Patents

Literature

761results about How to "Improve cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

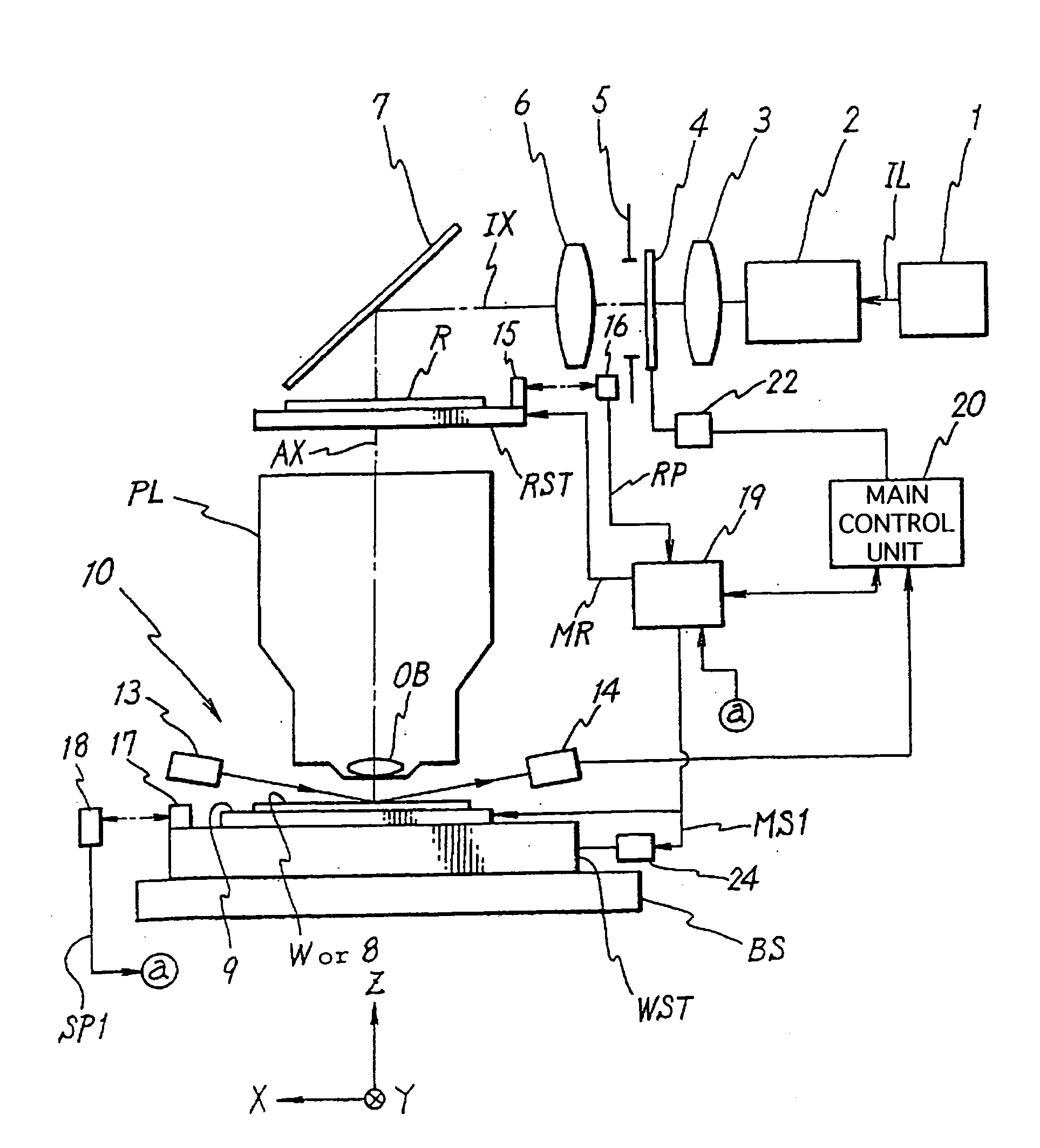

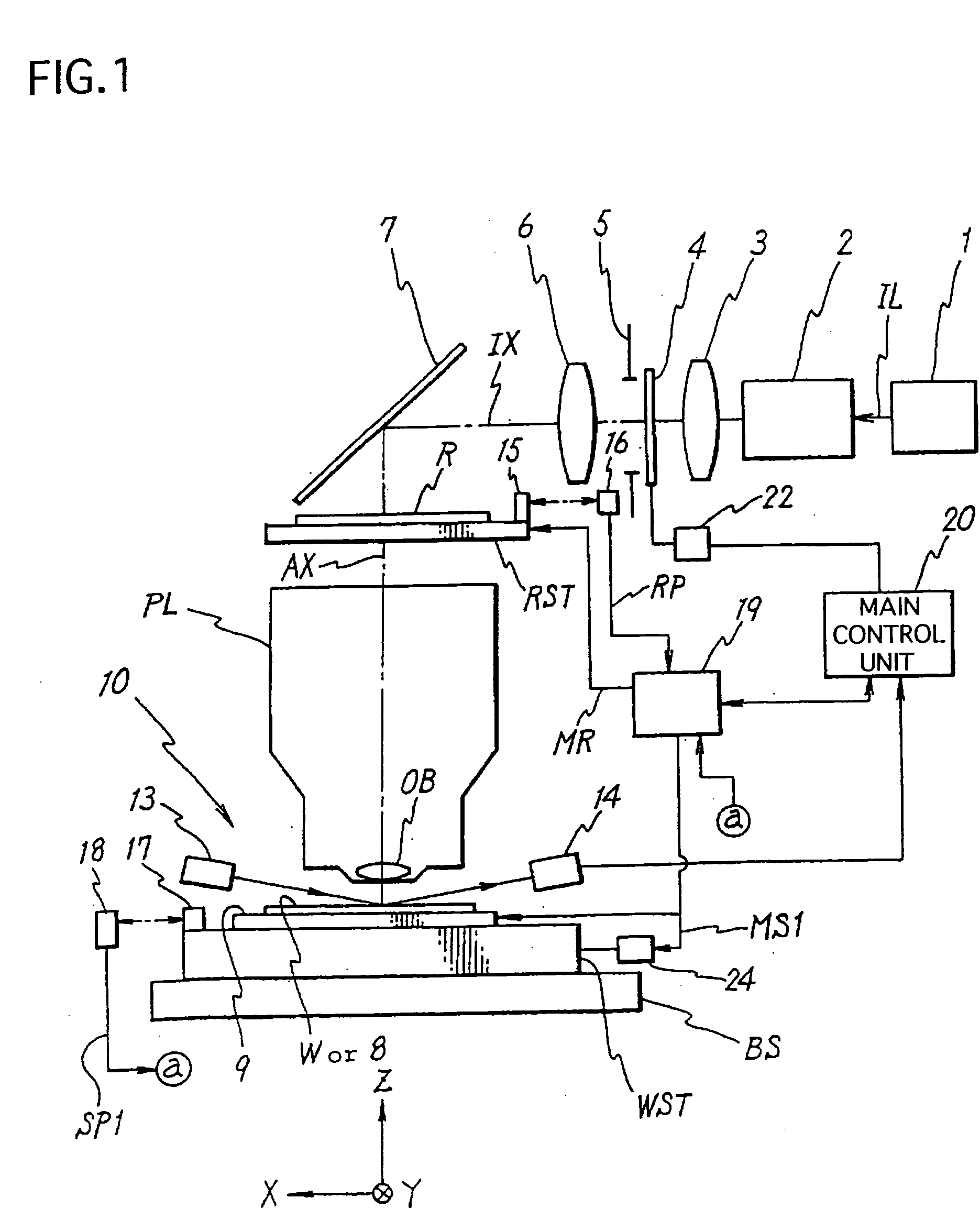

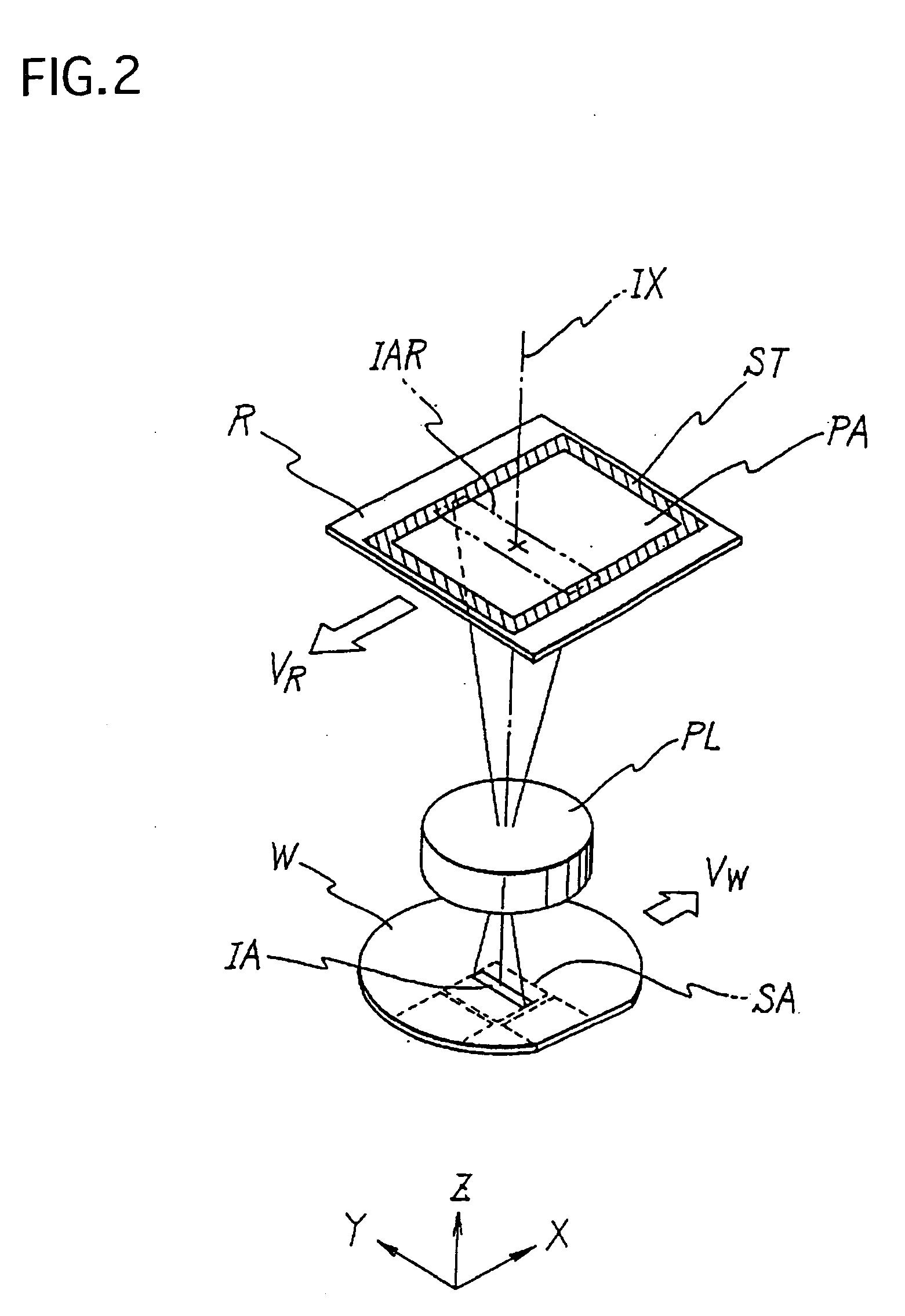

Projection exposure apparatus and method

InactiveUS20050094115A1Cleaning effect can be moreImprove cleaning effectMaterial analysis by optical meansPhotomechanical exposure apparatusPhysicsExposure

Pattern transfer can be performed with improved exposure accuracy, by reducing the contamination caused by the attachment of a photosensitive agent or the like on an optical member of a projection optical member or the like. The pattern transfer onto a substrate W is performed after cleaning the objective member OB disposed at a given position by a cleaning device 8 at the time when pattern transfer is not performed, or while making flow a gas in a space between the substrate W and the optical member OB by a contamination protection device 98. Alternatively, the optical member OB disposed at a given position is inspected for contamination by a contamination inspection device 84 at the time when pattern transfer is not performed, and the pattern transfer or the cleaning or replacement of the optical member is performed based on the result.

