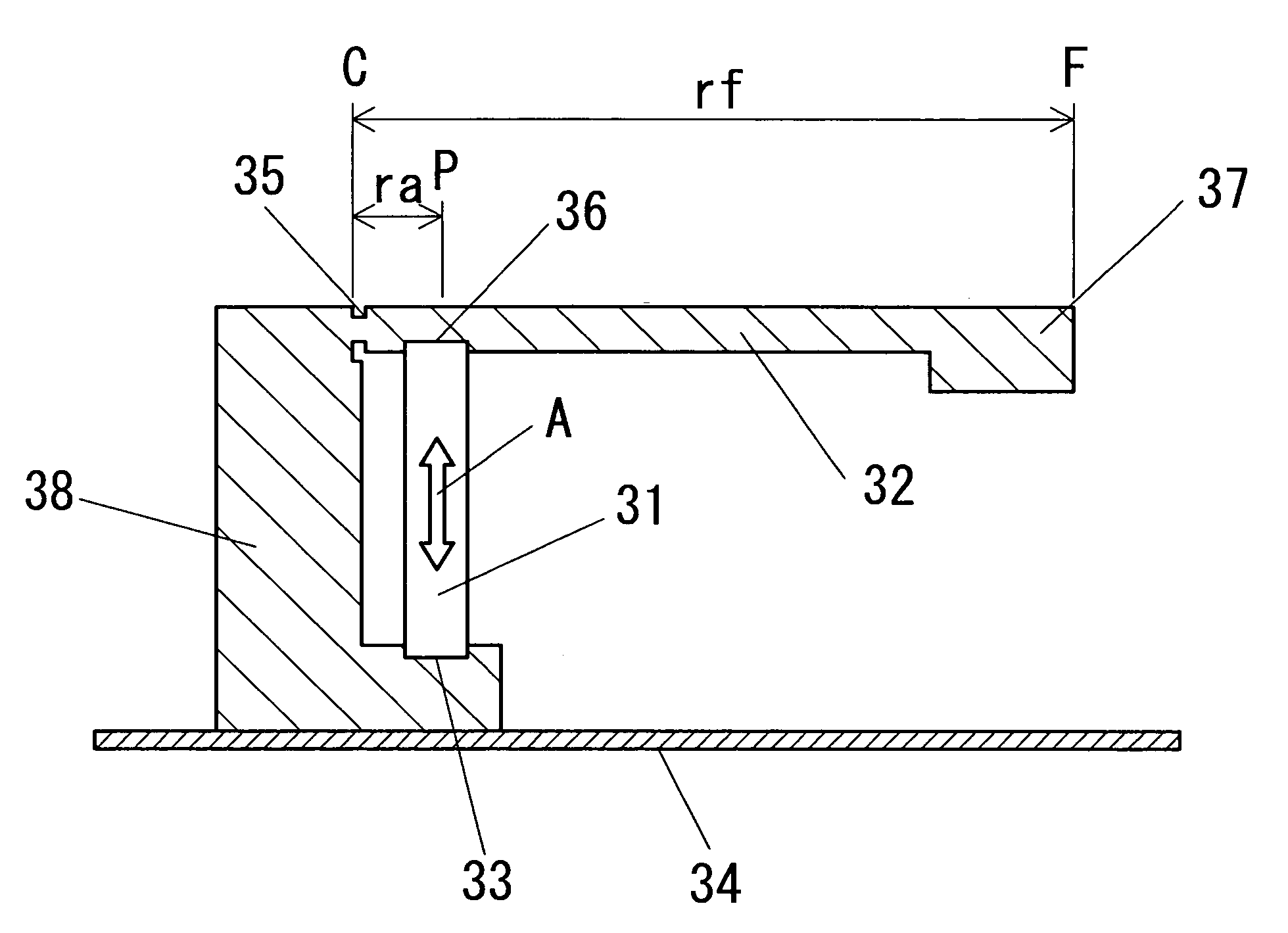

Piezoelectric device for generating acoustic signal

InactiveUS7382079B2Increase the vibration areaLarge amplitudePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersDrop impactPiezoelectric actuators

There is provided a piezoelectric device for generating an acoustic signal in which an expansion mechanism expands a disposition of a laminated piezoelectric actuator by the principle of leverage. The mass of a base member placed in the expansion mechanism is larger than the mass of a vibration output member. An overall device size is small. The piezoelectric device has a pressurization structure for reducing a tractive force acting on the laminated piezoelectric actuator which is generated by the amplification. This enables provision of a piezoelectric device for generating an acoustic signal that is a small size, highly resistant to dropping impact, and has god acoustic performance with less sound leakage.

