Concrete vibrator

A vibrating rod and concrete technology, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of uneven concrete tamping, single vibrating rod structure, small vibration coverage area, etc., to prevent delamination Segregation phenomenon, space saving, short vibrating time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

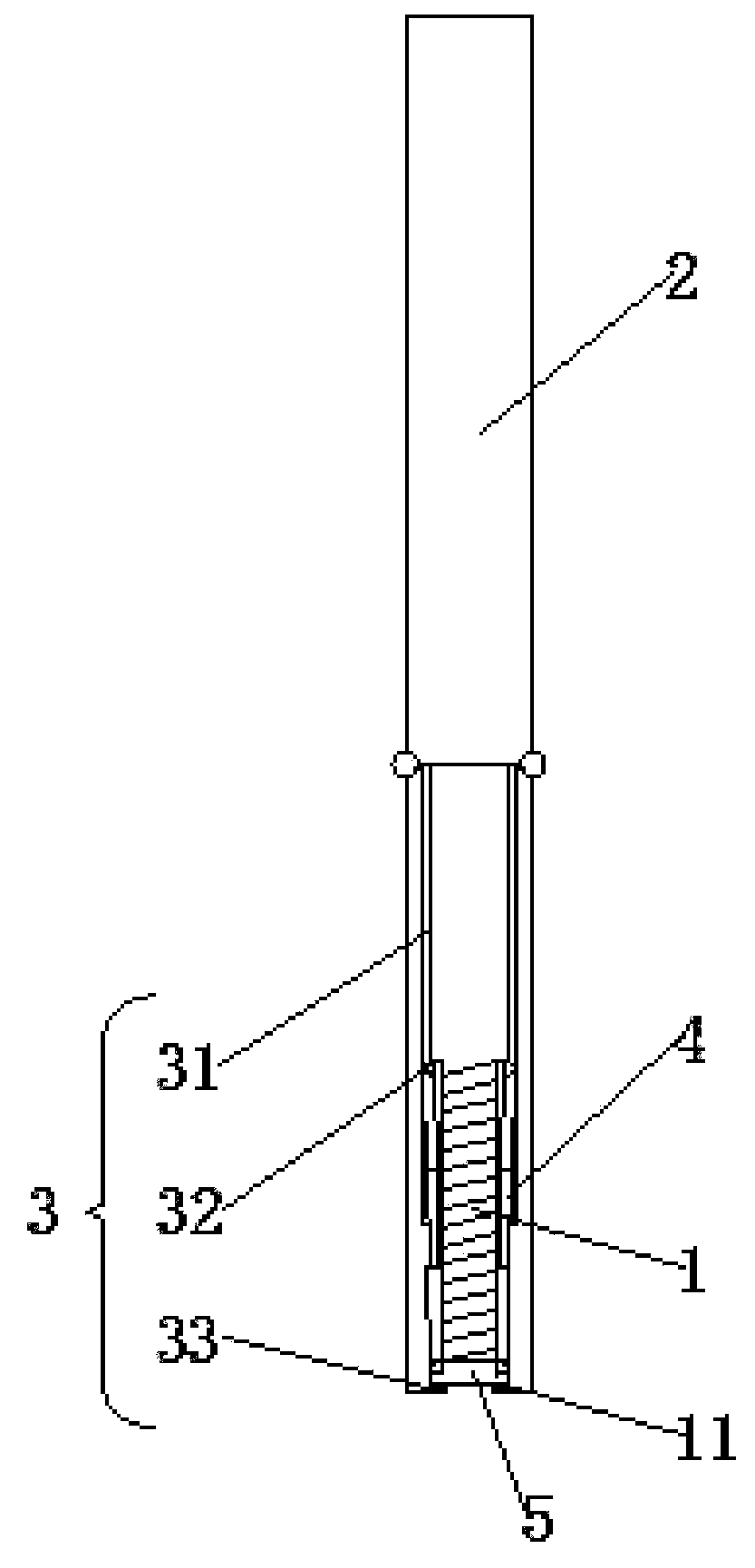

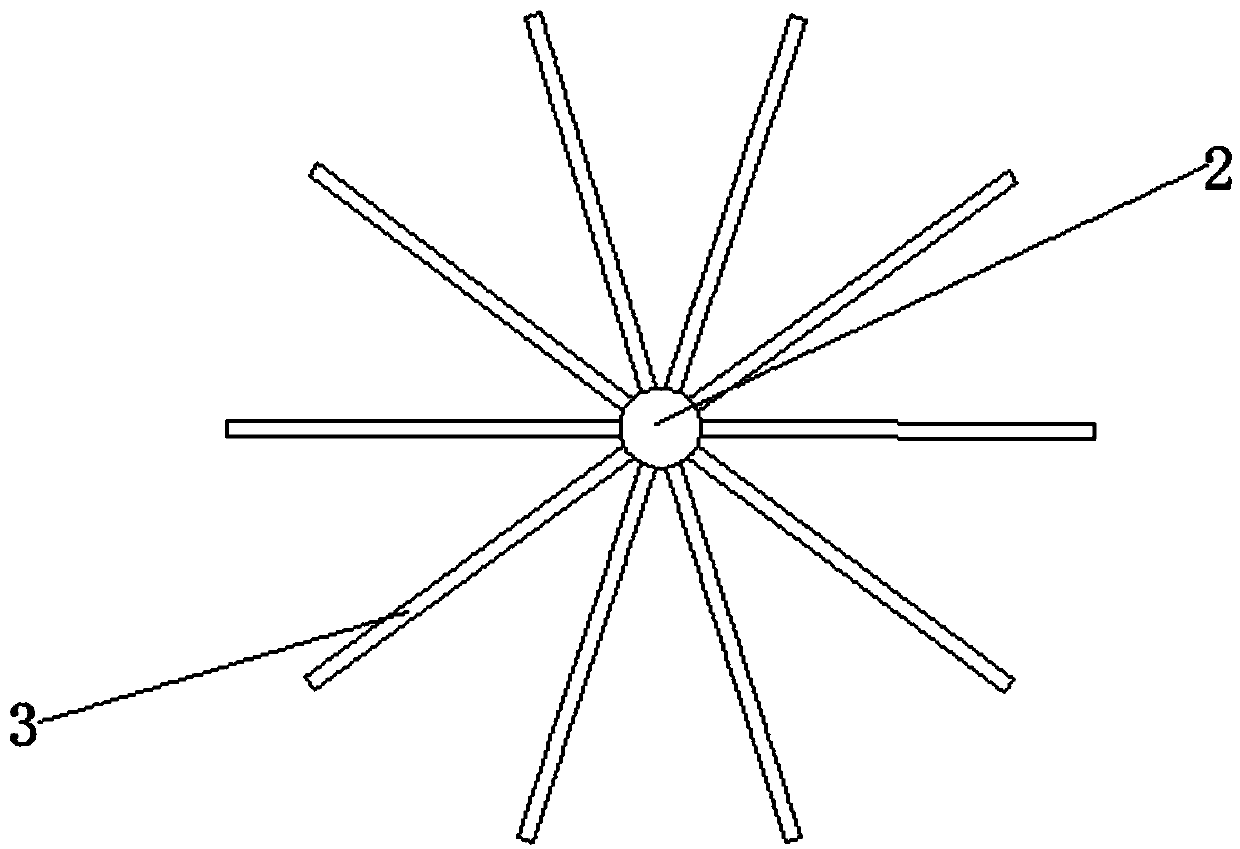

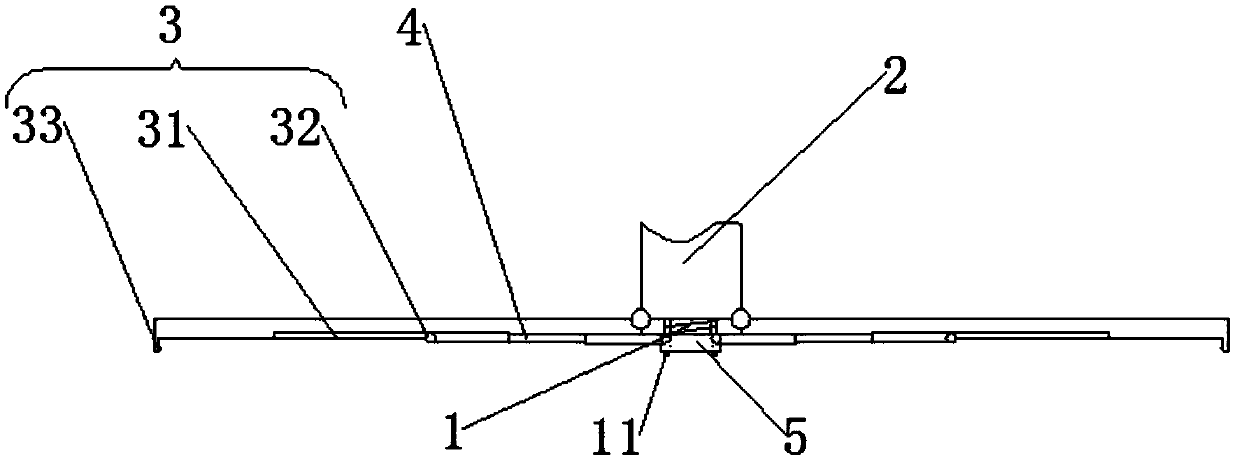

[0023] Embodiments of the present invention are as follows: Figure 1~4 As shown, a concrete vibrating rod includes a main rod 1, a sleeve 2 is sleeved on the main rod 1, and the end of the sleeve 2 away from the main rod 1 is provided so that the sleeve 2 can reciprocate along the axial direction of the main rod 1. The driving device of the movement, the other end of the sleeve 2 is hinged with at least two vibrating pieces 3, the side of the vibrating piece 3 close to the main rod 1 is provided with a guide rail 31, and the guide rail 31 is provided with a slider 32 that can slide along the guide rail 31, The slide block 32 is hinged with one end of a pole 4, and the other end of the pole 4 is hinged with the main rod 1. The invention is used for the improvement of the concrete vibrating rod, which can expand the vibrating area of the vibrating rod, so that a larger area of concrete can be simultaneously removed by the vibrating rod, and the overall vibrating time is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com