Owner:NIKON CORP

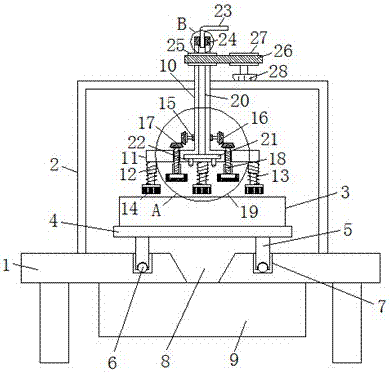

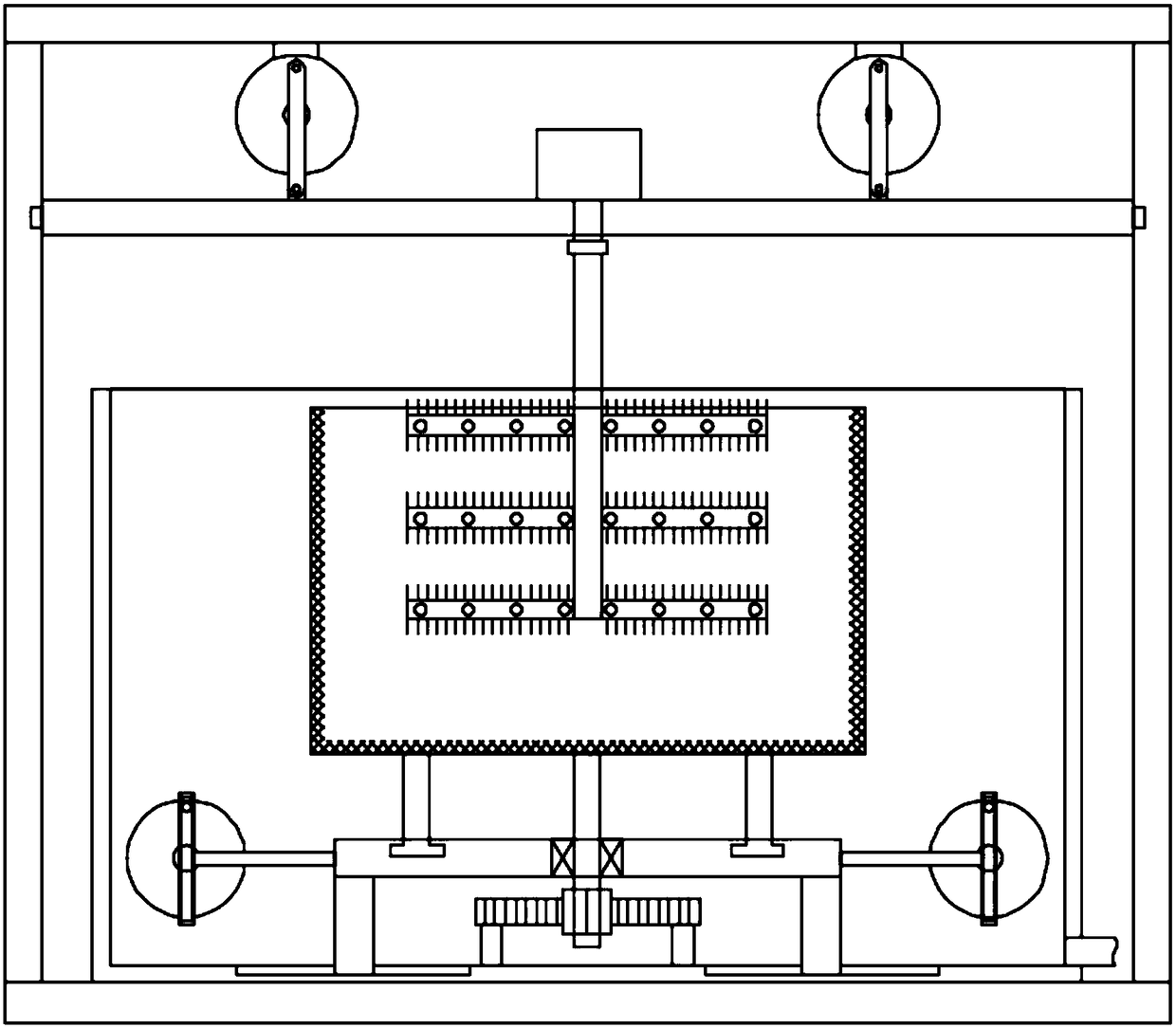

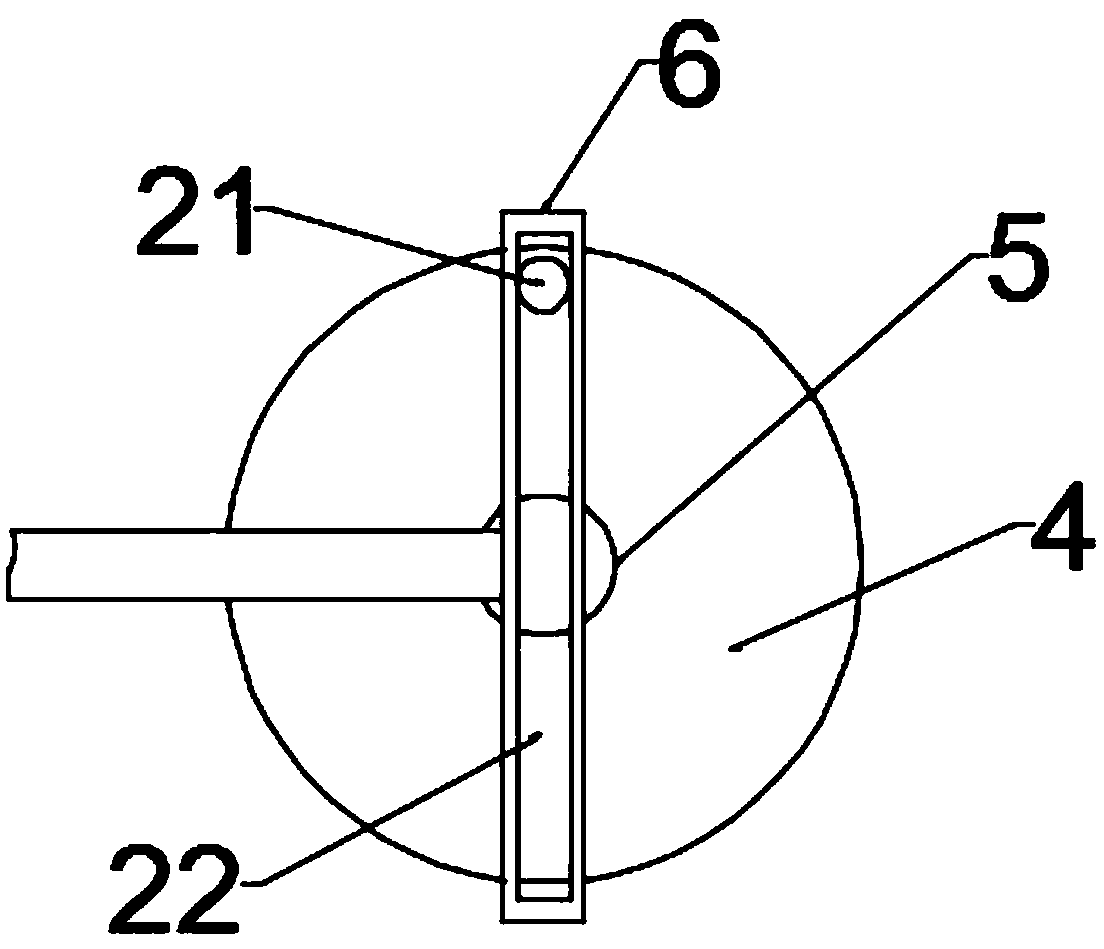

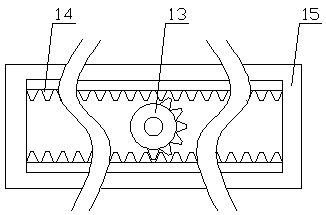

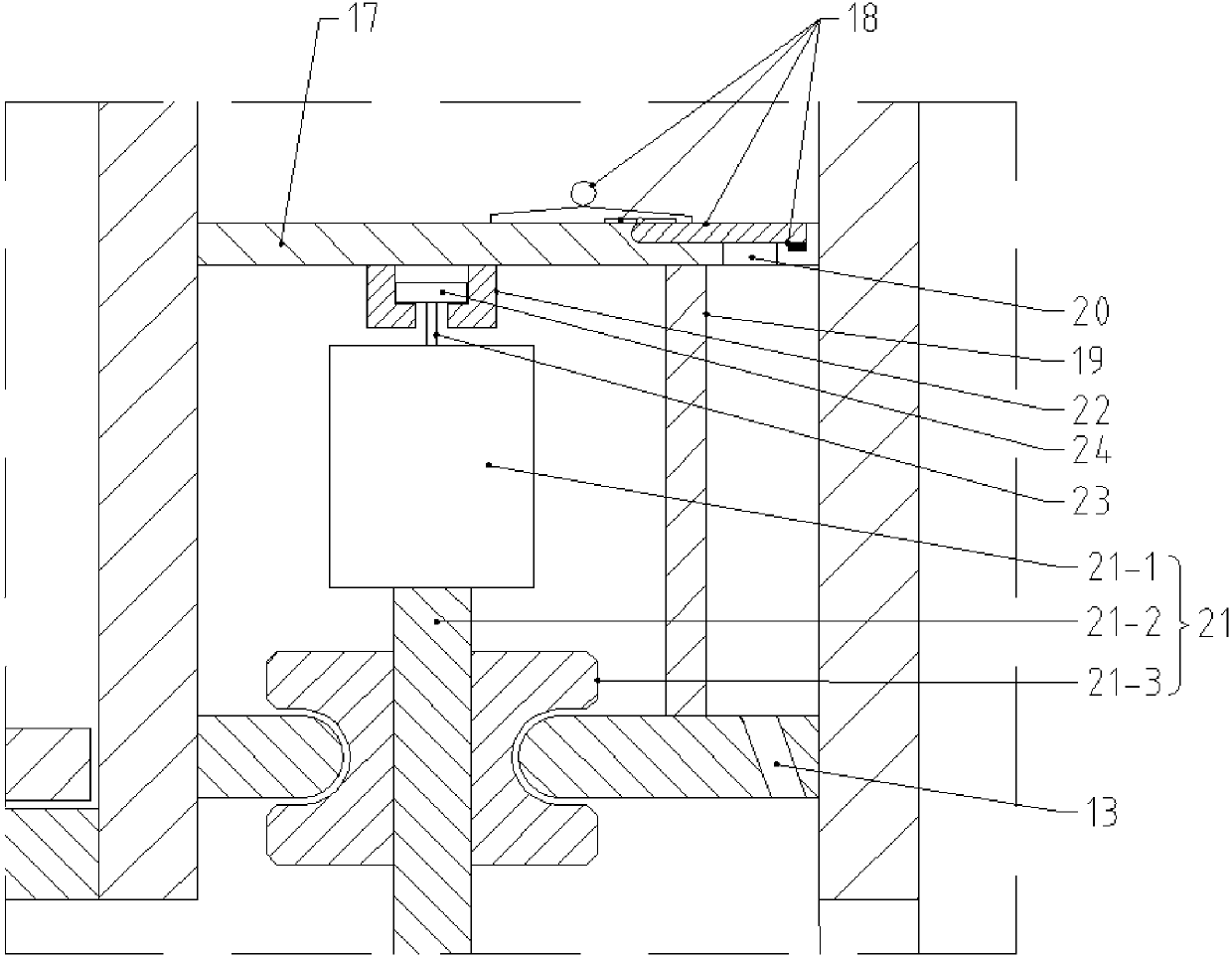

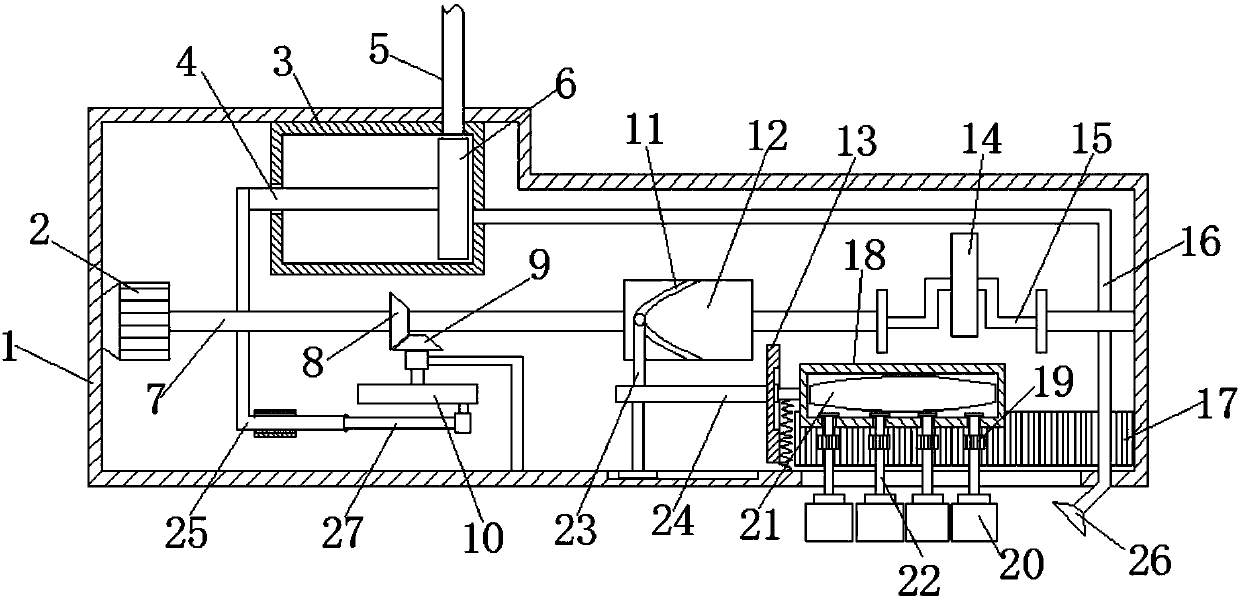

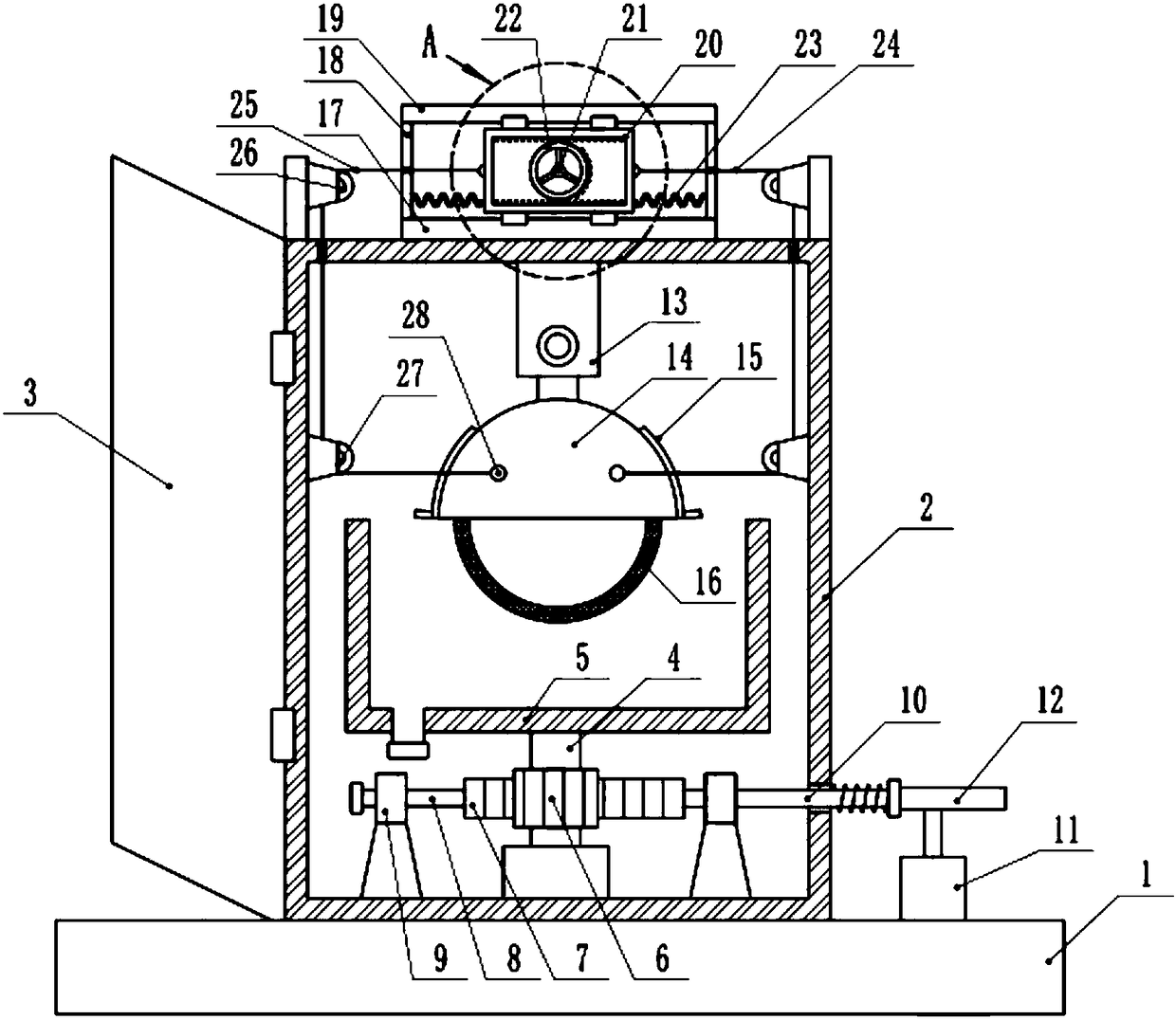

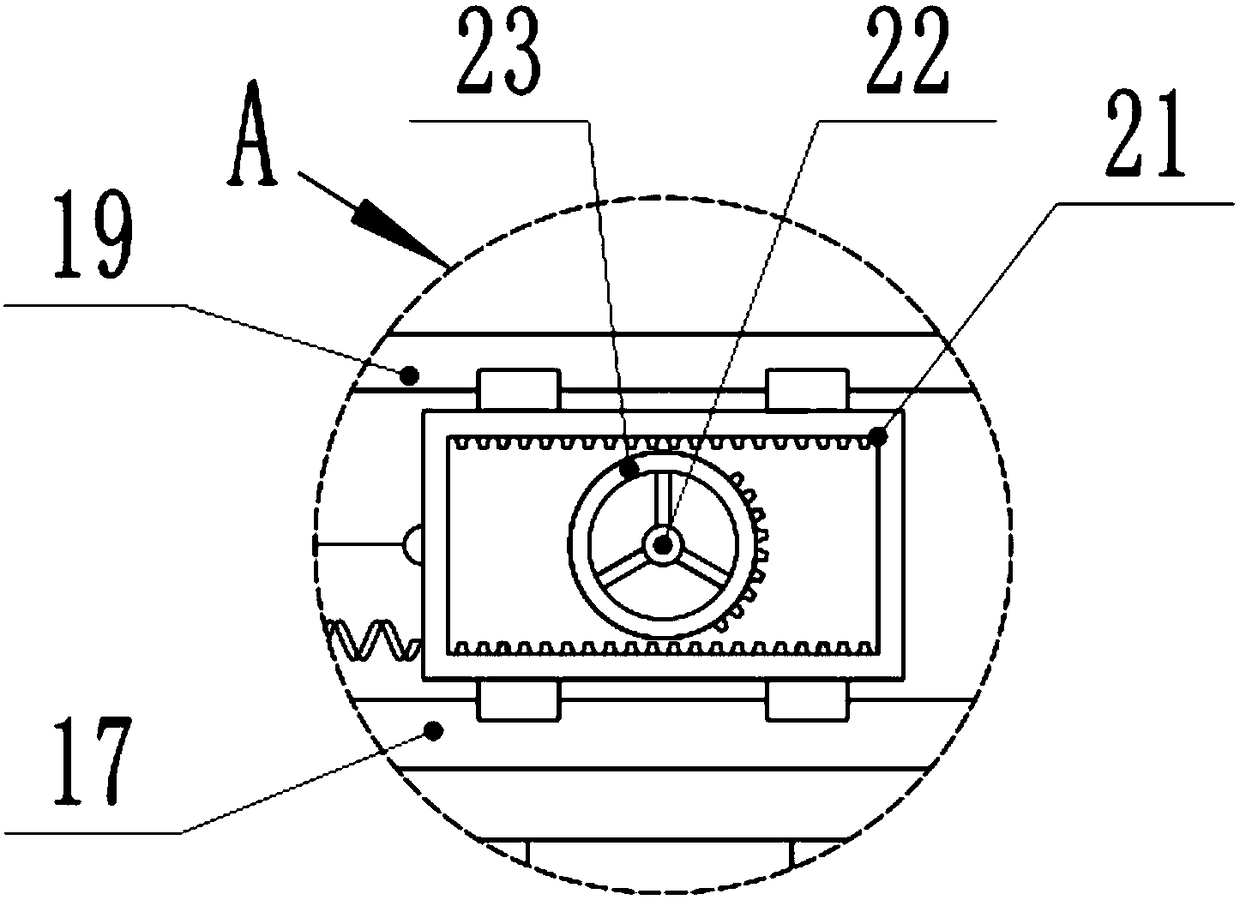

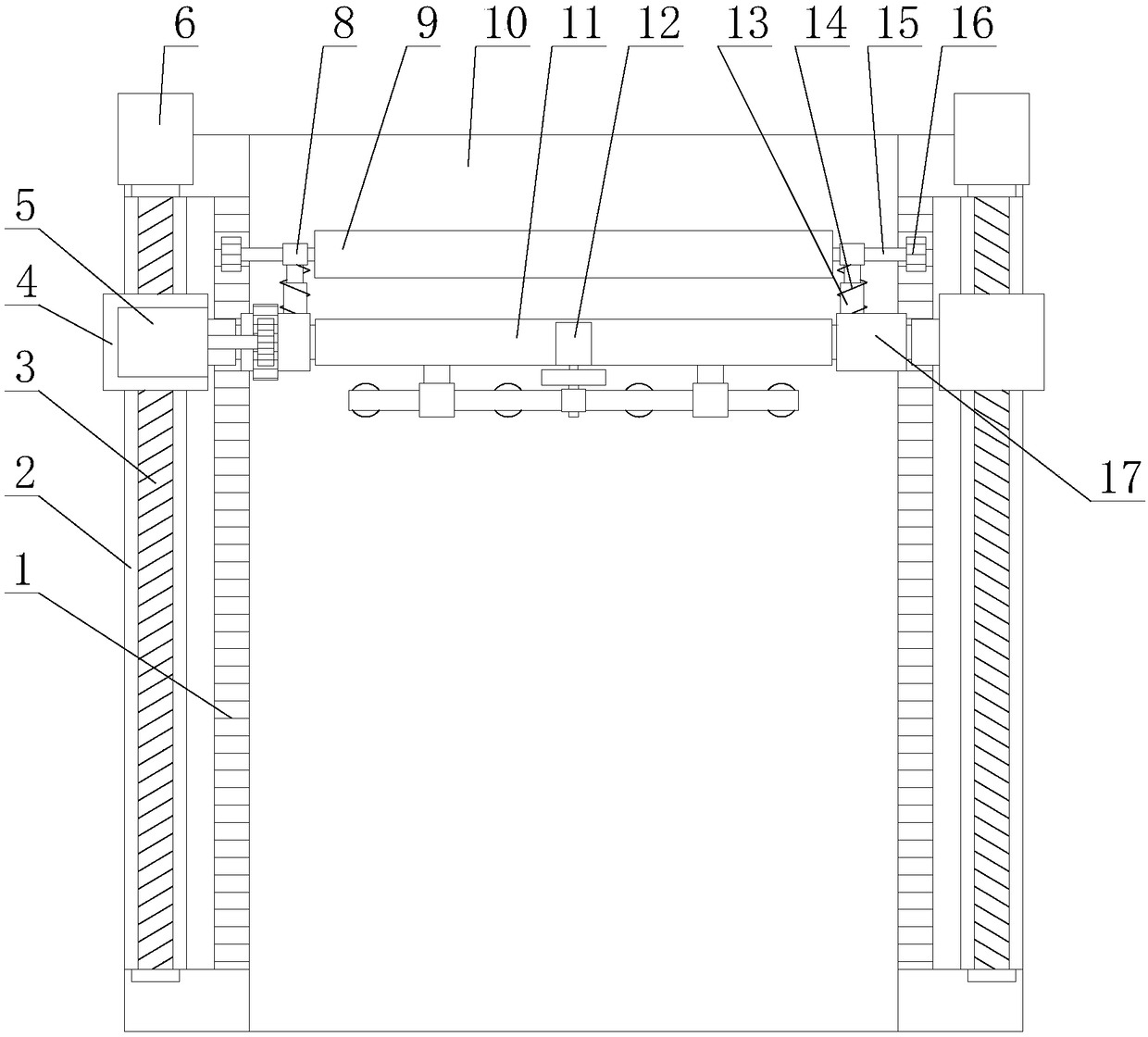

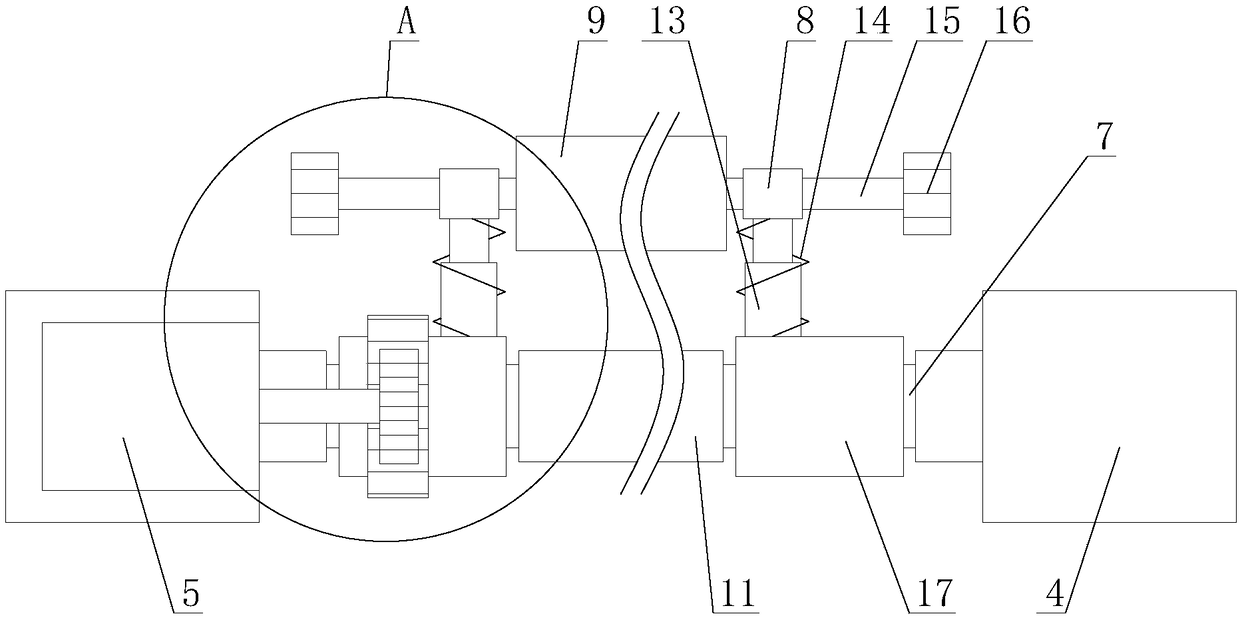

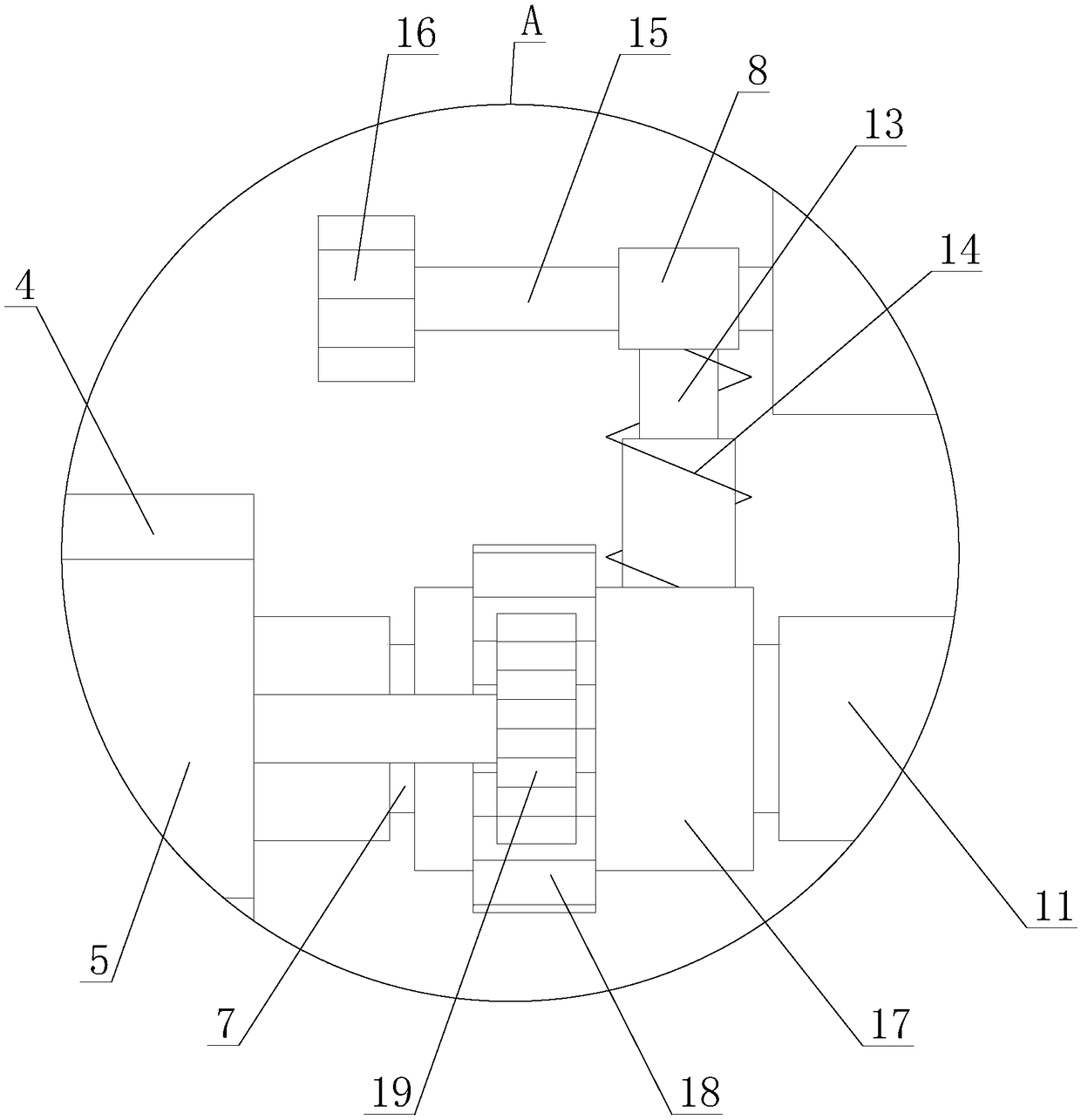

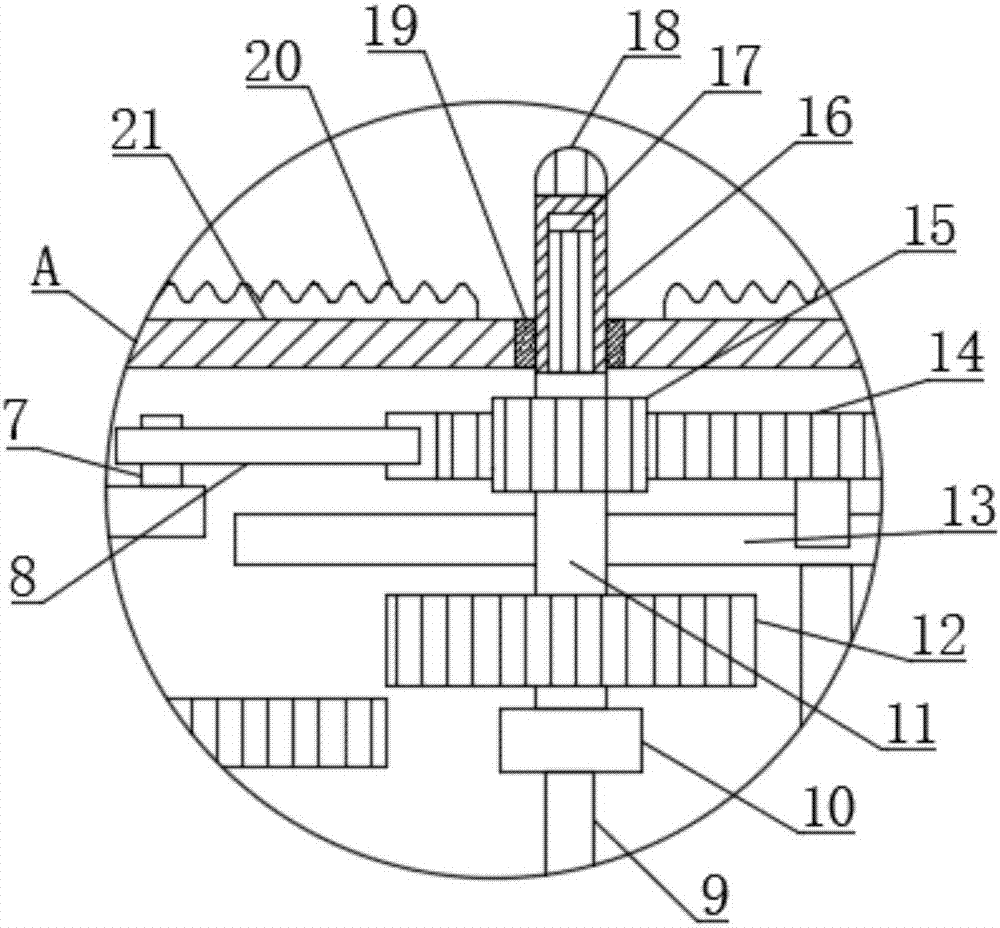

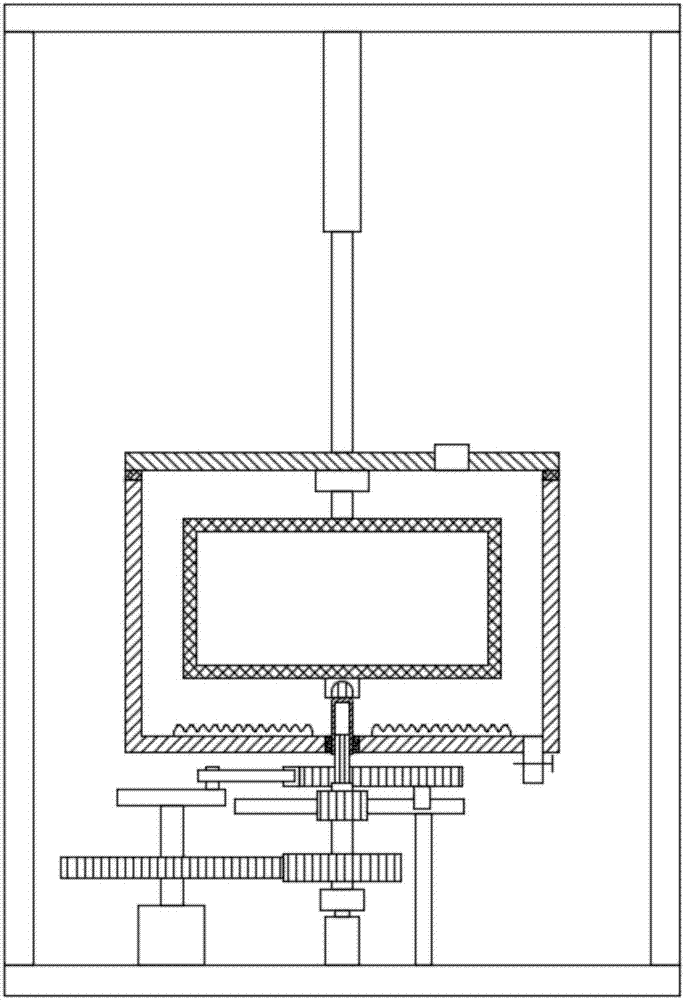

Efficient cleaning device used for mechanical casting mould

PendingCN107442471AImprove cleaning effectSimple structureCleaning using toolsCleaning using liquidsFixed frameEngineering

The invention discloses an efficient cleaning device used for a mechanical casting mould. The efficient cleaning device comprises a workbench, wherein the upper end of the workbench is fixedly connected with a machine body housing; a fixing frame is arranged in the machine body housing; a mould is placed at the upper end of the fixing frame; the periphery of the lower end of the fixing frame is fixedly connected with supporting posts; bottoms of the supporting posts are equipped with rolling balls; a rotary shaft is perpendicularly inserted into the upper-end center of the machine body housing; the lower end of the rotary shaft is horizontally fixedly connected with a cross rod; the end, away from the cross rod, of each telescopic pole is equipped with a cleaning brush; the outer wall of the end, penetrating through the inner wall of the machine body housing and extending outwards, of the rotary shaft is sleeved with a first transmission wheel; a belt is connected between a second transmission wheel and the first transmission wheel; and a water inlet tube is inserted into the inner wall of the upper end of the rotary shaft. The efficient cleaning device is simple in structure, is easy to operate, can effectively remove dust adhered on the inner wall of the casting mould, and ensures quality of cast products.

Owner:湖州永盛机械铸造有限公司

Vegetable washing machine and its method of washing vegetable and fruit and eliminating pesticide and pollutants

InactiveCN1931036AReduce wearImprove cleaning effectKitchen equipmentFood treatmentPollutantPesticide

The present invention is method of washing vegetable and fruit and eliminating pesticide pollutant in the vegetable washing machine, and features that under the driving of the motor, vegetable and fruits inside the washing basket rotate in the same direction and circular flushing water flow is formed inside the vegetable washing machine to wash vegetable and fruits effectively while resulting in less damage to the washed vegetable and fruits.