Owner:TOKIN CORP

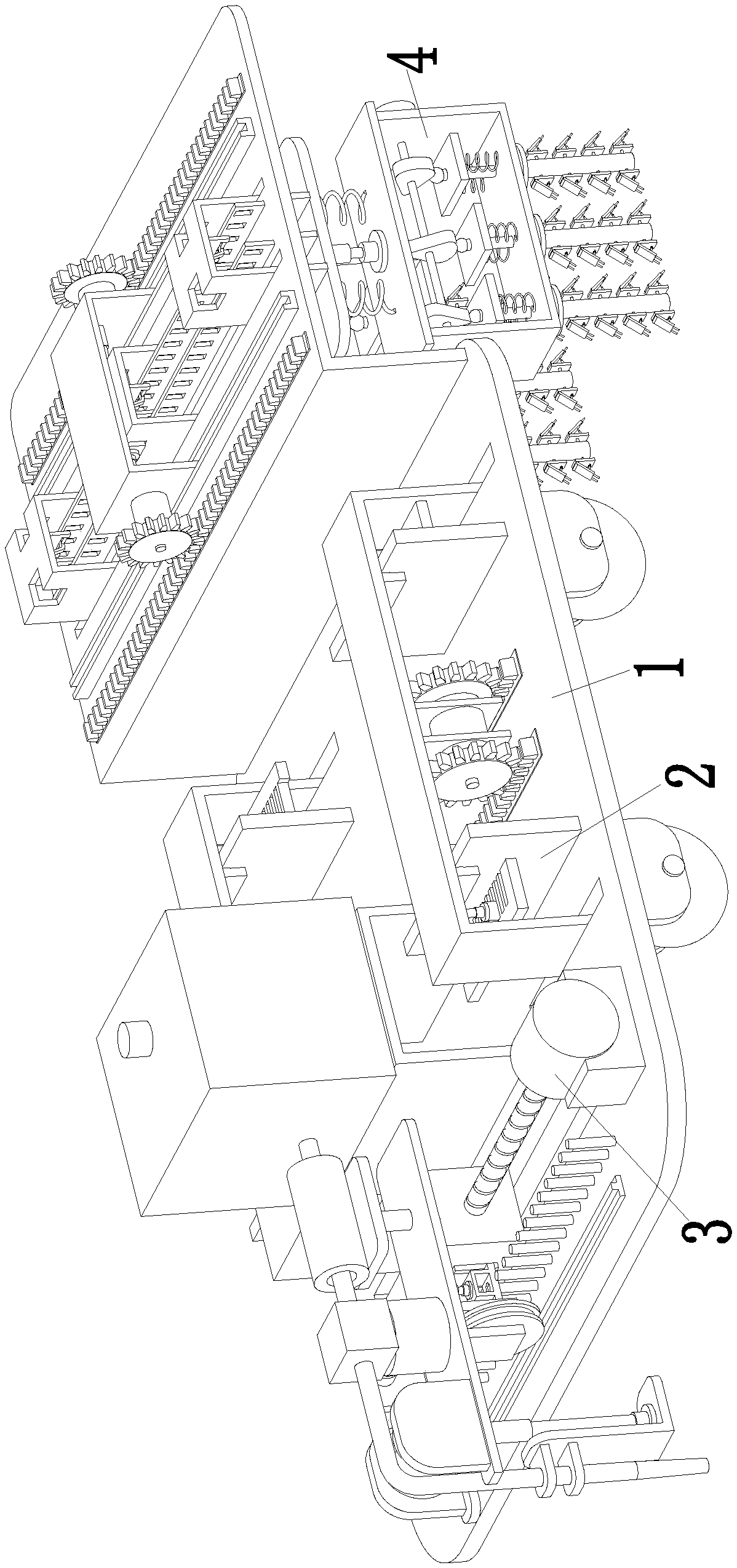

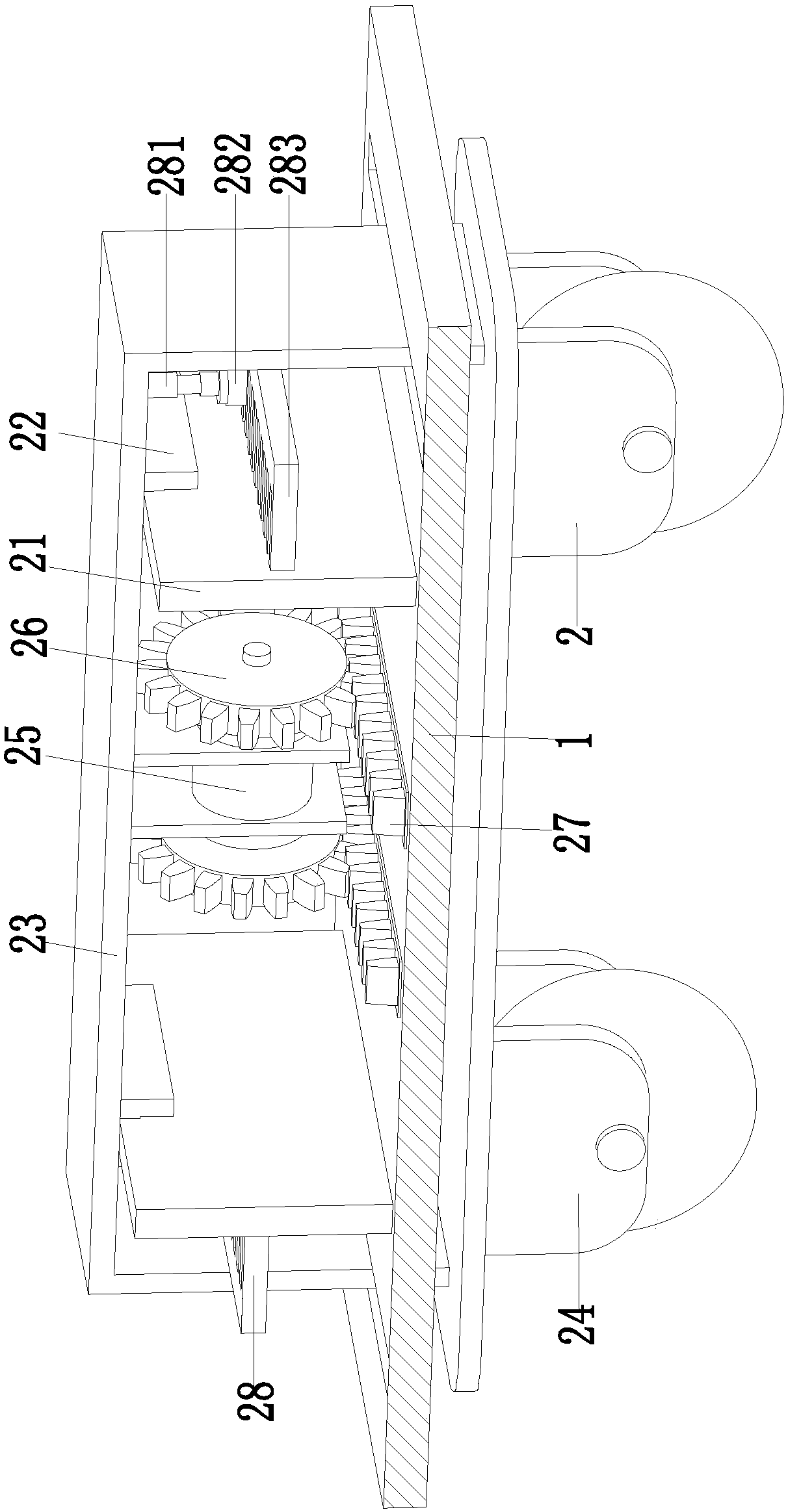

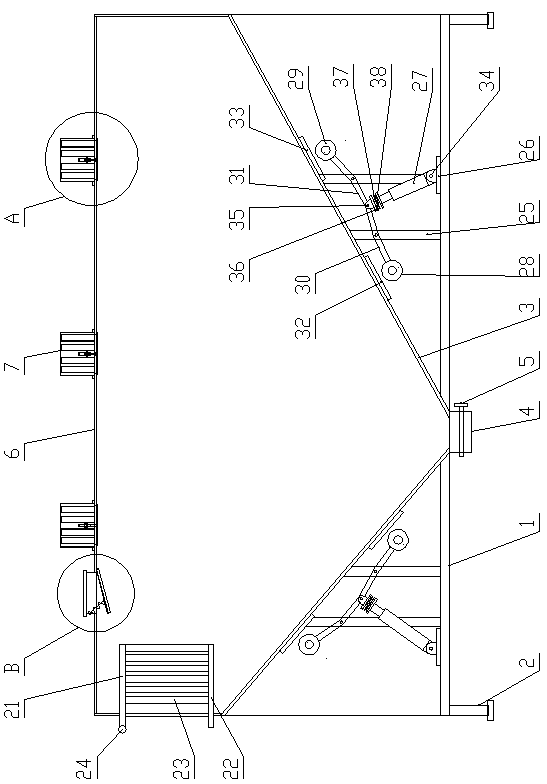

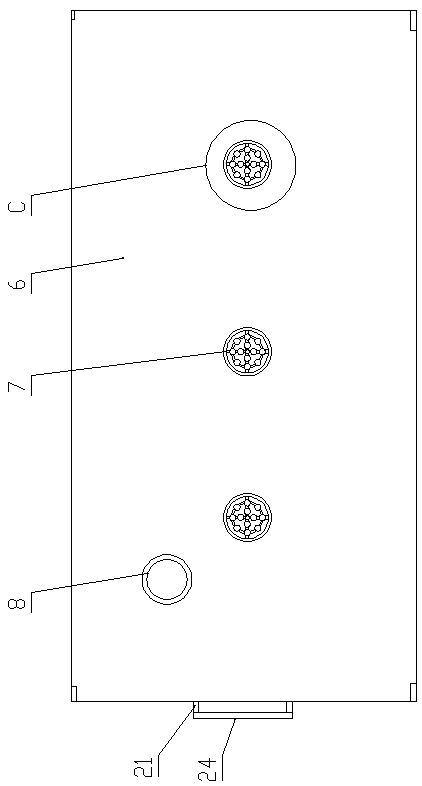

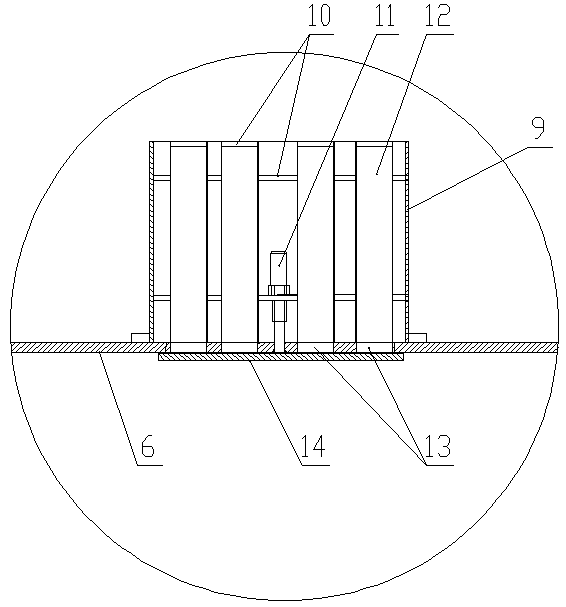

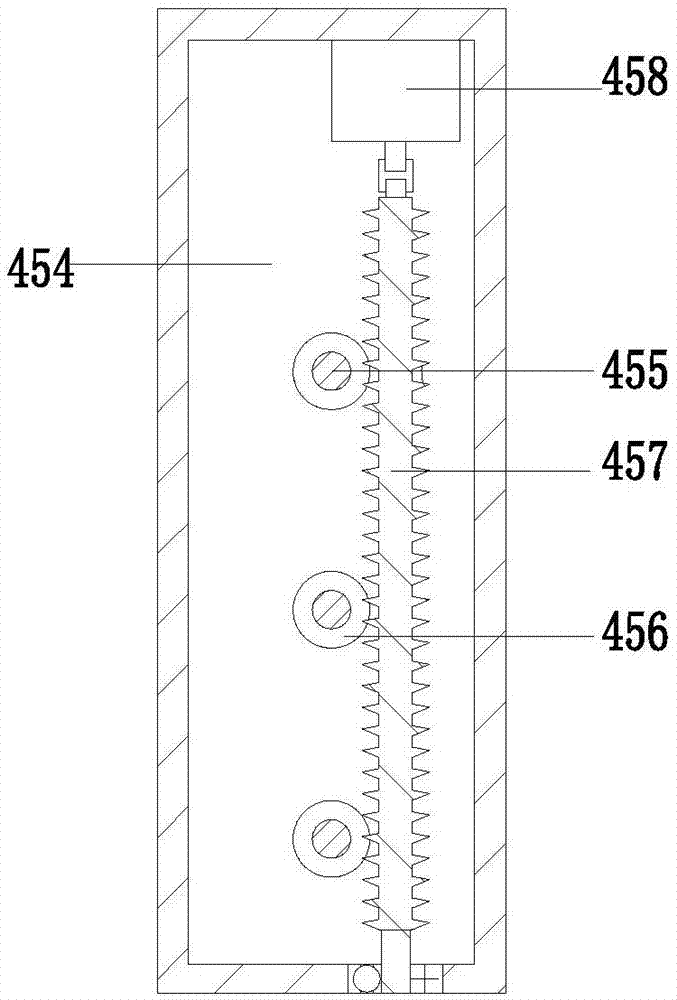

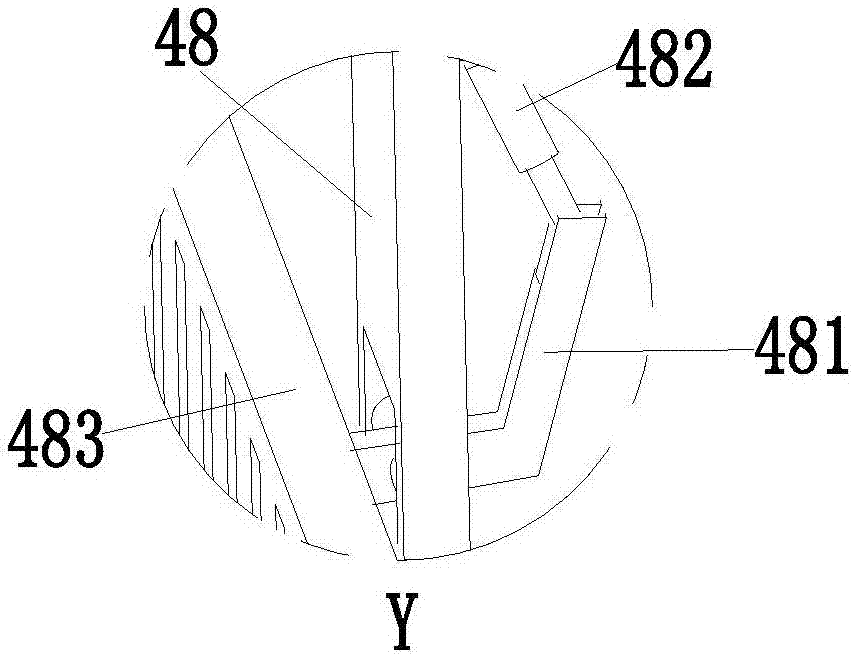

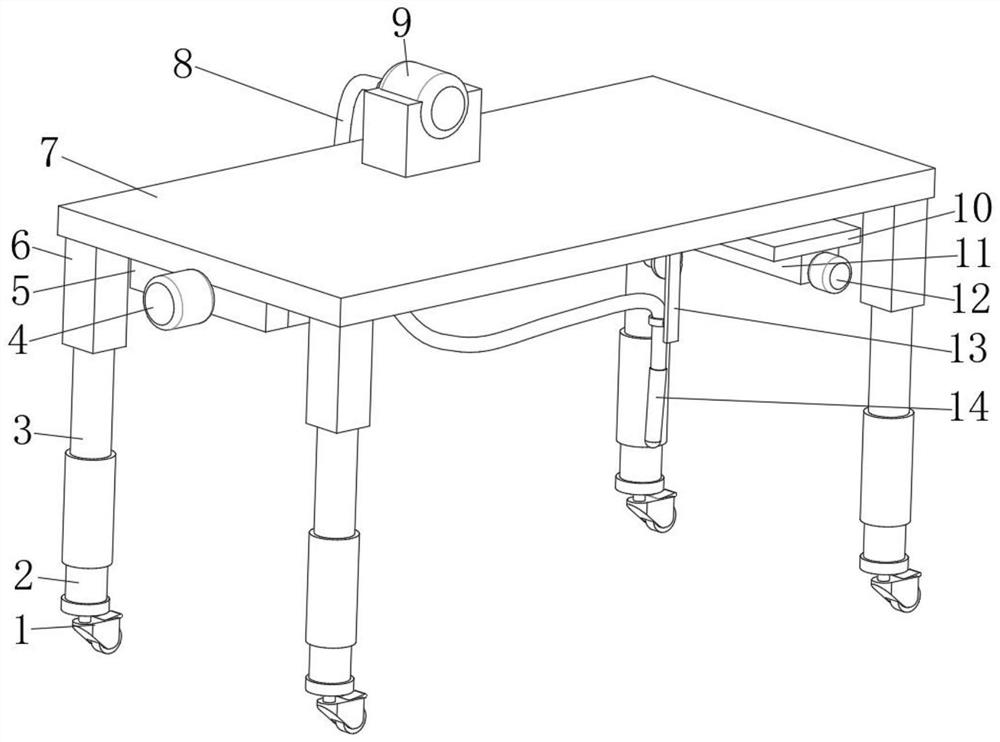

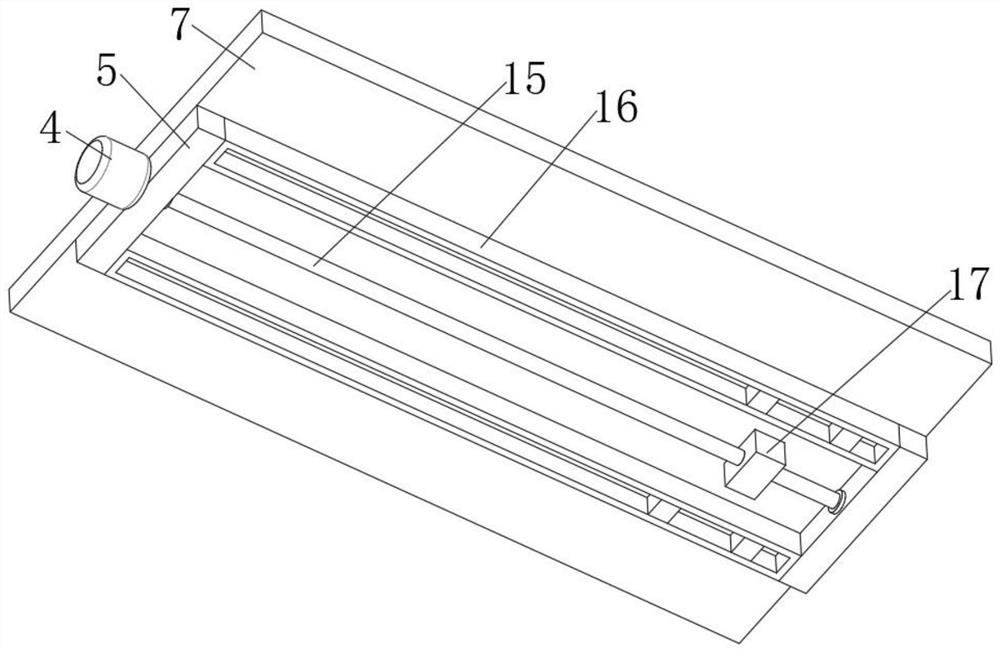

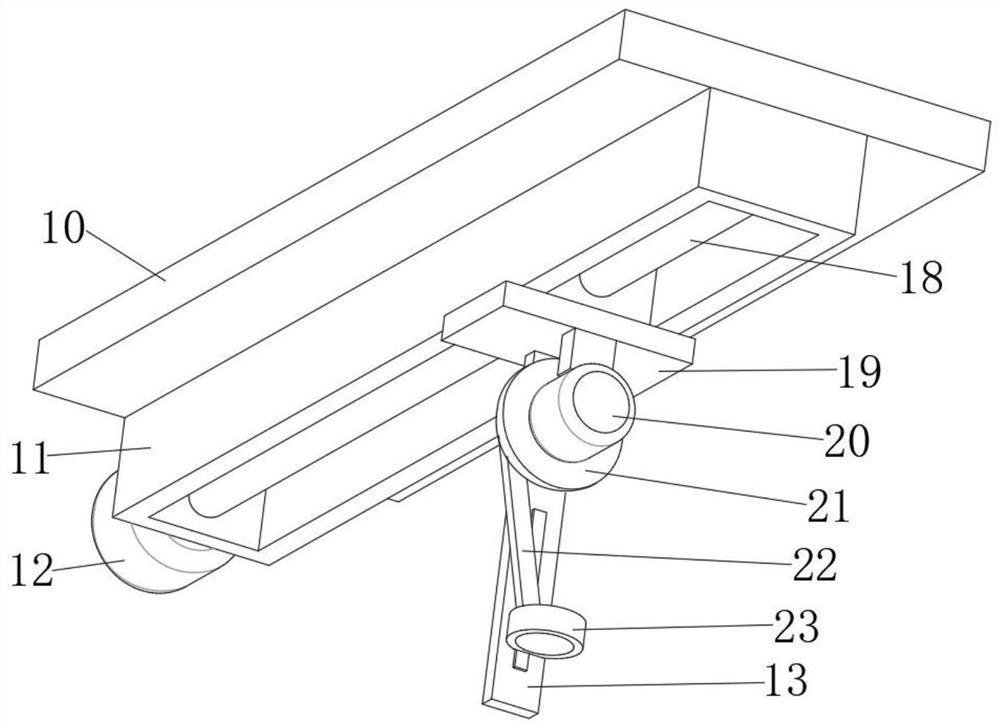

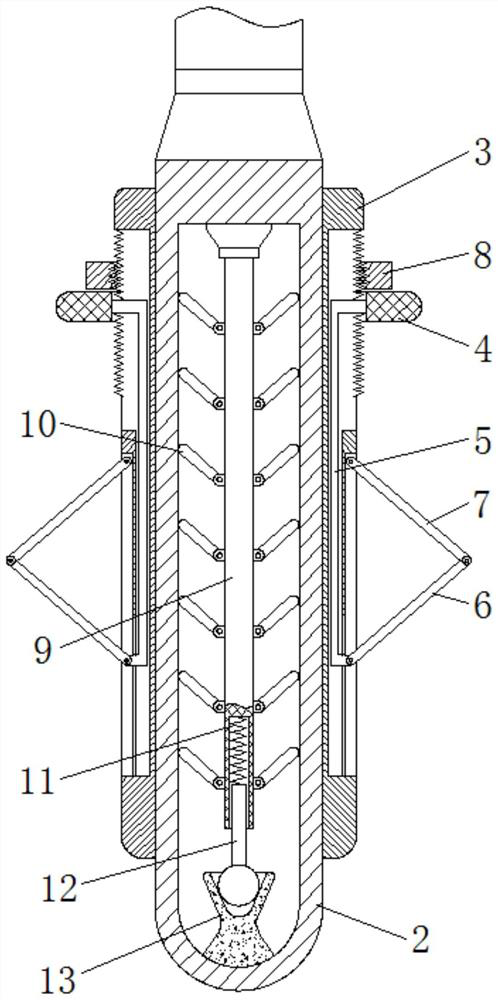

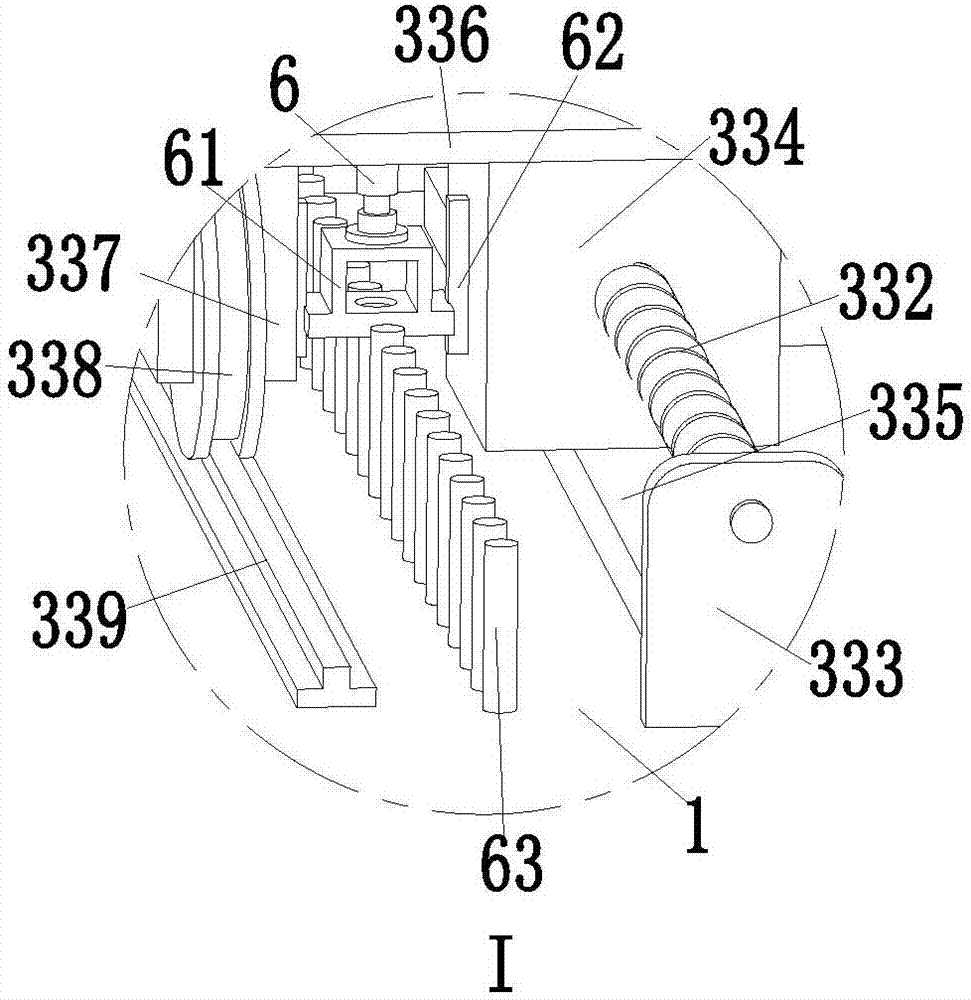

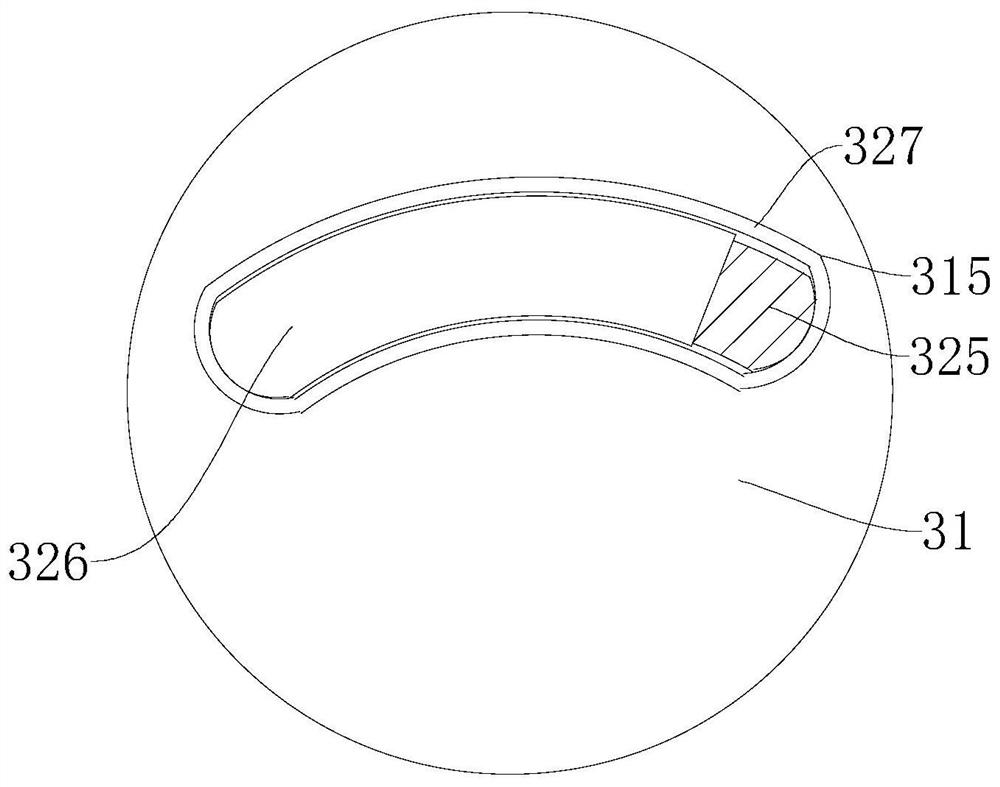

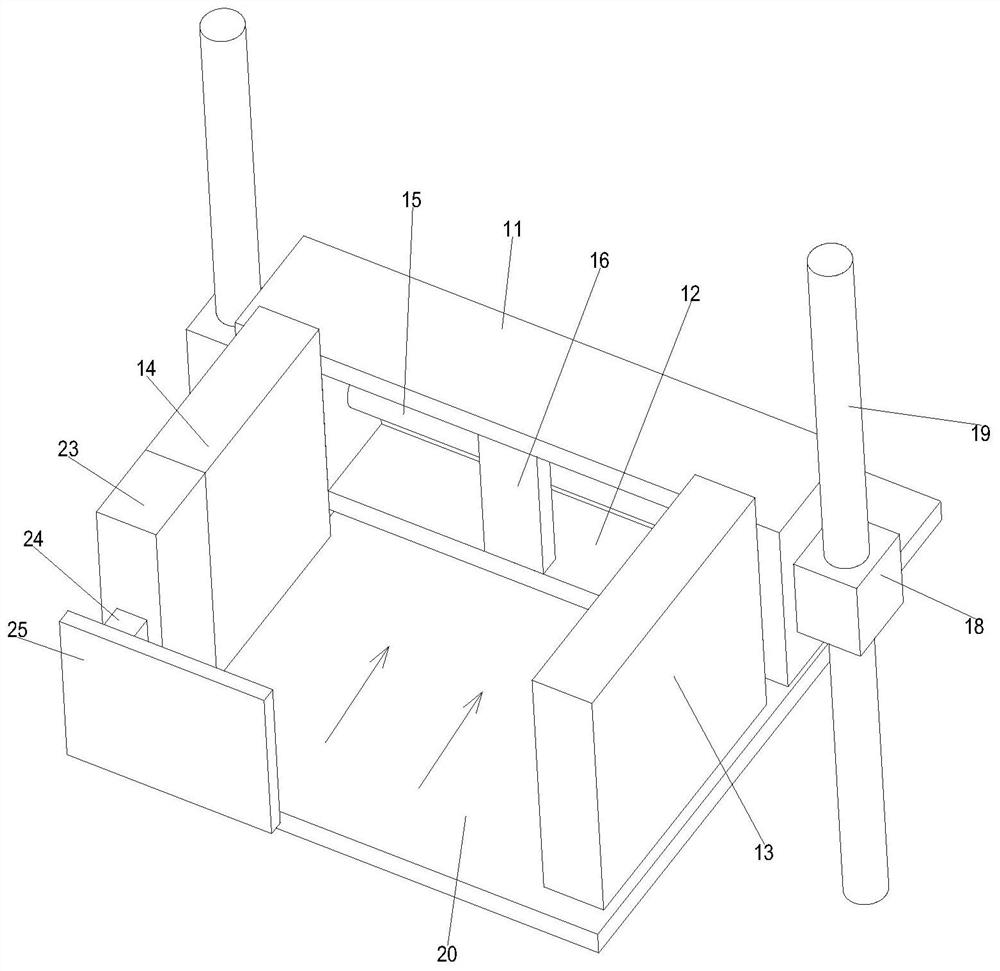

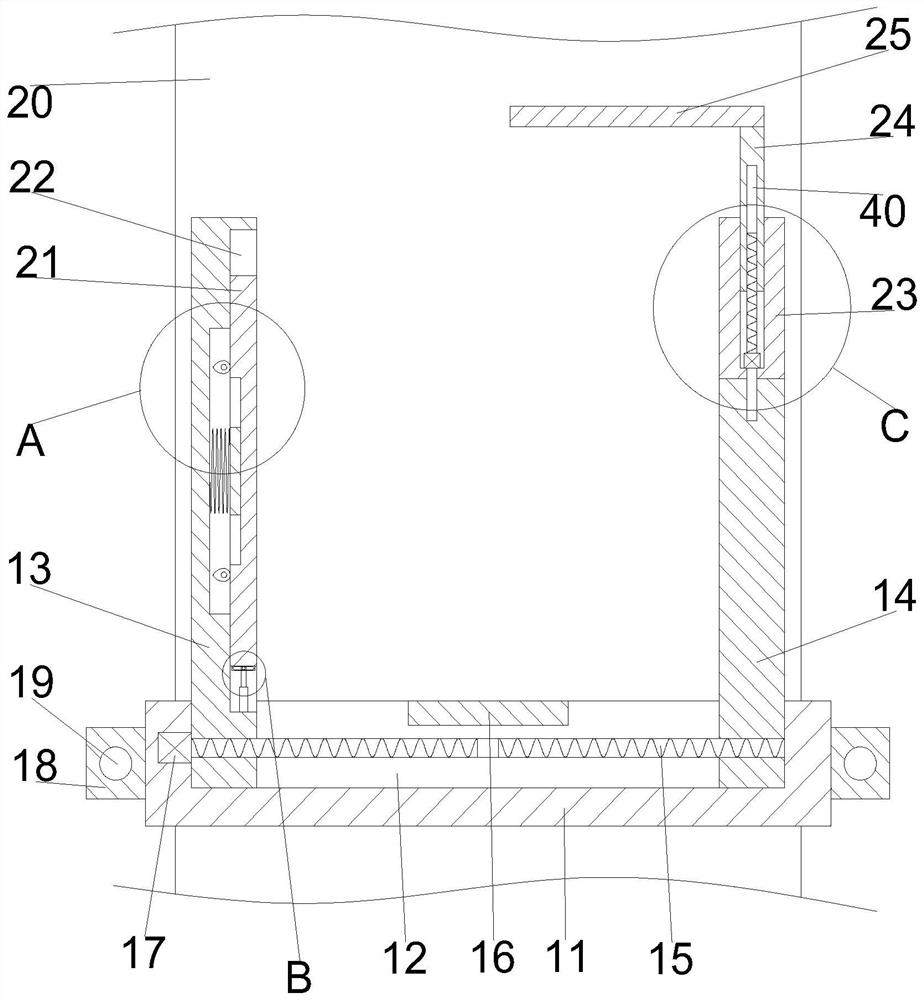

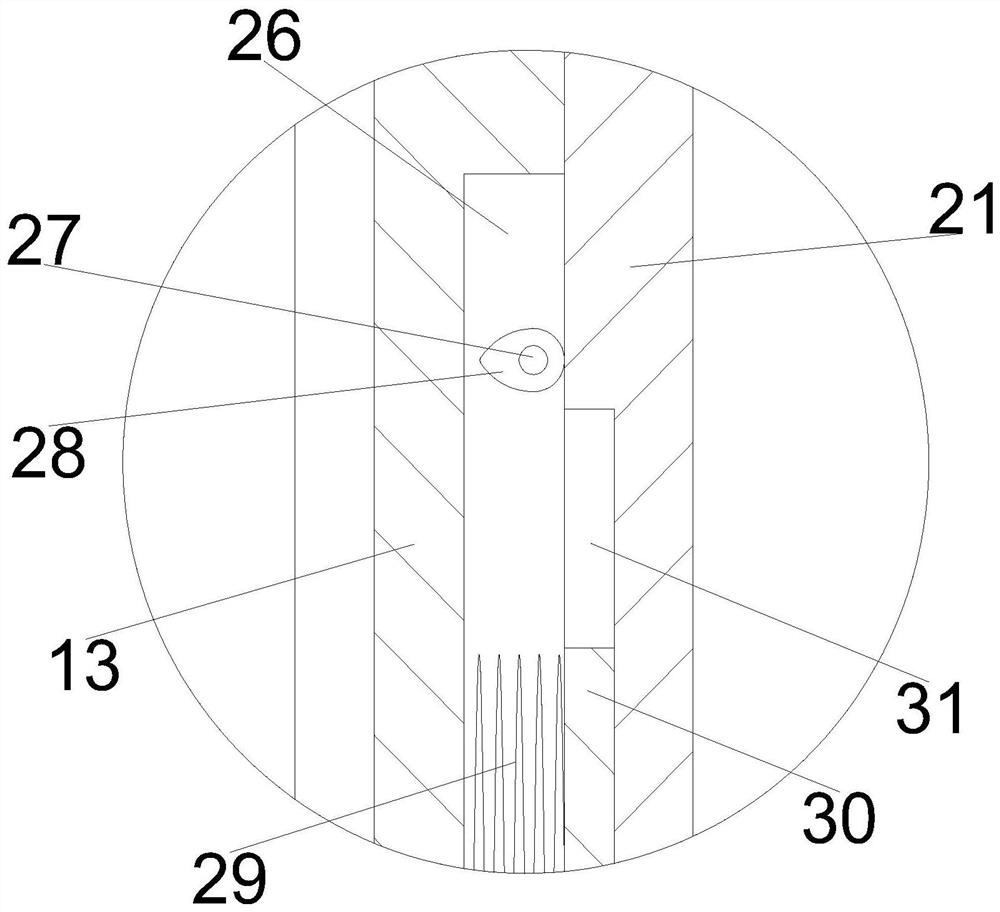

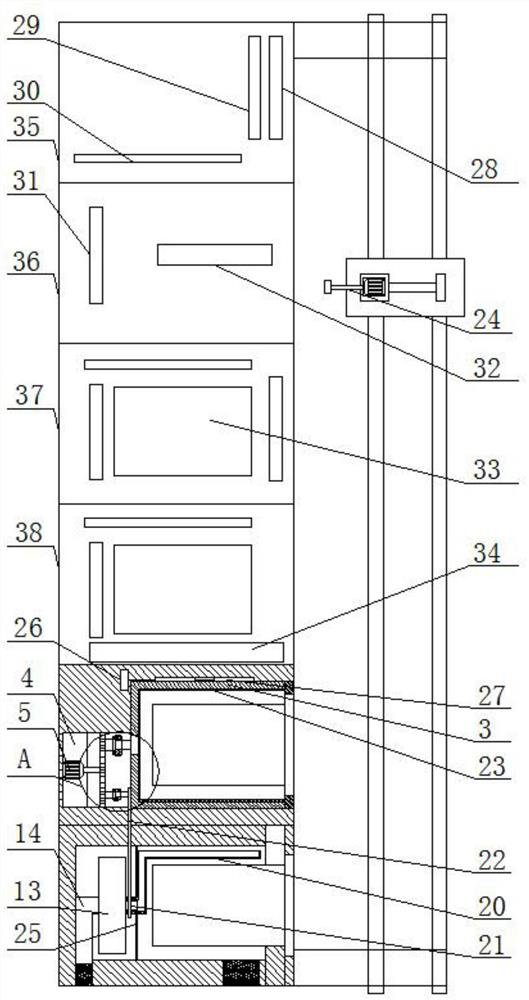

Reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine

InactiveCN107815972AStable jobThere is no security riskBridge erection/assemblyBridge materialsReinforced concreteEngineering

The invention relates to a reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine comprises a base plate, wherein two pairs of movable regulating tanks are formed in the base plate, the two pairs of movable regulating tanks are symmetrically formed in the left side and the right side of the base plate, a movable regulating device is arranged in each pair of movable regulating tanks, a perfusion device is arranged at the front end of the base plate, a vibrating and compacting device is arranged at the rear end of the base plate, the perfusion device comprises a perfusion storage tank arranged on the base plate by virtue of a perfusion supporting frame, a discharging hole is formed in the lower side of the front end of the perfusion storage tank, and a perfusion regulating mechanism is arranged at the front end of the base plate. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine provided by the invention can be used for solving the problems that concrete needs to be manually conveyed by virtue of existing movable equipment in an existing wet joint concrete pouring process, the poured concrete needs to be vibrated and compacted manually by virtue of existing vibrating equipment, a reinforcement cage needs to be avoided in a wet joint concrete pouring and vibrating process and the concrete can not be comprehensively vibrated by virtue of manpower.