Owner:覃江碧

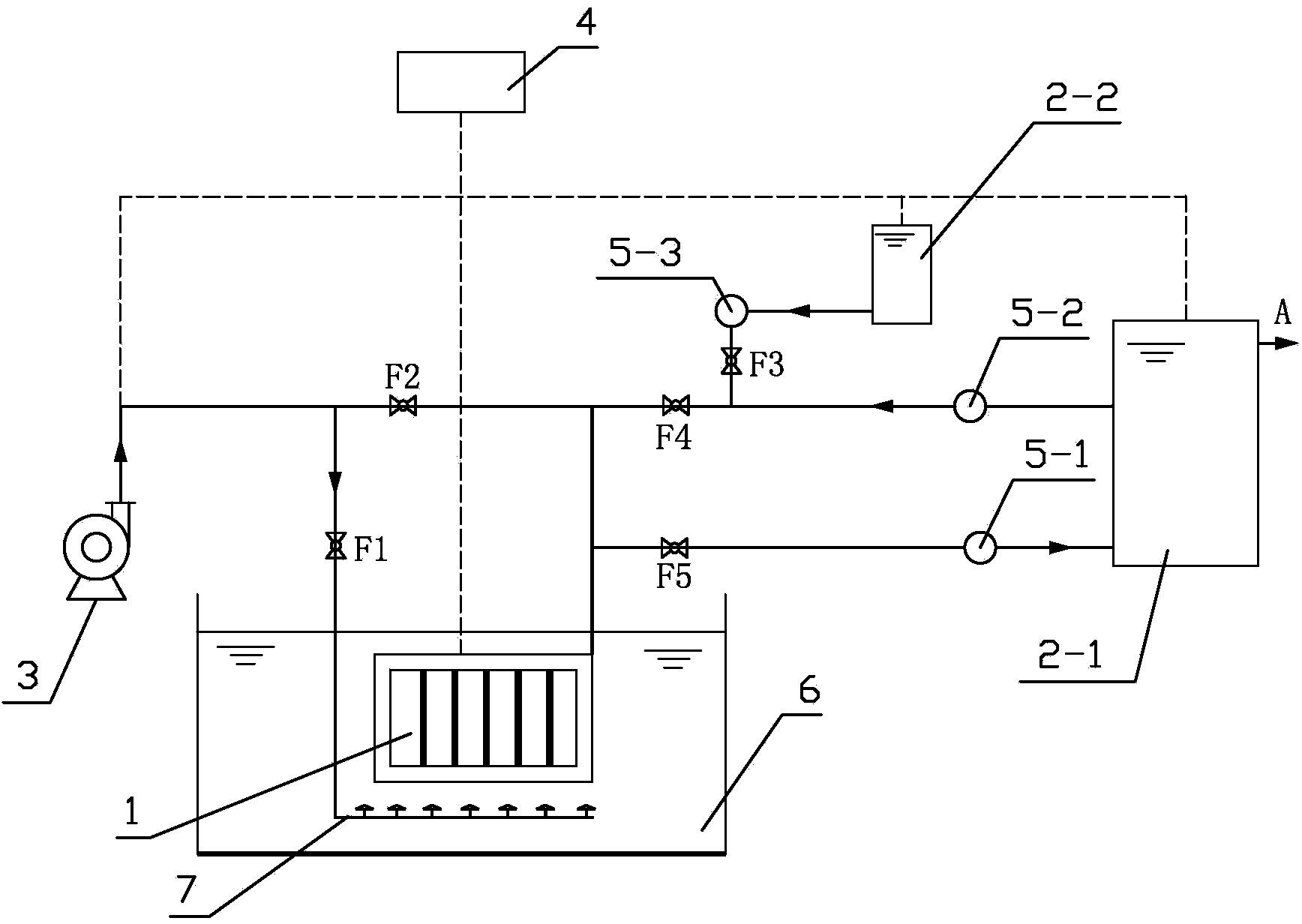

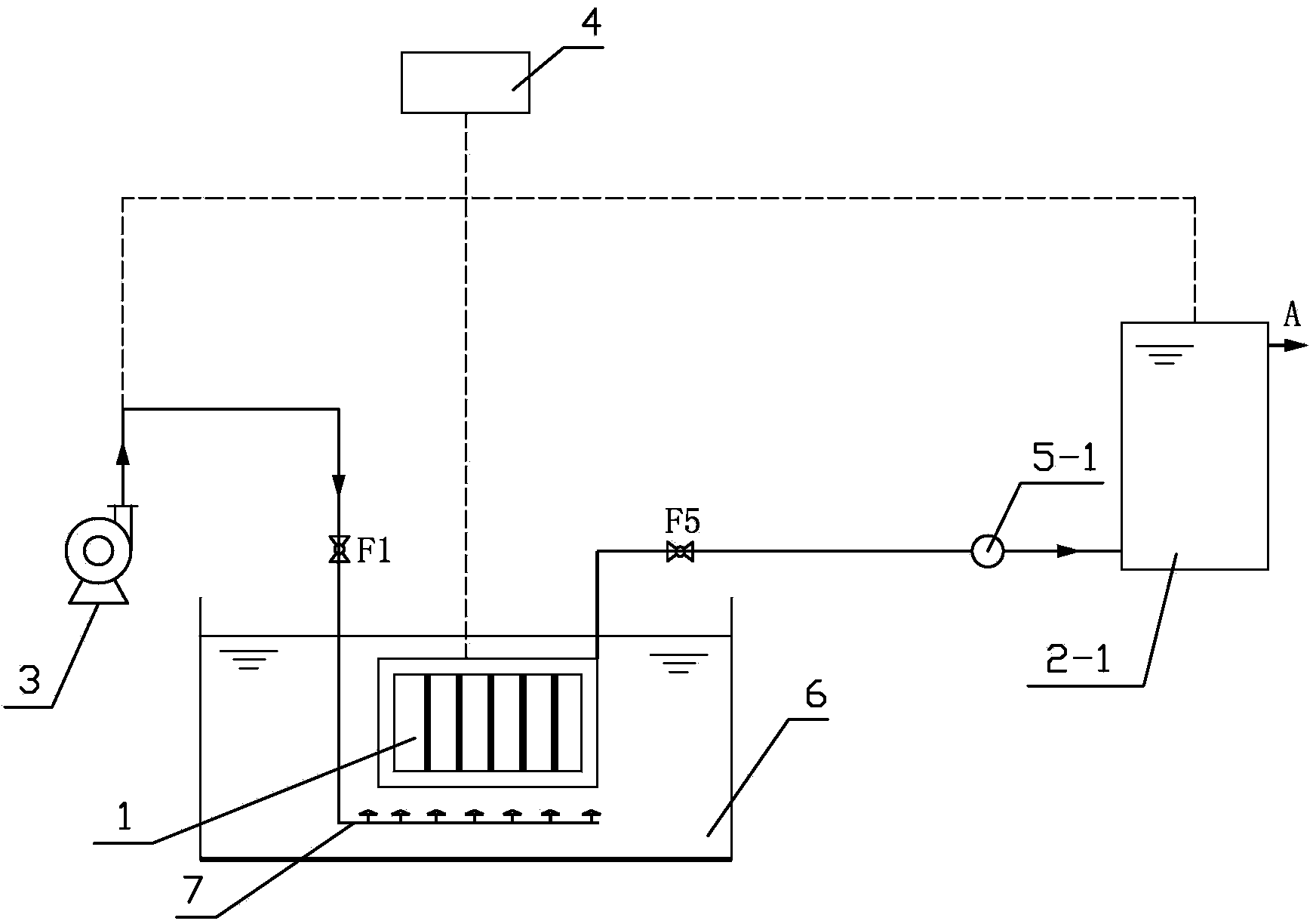

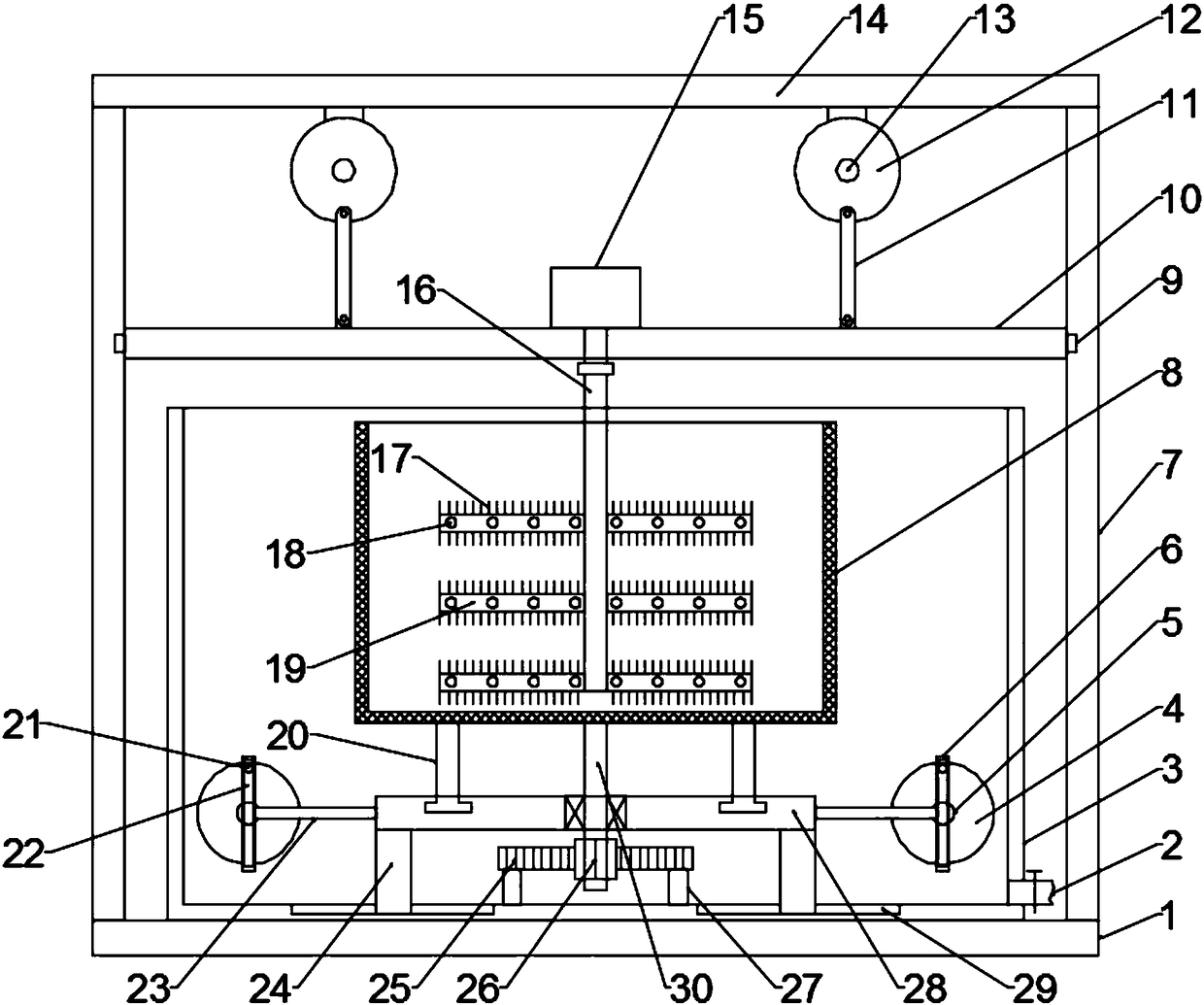

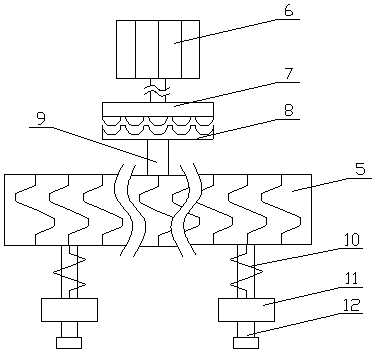

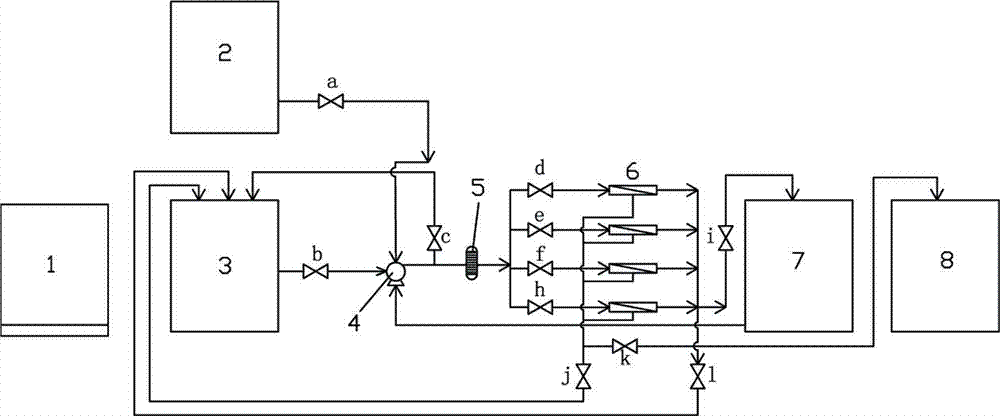

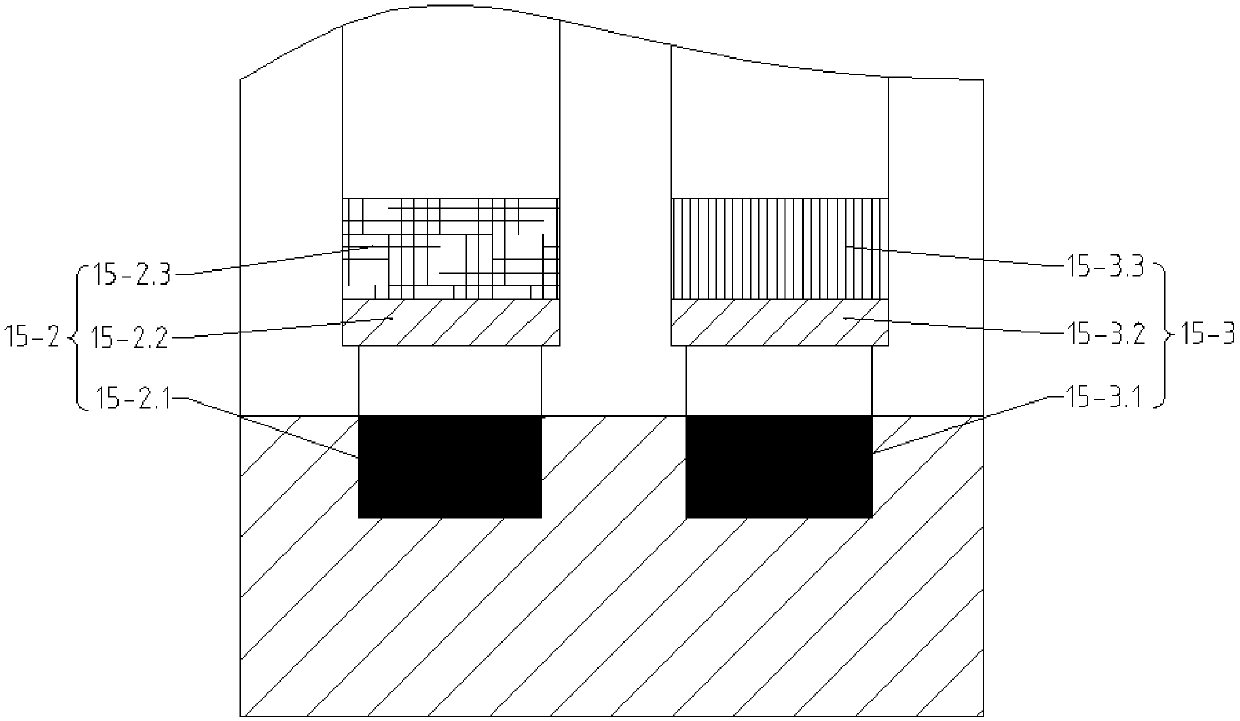

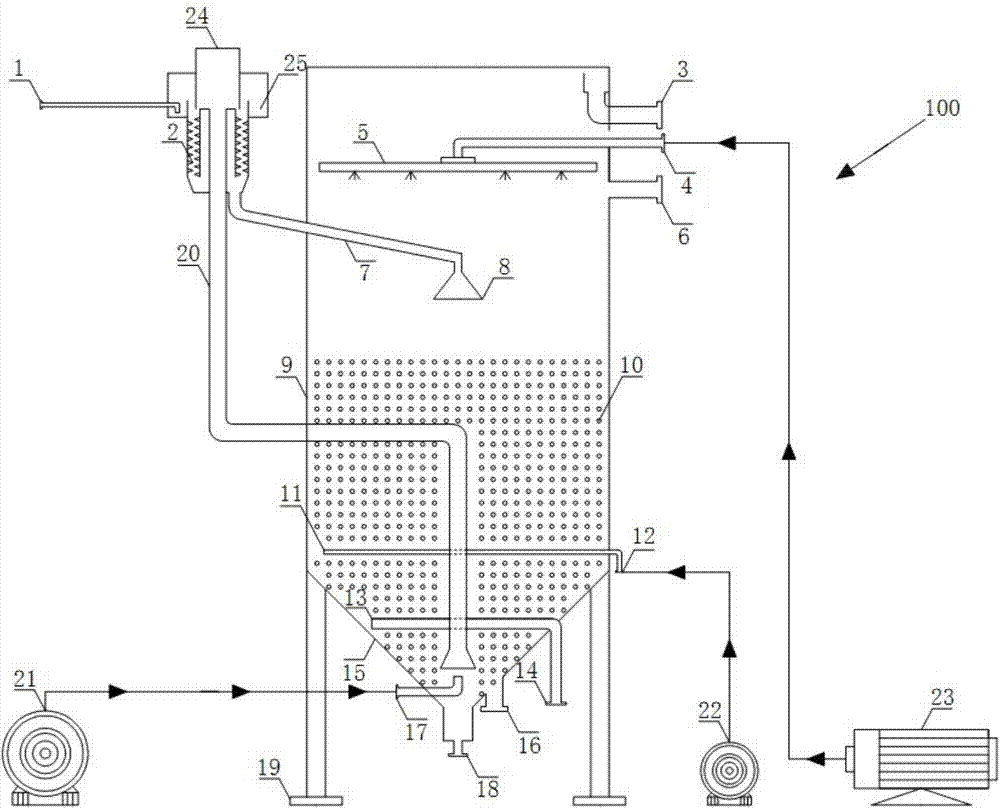

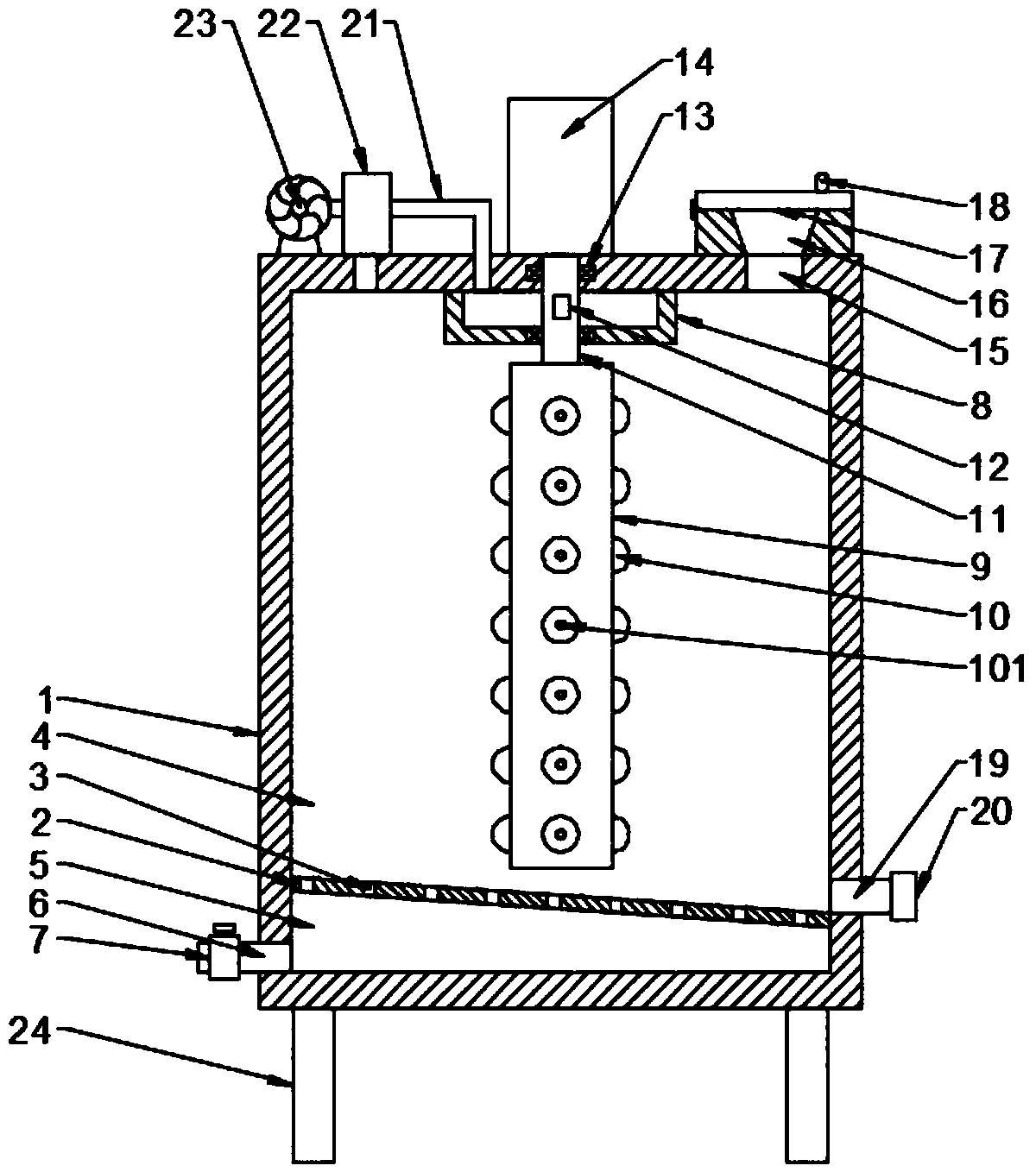

Immersed type on-line cleaning method and device for slab ceramic membrane

InactiveCN103752175AImprove cleaning effectGood system integrationSemi-permeable membranesAutomatic controlFlat panel

The invention relates to an immersed type on-line cleaning method and device for a slab ceramic membrane. The invention aims to provide the method which can be used for cleaning the slab ceramic membrane in an in-situ or online manner without separating the ceramic membrane and a reactor, and the method has the characteristics of high membrane flux recovery speed, low energy consumption, high cleaning efficiency, low operation cost and automatic control. The provided device has the characteristics of simple structure and convenience in use. According to the technical scheme, the immersed type on-line cleaning process for the slab ceramic membrane comprises the following steps in sequence: (1) turning on on-line cleaning; (2) back-flushing a liquid phase; (3) back-flushing gas and liquid in a combined manner; and (4) finishing the on-line cleaning. The immersed type online cleaning device for the slab ceramic membrane comprises an aeration pipeline and a control system, wherein the on-line cleaning device further comprises a liquid-phase back-flushing system; the liquid-phase back-flushing system is assorted with a back-flushing pump and is communicated with the aeration pipeline through a pipeline; a cleaning agent preparation device is communicated with the liquid-phase back-flushing system through a pipeline.

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

Sweet potato cleaning device for food processing

The invention discloses a sweet potato cleaning device for food processing. The sweet potato cleaning device comprises a bottom plate, a cleaning frame, a water containing box, a mounting plate, a driving device, a lifting plate, a second motor, a second disc, a connecting rod, a third motor, a stirring shaft, a hairbrush, a rotating shaft, a gear and a rack, wherein the driving device comprises afirst motor, a first disc, a movable rod and a connecting rod. The sweet potato cleaning device disclosed by the invention is provided with the driving device, the third motor, the stirring shaft andthe stirring rod, and the cleaning box is driven to move from the left to right by virtue of matching, so that sweet potatoes in the cleaning box continuously shake, sediments on the sweet potato surface are shaken off, and cleaning is complete. Due to the arrangement of the rotating shaft, the gear and the rack, the cleaning box continuously rotates forwards and backwards by virtue of matching,and the cleaning effect is further improved, so that cleaning is rapid and fully complete. Due to the arrangement of the second motor, the second disc and the connecting rod, the second disc is drivento rotate by the second motor, the stirring shaft and the stirring rod are driven to move up and down by virtue of matching, the cleaning is full, and the cleaning efficiency is further improved.

Owner:侯小芳

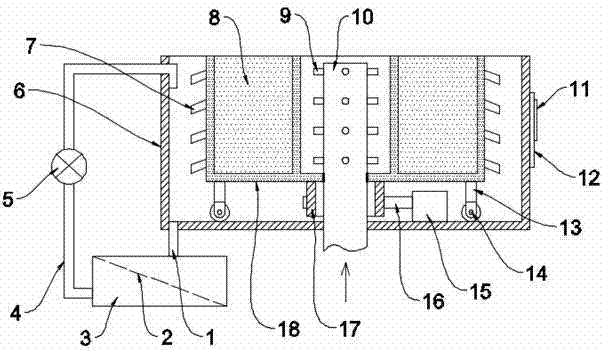

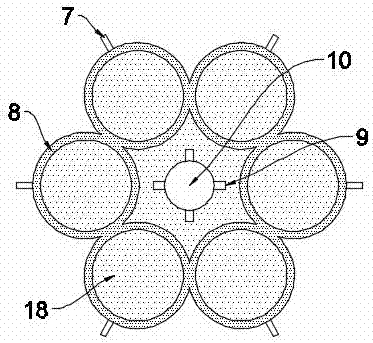

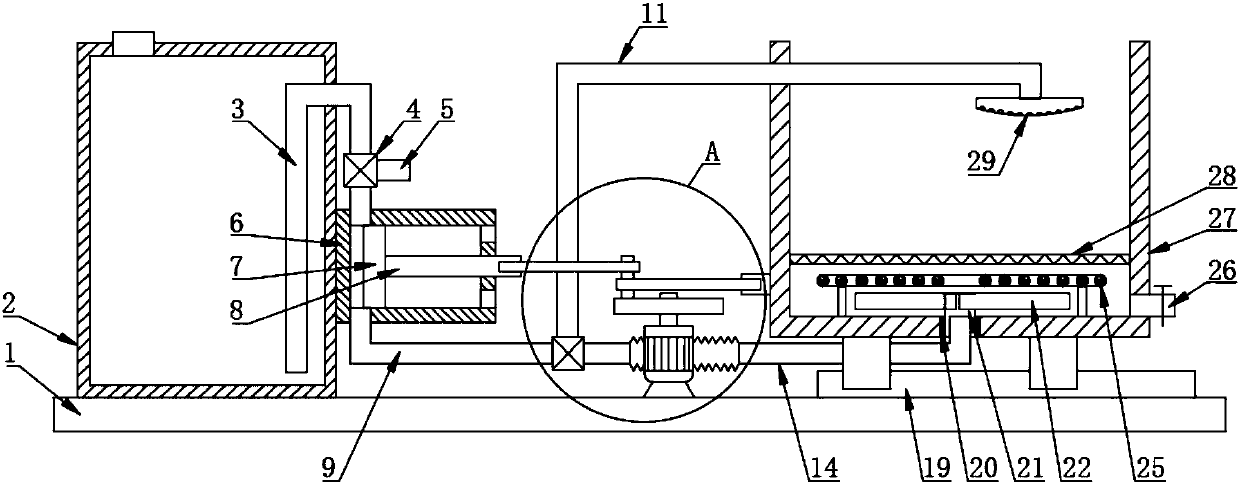

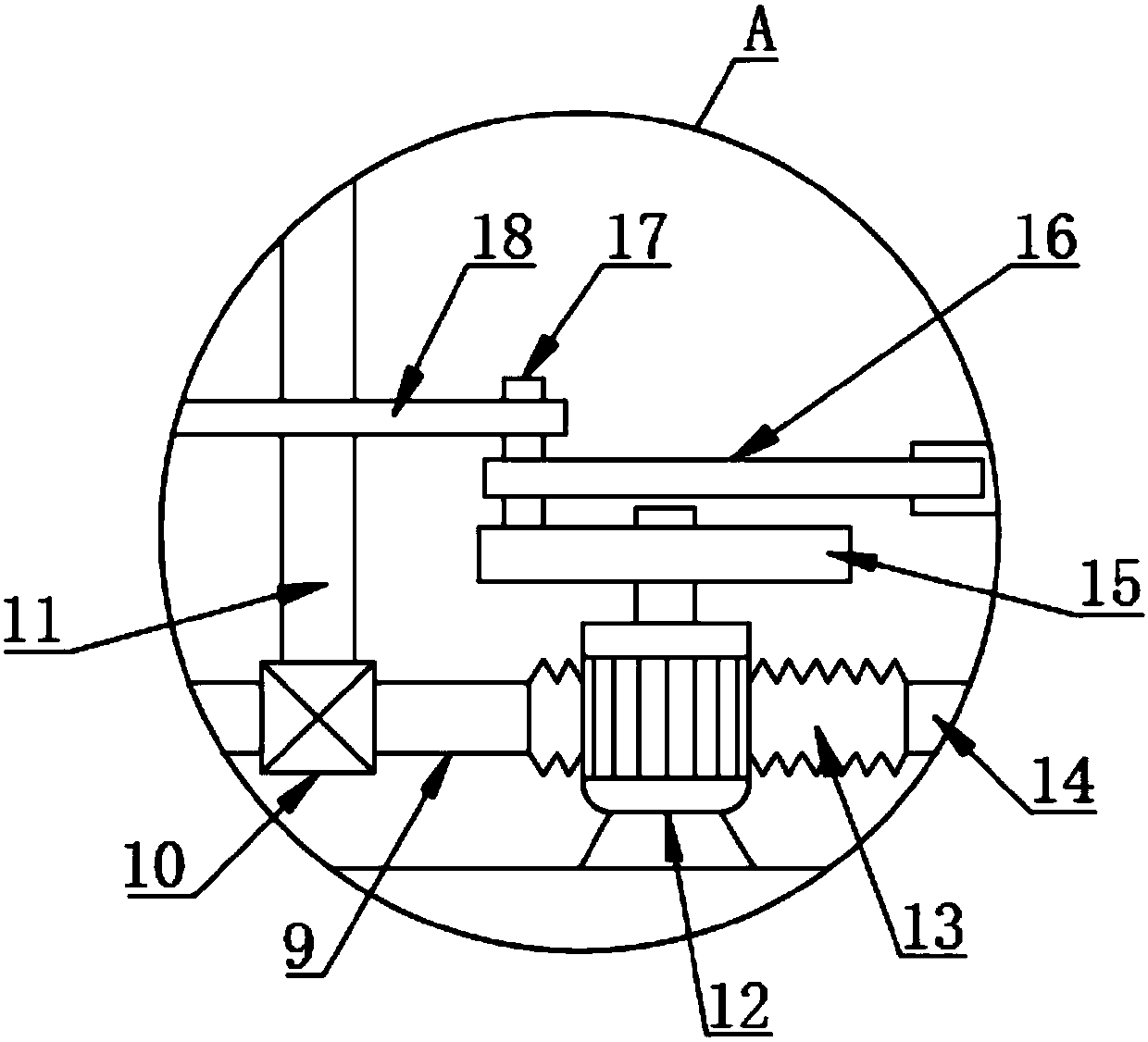

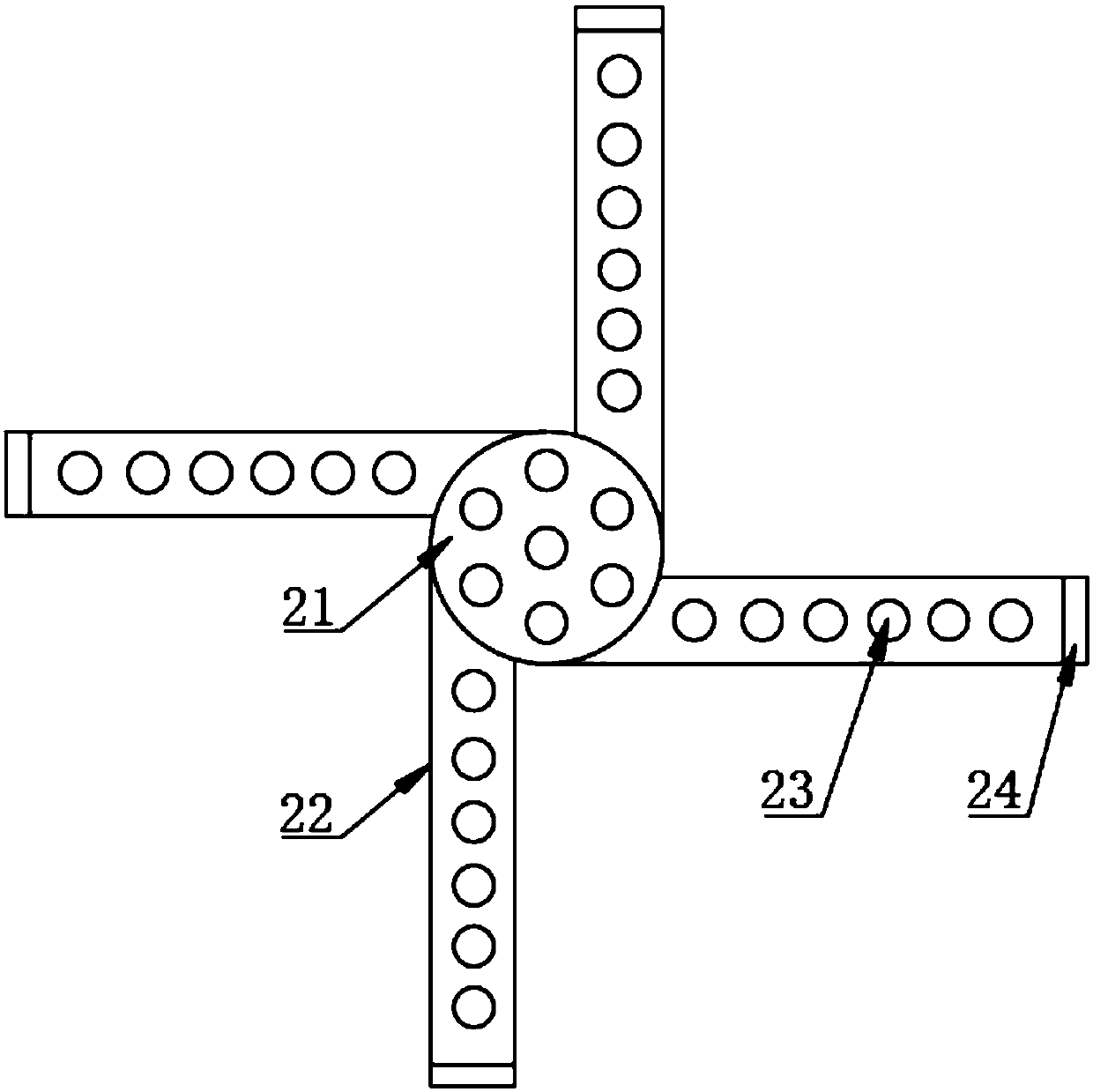

Cleaning machine capable of processing multiple types of traditional Chinese medicine simultaneously

InactiveCN107282522AImprove cleaning effectWide range of applicationsDrying gas arrangementsCleaning using liquidsDrive motorEngineering

The invention discloses a cleaning machine capable of processing various kinds of Chinese medicinal materials at the same time. The lower part is rotated on the water and air inlet pipe and installed with a mesh bottom plate, on which a plurality of drug storage net tubes are installed, and on the upper side of the mesh bottom plate is installed a number of nozzles on the water and air inlet pipe, and the bottom of the cleaning box is placed on the water and air inlet pipe. The upper end of the air inlet pipe is set with a drum, the upper end of the drum is connected and fixed to the mesh bottom plate, the drum is connected to the driving motor installed at the bottom of the cleaning box through the transmission belt, and the bottom of the cleaning tank is provided with a drain pipe, and the lower end of the drain pipe is connected to On the top of the water tank, there is a return pipe on the lower left side of the water tank. A circulation pump is installed on the return pipe. The other end of the return pipe is located on the upper part of the inner wall of the cleaning tank. The invention has the functions of cleaning and drying at the same time, one machine is multi-purpose, and the application range is wide.

Owner:李爱禄

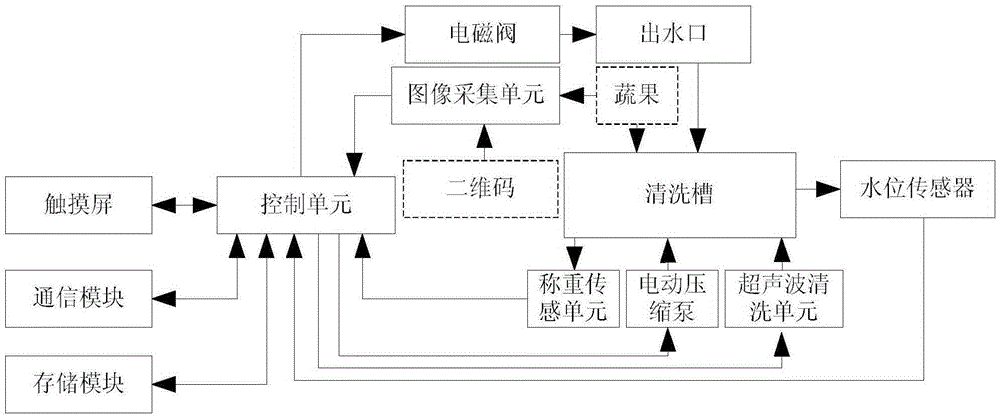

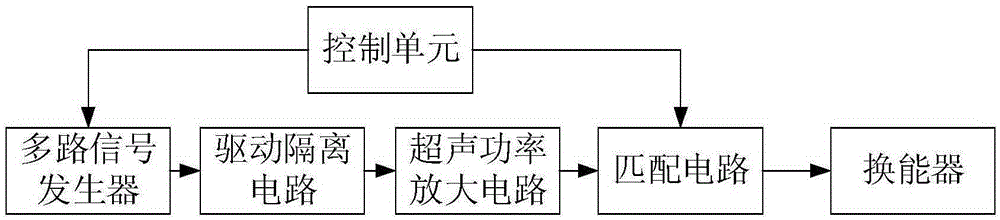

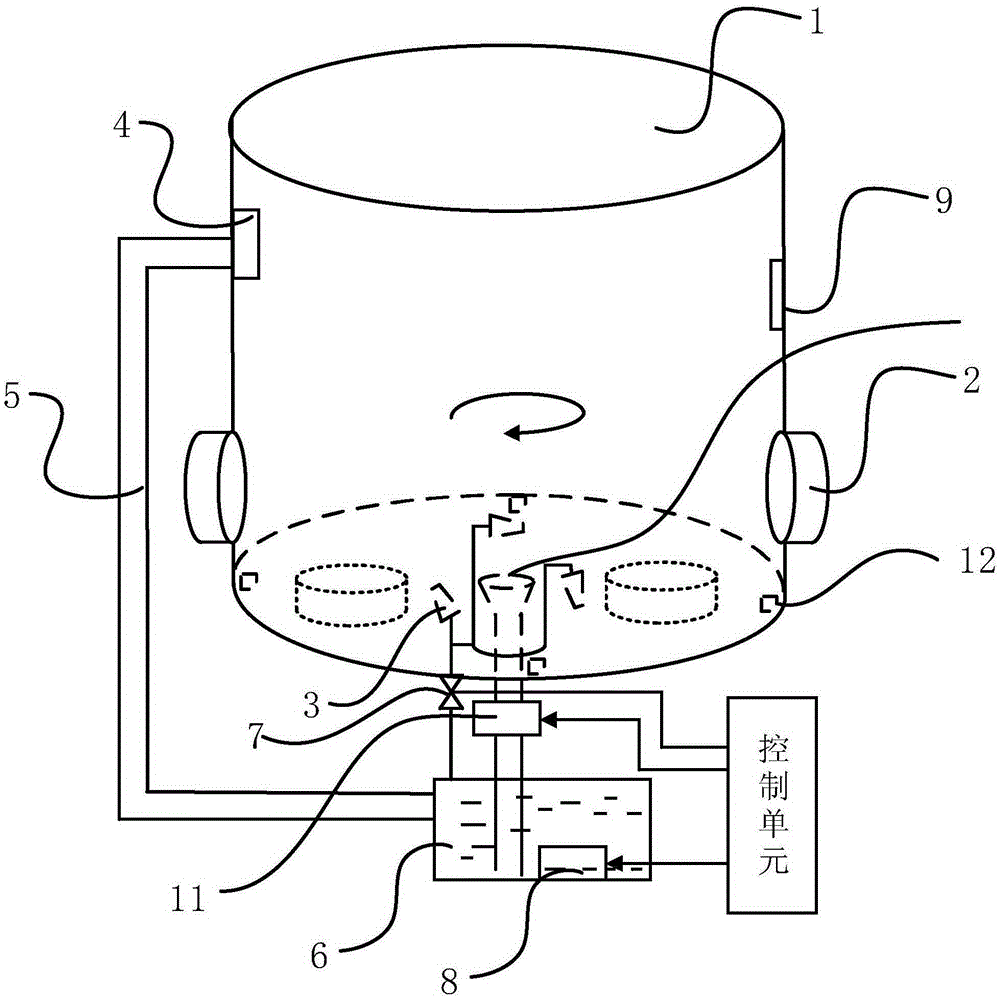

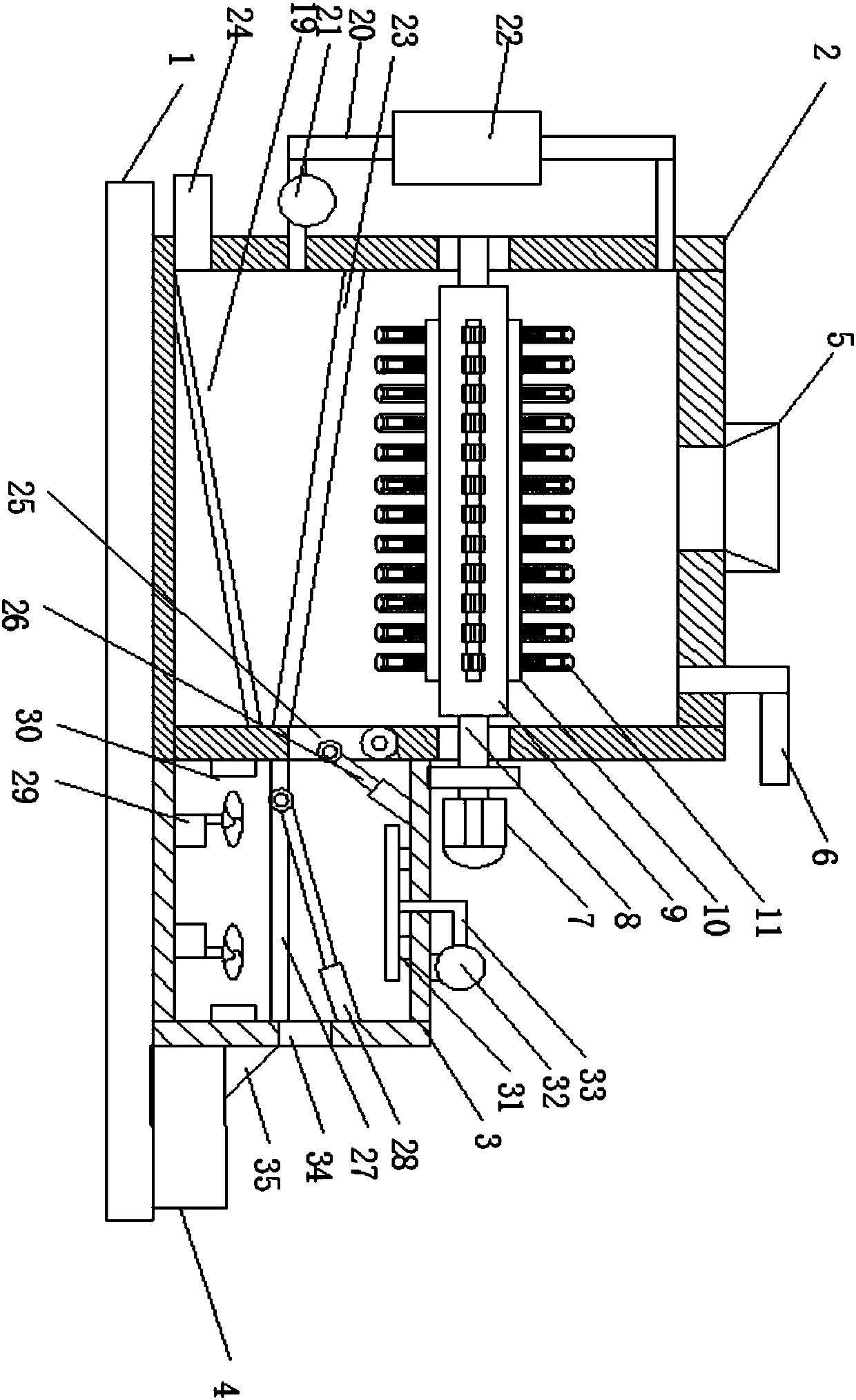

Automatic ultrasound cleaning machine based on image processing and operating method thereof

InactiveCN105231468AImprove cleaning effectSimple and efficient operationClimate change adaptationFood treatmentWater circulationPesticide

The invention relates to an automatic ultrasound cleaning machine based on image processing and an operating method thereof. The automatic ultrasound cleaning machine comprises an image acquiring unit for acquiring fruit and vegetable image data; a weighing sensing unit for obtaining weight data of fruits and vegetables placed in a cleaning tank; and a control unit connected with the image acquiring unit and the weighing sensing unit, wherein the control unit is suitable for identifying the kinds of the fruits and vegetables according to the fruit and vegetable image data, and cleaning the fruits and vegetables based on the weight data of the fruits and vegetables. With the adoption of the automatic ultrasound cleaning machine and the operating method thereof, fruits and vegetables can be automatically cleaned according to the kinds and weights of the fruits and vegetables, and pesticides and contaminants on the fruits and vegetables can be effectively eliminated. With a set of water circulation system, the cleaning effect is improved on the premise of saving water. Furthermore, the automatic ultrasound cleaning machine is simple and convenient for a user to operate, and the user experience is improved.

Owner:HOHAI UNIV CHANGZHOU

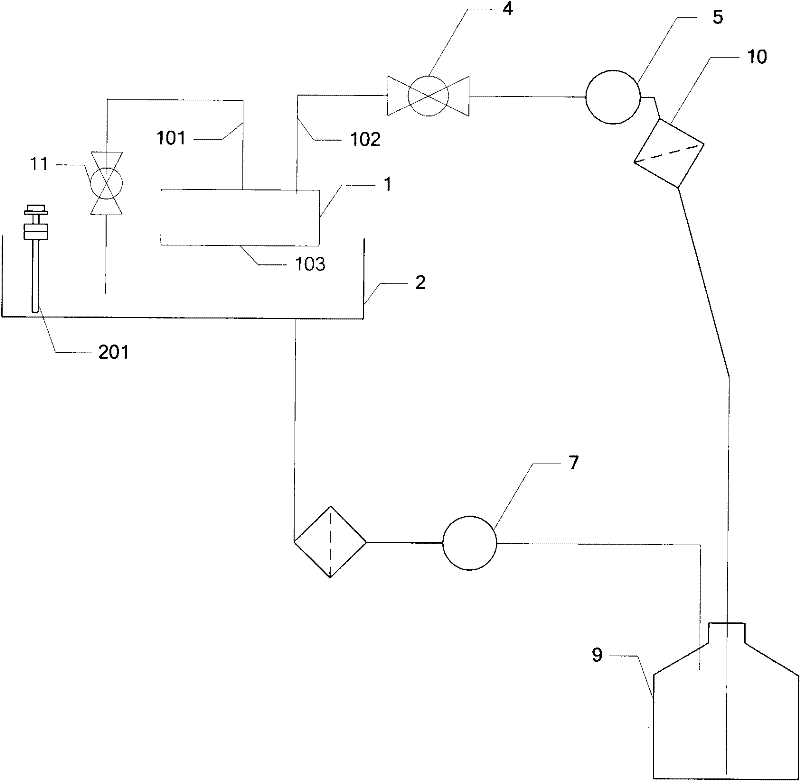

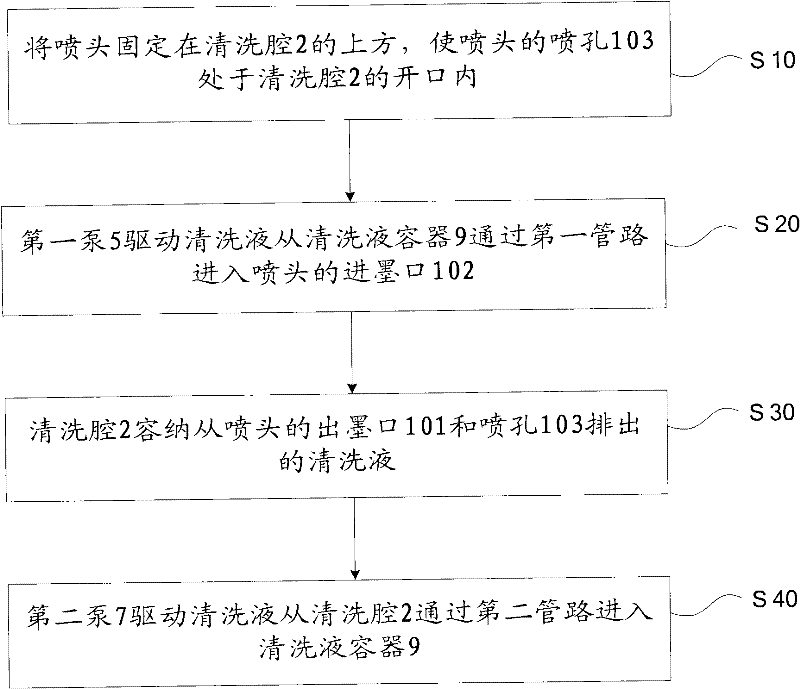

Spray head cleaning device and working method thereof

InactiveCN102442068AOvercome poor cleaning effectImprove cleaning effectPrintingMechanical engineering

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

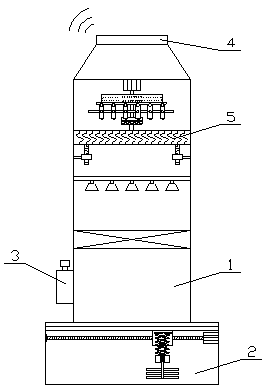

Spray tower with automatic cleaning function based on internet of things

InactiveCN107854933AImprove securityImprove cleaning effectDispersed particle filtrationRotary stirring mixersSpray towerInternet of Things

The invention relates to a spray tower with an automatic cleaning function based on the internet of things. The tower comprises a main tower body, a sedimentation pool, an air inlet, an air outlet, afilling layer, a spraying layer and a demisting layer and further comprises a cleaning mechanism and a decontamination mechanism. The cleaning mechanism comprises a vibration component and a washing component, and the decontamination mechanism comprises a mobile component and a stirring component. According to the spray tower with the automatic cleaning function based on the internet of things, solid particulate matter and remaining liquid drops in the demisting layer can be shaken off through the cleaning mechanism, the situation can be avoided that contaminants on a baffle in the demisting layer block the demisting layer, the contaminants on the baffle in the demisting layer are flushed away by the water flow, and the cleaning effect is improved; sediment in the sedimentation pool can bestirred through the decontamination mechanism and can be sufficiently mixed with pool water, so that the sediment is driven to be discharged, the decontamination effect is achieved, and compared witha manual cleaning mode, the spray tower is convenient and efficient in cleaning, the working intensity of people is greatly lowered, and the practicability of the spray tower is improved.