Owner:吴秋敏

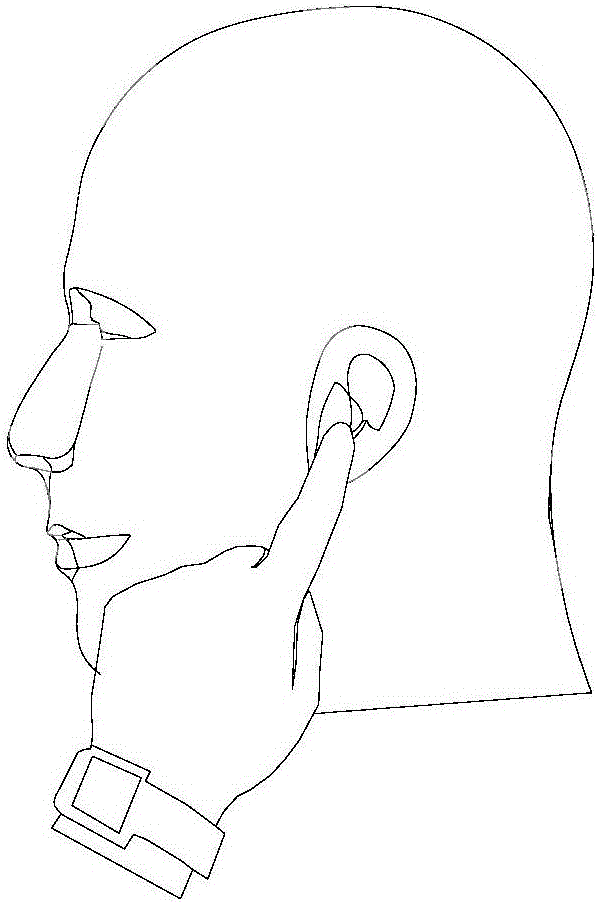

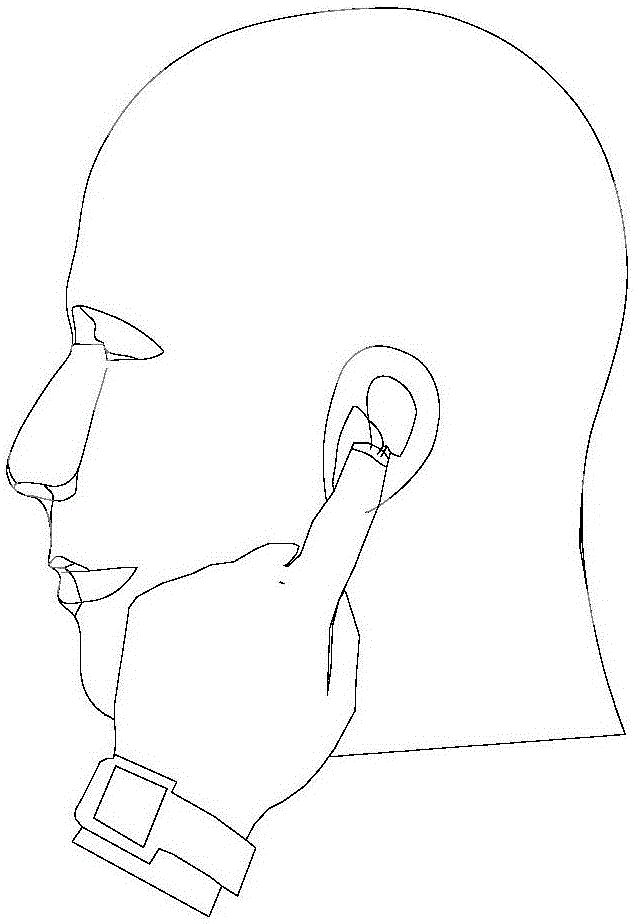

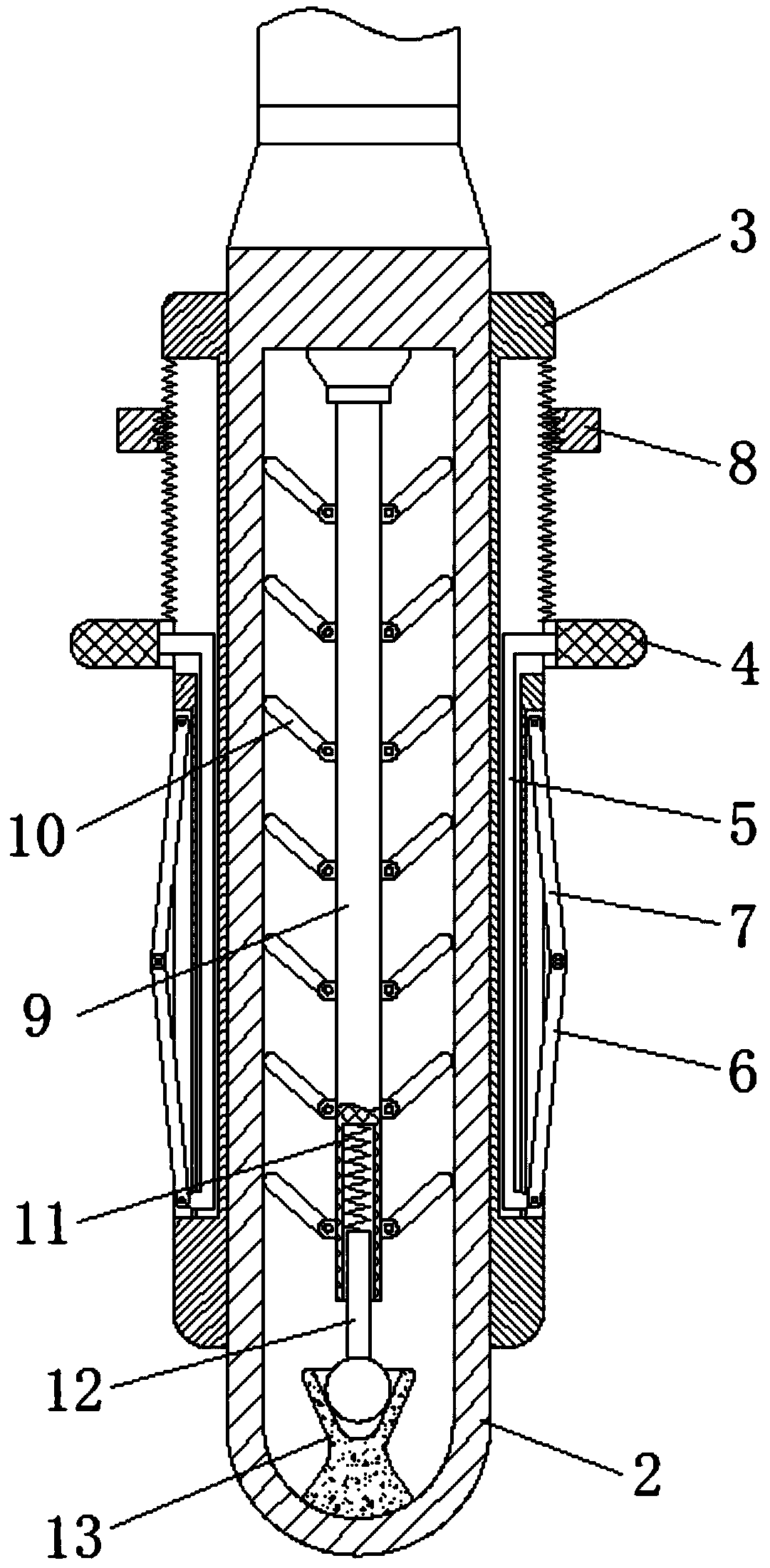

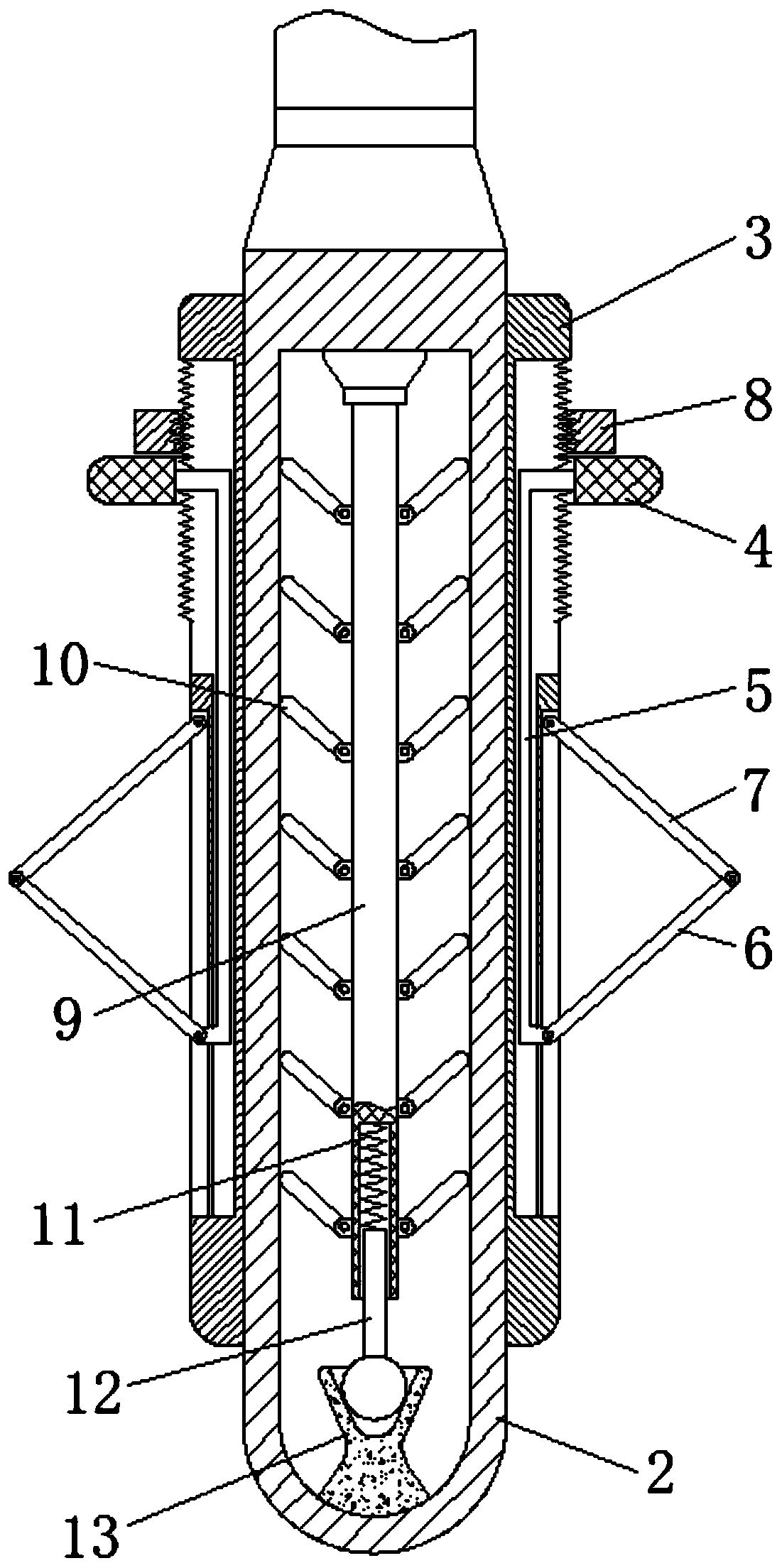

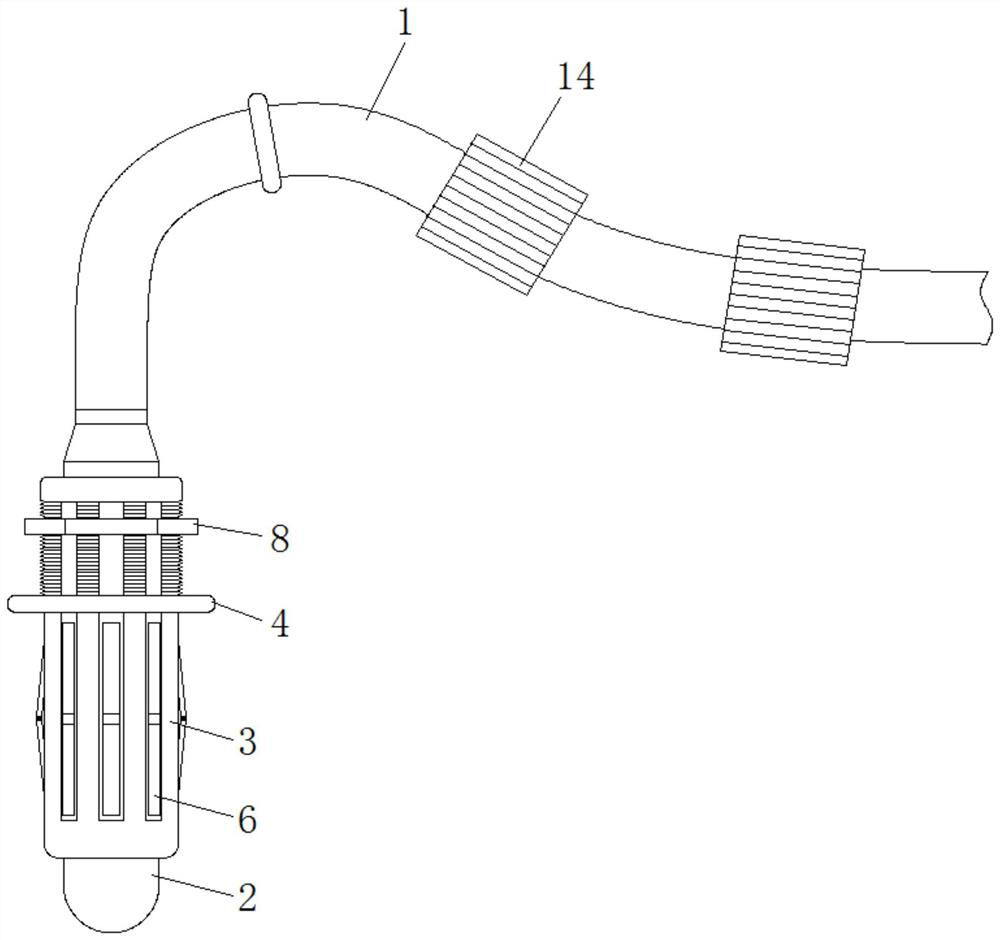

Medium-distance bone conduction driver

InactiveCN104994457AReduce vibrating massIncrease the vibration areaElectrical transducersEngineeringBone conduction hearing

The invention relates to the field of a sounder and specifically discloses a medium-distance bone conduction driver, comprising a suspension system, a vibration system, a magnetic bowl, a back cover, a mild contactor, a first voice coil, a second voice coil and a magnetic conductive bracket, wherein the suspension system is fixedly connected with the upper surface of the magnetic conductive bracket; the mild contactor is stuck with the upper part of the magnetic conductive bracket; the magnetic bowl is ring-shaped and is used for surrounding the vibration system; the lower surface of the magnetic bowl is fixedly connected with the back cover; the upper surface of the magnetic bowl is fixedly connected with the suspension system; the first voice coil and the second voice coil are fixed on the upper surface of the back cover. Double magnetic circuits are used to drive the vibration system to work, and the suspension system is used to match with the work, so the amplitude is larger and the driving force is larger. The medium-distance bone conduction driver is more suitable for transmitting medium-distance bones, and the driving force is twice as that of a single driver.

Owner:BESTAR HLDG

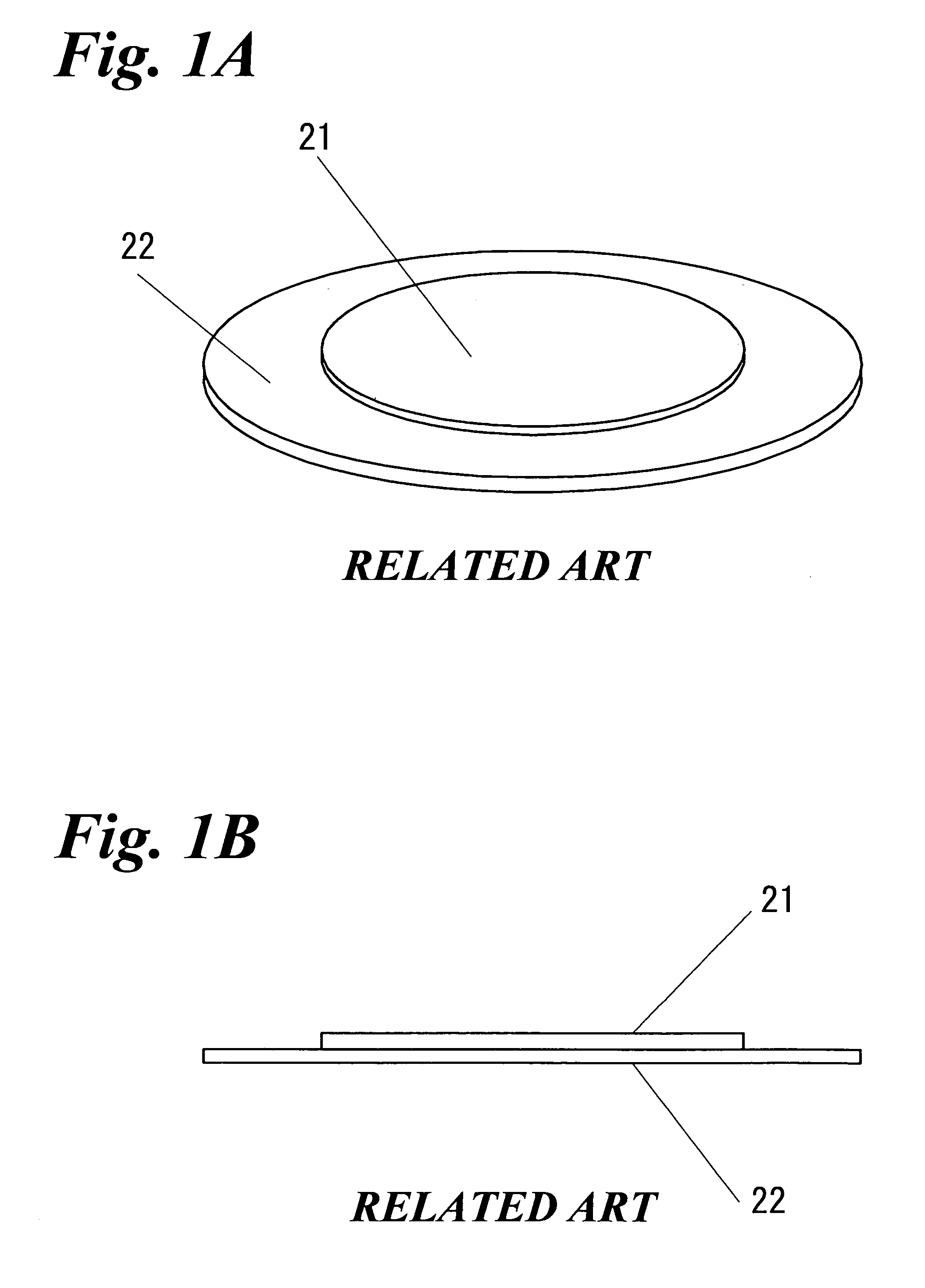

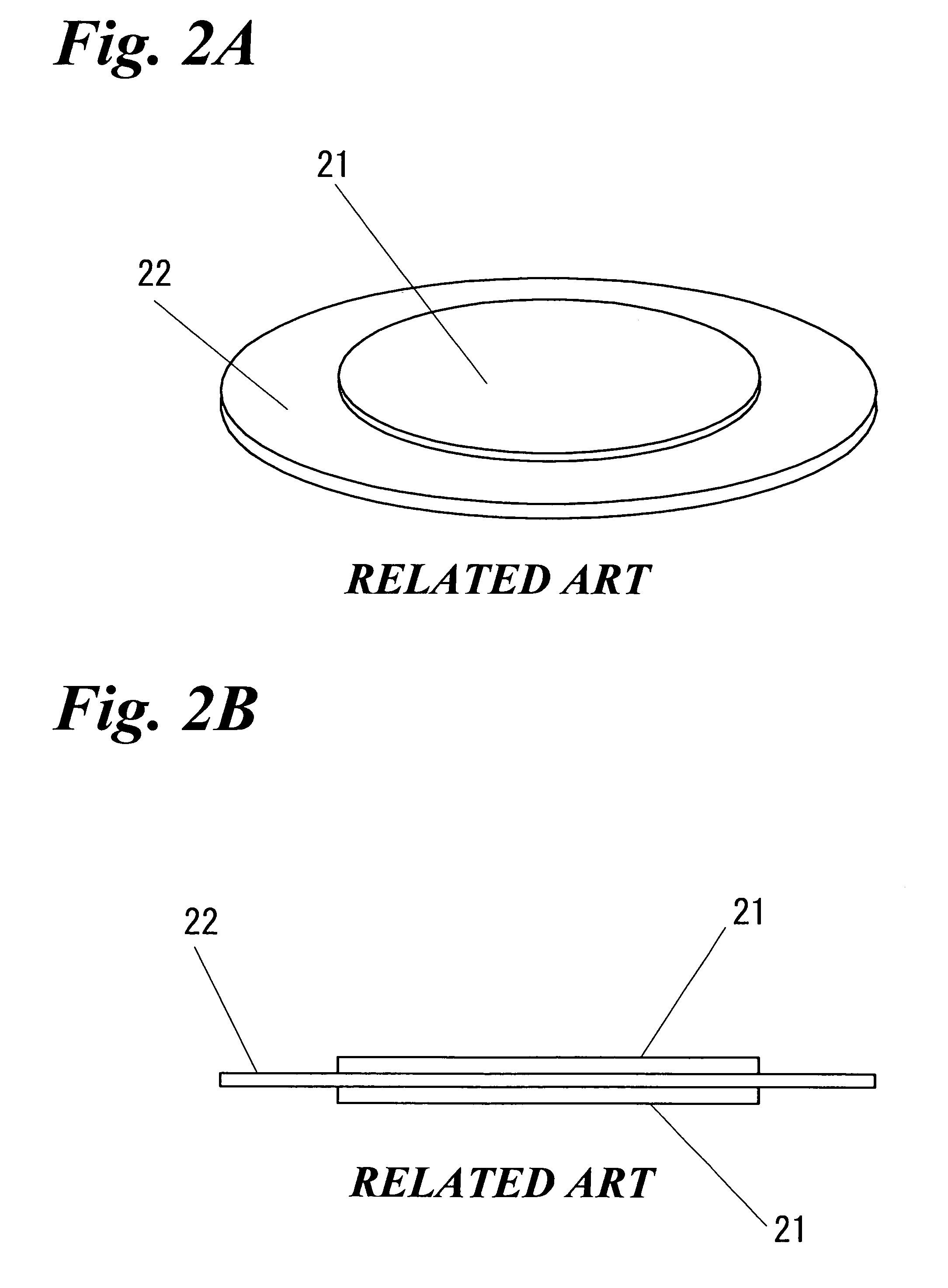

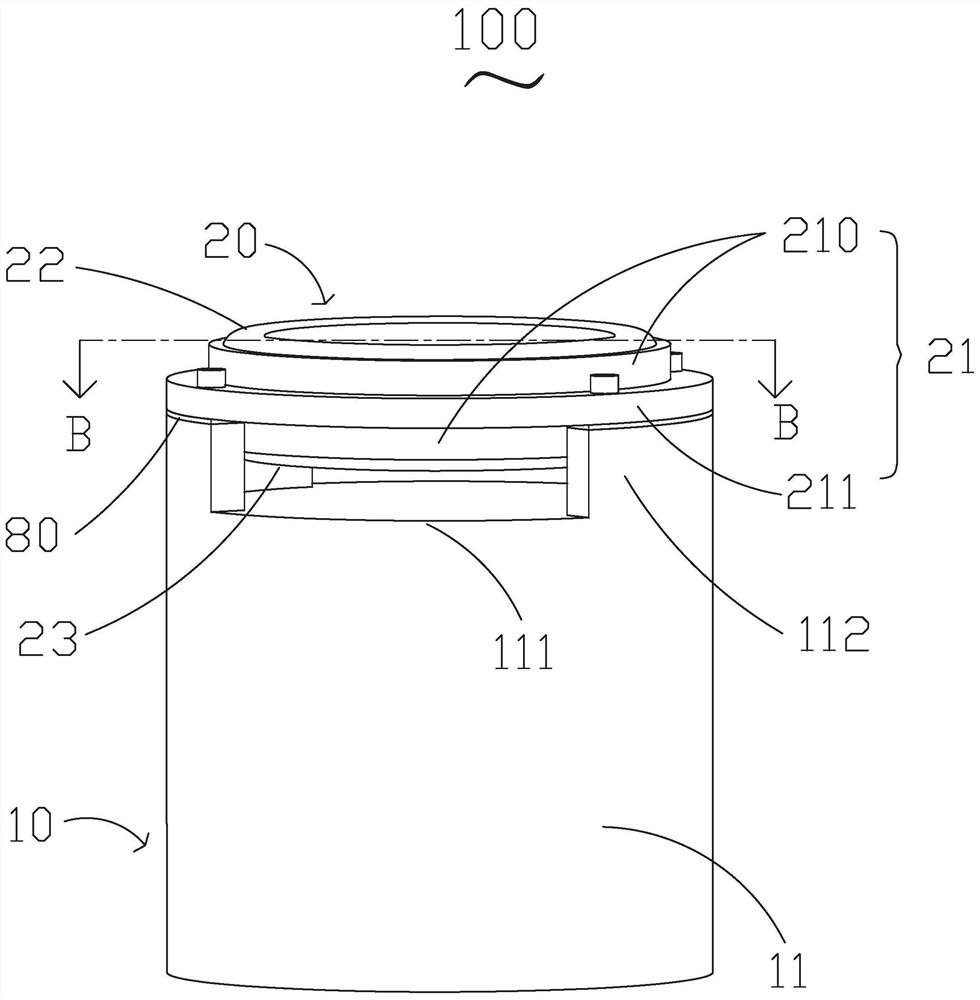

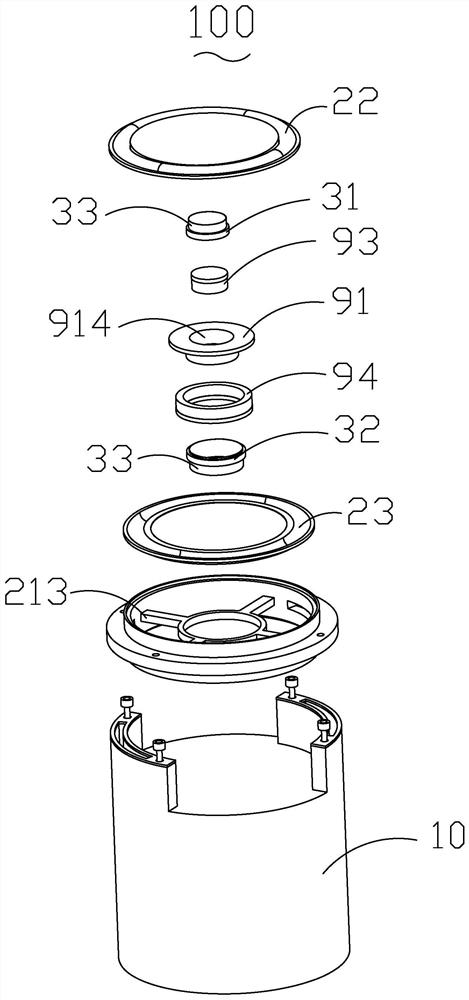

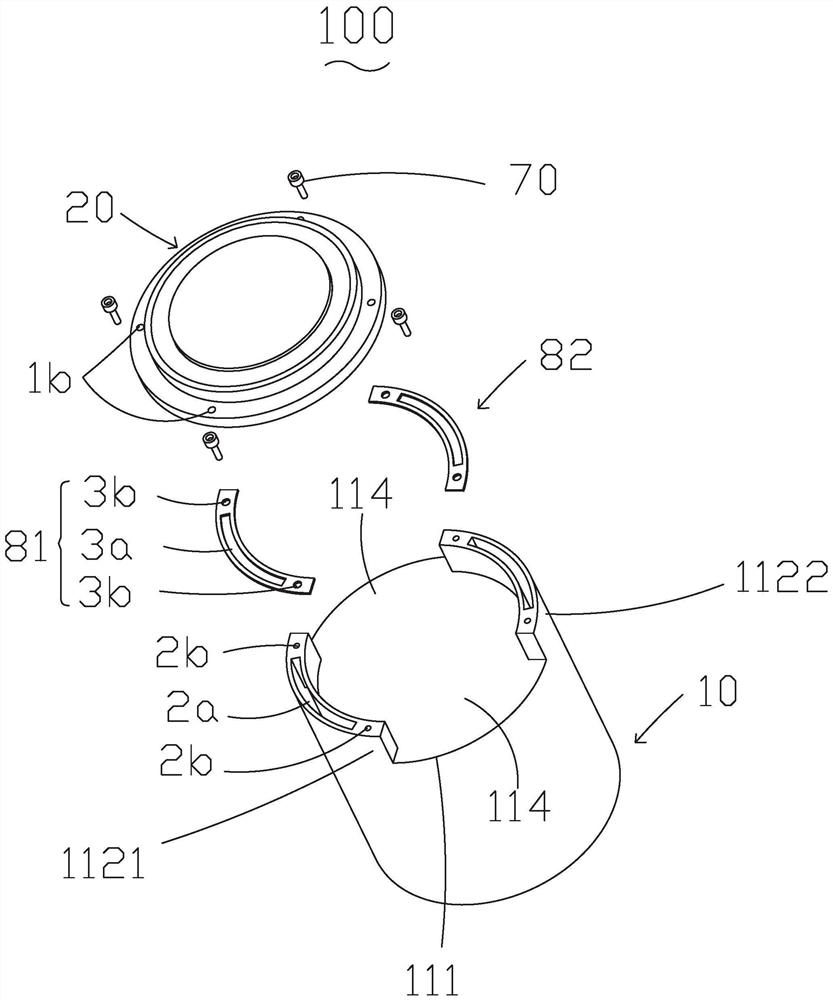

Dual base of an electret condenser microphone and electret condenser microphone using the same

InactiveUS20060256984A1Improve acoustic propertiesImprove performanceMicrophonesLoudspeakersEngineeringCondenser microphone

The present invention describes an electret condenser microphone having a dual base structure wherein a metal ring and an insulation ring are bonded. The electret condenser microphone includes a metal ring having a shape of a spool wherein a center portion is concaved and end portions extrude, an insulation ring surrounding the center portion and extruding with respect to the extruding end portions of the metal ring to form an insulation space between a casing and the metal ring.