Owner:NANJING LINGYA AUTOMOBILE TECH RES INST

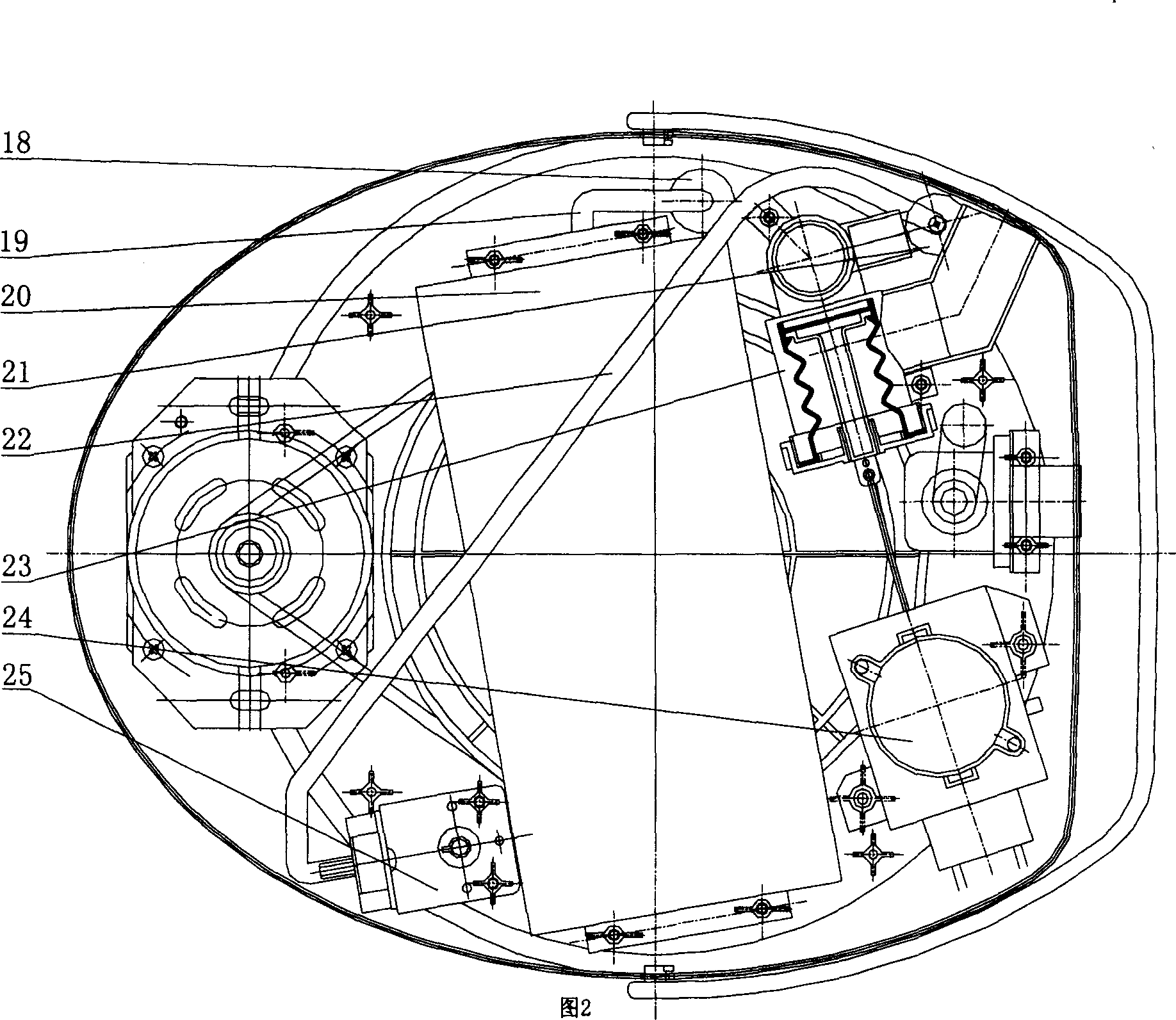

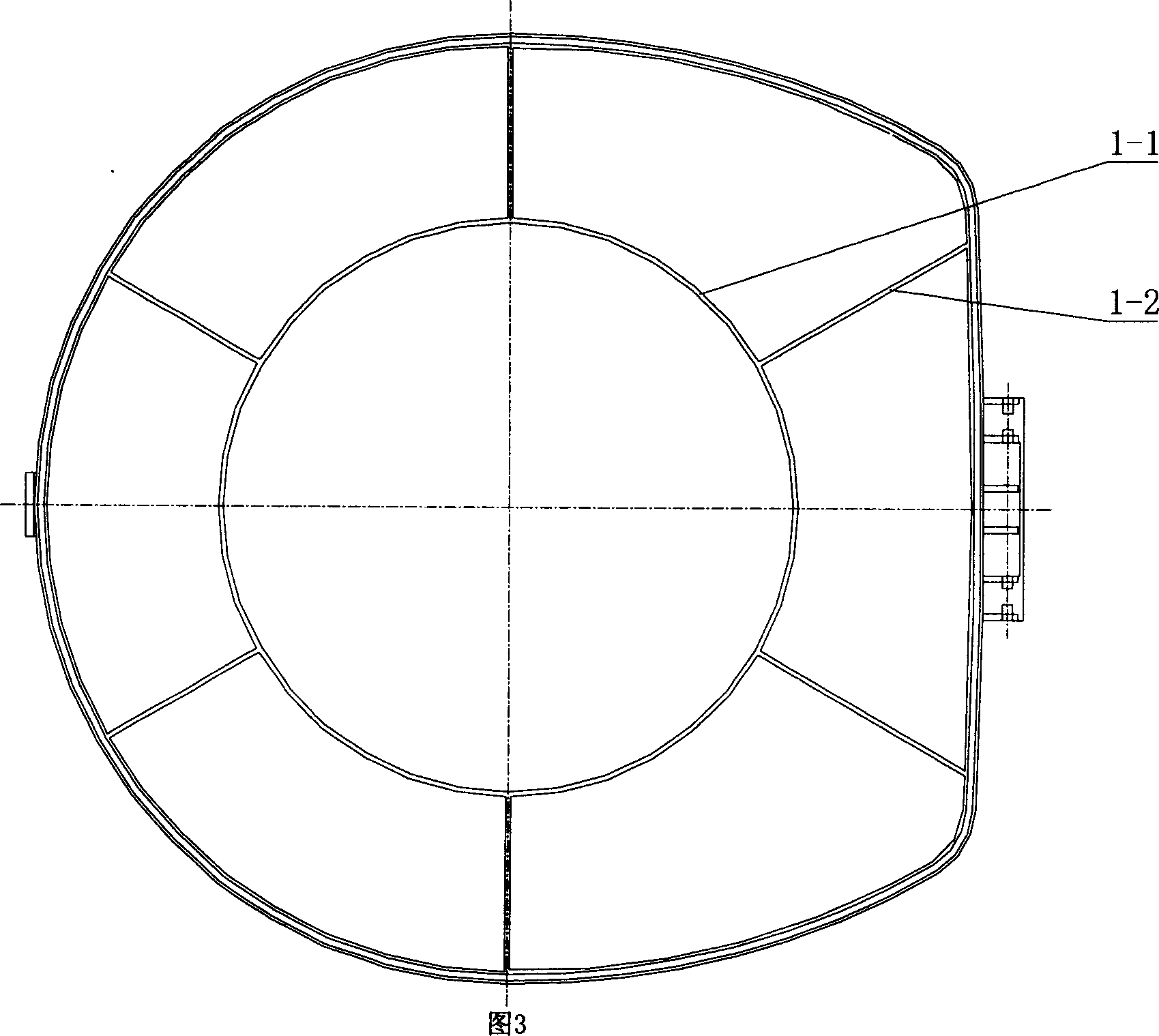

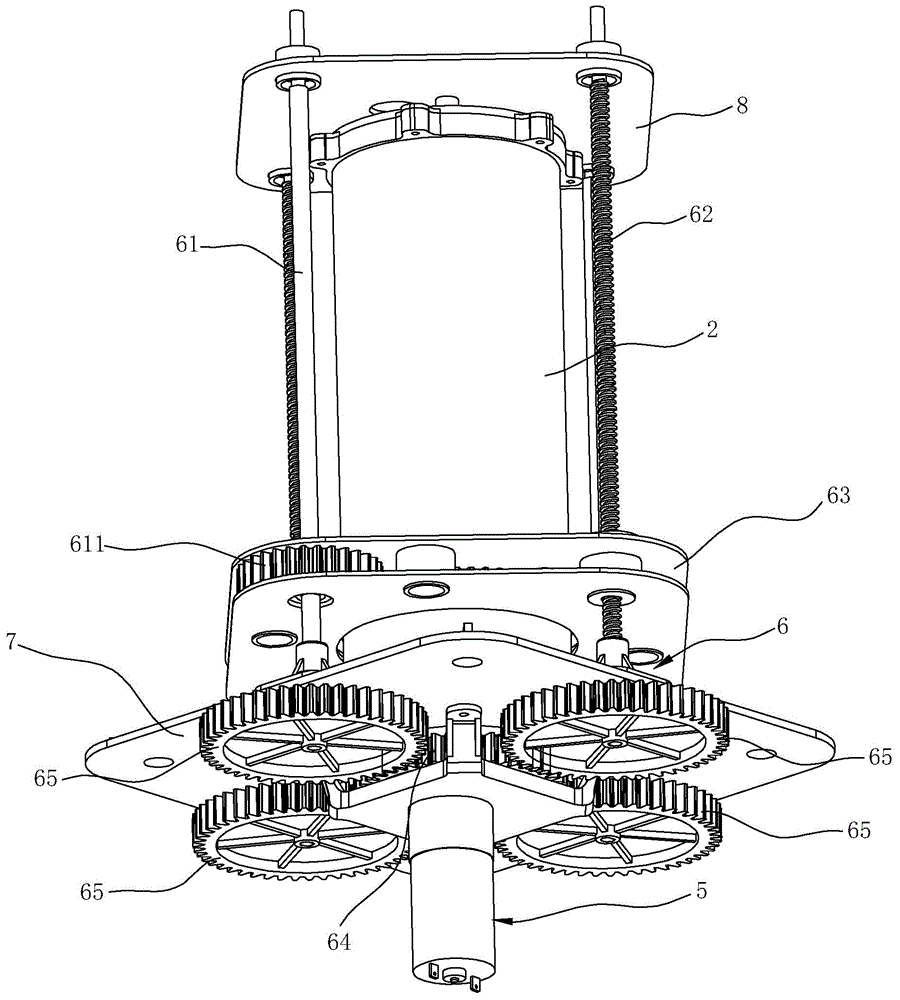

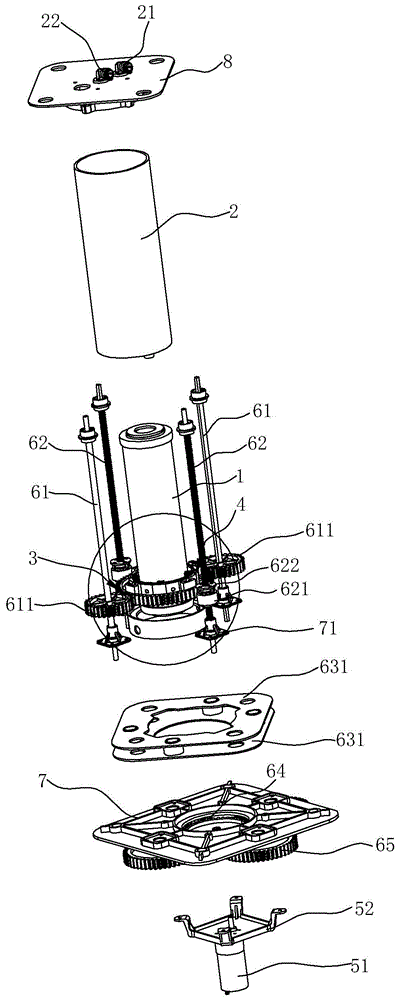

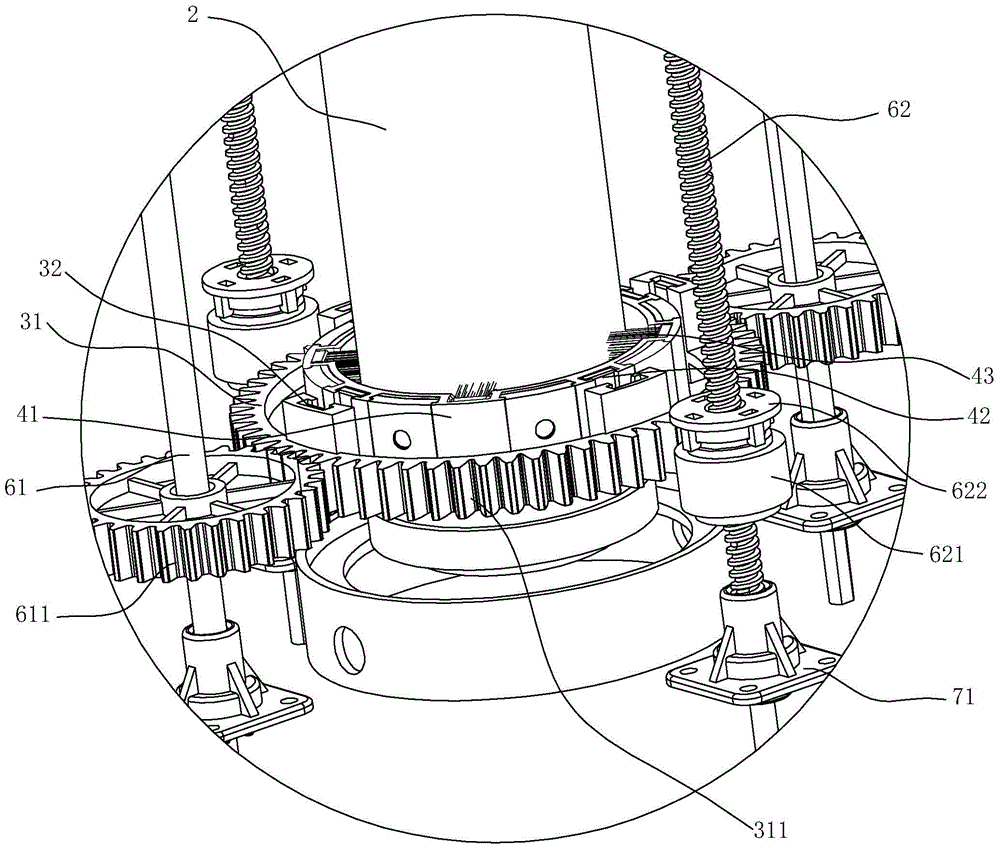

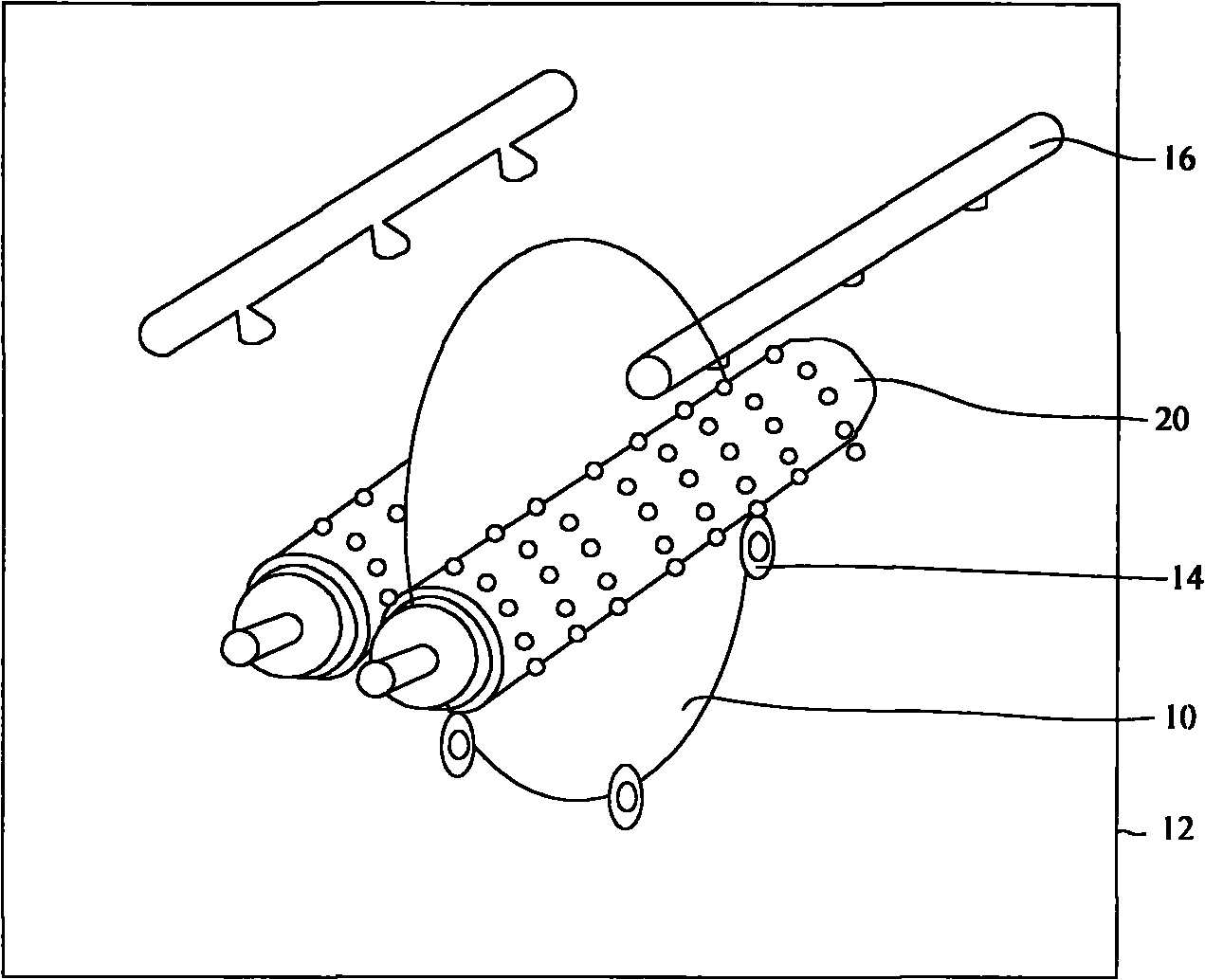

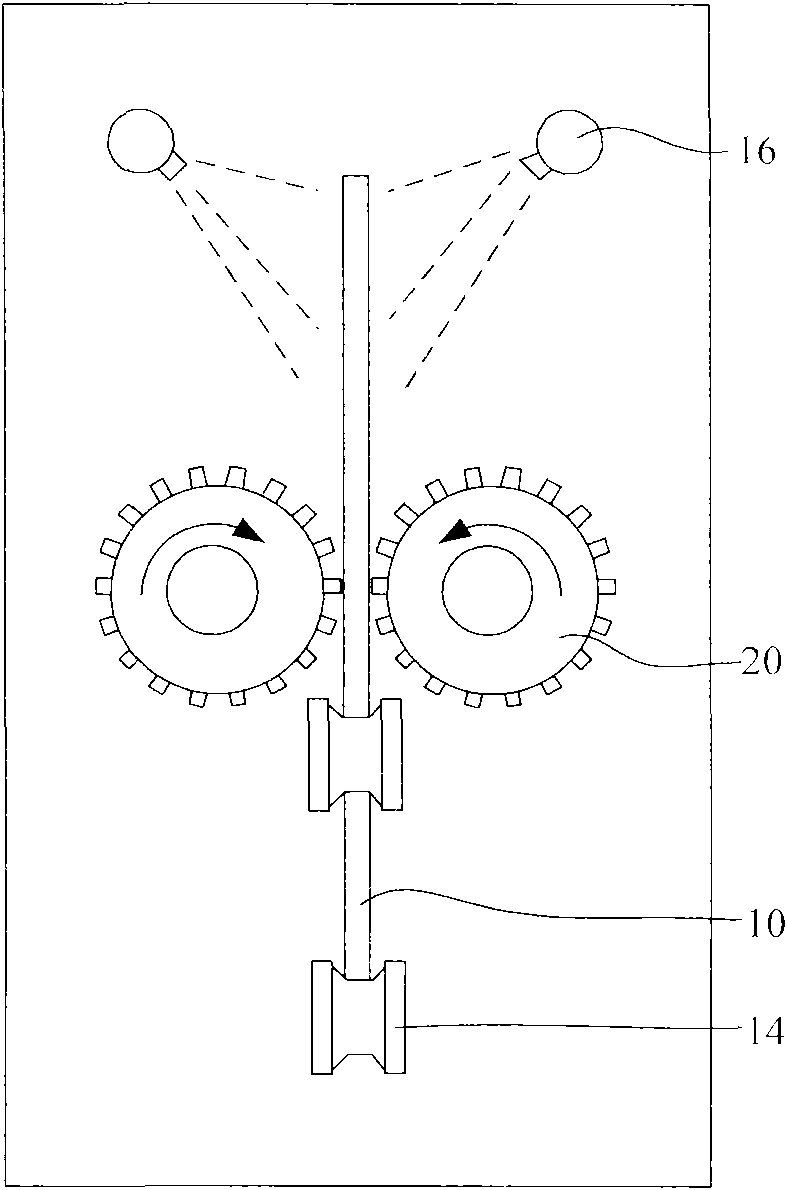

Ceramic filter element automatic cleaning device

ActiveCN104801093AImprove cleaning effectSave human effortStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a ceramic filter element automatic cleaning device. A cylindrical filter element casing is arranged outside a ceramic filter element; the automatic cleaning device includes a driving outer ring component arranged on the outer periphery of the filter element casing, and a driven inner ring component arranged on the inner periphery of the filter element casing and linked with the driving outer ring component; brushes for brushing the ceramic filter element are arranged on the driven inner ring component; the automatic cleaning device also includes a driving mechanism and a transmission mechanism both enabling the driving outer ring component to rotate and move in the axial direction of the filter element casing; the transmission mechanism includes guide rods and screw rods all parallel to the filter element casing and driven by the driving mechanism to rotate, and a support base; the guide rods and the screw rods penetrate through the support base; the screw rods are in threaded connection with the support base to enable the support base to perform axial movement; the guide rods axially move along with the support base and drive a driving outer ring to rotate; the driving outer ring component is rotationally connected with the support base.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

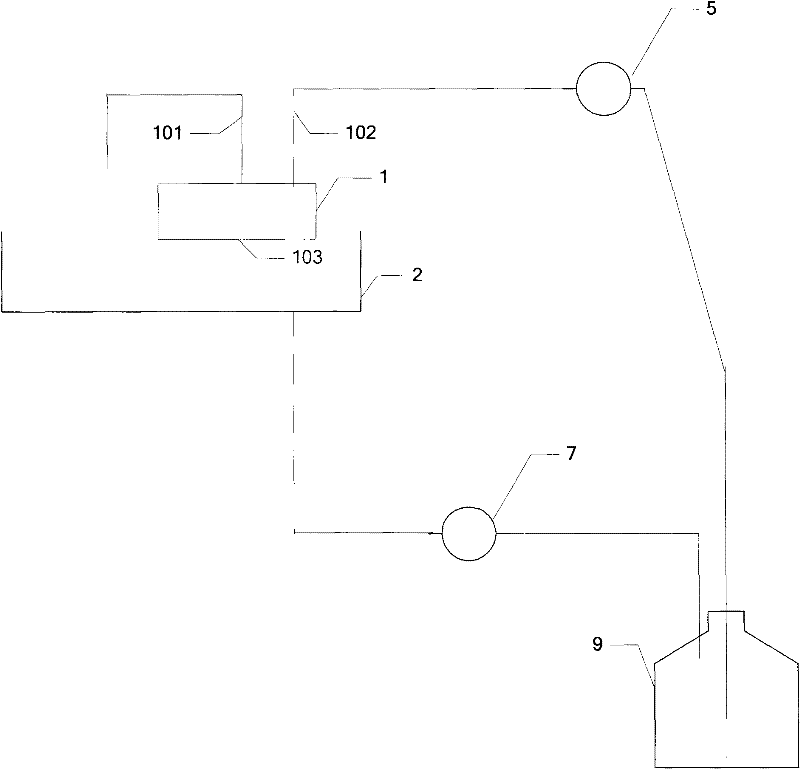

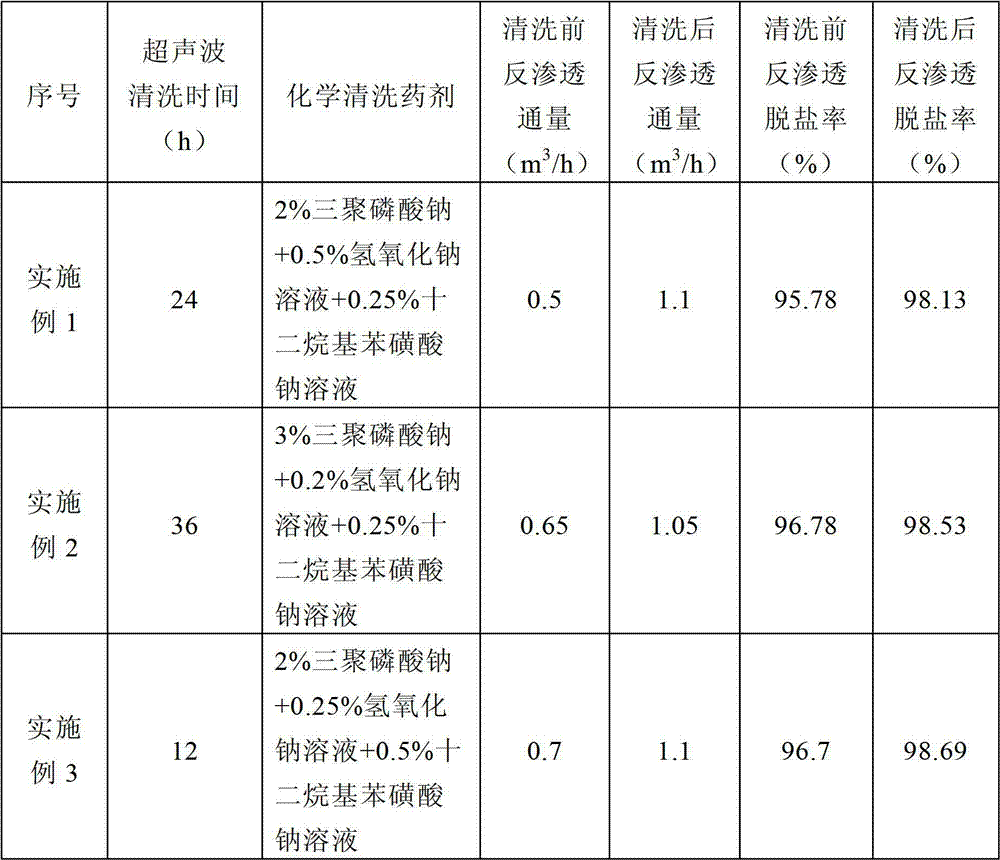

Off-line cleaning method for reverse osmosis membranes

InactiveCN102806016AReduce damageImprove cleaning effectSemi-permeable membranesChemistryLiquid storage tank

The invention discloses an off-line cleaning method for reverse osmosis membranes, which comprises the following steps of: 1) preparation of a cleaning solution with pH value of 10-13, wherein the cleaning solution comprises the following components in percentage by weight: 2-3% of sodium tripolyphosphate, 0.25-0.5% of sodium hydroxide solution, 0.25-0.5% of sodium dodecyl benzene sulfonate solution, and the balance of pure water; 2) ultrasonic cleaning: placing the reverse osmosis membranes into an ultrasonic cleaner, and ultrasonically oscillating to drop off the dirt from the surfaces of the reverse osmosis membranes; 3) circulatory cleaning: placing the reverse osmosis membranes into membrane shells, pumping the cleaning liquid medicine in a cleaning liquid storage tank into the membrane shells by a water supply pump so as to wash the reverse osmosis membranes, and recirculating the cleaning solution to the cleaning solution storage tank; circularly cleaning at low flow for 30-35 min, wherein the flow of a pressure container of each reverse osmosis membrane is 50-100L / min; circularly cleaning at high flow for 1-2 h, and the flow of a pressure container of each reverse osmosis membrane is 101-150L / min; and 4) washing: washing by pure water at low pressure for 20-30 min, thereby guaranteeing to remove the cleaning solution and impurities.

Owner:BAOSTEEL STAINLESS STEEL

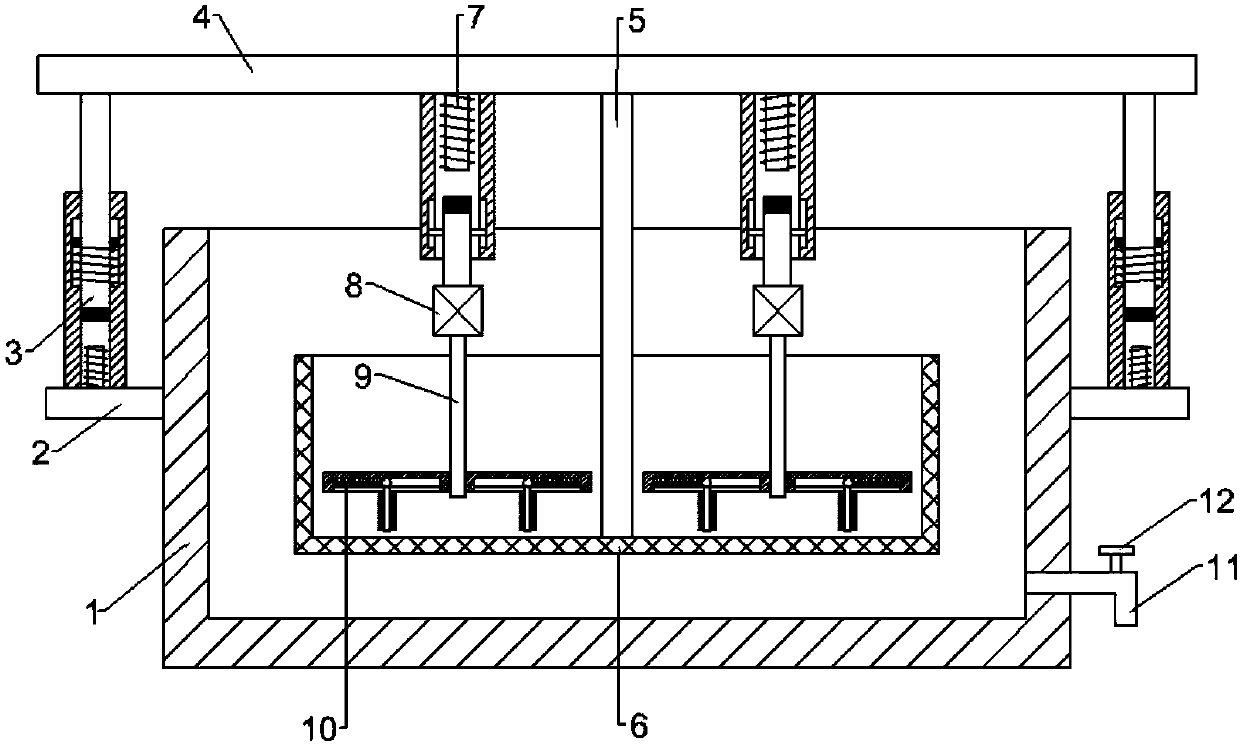

Wafer cleaning device and method

InactiveCN102485358AImprove cleaning effectImprove work efficiencySemiconductor/solid-state device manufacturingCleaning processes and apparatusEngineeringElectrical and Electronics engineering

The invention provides a wafer cleaning device which comprises a cleaning trough, a wafer rotating device, a spray tube and a cleaning mechanism, wherein the wafer rotating device is configured in the cleaning trough and used to fix and drive a wafer to be cleaned to rotate; the spray tube comprises a plurality of nozzles and is configured in the cleaning trough and positioned above the wafer to be cleaned; the cleaning mechanism is positioned on the side of the wafer to be cleaned and comprises a loading mechanism and cleaning brushes; and the loading mechanism is provided with at least two cleaning brushes, and the cleaning brushes can alternately clean the wafer to be cleaned. The wafer cleaning device provided by the invention can realize multi-channel cleaning technical mode, namely that a plurality of cleaning brushes can be arranged in one cleaning device, and the cleaning brushes alternately clean the wafer in the cleaning process, thus under the condition of not affecting the cleaning process, the wafer to be cleaned can be brushed and washed and the cleaning brushes can be cleaned. Therefore, the cleaning effect of the cleaning brushes can be increased, the working efficiency can be increased, and the service life of the cleaning brushes can be prolonged.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Washing device for surgical instrument

InactiveCN109622494AImprove cleaning effectHighly integratedDrying solid materials without heatDrying gas arrangementsDrive motorSurgical instrument