Owner:BSE CO LTD

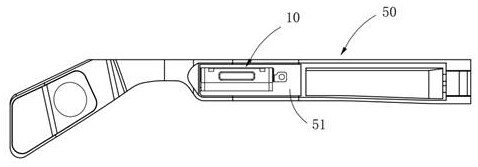

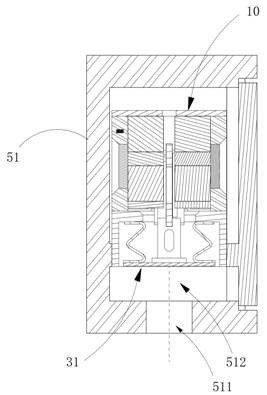

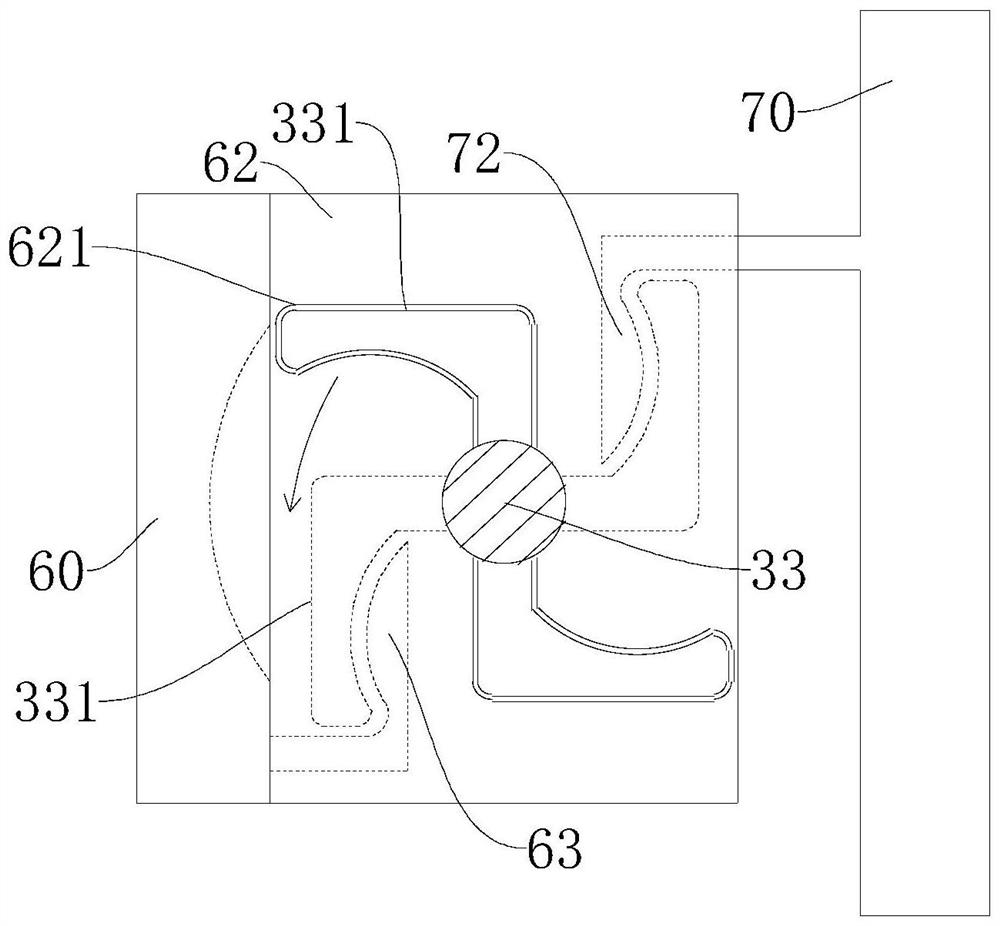

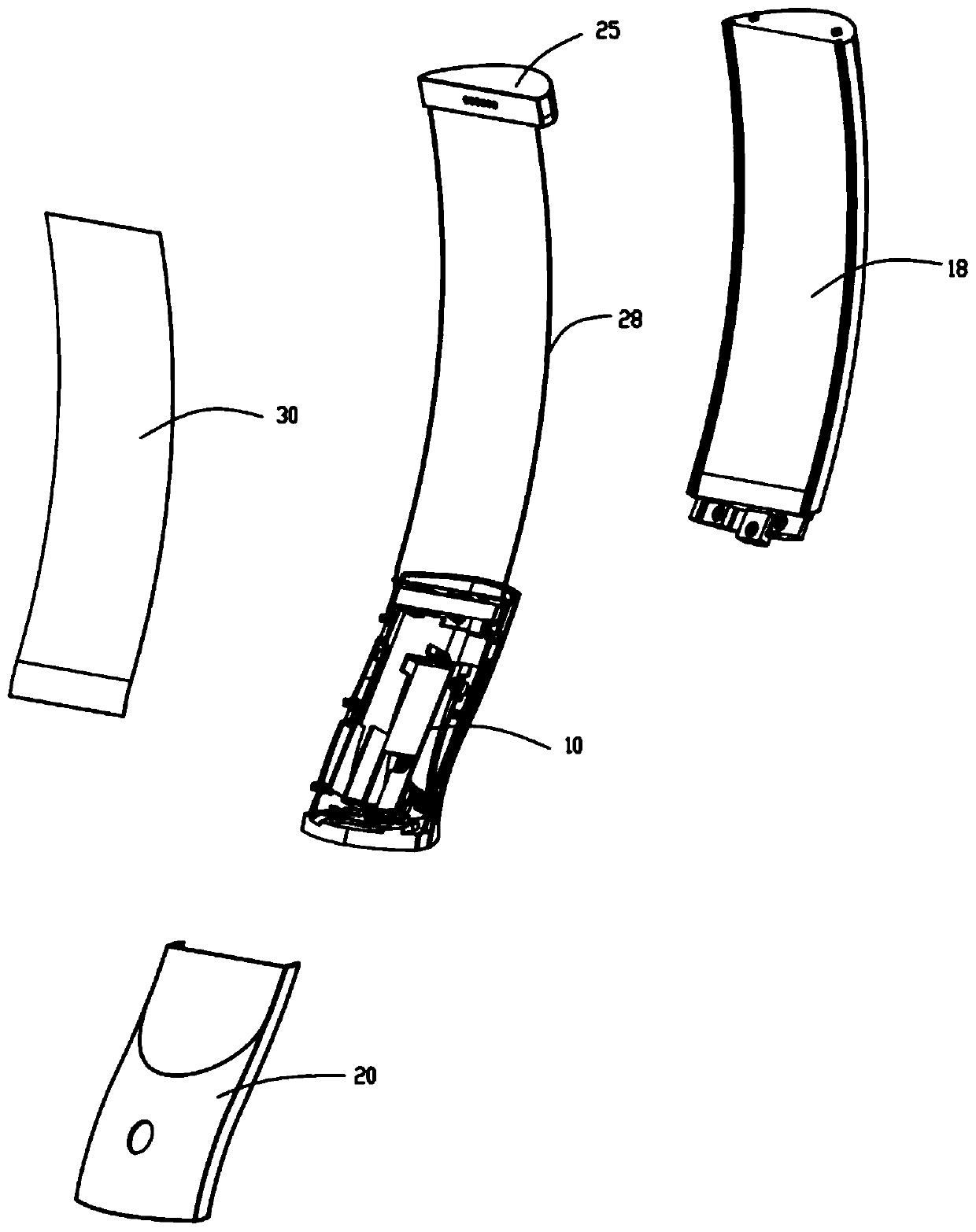

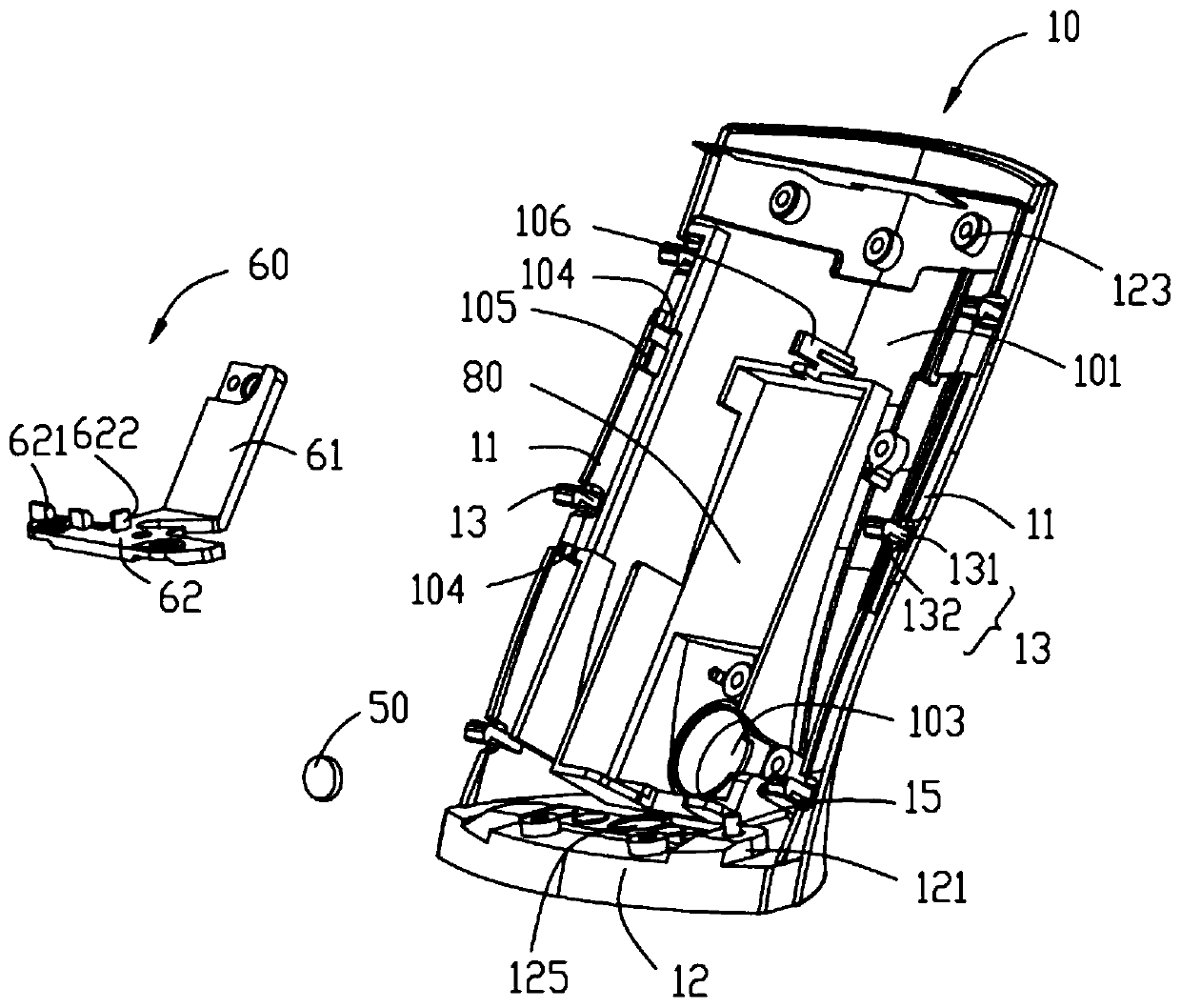

Sound production device and wearable equipment

ActiveCN111970617AReduce widthIncrease the vibration areaNon-planar diaphragms/conesSound productionVoice coil

The invention discloses a sound production device and wearable equipment. The sound production device comprises a vibration system and a magnetic circuit system, the vibration system comprises a flatvoice coil. The magnetic circuit system comprises a magnet assembly and a magnetic conduction assembly. The voice coil is inserted into a magnetic gap formed by the magnetic circuit system. The magnetization direction of the magnet assembly and the vibration direction of the voice coil are parallel to the vertical direction of the sound production device. The magnet assembly comprises an upper magnet unit and a lower magnet unit, the magnetic conductive assembly comprises a first magnetic conductive plate and a second magnetic conductive plate which are arranged corresponding to the long axisof the voice coil, the first magnetic conductive plate is located between the upper magnet unit and the lower magnet unit, and the second magnetic conductive plate is located at the end, away from thefirst magnetic conductive plate, of the upper magnet unit. According to the sound production device, the space is saved, the vibration area of the dome piece can be increased through the vertically-arranged folding ring piece, and the acoustic performance of the sound production device is improved.

Owner:GOERTEK INC

Anti-blocking and flying-dust-free type cement transfer tank for highway construction site

PendingCN108945849APlay the role of cushioning and shock absorptionAvoid damageLarge containersTank truckWaste management

The invention discloses an anti-blocking and flying-dust-free type cement transfer tank for a highway construction site. The cement transfer tank comprises a container which is in a cuboid shape, a tank body is arranged in the container, a discharging opening extending out of the bottom of the container is formed in the lower end of the tank body, a discharging valve is arranged at the dischargingopening, the top of the container is provided with a top cover used for sealing the tank body, a feeding hole and a feeding exhausting device are arranged on the top cover, an automatic feeding sealing device is arranged at the feeding hole, a discharging pressurizing mechanism is arranged on the upper side part of the container, and a knocking anti-discharging-blocking device is arranged betweenthe bottom of the container and the outer side of a conical structure of the tank body. The cement transfer tank has the advantages that the structural design is reasonable, feeding and discharging are convenient and rapid, good sealing performance is achieved, moreover, vibration unblocking can be achieved when blockage occurs in the tank body, cement powder conveyed by a cement tank truck can be directly discharged into the tank body of the cement transfer tank, so that the cement tank truck is liberated, then the cement tank truck can transport cement for a plurality of times, the cement transfer tank can be placed on the construction site and can also be placed on an engineering transport vehicle.

Owner:河南省交通建设工程有限公司

Method for improving modulation tone and sound volume of Zeng-(a2l-or 25-stringed plucked instrument)

InactiveCN1811902AImprove sound transmissionIncrease the vibration areaStringed musical instrumentsEngineeringOrbit

This invention relates to a method for improving tone color and volume of inflexion zither characterizing that a frame is added between the inflexion orbits and a tone plate, both ends of the frame cross over the wood grain direction and are fixed on the plate while the middle is hung in the air, the inflexion orbits of strings are fixed on the frame to make up of codes of the instrument and the height of the device should be lower than that of the middle code or the two mountains at both sides, in which, the inflexion orbits do not contact with the plate directly after adding a frame between them, thus the sound is spread more elastically.

Owner:潘仲文

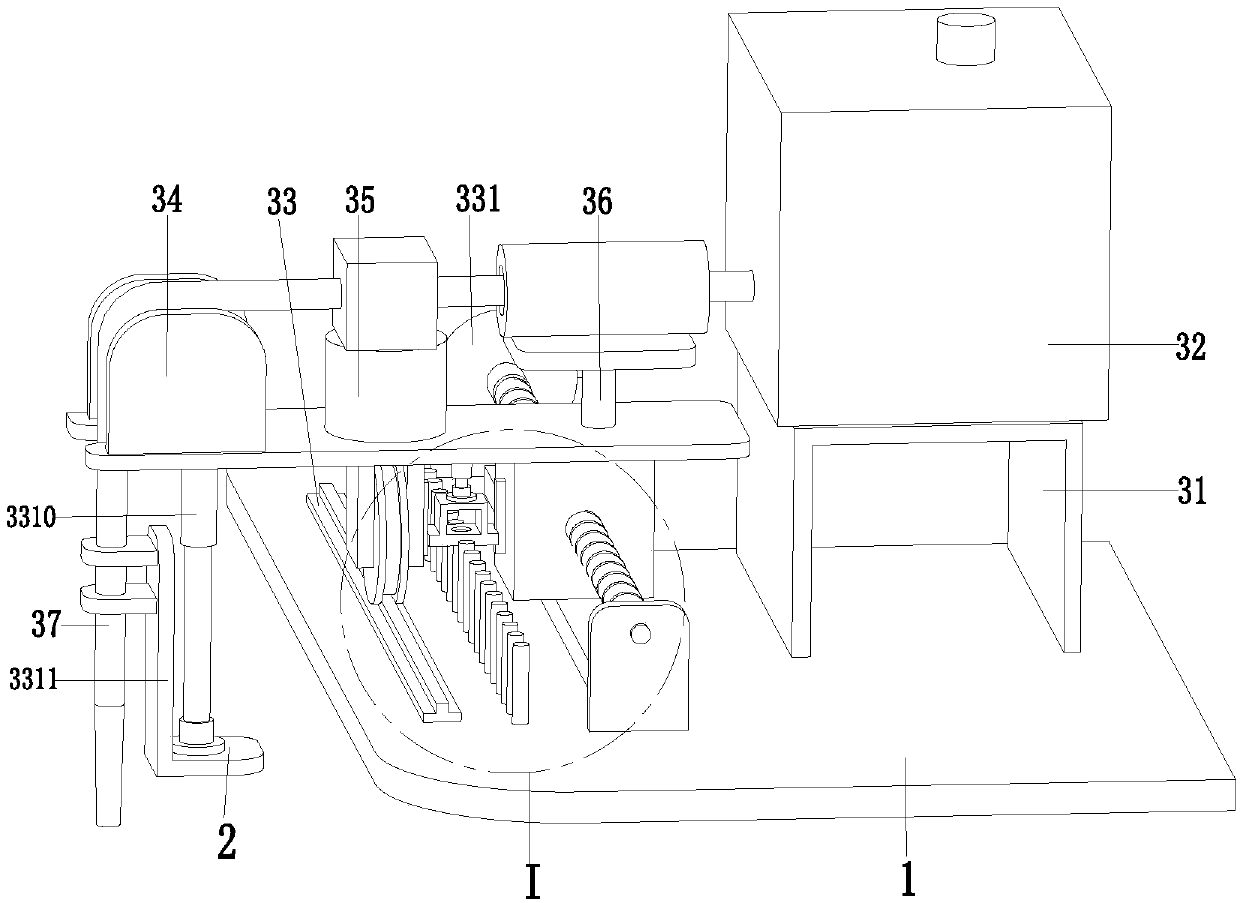

Bridge wet joint cast-in-place concrete automatic vibration compacting device

InactiveCN107964879AImprove work efficiencyThere is no security riskBridge erection/assemblyStructural engineering

Owner:吴丹

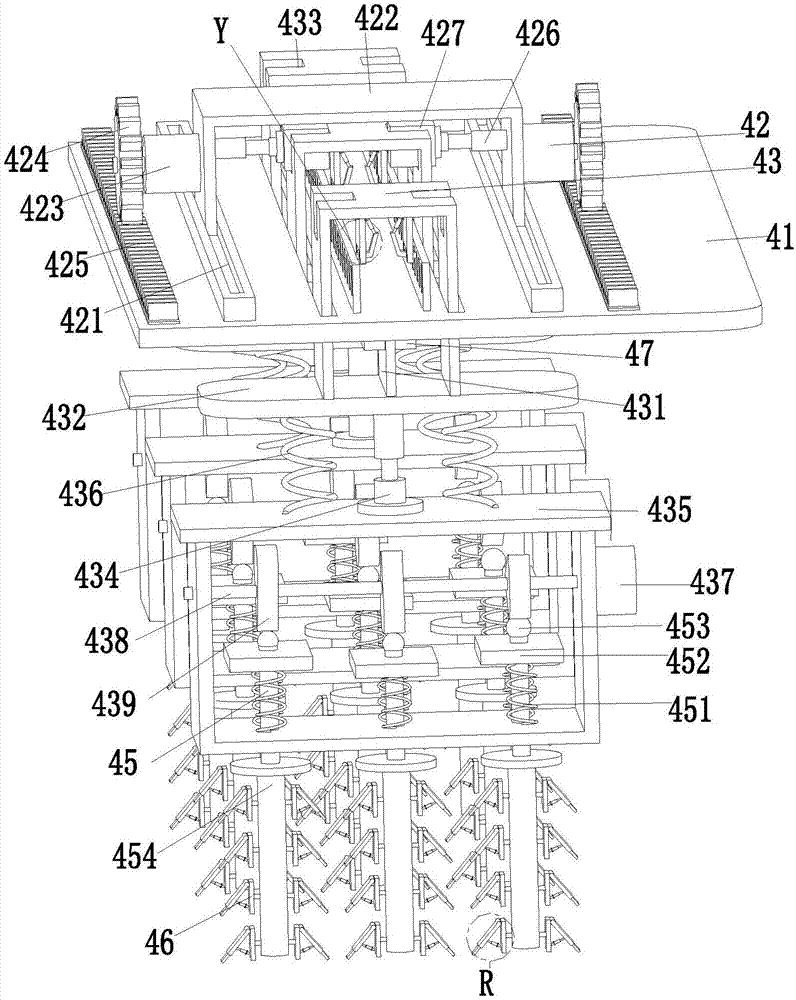

Movable concrete mechanical vibrating device

InactiveCN112252731AVibrate a wide rangeIncrease the vibration areaBuilding material handlingElectric machineryStructural engineering

The invention belongs to the technical field of concrete vibration, and particularly relates to a movable concrete mechanical vibrating device. Aiming at the problems that when concrete is vibrated, adevice needs to be continuously pushed manually to move, and manpower is consumed, the following scheme is proposed, the movable concrete mechanical vibrating device comprises a top plate, two firstmounting blocks which are symmetrically distributed are fixed to the outer wall of the bottom of the top plate, first rectangular grooves are formed in the outer wall of the bottom of the first mounting blocks, first sliding rails are fixed to the inner walls of the left sides and the right sides of the first rectangular grooves, sliding blocks are slidably connected to the inner walls of the first sliding rails, and first movable plates are fixed to the outer walls of the bottoms of the sliding blocks. Through the arrangement of a third motor, a rotating disc, a connecting rod, a mounting sleeve and a fixing plate, an output shaft of the third motor drives the rotating disc to rotate so as to drive the upper end of the connecting rod to do circular motion, the lower end of the connectingrod drives the mounting sleeve to move up and down, so that a vibrating rod continuously moves up and down in concrete, the honeycomb pitted surfaces with different depths of the concrete are vibratedand compacted, the vibrating efficiency is high, and manpower is saved.

Owner:曾祥瑞

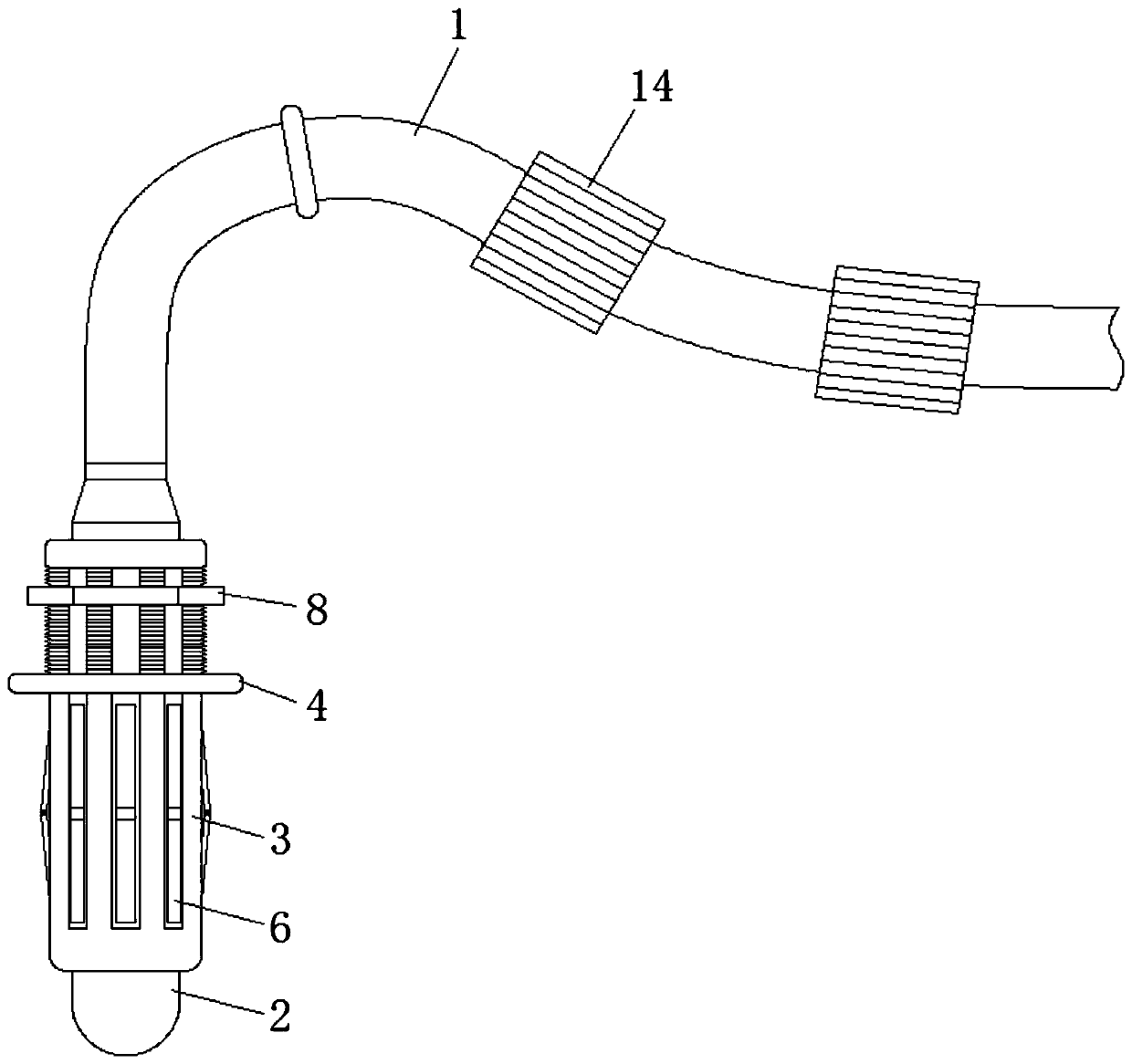

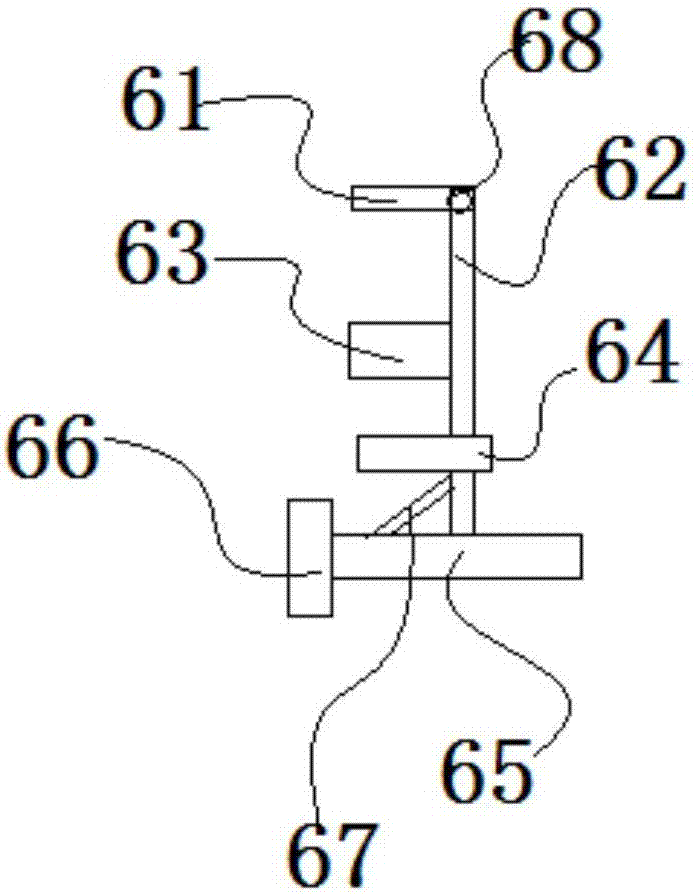

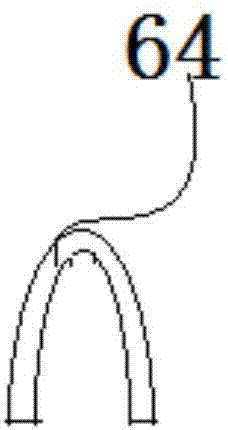

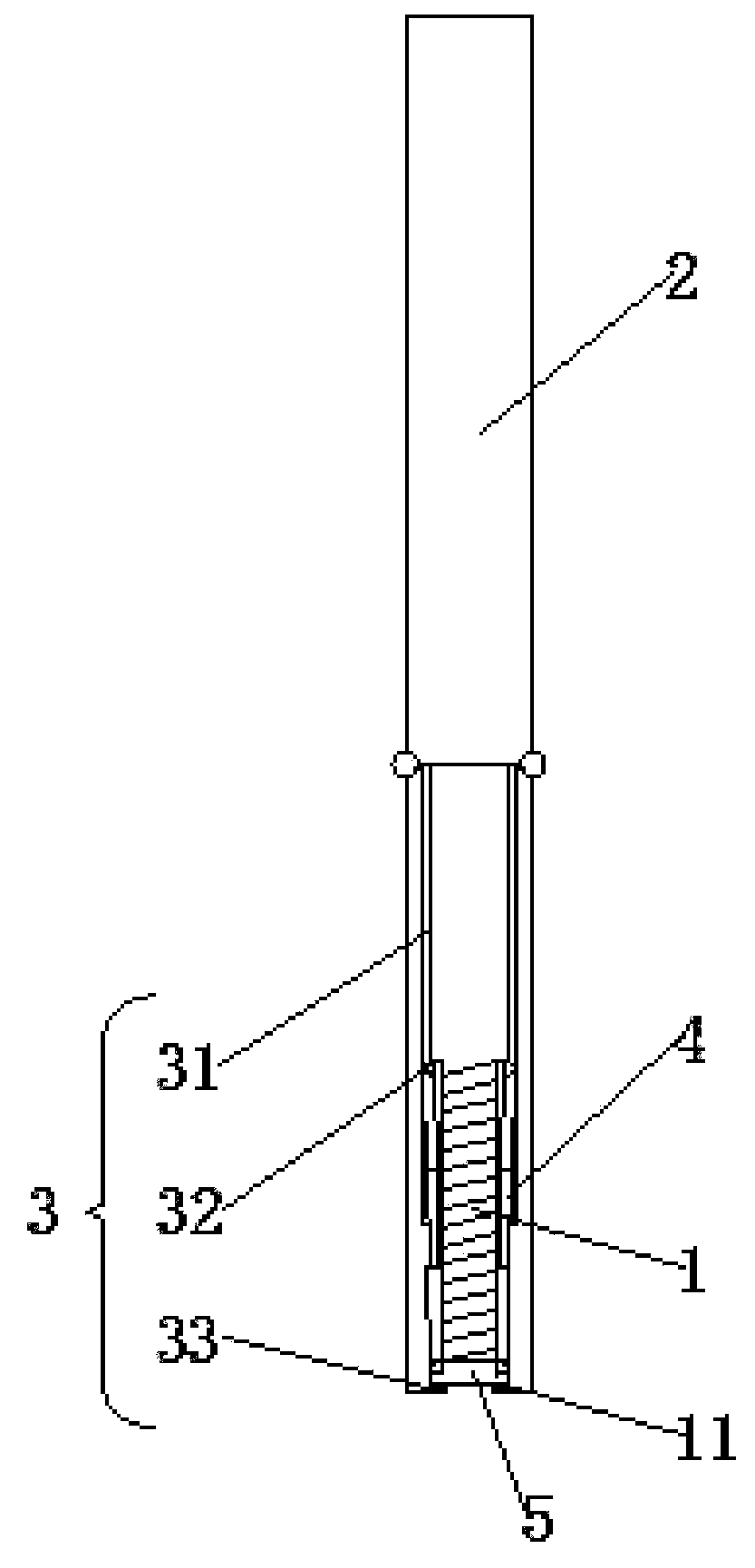

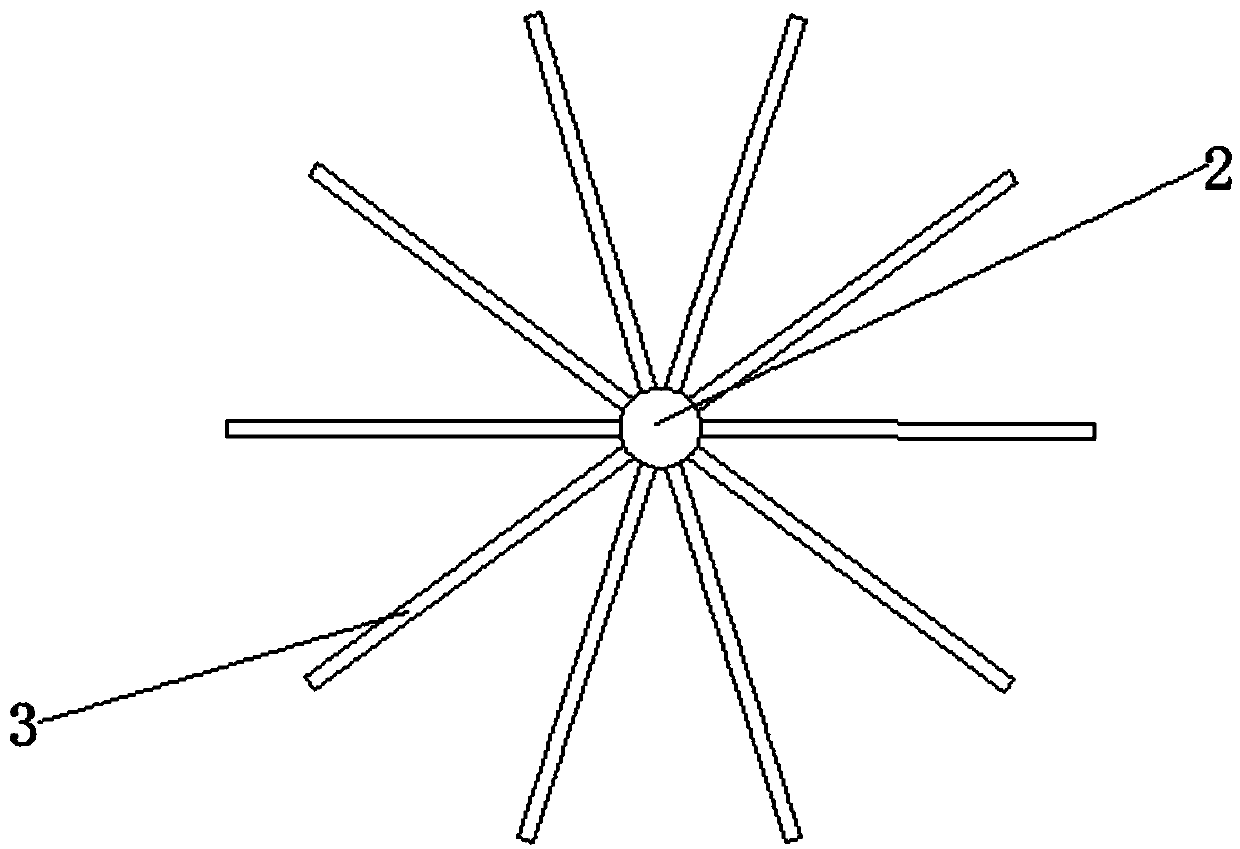

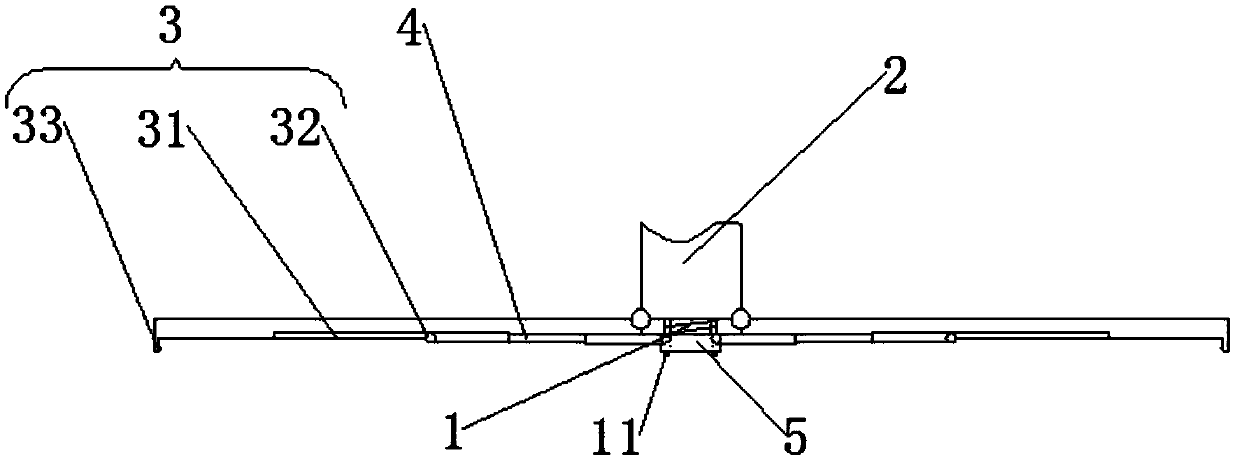

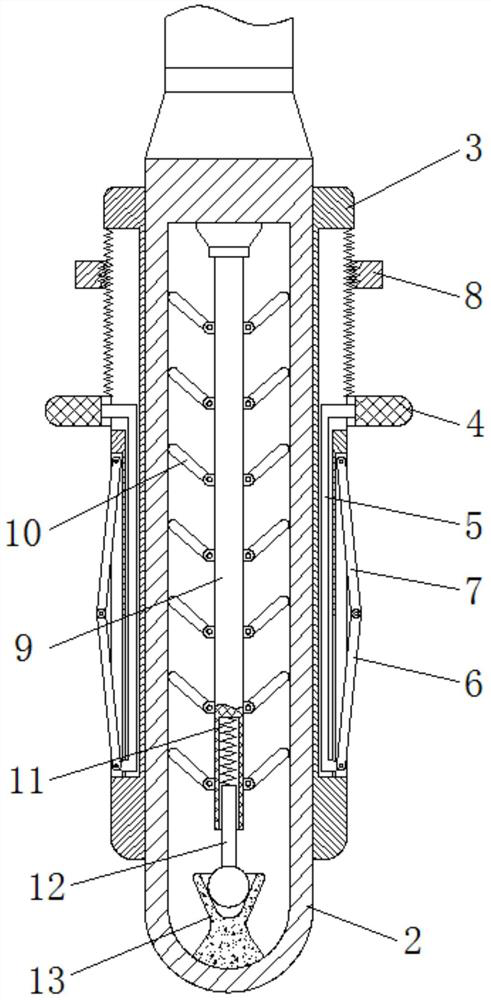

High-efficiency concrete vibrating bar folding and stretching based on reactive force

InactiveCN111364772AImprove work efficiencyIncrease the vibration areaBuilding material handlingClassical mechanicsEngineering

The invention provides a high-efficiency concrete vibrating bar folding and stretching based on reactive force, and relates to the technical field of concrete leveling. The high-efficiency concrete vibrating bar folding and stretching based on the reactive force comprises a hose, wherein one end of the hose is in threaded connection with a steel pipe bar; a sleeve is fixedly installed at the periphery of the steel pipe bar; a sliding plate is slidably connected at the periphery of the sleeve; a lifting rod is fixedly installed at the inner side of the sliding plate; lower folding rods are rotatably connected to the outer side of the bottom end of the lifting rod; and upper folding rods are rotatably connected to the other ends of the lower folding rods. According to the high-efficiency concrete vibrating bar folding and stretching based on the reactive force, the acting area of the vibrating bar is increased while the steel pipe bar is not prevented from extending into a steel bar support, so that the working efficiency of the vibrating bar is improved, and the extending length of the steel pipe bar is adjusted; and the vibration of the hose is buffered, so that the stimulation tohands is relieved, and the working strength is reduced.

Owner:南京旭浦建材科技有限公司

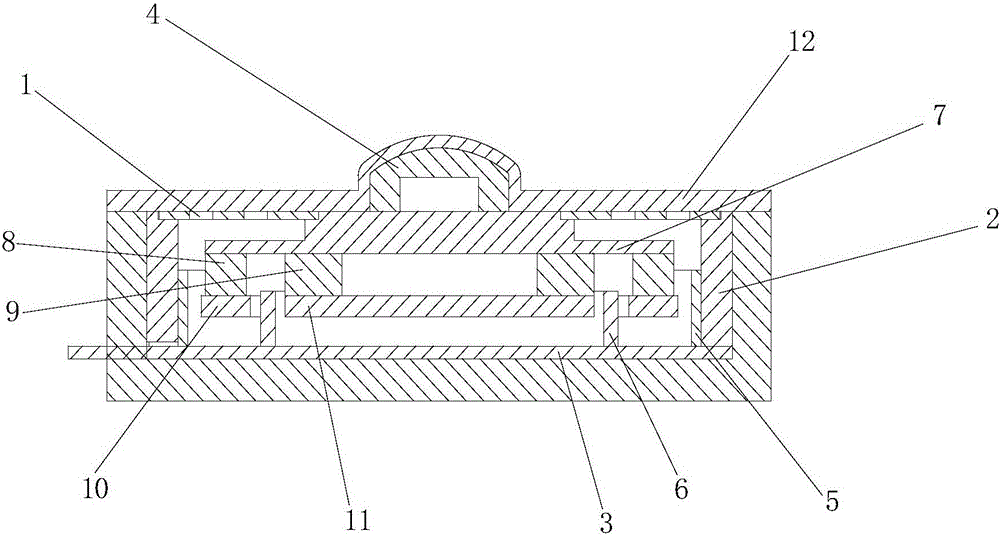

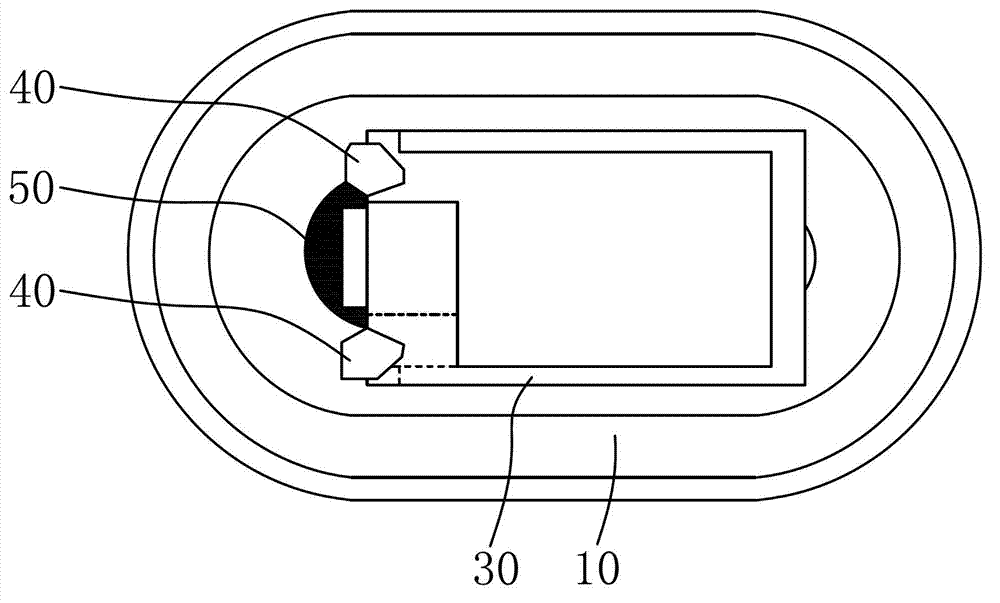

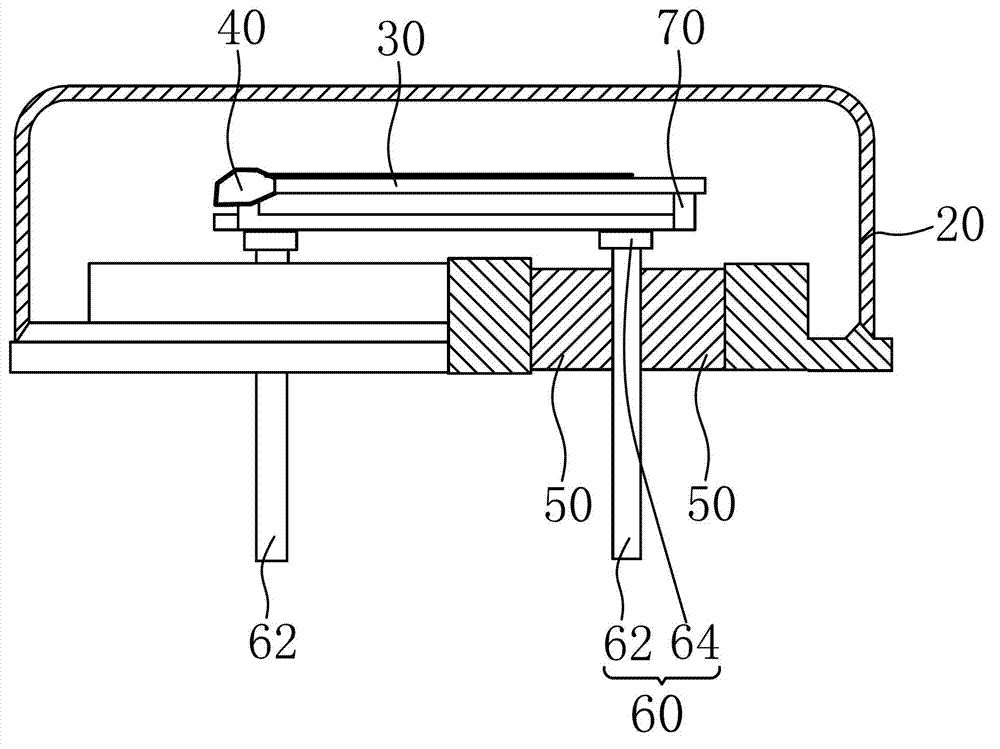

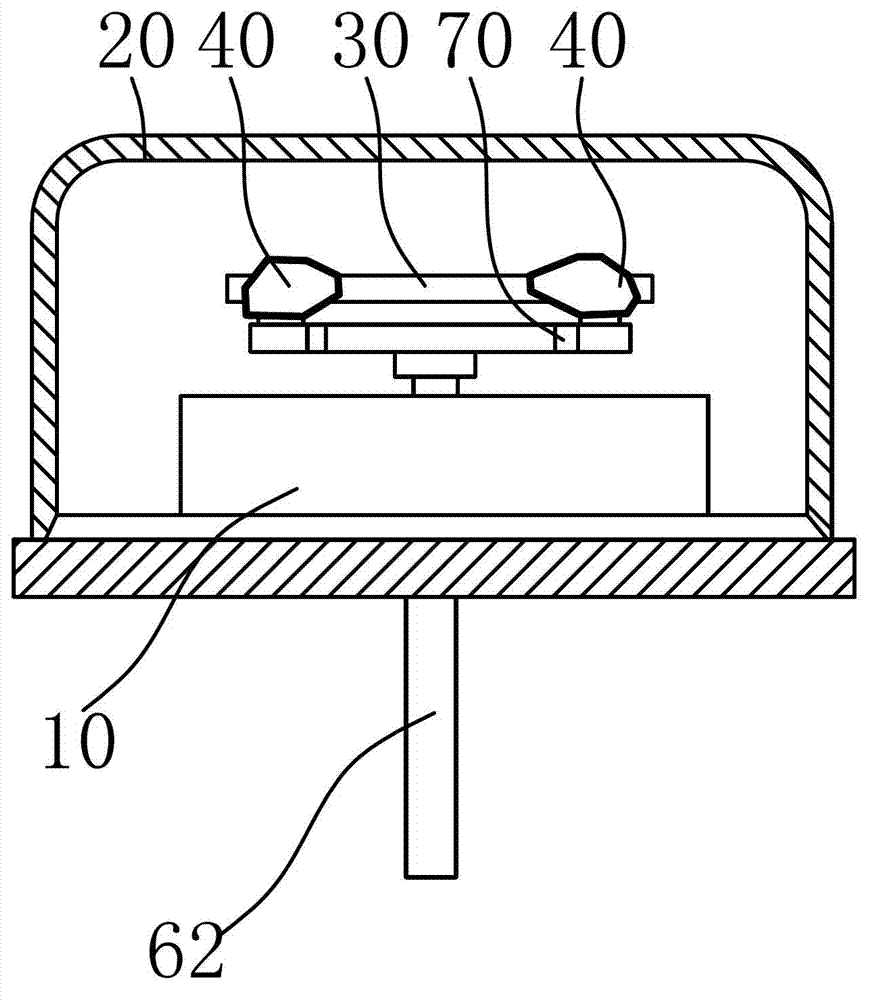

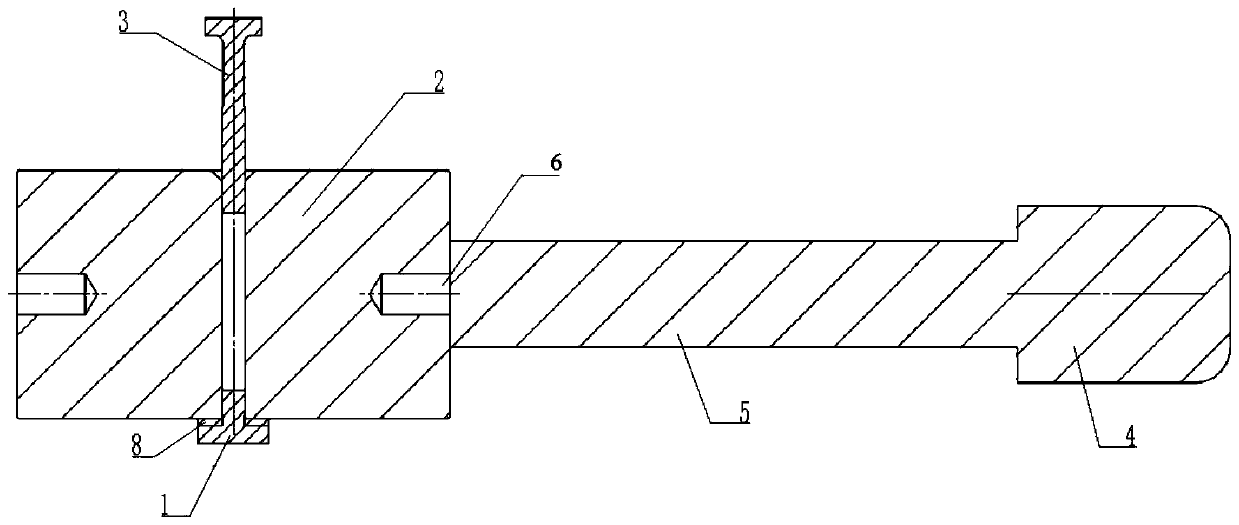

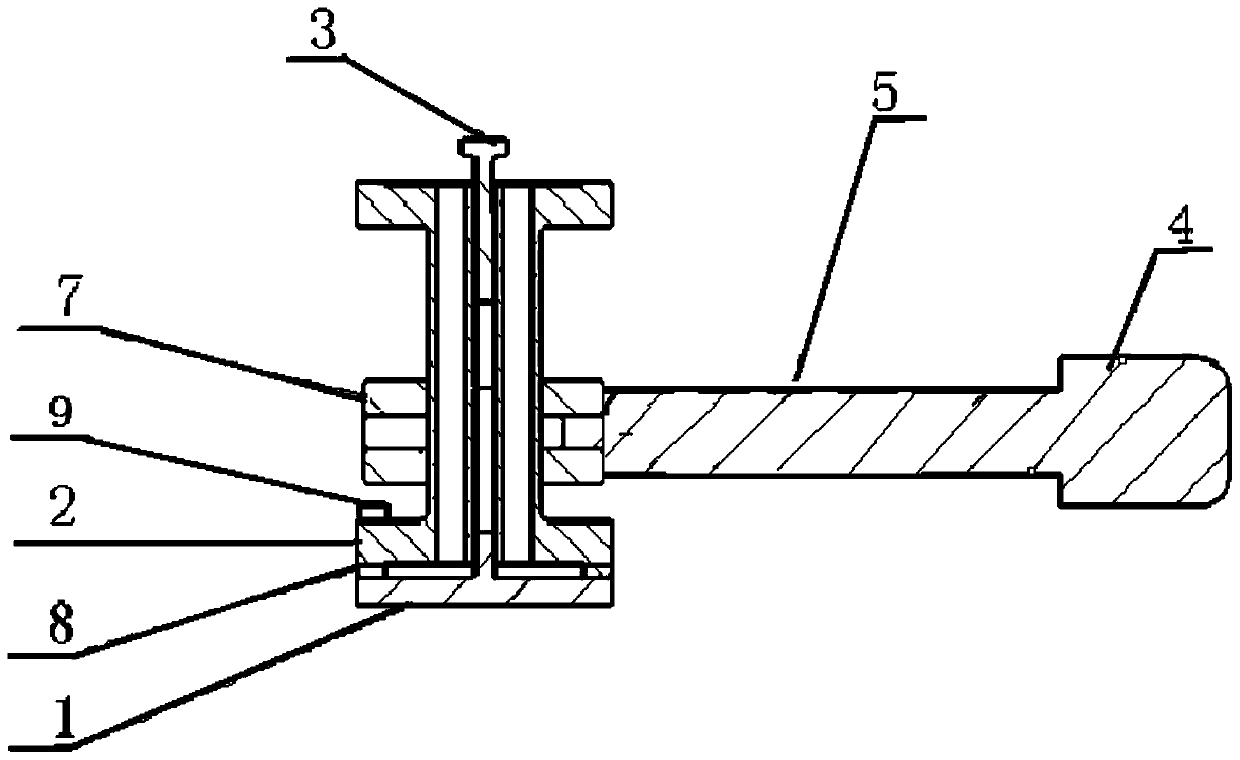

Electric-resistance-welded small size quartz-crystal resonator with one-end-fixed chip

InactiveCN103117726ALower resonance internal resistanceIncrease the vibration areaImpedence networksQuartz crystal resonatorElectrical resistance and conductance

The invention discloses an electric-resistance-welded small size quartz-crystal resonator with a one-end-fixed chip. The quartz-crystal resonator comprises a cavity shell consisting of a substrate and a shell. A silver electrode quartz plate, a base and spring pieces are arranged in the cavity shell. The base comprises two glass insulators arranged at the bottom of the substrate, and two lead terminals penetrating through the two glass insulators. Each of the two lead terminals consists of a pin head part and a lead foot part. The silver electrode quartz plate is fixed on the spring pieces through two conductive adhesives. The spring pieces are bonded on two sides of one end of the quartz plate by the conductive adhesives. The quartz-crystal resonator has the advantages that vibration areas during the resonance process of the silver electrode quartz plate are enlarged, affects caused by boundary effect are decreased, resonance resistance of the quartz-crystal resonator can be reduced efficiently, and requirements of work stability are met.