Owner:刘洁

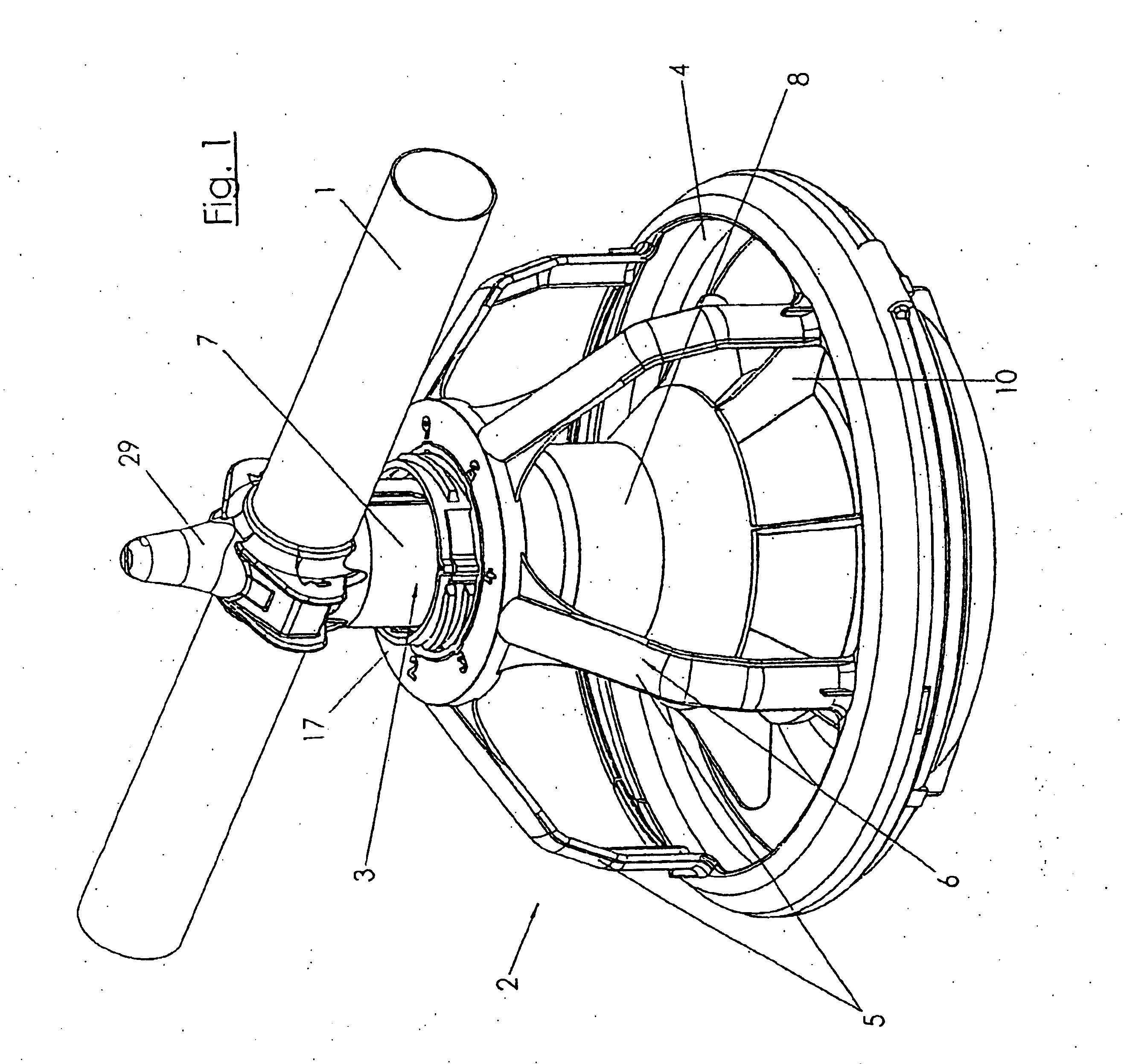

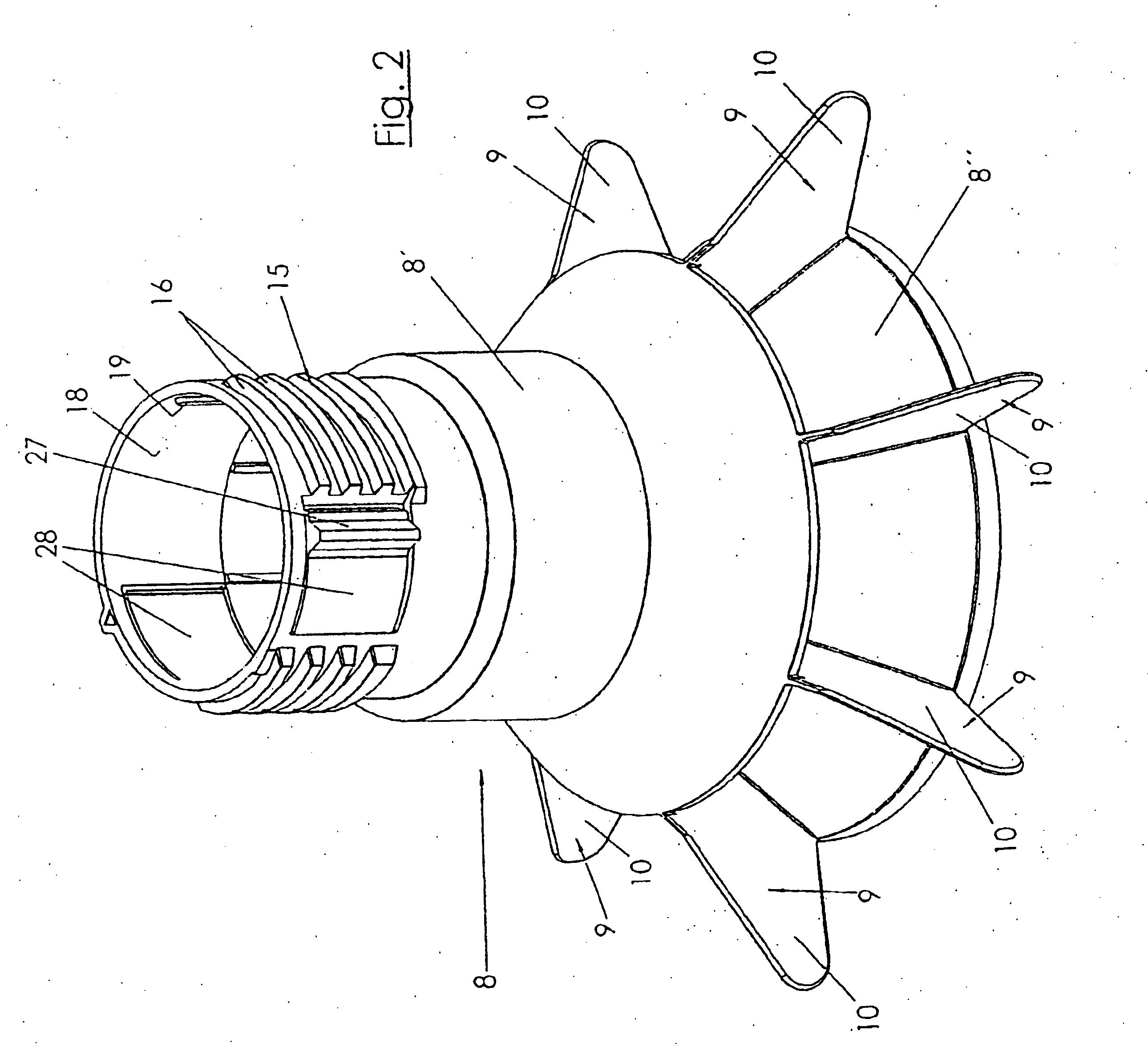

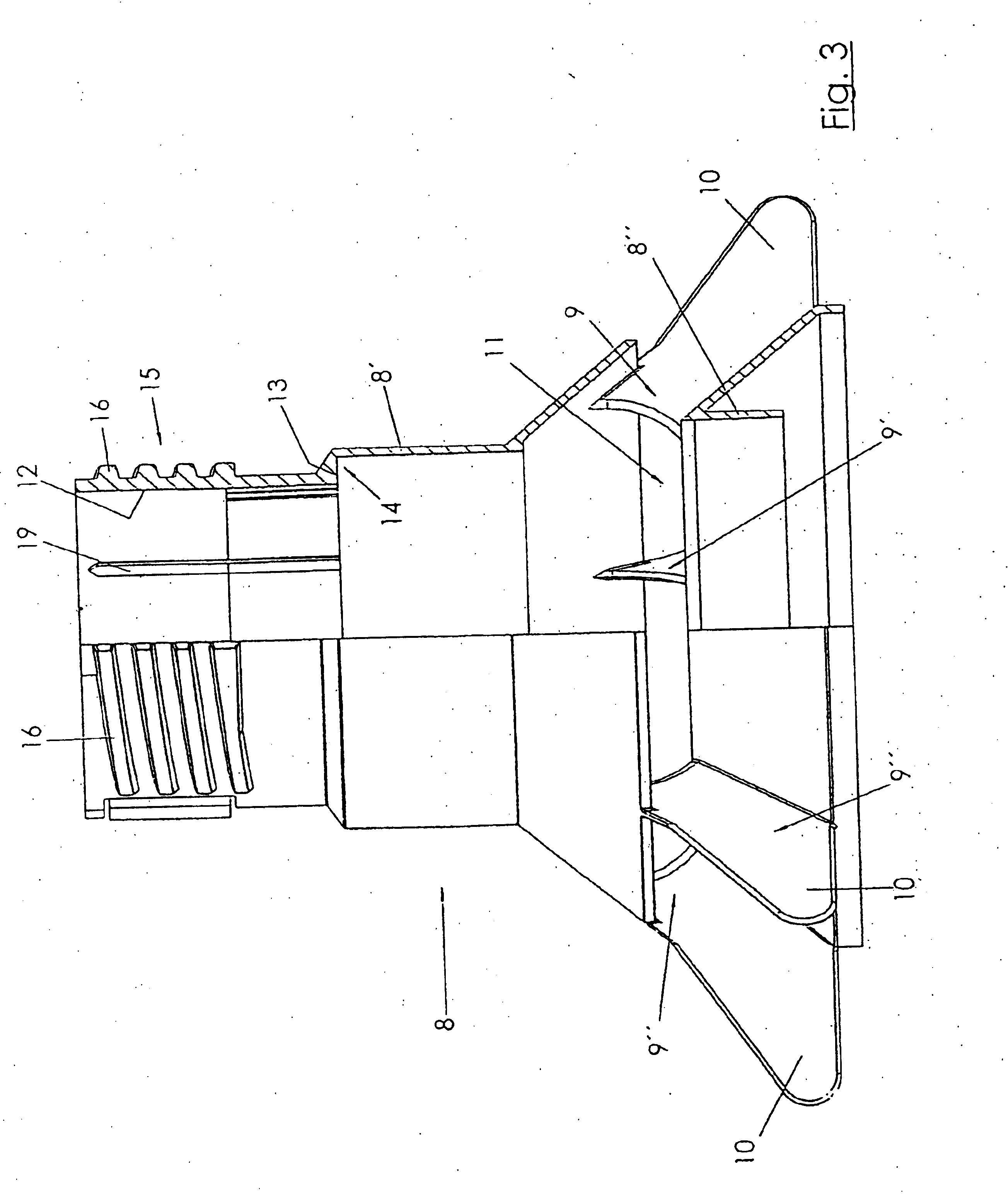

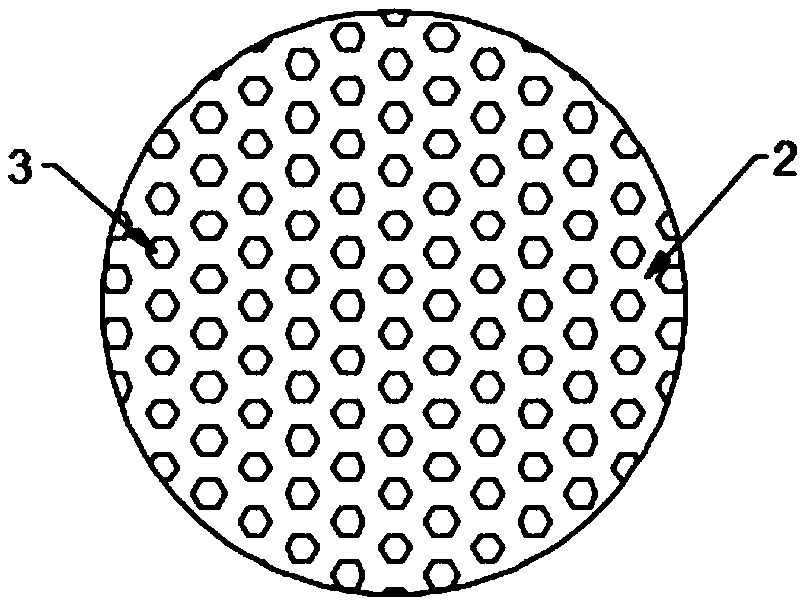

Device for feeding poultry in particular fattening poultry, preferably boilers

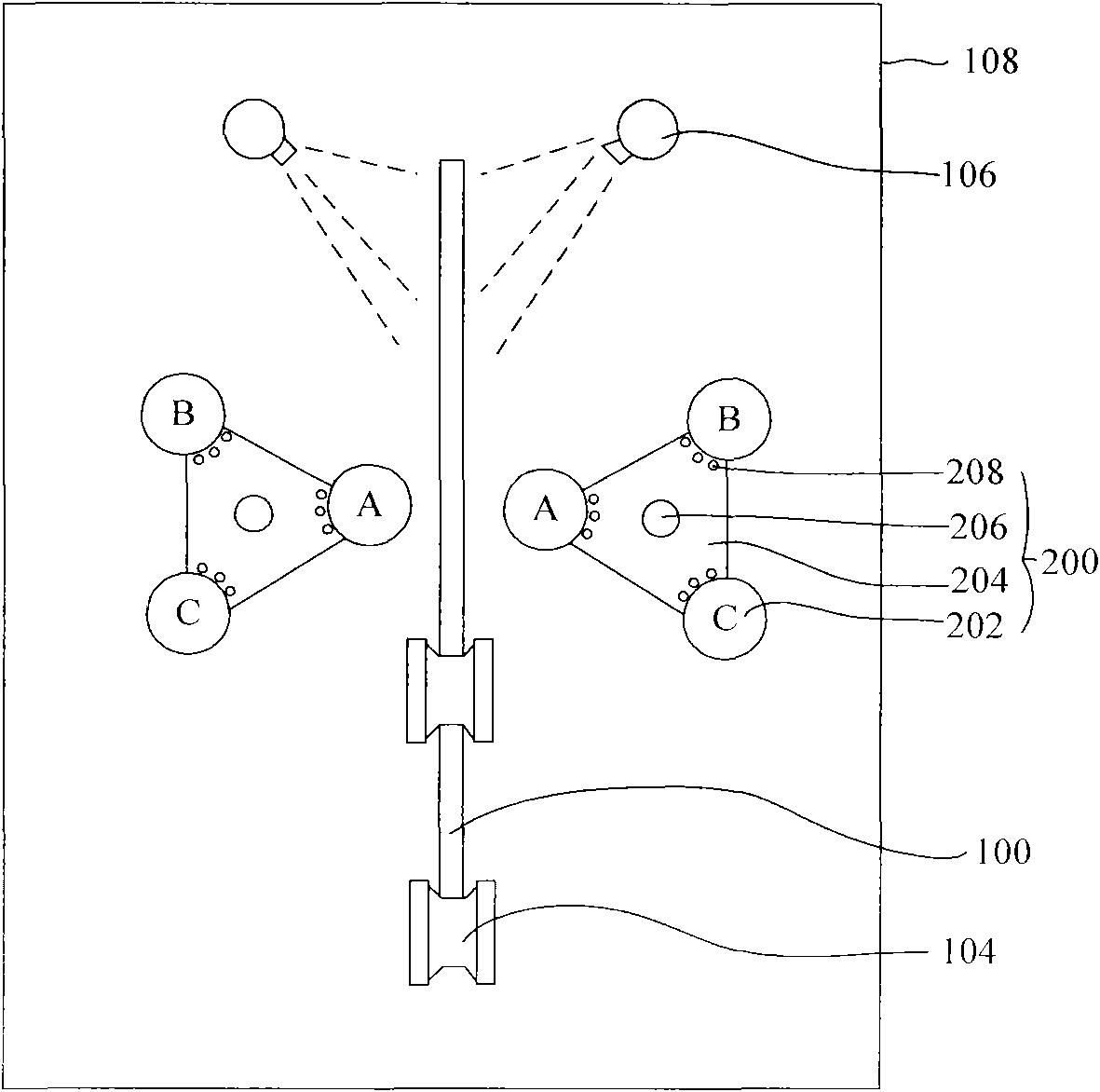

InactiveUS20050076842A1Increase effectImprove cleaning effectAnimal feeding devicesAnimal housingFood supplySpoke

A device for feeding poultry kept in a barn, comprises at least one food supply tube (1) which is held above the floor of the barn such as to be able to be lowered or raised, with a series of branch openings, each provided with a dish device (2) hanging on the supply tube, comprising a dropping tube extending from the branch opening and a feeding dish (4) arranged below, the dropping tube with a spoked arrangement of lattice bars (5) forming the cup of the dish. The dropping tube comprises an inner cylinder (7) leading off from the branch opening and an outer cylinder (8) surrounding the inner cylinder, from which the dish hangs by means of the lattice bars, such as to be placed on the floor of the barn in the lowered state of the food supply tube. The outer cylinder runs on the inner cylinder such as to rotate, be raised or lowered and at least one stop is provided for limiting the raising and lowering stoke. The outer and the inner cylinder each comprise adjacent cylindrical sections (8′, 8, 7′, 7) coaxial to each other, whereby front face regions of the cylinder sections turned to face other are connected to each other by means of bridging bodies (9, 23), which bridge a gap region corresponding to the separation between the cylinder sections.

Owner:BIG DUTCHMAN INT

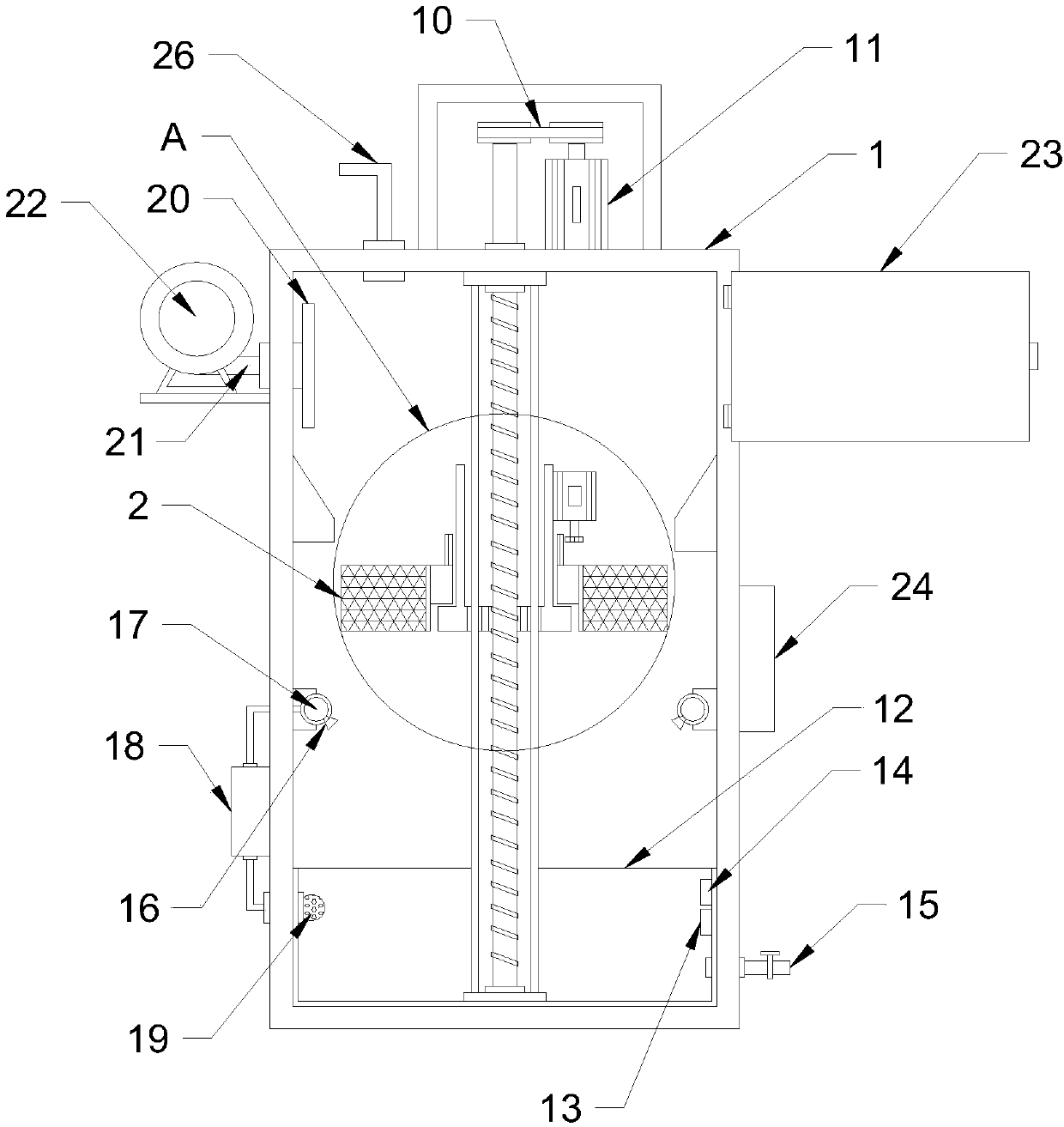

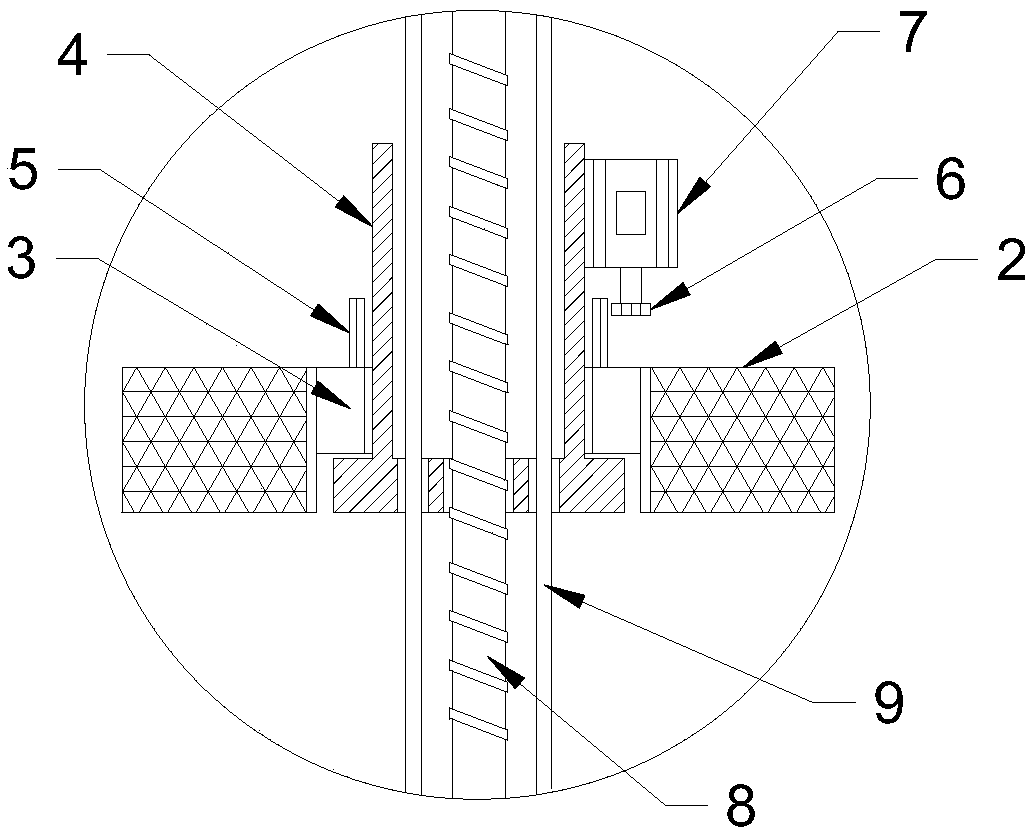

Spherical camera easy to clean

InactiveCN107800941AGood cleaning effectImprove cleaning effectTelevision system detailsColor television detailsStructural engineeringPower apparatus

The invention discloses a spherical camera easy to clean, relates to the technical field of monitoring equipment, and solves the problem that the self-cleaning effect of the existing spherical camerais poor. The spherical camera comprises a protective cover as well as a control system and a camera which are arranged in the protective cover, the protective cover is vertically divided into a waterproof cover and a glass cover, an outer cover is sleeved on the waterproof cover, an annular slide rail is arranged between the outer cover and the protective cover, a power device is arranged on the slide rail, a cleaning device is connected below the power device, the cleaning device comprises a cleaning brush mechanism and a cleaning sponge mechanism, the cleaning brush mechanism and the cleaning sponge mechanism are controlled by a control system to clean the glass cover, and a cleaning brush and cleaning sponge can perform targeted cleaning on different types of stains, so that the cleaning effect is good. The spherical camera has a broad application prospect in the field of monitoring equipment.

Owner:CHENGDU YANXINGGUO TECH CO LTD

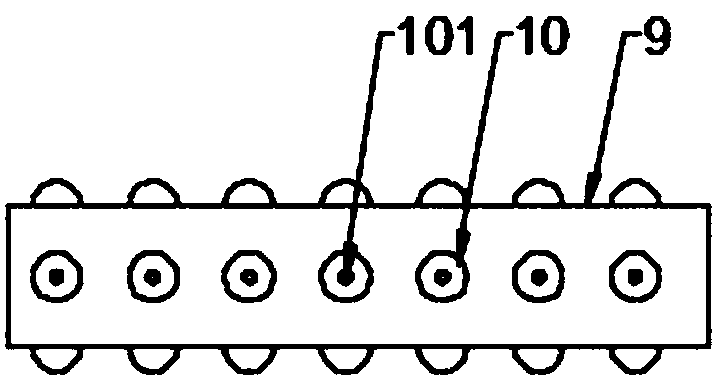

Outside cycle continuous biological aerated filter for composite fillers

InactiveCN103613188AImprove cleaning effectEnhanced film-hanging and adsorption propertiesTreatment using aerobic processesSustainable biological treatmentFiller particleConvex structure

The invention provides an outside cycle continuous biological aerated filter for composite fillers. The outside cycle continuous biological aerated filter is characterized by comprising a filler washing part, wherein the filler washing part comprises a compressed air lift pipe, a compressed air supply unit, a filler washing unit, a washing wastewater discharge unit, a filler backflow unit and a material guide pipe, the inlet of the compressed air lift pipe is arranged at the bottom of a filler layer in the biological aerated filter, the outlet of the compressed air lift pipe is arranged outside the biological aerated filter, the outlet of the compressed air supply unit is opposite to the inlet of the compressed air lift pipe and is used for blowing the filler particles into the compressed air lift pipe for air-water washing, the filler washing unit is used for receiving filler particles conveyed by the compressed air lift pipe, the inner wall of the filler washing unit has a convex structure used for washing the filler through friction when the fillers fall, and the filler backflow unit is connected with the material guide pipe at the bottom of the washing part. The biological aerated filter can be used for washing the filler particles while working continuously, thus being capable of running constantly.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

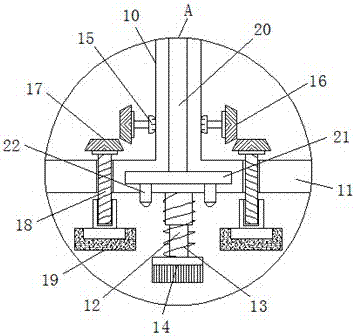

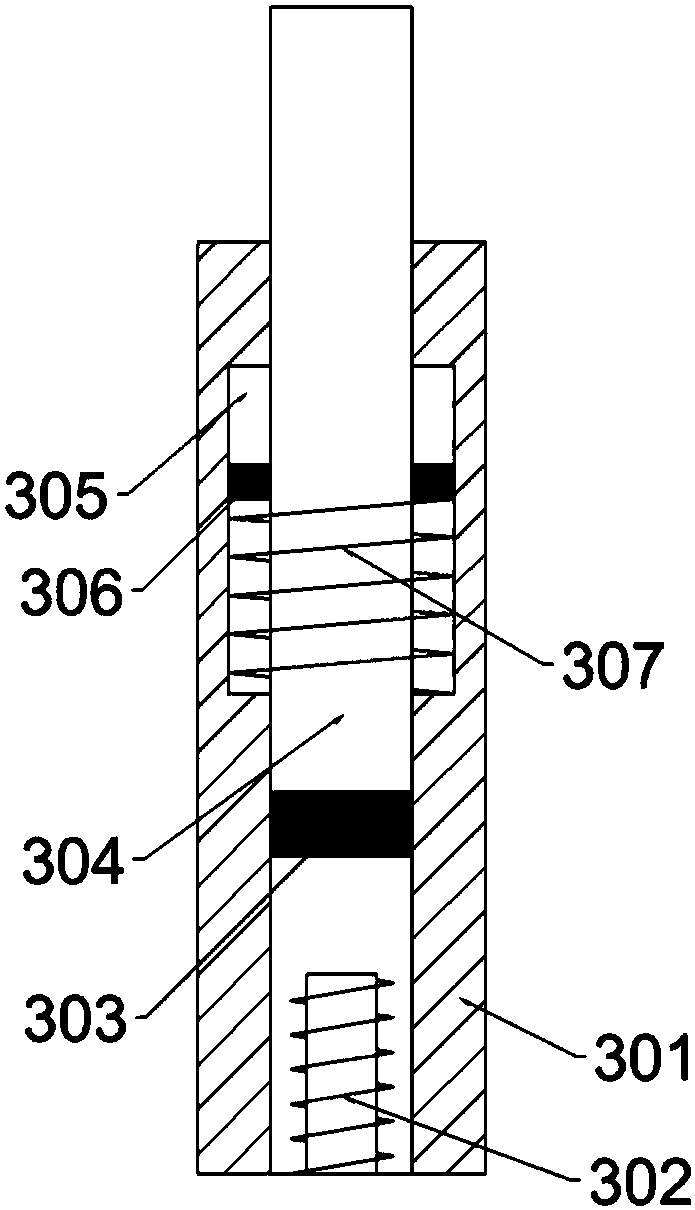

Traditional Chinese medicine cleaning equipment with reciprocating lifting function