Owner:SHENZHEN JINGFENG TECH DEV CO LTD

Pouring device for aerated bricks

InactiveCN107243983AAffect qualityQuality improvementMixing operation control apparatusPretreatment controlBrickEngineering

The invention discloses an aerated brick pouring device, which belongs to the technical field of building bricks. The aerated brick pouring device of the present invention includes a pouring tank, a slurry tank and a powder tank, and also includes an auxiliary material tank, wherein: the slurry tank communicates with the pouring tank through a slurry pipe, and the powder tank communicates with the pouring tank through a bottom of the powder tank The conveying mechanism communicates with the pouring tank, and the auxiliary material tank sends the auxiliary material into the pouring tank through the auxiliary material pipe and the auxiliary material pump; the pouring tank is connected with a pouring nozzle, and a pouring car is arranged directly below the injection nozzle. By adding auxiliary material tanks, the auxiliary materials that need to be added in a small amount and with many varieties are mixed uniformly through the auxiliary material tanks and then added into the pouring tank, so that the quality of the prepared aerated bricks is stable. The invention solves the problems in the prior art that the auxiliary materials of the aerated bricks are less added, have many varieties, and are unevenly mixed during addition, thereby affecting the quality of the aerated bricks.

Owner:马鞍山市恒达轻质墙体材料有限公司

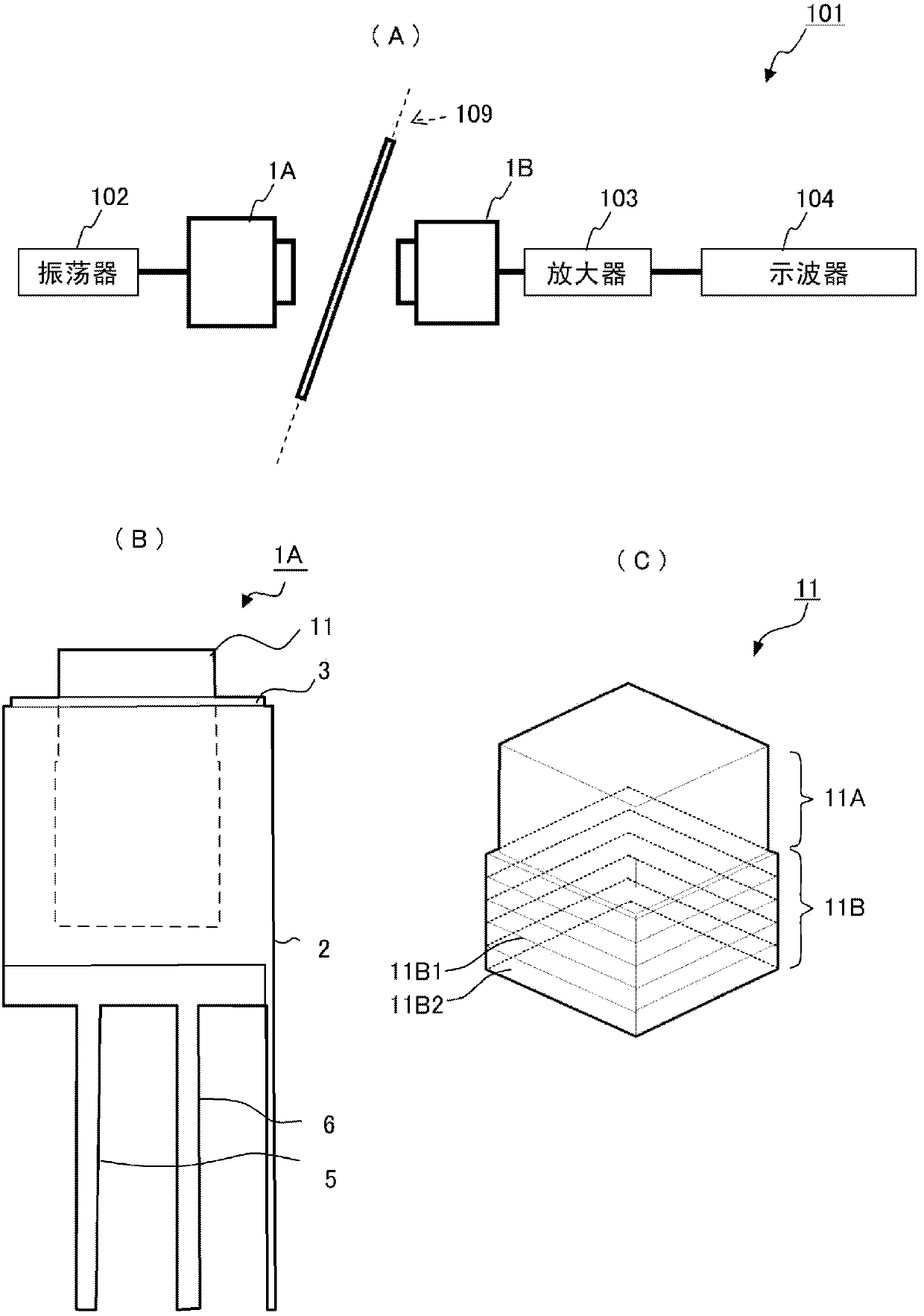

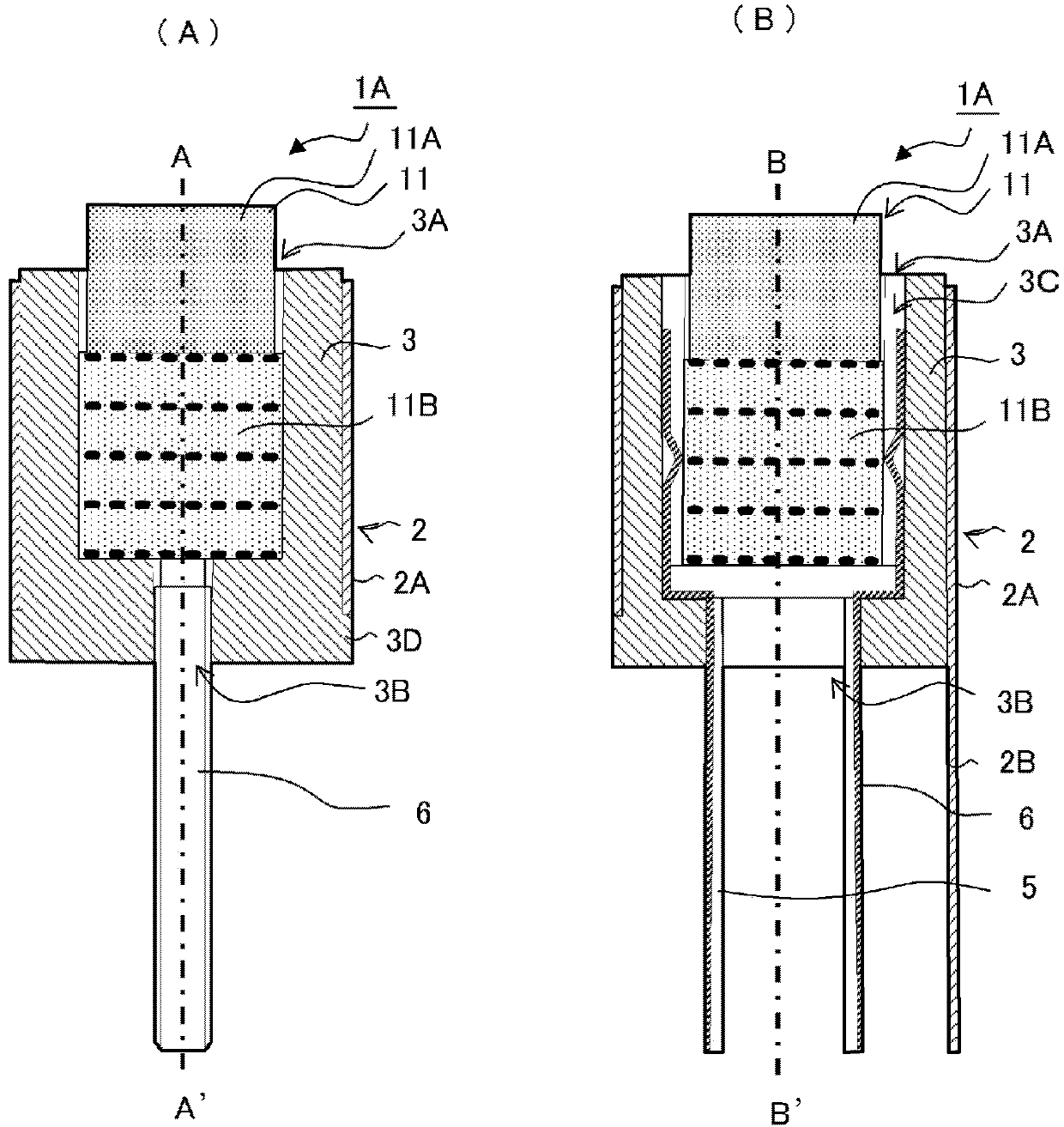

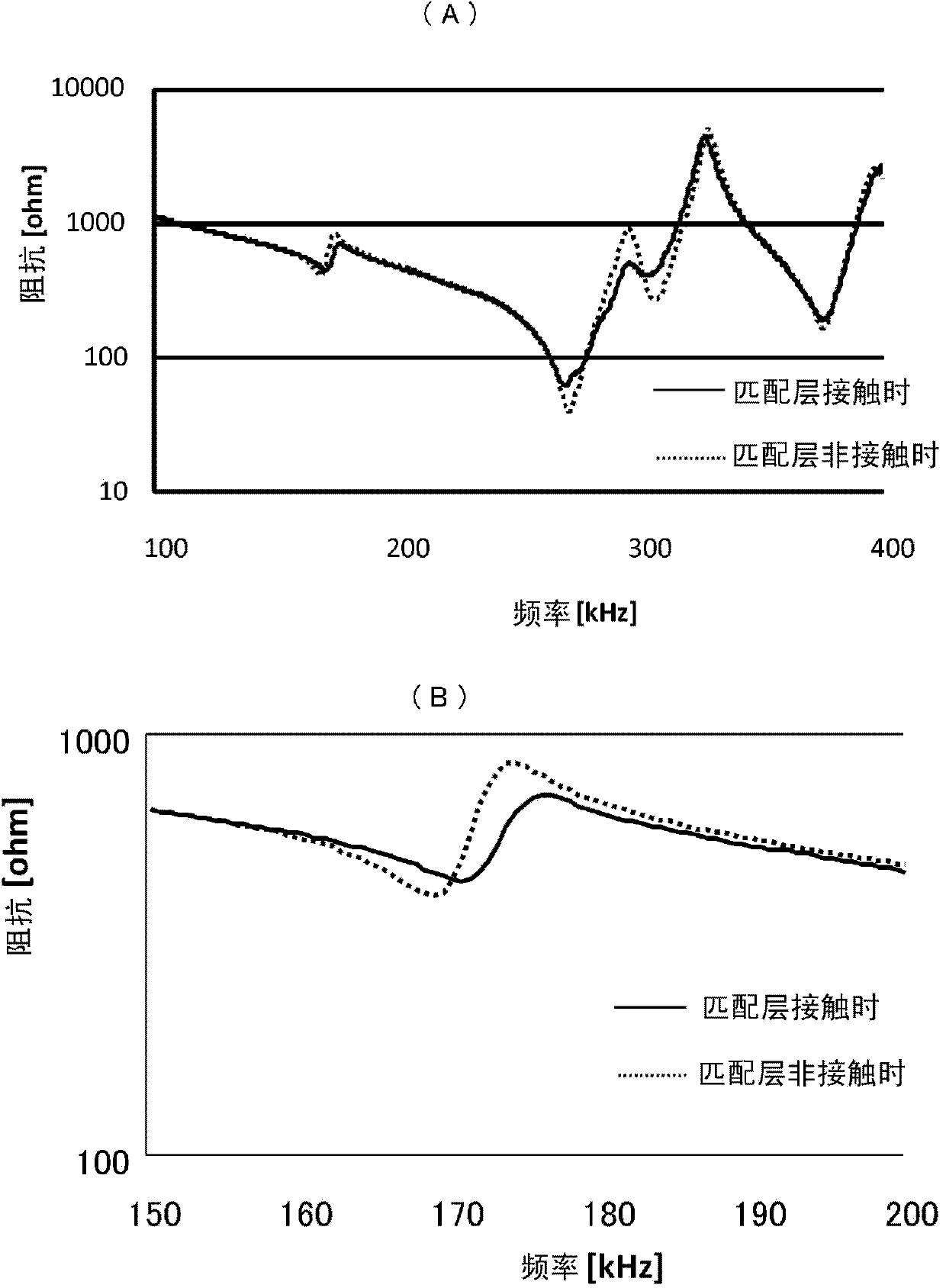

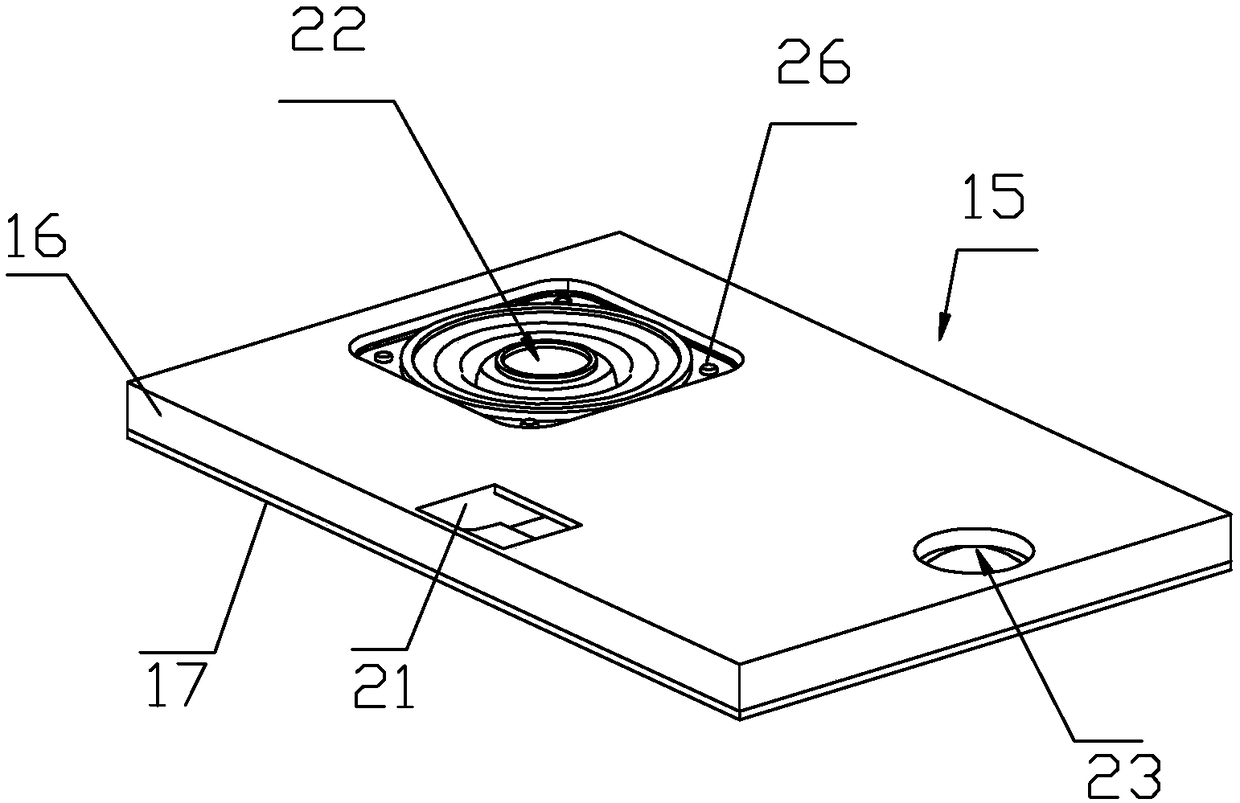

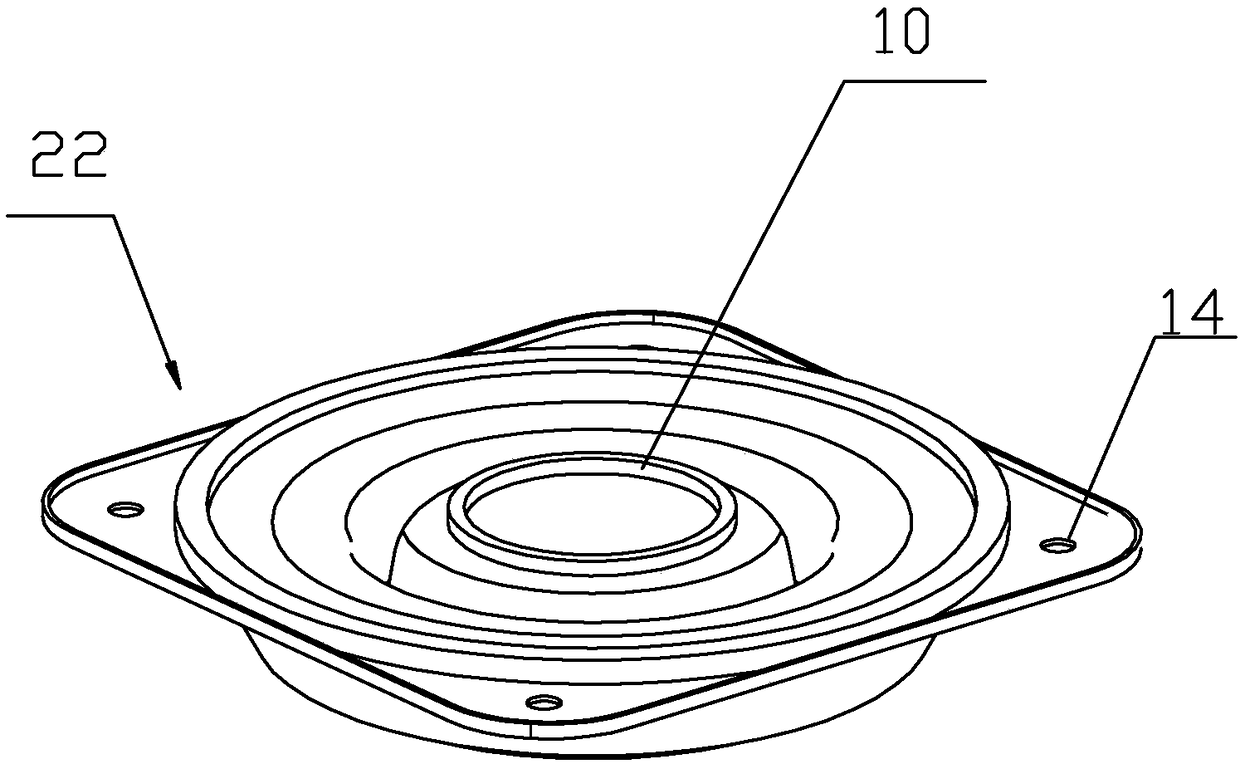

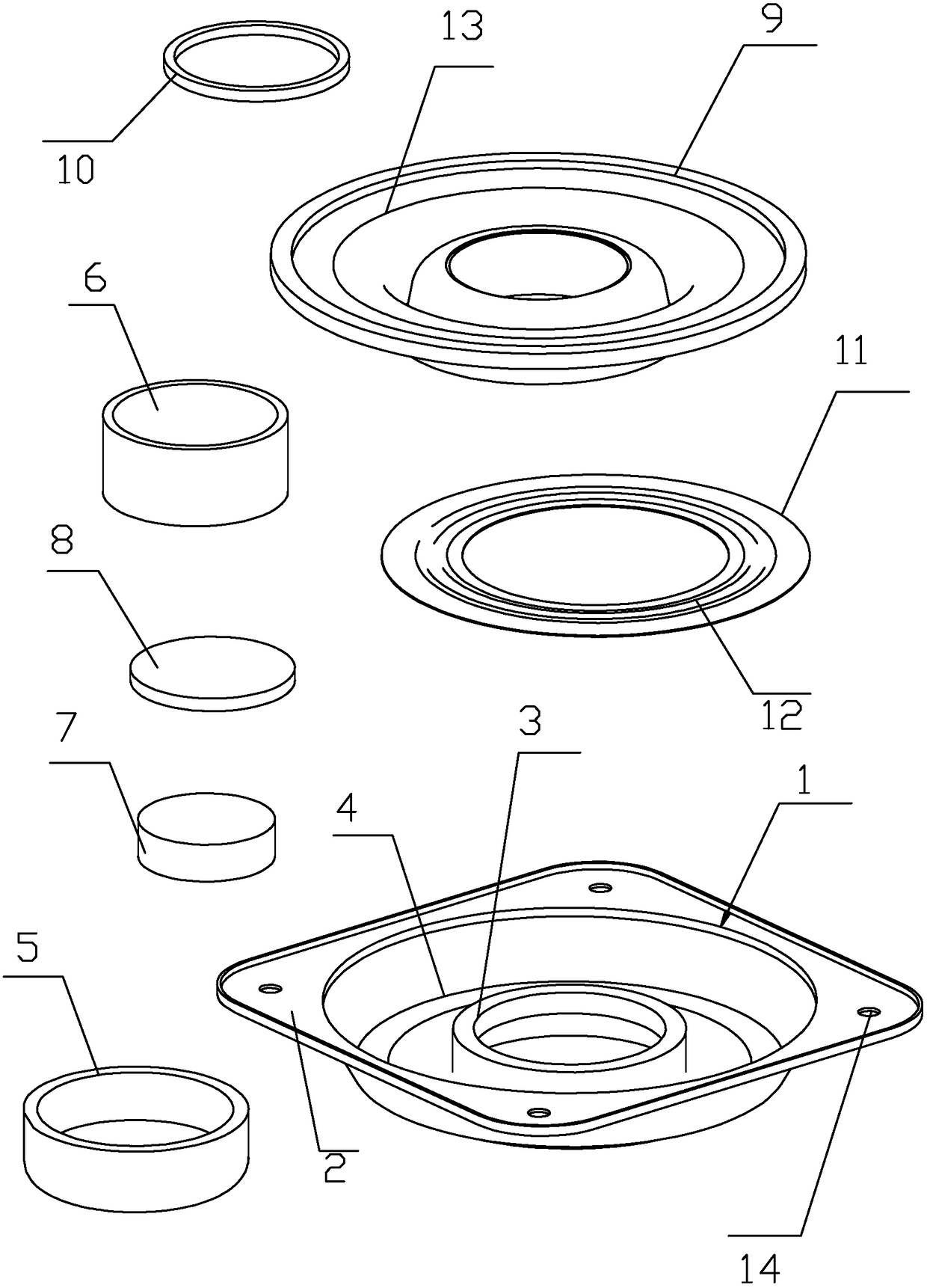

Ultrasonic transducer

InactiveCN103875257AIncrease the vibration areaImprove durabilityPiezoelectric/electrostrictive transducersMechanical vibrations separationBonding strengthUltrasound

The present invention achieves an ultrasonic transducer that has a structure suitable for use in the high-frequency band and that is highly durable. In addition, the sonic characteristics of the ultrasonic transducer are less likely to be affected by the bonding strength, contact pressure, and / or physical variation between members. The ultrasonic transducer (1A) is provided with a resin case (3) and a transducer (11). The resin case (3) has an opening (3A). The transducer (11) is provided with a matching layer (11A) and a piezoelectric element layer (11B). The piezoelectric element layer (11B) is configured so as to perform stand-alone thickness vibration, and the side surface of the piezoelectric element layer that intersects the main surface of the thickness direction faces and is in contact with the inner wall surface of the opening (3A). The matching layer (11A) is layered in the thickness direction of the piezoelectric element layer (11B), and the side surfaces that protrude from the opening (3A) in the thickness direction of the piezoelectric element layer (11B) and intersect the main surface of the thickness direction are free from the inner wall surface of the opening (3A).

Owner:MURATA MFG CO LTD

Ultra-thin sound box structure

ActiveCN108429988AIncrease the vibration areaEnhance the sense of strengthFrequency/directions obtaining arrangementsEngineeringSound quality

The invention discloses an ultra-thin sound box structure comprising a sound guiding sound box, a full-frequency loudspeaker and a tweeter, wherein the full-frequency loudspeaker comprises a basin frame, magnetic steel, a voice coil, a magnet, a magnetic conductive plate, a sound basin, a dust cap and a centring disk, the back surface of the centring disk is adhered in a groove, the front face ofthe centring disk is fixedly connected with the sound basin, the sound basin is of a V-shaped structure, an arc-shaped folding ring is arranged on the sound basin, through the cooperative use of the full-frequency loudspeaker and the tweeter, the sound of the whole ultra-thin sound box is more balanced, and the ultra-thin sound box can achieve the same effect as the sound quality of the large-volume sound boxes on the market.

Owner:刘芳

Concrete vibrator

PendingCN108678381AIncrease the vibration areaVibration time is shortBuilding material handlingStructural engineeringReciprocating motion

Owner:衡阳泰源商砼有限公司

A high-efficiency concrete vibrating rod based on reaction force folding and stretching

InactiveCN111364772BImprove work efficiencyIncrease the vibration areaBuilding material handlingClassical mechanicsSlide plate

The invention provides a high-efficiency concrete vibrating rod that is folded and extended based on reaction force, and relates to the technical field of concrete leveling. The high-efficiency concrete vibrating rod folded and stretched based on reaction force includes a hose, one end of the hose is threadedly connected with a steel pipe rod, the periphery of the steel pipe rod is fixedly installed with a sleeve, and the periphery of the sleeve is slidably connected with A slide plate, the inside of the slide plate is fixedly equipped with a lifting rod, the outer side of the bottom end of the lifting rod is rotatably connected with a down-folding rod, and the other end of the down-folding rod is rotatably connected with an up-folding rod. The high-efficiency concrete vibrating rod based on the folding and stretching of the reaction force increases the area of the vibrating rod while not hindering the extension of the steel pipe rod into the steel support, thereby improving the working efficiency of the vibrating rod and being able to control the extension of the steel pipe rod. The output length can be adjusted, and the vibration of the hose is buffered, which reduces the stimulation to the hands and reduces the intensity of work.

Owner:南京旭浦建材科技有限公司

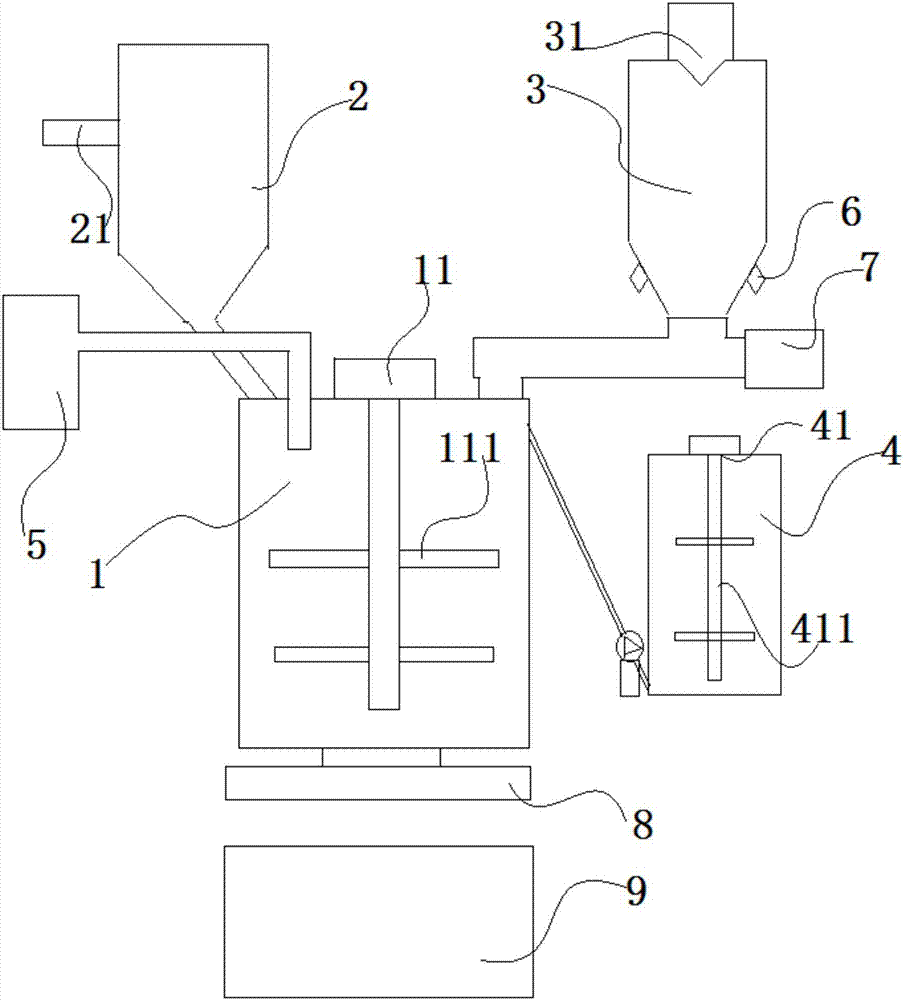

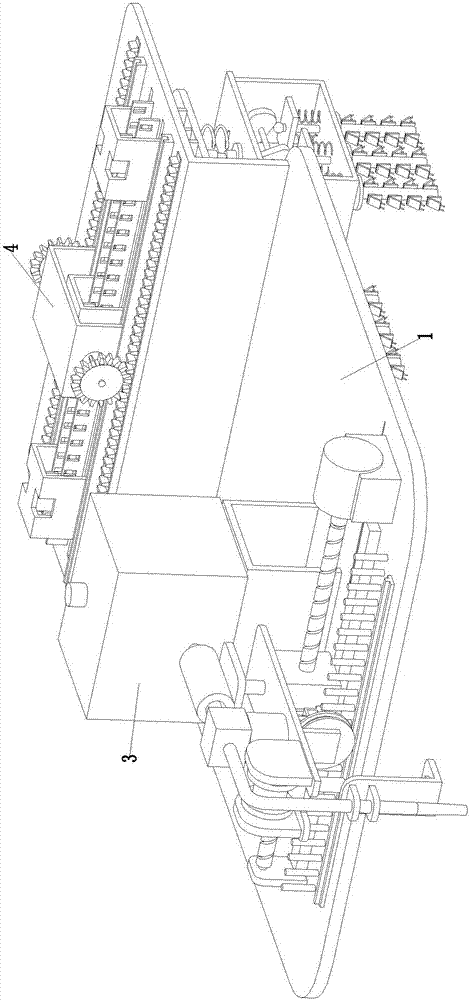

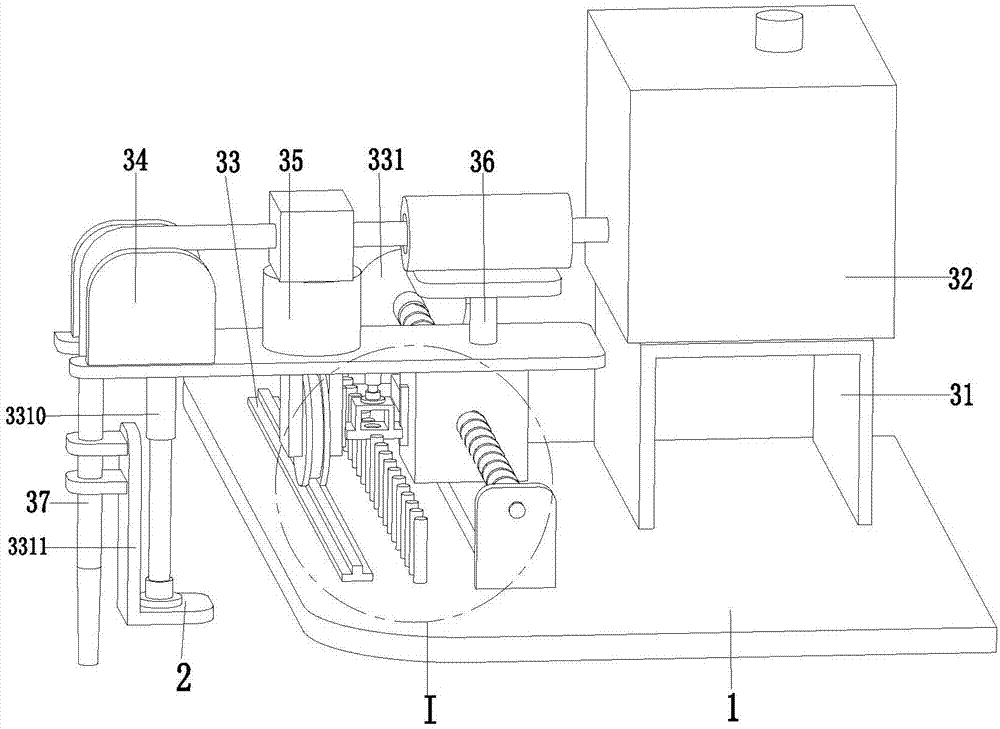

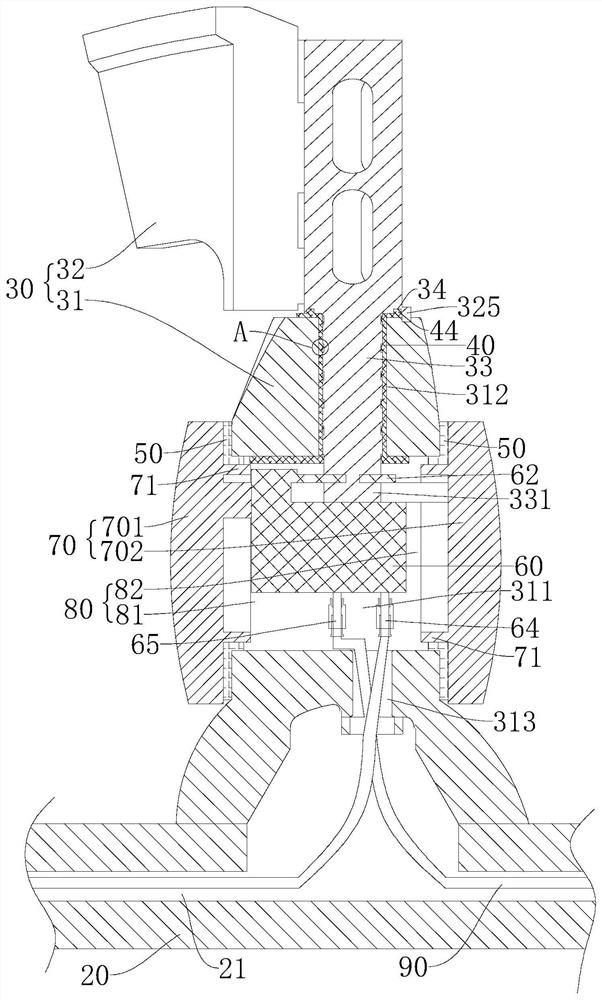

Intelligent cantilever assembling type long-span bridge wet joint pouring device

InactiveCN107964876AReduce labor intensityImprove perfusion efficiencyBridge erection/assemblyBridge materialsEngineeringLong span

The invention relates to a cantilever-assembled large-span bridge wet joint pouring intelligent equipment, comprising a bottom plate, a pouring device is arranged at the front end of the bottom plate, a vibrating compaction device is arranged at the rear end of the bottom plate, and the pouring device includes a pouring support frame installed In the perfusion storage box on the bottom plate, a discharge port is arranged on the lower side of the front end of the perfusion storage box, and a perfusion adjustment mechanism is installed on the front end of the bottom plate. The present invention can solve the instability of artificially conveyed and poured concrete existing in the existing wet joint concrete pouring process, and it is easy to make the concrete splash to the position other than the connecting joint. Manual conveying of concrete cannot ensure the uniformity of concrete pouring, and manual use of existing vibration is required. The equipment vibrates and compacts the poured concrete. During the vibration process of wet joint concrete pouring, it is necessary to avoid the reinforcement cage. The operation is complicated, and the concrete cannot be fully vibrated manually, and the compactness of the concrete cannot be ensured, and the concrete will have holes. .

Owner:范满香

Method for improving modulation tone and sound volume of Zeng-(a2l-or 25-stringed plucked instrument)

InactiveCN100492490CImprove sound transmissionIncrease the vibration areaStringed musical instrumentsEngineeringOrbit

Owner:潘仲文

Stirring device with vibrating blades

The invention provides a stirring device with vibrating blades. According to the device, a stirring arm comprises a fixed part fixedly connected to a stirring shaft and a stirring blade mounted on the fixed part, the fixed part is provided with a mounting cavity, the fixed part is provided with a mounting hole, the stirring blade is provided with a mounting part, the mounting part extends into the mounting cavity via the mounting hole, an elastic sealing part is arranged between the stirring blade and the mounting hole, the elastic sealing part separates the stirring blade and the fixed part, a vibrator mounted on the mounting part is arranged in the mounting cavity, the elastic sealing part separates the fixed part and the vibrator, the mounting cavity is provided with an opening communicating with a stirring cavity, a vibrating stirrer further comprises a vibrating blade connected with the vibrator via the opening, an elastic washer is arranged between the vibrating blade and the fixed part, and the vibrating blade and the elastic washer can seal the opening. The device does not need to vibrate the stirring shaft, and can achieve a good vibration stirring effect.

Owner:SHANDONG MIX MACHINERY EQUIP

Paper pushing mechanism for corrugated paper production

InactiveCN113666174AAvoid extrusion deformationIncreased vibration rangePile receiversPaper manufacturingEngineering

The invention discloses a paper pushing mechanism for corrugated paper production, and belongs to the related field of corrugated paper manufacturing. The paper pushing mechanism for corrugated paper production comprises a moving seat, a first alignment plate, a second alignment plate, a rotating block, a sliding strip, a front side baffle and an alignment device. Corrugated paper to be aligned is located between the first alignment plate and the second alignment plate, the alignment device is arranged in the first alignment plate, a vibration element and a sliding adaptation element are arranged in the alignment device, the vibration element can generate vibration to conduct vibration alignment on the corrugated paper to be aligned between the first alignment plate and the second alignment plate, and the sliding adaptation element can enable the vibration element to slide while vibrating, so that the vibration range of the vibration element is enlarged. According to the scheme, the alignment device is arranged, the alignment device comprises the vibration element and the sliding adaptation element, the vibration element can conduct vibration alignment on the corrugated paper, and then the situation that some irregular corrugated paper is extruded and deformed due to extrusion alignment is prevented.

Owner:浙江佳鹏电脑科技股份有限公司

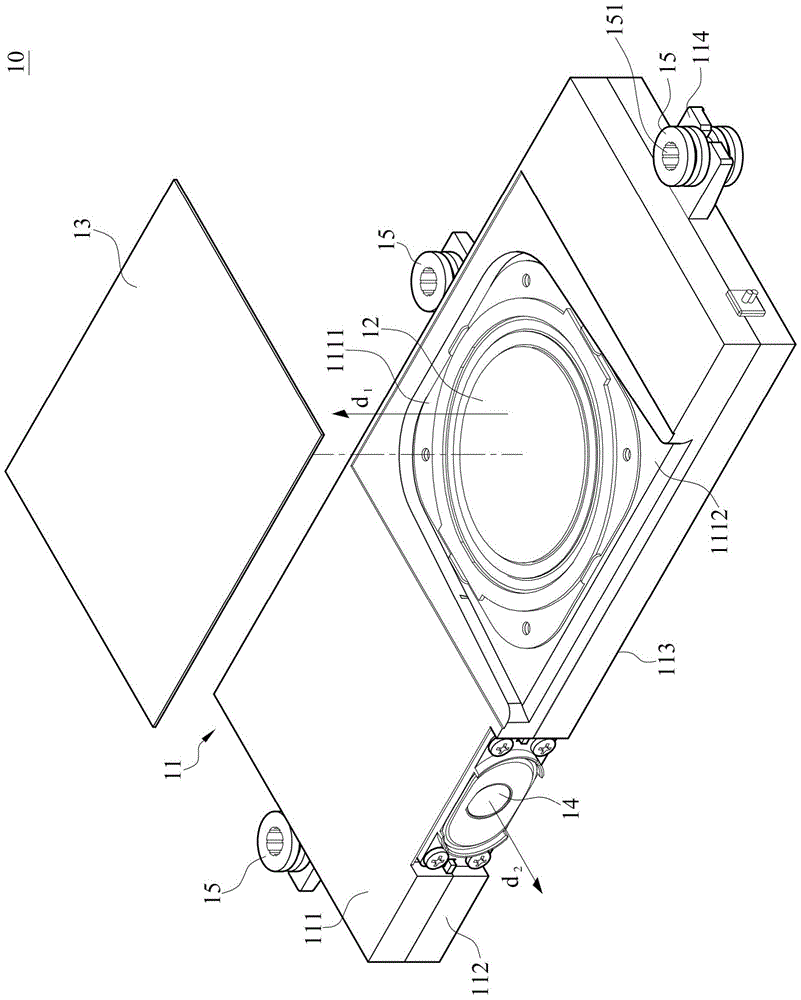

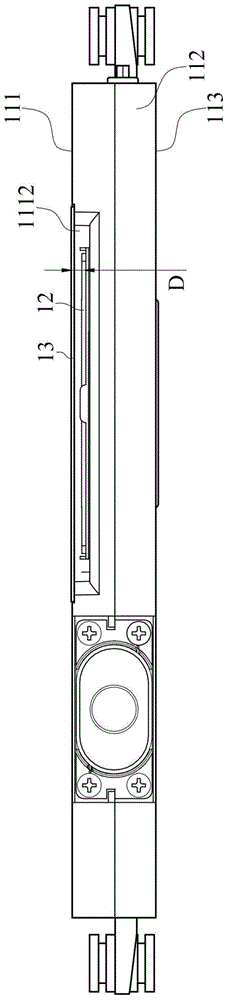

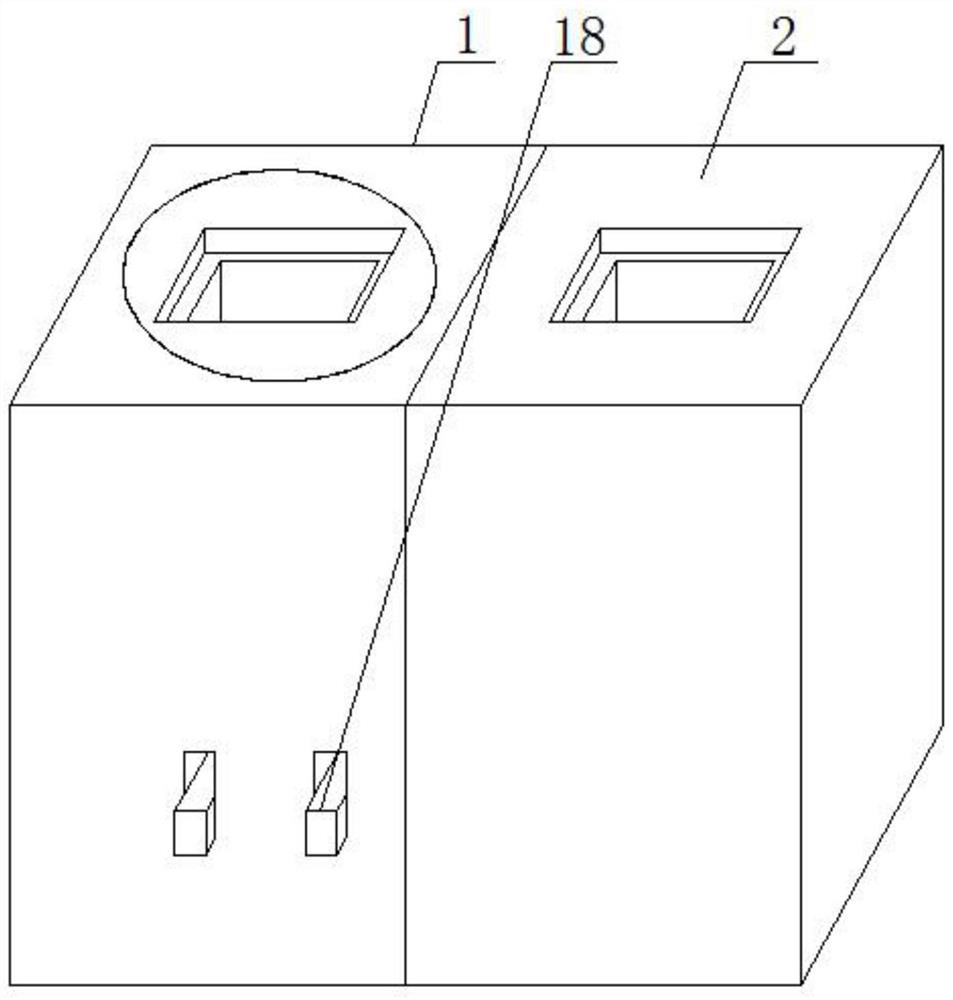

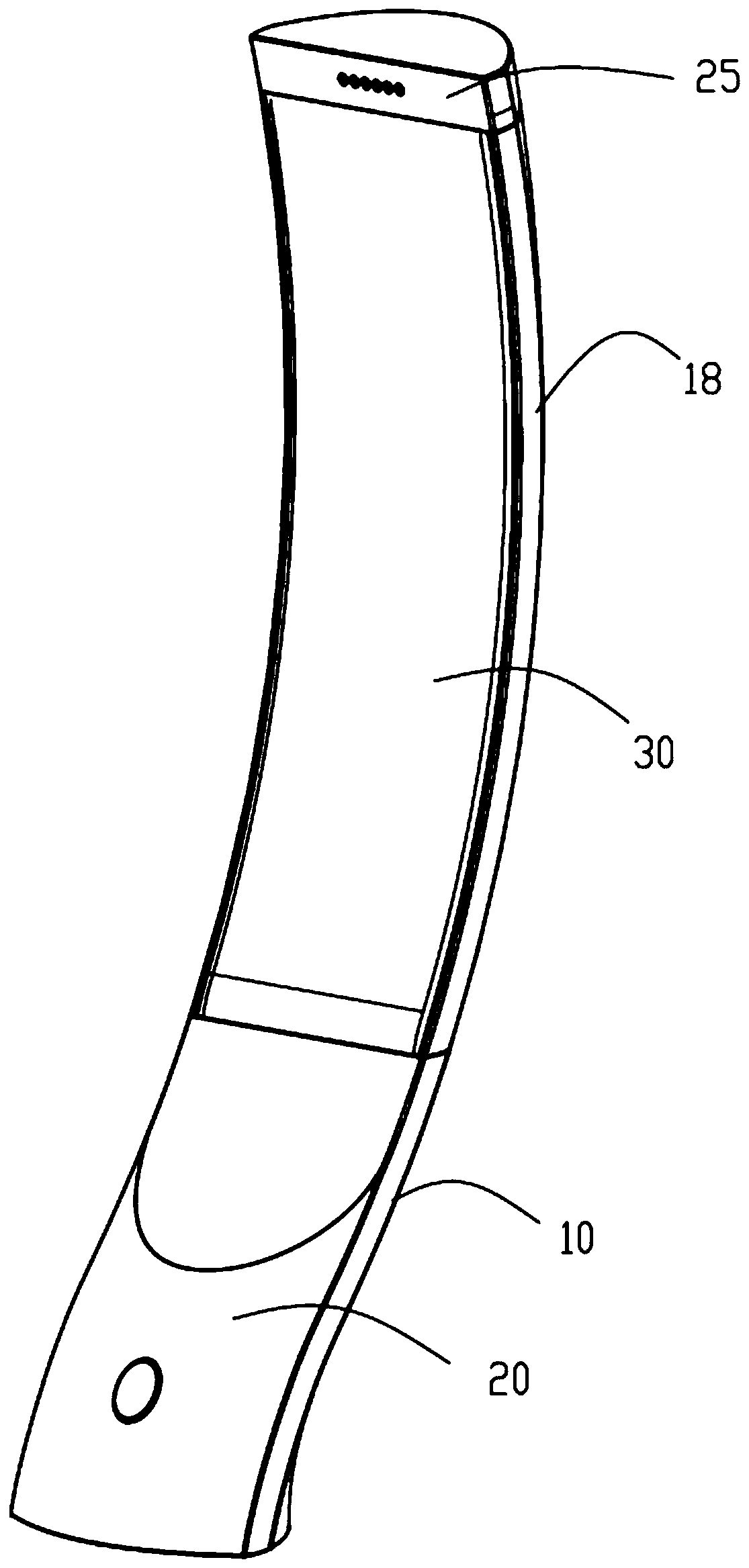

Sound source output device and audio-visual output device using the sound source output device

ActiveCN104640030BImprove qualityIncrease sound pressureLoudspeaker spatial/constructional arrangementsSound sourcesEngineering

The invention discloses an audio source output device. The audio source output device comprises a shell, a first loudspeaker part, a second loudspeaker part and a sound guide board, wherein the first loudspeaker part is a circular trumpet, and is arranged on the shell; the first loudspeaker part faces a first direction; the second loudspeaker part is arranged on the shell, and faces a second direction opposite to the first direction; the sound guide board is a square board body, is positioned on the first loudspeaker part, and is kept a predetermined distance away from the first loudspeaker part.