InactiveCN107597709AExpand the range of scrubbingImprove cleaning effectCleaning using toolsCleaning using liquidsEngineeringTraditional Chinese medicine

The invention discloses traditional Chinese medicine cleaning equipment with a reciprocating lifting function. The traditional Chinese medicine cleaning equipment comprises a cleaning tank, wherein two mounting bases are symmetrically and fixedly arranged on the outer side wall of the cleaning tank; a height regulating device is fixedly connected on each mounting base; the top ends of the two height regulating devices are fixedly connected with a mounting plate; the lower side of the middle part of the mounting plate is fixedly connected with a vertical post; the bottom end of the vertical post is fixedly connected with a cleaning basket; the bottom wall and the side walls of the cleaning basket are screen-shaped; the lower side of the mounting plate is fixedly connected with a plurality of reciprocating lifting devices; the bottom ends of the reciprocating lifting devices are connected with motors; rotary shafts are fixedly connected on output shafts of the motors; and two cleaning devices are fixedly connected on the rotary shafts. The traditional Chinese medicine cleaning equipment has the beneficial effects that: current is accessed into a first magnet, and magnetism is generated for attracting an iron block after current is accessed into the first magnet, so that the iron block drives a regulating post to move downwards; and the regulating post moves downwards to move themounting plate to descend.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

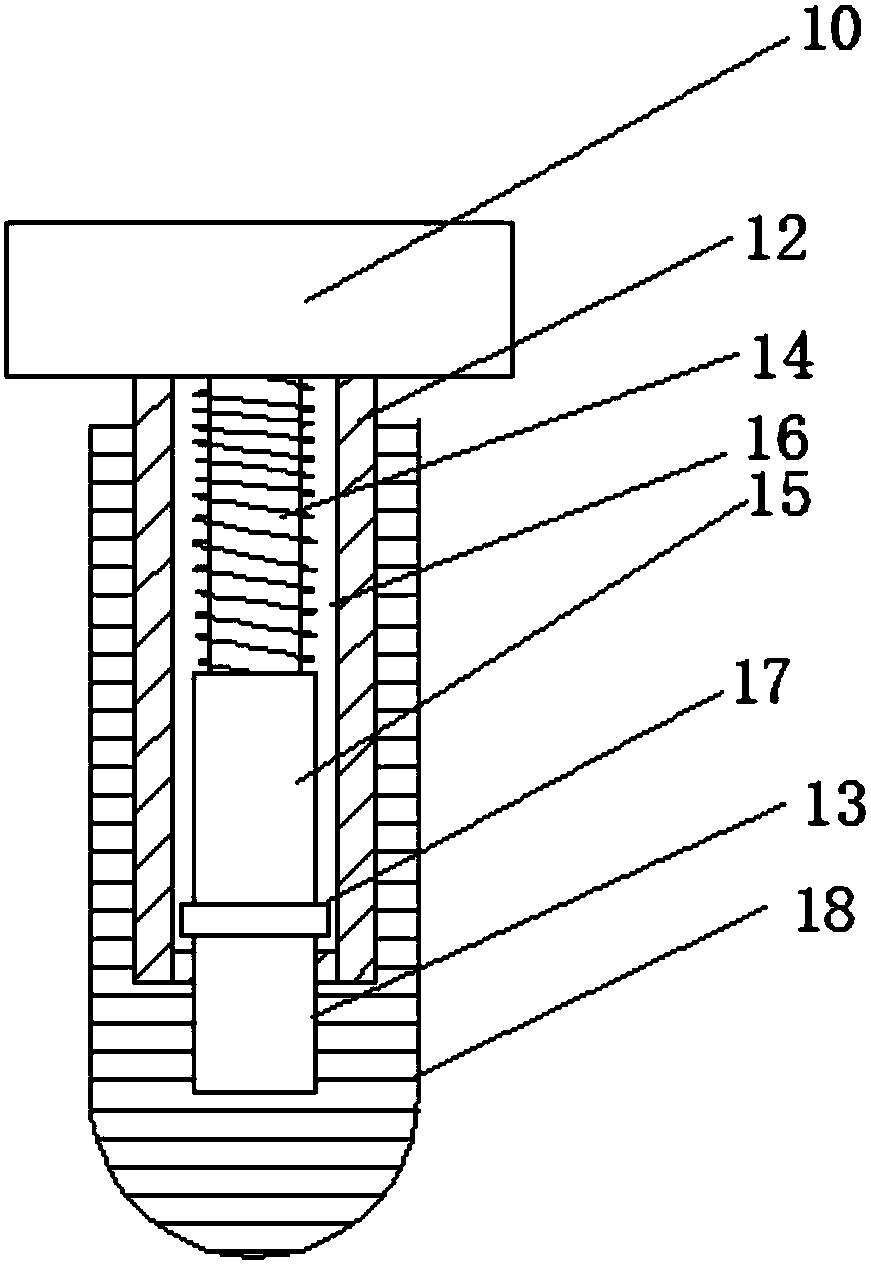

Ping-pong ball cleaning device used in efficient and batched cleaning mode

PendingCN107551495AImprove cleaning effectAvoid scratchesBall sportsElectric machineryStructural engineering

The invention discloses a ping-pong ball cleaning device used in an efficient and batched cleaning mode. The device includes a base, a cleaning chamber, a drying chamber and a material containing box,wherein the cleaning chamber, the drying chamber and the material containing box are all installed on the upper surface of the base, a feeding hopper is installed in the middle of the top end of thecleaning chamber, a driving motor is installed on the right side of the cleaning chamber, the left end of the driving motor is provided with a rotating shaft which is provided with side plates at equal intervals, and a plurality of cleaning brushes are installed on the side plates at equal intervals; each cleaning brush is provided with a fixing sleeve which is internally provided with a frameworkrod in a penetrated mode, the framework rods can be divided into top rods and bottom canisters, each top rod is wound with a reset spring, and the tail end of each reset spring is fixed to the corresponding bottom canister. Designed spring mechanisms can prevent ping-pong balls from damage caused by stirring and extrusion, and meanwhile, the ping-pong balls are in much closer contact with brush layers to improve the cleaning effect.

Owner:ZHENGZHOU UNIV

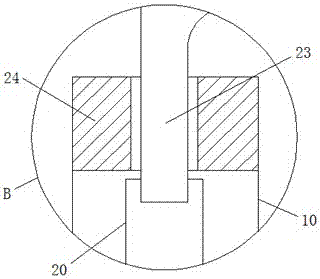

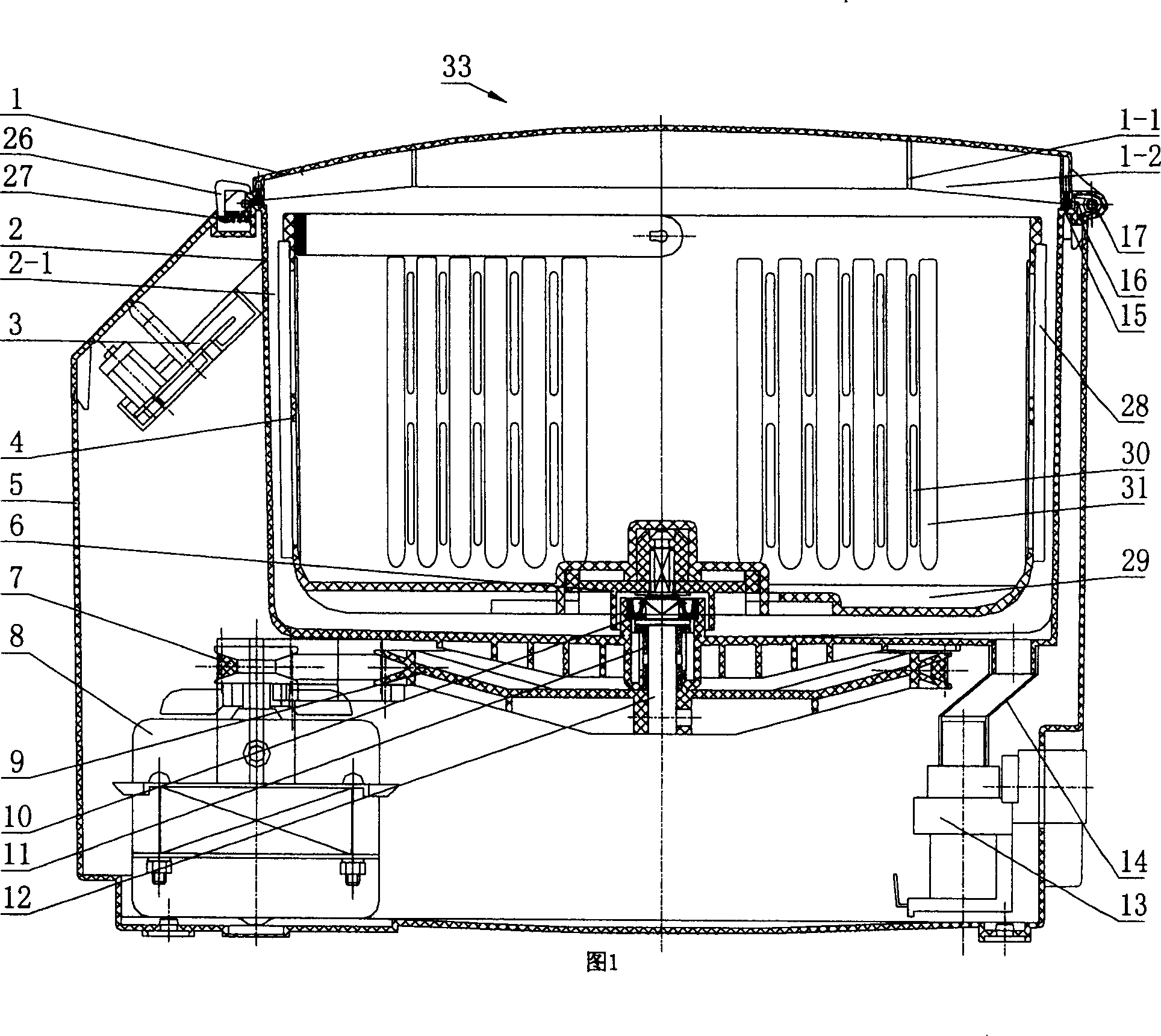

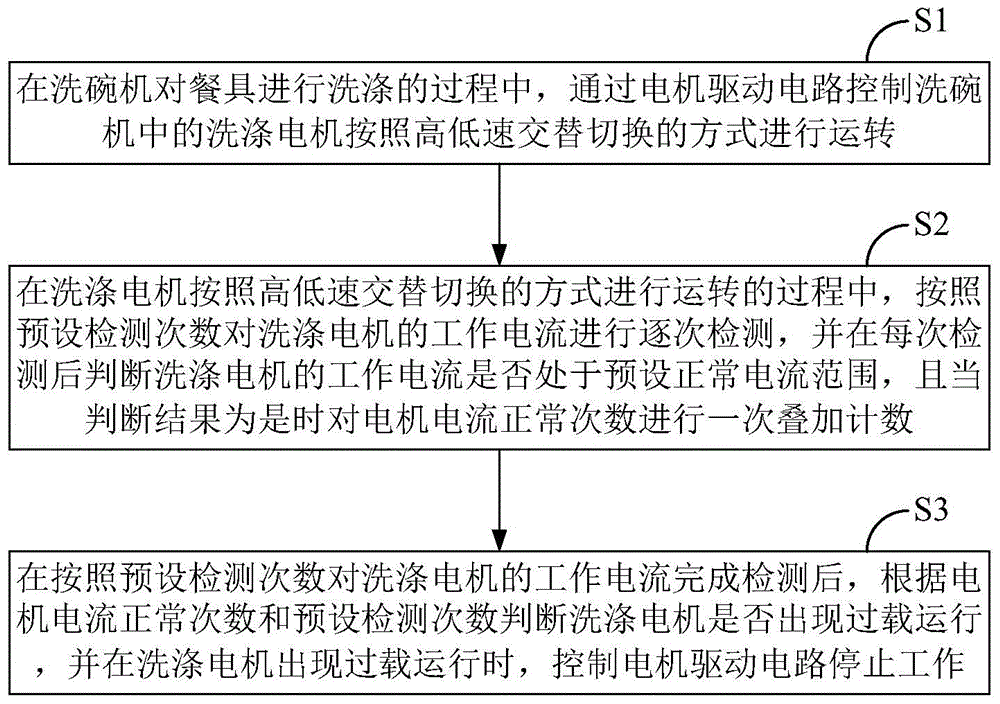

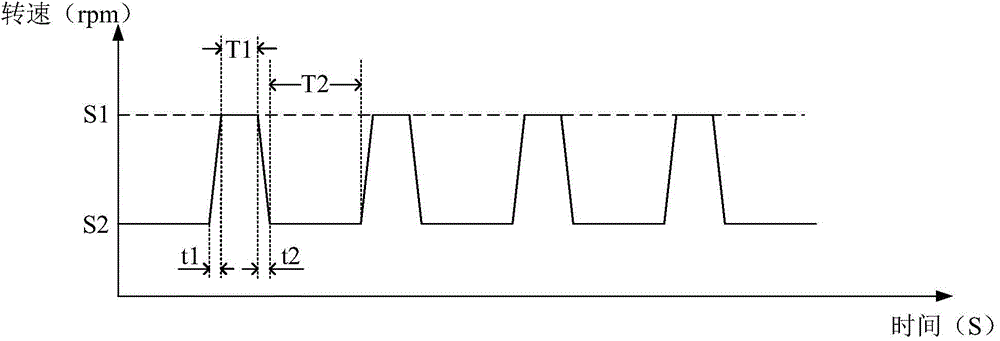

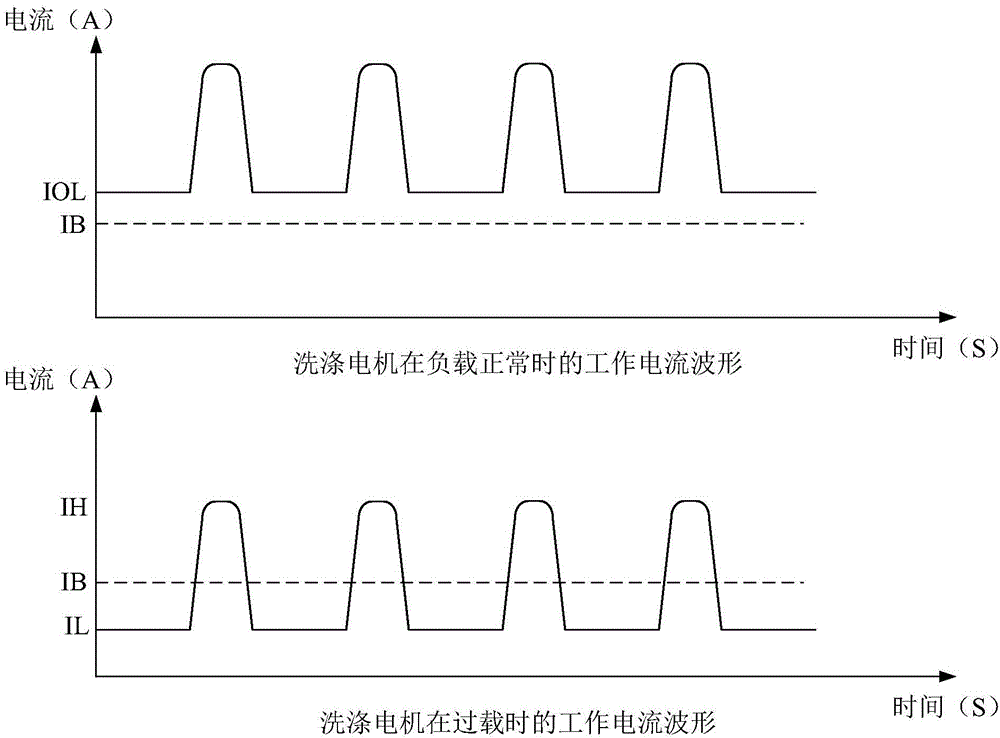

Dish-washing machine and washing control method and system for same

ActiveCN104622407AImprove cleaning effectGuaranteed temperature riseTableware washing/rinsing machine detailsMachine controlMode control

The invention belongs to the technical field of dish-washing machine control, and provides a dish-washing machine and a washing control method and system for the same. During a dish washing process conducted by the dish-washing machine, a washing motor runs in a high-speed and low-speed alternate switch mode controlled by a motor drive circuit, the dish cleaning effect can be improved during high speed running of the washing motor, and an average working current of the washing motor can be reduced through the high-speed and low-speed switch at the same time, so that non standard-exceeding of temperature rise of the motor drive circuit is guaranteed; meanwhile, the working current of the washing motor is subjected to successive detection according to preset detection times, the normal times of the motor current are subjected to superposition counting if overflowing does not occur in the working current of the washing motor; after the completion of the detection, if it is concluded that overload running occurs in the washing motor according to the normal times of the motor current and the preset detection times, the motor drive circuit is controlled to stop working, so that overloading of the washing motor is accurately judged and the motor drive circuit is timely shut off to avoid the component damage due to the temperature rise.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

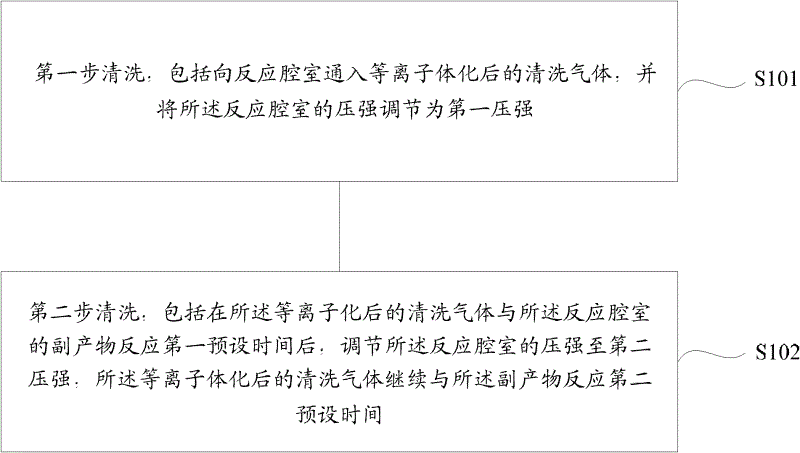

Cleaning method of reaction chamber

ActiveCN102623298AImprove cleaning effectImprove yieldSemiconductor/solid-state device manufacturingCleaning using gasesReaction chamberControl valves

The invention discloses a cleaning method of a reaction chamber. The method is used to clean a by-product of the reaction chamber. The method comprises: a first step of cleaning, which includes feeding a plasma cleaning gas into the reaction chamber and adjusting the pressure of the reaction chamber into a first pressure; a second step of cleaning, which includes adjusting the pressure of the reaction chamber into a second pressure after the plasma cleaning gas reacts with the by-product of the reaction chamber for first preset time and then continuously carrying out the reaction between the plasma cleaning gas with the by-product for second preset time. By using the cleaning method of the reaction chamber, parts of pipelines among a pressure control valve, the reaction cavity and a suction pump can be cleaned so that normal working of the pressure control valve can be guaranteed and a yield rate of a product can be increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

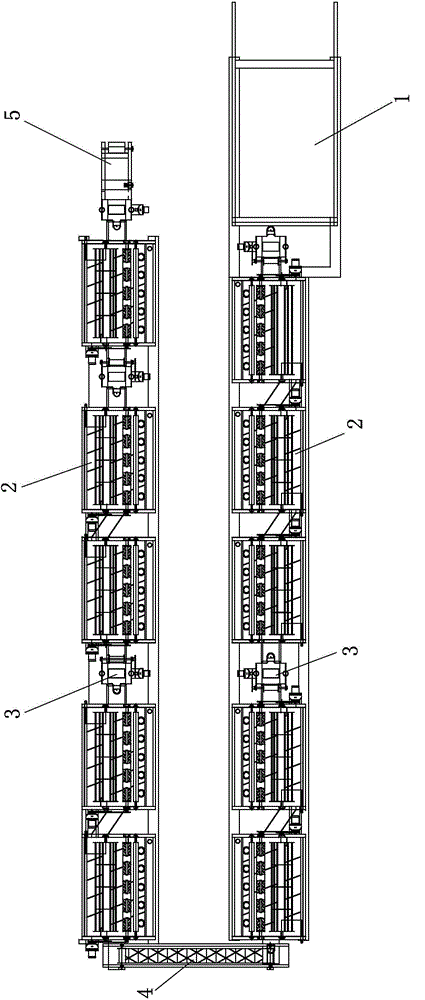

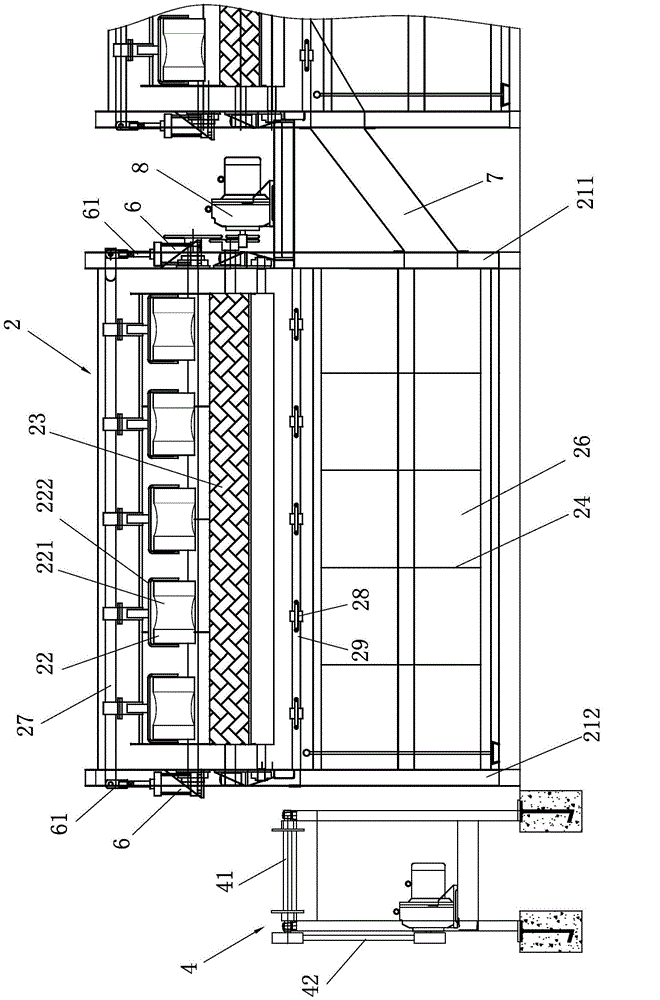

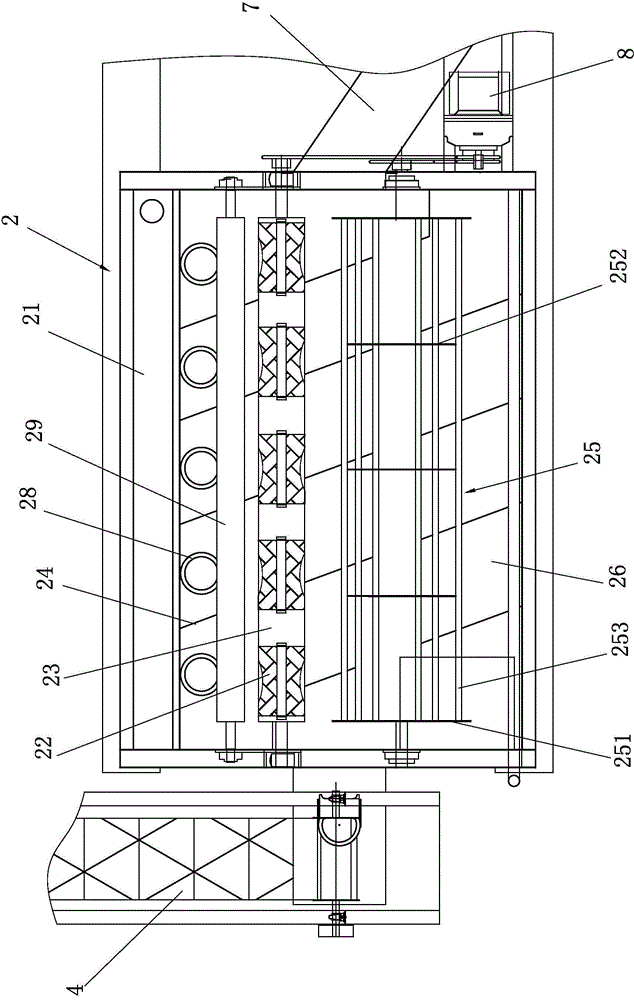

Washing production line after printing and dyeing

ActiveCN103556423AReduce labor intensityImprove cleaning effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingEngineering

The invention provides a washing production line after printing and dyeing. The washing production line comprises wash water units, inter-box wringing devices as well as a fabric feeding device and a fabric discharge device which are distributed at the head and the tail of the production line respectively. The washing production line is characterized in that the production line is distributed in a U shape; and each wash water unit comprises a wash water groove, upper wringing rollers, lower wringing rollers, flow partition boards and cropping rollers, the upper wringing rollers and the lower wringing rollers are vertically opposite and located above isolation grooves, and are arranged in the length direction of the production line, the cropping rollers are located on the near sides of the lower wringing rollers, and each upper wringing roller is located above the corresponding isolation groove and can perform wringing movement of approaching and leaving the lower wringing rollers. With the adoption of the washing production line after printing and dyeing, the labor intensity of an operator can be reduced, a fabric is separated from a washing liquid after every time of cleaning and subjected to repeated wringing piece by piece, the cleaning gradient of the washing liquid is changed, and efficient, high-quality and environment-friendly production with low water and energy consumption is realized.