Owner:AMTRAN TECH CO LTD

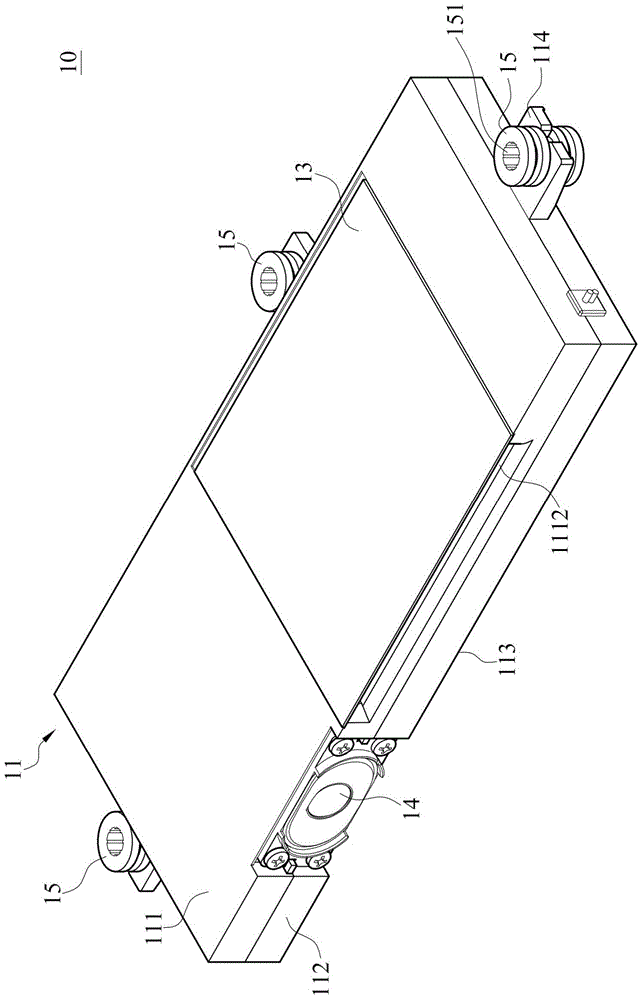

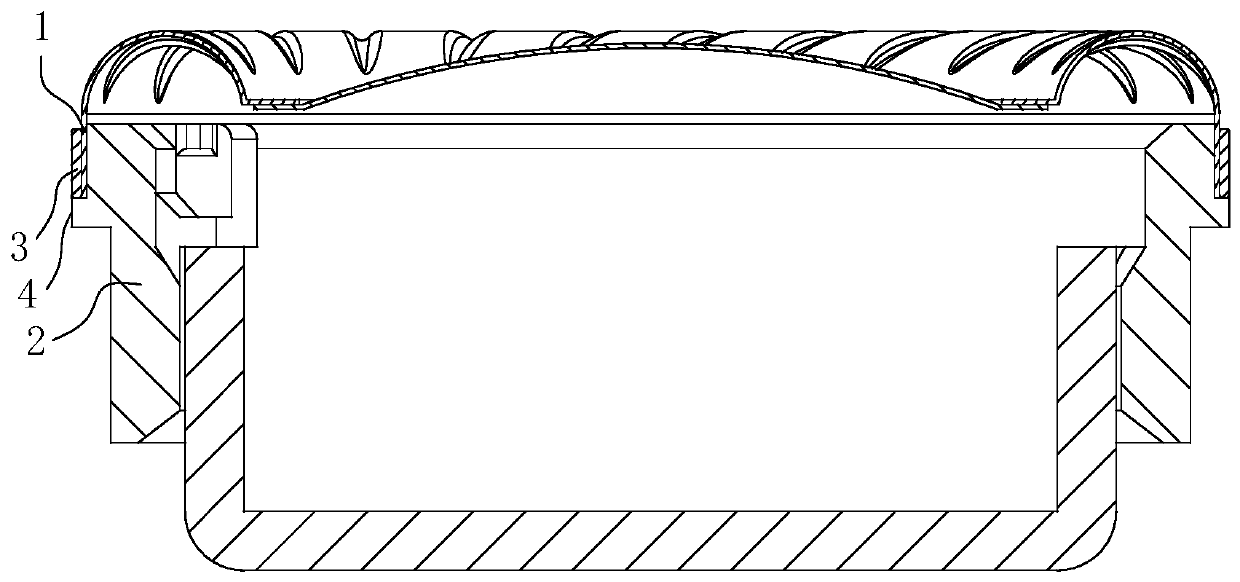

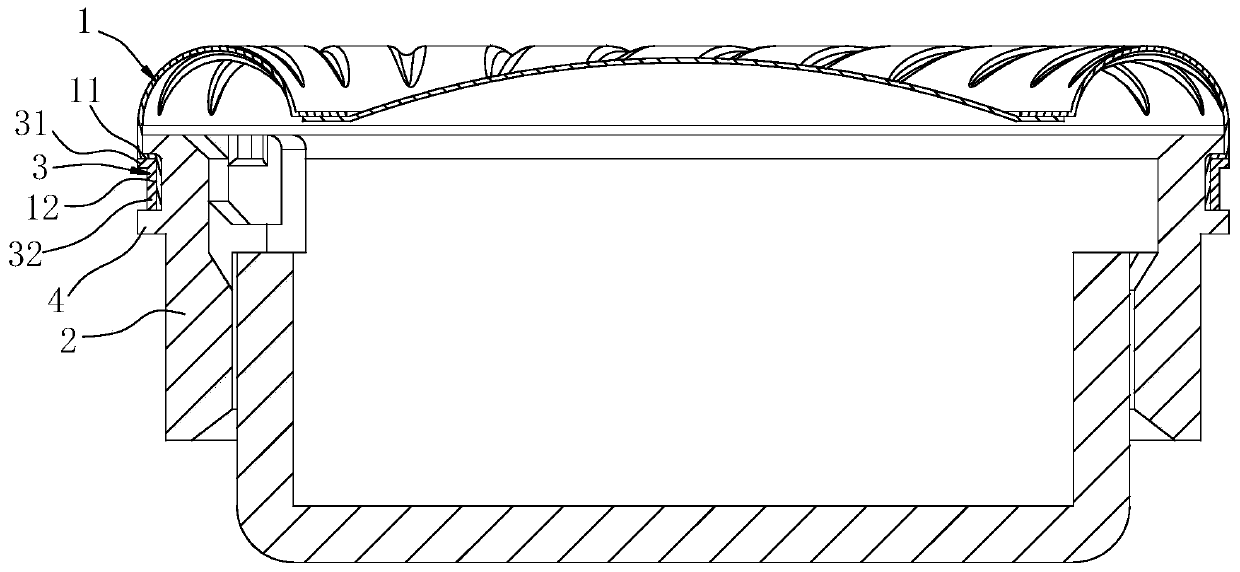

Loudspeaker and diaphragm fixing method of loudspeaker

ActiveCN110267168AIncrease the vibration areaSave time for dispensing and curingElectrical transducersLoudspeakersLoudspeakerEngineering

The invention discloses a loudspeaker and a diaphragm fixing method of the loudspeaker. The loudspeaker comprises a basin frame, a fixing ring and a vibrating diaphragm arranged above the basin frame; the basin frame comprises a first connecting part which is arranged close to the vibrating diaphragm; and the vibrating diaphragm comprises a second connecting part arranged close to one side of the basin frame, the second connecting part sleeves the periphery of the first connecting part, and the fixing ring is clamped at the periphery of the second connecting part, so that the second connecting part is pressed at the periphery of the second connecting part. The loudspeaker provided by the invention is convenient for fixing the vibrating diaphragm, is high in production efficiency, and enables the effective vibration area of the vibrating diaphragm to be large.

Owner:GUOGUANG ELECTRIC +2

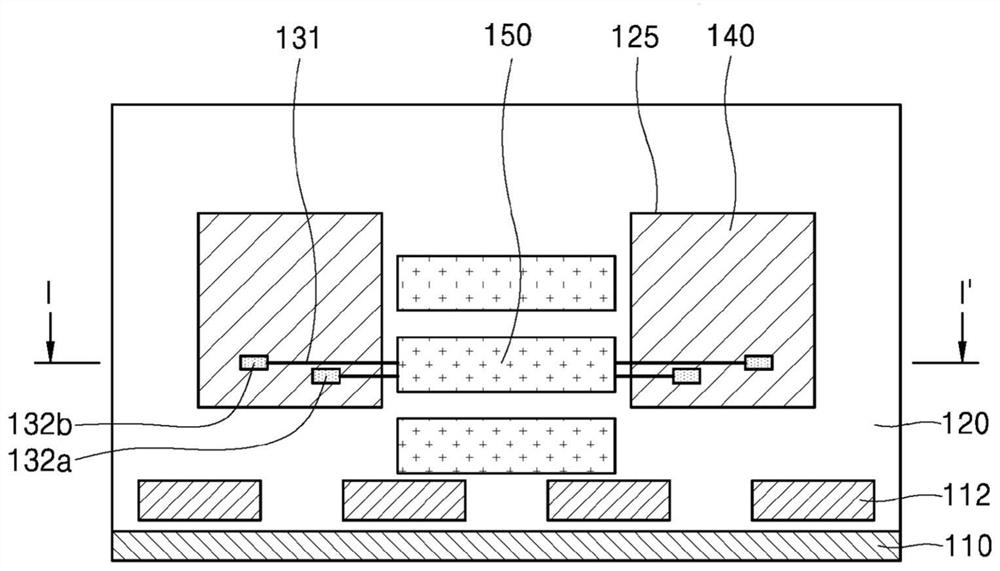

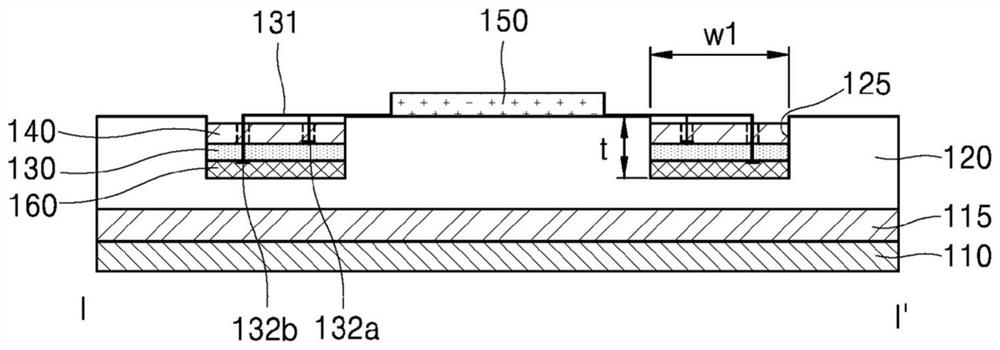

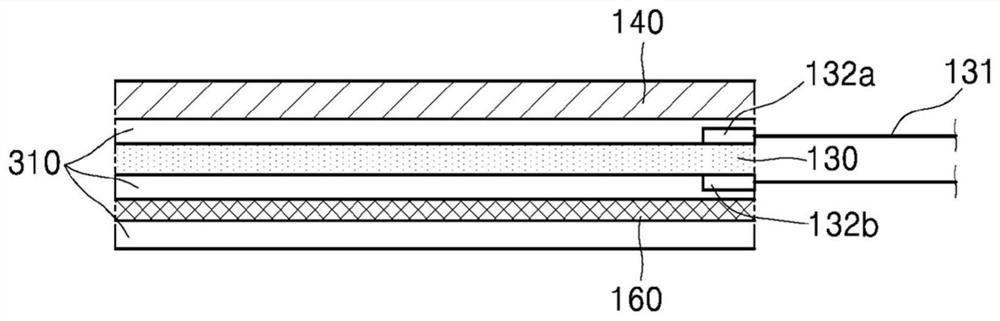

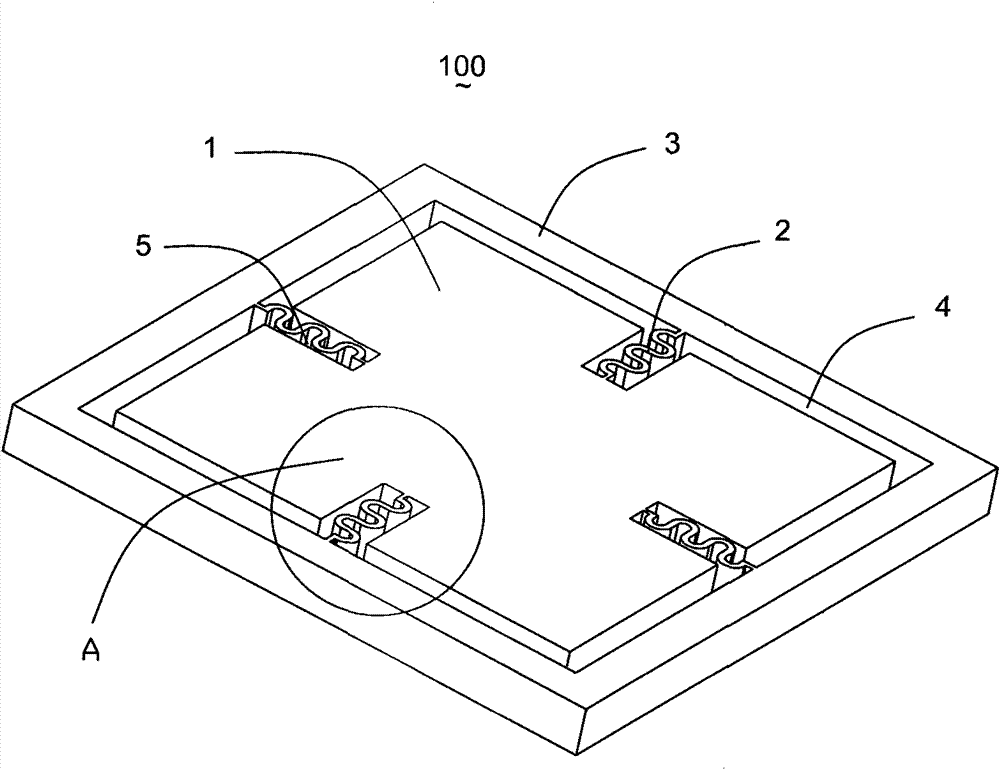

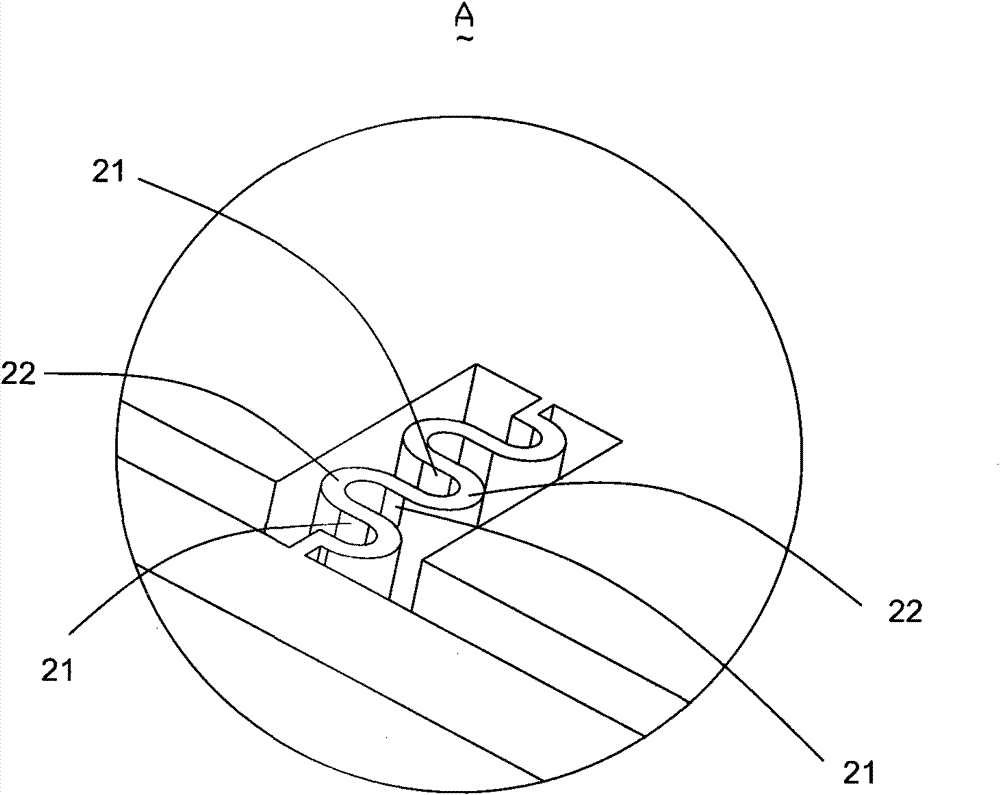

Display device

PendingCN114762358AReduce thicknessIncrease the vibration areaSolid-state devicesPlane diaphragmsDisplay devicePiezoelectric membrane

The present disclosure relates to a display device including a piezoelectric film type actuator, the display device having a structure in which a groove is provided in a rear surface of a metal layer for supporting and encapsulating a rear surface of a display panel, and the piezoelectric film type actuator is provided in the groove. Accordingly, the display device may reduce the total thickness and improve heat dissipation performance.

Owner:LG DISPLAY CO LTD

Silicon carbide composite plating equipment

The invention belongs to the technical field of composite plating equipment, particularly relates to silicon carbide composite plating equipment. The following solution aiming at the problems of incomplete cleaning and low blow-drying efficiency in the prior art is provided, the silicon carbide composite plating equipment comprises a cleaning box, a blow-drying box, a preheating tank, a pre-plating cleaning tank, an activating tank and an electroplating tank, wherein exhaust openings are correspodningly formed in the preheating tank and the activating tank, a spraying pipe is arranged in the preheating tank, heating rods are arranged in the preheating tank, the activating tank and the electroplating tank correspondingly, stirring air pipes are arranged in the pre-plating cleaning tank, the activating tank and the electroplating tank correspondingly, and an ultrasonic vibration plate is arranged in the pre-plating cleaning tank. According to the silicon carbide composite plating equipment, the cleaning effect can be improved, the blow-drying efficiency can be improved, and the equipment is easy to use and convenient to operate.

Owner:唐山科德轧辊股份有限公司

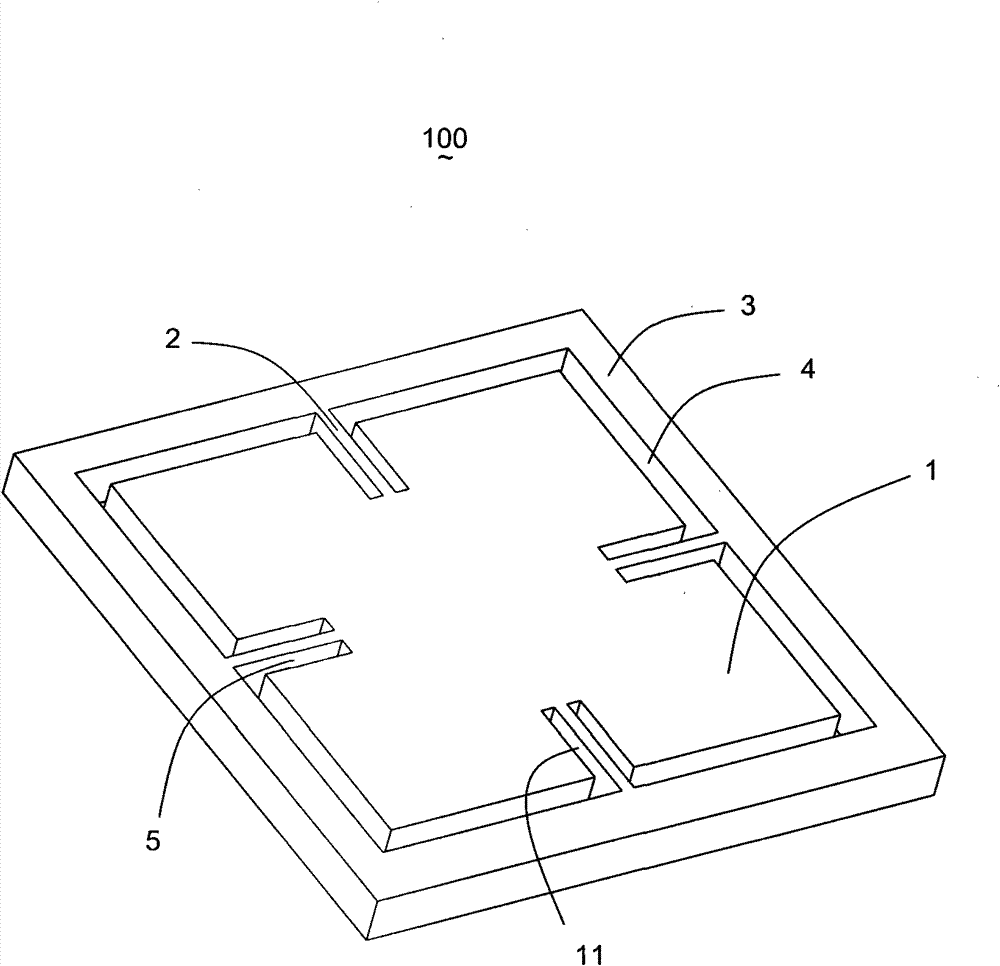

Diaphragm and silicon-based microphone employing diaphragm

ActiveCN101883305BIncrease the vibration areaHigh sensitivityElectrostatic transducer microphonesTransducer diaphragmsEngineeringSilicon based

The invention discloses a diaphragm, which comprises a vibrating part. The vibrating part is provided with at least two grooves which recess from the periphery to the center of the vibrating part. The diaphragm also comprises a connecting part and a supporting part, wherein the connecting part is connected with the vibrating part and partially accommodated in the grooves; and the supporting part is connected with the connecting part. A first gap is formed between the supporting part and the vibrating part, and a second gap is formed between the connecting part and the grooves of the vibrating part. The grooves are formed on the vibrating part, the grooves of the vibrating part and the supporting part are connected through the connecting part, the air damping is controlled through the first and second gaps, and the vibrating area of the diaphragm is increased. Therefore, the sensitivity of a silicon-based microphone employing the diaphragm is improved. The invention also provides a silicon-based microphone employing the diaphragm.

Owner:AAC TECH PTE LTD +1

Powder Blank Forming Method

The invention discloses a powder billet forming device. The powder billet forming device comprises a die, an extruding rod, an amplitude-change pole and an energy converter, wherein the extruding rod is axially mounted in the die; one end of the amplitude-change pole is radially connected with the die, and the other end of the amplitude-change pole is connected with the energy converter; the electricity energy can be converted into mechanical vibration for driving the amplitude-change pole through the energy converter while axial pressure is applied to powder in the die through the extruding rod, and the die is driven to vibrate to apply radial pressure to the powder through the amplitude-change pole. The device is simple in structure, reliable in performance, and capable of quickly releasing the die; the powder is driven to vibrate through the die, so that the powder vibrating area is increased, and the powder can be uniformly vibrated, and as a result, the formed body density is improved, and the stress of the body is uniformly distributed. In addition, the invention also discloses a powder billet forming method.

Owner:沈阳赫声装备科技有限公司

a speaker box

ActiveCN111629288BSave spaceReduce volumeFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsSound filmEngineering

The invention provides a loudspeaker box, which includes a box body and a sounding unit, the sounding unit includes a casing and an upper sound film and a lower sound film installed on the casing, and the upper sound film, the lower sound film and the casing surround A first cavity is formed, the casing includes a main body part fixedly connected with the upper sound film and the lower sound film and a connecting platform protruding outward from the main body part, and the box body includes a support part having a second cavity and a projection , the sounding unit is fixed to the bump through the connecting platform, the housing is provided with a first leakage channel communicating with the first cavity, the box is provided with a second leakage channel communicating with the second cavity, and the first leakage channel is It communicates with the second leakage channel to form a rear cavity leakage channel, and the first cavity communicates with the second cavity through the rear cavity leakage channel; Groove through which the anterior cavity communicates with the outside world. The loudspeaker box of the present invention increases the vibration area of the sounding unit and can counteract its own vibration, thereby improving the quality of sounding.

Owner:AAC TECH PTE LTD

mobile terminal

ActiveCN107624242BIncrease the vibration areaImprove the vibration effectCurrent supply arrangementsTelephone set constructionsTelecommunicationsControl theory

The present application provides a mobile terminal, including a casing and a vibrator, the casing includes a first position and a second position, the mobile terminal further includes a limiter connected to the first position of the casing, the vibrator is set In the second position of the housing, the first position is different from the second position, and the stopper extends from the first position to the second position to conduct the vibration of the vibrator from the vibrator to the second position. first position.

Owner:SHENZHEN ROYOLE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com