Owner:JINJIANG CITY LONGSHENG KNITTING PRINTING & DYEING CO LTD

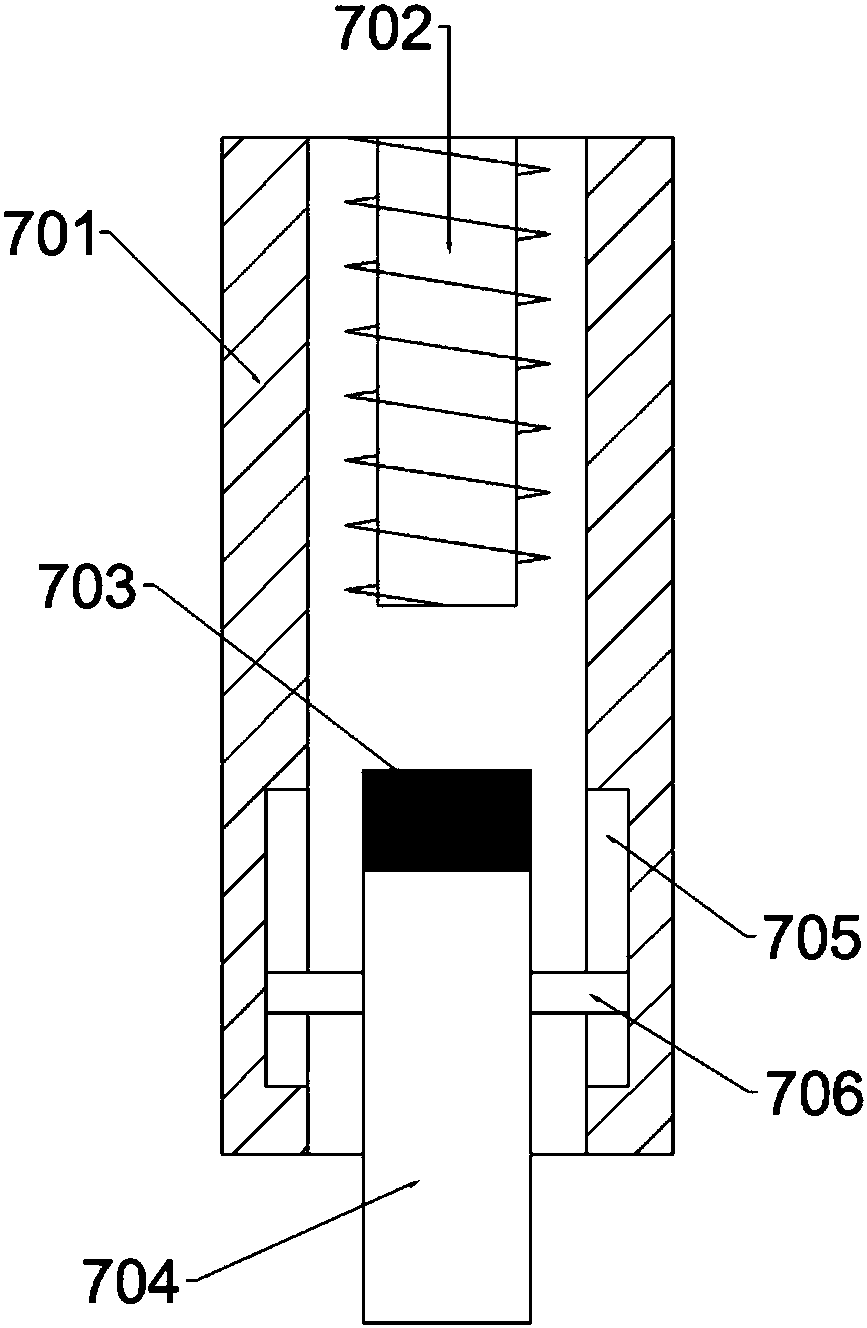

Oral care device for removing tartar

The invention discloses an oral care device for removing tartar. The oral care device comprises a device shell, a motor and a water injection cylinder, wherein the motor is fixedly connected to the inner side wall of the device shell, the inner top wall of the device shell is fixedly connected with the water injection barrel, and the top wall of the water injection barrel is communicated with a water inlet pipe which fixedly penetrates through the top wall of the device shell; through the combination of a first rotary shaft, a roller and a movable box, the tartar can be loosened and scoured inall directions; the roller rotates, an ejector wheel conducts jacking, and a gear moves rightward to be meshed with a wide rack for rotation, so that a bristle bundle is intermittently inserted intothe tartar for left and right brushing, the cleaning effect is enhanced due to rotation of the bristle bundle, a piston moves left and right intermittently due to rotation of a rotary disc so as to output water to wash teeth, and efficient tartar removal is effectively achieved.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

Rapid cleaning and drying device for Chinese medical herbs

InactiveCN107702487AEasy to controlImprove cleaning effectDrying gas arrangementsDrying solid materialsMotor shaftAirflow

The invention discloses a rapid cleaning and drying device for Chinese medical herbs. The rapid cleaning and drying device for Chinese medical herbs comprises a base. A sliding rail is further fixedlyarranged at the top of the base, and a work box is slidably connected to the sliding rail through a sliding block. A rotary pipe is rotatably connected to the inner bottom of the work box, and a plurality of exhaust pipes are evenly connected to the side wall of the rotary pipe. A plurality of through holes are evenly formed in the top of the rotary pipe and the tops of the exhaust pipes. A spiral heating pipe is fixedly arranged at the inner bottom of the work box through supports. A gear motor is further fixedly arranged at the top of the base and located between a water tank and the work box. A disc is mounted on a motor shaft at the top end of the gear motor. A hinge pin is fixedly connected to the right side of the top of the disc. The hinge pin is rotatably connected with a first connecting rod, and the right end of the first connecting rod is hinged to the left side wall of the work box. According to the rapid cleaning and drying device for Chinese medical herbs, the work box moves left and right in the cleaning process, medical herbs are driven to shake and turn, and thus the cleaning effect is better; and in the heating and drying process, the exhaust pipes spray out airflow rotatably, and the medical herbs roll in the work box at the same time, so that it is ensured that medical herbs are heated evenly, and the drying effect is better.

Owner:浙江燕思志网络科技有限公司

Cleaning method of optical lens

InactiveCN107755340AImprove cleaning effectGood cleaning effectFlexible article cleaningCleaning using liquidsChemistryOrganic solvent

The invention discloses a cleaning method of an optical lens. The cleaning method comprises the following specific steps that 1, the lens is cleaned with an organic solvent cleaning solution; 2, the lens is cleaned with an alkalinity cleaning solution; 3, the optical lens is cleaned with an acidity cleaning solution; 4, the lens is cleaned with deionized water; 5, the lens is cleaned with alcohol;and 6, the lens is dried. After each step from one to three, a water cleaning solution is utilized for carrying out cleaning; and ultrasonic vibration is accompanied in the step 4. By means of the manner, the cleaning method can improve the cleaning effect of the optical lens, and especially residues on the cylinder surface (non-polished surface) of the lens can be eliminated. As the acidity cleaning solution is added, alkaline matter attached to the surface of the lens is neutralized, the cleaning effect can be enhanced, and other impurities are not introduced.

Owner:II VI OPTICS (SUZHOU) CO LTD

Swinging type high-efficiency washing device for edible fungi

The invention discloses a swinging type high-efficiency washing device for edible fungi. The swinging type high-efficiency washing device comprises a bottom seat, a washing tank, a washing liquid accommodating tank, a driving motor, a swinging basal seat, a fungus accommodating tank and a driving motor, wherein the washing tank is arranged on the bottom seat; a main shaft is vertically arranged upwards; the washing liquid accommodating tank is arranged at the upper end of the main shaft; the swinging basal seat is welded to the upper side inner wall of the inner part of the washing tank; and the fungus accommodating tank is rotataby mounted on the swinging basal seat through a rotating shaft. According to the swinging type high-efficiency washing device disclosed by the invention, throughthe clockwise and anticlockwise rotation of the washing liquid accommodating tank, the inner part of the fungus accommodating tank is washed, so that the flow rate of washing liquid in the fungus accommodating tank is increased, the exchange of the washing liquid between the fungus accommodating tank and the washing liquid accommodating tank is facilitated, and the washing effect is greatly improved; and the fungus accommodating tank swings left and right along the swinging basal seat, and edible fungi in the fungus accommodating tank overturn in the fungus accommodating tank, so that the situation that the washing of the fungi in the middle position is not thorough is effectively avoided.

Owner:鲍春国

High-efficiency solar panel cleaning device

ActiveCN108964602AImprove power generation efficiencyImprove cleaning effectSolar heating energyPhotovoltaicsMoving frameEngineering

The invention relates to a high-efficiency solar panel cleaning device comprising a main body, a cleaning mechanism and a water spraying mechanism. The cleaning mechanism includes a first driving assembly, a connecting rod, a roller brush, a rotating shaft, two first gears, two racks, two connecting assemblies, two supporting assemblies and two moving bases. The water spraying mechanism includes asecond driving assembly, a moving rod, a moving frame, two connecting casing pipes and at least two nozzles. According to the high-efficiency solar panel cleaning device, the roller brush is driven by the cleaning mechanism to move above the main body and also rotates around the rotating shaft simultaneously and thus the solar panel is cleaned by the roller brush, so that the power generation efficiency of the solar panel is improved; and nozzles are driven by the water spraying mechanism to move above the main body and also reciprocate left and right simultaneously and thus impurities and stubborn stains on the main body are washed away by high-pressure water from the nozzles, so that the leaning effect of the cleaning device is improved.

Owner:瑞安市本富机电设备有限公司

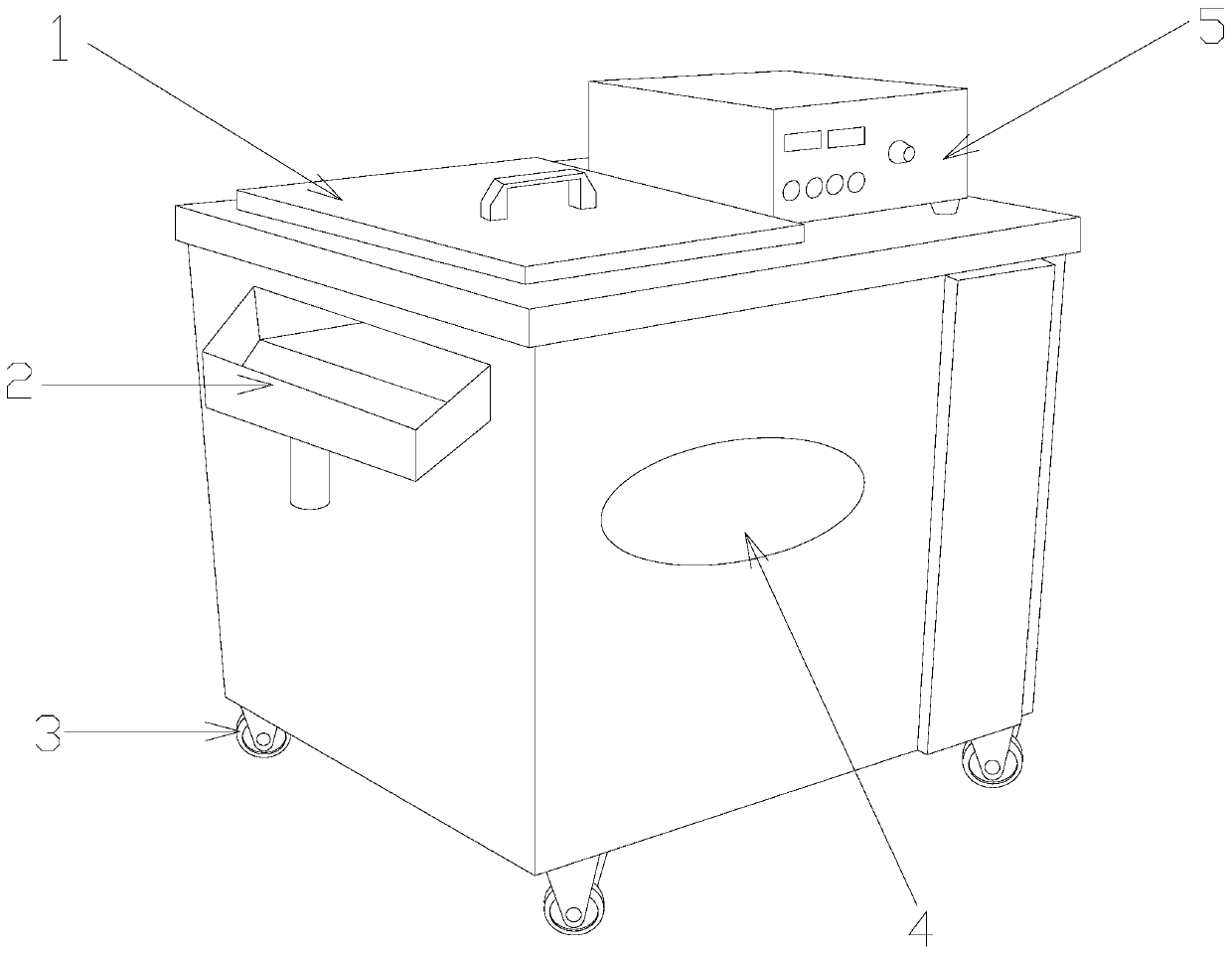

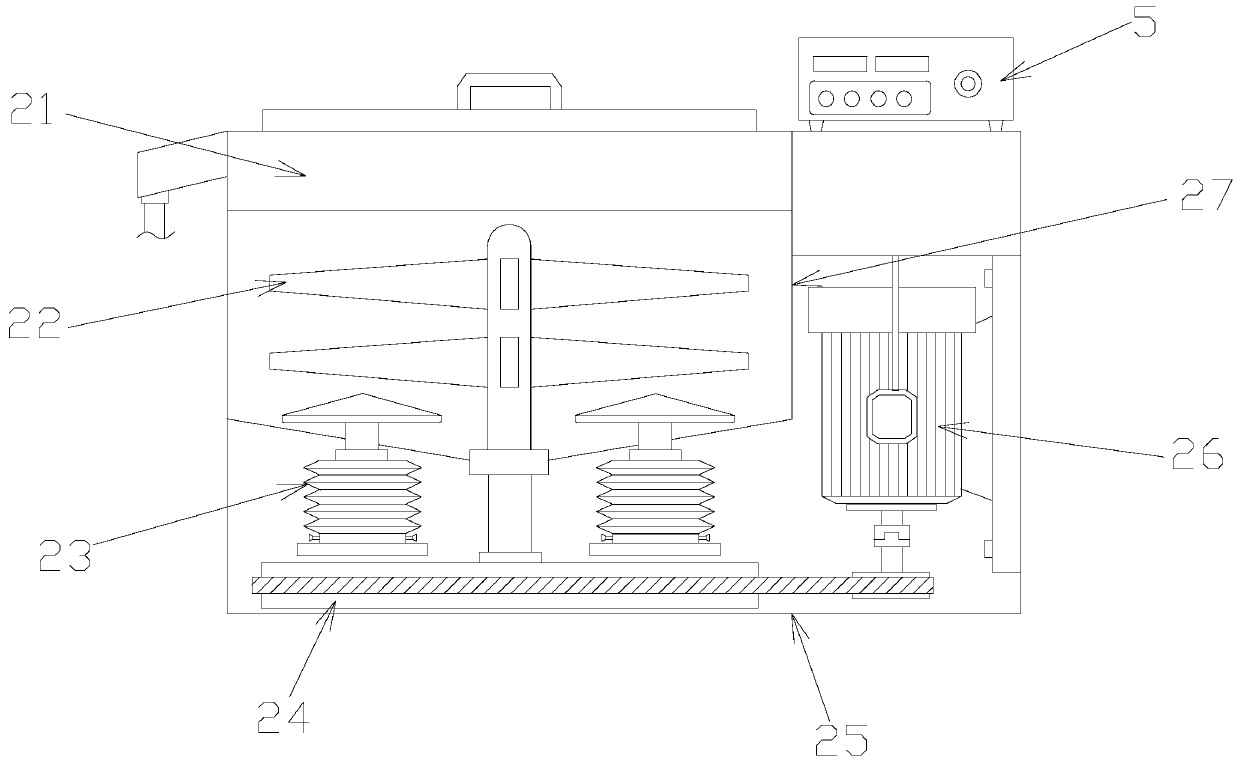

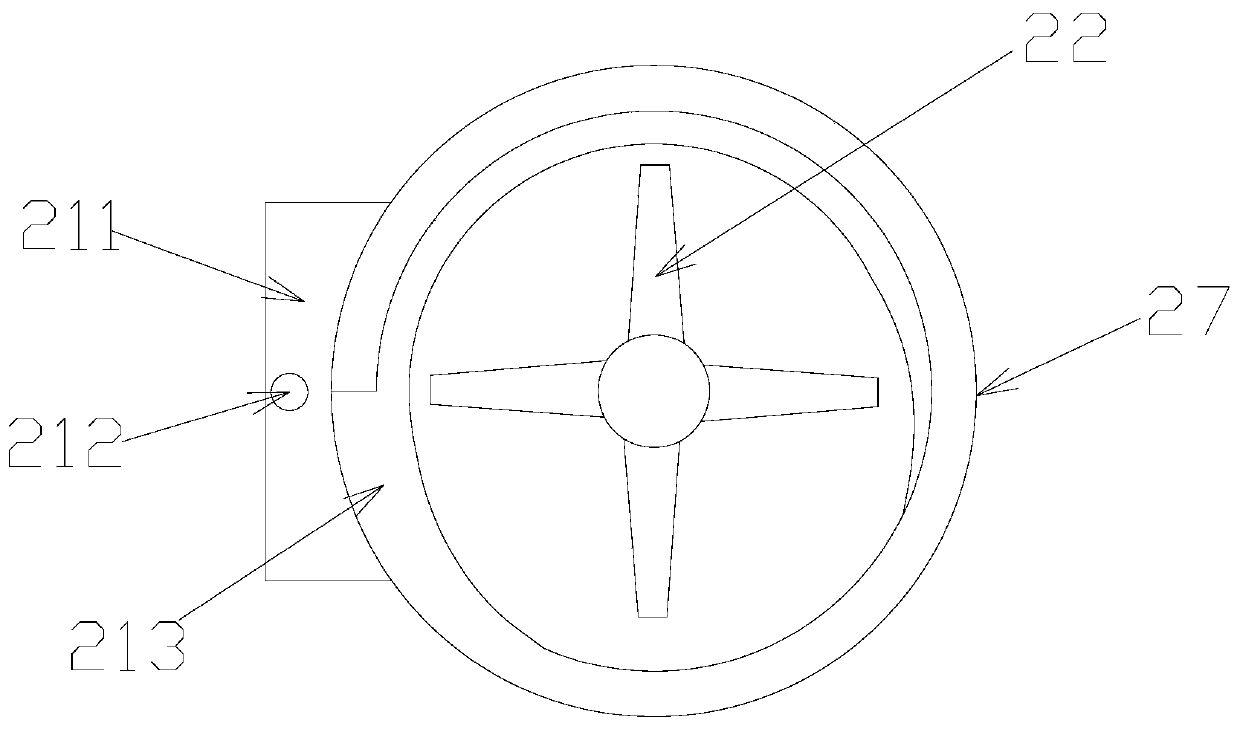

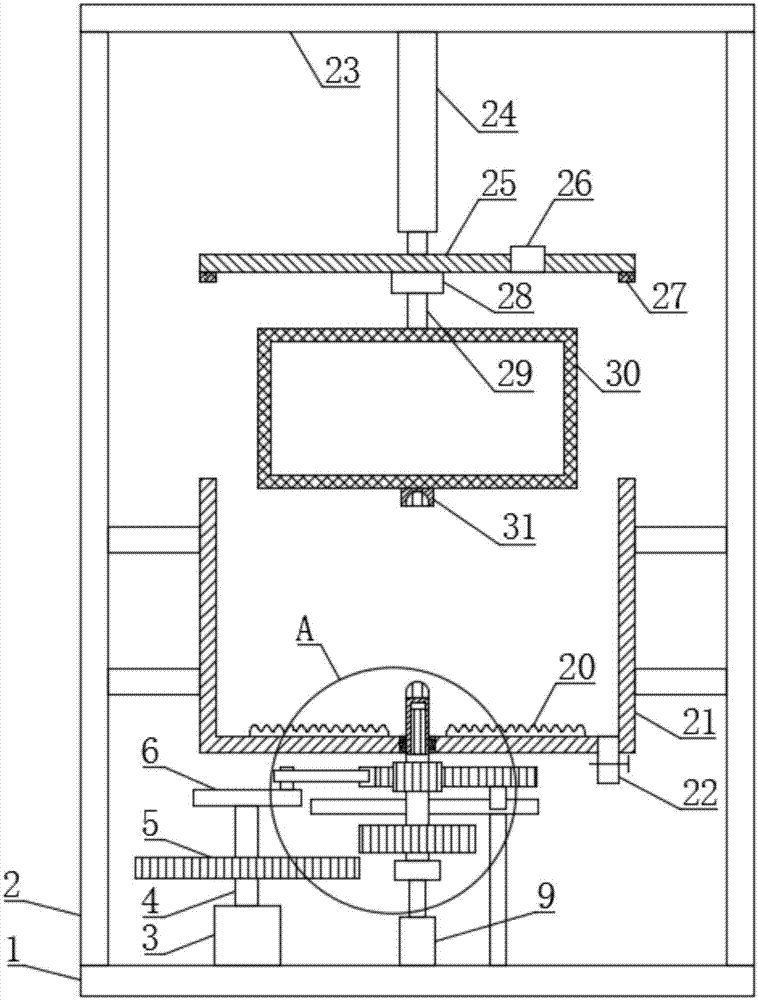

Bearing cleaning machine using bubble enhancement reaction

ActiveCN109865708APromote sheddingImprove cleaning effectCleaning using liquidsMachine controlAir bubble

The invention discloses a bearing cleaning machine using a bubble enhancement reaction. The bearing cleaning machine structurally comprises a splashing proof sealing cover, a cleaning machine main body, universal moving wheels, a product nameplate and a cleaning machine control machine. The bearing cleaning machine is combined with a bubble generating structure through a grease collecting structure, when a bearing is put into the cleaning machine to be cleaned, bubbles can be generated in the cleaning machine through the bubble generating structure, the overturning effect is generated throughthe bubbles and a cleaning solution, thus balls in the bearing rotates, and thus attachments on the surface of the bearing are dropped off; meanwhile the grease floating at the top of the cleaning solution can be effectively collected to be treated centrally, the situation that the grease at the top of the cleaning solution is attached on the surface of the bearing after being sunk when water is discharged from the cleaning machine, and the cleaning effect of the cleaning machine is effectively improved.

Owner:莆田市松尚家具有限公司

Cleaning and sterilizing device for medical towels

InactiveCN107541889APrevent splashImprove cleaning effectOther washing machinesLavatory sanitoryDisinfectantAgricultural engineering

The invention discloses a medical towel cleaning and disinfection device, which comprises a base, support plates are arranged on the left and right sides of the top of the base, a cleaning bucket is fixed between the left and right support plates through brackets, and the inner bottom of the cleaning bucket is rotatably connected with a third rotating shaft. The top of the third rotating shaft is fixedly connected with a spline seat, and the bottom end of the third rotating shaft passes through the bottom of the cleaning bucket; the top of the base is provided with a first electric push rod, and the top of the first electric push rod is rotatably connected by the first bearing with seat There is a second rotating shaft, the top of the second rotating shaft is connected with a spline shaft, and the spline shaft is connected to the third rotating shaft, the bottom of the third rotating shaft is provided with a groove matching with the spline shaft, and the spline shaft slides with the third rotating shaft connect. The cleaning box of the present invention rotates positively and negatively during the cleaning process, so that the towel rolls in the cleaning box to improve the cleaning effect; after cleaning, the cleaning box can be quickly rotated for drying by meshing the driving gear with the driven gear, reducing the amount of disinfectant, etc. residue for easy subsequent washing and drying.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

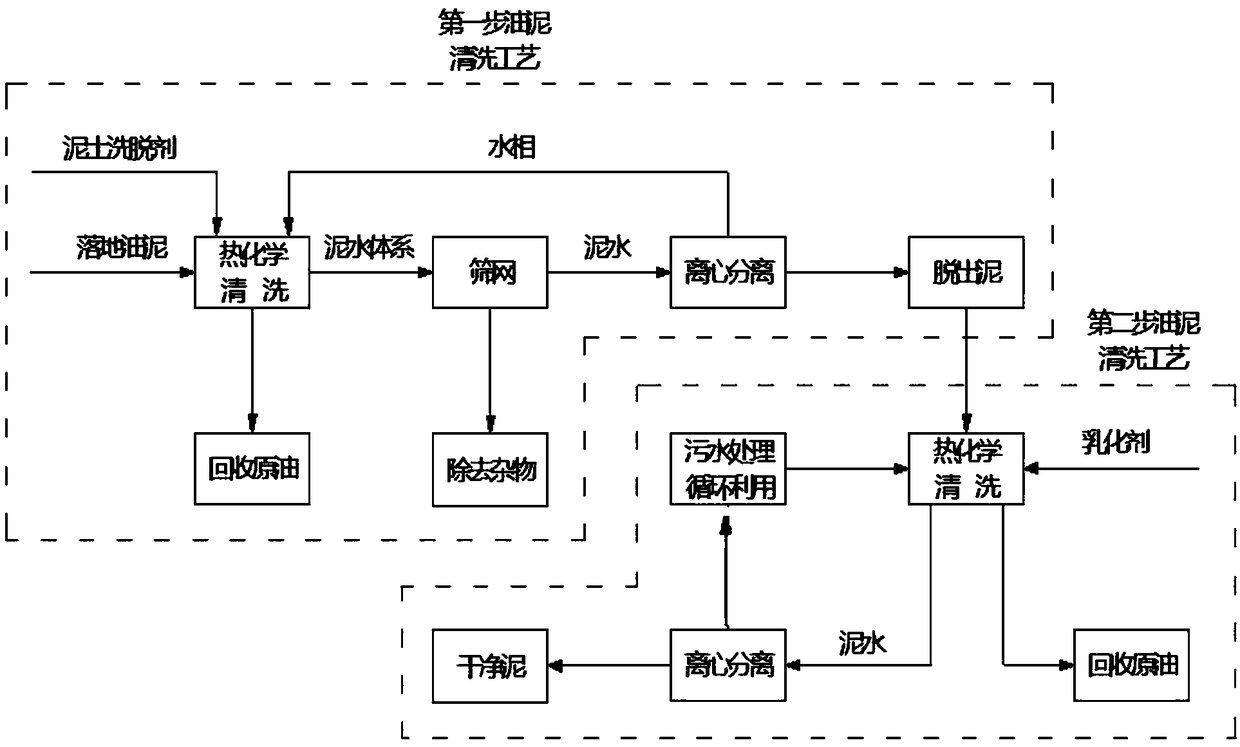

Oil sludge cleaning agent and method for treating oil sludge by using oil sludge cleaning agent

ActiveCN108059313AImprove cleaning effectLow raw material costSludge treatmentLiquid hydrocarbon mixture productionLimoneneChemistry

The invention discloses an oil sludge cleaning agent which is prepared from a soil detergent and an emulsifier. The soil detergent is prepared from the following raw material components: sodium sulfate, limonene, organic acid, trimethylene-based di(octadecyl dimethyl ammonium chloride) and water; the emulsifier is prepared from raw material components of fatty alcohol-polyoxyethylene ether, hydroxyethyl ethylenediamine, sodium carbonate and rhamnolipid. An oil sludge cleaning method comprises the following steps: Step I, adding the oil sludge cleaning agent into oil sludge to be treated for primary thermochemical cleaning, then stewing to enable a mixed system to be divided into three layers: the upper layer being cleaned crude oil, the middle layer being a water layer and the lower layerbeing a sludge and water system, performing centrifugal separation on the sludge and water system after the sludge and water system is filtered, and collecting centrifugated sludge; Step II, mixing the collected sludge with clean water, adding the emulsifier for secondary thermochemical cleaning, and then performing centrifugal separation, thus obtaining clean sludge. According to the oil sludge cleaning agent cooperating with the oil sludge cleaning method, a brand-new technical solution for twice thermochemical cleaning is adopted, so that the oil sludge cleaning efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Wool cleaning device based on bubble vortex cleaning technology for animal husbandry

InactiveCN108588846AImprove cleaning effectAvoid entanglementWool fibre washing/scouringSpray nozzleElectric machinery

The invention discloses a wool cleaning device based on a bubble vortex cleaning technology for the animal husbandry. The wool cleaning device comprises a cleaning box, wherein a partition is arrangedat the bottom of an inner chamber of the cleaning box and divides the inner chamber of the cleaning box into a cleaning chamber and a draining chamber; the bottom end of one side end of the drainingchamber is in penetration connection with a water outlet pipe; an air transfer box is arranged in the center of the top wall of the inner chamber of the cleaning box; a stirring roller is arranged inthe middle of the inner chamber of the cleaning box; a plurality of stirring blades are uniformly arranged on the excircle surface of the stirring roller; one side of the top end of an air transfer box is in penetration connection with an air inlet pipe; a feeding hole is formed in the other side of the top end surface of the cleaning box; the bottom end of one side end of the cleaning chamber isin penetration connection with a discharging pipe. A connecting pipe is driven by a motor to rotate at a high speed and then drives the stirring roller to rotate at a high speed, the stirring roller stirs water flow through the stirring blades, and a vortex is formed in the cleaning chamber; meanwhile, high-speed gas is sprayed from spray nozzles, directly enters the cleaning chamber and moves spirally along with vortex rotation, so that wool in the cleaning chamber is stirred, and the wool cleaning effect is improved substantially.

Owner:灵武市绒嘉绒业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com